USER MANUAL

MINI 100

MIDI 200

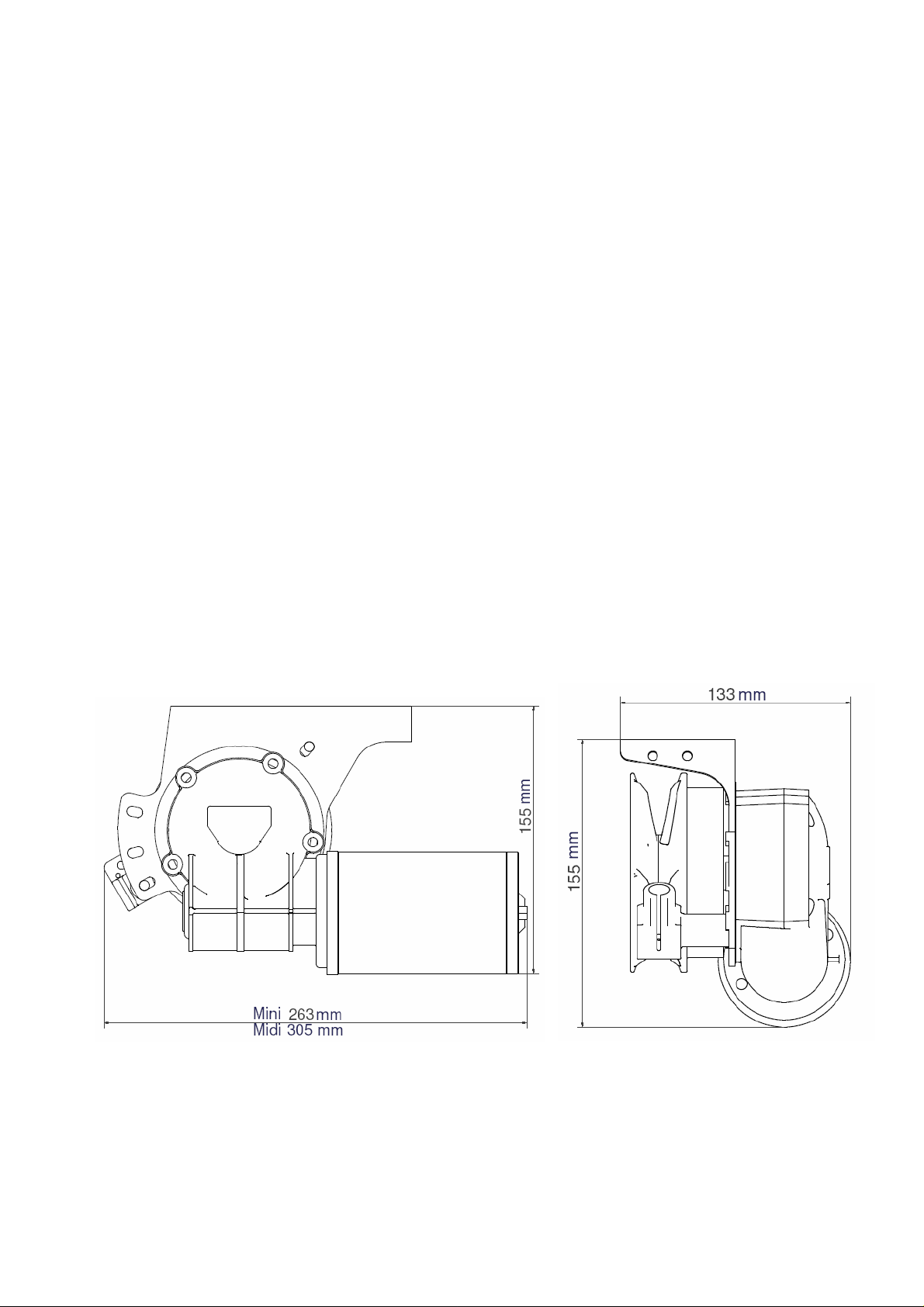

The picture shows a Midi 200 system.

(Wireless remote control and battery cables are optional.)

Rev: 2

FCC ID: R78-ECU-01

R78-RC-01

ENGBO AS – a company in the Engbo Group

OFFICE: Wirgenes vei 7, N-3159 Barkåker POSTAL ADDR.: P.O. Box 2288 Postterminalen, N-3103 Tønsberg

E-MAIL: support@engbo.no WEB: www.engbo.no TEL.: +47 33 00 31 50 FAX: +47 33 00 31 60

TABLE OF CONTENTS

INTRODUCTION............................................................................................................................. 3

Brief description of the winches ...................................................................................................................3

Dimensioned drawings............................................................................................................................................3

TECHNICAL DATA......................................................................................................................... 4

WIRING............................................................................................................................................. 5

Connection of switch panel......................................................................................................................................5

Connection of end stop sensor................................................................................................................................. 5

Connection of motor leads and battery ca bles........................................................................................................ 6

Battery connection...................................................................................................................................................6

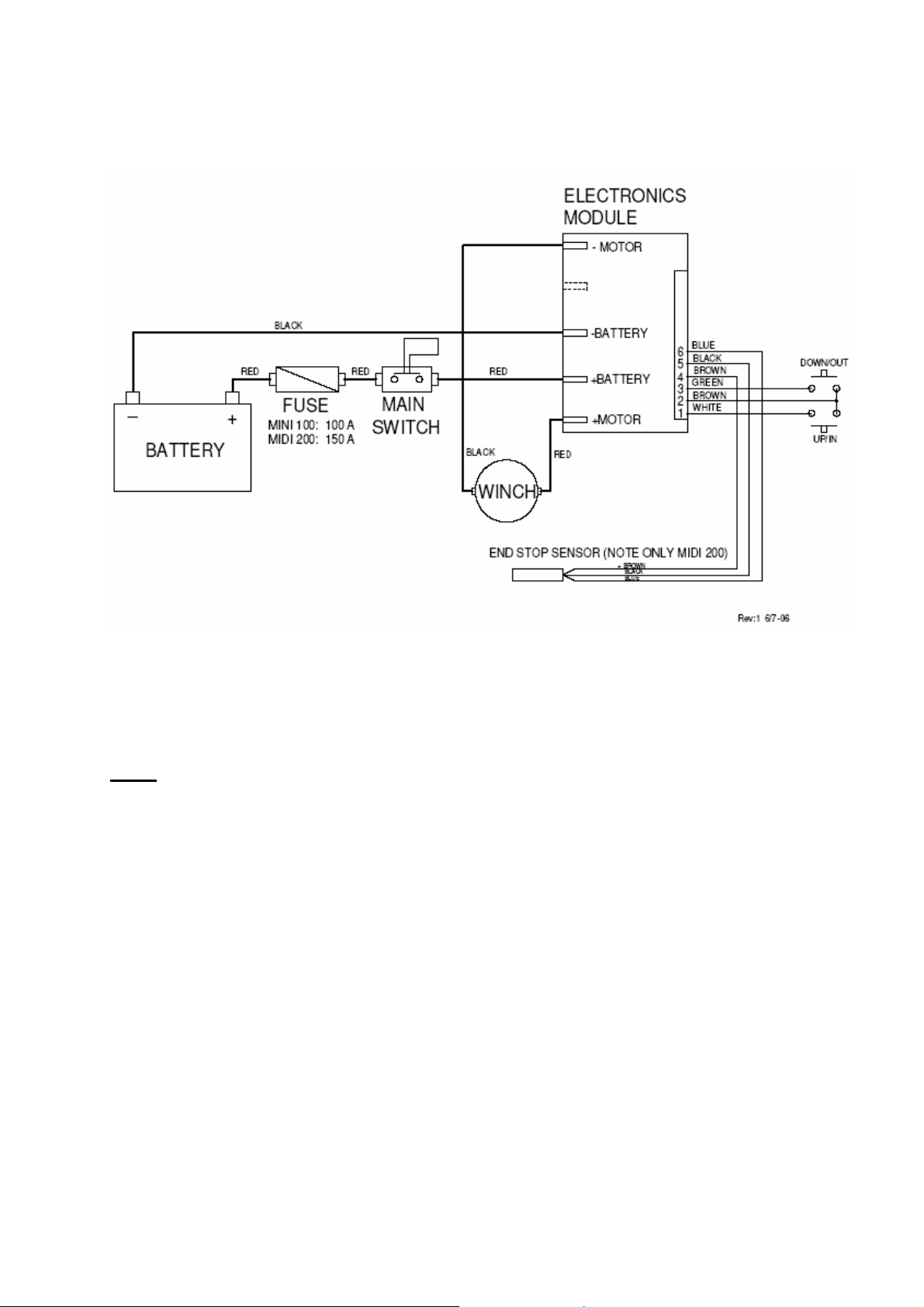

Wiring diagram.............................................................................................................................................7

INSTALLATION INSTRUCTIONS ................................................................................................ 8

General....................................................................................................................................................................8

Use of anchor bracket ............................................................................................................................................. 8

Stern penetrations....................................................................................................................................................8

Fixed anchor bracket or hinged anchor bracket..................................................................................................... 8

Cover with rollers for hole ...................................................................................................................................... 8

INSTALLATION EXAMPLES ........................................................................................................ 9

OPERATING INSTRUCTIONS .................................................................................................... 10

General..................................................................................................................................................................10

Dropping anchor ................................................................................................................................................... 11

Hauling in....................................................................................................................................................11

Automatic end stop .....................................................................................................................................11

Forced operation .........................................................................................................................................11

Installation of end stop wires................................................................................................................................. 12

WIRELESS REMOTE CONTROL................................................................................................ 14

Operating instructions.................................................................................................................................14

Dropping anchor ................................................................................................................................................... 14

Hauling in..............................................................................................................................................................15

Forced operation...................................................................................................................................................15

Battery replacement ....................................................................................................................................15

Retrofit........................................................................................................................................................16

Coding the unit............................................................................................................................................17

MAINTENANCE ............................................................................................................................ 18

Winter storage.......................................................................................................................................................18

Adjustment of end stop device....................................................................................................................18

Adjustment of the rope roller guide....................................................................................................................... 18

TROUBLESHOOTING – MINI 100/MIDI 200............................................................................ 19

FCC Statements............................................................................................................................... 20

ENGBO AS – a company in the Engbo Group

OFFICE: Wirgenes vei 7, N-3159 Barkåker POSTAL ADDR.: P.O. Box 2288 Postterminalen, N-3103 Tønsberg

E-MAIL: support@engbo.no WEB: www.engbo.no TEL.: +47 33 00 31 50 FAX: +47 33 00 31 60

2

INTRODUCTION

Congratulations on your new winch and thank you for choosing an Engbo product. We

hope your winch will meet your expectations. Please note that this requires that the winch

be installed and used in accordance with this manual in an environment with the correct

conditions for proper operation. This includes the necessary battery capacity for the winch

motor as well as correct placement of winch, rope, anchor and anchor bracket.

Brief description of the winches

Engbo MINI 100 is designed for boats up to approximately 20 feet and Engbo MIDI 200

for boats between 20 to 25 feet. These winches are true free-fall winches and equipped

with a new power electronics that replaces the traditional contactor. The new electronics

have no open contacts and are very flexible as regards voltage. Engbo MINI 100 and

MIDI 200 are also equipped with new control electronics with an integrated radio

receiver for the wireless remote control as well as an integrated protection of the winch

motor and electronics.

The winches are supplied with control panel as standard. A wireless remote control with a

range of > 30 m under normal conditions can optionally be used.

Dimensioned drawings

ENGBO AS – a company in the Engbo Group

OFFICE: Wirgenes vei 7, N-3159 Barkåker POSTAL ADDR.: P.O. Box 2288 Postterminalen, N-3103 Tønsberg

E-MAIL: support@engbo.no WEB: www.engbo.no TEL.: +47 33 00 31 50 FAX: +47 33 00 31 60

3

TECHNICAL DATA

Motor power nom.

Rope

Maximum pull

Haulage speed

Current draw

Standby current

consumtion

Recommended fuse

Recommended min.

battery capacity

Weight: Winch with

motor leads

Weight: Control

electronics

End stop function

Recommended

anchor

Recommended

vessel size

Installation

Standard equipment

Optional equipment

ENGBO – MINI 100 ENGBO – MIDI 200

12 V DC/350 W 12 V DC/600 W

Braided leaded rope: Dia 12 mm,

30 m

Weight:7,2 kg

Breaking load: 1200 daN

Up to 100 kg

(Electronic limit)

15-35 m/min

approx. 20 m/min with 20 kg load

10-150 A

approx. 50 A with 20 kg load

Braided lead rope diameter 12

mm, 30/50 m

Weight: 7.2 kg/12 kg

Breaking load: 1600 daN

Up to 200 kg

(Electronic limit)

15-30 m/min

approx. 20 m/min with 30 kg load

10-200 A

approx. 40 A with 30 kg load

‹ 0.3 A at 12 V ‹ 0.3 A at 12 V

100 A 150 A

12 V/75 Ah 12 V/75 Ah

5.5 kg 7.7 kg

2.3 kg 2.3 kg

No Yes

5-8 kg Bruce or plate 7.5-16 kg Bruce, plate or Engbo

Max. 6.0 m (20 feet) Max. 7.6 m (25 feet)

Vertical, hanging, forward or side

(may require additional bracket).

Winch, electronic module, control

panel and main switch.

Basic installation bolt set.

Vertical, hanging, forward or side

(may require additional bracket).

Winch with end stop device,

electronic module, control panel

and main switch.

Basic installation bolt set.

Lead rope

Anchor (several types available)

Anchor bracket (several types)

Shackles

Wireless remote control

Fuse and fuse holder

Installation bracket(s)

Battery cable

Lead rope

Anchor (several types available)

Anchor bracket (several types)

Shackles

Wireless remote control

Fuse and fuse holder

Installation bracket(s)

Battery cable

ENGBO AS – a company in the Engbo Group

OFFICE: Wirgenes vei 7, N-3159 Barkåker POSTAL ADDR.: P.O. Box 2288 Postterminalen, N-3103 Tønsberg

E-MAIL: support@engbo.no WEB: www.engbo.no TEL.: +47 33 00 31 50 FAX: +47 33 00 31 60

4

WIRING

The sticker on top of the electronics module also shows the wiring of the unit.

All wiring and connections must be done with the main switch turned off or the battery

disconnected.

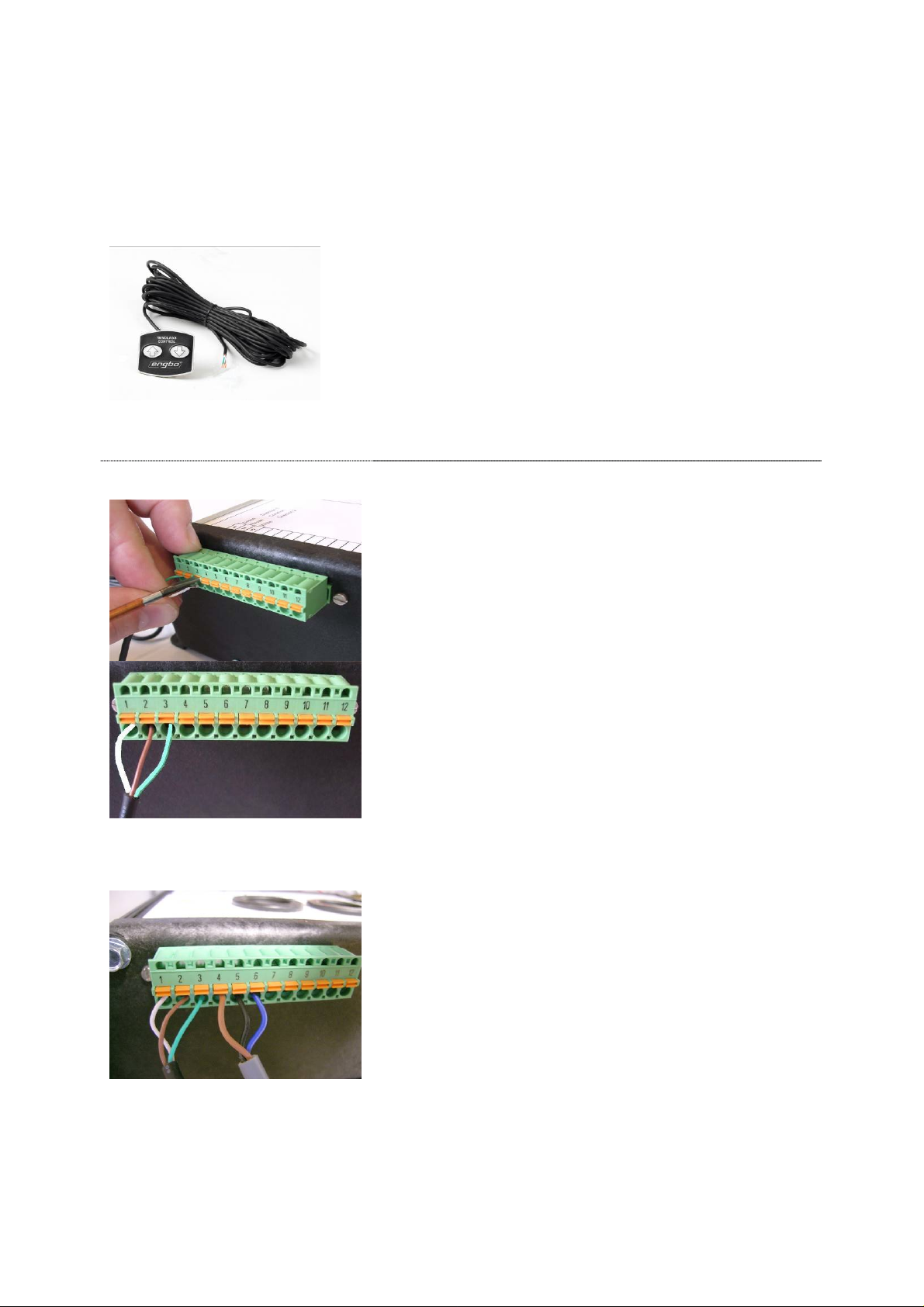

Control panel for fixed installation.

Watertight (IP 68) control panel for installation

exposed to sea spray and sun. Designed to allow

installation directly on gently curved surfaces as

well (double-sided tape). The enclosed screws may

also be used.

An optional adapter plate (part no. 112-10015) can

be used for installation in existing 62 x 62 mm hole.

Several panels can be connected in parallel to the

same electronics unit.

Connection of switch panel

One switch panel is supplied as standard with a

10m cable. The wires are cut and the insulation

stripped to the correct length and connected by

pushing the wires in while holding down the orange

button above the selected hole. Release the button

when the wire is in place. Check to make sure that

the insulation is not inside the terminal and that

there are no loose strands sticking out.

The wires must be connected as follows:

1: White

2: Brown

3: Green

If more than one panel is to be installed, connect

the wires in parallel to 1, 2 and 3 (2 is common 0 V)

(Spring-clamp terminal strips are used to avoid the

risk of the connections coming loose due to

vibration or temperature changes.)

Connection of end stop sensor

(Note: MIDI 200 ONLY)

The wires from the end stop sensor are connected

as described above.

The wires must be connected as follows:

4: Brown (BN) = +V

5: Black (BK) = Signal

6: Blue (BU) = Gnd

ENGBO AS – a company in the Engbo Group

OFFICE: Wirgenes vei 7, N-3159 Barkåker POSTAL ADDR.: P.O. Box 2288 Postterminalen, N-3103 Tønsberg

E-MAIL: support@engbo.no WEB: www.engbo.no TEL.: +47 33 00 31 50 FAX: +47 33 00 31 60

5

WARNING !!

!

!

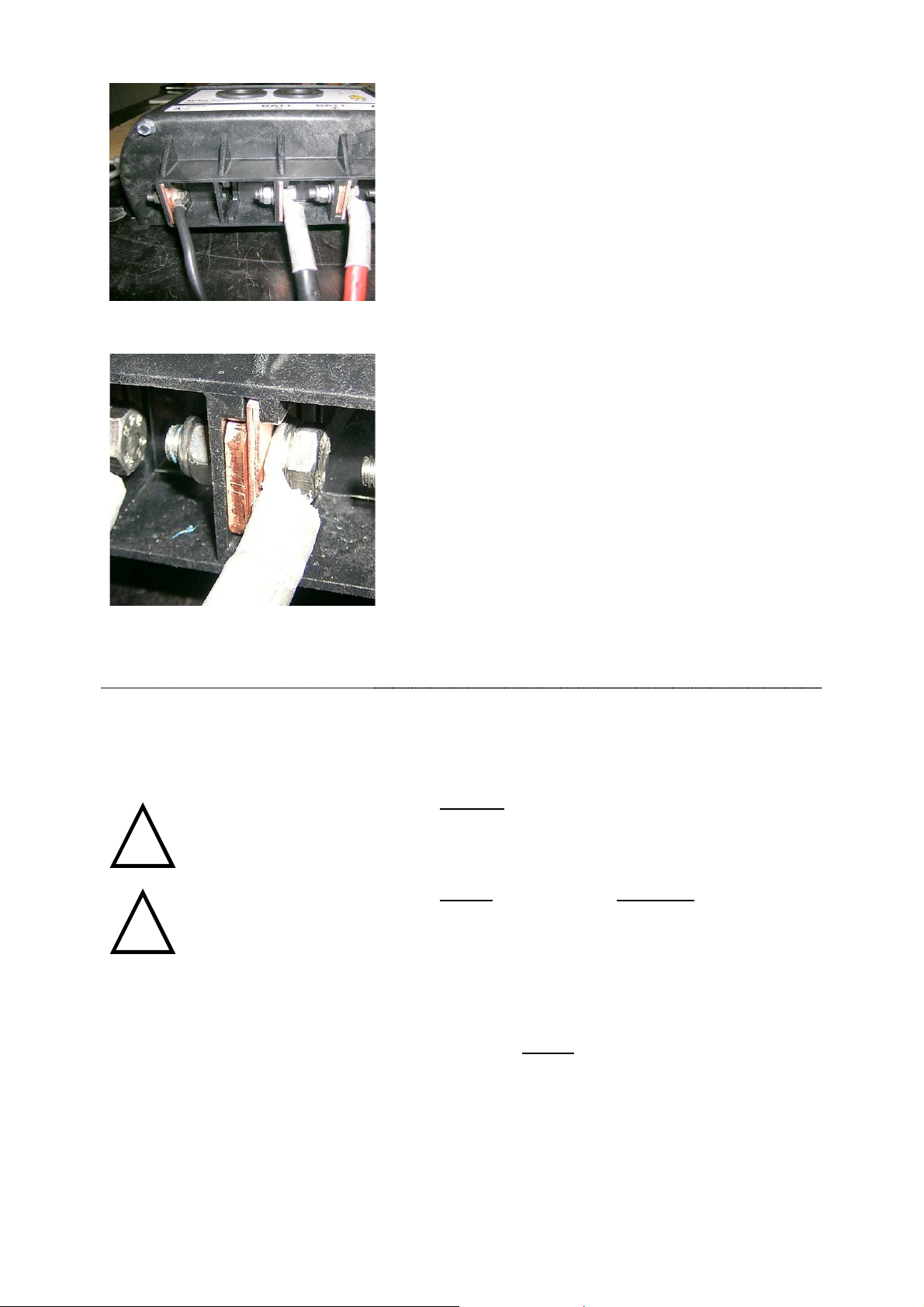

Connection of motor leads and battery

cables

The preferred method is to first fit the cables on the

unit before installing it standing against the

bulkhead with the power cables pointing downward.

The motor leads are supplied fitted on the motor.

Start by connecting the motor's black negative lead

to the left before the battery's black negative cable,

then the battery's positive cable and finally the

motor's positive lead. (Disassemble in opposite

order if necessary.)

The picture shows the correct connection and

orientation of bolts and cables (the lock nuts on the

left side).

(The cable terminals must be connected directly to

the copper rails without any washers, etc. in

between. Use a flat washer between the bolt head

and the top of the cable terminal and between the

plastic side of the end wall and lock nut.)

The M8 x 25 mm bolt is for the battery's positive

conductor.

Note the copper plate used as a spacer in the end

wall.

For normal distances from the battery to the

electronics module (< 4 m), use 25 mm

100 and 35 mm

2

for MIDI 200. If the distance is

longer, use the next size larger cable dimension.

2

for MINI

Battery connection

• INCORRECT BATTERY POLARITY WILL

PERMANENTLY DESTROY THE POWER

ELECTRONICS

BEFORE CONNECTING THE BATTERY - MAKE

•

SURE NO CABLES ARE SHORT-CIRCUITED OR

DAMAGED

• CHECK ALL POWER CABLES AND TERMINALS;

TIGHTEN UP IF NECESSARY

NEVER USE WASHERS BETWEEN CABLE

•

TERMINALS AND TERMINAL POINTS WITH

HEAVY CURRENTS.

The battery's positive cable must have a fuse as close to

the battery as possible and the main switch must be

installed in an accessible location before the electronics

unit.

Windlasses must

battery.

always be connected to the start

ENGBO AS – a company in the Engbo Group

OFFICE: Wirgenes vei 7, N-3159 Barkåker POSTAL ADDR.: P.O. Box 2288 Postterminalen, N-3103 Tønsberg

E-MAIL: support@engbo.no WEB: www.engbo.no TEL.: +47 33 00 31 50 FAX: +47 33 00 31 60

6

Wiring diagram

NOTE!

The winch must be connected to the boat's start battery and connected

after the boat's main switch.

ENGBO AS – a company in the Engbo Group

OFFICE: Wirgenes vei 7, N-3159 Barkåker POSTAL ADDR.: P.O. Box 2288 Postterminalen, N-3103 Tønsberg

E-MAIL: support@engbo.no WEB: www.engbo.no TEL.: +47 33 00 31 50 FAX: +47 33 00 31 60

7

INSTALLATION INSTRUCTIONS

General

Locate the winch as high as possible to allow plenty of room for rope below the winch.

The height from lower edge of the gypsy should be at least 40 cm above the bottom of the

rope locker or where the rope will be placed. This is to allow space for 50 metres of 12

mm Engbo braided anchor rope. If the height is less than 40 cm, make sure the rope does

not pile all the way up to the winch. If this is the case, use a shorter rope.

The winch should be installed far enough to the centre of the stern that the anchor does

not drag in the wave curving in right behind the boat.

Use of anchor bracket

The bracket for the rope must be installed with the sheaves outside the platform to ensure

the anchor/rope clears the platform.

Stern penetrations

Make sure the hole in the hull is located correctly based on the direction of the rope. To

avoid unnecessary wear and tear the rope should not touch the sides of the hole vertically

or horizontally, and the hole must be elliptical vertically to allow for rope movement on the

roller when winching.

Fixed anchor bracket or hinged anchor bracket

If the winch must be installed so low in relation to the swim platform that it will pull the

anchor forward/inward rather than upward/inward, it is preferable to use our hinged

anchor bracket (see catalogue).

Cover with rollers for hole

If it proves difficult to route the rope straight vertically from the gypsy to the anchor roller,

it may be beneficial to use a cover with rollers to allow for the rope angle.

NOTE! Remember to fasten the end of the rope to the boat.

ENGBO AS – a company in the Engbo Group

OFFICE: Wirgenes vei 7, N-3159 Barkåker POSTAL ADDR.: P.O. Box 2288 Postterminalen, N-3103 Tønsberg

E-MAIL: support@engbo.no WEB: www.engbo.no TEL.: +47 33 00 31 50 FAX: +47 33 00 31 60

8

INSTALLATION EXAMPLES

The pictures below show different installations

Mini 100 only

ENGBO AS – a company in the Engbo Group

OFFICE: Wirgenes vei 7, N-3159 Barkåker POSTAL ADDR.: P.O. Box 2288 Postterminalen, N-3103 Tønsberg

E-MAIL: support@engbo.no WEB: www.engbo.no TEL.: +47 33 00 31 50 FAX: +47 33 00 31 60

9

OPERATING INSTRUCTIONS

General

Read the entire operating instructions carefully before using the winch.

1. Please remember that heavy loads are involved. Therefore use common sense

when operating the winch and make sure that:

Fingers do not become entangled in rope, rollers or gypsy.

The rope is always monitored when hoisting the anchor.

Everyone on board is informed about how to operate the winch.

2. Always operate the winch from a location with full overview when hauling the

anchor. This is necessary in case the anchor hooks on something unexpected that

may damage the boat.

3. If the winch works hard when raising the anchor, release the button for a moment.

When the boat has started moving aft, start the winch again. This will ensure that

the winch will work less hard and draw less current.

4. Keep the anchor rope taut when winding long lengths of rope.

5. Should the anchor be stuck on the bottom, do as follows: Pay out some rope and

fasten it to a cleat in the boat. Use the boat to loosen the anchor. When the anchor

is loose, use the winch in the normal manner.

6. The winch can be operated for a maximum of 3 minutes with a normal load.

7.

Always secure the anchor to the boat with a safety rope when sailing. A snap

hook can be used to fasten it to an eye/shackle, for example. A safety rope is

enclosed.

8. Children must not operate the winch.

9. Careless use may result in unnecessary damage/injury.

10. Always make sure there is sufficient battery capasity when using the winch.

Always keep the engine running while using the winch.

11. The winch has an electronic overload protection. If necessary, let the winch cool

down for approximately 15 min and try again. In an emergency, this protection may

be overridden by turning the winch off and back on again. (Overrides are saved by

the processor.)

12. Engbo AS is not responsible for injury or damage as a result of the use of the

winch.

NOTE! ALWAYS KEEP THE ENGINE RUNNING WHEN USING THE WINCH AND ALWAYS

TURN OFF THE POWER TO THE WINCH WHEN NOT IN USE.

ENGBO AS – a company in the Engbo Group

OFFICE: Wirgenes vei 7, N-3159 Barkåker POSTAL ADDR.: P.O. Box 2288 Postterminalen, N-3103 Tønsberg

E-MAIL: support@engbo.no WEB: www.engbo.no TEL.: +47 33 00 31 50 FAX: +47 33 00 31 60

10

Dropping anchor

Engbo MINI 100 and MIDI 200 has a true free-fall anchor drop function. One press of the

button and the anchor drops freely to the bottom.

The anchor should be dropped a distance from where the boat will be located

corresponding to 3-5 times the water depth.

When the anchor winch has been turned off with the main

switch, always press the "DOWN/OUT" button first (marked

with an arrow pointing downward). This button must be held

in for at least 1 second to drop the anchor.

The winch will then pay out for 3 seconds to ensure correct

free-fall function. (This time period is 3 seconds regardless

of how long the button is pressed.)

Hauling in

When the anchor is out, haul in the anchor by pressing the

"UP/IN" button (marked with an arrow pointing upwards).

The winch will haul in the rope for as long as the button is

held in.

The winch always starts with 3 seconds at low speed before

increasing to full speed.

The winch can also be operated at low speed by pushing

and releasing the "IN" button several times.

Automatic end stop

Note! MIDI 200 ONLY

Assumes correctly positioned end stop wires on the anchor

rope.

When the first end stop wire is sensed by the end stop

sensor when hauling in the anchor, the winch will stop. The

button must then be released and pushed once more. The

winch will then operate at low speed until the second end

stop is sensed by the sensor. The winch will then stop

completely.

Forced operation

NOTE! MIDI 200 ONLY

If the anchor needs to be lifted a little further after end

stop 2, this can be done by holding down the "IN"

button for more than 10 seconds. The winch will then

operate at extra low speed for as long as the button is

held down.

NOTE! This operation must only be carried out

under very controlled circumstances to prevent

damage.

NOTE! ALWAYS KEEP THE ENGINE RUNNING WHEN USING THE WINCH AND

ALWAYS TURN OFF THE CURRENT TO THE WINCH WHEN NOT IN USE.

ENGBO AS – a company in the Engbo Group

OFFICE: Wirgenes vei 7, N-3159 Barkåker POSTAL ADDR.: P.O. Box 2288 Postterminalen, N-3103 Tønsberg

E-MAIL: support@engbo.no WEB: www.engbo.no TEL.: +47 33 00 31 50 FAX: +47 33 00 31 60

11

Installation of end stop wires

NOTE! MIDI 200 ONLY

Integrated in the rope rejector is an inductive sensor that signals end stop when the

anchor has been lifted all the way up. To activate the sensor, two brass wires (included)

are fitted on the rope (see procedure below).

The outer diameter of the brass wire winding must be similar to the outer diameter of the

rope, or as close as possible. This is necessary in order for the inductive sensor to be

able to detect the wire.

To locate the brass wires correctly on the rope, haul in the anchor until the thumble is 2550 cm below the rope roller (operate at slow speed for the final length), and mark the rope

with a marker pen at the inductive sensor. The anchor is then reeled in at low speed to

the desired final resting position. Mark the rope once more at the sensor. These marked

positions are where the wires shall be fastened.

These wires will be exposed to wear by the gypsy, especially during heavy loads, and

must therefore be inspected regularly. Replace damaged wires as needed.

ENGBO AS – a company in the Engbo Group

OFFICE: Wirgenes vei 7, N-3159 Barkåker POSTAL ADDR.: P.O. Box 2288 Postterminalen, N-3103 Tønsberg

E-MAIL: support@engbo.no WEB: www.engbo.no TEL.: +47 33 00 31 50 FAX: +47 33 00 31 60

Cut approximately 25 cm of brass wire for each

signal location. (The length of the supplied brass

wire is approximately 1m.)

The rope and installation is shown with the

anchor at the bottom right.

Use an awl to make a hole for the wire where

the rope is marked.

Bend 6-7 mm at 90 degrees and push this end

into the hole.

It may be beneficial to use a pair of pliers to

force the wire into the rope and to keep it in

place initially while winding the wire around the

rope.

12

Wind the wire four complete turns around the

rope.

After four turns and on the opposite side of

where you started, "sew" the wire into the rope.

Use the awl to carefully make a hole for the wire,

push the wire through and tighten.

Repeat the sewing operation once more.

Then cut the wire and bend the end at 90

degrees towards the middle of the rope.

Force the end into the rope with the pliers.

A fitted end wire should look like this with close

windings and the ends secured inside the rope.

ENGBO AS – a company in the Engbo Group

OFFICE: Wirgenes vei 7, N-3159 Barkåker POSTAL ADDR.: P.O. Box 2288 Postterminalen, N-3103 Tønsberg

E-MAIL: support@engbo.no WEB: www.engbo.no TEL.: +47 33 00 31 50 FAX: +47 33 00 31 60

13

WIRELESS REMOTE CONTROL

Floating, splash-proof, hand-held remote control unit. The operating range is > 30 m

under normal conditions. The Engbo remote control is a high quality, narrow band unit

with two-way communication with the electronics unit. Each unit has a unique code.

It uses three standard AAA (LR03) batteries (included).

It has anti-slip strips on the back.

Fits in a standard mobile phone holder.

Hand cord is included as standard (easily removed).

The battery lifetime is > 2 seasons based on normal use.

One remote control can be used to operate two winches. The remote control units are

normally supplied programmed for the enclosed electronics unit. Both button pairs are

then programmed.

Operating instructions

The remote control is battery-operated. To ensure longer

lifetime, it will automatically go to “sleep” mode five

minutes after the last button was pushed. Deactivation is

signalled with two short sound bursts and blinks in the

"POWER" indicator. The remote control is activated by

holding down any button for 1.5 seconds. Activation is

indicated by a steady green light in the "POWER"

indicator and a short sound. All subsequent use of

buttons is shown on the associated indicator above the

button and a short sound.

The "POWER" indicator is also used to indicate low

voltage at the electronics unit. This is indicated by an

orange light. If the winch is overloaded and requires time

to cool down, this will also be indicated by an orange

light. The indicator will be red in case of system faults

and slowly blink red together with short sounds if the

remote is unable to communicate with the electronics

unit. These error messages are shown when buttons are

pushed.

Dropping anchor

When the remote control has been activated, the anchor

can be dropped by pressing the "DOWN/OUT" button

(marked with downwards arrow) again. This button must

be held in for at least 1 second to drop the anchor.

The winch will then pay out for 3 seconds to ensure

correct free-fall function. (This time period is 3 seconds

regardless of how long the button is pressed.)

ENGBO AS – a company in the Engbo Group

OFFICE: Wirgenes vei 7, N-3159 Barkåker POSTAL ADDR.: P.O. Box 2288 Postterminalen, N-3103 Tønsberg

E-MAIL: support@engbo.no WEB: www.engbo.no TEL.: +47 33 00 31 50 FAX: +47 33 00 31 60

14

Hauling in

When the anchor has been dropped, start weighing

anchor by pressing once on the "UP/IN" button (marked

with upwards arrow). If the remote control has been

deactivated (more than five minutes elapsed since the

last button activation), it will first be turned on and then

immediately start hauling in the anchor. The winch

always starts with 3 seconds at low speed before

increasing to full speed.

The winch can thereby also operate at low speed by

pushing and releasing the "IN" button several times.

Forced operation

NOTE! MIDI 200 ONLY

If the anchor needs to be lifted a little further after end

stop 2, this can be done by holding down the "IN" button

for more than 10 seconds. The winch will then operate at

low speed for as long as the button is held down.

This is indicated on the remote control by a green light

slowly blinking above the "IN" button and rapid, brief

sound bursts.

NOTE! This operation must only be carried out under

very controlled circumstances to prevent damage.

Battery replacement

The remote control uses three regular AAA/LR03

alkaline batteries. The battery lifetime is more than two

seasons under normal use.

When replacing batteries, open the unit by unscrewing

all five screws.

NOTE! The screws are of different lengths and have

O-rings under the screw heads.

Replace the batteries and make sure all point the same

way with the + up and the – downwards towards the

edge as illustrated.

Reassemble the back cover and carefully screw the

parts together until the housing gasket is

lightly

compressed. The impermeability of this unit depends

on intact O-rings and intact gasket with the right

compression.

NOTE! To ensure a long lifetime, this remote

control has acid-proof machine screws and screw

inserts in the housing. The screws may penetrate

the housing if screwed carelessly or too much

force is used.

(Not covered by the warranty.)

ENGBO AS – a company in the Engbo Group

OFFICE: Wirgenes vei 7, N-3159 Barkåker POSTAL ADDR.: P.O. Box 2288 Postterminalen, N-3103 Tønsberg

E-MAIL: support@engbo.no WEB: www.engbo.no TEL.: +47 33 00 31 50 FAX: +47 33 00 31 60

15

Retrofit

If the remote control is purchased after the electronics unit, the electronics unit must be

fitted with an antenna. The remote control and electronics unit must also be coded/taught

electronically to communicate with each other.

Remove the left rubber cover (the one closest to

the Engbo logo). Then push the antenna through

the cover (on one side).

While holding down the antenna connector

handle, push the antenna all the way down into

the bottom of the clamp. Release the handle and

the antenna is fixed in place.

Replace the rubber cover. Start by pushing the

rubber cover in by the antenna and continue

around the edge until the cover is fixed in place.

Make sure not to twist the cover with the

antenna.

(The remote control will function over short

distances also without the antenna.)

ENGBO AS – a company in the Engbo Group

OFFICE: Wirgenes vei 7, N-3159 Barkåker POSTAL ADDR.: P.O. Box 2288 Postterminalen, N-3103 Tønsberg

E-MAIL: support@engbo.no WEB: www.engbo.no TEL.: +47 33 00 31 50 FAX: +47 33 00 31 60

16

Coding the unit

The remote control (transmitter) can be

coded/taught electronically to communicate with

the selected

two). The electronics unit and remote control must

be close to each other and set to code/teaching

mode at the same time as described below:

1.

The remote control unit is set in

code/teaching mode by holding down both

buttons in the pair of buttons to be used for

10 seconds (see Image A).

control indicates that it is in the

code/teaching mode by the "POWER"

indicator starting to slowly blink green and

a short sound. The remote control will

Image A

remain in this mode until correctly coded or

until the same two buttons are pushed

again. If not, it will automatically turn off

after five minutes. When exiting from this

mode, there will be a short sound burst and

the "POWER" indicator will no longer be lit.

2. Hold down both switches on the

permanently installed switch panel while

turning on the main switch. Then release

the switches (see Images B and C).

electronics unit will now be in code mode.

(This can also be done by temporarily

connecting between 1, 2 and 3 on the

electronics unit.)

now remain in the programming mode for

only 10 seconds, and then switch back to

the normal mode again.

3. Press one of the two switches on the

Image B

remote control that controls either the bow

or aft winch. This must be done within the

10 seconds that the electronics unit is in

the code mode. Correct coding is confirmed

with a short sound signal from the remote

control.

4. The remote control is now coded and ready

for use.

Image C

This coding/teaching can be done an unlimited

number of times.

electronics unit(s) (receiver), (max.

The electronics unit will

The remote

The

ENGBO AS – a company in the Engbo Group

OFFICE: Wirgenes vei 7, N-3159 Barkåker POSTAL ADDR.: P.O. Box 2288 Postterminalen, N-3103 Tønsberg

E-MAIL: support@engbo.no WEB: www.engbo.no TEL.: +47 33 00 31 50 FAX: +47 33 00 31 60

17

MAINTENANCE

Winter storage

• Before winter storage, the winch and all electrical terminals and connections must

be coated with a moisture proofing spray.

• Make sure the winch is protected against snow during winter storage.

• Do not cover up the winch to avoid condensation during winter storage.

• Remove the rope before winter storage. Soak it in mild soapy water overnight to

remove salt deposit and dirt. This will ensure that the rope remains supple for

many years and allows for checking and possible replacement of the end stop

wires.

If relevant, clean the rope locker on the inside and remove any seaweed, mud, etc.

Adjustment of end stop device

NOTE! MIDI 200 ONLY

The device will normally be adjusted and

extend approximately 1 mm from the

holder. If adjustment is necessary, loosen

the screw holding the inductive sensor.

Move the sensor to the correct position,

but make sure that the rope will not be

caught in it. Retighten the screw.

(Previous model shown. Latest models:

Install sensor onto end wall.)

Adjustment of the rope roller guide

The guide will normally be adjusted for 12

mm rope.

The guide must be at a straight angle in

relation to the rope with a gentle pressure

against the rope when the rope is located

in its normal position in the gypsy.

If adjustment is needed, loosen the screw

under the bracket to adjust the pressure

against the rope. Loosen the screw on

top of the holder to adjust the angle and

distance.

ENGBO AS – a company in the Engbo Group

OFFICE: Wirgenes vei 7, N-3159 Barkåker POSTAL ADDR.: P.O. Box 2288 Postterminalen, N-3103 Tønsberg

E-MAIL: support@engbo.no WEB: www.engbo.no TEL.: +47 33 00 31 50 FAX: +47 33 00 31 60

18

TROUBLESHOOTING – MINI 100/MIDI 200

(For wiring, see diagram under the section "Wiring".)

Symptom: Action and please note the

following:

1 The winch is totally

"dead". Nothing

works.

2 The winch will not

drop the anchor,

and only reels in for

3 s.

3 The winch does not

work or pulls very

poorly.

4 If the winch still

does not function.

5 If the end stop does

not function:

(MIDI 200 ONLY)

or Engbo AS, Tønsberg. Tel.: +47 33003150, Fax: +47 33003160, E-mail: support@engbo.no

ENGBO AS – a company in the Engbo Group

OFFICE: Wirgenes vei 7, N-3159 Barkåker POSTAL ADDR.: P.O. Box 2288 Postterminalen, N-3103 Tønsberg

E-MAIL: support@engbo.no WEB: www.engbo.no TEL.: +47 33 00 31 50 FAX: +47 33 00 31 60

NOTE! The main current switch

must be turned off when

connecting and disconnecting

cables and performing

mechanical work.

Check that:

- the main switch is turned on,

- the fuse is intact

- all terminals have good contact

- all connections are according

to diagram in the manual

- there is sufficient power to the

winch motor.

(See Item 3)

Check that:

- connections to 1, 2 and 3 are according to diagram. By

switching 1 and 3, the winch should function correctly.

IMPORTANT!

Based on previous

experience, this is the most

common problem.

Look for main current faults:

Measure the battery voltage at

the input to the winch while

operating the winch.

Disconnect cables to 1, 2 and 3.

--------

Strip the insulation on the ends

of a loose cable (approx. 10 cm)

and establish contact between

these points:

Cable between 2 and 3

Cable between 1 and 2

Check that:

- connections to 4, 5 and 6 are

according to diagram.

- the power to sensor (between

4 and 6) is more than 10 V DC

- end stop wires are in place.

If the winch still does not function normally after this procedure,

the fault is located in the winch itself. Contact the nearest dealer,

Action results in: Result

The voltage must be

minimum 10.5 V when

operating the winch to

ensure normal motor

function.

Functions that normally are

controlled from the switch

panel are disconnected to

allow forced operation of the

winch directly from the

electronics unit.

--------

The winch is released and

the anchor dropped.

Winch reels in.

The indicator lamp on the

sensor must light up when

the brass ring on the rope is

by the sensor.

(Can also be tested using a

screwdriver, or similar, by

the sensor.)

If the voltage is below 10.5 V, the

reason must be determined.

Check all connections, e.g. main

switch, fuse, battery terminals,

battery voltage and the battery's

general condition.

If the voltage is higher than

10.5 V but the motor will still not

run, the reason may be that

extended use/overloading of the

winch has resulted in the

electronic protection shutting off

the motor.

Wait 20 min. to let it cool down

and try again.

The switch panel is disconnected.

--------

If the winch functions normally

using this procedure, the fault is

located in a cable to the switch

panel, or the switch panel itself,

and must be replaced.

If the voltage is OK and the lamp

does not light, the sensor must be

replaced.

19

FCC Statements

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

two conditions: (1) this device may not cause harmful interference, and (2) this device

must accept any interference received, including interference that may cause undisired

operation.

Changes or modifications to the equipment not expressly approved by the party

responsible for compliance could void the user’s authority to operate the equipment.

NOTE: This equipment has been tested and found to comply with the limits for a Class

B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential installation.

This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference

to radio communications. However, there is no guarantee that interference will not occur

in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is encouraged to try to

correct the interference by one or more of the following measures:

-- Reorient or relocate the receiving antenna.

-- Increase the separation between the equipment and receiver.

-- Connect the equipment into an outlet on a circuit different

from that to which the receiver is connected.

-- Consult the dealer or an experienced radio/TV technician for help.

ENGBO AS – a company in the Engbo Group

OFFICE: Wirgenes vei 7, N-3159 Barkåker POSTAL ADDR.: P.O. Box 2288 Postterminalen, N-3103 Tønsberg

E-MAIL: support@engbo.no WEB: www.engbo.no TEL.: +47 33 00 31 50 FAX: +47 33 00 31 60

20

Loading...

Loading...