EngA G-TRAC 1.1 Installation, Operation And Maintenance Manual

A

INSTALLATION, OPERATION

AND MAINTENANCE MANUAL

FOR

G-TRAC

Model 1.1

INDIRECT FIRED HEATING CONTROLLER

UNIT MODEL NO.

_________________

UNIT SERIAL NO.

_________________

SERVICED BY: ___________________

TEL. NO:

________________________

CANADIAN

HEAD OFFICE

AND FACTORY

1401 HASTINGS CRES. SE

CALGARY, ALBERTA

T2G 4C8

Ph: (403) 287-4774

Fx: 888-364-2727

USA

HEAD OFFICE

AND FACTORY

rd

32050 W. 83

DESOTO, KANSAS

66018

Ph: (913) 583-3181

Fx: (913) 583-1406

STREET

SALES OFFICES ACROSS CANADA AND USA

Retain instructions with unit and maintain in a legible condition.

Please give model number and serial number when contacting

factory for information and/or parts.

www.engineeredair.com

CANADIAN

EASTERN FACTORY

1175 TWINNEY DRIVE

NEWMARKET, ONTARIO

L3Y 5V7

Ph: (905) 898-1114

Fx: (905) 898-7244

IOM-24 March 1999 R1

A G-TRAC MANUAL

TABLE OF CONTENTS

I. PURPOSE ................................................................................................................ 1

II. CAUTION ................................................................................................................. 1

III. SIMPLIFIED OPERATION ....................................................................................... 1

IV. TEMPERATURE CONTROL .................................................................................... 2

G-TRAC as a Slave to the CTRAC ...................................................................................................... 2

Suggested Settings Re Hunting Problems ........................................................................................ 2

G-TRAC as a “Stand Alone Device” ................................................................................................... 2

V. MASTER SET-POINT .............................................................................................. 3

TE 6100 Wiring Connections and Resistance Values ...................................................................... 3

Sensor Resistance Chart for TE 6100-960 and TE 6000-960 ............................................................ 4

Temperature Can Be Controlled By ................................................................................................... 4

VI. RESET CONTROL ................................................................................................... 4

Example 1 ............................................................................................................................................. 5

Example 2 ............................................................................................................................................. 5

Example 3 ............................................................................................................................................. 5

Multiple Room Sensors ....................................................................................................................... 6

Room Reset Authority Pot .................................................................................................................. 6

VII. TO TEMPORARILY DRIVE THE UNIT TO HIGH OR LOW FIRE ............................ 6

VIII. G-TRAC DISCHARGE TEMPERATURE SENSOR/SETPOINT CALIBRATION ..... 6

Method 1 ............................................................................................................................................... 6

Method 2 ............................................................................................................................................... 7

IX. ROOM RESET CONTROL CALIBRATION ............................................................. 7

Method 1 (Most accurate method) ............................................................................................................ 7

Method 2 (Does not correct for remote wire resistance) ............................................................................. 7

IOM-24 Page i March 1999 R1

A G-TRAC MANUAL

Method 3 ............................................................................................................................................... 8

Method 4 (May correct minor electrical noise on remote wire) ................................................................... 8

X. BMS RESET OF THE DISCHARGE AIR TEMPERATURE ..................................... 8

XI. POTENTIOMETERS ON THE G-TRAC ................................................................. 10

XII. DIAGNOSTIC LIGHTS ........................................................................................... 10

Heat Call Light .................................................................................................................................... 10

Pre-Purge Timer Light ....................................................................................................................... 11

Burner Enabled Light ........................................................................................................................ 11

XIII. TROUBLE SHOOTING .......................................................................................... 11

Supply Blower Not Starting .............................................................................................................. 11

No Heat (Burner Not Firing) ................................................................................................................ 12

Low Heat (Burner Firing) .................................................................................................................... 12

Unit Short of Temperature Rise ........................................................................................................ 12

Over Delivering Air ............................................................................................................................ 13

Inlet Gas Pressure Low or Burner Rumbles.................................................................................... 13

Regulator/Manifold Pressure Low or Slow to Respond ................................................................. 13

Gas Valve Won’t Open Fully (G-TRAC Slave to CTRAC) ................................................................... 13

Water and Ice From Combustion ...................................................................................................... 13

Over Heating ....................................................................................................................................... 14

Rapid Cycling of SA Contacts on G-TRAC Connected to BMS Reset .......................................... 14

G-TRAC not responding to BMS signal ........................................................................................... 14

Flame Failure Lockouts ..................................................................................................................... 14

“B” and “C” BURNER ELECTRODE DETAIL ............................................................................ 15

XIV. CHANGING A G-TRAC IN THE FIELD .................................................................. 15

TO SET PRE-PURGE TIME DELAY ................................................................................................... 15

TO SET THE MAINTAIN PURGE TIME DELAY ................................................................................ 16

IOM-24 Page ii March 1999 R1

A G-TRAC MANUAL

ESTIMATED POT SETTINGS (Use for situations where design values not available) .............................. 16

Combustion Set Up ............................................................................................................................ 17

High Fire Combustion Set Up .................................................................................................... 17

Low Fire Combustion Set Up ..................................................................................................... 17

Mid-Fire Range Combustion Set Up .......................................................................................... 17

CHECK OUT FOR G-TRAC-1 NORMAL OPERATION .................................................... 18

IOM-24 Page iii March 1999 R1

A G-TRAC MANUAL

A

G-TRAC

CONTROL FOR MODULATING DG UNITS

If you note any errors, omissions, or items that require further clarification, please contact Wade Pascoe at

(403) 287-4775 or Fax (403) 287-4799 or (403) 243-5059.

To ensure warranty is honoured, only a qualified HVAC service person or gas fitter that has received training

on the G-TRAC, should be employed for service and troubleshooting. If information is required please contact

the nearest Engineered Air office.

If conversion of degrees F to C is wanted, refer to table on page 4.

I. PURPOSE

The G-TRAC is designed to provide an accurate method of temperature control by modulating the size of the

flame on the DG Series heaters. It has been designed to operate with a variety of discharge control devices

and has the ability to utilize a room sensor for set point override control. The usual controls being applied to

the

G-TRAC are arranged to Johnson Controls TE 6000/TE 6100 series or the G-TRAC is being operated as

a slave to the CTRAC. It is often applied to Gordon Piatt or Maxon Burner Systems.

II. CAUTION

The G-TRAC has a number of internal potentiometers. These are set up at the factory. These potentiometers

should not be field adjusted unless consultation has been made with someone who is familiar with the control.

Tampering may misalign the control operation resulting in poor combustion and/or poor temperature control or

calibration.

III. SIMPLIFIED OPERATION

24 V power to terminals "H" and "N"

36 seconds later terminals "SA" and "SA" make to start supply fan if the heat switch is not “on”.

NOTE: If the heat switch is already "on" there may be a further delay before the supply

blower starts while the heat starts.

Closing the remote heat switch places 24 V power to "HS" (heat switch).

If there is a call for heat from the temperature control device attached to the G-TRAC:

- As a safety procedure, the G-TRAC checks if "AS" is closed before the combustion blower starts. If it

is, then "CB" contacts will not close to start the combustion blower due to a closed air switch.

- If “AS” is open then "CB" to "CB" will close to start the combustion burner motor. Pre-purge is factory

set between 1 and 8 minutes. The length of pre-purge time is determined by the size of the heat

exchanger. (Jumper selection listed in Section XIV about replacing the G-TRAC.)

- The combustion blower moves air into the combustion chamber and the airflow closes the air switch

putting 24 volts on G-TRAC terminal "AS" (air switch).

- After pre-purge is complete "FR" to "FR" (flame relay) closes to power the flame relay for an ignition

attempt.

- If the supply blower had been shut off, "SA" to "SA" will close again 36 seconds after the pre-purge is

done to re-start the supply air fan. This is to allow for heat exchanger warm-up.

IOM-24 Page 1 March 1999 R1

A G-TRAC MANUAL

The flame relay (external to the G-TRAC) energizes the ignition transformer and pilot solenoid valve.

When the pilot is established, the flame relay will power the main gas valve and shut off the spark.

The G-TRAC and its associated controls maintain the discharge air temperature.

If the rise in discharge air temperature at low fire is greater than that required to satisfy the set-point, it is

necessary to cycle the burner on and off. The normal G-TRAC will likely cycle at about one minute intervals

and at a 20ºF-temperature swing when a low temperature rise is required. At extra cost the G-TRAC can be

tuned to "high sensitivity" which causes more burner cycling but gives better discharge control during

conditions when only a small increase is needed in discharge temperatures.

When higher temperature rise is required the G-TRAC will modulate the size of the flame rather than cycle

the burner. Note that burner cycling may occur in temperatures where theory suggests modulation should be

possible. This is caused by the mass of the heat exchanger, the time heat transfers to the air and the time for

the discharge temperature control device to react.

After a heat call is complete the combustion blower will remain in a "maintain purge” mode for 7 to 15

minutes (depending on jumper selection noted later). If the combustion blower is running it will allow a heat

call to start immediately without going through pre-purge.

IV. TEMPERATURE CONTROL

G-TRAC as a Slave to the CTRAC

In this application there is no temperature control sensor or set point attached to the G-TRAC. The G-TRAC’s

ability to control the firing rate is done with a 0 to 10 VDC volt signal from a CTRAC2.1 terminals "HD and B",

(0 to 8.5 VDC on the CTRAC2 version terminal "HT and B"). The CTRAC2.1 is the master control of the system.

G-TRAC heat call light will be activated when about a 4.5 VDC signal is received from the CTRAC. Terminal

HT to B are connected to D and W of G-TRAC. Refer to C-TRAC manual also.

Suggested Settings Re Hunting Problems

C-TRAC2.1 with G-TRAC with TE 6000-960 discharge sensor – may modulate through 20 degrees.

Set C-TRAC Pots Set G-TRAC Pots

P3 = 6 min. as high as 9

P6 = 5 ***

P11 = 2

C-TRAC2.1 with G-TRAC and hyper sensor – may modulate whtough 10 degrees.

Set C-TRAC Pots Set G-TRAC Pots

P3 = 6 min. as high as 9

P6 = 5 ***

P11 = 2

*** On C-TRAC2.1 pot 6 does not exist.

P5 = 2

P6 = 4

P8 = 4

P5 = 2

P6 = 4

P8 = 4

G-TRAC as a “Stand Alone Device”

Either the internal set point or an external set point will be used as the discharge set point. Most installations

will use an external set point.

The usual discharge set-point control is a Penn TE 6100-960 control (which is both a set point and sensor, but

only the set point half is wired). The TE 6100-960 set-point device requires a cover such as T4000-264S. The

discharge sensor is a Penn TE 6000-960 sensor located in the discharge air stream.

IOM-24 Page 2 March 1999 R1

A G-TRAC MANUAL

V. MASTER SET-POINT

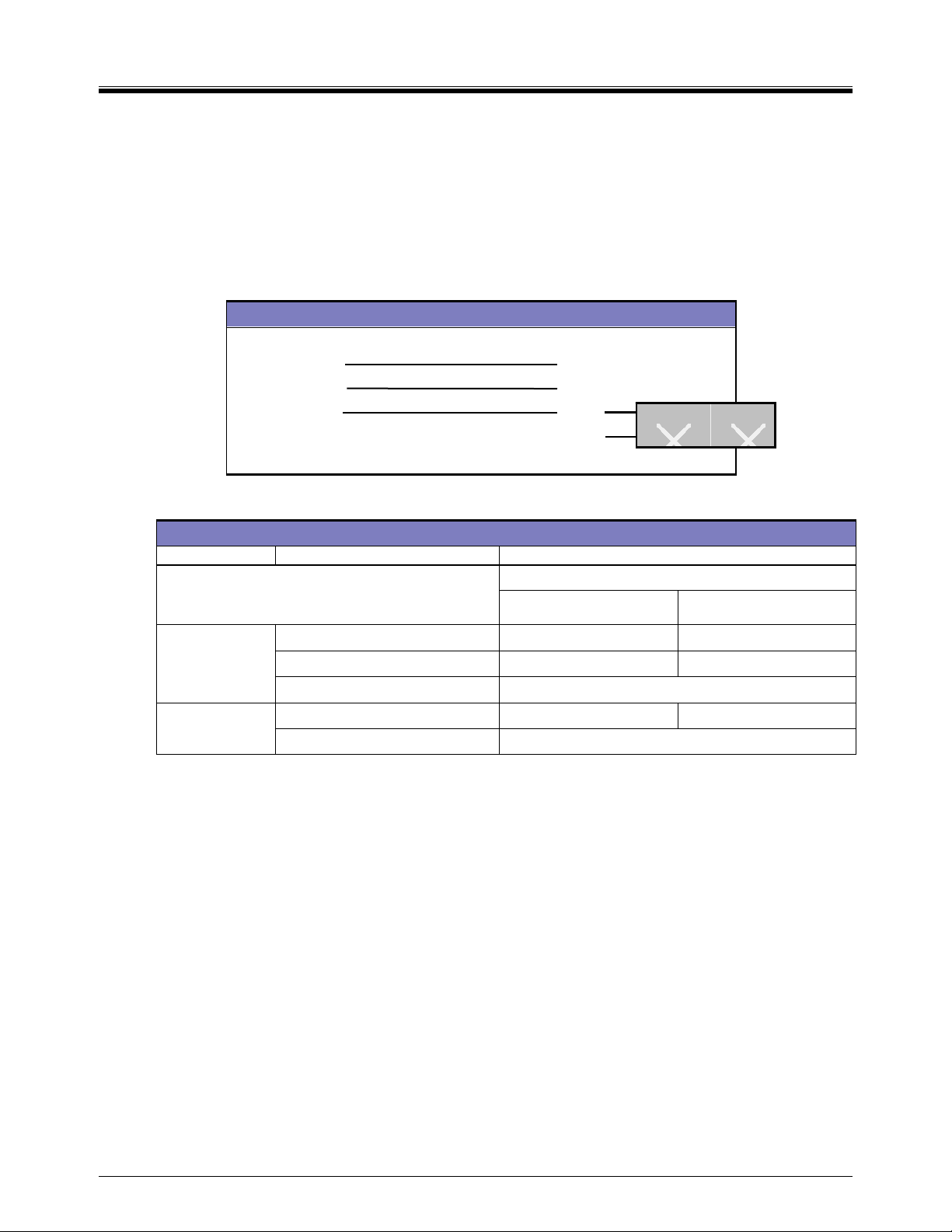

TE 6100 Wiring Connections and Resistance Values

As a SET POINT, the G-TRAC is designed to use either:

The set point pot 4 (auxillary setpoint) (range of 12-35°C or 55- 95°F) . If the G-TRAC pot 4 auxillary set-point

is used, terminals “SP and S” must be jumped, or;

The Johnson TE 6100-960 set point (range of 50-85°F and often remote mounted). If the TE 6100-960 is

used as a set-point, “S to SP” must not be jumpered and the TE 6100 must be wired:

TE 6100 Wires CTRAC2.1 Terminals

Violet (not used, sensor)

Blue U

Orange S

Grey M

Red (not used) Q

(No jumper S-SP)

TE6100-960 Sensor/Set Point

SENSOR (purple and blue) Same resistance as TE 6000-960

Set-Point Dialled To

60 degrees 90 degrees

TE 6000 Sensor

POT

OTHER

(orange and grey)

(orange and blue)

(blue and grey) 970

(purple and orange)

(purple and grey)

2.725 K 3.272 K

3.184 K 2.702 K

4.19 K 3.71 K

About 1.981 K (varies with element temp.)

IOM-24 Page 3 March 1999 R1

Loading...

Loading...