EngA C-TRAC3 Installation, Operation And Maintenance Manual

UNIT MODEL NO. _________________

UNIT SERIAL NO. _________________

SERVICED BY: ___________________

TEL. NO: ________________________

CANADIAN

HEAD OFFICE

AND FACTORY

USA

HEAD OFFICE

AND FACTORY

CANADIAN

EASTERN FACTORY

1401 HASTINGS CRES. SE

CALGARY, ALBERTA

T2G 4C8

Ph: (403) 287-4774

Fx: 888-364-2727

32050 W. 83rd STREET

DESOTO, KANSAS

66018

Ph: (913) 583-3181

Fx: (913) 583-1406

1175 TWINNEY DRIVE

NEWMARKET, ONTARIO

L3Y 5V7

Ph: (905) 898-1114

Fx: (905) 898-7244

SALES OFFICES ACROSS CANADA AND USA

Retain instructions with unit and maintain in a legible condition.

Please give model number and serial number when contacting

Engineered Air for information and/or parts.

A

INSTALLATION, OPERATION

AND MAINTENANCE MANUAL

FOR

C-TRAC3

COOLING CONTROLLER

Jan 13 R5

www.engineeredair.com

A

Warning:

This unit is connected to high voltages. Electrical shock or death could occur if

instructions are not followed. This equipment contains moving parts that may start

unexpectedly. All work should be performed by a qualified technician. Always

disconnect and lock out power before servicing. DO NOT bypass any interlock or

safety switches under any circumstances.

C-TRAC3

If any errors or omissions are noted please contact Engineered Air – Calgary Service at

(403) 287-2590 or Fax (403) 287-4799 or email service@engineeredair.com.

To ensure warranty is honored, only a qualified HVAC service person, who has received training on the

C-TRAC3, should be employed for service and troubleshooting. If further information is required please

contact the nearest Engineered Air office.

Under no conditions (except for temporary copying) should the unit function description be removed from

the unit. There are two copies provided with the unit. One is in an envelope for copying, then return it to

the unit or store in a safe place. The other is attached to the control panel door and should never be

removed. If a copy of the function for a particular unit is needed, contact Engineered Air with the unit

serial number, C-TRAC3 model number (ex model C-TRAC3.3.1) and the C-TRAC3’s program number noted

near the top right corner of the controller. The program number should also be noted on the electrical

drawing.

2 of 21 Jan 13 R5

A C-TRAC3

Table of Contents

INTRODUCTION ................................................................................................................................................................ 5

STARTUP AND SHUT DOWN ............................................................................................................................................. 5

SERVICE SWITCH ............................................................................................................................................................... 5

TEMPERATURE CONTROL ................................................................................................................................................. 6

BASE SETPOINT ................................................................................................................................................................. 6

SETPOINT RESET ............................................................................................................................................................... 6

SETPOINT LIMITS .............................................................................................................................................................. 6

MODES OF OPERATION .................................................................................................................................................... 6

SENSOR #2 ........................................................................................................................................................................ 7

MEASURING TEMPERATURE AND SETPOINT ................................................................................................................... 7

OPERATION ....................................................................................................................................................................... 7

AMBIENT SENSING ............................................................................................................................................................ 8

BLOWER CONTROL ........................................................................................................................................................... 8

ECONOMIZER MODE ........................................................................................................................................................ 8

MINIMUM POSITION ........................................................................................................................................................ 9

Ambient Compensation .................................................................................................................................................. 10

HEATING MODE .............................................................................................................................................................. 10

COOLING MODE .............................................................................................................................................................. 10

DUAL MODE .................................................................................................................................................................... 10

OCCUPIED/UNOCCUPIED ................................................................................................................................................ 11

INDICATION AND DIAGNOSTIC LIGHTS ........................................................................................................................... 11

LOW LIMIT ...................................................................................................................................................................... 13

VARIABLE AIR VOLUME .................................................................................................................................................. 13

WIRING ........................................................................................................................................................................... 14

EMS Wiring ..................................................................................................................................................................... 15

TROUBLE SHOOTING ...................................................................................................................................................... 15

BASIC (MULTIMETER) ..................................................................................................................................................... 15

DIP Switches (C-TRAC 3.2 and higher) ............................................................................................................................ 15

SIMULATING A HEAT/COOL CALL ................................................................................................................................... 16

ENCHANCED (COMPUTER) ............................................................................................................................................. 16

Calibration ...................................................................................................................................................................... 17

SENSOR TABLES .............................................................................................................................................................. 18

SERVICE NOTES ............................................................................................................................................................... 19

3 of 21 Jan 13 R5

A C-TRAC3

4 of 21 Jan 13 R5

A C-TRAC3

The C-TRAC3 is designed to control Engineered Air equipment only. It is not designed to simulate or

copy other controllers on the market today, nor can it be modified to do so.

CAUTION:

All of the remote wiring must be complete and functional before attempting to start

the unit.

CAUTION:

It is important that the service technician understands the C-TRAC3 is a configurable

controller. While the terminal designation remains the same, the operation of the

terminal is dependent on the required function, and may differ from unit to unit.

The C-TRAC3 is not field programmable. If the C-TRAC3 program becomes damaged or corrupted, it

must be replaced or returned to Engineered Air for re-programming.

INTRODUCTION

The CTRAC-3 is designed to control the cooling, heating, mixing economizer and fan(s). Additionally, it

allows for independent control of other types of equipment operations such as multi-zone and

dehumidification.

The CTRAC-3 requires a 24Vac grounded power supply. The fuse is located on the back of the control, and

has a rating of 800mA (slow blow). Fuse failure can be checked by having 24Vac across terminals H and N,

but the small green light on the face of the C-TRAC3 is not illuminated. There should also be no Vdc

reading across V and Z.

This information in this manual should be used in conjunction with the unit function sheet(s) and the

terminal designation list that accompanied the equipment.

The C-TRAC3 configuration program number is noted on the face of the C-TRAC3. This number is

important when contacting the factory about the unit operation, or for replacement parts. This number

should accompany the unit serial and tag number, and model number.

STARTUP AND SHUT DOWN

Startup and shutdown should always be accomplished by the use of the remote start contacts and/or

switches, or the unit on/off switch or an EMS control signal. This will allow the C-TRAC3 to disable unit

operation in sequence, protecting the unit components from damage.

SERVICE SWITCH

The service switch, located in the main electrical control panel, is designed for service and maintenance

use only, and should not be used to regularly enable or disable normal operation. Once the unit has

5 of 21 Jan 13 R5

A C-TRAC3

Additional details regarding startup and shutdown are noted in the unit function and in the Installation,

Operation and Maintenance manual.

completely shut down, turn the main disconnect switch off prior to attempting any service or

maintenance.

TEMPERATURE CONTROL

BASE SETPOINT

The C-TRAC3 is designed to be a discharge air temperature controller. The base discharge air temperature

setpoint is typically set from the setpoint 1 control knob located on the face of the

C-TRAC3. Optionally, this setpoint may be replaced by a remote mounted potentiometer, directly set from

a remote BMS signal (0-10Vdc), preset from a computer, or commanded from an EMS signal. If not used,

set this knob to maximum (fully clockwise), as noted on the face of the C-TRAC3.

The C-TRAC3 has the ability to perform 2 independent operations at the same time, such as a

dehumidification system (pre-cool and reheat) or a multizone system (hot deck, and cold deck). These

types of systems normally incorporate both face-mounted setpoint dials, but the optional setpoints noted

above can still apply to both or either setpoint. As above, if setpoint 2 is not used, set to maximum, as

indicated on the face of the C-TRAC3.

SETPOINT RESET

The base discharge air temperature is normally modified from a remote signal to maintain the desired

temperature of the supplied space. This is called reset. The C-TRAC3 discharge temperature can be reset

from a variety of sources such as ambient air temperature, modulating or staged room thermostats, return

air temperature, or a BMS signal (0-10Vdc).

The resulting change in the discharge temperature setpoint from reset is the actual, or calculated,

discharge air temperature setpoint. This is normally referred to as the SPC.

SETPOINT LIMITS

The discharge air setpoint range is set, and limited to, a specified temperature range programmed prior to

shipment. For example, if the minimum discharge temperature is programmed at 60°F, then that is the

minimum possible temperature setting. Even though the setpoint dial may go as low as 50°F, the

calculated, or actual, setpoint can never go below 60°F.

MODES OF OPERATION

The C-TRAC3 has 3 distinct sequential modes of operation: heating, economizer and cooling. Depending

on ambient conditions the C-TRAC3 may start in any of the three modes. Mode change time is five

minutes (six minutes from heat to mechanical cooling if there is no economizer). If the C-TRAC3 is unable

6 of 21 Jan 13 R5

A C-TRAC3

Mode

Terminal

Operation

Heat

HS

Heating is allowed with 24Vac at the terminal.

Economizer

E

Economizer is disabled to minimum with 24Vac.

Cool

A

Cooling is allowed with 24Vac at the terminal.

CAUTION:

All of the remote wiring must be complete and functional before attempting to start

the unit.

to satisfy the SPC in its present mode and the discharge temperature slips outside of the discharge

temperature dead band then it will begin timing for a mode change. Once the timing is completed, it can

change modes. If the timer is active and the discharge temperature slides back into the dead band, the

mode change timer is reset. If the current operating mode becomes disabled the C-TRAC3 will immediately

move into the next mode. A preprogrammed option can disable the unit operation if no modes are

available. The table below indicates which 24Vac input terminal can enable or disable its corresponding

mode.

Table 1

The C-TRAC3 will not always be able to exactly maintain the SPC. Enabling a cooling compressor, for

example, may cause the discharge temperature to fall below the SPC. When the compressor is disabled

the temperature may rise above the setpoint. On average, however, the discharge temperature will

closely match the SPC.

The C-TRAC3 controls to a +/-2°F dead band of the SPC when in heating and economizer mode. The

cooling dead band is based on the dry bulb temperature drop of each stage of mechanical cooling.

SENSOR #2

The C-TRAC3 is has the option of using, and controlling to, two sensors. Some equipment may incorporate

2 discharge air sensors for improved temperature control. Multi-zone equipment use sensor #1 for the

hot deck, and sensor #2 for the cold deck. Dehumidification equipment use sensor #1 for the reheat

(leaving) section, and sensor #2 for the pre-cool section.

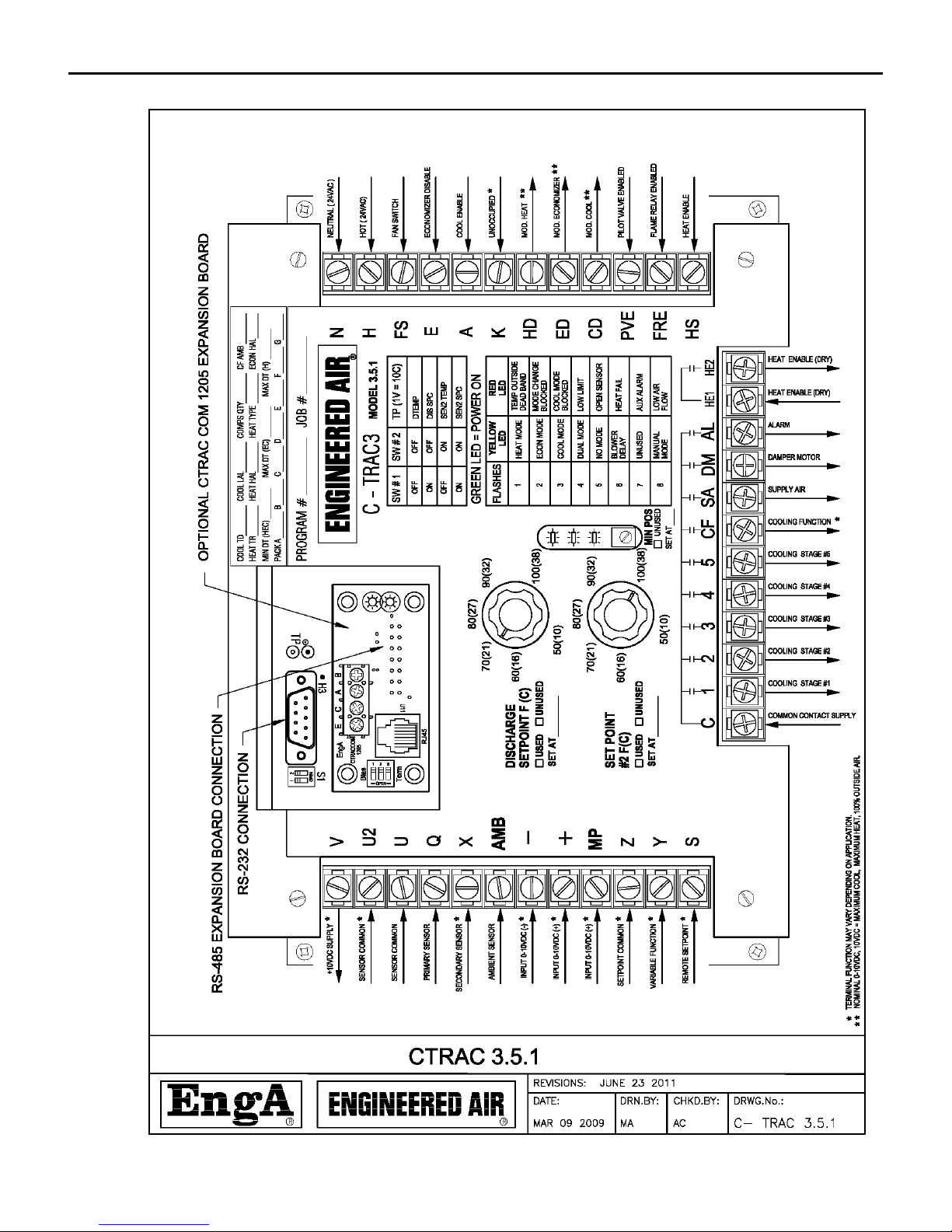

MEASURING TEMPERATURE AND SETPOINT

The calculated setpoint (SPC) and the actual temperature can be monitored using a DC voltmeter and the

temperature test points and a DIP switch block mounted on the face of the C-TRAC3 (located near the

RS232 serial connection). Note that the calculated setpoint includes any resets to the setpoint. Refer to

Table 4 on page 14.

OPERATION

As the C-TRAC3 is configurable and will vary in its operation unit to unit, it is imperative that the unit

function, terminal designation sheet and wiring diagram be reviewed to understand how the control is

operating for each particular application.

7 of 21 Jan 13 R5

Loading...

Loading...