EnerWorks EWRA2, EWRA1 Installation Manual

Module 4

Solar Collector

Installation Manual

1, 2, 3 & 4 Collector Pre-Heat Appliances

(EWRA1, EWRA2)

Rev. 2013,04,23

1 & 2 Collector Single Tank Appliances (USA only)

( )EWRA1-ST, EWRA2-ST

Solar Water Heating Appliances

EnerWorks Inc.

969 Juliana Drive

Woodstock, ON

N4V 1C1, Canada

Tel: (519) 268-6500

Toll-free: 1-877-268-6502

Fax: (519) 268-6292

www.enerworks.com

© 2013 enerworks

Solar Collector

Installation Manual

Foreword

EnerWorks encourages installers of EnerWorks products to always keep workmanship, best practices

and safety in mind. An organized installation will benefit both installer and end-user.

The EnerWorks Solar Collector is one of the highest-rated in North America. This assessment was

carried out by third-party testing under the supervision and scrutiny of the Solar Rating & Certification

Corporation™ (SRCC™). The EnerWorks Heat Safe Solar Collector has SRCC™ OG-100 certification

(Certification #: 100-2005-014A) and the EnerWorks Residential Solar Water Heating Appliances are

certified to OG-300 standards. This certification does not imply endorsement or warranty of these

products by the SRCC™.

The Pre-Heat and Single Tank Appliances described in this manual, when properly installed and

maintained, meet or exceed the standards established by the Florida Solar Energy Center (FSEC), in

accordance with Section 377.705, Florida Statutes. This certification does not imply endorsement or

warranty of this product by the Florida Solar Energy Center or the State of Florida.

The EnerWorks Pre-Heat Appliance is the first system in North America to achieve the Canadian

Standards Association (CSA) certification (CSA F379.1). This certification does not imply endorsement

or warranty by CSA.

Appliance must only be installed by an EnerWorks-authorized

dealer or warranty is void.

Recognize this symbol as an indication of important safety information!

EnerWorks Residential Solar Water Heating Appliances must be installed as

directed by this manual by an EnerWorks-authorized dealer or warranty is void.

CALIFORNIA PROPOSITION 65 WARNING: This product contains

chemicals known to the State of California to cause cancer,

birth defects or other reproductive harm.

Solar Collector

Installation Manual

CARE, HANDLING & STORAGE

EnerWorks Solar Collectors are manufactured with tempered glass. Though extremely resistant to

impact, tempered glass can break if an edge is subjected to stress. During storage and installation,

protect glass edges. Glass breakage is not covered by warranty.

Store collectors in a dry place, lying flat with glass up, or leaning on long edge with glass facing out and

connections at top. Protect collector from scratches and damage by placing it on a soft surface such as a

blanket or cardboard. When hoisting collectors to roof, be very careful not to bang glass edge.

Collectors must not be levered over ladder or eave as they may be damaged. Be very careful of collector

connections as they are soft copper and may be easily damaged. A leak-proof heat-transfer fluid loop

can only be achieved if collector connections are not damaged.

Do not store collectors outside with glass face down. Due to EnerWorks’ patented stagnation-control

device, back of collector is not sealed to atmosphere. Rain may enter collector if it is stored face down.

Any damage due to ingress of water is not covered by warranty.

It is best to store both the EnerWorks Solar Collectors and the EnerWorks Energy Station in a cool, dry

place.

Module 4

1

Contents

Solar Collector

Installation Manual

1 – Safety

.................................................................................................................................... 3

2 – EnerWorks Solar Water Heating Appliance

2.1 Description

..................................................................................................................4

2.2 Pre-heat Appliance Schematic

2.3 Single Tank Appliance Schematic (USA only)

3 – Site Evaluation

.......................................................................................................................7

3.1 Collector Location, Orientation and Shading

3.2 Available Roof Space

3.3 Collector Racks

3.4 Line-Set

...................................................................................................................... 8

.................................................................................................... 8

............................................................................................................ 8

3.5 Location of Energy Station and Solar Storage Tank

4 – Line-Set Installation

4.1 Line-Set Description

4.2 Line-Set Routing

4.3 Line-Set Installation

5 – C-Channel Installation

............................................................................................................... 8

..................................................................................................... 8

........................................................................................................... 9

....................................................................................................10

......................................................................................................... 11

5.1 Locating Rafters and Positioning C-Channel

5.2 Securing C-channel Asphalt roof (Shingles)

5.3 Securing C-channel to S etal Roof

5.4 Roof-Penetration Flashing Boot

6 – Solar Collector Installation

6.1 Preparation of Collector(s)

tanding Seam M

................................................................................... 15

..................................................................................................... 16

.......................................................................................... 16

6.1.1 Converting Collector(s) from Left to Right

6.1.2 Installing Temperature Sensor (Thermistor)

6.1.3 Installing Collector Mounting Brackets

6.2 Hoisting and Securing Collectors to Roof

6.2.1 Ladder Hoist or Shingle-Lift

...................................................................................... 23

6.2.2 Scissor Lift or Articulating or Forklift Boom

6.2.3 Scaffolding

6.2.4 Ladder and Lift Line

6.3 Securing Collectors to C-Channel

6.4 Collector Configurations

6.4.1 One-Collector Configuration

6.4.2 Two-Collector Configuration

6.4.3 Three-Collector Configuration

6.4.4 Four-Collector Configuration

............................................................................................................. 23

.................................................................................................. 24

................................................................................ 25

................................................................................... 26

.................................................................................... 26

................................................................................... 27

................................................................................... 27

.................................................................................... 28

6.5 Line-Set and Control-Wire Connections

7 – Collector Flashing and Leaf-Guard Installation

7.1 Side-Flashing for 1-Collector Appliances

7.2 Center-Flashing for 2, 3 and 4-Collector Appliances

7.3 Leaf-Guard Installation

................................................................................................ 33

............................................................................... 4

........................................................................5

...............................................................6

................................................................... 7

........................................................... 8

................................................................. 11

................................................................. 13

........................................................ 15

................................................................... 17

............................................................... 20

...................................................................... 21

...................................................................... 22

................................................................... 23

......................................................................... 29

......................................................................... 30

..................................................................... 31

...................................................... 31

Product and Installation Registration Form

Residential Site Survey

Tool & Supply Checklist

2

................................................................................................................. 35

.................................................................................................................. 36

..................................................................................... 34

Module 4

Solar Collector

Installation Manual

1 – Safety

EnerWorks assumes no responsibility for damage, loss or injury related to installation of this

appliance.

Observe any and all regulations relating to installation of solar appliances and to plumbing to

potable water supply. Plumbing and/or building permits may be necessary. EnerWorks Solar

Water Heating Appliances utilize a single-wall as well as double-wall heat exchangers.

Selection must be acceptable in the jurisdictions.

Assemblies, installation and materials used during installation shall meet applicable

requirements of local, regional, state, provincial, and federal regulations and fire codes,

national roofing contractors association practices. Any penetrations made in drywall or any

other firewall must be fixed to maintain integrity of fire protection.

All persons working on roofs should have successfully completed a fall-safety course and

should be properly equipped with appropriate safety equipment.

Module 4

3

Solar Collector

Installation Manual

2 – EnerWorks Solar Water Heating Appliance

2.1 Description

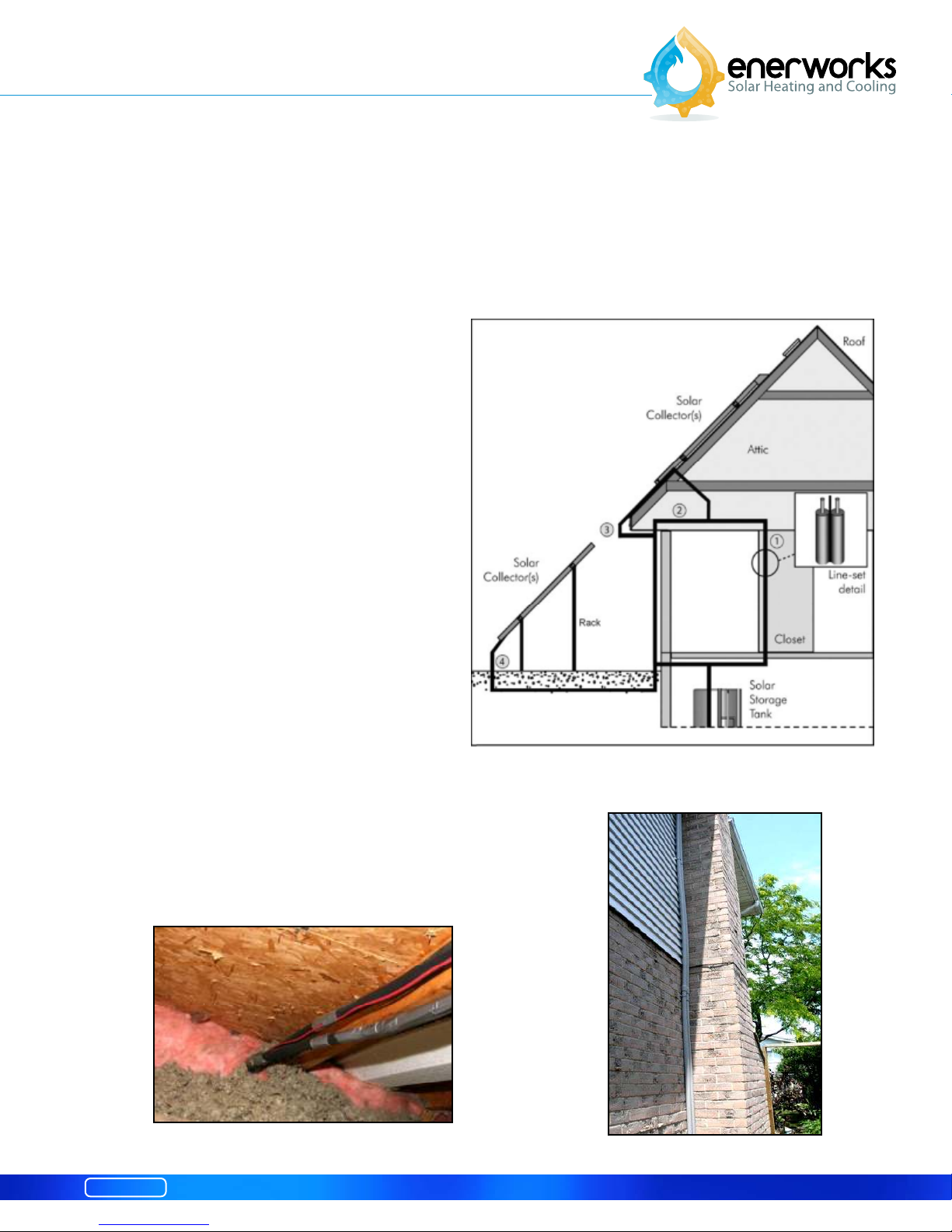

The EnerWorks Solar Water Heating Appliance has four main parts – the solar collectors, the line-set,

the Energy Station and the solar storage tank.

The Energy Station uses a pump to circulate a heat-transfer fluid through the “collector loop”. This

collector loop includes the solar collectors, the fluid lines or “line-set” and a heat exchanger. The

collector loop is a “closed loop”, meaning there is no contact of the heat transfer fluid with your potable

water or with the atmosphere. The collector loop contains only a small volume of heat-transfer fluid

which is freeze-protected. Though freeze protection may not be necessary in all areas, the heat-transfer

fluid also has an elevated boiling point and so is suitable throughout North America.

When exposed to sunlight, the solar collectors get hot. Passive overheat-protection prevents

temperature exceeding 275°F (135°C); pressure and flow conditions depends on the system. As the

heat-transfer fluid passes through the collectors, it absorbs heat and then travels down the line-set to

the Energy Station. The hot fluid passes through the heat exchanger and heat is transferred to the

potable water. After giving up its heat to the potable water, the cool heat-transfer fluid is pumped back

to the solar collectors to be heated again. Hot potable water is stored in the solar storage tank.

In the Pre-Heat Solar Water Heating Appliance (Fig. 2.2), the solar storage tank is a standard, North

American, electric hot-water tank. No power is connected to this tank – it only stores solar-heated water.

The solar storage tank is plumbed in series with the original water-heater (electric, fossil fuel, or ondemand). Whenever hot water is used in the home, solar heated water leaves the solar storage tank

and enters the original water-heater. The original water-heater now requires much less energy for water

heating.

Thus, the Appliance displaces energy, but it does not replace the original water-heater. The original

heater guarantees hot water even under poor solar conditions (at night or when very cloudy). It also

ensures that hot water is stored or supplied at an appropriate temperature to kill harmful bacteria. The

acceptable temperature set-point is specified in local plumbing codes. Do not turn off or bypass the

back-up water-heater. Even in summer months, additional heat from the back-up heater may be

required.

The Single Tank Solar Water Heating Appliance (Fig. 2.3) incorporates solar water-heating and

auxiliary water-heating in a single tank. The Single Tank Appliance is the solar solution for homes (in the

United States) that cannot accommodate two tanks. For more information on Appliance components

and function, please see the Owner Manual.

4

Module 4

Solar Collector

Installation Manual

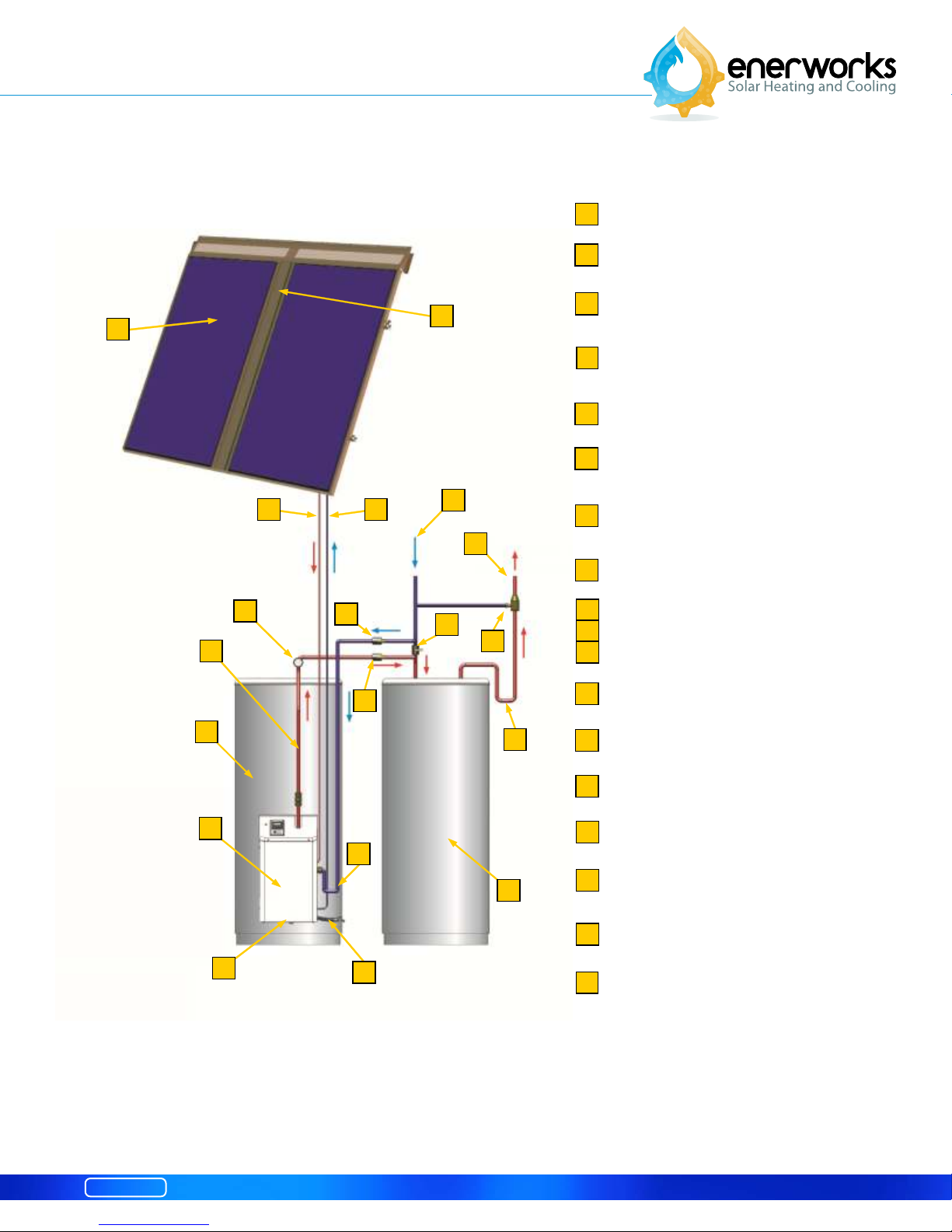

2.2 Pre-Heat Appliance Schematic

1

Solar collectors (1 to 4)

2

Line-set roof-penetration (behind flashing)

1

3 4

8

7

13

9

10

2

5

6

11

12

14

Heat transfer fluid line from collectors to

3

Energy Station (red – carries hot fluid)

Heat transfer fluid line from Energy Station to

4

collectors (blue – carries cool fluid)

5

Cold mains water supply (blue)

6

Hot water supply to home (red)

Thermosiphon loop,

7

solar-heated water to storage tank (red)

8

Thermometer

9

Bypass valves

10

11

12

13

(to isolate Appliance for service)

Anti-scald valve

(not included, may be required by code)

Solar storage tank

15

9

17

Fig. 2.2 EnerWorks Pre-Heat Solar Water Heating Appliance (with optional leaf-guard)

Module 4

14

18

16

14

Heat trap (U-bend limits heat loss)

15

Energy Station

Pre-existing or auxiliary hot water tank or

16

17

18

on-demand heater

Pressure relief valve (inside cover)

Thermosiphon loop feed (from storage)

5

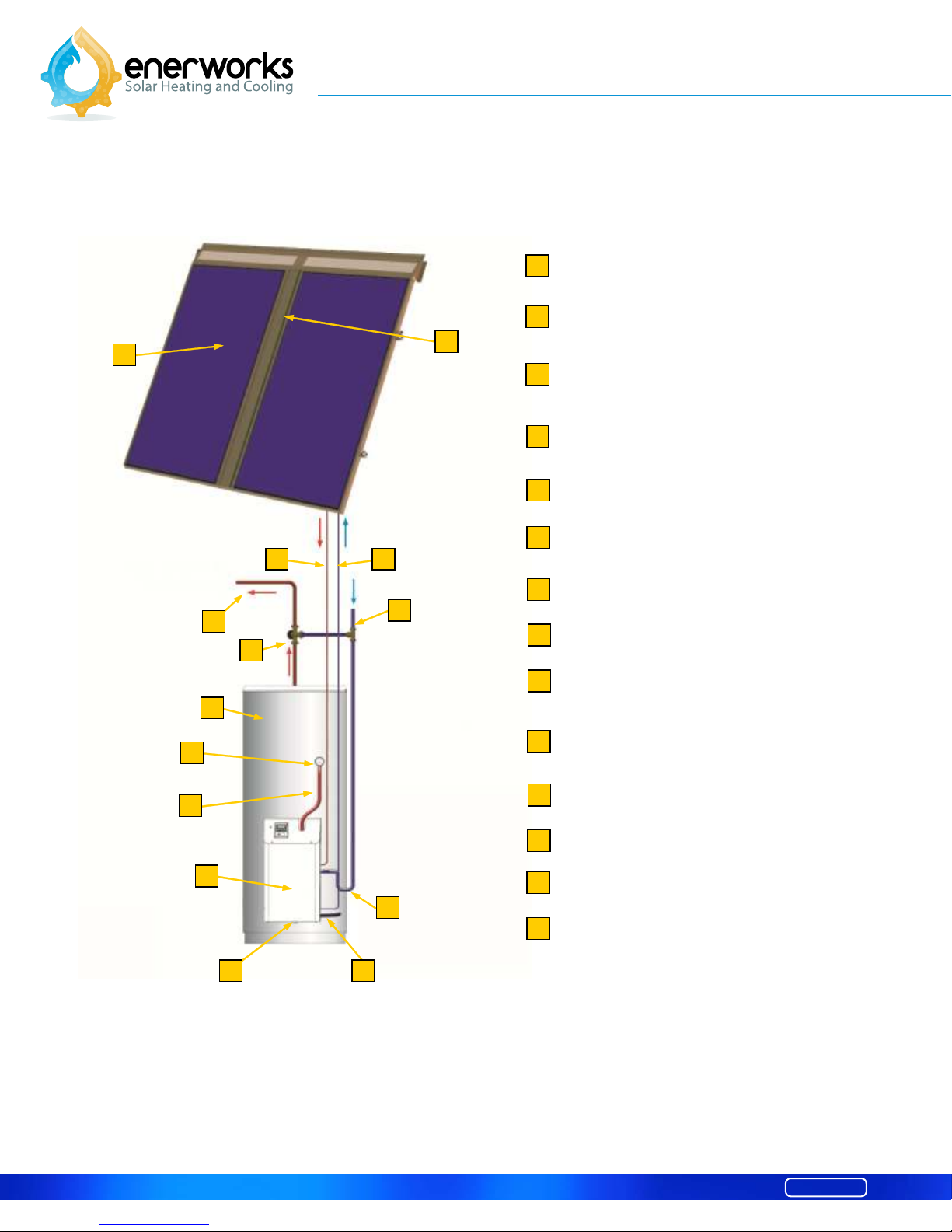

2.3 Single Tank Appliance Schematic (USA only)

Solar Collector

Installation Manual

1

Solar collectors (1 or 2)

2

1

3 4

5

6

8

9

7

2

Line-set roof-penetration (behind flashing)

Heat transfer fluid line from collectors to

3

Energy Station (red – carries hot fluid)

Heat transfer fluid line from Energy Station

4

to collectors (blue

5

Hot water supply to home (red)

6

Anti-scald valve (required)

7

Cold mains water supply (blue)

8

9

10

Solar storage tank with electric back-up

Thermometer

Thermosiphon loop,

– carries cool fluid)

solar-heated water to storage tank (red)

10

11

12

Fig. 2.3 EnerWorks Single Tank Solar Water Heating Appliance (with optional leaf-guard)

6

13

14

11

12

13

14

Energy Station

Pressure relief valve (inside cover)

Thermosiphon loop feed (from storage)

Heat trap (U-bend limits heat loss)

Module 4

Solar Collector

Installation Manual

3 - Site Evaluation

To achieve good performance and a good return on investment, the Appliance must be sized correctly

and it must be oriented properly. Site evaluation is necessary to determine whether a site is appropriate

and to evaluate the complexity of the installation. It is also necessary to determine the hot water loads,

number of individuals in a home, number of collectors and size of solar storage tank.

A site survey (see Appendix – Residential Site Survey) has been developed to assist installers in

evaluating potential installation locations. This can be removed from the Appendices and copied as

needed. Solar simulation software may assist in determining the best location and orientation for the

solar collectors.

For roof-mounting, installer should ensure that roof cladding or sheathing is in good repair. Also

ensure that rafters and trusses are adequate to support weight of solar collector(s) and mounting

assembly.

Building and plumbing permits and/or inspections may be necessary to proceed with installation.

Follow all code requirements and regulations.

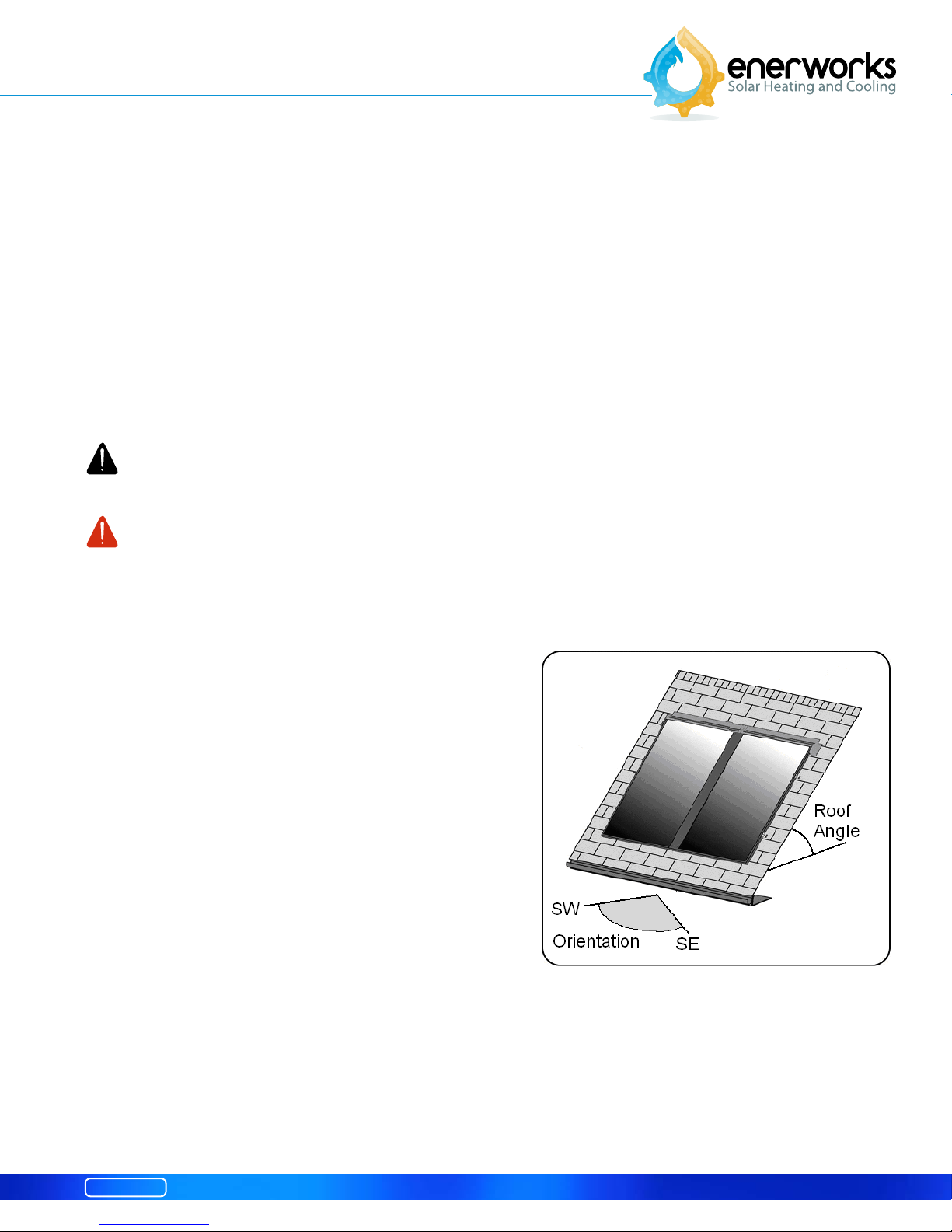

3.1 Collector Location, Orientation and Shading

Collector(s) should face as close to south as possible for

optimal performance. Within 45° of south is acceptable

as there is less than 10% loss (Fig. 3.1.1).

The roof angle from horizontal for optimal year-round

performance is equivalent to latitude of location plus or

minus 15°. A steeper angle provides better winter

performance as the sun is lower in the sky. Collectors will

also shed snow more effectively. A shallow angle

maximizes energy capture in summer when sun is high.

Be cautious of placement on low angle roofs due to

snow shedding and potential for ice-damming. A

minimum collector angle of 14° (3:12 pitch) is necessary

for stagnation-control device to function.

Shading of collectors greatly reduces performance.

When selecting installation location, consider potential

shading by trees and other buildings, especially

between peak solar hours of 10:00 and 15:00. A Solar

Pathfinder or similar device may be used to determine

potential shading throughout the year.

Module 4

Fig. 3.1.1 – Collector Orientation.

7

Solar Collector

Installation Manual

3.2 Available Roof Space

Appliance may consist of one to four collectors depending on required volume of hot water. Check

appliance specification sheet for sizing guidelines. Each collector is 4’ x 8’ (1.219 m x 2.438 m) and

must be mounted in “portrait” orientation. Installation area must be clear of roof vents, fans, satellite

dishes, etc. Refer to section 5.1 Locating rafters and positioning C-channel for more details.

3.3 Collector Racks

A rack may be used on the ground or to increase collector-angle on low-angled roofs. Consideration

must be given to wind and snow loads, and to aesthetics.

EnerWorks Solar Collectors are not as sensitive to orientation as photovoltaic panels (PV). Due to

size and weight of solar thermal collectors, tracking systems are not advisable.

Racking may require approval or certification by a building engineer and/or local authorities. It is

the responsibility of the installer to ensure appropriate design and safety criteria are met.

3.4 Line-Set

Line-set carries heat-transfer fluid from collectors to Energy Station and back again. Line-set must be

flexible, refrigeration-grade 3/8” soft-copper tube. A proper and dedicated bending tool must be used

for tight bends. Line should be as smooth as possible with no unnecessary fittings or bends. Site

evaluation should include examining location and difficulty of roof and wall penetrations. Appropriate

techniques and materials for sealing penetrations are necessary.

3.5 Location of Energy Station and Solar Storage Tank

Energy Station and solar storage tank will be located in mechanical or utility room, close to existing

water-heater. Stairway and doorway clearance must be examined. Additional floor space is

required for solar storage tank and Energy Station. Consideration must be given to location and

complexity of wall and ceiling penetrations, and to plumbing of appliance to existing water-heater

and to water distribution network.

Energy Station requires AC power. Solar storage tank and Energy Station must be installed in

proximity to AC outlet. Surge protection is recommended.

4 – Line-Set Installation

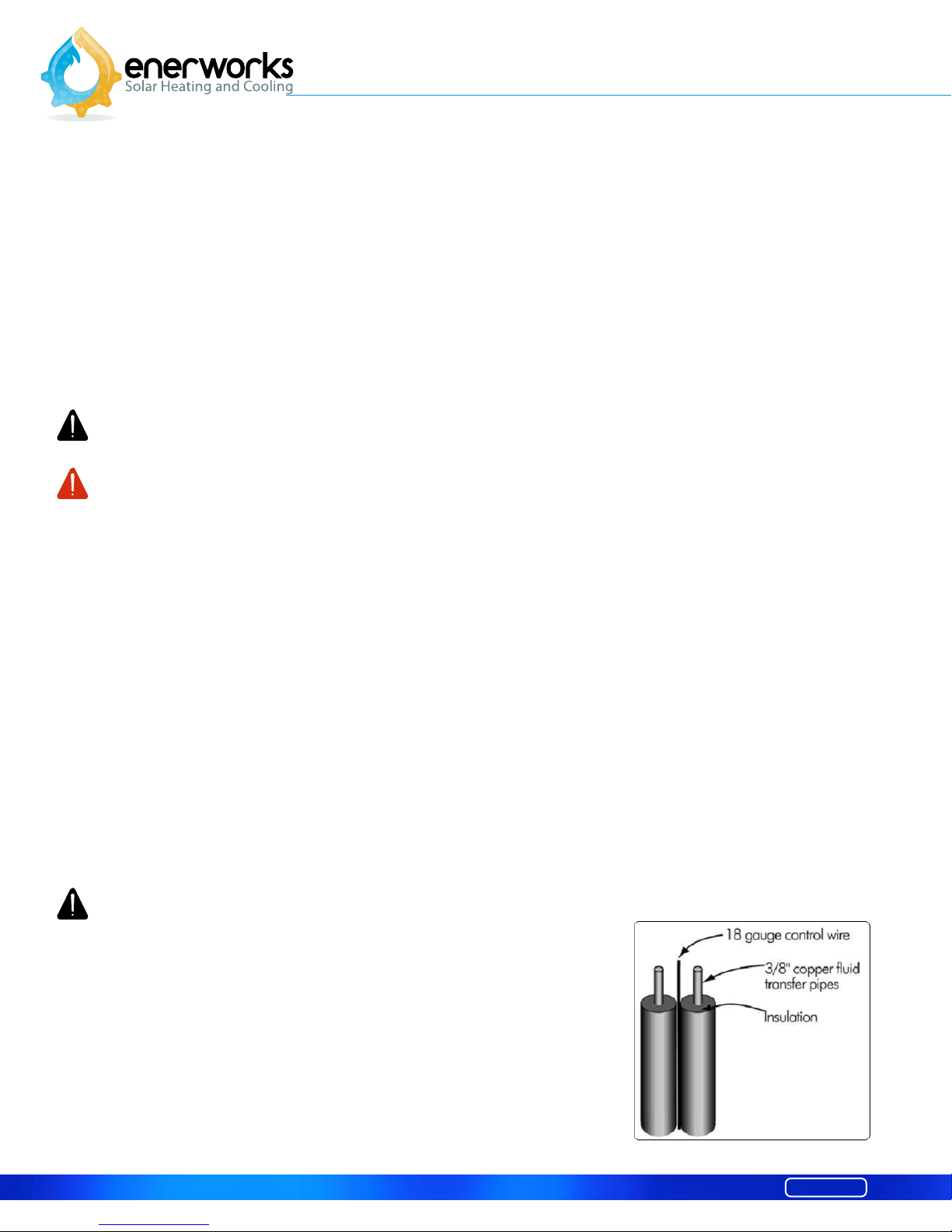

4.1 Line-set Description

Line-set connects Energy Station to solar collectors. Line-set consists of

two 3/8” refrigeration-grade, flexible soft-copper tubes. Tubes are

individually insulated with refrigeration insulation (3/8” ID - 3/8”-wall).

Bundle with the line-set an 18-gauge, two-conductor control wire that

connects the Energy Station Controller to the solar collector

temperature sensor (Fig. 4.1.1).

8

Fig. 4.1.1 – Line-set

Module 4

Solar Collector

Installation Manual

4.2 Line-Set Routing

Selection of line-set route should be discussed with homeowner with consideration to aesthetics,

complexity and cost of installation (Fig. 4.2.1). Line-set through home will have lowest heat-loss and

possibly shortest length (Fig. 4.2.1 option 1). Interior line-set should not run next to bedrooms or daytime living space as some vibration noise from pump may be transferred through line-set. Interior lineset may be more appropriate for bungalow or single-storey applications.

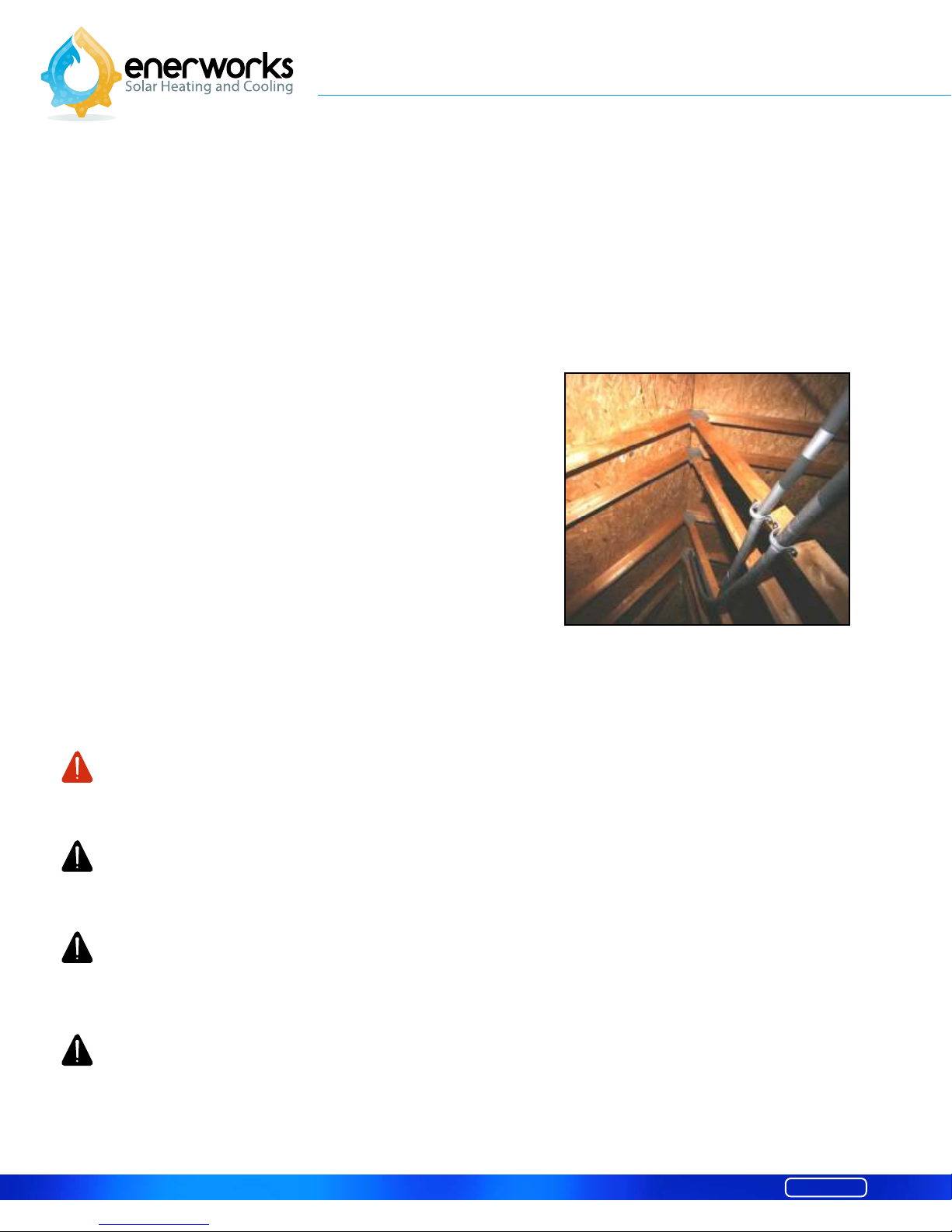

Line-set may penetrate roof into attic (Fig.

4.2.2) and drop from soffit down exterior

wall to above foundation or through

foundation to mechanical room (Fig. 4.2.1

option 2). This may facilitate installation and

minimize vibration noise transferred through

lines. Exterior line-set and insulation must be

protected by molding, electrical conduit or

false downspout that matches existing siding

or eavestrough (Fig. 4.2.3). Exterior line-set

may be best for two or three-storey

applications.

Line-set may run around eave and down

exterior wall if access to attic is limited (Fig.

4.2.1 option 3). All exterior insulation shall

be protected from ultraviolet radiation and

moisture damage. Line-set of rack-mounted

col lectors on ground may be run

underground through conduit such as big‘O’ to protect insulation (Fig. 4.2.1 option 4).

For new homes, consider installing 3 – 4” diameter PVC

or ABS chase from attic to hot-water tank location. This

will facilitate future removal or replacement of line-set if

necessary.

Fig. 4.2.1 – Line-set routes

Fig. 4.2.2 – Line-set and control-wire in attic.

Module 4

Fig. 4.2.3 – Exterior line-set in downspout

9

Solar Collector

Installation Manual

4.3 Line-Set Installation

Use care to unroll coiled copper tube. Leave protective end-caps in place to prevent contamination of heattransfer fluid. System degradation due to the contamination of fluid is not covered by warranty.

Seams should be taped with tape that will not dry out and disintegrate (i.e., duct tape). Lines may be pulled

as a bundled. Use straps to secure lines to rafters. Ensure straps are not in contact with copper lines due to

risk of galvanic corrosion (copper or plastic straps are recommended). Do not compress insulation when

bundling or securing lines (Fig. 4.3.1).

Line-set tube coils are available in 50’ and 75’ lengths.

Line-sets longer than 100’ are not recommended due to

the pressure drop through the system. It is best not to have

any joints or fittings. If line-set tube must be extended, do

not use lead or tin solder. The heat-transfer fluid will

degrade lead and tin solder, eventually causing leaks.

Brazing and flare union-fittings are permissible.

Wall, ceiling and roof-penetration may be a 2½” hole or

two 1¼” holes. Penetrations must be sealed appropriately

to maintain weather-proofing, sound-proofing, vermin

intrusion and fire integrity without impairing enclosure

functions. Roof penetration between collectors is

recommended as collector flashing hides line-set

penetration and eliminates need to protect insulation from

damaging UV.

When working in attics or confined spaces, determine type and quality of insulation material. Use

appropriate respirators or masks as necessary to prevent inhalation of insulation material.

A dedicated tube-bending tool must be used for tight bends. 3- and 4-collector

installations have tight tube bends on roof and a proper tube-bending tool is required. A proper

tube-bending tool may be necessary for 1- and 2-collector installations. A tube-bending tool is

recommended for line-set connections to Energy Station to provide clean, vertical lines.

Supply and return lines do not have to be differentiated. Control wire conductors do not have

to be differentiated.

Line-set must be insulated with refrigeration Insulation suitable for high temperatures such as

Armaflex, Aerocel or Gulf-O-Flex. Lower quality insulation (e.g. split foam tube) will degrade or

melt at high temperatures. Building materials must be insulated from elevated temperatures of

system components. Protective caps must be kept on ends of tubes until final connections are made

to prevent contamination of tubes and of heat-transfer fluid.

Fig. 4.3.1 – Line-set straps.

10

Module 4

Loading...

Loading...