ENERVEX

RS CHIMNEY FAN FOR GAS & OIL APPLICATIONS

3000270 05.16

Installation & Operating Manual

READ AND SAVE THESE INSTRUCTIONS!

ETL514733

ENERVEX Inc.

1685 Bluegrass Lakes

Parkway

Alpharetta, GA 30004

USA

P: 770.587.3238

F: 770.587.4731

T: 800.255.2923

info@enervex.com

www.enervex.com

3000270 05.16

ETL514733

This symbol shows that ENERVEX RS Chimney Fans for solid fuel applications are listed under ETL File no. 514733.

Symbol Legend

The following terms are used throughout this manual to bring

attention to the presence of potential hazards, or to important

information concerning the product.

DANGER: Indicates an imminent hazardous

situation which, if not avoided, will result in death,

serious injury or substantial property damage.

WARNING: Indicates an imminent hazardous

situation which, if not avoided, may result in

personal injury or property damage.

DANGER: Indicates an imminent electrical shock

hazard which, if not avoided, will result in death,

serious injury or substantial property damage.

How to use this manual

This installation manual does not contain any system design

documentation. System design documentation is available

from any authorized ENERVEX representative. Accessories,

fans, and variable frequency drives are not covered by

this manual. Please refer to these component’s individual

manuals.

TO REDUCE THE RISK OF FIRE,

ELECTRICAL SHOCK OR INJURY TO

PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit in the manner intended by the manufacturer.

If you have questions, contact the manufacturer at the

address or telephone number listed on the front of the

manual.

2. Before servicing or cleaning the unit, switch off at service

panel and lock service panel to prevent power from being

switched on accidentally.

3. Installation work and electrical wiring must be done by a

qualified person(s) in accordance with applicable codes

and standards.

4. Follow the appliance manufacturer’s guidelines and safety

standards such as those published by the National Fire

Protection Association (NFPA), and the American Society

for Heating, Refrigeration and Air Conditioning Engineers

(ASHRAE), and the local code authorities.

5. This unit must be grounded.

2

Content

1. GENERAL INFORMATION

1.1 Function ............................................................................................4

1.2 Shipping ............................................................................................ 4

1.3 Warranty ............................................................................................4

2. SPECIFICATIONS AND DIMENSIONS

2.1 Dimensions and Capacities ...............................................................5

2.2 Planning Ahead .................................................................................6

3. MECHANICAL INSTALLATION

3.1 Transport Safety Device .....................................................................7

3.2 Single Fan on Steel Chimney .............................................................7

3.3 Single Fan on Brick Chimney .............................................................8

3.4 Multiple Fans on Steel Chimney .........................................................9

3.5 Multiple Fans on Brick Chimney - Oversized Flue ...............................9

3.6 Installation for High Temperatures ......................................................9

3.7 Wall Mounting of Chimney Fan ..........................................................10

3.8 Installation of Proven Draft Switch (PDS) ............................................10

3.9 Termination of Venting System ...........................................................10

4. ELECTRICAL INSTALLATION

4.1 General .............................................................................................12

4.2 Wiring Diagram for Single Fan with FSC ............................................12

4.3 Wiring for Two Fans with FSC ............................................................ 13

4.4 Wiring Diagram for Single Fan with ADC 100 .....................................13

5. STARTUP AND CONFIGURATION

5.1 System Testing .................................................................................. 14

5.2 Adjusting the Chimney Fan Speed .....................................................14

5.3 Adjusting the Proven Draft Switch Setting ..........................................14

6. MAINTENANCE AND TROUBLESHOOTING

6.1 Prior to Cleaning ................................................................................15

6.2 Care and Cleaning .............................................................................15

6.3 Chimney Cleaning Intervals ................................................................15

6.3 Troubleshooting .................................................................................. 16

3000270 05.16

3

3000270 05.16

1. GENERAL INFORMATION

1.1 FUNCTION

The RS Chimney Fan is a chimney top mounted ventilator

that is designed to provide large flue gas volume capacities.

It is designed and intended for use with residential gas or oil

fired central space heating systems, for volume water heating

or for combination space heating/volume water heating. It is

also suitable for use with gas-fired fireplaces, stoves, BBQ’s

or residential pizza ovens.

This product is developed to prevent draft problems from

occurring by creating a mechanical draft in venting systems

and thereby also increasing the capacity and efficiency of a

venting system.

The use of the RS Chimney Fan is not restricted to any type

of chimney, because the fan creates a negative pressure

(below atmospheric) in the chimney or vent.

Code Compliance

Installations must conform to requirements of the authority

having jurisdiction. Where required by the authority having

jurisdiction, the installation must also conform to the

Standard for Draft Equipment and The National Fuel Gas

Code, ANSI Z223.1/NFPA 54.

All electrical wiring must be in accordance with the

requirements of authority having jurisdiction or, in the

absence of such requirements, with the National Electrical

Code, NFPA70.

Listings

The Model RS is tested and listed to UL Standard 378,

Standard for Draft Equipment. The fan is manufactured

at an ISO9001 certified plant and bears the European CE

compliance label.

The chimney fan must be interlocked with the connected

appliance(s) to insure proper combustions and to avoid flue

gas spillage.

1.2 SHIPPING

The packing list (attached to one of the packages) clearly

lists all items in the shipment and each package has a label

showing the contents. Check the list against all materials on

the job site for completeness.

NOTE: All single phase fans are shipped with a capacitor and

junction box connected via conduit. The capacitor is located

INSIDE the junction box. Please do not discard.

1.3 WARRANTY

ENERVEX products are warranted for a period of two (2)

years following the date of invoice. Replacement or repair

will be at ENERVEX’s discretion, provided factory inspection

shows a defect in material or workmanship.

Complete warranty conditions are available from ENERVEX.

4

2. SPECIFICATIONS

1.0

2.1 DIMENSIONS & CAPACITIES

3000270 05.16

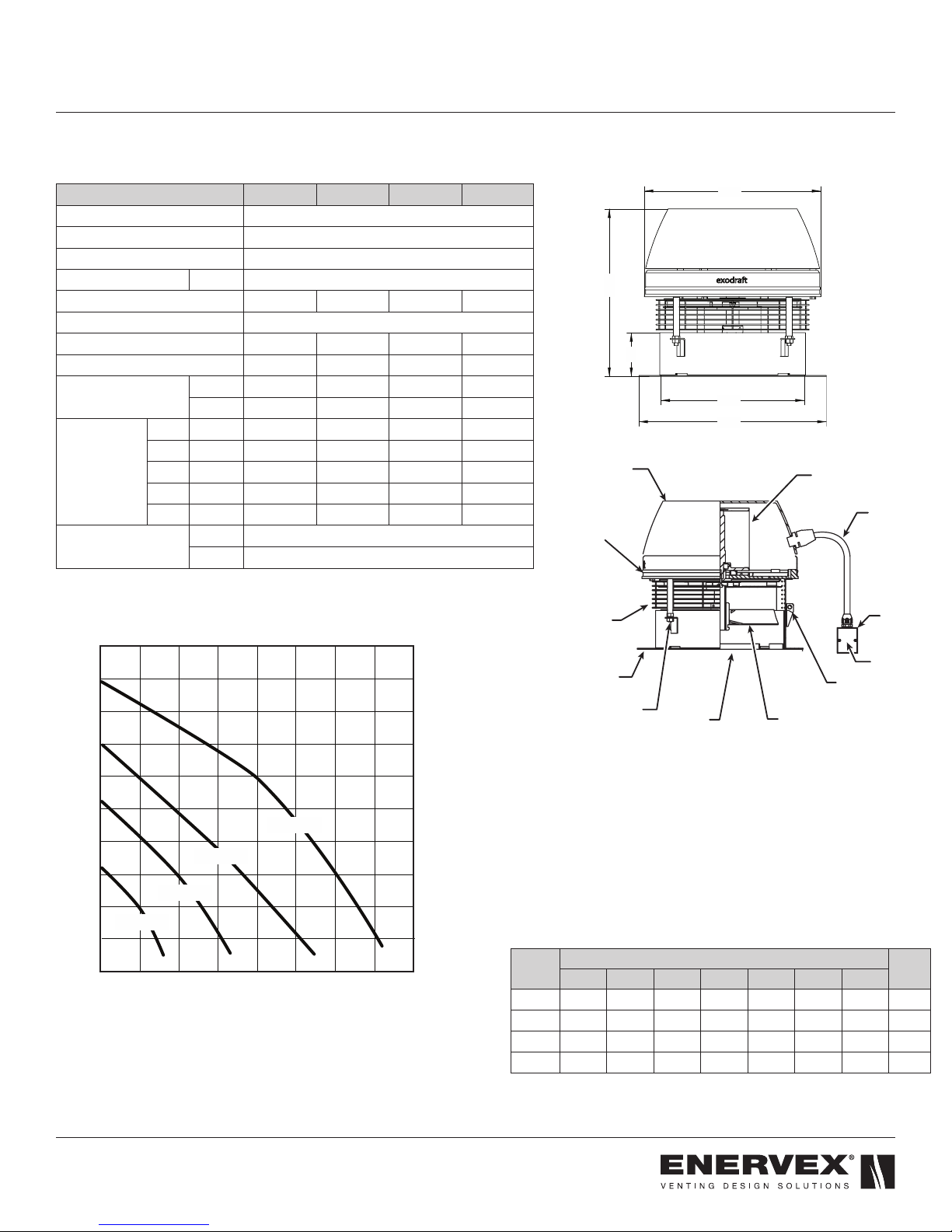

Model RS 009 RS 012 RS 014 RS 016

Discharge Horizontal

Fan Type Axial Vane

Motor Type Totally enclosed, Variable speed, Class H

Voltage VAC 1x120V @ 60 Hz

Amperage Amps 0.5 1.2 1.4 3.9

RPM 1600

CFM @0.0 Ps 450 950 1400 1950

Motor Output hp / kW 1/30 / .025 1/10 / 0.08 1/7 / 0.1 1/3 / 0.25

Weight

Dimensions

Temperature

Rating

lbs / kg 29 / 13 37 / 17 47 / 21 61 / 28

kg 13 17 21 28

A in / mm 10.2 / 259 11.5 / 292 13.1 / 334 16.0 / 407

B x B in / mm 11.7 / 296 14.3 / 364 16.6 / 422 18.8 / 478

C in / mm 10.8 / 275 13.5 / 344 15.5 / 395 17.4 / 441

D in / mm 3.0 / 75 3.3 / 85 3.9 / 100 3.9 / 100

E in 9.4 / 238 11.6 / 294 13.5 / 342 15.4 / 391

Interm. 575°F / 300°C

Cont. 482 °F / 250°C

Capacity

C

A

D

E

B

4

3

2

5

6

1

0.9

0.8

0.7

0.6

0.5

Ps (inW.C.)

0.4

0.3

0.2

RS 0 09

0.1

0.0

0250 500 750 1000 1250 1500 1750 2000

RS 0 14

RS 0 12

RS 0 16

Volume (cfm)

7

8

1 Junction box

2 Conduit/cord

3 Motor

4 Motor housing

5 Motor plate

6 Bird screen

9

10

8 Locking nut

9 Inlet

10 Axial vane

11 Hinges

12 Capacitor

(inside junction box)

11

7 Base plate

Sound Data

12

Model

RS009 54 50 47 43 38 31 25 21

RS012 64 60 55 52 48 42 34 30

RS014 75 69 65 62 57 51 44 41

RS016 81 76 72 69 64 58 52 47

Lw dB (measured in accordance with ISO 3744)

125Hz 250Hz 500Hz 1000Hz 2000Hz 4000Hz 8000Hz

Lp

dB(A)

5

3000270 05.16

!

!

2.2 PLANNING AHEAD

Observe proper combustion air requirements.

Provide a firm support system for the chimney fan.

Determine the type of system involved.

Observe proper safety measures are taken

to assure safe use of the wood burning

appliances.

Combustion Air Requirements

Provisions for combustion air must be in accordance with

applicable local codes.

If the heating system is installed in an unconfied space,

adequate air vill be available via normal infiltration.

If the heating system in installed in a confined space, (a space

with a volume less than 50 cubic feet per 1,000 Btu/hr of

input for all fuel burning equipment) or building construction

is unusually tight, adequate air for combustion must be

provided by two openings: one located about 6" below the

ceiling, the other about 6" above the floor. Each opening

must have a minimum free area as follows:

1. One square inch per 4,000 Btu/hr of input when

communicating directly with the outside or through

a vertical duct.

2. One square inch per 2,000 Btu/hr when communication

through horizontal ducts to the outisde.

3. One square inch per 1,000 Btu/hr when ventilation air

is provided by openings in doors, etc. to adjoining spaces

having adequate infiltration.

System type

Direct connect oil or gas appliances (no draft hood) normally

do not require any mechanical draft adjustment. However,

if there are long horizontal breechings and far between

the appliances, it is a good idea to install mechanical vent

dampers, so adjustments of the draft can be easily made.

Draft hood systems could generally speaking have vent

dampers installed. The vent dampers are used to balance

the system and assure that only a minimum of dilution air is

pulled through the draft hoods.

Safety Devices

Local codes usually require installation of safety devices,

when mechanical draft is provided in an oil or gas fueled

system.

Make sure a differential pressure switch (proven draft switch)

is installed to assure that no appliance will fire unless there is

a proven draft.

Adequate fresh air must be provided for

combustions; otherwise improper operation

and inadequate venting of deadly flue gases

may result.

Support system for the chimney fan

Prior to installation of the chimney fan, it must be assured the

chimney can safely carry the weight of the chimney fan.

A steel chimney should be well supported at the roof

penetration point. If the chimney extends more than 20'

above the roof, the chimney and the fan should be secured

by wires attached on the chimney and on the roof at 2 to 3

different points.

Brick chimneys usually do not need any kind of support to

carry the weight of the chimney fan.

6

3. MECHANICAL INSTALLATION

!

!

3.1 TRANSPORT SAFETY DEVICE

If a transport safety device is present, remove it from the

vane and make sure that the vane can revolve without

hindrance.

RS 14/16: Before mounting, the transport safety device on

the hinges must be removed.

3.2 SINGLE FAN ON STEEL CHIMNEY

Step 1: Prepare fan location

If a stack cap is already installed, it must be removed. The

steel chimney adapter (SCA) slides right into the chimney,

where the long collar engagement ensures safe anchoring.

If necessary, the adapter can be secured by means of long

self-tapping stainless steel screws into the side of the collar

through the chimney wall.

If the steel chimney is air-cooled, a special

adapter for such chimney must be used.

3000270 05.16

Measure the inside diameter of the flue and cut a

corresponding hole in the center of the fiber mat. If the flue

is so big that the throat in the adapter has been reduced

to fit the throat of the fan, the hole in the fiber mat should

correspond to the throat.

The aluminum foil on the fiber mat must face upward (against

fan base).

Step 2: Preparation of fan

Locate the installation brackets in the grooves on the

underside of the fan base, using the bolts and nuts supplied

to secure the brackets. Note that the bolts shall be installed

from the bottom side in the two inner holes.

Adjust the final position of the installation brackets ensuring

that there is a small gap between the brackets and the flue

wall/adapter throat. Tighten the nuts. If the brackets touch

the flue wall, it may create some vibration noise.

Step 3: Attaching the fan

The chimney fan is now ready for installation on the top of the

chimney. Place the fiber mat with the aluminum foil facing

upwards on the top of the adapter, and place the fan on top

of the mat. High temperature silicone can be applied on the

side of the mat, but is not required. It can also be painted. It

is not necessary to bolt the fan to the chimney.

CAUTION

Under conditions with extremely strong winds

surrounding the top of the chimney, the

chimney fan must be secured by steel wires

supplied with the fan.

7

3000270 05.16

!

3.3 SINGLE FAN ON BRICK CHIMNEY

Step 1: Prepare fan location

The installation procedure is the same whether the flue is

round or square. If a clay tile flue liner is installed, it might

stick up a few inches. Cut it back so it is flush with or no

more than 1/2 inch above the chimney crown.

Measure the inside diameter of the flue, cut a corresponding

hole in the fiber mat leaving a minimum distance of 3/4" to

any side of the fiber mat.

The aluminum foil on the fiber mat must face upwards

(against fan base).

Step 2: Preparation of fan

Locate the installation brackets in the slots going through

the fan base, using the bolts and nuts supplied to secure the

brackets. If the flue diameter is larger than the chimney fan

inlet, the bracket can be installed underneath the base. Note

that the bolts must be installed from the bottom side.

Adjust the final position of the brackets ensuring that there

is clearance between the brackets and the flue wall. If the

brackets touch the wall, it may generate some vibration

noise.

Step 3: Attaching the fan

The chimney fan is now ready for installation on the top of

the chimney. Place fiber mat with the aluminum foil facing

upwards on the top of the chimney, and place the fan on top

of the mat.

High temperature silicone can be applied on the side of the

mat, but is not required. It can also be painted.

It is not necessary to bolt the fan to the chimney.

CAUTION

Under conditions with extremely strong winds

surrounding the top of the chimney, the

chimney fan must be secured by steel wires

supplied with the fan.

8

3.4 MULTIPLE FANS ON STEEL CHIMNEY

If two or more chimney fans are required to create sufficient

draft, installation procedures are the same as for single fan

installation on a steel chimney. The only difference is that the

fans are sitting next to each other on the top of the chimney.

A special adapter plate is required.

When installing multiple fans, it is extremely important that

the fans are of the same model and size, and they must be

controlled in tandem by one (1) motor speed control.

3.5 MULTIPLE FANS ON A BRICK CHIMNEY OVERSIZED FLUE

If two or more fans are required to create sufficient draft, a

special adapter plate is required. The adapter plate should be

made of stainless steel (14 GA or thicker), depending on the

size and the fan models used.

The two holes in the plenum box should match the throat

diameter of the fan model used and the distance from center

to center should be at least equal to the fan width (dimension

“B” in 1.5. Dimensional data).

The adapter should be sealed with silicone and bolted

onto the top. When installing multiple fans, it is extremely

important that the fans are of the same model and size, and

they must be controlled in tandem by one (1) motor speed

control.

A similar approach should be taken if the flue size exceeds

the fan base dimensions. The adapter plate should be sized

so it covers the flue and secured. A hole should be cut in the

center of the plate and the fan mounted centered over the

hole.

3000270 05.16

3.6 INSTALLATION FOR HIGH TEMPERATURES

If the fan is used for applications where the flue gas

temperatures exceed 400°F at the flue exit, and does not

exceed 650°F, dilution bolts must be used.

Dilution bolts will cause cool air to dilute the warm flue gas,

by lifting the fan and leaving space so the cool air can get in

under the fan base.

The dilution bolts should be installed in the outer holes in the

fan base.

The dilution bolts are adjustable and should be adjusted

so the flue gas temperature does not exceed 400°F when

discharged through the fan. When using dilution bolts the

fan’s actual capacity is reduced and a stronger model may

be required. The fiber mat is not required when using dilution

bolts.

9

3000270 05.16

!

3.7 WALL MOUNTING OF CHIMNEY FAN

When mounting the chimney fan on a wall, the installation

instructions for installation on a steel chimney should be

followed. Use of the adapter SCA can make the installation

easier, but is not a requirement.

To ease installation, detach the fan base by removing the

bolts holding the hinges together. Center the fan base over

the outlet and bolt the base onto the wall with the hinges

pointing upwards.

After mounting the base securely, attach the fan motor

housing by reassembling the fan hinges. Seal with silicone all

around the fiber mat to prevent rain from entering the flue.

3.8 INSTALLATION OF PROVEN DRAFT SWITCH (PDS)

A safety system must be interlocked with the appliance(s).

The safety system could utilize a Proven Draft Switch,

a thermal switch or a flow switch. The device must be

interlocked with the heating appliance so it shuts down in

case of insufficient draft, fan failure or power failure. Please

refer to the PDS Installation Manual if this control is used.

For more information on alternative safety systems, please

contact ENERVEX, Inc.

The figure shows the location of the probe for the PDS.

Location is important to make sure there is enough pressure

or draft available or the switch to work.

Bolt

Bolt

CAUTION

A safety device that prevents the heating

appliance operation, in case of a power failure

or inadequate draft situation, must be installed.

3.9 TERMINATION OF VENTING SYSTEM

In order to achieve optimal performance and energy

consumption for the RS Fan or GSV Fan, the duct must be

installed as shown below and the distances observed. From

the last elbow to the termination point the distance has to be

3 times the diameter of the flue. For example if you using 12in

flue (12 X 3 = 36in). So the distance from the last elbow to

the fan termination point should be 36 inches..

A venting system that terminates in the sidewall of a structure

shall terminate at least 3 ft (0.9 m) above any air inlet to the

structure that is within 10 ft (3 m) of the termination point.

Exception No. 1: This requirement shall not apply to the

combustion air intake of a direct vent appliance.

Exception No. 2: This requirement shall not apply to the

separation distance between the circulating air inlet and the

vent discharge of a listed outdoor appliance.

The flue gas outlet of an appliance other than a direct vent

appliance shall terminate at least 4 ft (1.2 m) below, 4 ft (1.2

m) horizontally from, or 1 ft (0.3 m) above any door, window,

or gravity air inlet of the structure. The outlet also shall

terminate at least 1 ft (0.3 m) above grade.

10

The combustion air inlet and flue gas outlet of a direct vent

appliance or the flue gas outlet of an appliance other than a

direct vent appliance shall terminate at least 1 ft (0.3 m) from

the soffit of the roof of the structure and at least 3 ft (0.9 m)

from an inside corner of an L-shaped structure.

The flue gas outlet terminal of a direct vent application with an

input of 50,000 Btu/hr (0.35 gal/hr) or less shall be located at

least 9 in. (230 mm) from any door, window, or air inlet to the

structure. The vent terminal of a direct vent appliance with an

input over 50,000 Btu/hr (0.35 gal/hr) shall be located at least

1 ft (0.3 m) from any door, window, or air inlet to the structure.

Regardless of input, the flue gas outletterminal shall also

terminate at least 1 ft (0.3 m) above grade.

The exit terminals of mechanical draft systems shall not be less

than 7 ft (2.1 m) above grade when located adjacent to public

walkways.

Any air inlet and any flue gas outlet of any appliance shall

terminate at least 5 ft (1.6 m) from the vent outlet of a supply

tank.

3000270 05.16

Source: NFPA 31: Standard for the Installation of Oil-Burning Equipment

11

3000270 05.16

!

4. ELECTRICAL INSTALLATION

4.1 GENERAL

DANGER

Turn off electrical power before servicing.

Contact with live components can cause shock

or death.

All electrical wiring must be in compliance with the local

codes or in their absence, with the National Electric Code,

NFPA 70 — latest edition. If an external electrical source is

utilized, system must be electrically grounded in accordance

with requirements of the authority having jurisdiction or, in the

absence of such requirements, with the National Electrical

Code NFPA 70 — latest edition.

Power requirements for the system depends on the fan size.

Electrical requirements are:

• RSHT009 1 x 120 V/60 Hz 0.4 Amps

• RSHT012 1 x 120 V/60 Hz 1.2 Amps

• RSHT014 1 x 120 V/60 Hz 1.4 Amps

• RSHT016 1 x 120 V/60 Hz 3.9 Amps

The chimney fans have a split capacitor motor with infinitely

variable speed.

The fan speed control supplied is rated 1 x 120 V/60 Hz and

5 Amps. It has an adjustable low voltage set point of min. 65

V +/- 5 V.

NOTICE

If any of the original wire supplied with the

system must be replaced, use similar wire

of the same terperature rating. Otherwise,

insulation may melt or degrade, exposing bare

wire.

4.2 WIRING DIAGRAM FOR SINGLE FAN WITH FAN

SPEED CONTROL

The wiring diagram at right shows the wiring of the chimney

fan and how it is connected to the fan speed control.

FAN

WEATHERPROOF BOX

ORANGE

MOTOR

RED

WHITE

BLACK

PROVEN DRAFT

SWITCH

24 VAC

COMTRHOT

TH

24V GAS VALVE

N

120/1/60

L

All wiring must be in

flexible or rigid metal

FAN SPEED

NOTES:

THE DISCONNECT MEANS AND CIRCUIT PROTECTION ARE TO

1

BE PROVIDED BY THE INSTALLER OF THIS DEVICE

LEGEND:

24 VAC

120 VAC

CONTROL

conduit

GREEN

12

4.3 WIRING DIAGRAM FOR TWO FANS WITH FAN

24V GAS VALVE

OR IGNITION

COMTRHOT

TH

24 VAC

ADC 100

SPEED CONTROL

The diagrams at right show the wiring of two chimney fans

and how they are connected to the fan speed control.

PROVEN DRAFT

SWITCH

24 VAC

COMTRHOT

24V GAS VALVE

3000270 05.16

FAN

MOTOR

ORANGE

TH

RED

WHITE

BLACK

GREEN

ORANGE

RED

FAN

MOTOR

WHITE

BLACK

GREEN

4.4 WIRING DIAGRAM FOR SINGLE FAN WITH

ADC100

The diagrams at right show the wiring of a single chimney fan

when used in conjunction with an ADC 100P or ADC 100-E

Control.

WEATHERPROOF BOX

N

120/1/60

L

WEATHERPROOF

FAN SPEED

CONTROL

NOTES:

1

THE DISCONNECT MEANS AND CIRCUIT PROTECTION ARE TO

BE PROVIDED BY THE INSTALLER OF THIS DEVICE

2

LEGEND:

24 VAc

120 VAC

BOX

WEATHERPROOF BOX

All wiring must be in

flexible or rigid metal

conduit

13

3000270 05.16

5. STARTUP AND CONFIGURATION

5.1 SYSTEM TESTING

Before any adjustments are made to the system, follow these

procedures:

1. Turn the chimney fan ON and make sure that it is

operating. Increase and decrease the speed of the fan by

adjusting the fan speed control to make

sure it is operating properly.

2. Turn the fan OFF and make sure the pressure switch

opens, on the power to the circuit it controls is

disconnected.

DANGER

Check other heating appliances (water heater,

furnace, etc.) for proper operation while the

chimney fan is operating. Make sure no flue

gases are spilling out as this can lead to carbon

monoxide poisoning.

5.2 ADJUSTING THE CHIMNEY FAN SPEED

Start up all appliances. Use the fan speed control to set the

speed of the chimney fan so no back pressure is experienced

anywhere in the system. Check the system for flue gas

spillage. Mark this setting on the fan speed control cover.

5.3 ADJUSTING THE PROVEN DRAFT SWITCH

SETTING

Remove the snap-on cover from the conduit enclosure by

loosening its retaining screw. Turn the slotted Adjustment

Screw clockwise to raise the set point pressure and counter

clockwise to lower the set point.

Set the adjustment to its lowest position. With all appliances

operating, reduce the speed of the fan to the set point, where

the appliance(s) starts to spill flue gas. Increase the speed of

the fan gradually to the point where there is no more spillage.

Raise the switch’s set point so it opens. Return the fan speed

to the original setting marked on the cover.

The system is now adjusted so the flue gas spillage will

disconnect the heating appliance(s).

The procedure described here may not cover all Proven Draft

Switches, so please review the Installation Manual for the

switch being used.

14

6. MAINTENANCE AND TROUBLESHOOTING

!

6.1 PRIOR TO CLEANING

Remove butterfly nut or screw from each hinge prior to

cleaning.

6.2 CARE AND CLEANING

The Chimney Fan System is designed for prolonged use.

The fan should be inspected at least one a year when the

chimney is inspected. Fuel residues and other deposits

should be removed from the fan blades and the bottom of

the motor housing.

The top of the fan is hinged and can be opened in order to

ease the cleaning.

3000270 05.16

Remove Butterfly Nut or

Screw from each Hinge

NOTICE

If any of the original wire supplied with the

system must be replaced, use similar wire

of the same terperature rating. Otherwise,

insulation may melt or degrade, exposing bare

wire.

6.3 CHIMNEY CLEANING INTERVALS

It is extremely important to keep the chimney flue clean from

combustion and deposits. Unburned oil residues can cause

chimney fires.

Cleaning intervals depend on the use of the appliance. The

more the appliance is used, the more often the chimney flue

needs cleaning. As there are no firm guidelines for cleaning

intervals, have the chimney inspected on a regular basis

(every quarter or so) to determine what the interval should be.

Then follow this interval.

No matter how much used, a chimney flue should be cleaned

and inspected at least once every year.

NOTE:

The chimney should be cleaned by a trained professional.

We recommend using a Certified chimney sweep certified by

Chimney Safety Institute of America.

You can find a Certified Chimney Sweep at www.csia.org or

www.ncsg.org or by calling (317) 837-5362 or (317) 837-1500.

15

3000270 05.16

6.4 TROUBLESHOOTING

Observation Problem Solution

– The circuit breaker may be off

There is no power going to the fan

There is power to the fan but it is not

operating

There is power to the fan but it hums and

does not turn

The fan seems to work fine, but there is

not enough draft

The fan vibrates – The motor shaft may be bent – Replace motor

There is airflow noise from the fireplace

opening

Mechanical noise can be heard

– Fan speed control is off

– Bad electrical connections

– Bad electrical connections

– The fan speed control’s low voltage

setting is too low

– The fan speed control is bad

– The motor run capacitor may be bad.

– Creosote may stick

– The fan may be undersized – Replace with a larger fan

– The flue is undersized.

– The fan is oversized and running too fast

– Foreign matter may be stuck

– Motor bearings may be worn out

– Check the circuit breaker

– Turn fan speed control on

– Check and correct problem

– Check and correct problems with

connections. Pay special attention to the

wiring in the junction box

– Increase the setting with the plastic

screw on the fan speed control’s front plate

– Replace the fan speed control

– Check capacitor and replace if necessary

– Clean fan

– There is not much to do about it. Try to

reduce the fireplace opening

– Reduce the fan speed

– Remove matters

– Replace bearings

16

Notes

3000270 05.16

17

3000270 05.16

ENERVEX Inc.

1685 Bluegrass Lakes

Parkway

Alpharetta, GA 30004

USA

P: 770.587.3238

F: 770.587.4731

T: 800.255.2923

info@enervex.com

www.enervex.com

Loading...

Loading...