ENERVEX

IPVB 300-500 INLINE POWER VENTER

3002600 08.17

Installation & Operating Manual

READ AND SAVE THESE INSTRUCTIONS!

ETL514733

ENERVEX Inc.

1685 Bluegrass Lakes

Parkway

Alpharetta, GA 30004

USA

P: 770.587.3238

F: 770.587.4731

T: 800.255.2923

info@enervex.com

www.enervex.com

3002600 08.17

ETL514733

This symbol shows that ENERVEX IPVB Inline Power Venters for solid fuel applications are listed under ETL File no. 514733.

Symbol Legend

The following terms are used throughout this manual to bring

attention to the presence of potential hazards, or to important

information concerning the product.

DANGER: Indicates an imminent hazardous

situation which, if not avoided, will result in death,

serious injury or substantial property damage.

WARNING: Indicates an imminent hazardous

situation which, if not avoided, may result in

personal injury or property damage.

DANGER: Indicates an imminent electrical shock

hazard which, if not avoided, will result in death,

serious injury or substantial property damage.

How to use this manual

This installation manual does not contain any system design

documentation. System design documentation is available

from any authorized ENERVEX representative. Accessories,

fans, and variable frequency drives are not covered by

this manual. Please refer to these component’s individual

manuals.

TO REDUCE THE RISK OF FIRE,

ELECTRICAL SHOCK OR INJURY TO

PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit in the manner intended by the manufacturer.

If you have questions, contact the manufacturer at the

address or telephone number listed on the front of the

manual.

2. Before servicing or cleaning the unit, switch off at service

panel and lock service panel to prevent power from being

switched on accidentally.

3. Installation work and electrical wiring must be done by a

qualified person(s) in accordance with applicable codes

and standards.

4. Follow the appliance manufacturer’s guidelines and safety

standards such as those published by the National Fire

Protection Association (NFPA), and the American Society

for Heating, Refrigeration and Air Conditioning Engineers

(ASHRAE), and the local code authorities.

5. This unit must be grounded.

2

Content

1. GENERAL INFORMATION

1.1 Function ............................................................................................4

1.2 Components .....................................................................................5

1.3 Shipping ............................................................................................ 5

1.4 Warranty ............................................................................................5

2. SPECIFICATIONS AND DIMENSIONS

2.1 Dimensions and Capacities ...............................................................6

3. MECHANICAL INSTALLATION

3.1 General .............................................................................................7

3.2 Positioning ........................................................................................7

3.3 Drain Installation ................................................................................8

3.4 Mounting of Power Venter .................................................................8

3.5 Location/Connections .......................................................................8

3.6 Vertical Installation .............................................................................9

3.7 Horizontal Installation .........................................................................9

4. ELECTRICAL INSTALLATION

4.1 General .............................................................................................10

4.2 Wiring Diagram - IPVB 300 ................................................................10

4.3 Wiring Diagram - IPVB 350-500 ........................................................11

4.4 Installing a Proven Draft Switch .........................................................12

4.5 Installation of Stack Probe for PDS Function ......................................13

4.6 Checking and Changing Rotation on IPVB 350, 400 and 500 ............13

5. STARTUP AND CONFIGURATION

5.1 General .............................................................................................14

5.2 System Testing .................................................................................. 14

5.3 Adjusting Fan Speed .........................................................................14

5.4 Testing Safety System .......................................................................14

6. MAINTENANCE AND TROUBLESHOOTING

6.1 General .............................................................................................15

6.2 Preparing the Power Venter for Cleaning ........................................... 15

6.3 Troubleshooting .................................................................................16

3002600 08.17

3

3002600 08.17

1. GENERAL INFORMATION

1.1 FUNCTION

The IPVB Power Venter is intended for use as a true in-line

draft inducer. It can be installed in-line in the vertical or

horizontal section of a chimney or stack. It is specifically

designed for applications where reliable and efficient

operation, low noise level, low energy consumption, variable

speed and compact design are critical.

The IPVB is for use with condensing and non-condensing

appliances at flue gas temperatures of 575°F (302°C) for

continuous operation.

Typical uses are mechanical venting of gas-fired or oil-fired

boilers and water heaters. The IPVB is for indoor or outdoor

installation where ambient temperatures are in the range of

-40°F to 122°F (-40°C to 50°C).

The IPVB Power Venter is an efficient, high-temperature

ventilator with backward-inclined impeller. The ventilator

housing is made of stainless steel and equipped with an

energy-efficient, totally enclosed, variable speed motor, which

is mounted outside the air stream. The design is a Type B,

Spark Resistant Construction. The motor and impeller is a

complete assembly (drive unit) that can be removed from the

fan housing without removing the fan from the stack system.

The stack connections are of the flanged connection type

and fit most commercial pre-fabricated chimney systems.

The fan is typically installed hung from ceiling mounting

brackets to support the weight. The IPVB model is approved

for temperatures up to 575°F (302°C). The IPVB is a

component in the ENERVEX CASITM, Chimney Automation

System.

The housing is made of 316L stainless steel. The impeller

is of the backward inclined type made of cast aluminum.

Commercial grade, totally enclosed (TEFC), variable speed,

Class A insulated motor with sealed and permanently

lubricated bearings. Thermal overload protection.

The IPVB Power Venter should only be used with appliances

operating on Natural Gas, LP-Gas/Butane or fuel oil (#2

through #6). It should never be used with incinerators,

incinerating toilets or solid-fuel burning equipment. The

temperature of the flue gases going through the Power

Venter should not exceed 575°F (302°C).

4

1.2 COMPONENTS

B

A

C

E

D

F

AIR

FLOW

A. Inlet

B. Outlet

C. Motor

D. Housing

E. Impeller

F. Motor Mounting Plate

3002600 08.17

Fig 1

1.3 SHIPPING

The IPVB is shipped on a pallet covered by a cardboard box.

STANDARD PACKING LIST

The IPVB is shipped with a junction box and drain installation

kit. If other components are shipped, these will appear as

separate items on the shipping packing list.

NOTE:

All single phase fans ae shipped with a capacitor and junction

box connected via conduit. The capacitor is located INSIDE

the junction box. Please do not discard.

SHIPPING WEIGHT*

Model Lbs

300 100

350 120

400 150

500 200

*Weight includes the shipping pallet

1.4 WARRANTY

ENERVEX products are warranted for a period of two (2)

years following the date of invoice. Replacement or repair

will be at ENERVEX’s discretion, provided factory inspection

shows a defect in material or workmanship.

Complete warranty conditions are available from ENERVEX.

5

3002600 08.17

0.0

1.0

0.5

2.0

1.5

3.0

2.5

4.0

3.5

5.0

4.5

P

(inW.C.)

2. SPECIFICATIONS

2.1 DIMENSIONS & CAPACITIES

Specifications

Model IPVB 300 IPVB 350 IPVB 400 IPVB 500

Fa n Type Centrifugal Impeller (B-wheel)

Motor Type TEFC

Voltage VAC 1 x 120 3 x 200-240 / 3 x 440-480

Amperage Amps 5.8 2.6 / 1.5 5.5 / 2.9 7.8 4.1

Motor

Max. RPM 160 0 174 0

Duct Connection in 12 14 16 20

(Nominal) mm 300 350 400 500

Dimensions

Weight

Max. Temperature 575°F (302°C) Continous

Removal of drive unit

Output HP 0.5 1.0 2.0 3.0

kW 0.35 0.75 1.5 2.2

in 19.3 22.4 26.4 29.5

A

mm 490 569 671 74 9

in 13.0 14. 6 17.0 21.3

B

mm 330 371 432 541

in 13.9 15.5 17. 8 22.1

C

mm 353 394 452 561

in 12.1 14.0 16. 0 20

D

mm 306 356 406 508

in 11.1 12.7 14.6 16.2

E

mm 282 322 370 411

in 6.9 7. 8 8.9 11.1

F

mm 175 198 226 282

in 15.8 15 .8 16.2 2 0 .1

G

mm 401 401 411 511j j

in 21.6 24.6 26.3 30.0

H

mm 549 625 668 762

in 2.5 2.5 2.6 2.7

J

mm 64 64 66 69

in 47.1 51.2 56.8 66.9

L

mm 119 9 1300 144 3 169 9

W

in 22.2 25.3 29.2 32.4

mm 564 643 74 2 823

lbs 75 94 128 18 2

kg 34 42.5 58 82.5

Fan without drive unit

Capacity

t

IPVB 500

IPVB 300

0 1000 2000 5000

NOTE:

The capacity data above is tested in accordance with ISO

Standard 5801-Industial Fans Performance Testing Using

Standardized Airways.

6

IPVB 350

IPVB 400

3000 4000

Volume (cfm)

6000

3. MECHANICAL INSTALLATION

3.1 GENERAL

WARNING

Failure to install, maintain or operate the

IPVB Power Venter in accordance with the

manufacturer’s instructions may result in

conditions which can produce bodily injury and

property damage.

The IPVB must be installed by a qualified installer in

accordance with these instructions and all local codes, or in

their absence, with the latest edition of The National Fuel Gas

Code (NFPA54/ANSI223.1), NFPA 211, NFPA 31 or Canada

CAN/CSA-B149.1-05 National Gas and Propane Installation

Code when applicable. The IPVB must be mounted so the

clearance to combustibles is at least 18 inches.

Preferably, the IPVB should be installed as close to the

termination as possible. It can also be installed near the outlet

of a heating appliance in the breeching itself. In addition,

it can be used for sidewall vented applications where it

discharges through a wall. A drain is provided with the IPVB

to be installed by the user.

The IPVB is for indoor and outdoor installation. Unless

installed adjacent to the wall it is discharging through, the

chimney material used on the discharge side must be airtight/

pressure rated. Traditional gas vent (B-vent) is not considered

pressure rated or airtight. The vent pipe must be installed

and supported according to the chimney manufacturer’s

instructions and/or in accordance with NFPA54, NFPA211

and Canada CAN/CSA-B149.1-05. The IPVB collars fit most

commonly available vents and stacks.

RS 14/16: Before mounting, the transport safety device on

the hinges must be removed.

3.2 POSITIONING

Acceptable fan positions are shown at right in Fig. 2. If

mounted horizontally, ENERVEX recommends that the motor

be positioned to the side as shown in Fig. 2, position B. The

IPVB must be mounted to provide clear and easy access to

the motor and impeller assembly.

NOTE: If the IPVB is mounted in position B or C, a drain must

be installed as described in Section 3.3.

*If the IPVB is oriented as shown in position C, the resulting

axial load on the bearings may shorten the life of the motor.

WARNING

Never install the power venter so the motor

points down. This will shorten the life. The

minimum clearance to combustibles is 18

inches.

3002600 08.17

B

A

C*

D

AIR

FLOW

AIR

FLOW

AIR

FLOW

Fig 2

7

3002600 08.17

3.3 DRAIN INSTALLATION

Install the provided drain if the IPVB is mounted in position B.

The drain should be installed near the outlet of the fan and

oriented so it points toward the ground.

To install the drain:

1. Use the drain as a template to drill (4) 1/8" holes in each

corner.

2. Use the (4) provided rivets to fasten the drain to the fan

housing.

3. Using the fitting as a guide, drill a 1/2" hole through the

housing to open the drain.

3.4 MOUNTING OF POWER VENTER

The IPVB has (4) 0.413" diameter mounting holes on each

end of the fan. Threaded rod or steel hangers should run

through these holes to hang the fan from the ceiling or other

support.

B

Fig 3

Ø0.41"

Ø0.41"

3.5 LOCATION/CONNECTIONS

Follow the recommendations by the vent or stack

manufacturer. The power venter should be located at least (3)

times the vent diameter from any elbow or tee.

A set of v-bands are shipped with the fan for connection to

the stack.

Fig 4

3 x D

D

Fig 5

8

3.6 VERTICAL INSTALLATION

To mount the IPVB vertically, suspend the power venter

with threaded rod. Once the position of the ran and rods

is finalized, hang 4 pieces of threaded rod through the

mounting holes of the fan as shown in Fig. 5. (On back

side of fan, run threaded rod through both top and bottom

mounting holes.) Once the power venter is leveled, secure

the rod with lock washers and locking hex nuts.

3/8" Threaded rod, lock washers

and locing hex nuts

(A tack weld may be placed on the hex nuts

for permanently fixation)

3002600 08.17

Flanged stack connections

3.7 HORIZONTAL INSTALLATION

To mount the IPVB horizontally, suspend the power venter

with threaded rod or steel hangers. It may be necessary to

cross brace the fan from end to end to prevent side sway.

Ensure the fan is level before permanently securing.

L-Brackets are installed for additional support and stability of

the fan. Neoprene strips (or similar) should be placed on

the brackets to dampen vibration noise. Do not attach them

to the fan itself.

Fig 6

HANG FAN FROM (4)

TOP MOUNTING HOLES

Fig 7

9

3002600 08.17

Motor Disconnect Switch

(Sold Separately)

NOTE:

A

MOTOR DISCONNECT IS AVAILABLE THROUGH ENERVEX.

THE CIRCUIT PROTECTION IS PROVIDED BY THE INSTALLER.

240/1/50

(Sold Separately)

4. ELECTRICAL INSTALLATION

4.1 GENERAL

DANGER

Turn off electrical power before servicing.

Contact with live electric components can

cause shock or death.

NOTICE

If any of the original wire supplied with the

system must be replaced, use similar wire

of the same terperature rating. Otherwise,

insulation may melt or degrade, exposing bare

wire.

All wiring must be in compliance with the local codes or in

their absence, the National Electric Code, NFPA70. All wiring

should be appropriate Class 1 wiring as follows: installed in

rigid metal conduit, intermediate metal conduit, rigid nonmetallic conduit, electrical metallic tubing, or be otherwise

suitably protected from physical damage.

IPVB models operate at different voltages, please pay

attention to the wiring details. IPVB 300 operates at

1x120VAC while all other models can operate at 3x208-230

VAC or 3x440-480VAC. This is indicated by the terminal wire

configuration in the motor junction box. See Section 4.3.

4.2 WIRING DIAGRAM - IPVB 300

Power Venter and motor specifications can be found under

“Section 2.1 Dimensions and Capacities”. The power venter

is equipped with a variable speed motor. The diagram below

shows a typical wiring diagram for a IPVB 300 utilizing a Fan

Speed Control.

Fig 8

10

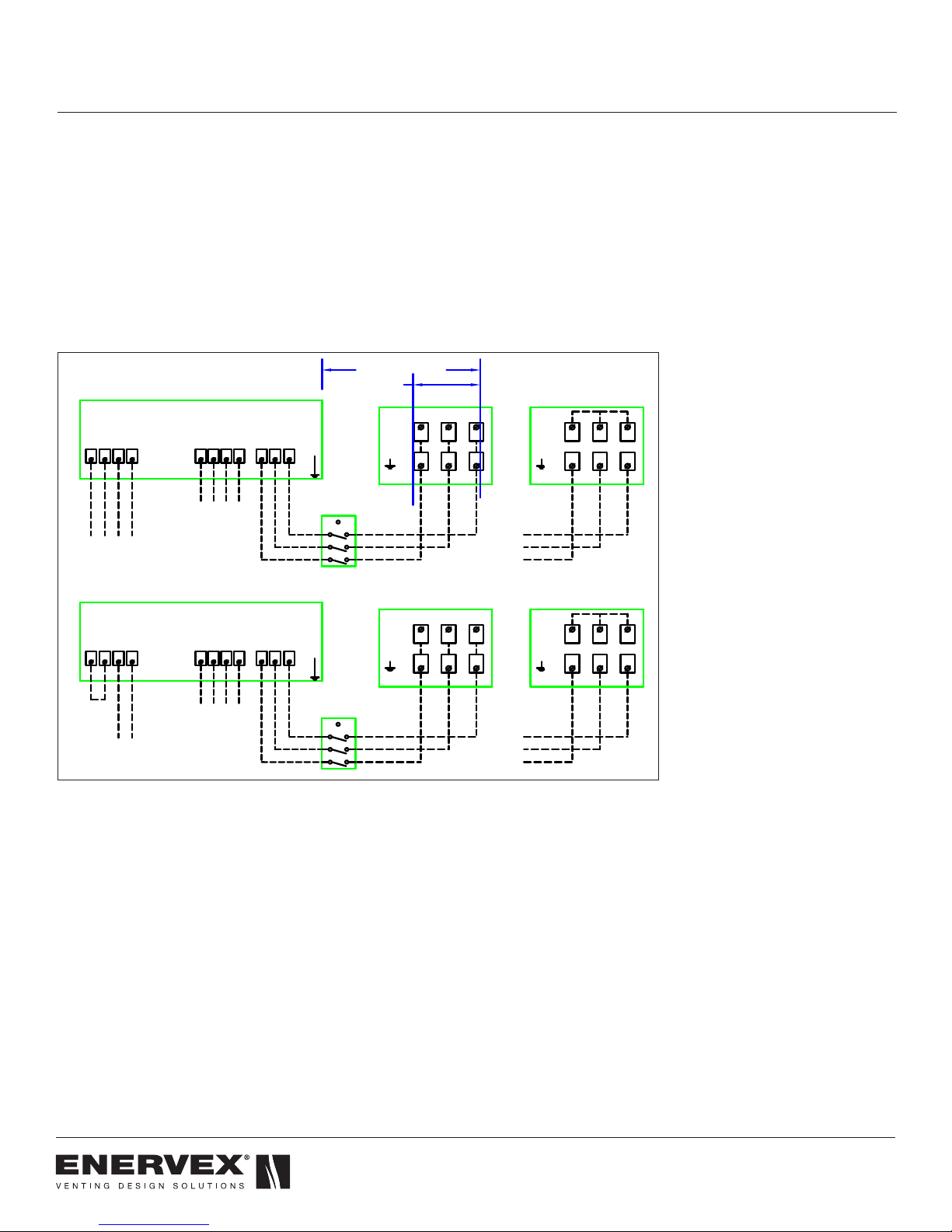

4.3 WIRING DIAGRAM - IPVB 350 - 500

IPVB 350 can operate at either 3x208-230 VAC or 3x440480 VAC (default) based on the configuration of the terminals

in the motor junction box.

The motor wiring terminals shown in Fig. 9 shows default

jumper positions for 3x440-480VAC operation. If the

application requires 3x208-230VAC operation, the jumper

positions must be changed according to Fig. 10.

Verify power supply voltage and motor terminal

configuration BEFORE connection to fan.

3002600 08.17

440-480/3/60 VAC

Fig 9 Fig 10

208-230/3/60 VAC

11

3002600 08.17

W2

U1 W1V1

V2 U2

IPVB MOTOR 200V

W2

U1 W1V1

V2 U2

IPVB MOTOR 200V

W2

U1 W1V1

V2 U2

IPVB MOTOR 400V

W2

U1 W1V1

V2 U2

IPVB MOTOR 400V

DISCONNECT

DISCONNECT

100FT (MAX)

50FT (MAX)

2 U V W

24VDC Out

Start

0-10VDC In

Gnd/Com

ENERVEX EDRIVE

71 6 L3L1 L2

L2L1

POWER SUPPLY

200-230/3/48-62

380-480/3/48-62

L3

G

G

TO EBC30/31

CONTROLLER

2 U V W

24VDC Out

Start

0-10VDC In

Gnd/Com

ENERVEX EDRIVE

71 6 L3L1 L2

L2L1

POWER SUPPLY

200-230/3/48-62

380-480/3/48-62

L3

G

G

TO MEC18/EBC12

CONTROLLER

Power Venter and motor specifications can be found under

“Section 2.1 Dimensions and Capacities”. The power

venter is equipped with a variable speed motor. Fig. 11

below shows a typical wiring diagram utilizing a Variable

Frequency Drive (adjusting the speed is possible). If it is not a

requirement that the speed can be adjusted, a motor starter

should be installed in lieu of the VFD, if required by local

codes.

After wiring, make sure the motor is rotating in the proper

direction. This is marked on the motor end cover. If the

rotation is incorrect, swap the two wires going to the motor

terminals, U1 and W1 as shown in paragraph 4.6 . (This does

NOT apply to the IPVB 300).

4.4 INSTALLING A PROVEN DRAFT SWITCH

A safety system must be interlocked with the appliance to

prevent flue gas spillage from the appliance and/or leakage

through the fan or stack. The safety system should utilize a

Proven Draft Switch (PDS-1) to ensure a negative pressure

in the stack at all times. The device must be interlocked

with the heating appliance(s) so it shuts down in case of

insufficient draft, fan failure or power failure. Please refer to

the PDS Installation Manual for wiring instructions.

If the installation includes an EBC12* or EBC 31 Fan Control,

a PDS-1 may not not required as the function is integrated in

the control.

We recommend to interlock the appliances with the

controller.

*The EBC12 can only interlock one appliance.

For more information, please consult ENERVEX.

Fig 11

12

4.5 INSTALLATION OF STACK PROBE FOR PDS

CLOCKWISE

ROTATION

FAN OUTLET

POWER SUPPLY

208-230/3/60

or

440-480/3/60

WEATHERPROOF BOX

VARIABLE FREQUENCY

DRIVE (typical)

FAN

MOTOR

L1 L2 L3 U V W

SWAP THESE WIRES ON THE OUTPUT SIDE!

FUNCTION

Install the probe for the Proven Draft Switch (PDS-1) in the

vent connector. The probe must be located between the

appliance and the power venter. The probe must be located

at least 3 vent diameters downstream of the draft hood, draft

diverter, or barometric damper. The probe placement should

also observe distances from elbows and tees as shown in

figure below. The tip of the probe MUST be flush with the

inner chimney wall to get a proper pressure reading.

3002600 08.17

Fig 12

4.6 CHECKING AND CHANGING ROTATION OF IPVB

350, 400 AND 500

To check the rotation of the impeller, it is necessary to be

able to see the impeller or the rotation of the cooling vanes at

the end of the motor housing.

Looking through the outlet of the fan, the rotation of the

impeller should be clockwise as shown in Fig. 13. Correct

rotation direction is also indicated by an arrow on the motor

end cover. There are holes in the end cover that allow you

to see the cooling vanes, but it is difficult to see the rotation

unless the fan is running very slowly.

It is possible for the fan to operate with improper rotation.

However, the fan will only provide 25-30% of full capacity.

Improper rotation damages the motor, and causes various

electrical faults at the Variable Frequency Drive.

Fan rotation can be changed by swapping the two phase

wires as shown on the wiring diagram in Fig.14.

DANGER

Turn off electrical power before servicing.

Contact with live electric components can cause

shock or death.

Fig 13

Fig 14

13

3002600 08.17

5. STARTUP AND CONFIGURATION

5.1 GENERAL

The purpose of this fan is to ensure safe venting for a single

or multiple appliances. This can be performed via modulation,

or through a single speed where modulation is not required.

This is accomplished by starting a chimney fan/power venter

when the appliance “calls for heat”, and stopping the fan

when the “call for heat” demand has been satisfied.

5.2 SYSTEM TESTING

1. Check the line voltage with the motor plate rating.

2. Determine if the impeller is running free, and has not

been subjected to misalignment in shipping or during

installation.

3. Apply power and check that the impeller is rotating in

the direction of the arrow on the side of the fan housing

(does not apply to IPVB 300). All IPVB fans run in a

clockwise direction when viewed from

the fanoutlet or when looking down at the motor.

4. Switching any two phases between the fan and the power

source (VFD is the power source if installed) will reverse

rotation (except on IPVB 300).

5.3 ADJUSTING FAN SPEED

Start all heating appliances connected to the chimney with

the fan installed.

1. If operating with fixed speed, set the fan speed control or

the Variable Frequency Drive to the speed where no

spoilage is experienced anywhere in the system.

2. If operating with variable speed, a modulating control

(EBC 12 or EBC 30) is required. Follow the instructions in

the control’s installation manual.

5.4 TESTING SAFETY SYSTEM

Adjust the setting of the Proven Draft Switch or other device

used.

Start the heating appliance and the fan, and make sure the

safety device is functioning. Turn the fan off. Shortly after, the

appliance should shut down.

14

6. MAINTENANCE AND TROUBLESHOOTING

REMOVE (4) HEX NUTS BEFORE

REMOVING MOTOR/IMPELLER ASSEMBLY.

6.1 GENERAL

The power venter is designed for prolonged use, and no

regular maintenance is required. It should be inspected

periodically (at least once a year), and cleaned, if needed.

This specifically applies in case it is being used with fuel oil.

The power venter is designed to make this an easy task. The

front part of the venter has the motor and impeller mounted

on it, and it slides out to provide easy access.

6.2 PREPARING THE POWER VENTER FOR

CLEANING

Referring to Fig. 15 below, follow these steps to open the

venter so it can be cleaned and inspected:

1. Remove the four hex nuts holding the motor mounting

plate to the housing

2. Motor and impeller assembly can be lifted out of the

housing. See table listing weights for each model.

3. Clean the impeller and inside of the housing as needed.

4. Replace the motor and impeller assembly and tighten hex

nuts to secure motor plate.

3002600 08.17

Fig 15

NOTE: The approximate weights of the IPVB motor/impeller

are as follows:

IPVB 300: 40 lbs

IPVB 350: 50 lbs

IPVB 400: 70 lbs

IPVB 500: 105 lbs

WARNING

Do not open the housing unless power to the

IPVB Power Venter has been disconnected

from the power supply.

15

3002600 08.17

6.3 TROUBLESHOOTING

Problem Possible Cause Solution

The fan is not operating - No power to the fan - Check the power supply wires in the junction box by the fan.

- Check the circuit breaker.

- Check that the fan is actually turned on.

The fan is not running

at full speed and/or is

humming

The fan is rotating

backwards (except IPVB

300)

- The capacitor is

improperly connected

or not connected at all

(IPVB 300 only)

Phase sequence in

the power to the fan is

reversed

- Check the connections inside the junction box. The capacitor must be installed

according to the wiring diagram.

- Swap two phases in the junction box.

The fan is vibrating

vigorously

The fan stops in the

middle of firing cycle

- Foreign matter is

stuck in the impeller.

- A ball bearing is

damaged.

- A balancing weight

has fallen off impeller

The motor is overheating

- Remove the transportation device.

- Turn off the fan and remove the foreign matter.

- Turn the fan off. After the motor has stopped revolving, spin the impeller and listen for a

grinding noise from the motor. If necessary, replace bearing or entire motor.

- Re-balance impeller or replace it. Check motor for damages.

Check the flue gas temperature at the fan inlet. The temperature should not exceed

575°F (302°C) during continuous operation. Call ENERVEX for assistance.

16

Notes

3002600 08.17

17

3002600 08.17

Notes

18

Notes

3002600 08.17

19

3002600 08.17

ENERVEX Inc.

1685 Bluegrass Lakes

Parkway

Alpharetta, GA 30004

USA

P: 770.587.3238

F: 770.587.4731

T: 800.255.2923

info@enervex.com

www.enervex.com

Loading...

Loading...