ENERVEX

GSV 009-016 GREASE FAN

3001361 08.17 Installation & Operating Manual

READ AND SAVE THESE INSTRUCTIONS!

ENERVEX Inc.

1685 Bluegrass Lakes

Parkway

Alpharetta, GA 30004

USA

P: 770.587.3238

F: 770.587.4731

T: 800.255.2923

info@enervex.com

www.enervex.com

3001361 08.17

!

The GSV 009-016 Grease Fan is ETL Listed in the U.S. and Canada.

Symbol Legend

The following terms are used throughout this manual to bring

attention to the presence of potential hazards, or to important

information concerning the product.

DANGER: Indicates an imminent

hazardous situation which, if not

avoided, will result in death, serious

injury or substantial property damage.

WARNING: Indicates an imminent

hazardous situation which, if not

avoided, may result in personal injury

or property damage.

How to use this manual

This installation manual does not contain any system design

documentation. System design documentation is available

from any authorized ENERVEX representative. Accessories,

fans, and variable frequency drives are not covered by this

manual. Please refer to these component’s individual manuals.

TO REDUCE THE RISK OF FIRE,

ELECTRICAL SHOCK OR INJURY TO

PERSONS, OBSERVE THE FOLLOWING:

TO REDUCE THE RISK OF INJURY TO

PERSONS IN THE EVENT OF A CHIMNEY

FIRE, OBSERVE THE FOLLOWING:

1. Immediately close all dampers and/or air entrance

openings to the cooking appliance. This includes doors.

2. Alert your patrons to the possible danger.

3. Inspect your cooking appliance and chimney surroundings

for possible fire. If in doubt, alert your fire department.

4. Do not continue to use your appliance until it and your

chimney have been throroughly inspected. Overheating

can cause metal parts to expand, buckle and crack. If

you are not certain, have a certified chimney sweep disassemble all parts so they can be inspected and cleaned.

5. Do not use salt or water on the fire in the cooking appliance. Salt is corrosive and water will cause a dangerous

steam explosion. You might be able to control the fire by

using ashes, sand or baking soda, since baking soda is an

ingredient used for dry chemical fire extinguishers.

6. After a chimney fire, when it is safe to do so, check internal locations such as an attic and under the roof and keep

watching for two or three hours. There may be delayed

smoldering and subsequent ignition, even if the fire inside

the chimney has been controlled.

1. Use this unit in the manner intended by the manufacturer.

If you have questions, contact the manufacturer at the

address or telephone number listed on the front of the

manual.

2. Before servicing or cleaning the unit, switch off at service

panel and lock service panel to prevent power from being

switched on accidentally.

3. Installation work and electrical wiring must be done by a

qualified person(s) in accordance with applicable codes

and standards.

4. Follow the appliance manufacturer’s guidelines and safety

standards such as those published by the National Fire

Protection Association (NFPA), and the American Society

for Heating, Refrigeration and Air Conditioning Engineers

(ASHRAE), and the local code authorities.

5. This unit must be grounded.

TO REDUCE THE RISK OF A CHIMNEY FIRE:

1. Keep chimney and grease fan clean.

2. Always turn ON fan when using the cooking appliance.

3. Do not leave cooking appliance unattended when in use.

CAUTION

Please read specification label on product for further

information and requirements.

2

Content

1. PRODUCT INFORMATION

1.1 Function ............................................................4

1.2 Components .....................................................4

1.3 Shipping ...........................................................5

1.4 Warranty ...........................................................5

2. SPECIFICATIONS AND DIMENSIONS

2.1 Dimensions and Capacities ...............................6

3. MECHANICAL INSTALLATION

3.1 Positioning ........................................................7

3.2 Installation on Steel Duct ...................................7

3.3 Installation on Roof Curb ...................................8

3.4 Installation on Side Wall ....................................8

3.5 High Temperature Applications ..........................8

4. ELECTRICAL INSTALLATION

4.1 Electrical Requirements .....................................9

4.2 Wiring Diagram .................................................9

5. STARTUP AND CONFIGURATION

5.1 System Testing .................................................10

5.2 Testing Pizza Oven Operation ...........................10

5.3 Adjusting Fan Speed .........................................10

5.4 Operation of Pizza Ovens ..................................11

6. MAINTENANCE AND TROUBLESHOOTING

6.1 Care and Cleaning ............................................12

6.2 Chimney Cleaning Intervals ...............................12

6.3 Creosote Formation and Need for Removal ......12

6.4 Inspection Schedule .........................................13

6.5 Chimney Fires and What to Do About Them .....14

6.6 Spare Parts Ordering ........................................15

6.7 Troubleshooting ................................................16

3001361 08.17

3

3001361 08.17

1. PRODUCT INFORMATION

1.1 FUNCTION

ENERVEX Model GSV Grease Fan is designed to provide a

large exhaust volume at a high discharge velocity.

It is intended for use as a part of a restaurant exhaust system

for solid fuel cooking appliances and grease applications

according to NFPA96.

The use of the ENERVEX Grease Fan is not restricted to any

type of chimney or grease duct. However, always follow the

solid fuel appliance manufacturer’s instructions regarding the

venting.

The GSV is suitable for use with natural gas, LP-gas or solid

fuel.

The fan is designed to create a mechanical draft in chimney

and grease duct systems. It can also be used to increase

the capacity or efficiency of such a system.

The housing is made in heavy cast aluminum and can

be opened for easy cleaning. The axial vane is made of

stainless steel and is completely in balance.

The motor is a direct-drive, variable speed, class H insulated,

high temperature motor. It has permanently lubricated and

sealed ball bearings and is maintenance free.

Installation must conform to the requirements of the authority

having jurisdiction. Where required by the authority

having jurisdiction, the installation must also conform to the

NFPA54, NFPA96 or NFPA211.

All electrical wiring must be in accordance with the

requirements of authority having jurisdiction or, in

absence of such requirements, with the National Electrical

Code, NFPA70.

ENERVEX Model GSV is tested and listed to UL Standard

705 for Power Ventilators and UL Standard 762 for Power

Ventilators for Restaurant Exhaust Ventilators.

The model is also tested and listed to ULC-S645-93,

Standard for Power Roof Ventilators for Commercial and

Institutional Kitchen Exhaust Systems.

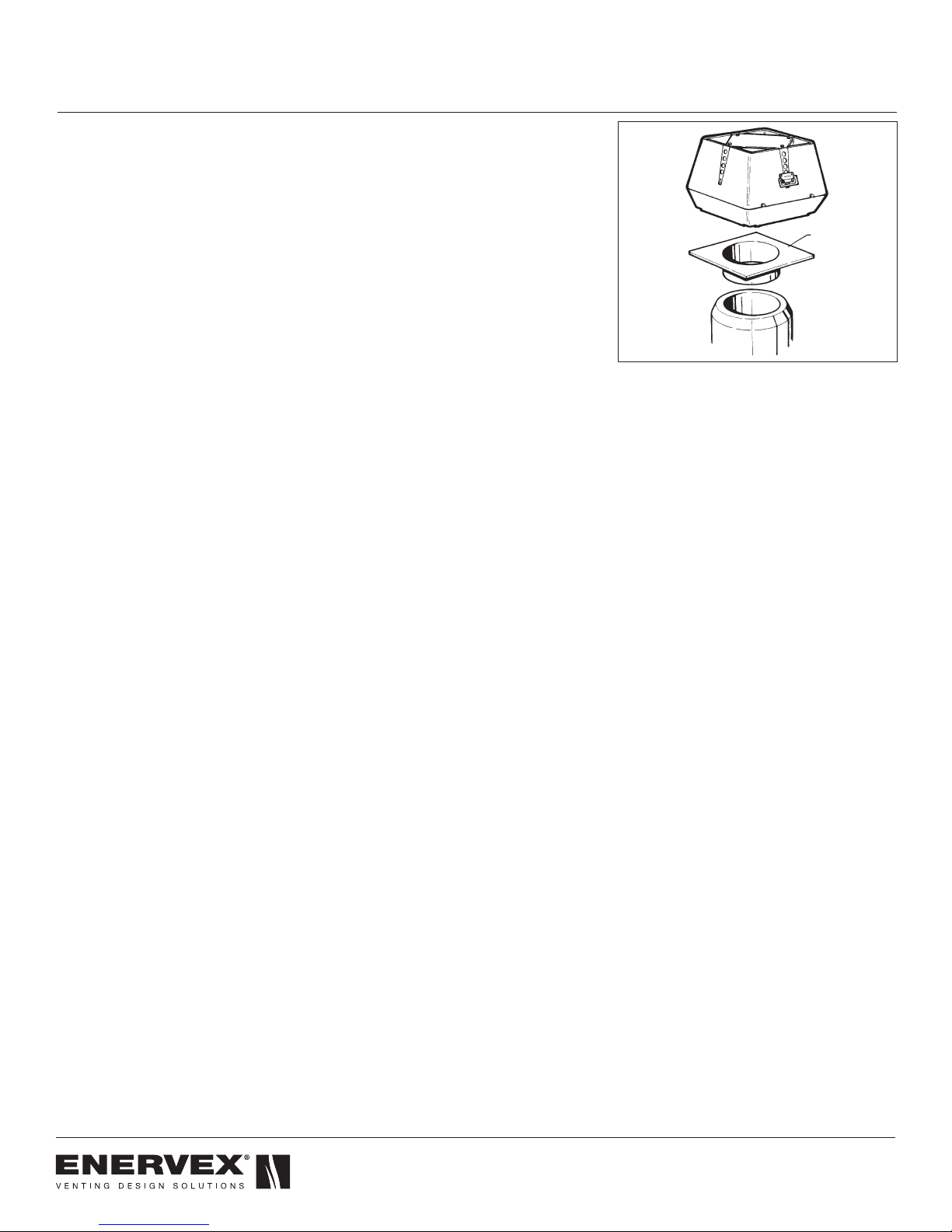

1.2 COMPONENTS

The GSV Grease Fan consists of the following components

a. Top section

b. Bottom section

c. Motor

d. Axial vane

e. Inlet for impeller

f. Locking hinge

g. Bird screen

h. Carrying handle

h. Wiring conduit

Fig. 1

Max. 575°F (300°C)

Fig 1

4

1.3 SHIPPING

!

The fan is shipped in a corrugated cardboard box. A

transport securing device may be attached to the bottom

of the fan to hold the motor and impeller in place. Do not

remove the device until the fan is at the installation point.

Do not remove the transport securing device

until the fan is being installed on the duct or the

roof curb. The motor shaft could be damaged.

STANDARD

Fan with flexible conduit terminating 2" x 4" x 4" weather

tight junction box.

PACKING LIST

If other components are shipped, these will appear on the

shipment packing list.

NOTE: All single phase fans are shipped with a capacitor and

junction box connected via conduit. The capacitor is located

INSIDE the junction box. Please do not discard.

3001361 08.17

1.4 WARRANTY

2-Year Factory Warranty. Complete warranty conditions are

available from ENERVEX, Inc.

Adequate fresh air must be provided

for combusion; otherwise, improper

operation and inadequate venting of

deadly flue gases may result.

If you are installing the fan on an existing

chimeny system or grease duct, you

must clean the chimney or duct prior to

installation.

Always use a certified chimney sweep,

certified by the Chimney Safety Institute of

America (CSIA) to clean the chimeny, duct

and grease fan.

5

3001361 08.17

2000

Ps (in H20)

Volume (cfm)

30

2000

Height (feet)

Volume (cfm)

2. SPECIFICATIONS AND DIMENSIONS

2.1 DIMENSIONS AND CAPACITIES

Specifications

Model GSV 009 GSV 012 GSV 014 GSV 016

Discharge Vertical

Fan Type Axial Vane

Max. Discharge

Velocity

Actual Discharge

Velocity

Voltage V AC 1x120

RPM 1600

Amps A 0.5 1.4 2.9 5.8

CFM @0.0 Ps 375 875 1550 1740

Motor Output kW / HP 0.025 / 0.03 0.13 / 0.10 0.21 / 0.16 0.47 / 0.35

Weight lbs / kg 28 / 12 46 / 18 60 / 26 86 / 35

A in / mm 9.85 / 250 11.03 / 280 13.20 / 335 14.97 / 380

B x B in / mm 12.21 / 310 15.37 / 390 19.11 / 485 22.85 / 580

Dimensions

C x C in / mm 9.46 / 240 12.22 / 310 15.17 / 385 18.32 / 465

D in / mm 8.63 / 219 10.72 / 272 13.04 / 331 14.26 / 362

E in / mm 2.76 / 70 3.15 / 80 3.94 / 100 4.53 / 115

Soft Start Required No No No No

Variable Speed Motor Yes Yes Yes Yes

Temperature Rating 575°F/300°C

FPM 2351 2592 2593 2169

FPM 5.9xCFM 2.9xCFM 1.9xCFM 1.2xCFM

A

E

D

C

B

Sound Diagram

Model

GSV 009 57 55 54 49 40 35 26 26

GSV 012 64 62 61 55 51 46 40 33

GSV 014 71 70 68 61 56 44 44 40

GSV 016 76 76 70 65 60 49 49 44

Lw dB (measured in accordance with ISO 3744)

125Hz 250Hz 500Hz 1000Hz 2000Hz 4000Hz 8000Hz

Lp dB(A)

Capacity Plume Height

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

GSV 012

GSV 009

500 750 1000 1250 1500 1750

2500

GSV 016

GSV 014

27

24

21

18

15

12

9

6

GSV 009

3

0

2500

GSV 014

GSV 012

500 750 1000 1250 1500 1750

GSV 016

a Top Section

b Bottom Section

c Motor

d Axial Vane

Hinged housing

e Inlet for Impeller

f Locking Hinge

g Wiring Conduit

h Handle

6

3. MECHANICAL INSTALLATION

3.1 POSITIONING

Considered a mechanical draft system, there are much

different code requirements than for a gravity venting system

or grease ducts used with gas or solid fuel applications. As

a general rule, the mechancal draft system must be installed

min. 3 feet away from any forced air inlet located within

10 feet, and min. 4 feet away from anydoor or window.

For complete information, consult ENERVEX or your local

building codes.

3.2 INSTALLATION ON STEEL DUCT

• Insert the steel chimney adapter into the chimney where

the long collar engagement ensures safeanchoring (see

Fig. 2). If necessary, the adapter can be secured by means

of long self-tapping stainless steel screws into the side of

collar through the chimney wall. Do not obstruct the flow.

• Turn the fan upside-down and lay a bead of hi-temp silicon

on the base close to the outer edge (not shown).

• Remove the transport securing device (if present) holding

the motor shaft and impeller in place.

• Place the fan on the adapter with the fan inlet centered

over the chimney outlet.

• Open the fan and secure the fan onto the adapter, through

the pre-drilled holes in the bottom, with lag bolts or self-

tapping sheet metal screws, one at each corner.

• Seal around the fan base to make sure it is watertight and

no water can slip in between the fan and the adapter. Do

not block the 4 drain holes.

3001361 08.17

Steel

Chimney

Adapter

Fig 2

7

3001361 08.17

3.3 INSTALLATION ON ROOF CURB

If the fan is installed on a roof curb, the curb will do the same

as the adapter. Follow the instructions under 3.2.

3.4 INSTALLATION ON SIDE WALL

• Make sure the vent terminates flush with the wall. Insert

the steel chimney adapter and secure it safely to the wall.

Seal around the edges of the adapter flange.

• Mark the locations of the wall anchors and predrill holes

for them.

• Turn the fan upside-down and lay a bead of hi-temp

silicone on the base close to the outer edge (not shown).

• Open the fan and secure the fan onto the adapter with

wall anchors, through the pre drilled holes in the bottom.

Make sure the conduit is located on one of the sides.

Never on the upside or downside.

• Seal around the fan base to make sure it is watertight and

no water can slip in between the fan and the adapter. Do

not block the 4 drain holes.

3.5 HIGH TEMPERATURE APPLICATIONS

• If the fan is used for applications that exceed its

temperature rating, dilution bolts must be used.

• Install the dilution bolts in the outer holes of the fan base.

• Adjust the height of the dilution gap by adjusting the

dilution bolts, so the temperature of the exhaust going

through the fan does not exceed the fan’s temperature

rating.

• Be aware the dilution bolts will have a negative impact on

the fan’s actual capacity and a stronger fan model may

be required. For more information, please refer to the

installation manual accompanying the dilution bolts.

Fig. 2

Steel

Chimney

Adapter

Fig 3

8

4. ELECTRICAL INSTALLATION

!

Refer to Fan Speed Contr

L1 N

To fan

Red

Green

4.1 ELECTRICAL REQUIREMENTS

Power requirements depend on the fan size. They can be

found on page 6.

DANGER

Turn off electrical power before servicing.

Contact with live electric components

can cause shock or death.

NOTICE

If any of the original wire supplied with the

system must be replaced, use similar wire

of the same temperature rating. Otherwise,

insulation may melt or degrade, exposing

bare wire.

4.2 WIRING DIAGRAM

The connection diagram below shows how the fan is

connected to the fan speed control and the power source

(see Fig. 4).

Use 2-conductor wire of minimum 14 AWG with ground.

3001361 08.17

FAN

MOTOR

Black

White

Green

M2M1

PE

wiring diagram

Red

Capacitor

Junction Box

supplied by contractor

Repair Switch

ol

Fig 4

M2

M1 PE

Fan Speed Control

Power Supply

1x120V AC

Wire Nut

Factory Wired

Not Connected

Field Wiring

Connected

9

3001361 08.17

5. STARTUP AND CONFIGURATION

5.1 SYSTEM TESTING

• Check the line voltage with the motor nameplate rating.

• Determine if the axial vane or impeller is running free

and has not been subject to misalignment in shipping or

installation.

• Turn the grease fan ON and make sure that it is operating.

Adjust the fan speed control to make sure it is operating

properly.

DANGER

Prior to using a cooking appliance,

make sure that sufficient air needed for

proper combustion and exhausting of

gases from oil/gas-fired appliances, like

water heaters, furnaces and boilers, is

provided.

• With the fan ON, check that other heating appliances

(furnace, water heater, etc.) are operating safely without

spillage (spillage is the escape of flue gases from the relief

opening of the draft hood of an atmospheric appliance.)

On start-up, a little spillage is normal, but it must stop

after a couple of minutes.

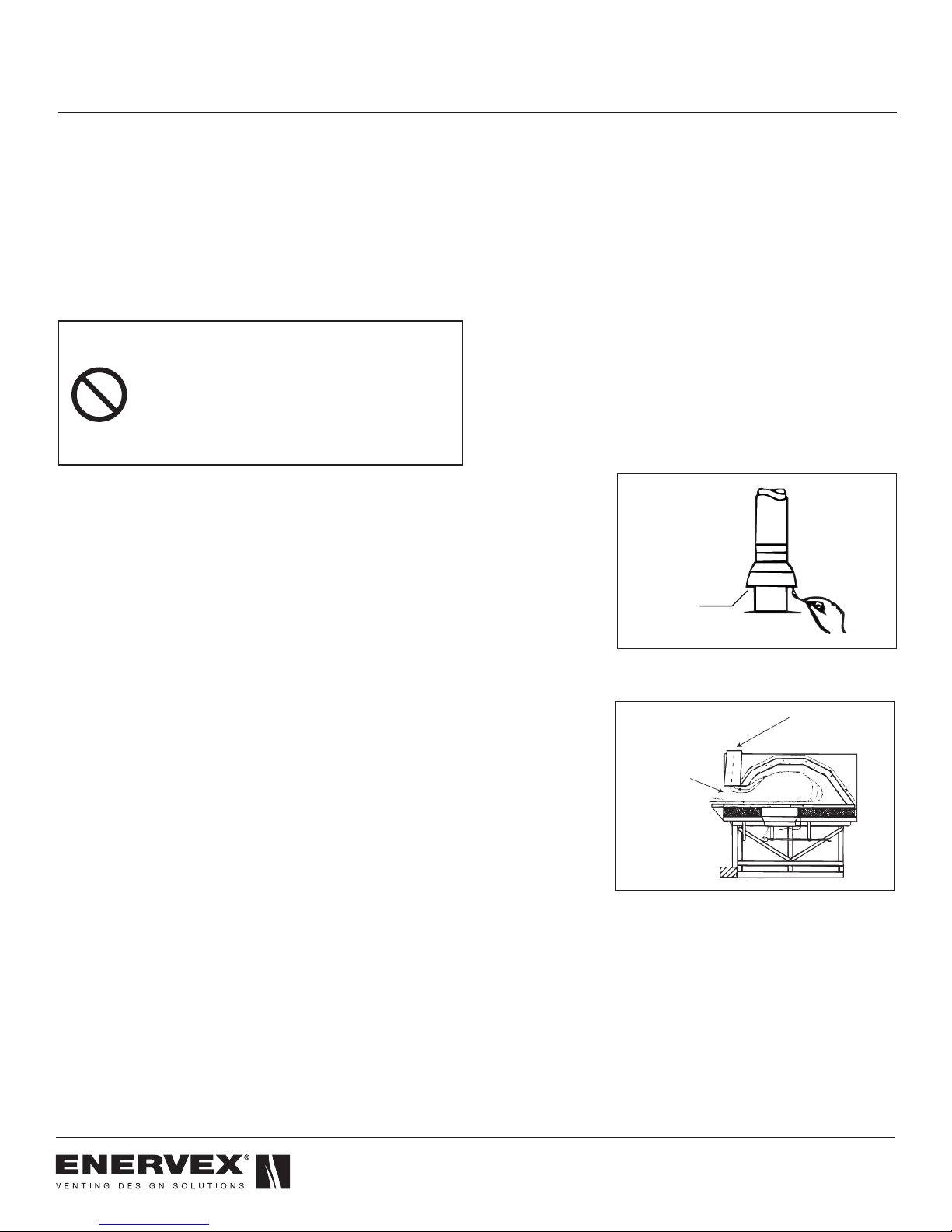

• Spillage can be detected by introducing smoke into the

flue products ahead of the draft hood or by observing if

the flame of a match goes out when it is held at the edge

of the draft relief opening (see Fig. 5).

5.2 TESTING PIZZA OVEN OPERATION

Most pizza ovens consist of a dome with a front opening

that can be closed with a cast iron door. Above the opening,

a hood connected to the flue assures smoke and odors are

collected and removed safely (see Fig. 6).

Place a few logs in the back of the dome and set the fan at

high/full speed. Light the fire. Turn on all exhaust fans (range

hoods, etc.) and make sure that there is no spillage from the

hood into the room. When the fire has caught on, reduce the

speed of the grease fan to a point where it still removes the

flue gases safely. Mark this setting on the fan speed control

cover, as this will be the operating position/speed of the

grease fan.

5.3 ADJUSTING FAN SPEED

Start all heating appliances connected to the chimney fan

installed. Set the fan speed control to the speed where no

spillage is experienced anywhere in the system.

Drafthood

Relief Opening

Fig 5

Flue connection

Check for

spillage here

Fig 6

10

5.4 OPERATION OF PIZZA OVENS

!

Prior to starting a fire, set the fan at high/full speed and start

the fire following the oven manufacturer’s instructions or, in

the absence of such instructions, follow normal instructions

on burning a fire in a fireplace or stove.

After the fire catches on, after 3-5 minutes, reduce the speed

of the grease fan to a level where it safely removes the flue

gases and a perfect flame can be maintained.

When adding wood to the fire, it may be necessary to

increase the fan speed for a short period of time.

Do not over-fire the pizza oven. Small deposits

of creosote could be ignited and start a small

chimney fire which could cause the chimney

flue to reach a hazardous temperature.

3001361 08.17

11

3001361 08.17

!

6. MAINTENANCE AND TROUBLESHOOTING

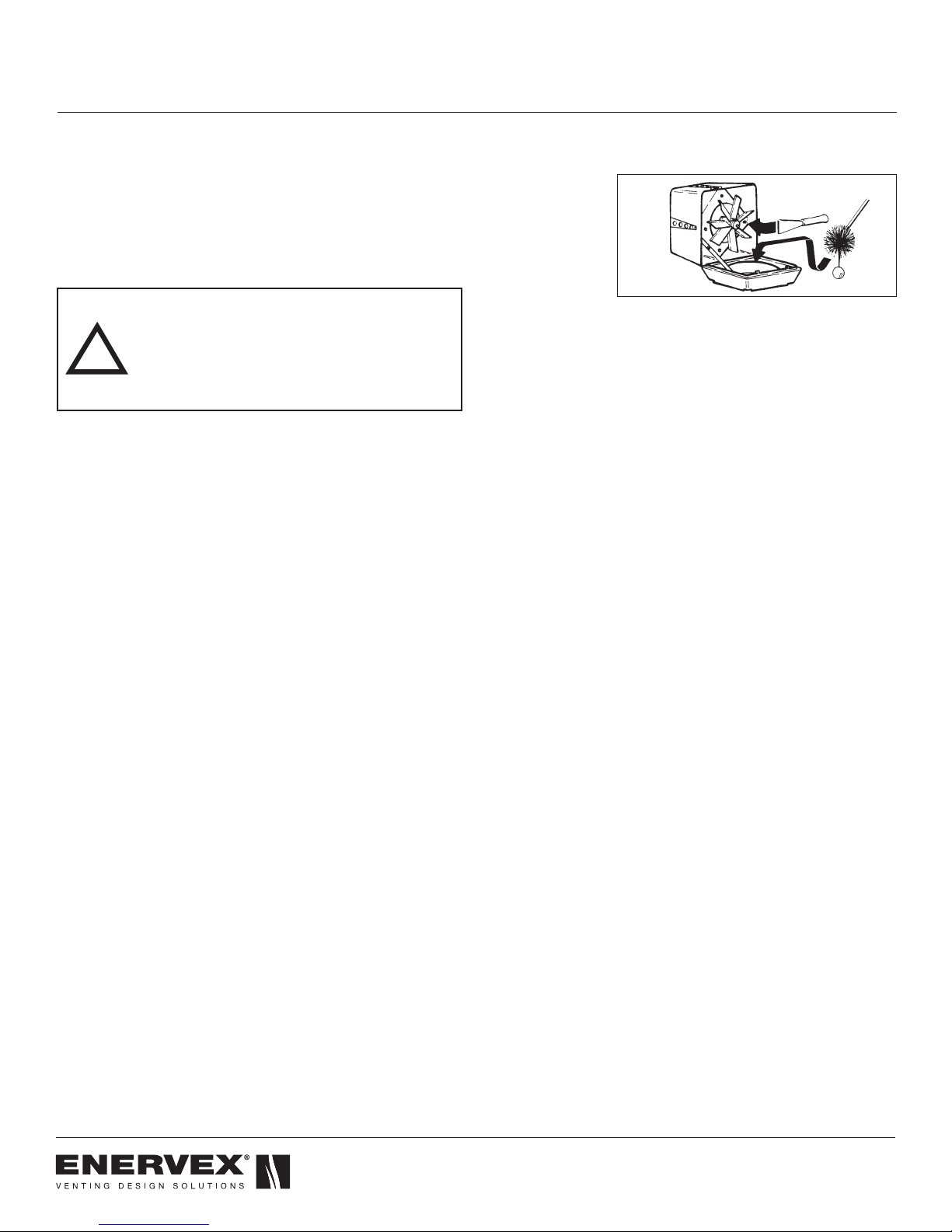

6.1 CARE AND CLEANING

The ENERVEX Grease Fan is designed for prolonged use.

The fan should be inspected at least once a year when the

chimney is inspected. Deposits should be removed from

the fan blades or the impeller and the bottom of the motor

housing. The top of the fan is hinged and can be opened in

order to ease the cleaning. See Fig. 7.

WARNING

Do not open the motor housing unless power

to the chimney fan has been disconnected.

6.2 CHIMNEY CLEANING INTERVALS

The need for chimney and chimney fan maintenance

depends on how the cooking appliance is operated.

Pizza ovens and BBQs need a great deal of chimney and

chimney fan maintenance. These appliances produce dense

smoke consisting of creosote and grease if it is loaded for

long durations or overnight fires.

6.3 CREOSOTE FORMATION AND NEED FOR

REMOVAL

When wood is burned slowly, it produces tar and other

organic vapors, which combine with expelled moisture to

form creosote. The creosote vapors condense in the relatively

cool chimney flue of a slow-burning fire. As a result, creosote

residue accumulates on the flue lining. When ignited, this

creosote makes an extremely hot fire.

Creosote causes many problems. Some are visible, while

others are not.It can make trouble if:

1.) It runs down outside the pipe to damage the finish on the

metal.

2.) It drips out of joints, damaging floors or furnishings.

3.) It plugs up the chimney causing poor combustion,

smoking, soiling walls and indoor pollution.

4.) It catches fire in the chimney to cause possible chimney

damage and damage to the building.

Fig 7

12

!

!

6.4 INSPECTION SCHEDULE

The chimney and the chimney fan should be inspected

at least every 2 weeks for the first couple of months to

determine at what rate the creosote builds up. If creosote has

accumulated, it should be removed to reduce the risk of a

chimney fire.

Evaluation of chimney systems installed in

commercial restaurants serving a wood-fired

cooking appliance indicates a build-up of 1/8"

- 1/4" of creosote for every 4 cords of wood

burned. This can be used as a guideline, but

each application is different.

As a guideline, a chimney and grease fan serving a

commercial wood-fired cooking appliance should be cleaned

at least once a month, unless the use has proven this to be

more than adequate.

Most chimney manufacturers require, if you see deposits

more than 1/16" thick, clean all chimney parts mechanically.

This means using brushes, scraping or equivalent.

3001361 08.17

Don’t start a chimney fire as a means to

clean the chimney!

With only slight deposits, try a hot fire to see if the black

deposits fall down the chimney. You can hear the sound of

falling deposits when the temperature conditions are right.

Afterwards, reinspect the chimney and the inside of the oven

for deposits.

Do not use chemical cleaners, they may corrode the inside

of the chimney. They may or may not prevent or remove the

creosote. When they are used together with a hot fire, it is

probably the fire that is doing the work.

Depending on the rate of build-up, as you learn what is going

on in the chimney, you can adjust your cleaning schedule.

If you have doubts about your ability to clean

the chimney, or if the deposits are very heavy

and hard to remove, do not tryt to burn them

off. Call a professional, certified chimney

sweep. The National Chimney Sweep Guild

can refer you to the nearest certified chimney

sweep. The Guild’s phone number is

(301) 963-5600.

It does not matter how careful you are loading fuel, selecting

wood or controlling draft, you should always observe the

above precautions with any solid-fuel burning cooking

appliance.

13

3001361 08.17

6.5 CHIMNEY FIRES AND WHAT TO DO ABOUT

THEM

No chimney or chimney fan is intended or designed for use

as a combustion or fire chamber. It is very easy to overfire

a wood burning oven with kindling, scrap, lumber, brush

or any fast burning fuel. This can produce flames and high

temperatures all the way up the chimney and may cause

chimney fan damage.

The creosote may be burning inside the chimney. If you can

see flames coming out of the top, you are either over firing or

there is a chimney fire.

If the fire in your cooking appliance/chimney has gotten out of

control, or if you suspect a chimney fire for any reason, follow

these steps:

1.) Immediately close all dampers and/or air entrance

openings to the cooking appliance. This includes doors.

2.) Alert your patrons to the possible dangers.

3.) Inspect your cooking appliance and chimney

surroundings for possible fire. If in doubt, alert your fire

department.

4.) Do not continue to use your cooking appliance until

it and your grease fan have been thoroughly inspected.

Overheating can cause metal parts to expand, buckle

and crack. If you are not certain, have a certified

chimney professional disassemble all parts so they can be

inspected and replaced, if necessary.

5.) Do not use salt or water on the fire in the cooking

appliance. Salt is corrosive and water will cause a

dangerous steam explosion. You might be able to control

the fire by using ashes, sand or baking soda, since baking

soda is an ingredient used for dry chemical fire

extinguishers.

6.) After a chimney fire, when it is safe to do so, check

internal locations such as an attic and under the roof

and keep watching for two or three hours. There may be

delayed smoldering and subsequent ignition, even if the

fire inside the chimney has been controlled.

14

6.6 SPARE PARTS ORDERING

When ordering spare parts please have the model number

and part position number available.

3001361 08.17

01 Motor

02 Motor mounting plate

03 Screw - SS (2)

04 Washer - SS (2)

05 Housing (top)

06 Housing (base)

07 Insert

08 Bird screen

09 Top plate

10 Axial vane

12 Locking hinge (2)

13 Cooling vane

14 Screw - SS

16 Washer - SS

17 Screw - SS (4)

21 Motor housing insulation

22 Screw - SS (2)

23 Washer - SS

24 Screw - SS

29 Screw - SS

31 Rivet

41 Fiber Mat

60 3/8” Conduit

61 3/8” Connector

62 Junction box with blank

cover

63 Wire nuts

64 Capacitor (1x120V fans only)

65 Wiring diagram (mounted on

inside cover)

15

3001361 08.17

6.7 TROUBLESHOOTING

Problem Possible Cause What to do

Check the power supply wires in the junction box by the fan.

The fan is not operating. No power to the fan.

The fan is not running at full

speed and/or is humming.

The fan is vibrating vigorously. The motor shaft is damaged.

The fan is noisy.

The fan suddenly stops. The motor is overheating.

The capacitor is improperly connected

or not connected at all (single-phase

fans only).

A transportation device has not been

removed.

Foreign matter is stuck in the fan.

A ball bearing is damaged.

Check the circuit breaker.

Check that the fan is actually turned ON.

Check the connections inside the junction box. The capacitor must be

installed according to wiring diagram.

Turn the power OFF immediately. Open the fan and check if the shaft is

straight. If not, contact ENERVEX.

Turn off power and remove the transportation device.

Turn off the power and remove the foreign article.

Turn off the power. Wait for the motor to stop revolving. Spin the wheel

and listen for any grinding noise from the motor. If necessary, replace

bearing.

Check the flue gas temperature below the fan. The temperature should

not exceed 400°F during continuous operation. Call ENERVEX.

16

Notes

3001361 08.17

17

3000775 08.17

ENERVEX Inc.

1685 Bluegrass Lakes

Parkway

Alpharetta, GA 30004

USA

P: 770.587.3238

F: 770.587.4731

T: 800.255.2923

info@enervex.com

www.enervex.com

Loading...

Loading...