Enervent Salla eWind

Installation instructions for the ventilation unit

19 September 2018

Copyright © Enervent Zehnder Oy 2018.

Unauthorised copying and distribution is

prohibited.

2

CONTENTS

READ FIRST ................................................................................................................4

Type plate .............................................................................................................5

SAFETY ....................................................................................................................6

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Electrical safety ........................................................................................................ 6

CONTENTS OF THE DELIVERY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Available accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

TECHNICAL SPECIFICATIONS OF THE UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Duct connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Checking the handedness in the type plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

BEFORE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Choosing the installation location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

INSTALLATION ............................................................................................................11

Wall installation without a bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Installation of the eWind control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installation to the Modbus bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Setting the Modbus parameters to the control system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

COMMISSIONING .........................................................................................................15

Requirements .........................................................................................................15

Air flow adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Commissioning checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Control system and the eWind operation panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Important information about the control system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Setting the operational parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Data display ...........................................................................................................19

eWind info list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Measurement display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

eWind measurement list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Commissioning documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Troubleshooting ......................................................................................................21

APPENDICES ..............................................................................................................23

Dimensional drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Technical dimensional drawing, 4-duct right-handed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Technical dimensional drawing, 4-duct left-handed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Technical dimensional drawing, 5-duct right-handed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Technical dimensional drawing, 5-duct left-handed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Electrical diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Connections ......................................................................................................27

EU declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

QUICK REFERENCE GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3Installation instructions for professionals

READ FIRST

This instruction manual is intended for all the persons

involved in the installation of the Enervent ventilation

units. Only qualified professionals may install the

equipment described in this manual in accordance with

the instructions in this manual and the local laws and

regulations. If the instructions provided in this manual are

not followed, the warranty for the equipment becomes

void and damages may be caused to persons or property.

The equipment described in this manual may not be

used by persons (including children) with reduced

physical, sensory or mental capacity or without sufficient

experience or knowledge, unless a person responsible for

their safety is supervising and advising them in the use of

the equipment.

FOR YOUR INFORMATION

If the delivery does not contain all of the

components listed in the section ‘Contents of

the delivery’, please check the order and contact

your distributor or Enervent before commencing

installation.

4

TYPE PLATE

TYYPPI/TYPE:

W/ V/ HZ / A:

SRJ. NRO/SERIAL NO:

ilmanvaihtolaite

ventilation unit

www.enervent.com

If you need technical support, please check the

equipment type and serial number from the type plate.

IP 20

5Installation instructions for professionals

SAFETY

General information

Electrical safety

DANGER DANGER

Always check that the supply voltage to the

equipment is switched off before opening the

service hatch.

WARNING

In case of a malfunction, always determine the

reason for the malfunction before restarting the

unit.

Only an authorised electrician may open the

electrical box.

DANGER

Follow the local regulations on electrical

installations.

WARNING CAUTION

When you have switched off the power to the

unit, wait for two (2) minutes before starting the

maintenance work. Even though the power is

switched off, the fans continue running and the

post-heating coil remains hot for a while.

Check that the unit is completely isolated from

the mains supply before conducting any voltage

tests, insulation resistance measurements or other

electrical work or measurements. Such work may

damage the sensitive electrical equipment.

CAUTION

Control equipment used in the ventilation units

may cause leakage current. This may affect the

operation of the residual current protection.

CAUTION

All ventilation units containing a control system

must be equipped with an overvoltage protector.

6

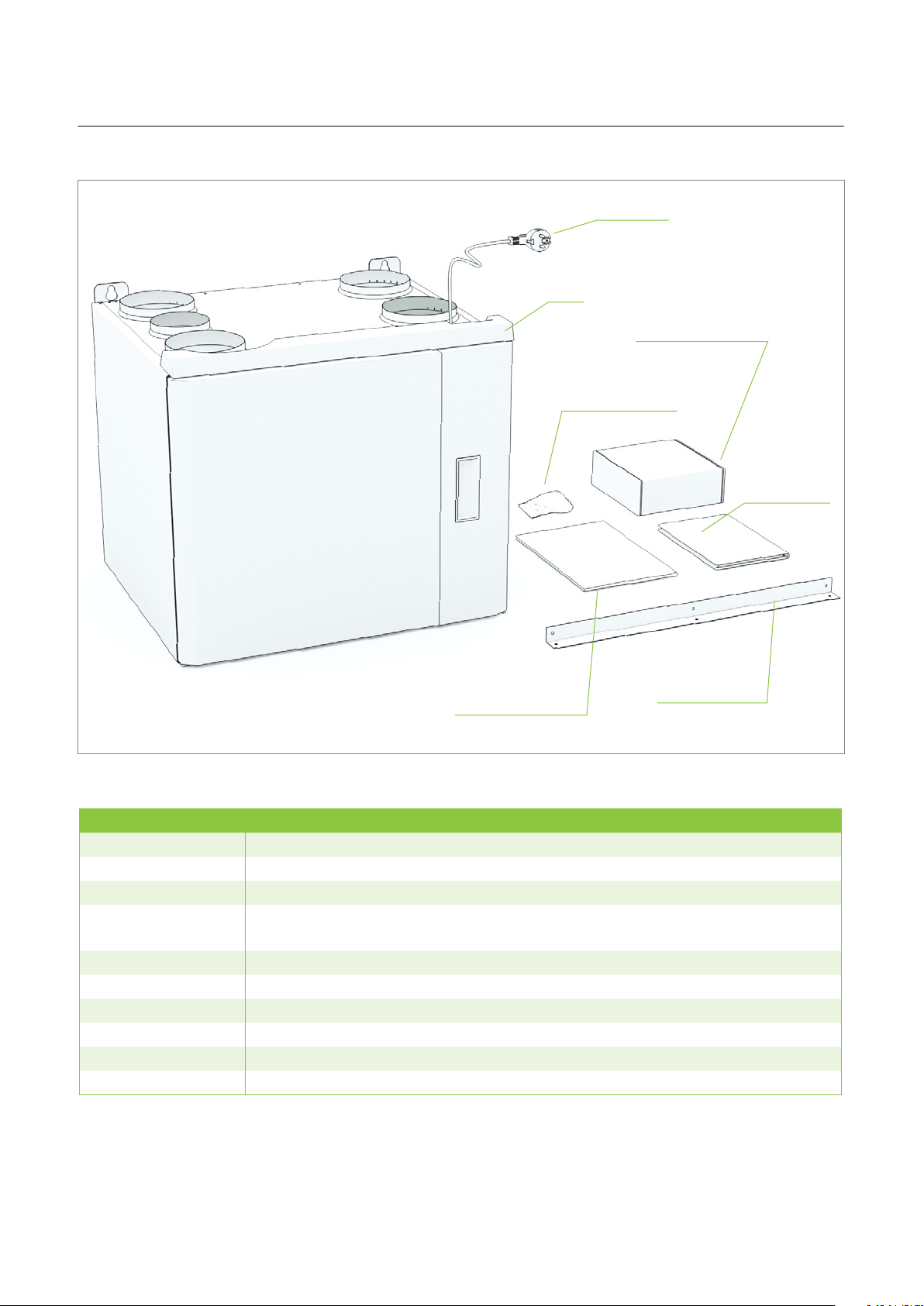

CONTENTS OF THE DELIVERY

power cable

unit

eWind control panel

vibration-damping

rubber pads

installation

and operating

instructions

warranty and

maintenance manual

installation panel

Available accessories

Product number Product name

K240130301 Range hood Standard Plus white

K240130302 Range hood Standard Plus stainless steel

K240130201 Range hood Premium white

K580040001 eWind controller. The package contains a controller, surface mounting box and a 10-metre

cable

K930030004 CO2 carbon dioxide transmitter for the room 0–10 V/24 V

K930030006 %RH humidity transmitter 0–10 V/24 V

M230110002 Humidity transmitter duct mounted KLK100

K930030008 Overpressure push button ‘fireplace switch’/boost

K930030029 KNX bus adapter

K900010010 Water trap Enervent Salla

7Installation instructions for professionals

TECHNICAL SPECIFICATIONS OF THE UNIT

Right-handed CHC

connection cable with plug

inlets for external sensors

motherboard

type plate

extract fan

extract filter

heat exchanger

inlet filter

supply fan

condensate connection G 1/4"

internal thread

Width 580 mm

Depth 500 mm

Height 490 mm

Weight 45 kg

Duct connection (duct size) Ø 160 mm

Duct connection (duct size) CHC Ø 125 mm

Range hood connection (duct size) CHC Ø 100 mm

Fans supply 118 W, 1.0 A; exhaust 118 W, 1.0 A

Heat exchanger motor with thermal protection 5 W, 0.04 A

Power of electric post-heating coil in E-models 400 W/230 V, 1~/50 Hz/1.74 A

Power of electric pre-heating coil in Arctic models 800 W/230 V, 1~/50 Hz/3.5 A

Input power, E-model (post-heating coil) 641 W/230 V, 1~/50 Hz/3.78 A

Input power E Arctic model (post-heating and pre-heating coil) 1441 W/230 V, 1~/50 Hz/7.26 A

Circuit breaker B10 A

Mains supply 230 V, 1~/50 Hz/10 A

heat exchanger’s drive belt

heat exchanger’s spare belt

8

Duct connections

supply air outdoor air

outdoor air

extract air exhaust air

right-handed 4-duct

range hood

outdoor air

extract air

exhaust air

supply air

exhaust air

supply air

left-handed 4-duct

supply air

exhaust air

extract air

range hood

outdoor air

extract air

right-handed 5-duct

left-handed 5-duct

Checking the handedness in the type plate

ilmanvaihtolaite

ventilation unit

TYYPPI/TYPE:

W/ V/ HZ / A:

SRJ. NRO/SERIAL NO:

www.enervent.com

Right-handed 4-duct

TYYPPI/TYPE:

W/ V/ HZ / A:

SRJ. NRO/SERIAL NO:

Salla eWind E RIGHT

IP 20

ilmanvaihtolaite

ventilation unit

Salla CHC eWind RIGHT

SRJ. NRO/SERIAL NO:

www.enervent.com

Left-handed 4-duct

SRJ. NRO/SERIAL NO:

TYYPPI/TYPE:

W/ V/ HZ / A:

IP 20

TYYPPI/TYPE:

W/ V/ HZ / A:

ilmanvaihtolaite

ventilation unit

Salla eWind E LEFT

ilmanvaihtolaite

ventilation unit

Salla CHC eWind LEFT

www.enervent.com

Right-handed 5-duct

IP 20

www.enervent.com

Left-handed 5-duct

IP 20

9Installation instructions for professionals

BEFORE INSTALLATION

Choosing the installation location

• Ensure that the ventilation system has been designed

and realised in accordance with the building

regulations.

• We recommend that the unit be installed in the

technical facility.

• Do not install the unit in a room where the

temperature and humidity are high. Under certain

conditions, condensation may occur on the outer

surface of the unit.

• Take the noise level of the unit into account when

choosing the installation location.

• Install the unit on a soundproof wall, if possible.

WOULD YOU LIKE TO KNOW MORE?

If you would like to know more about the

construction of ventilation systems and the

insulation of ventilation ducts, you can read about

them on our website at www.enervent.com.

• Do not install the ventilation unit directly outside

the bedroom, as the unit is never completely silent,

although it is quiet.

• Install an insulation plate behind the ventilation unit,

or try to prevent the sound from being conducted to

the structure by other means. Using soft foam sheets

is recommended (not included in the delivery).

• Ensure that connecting the condensation water

discharge pipe and water trap is possible. Remember

to take the space required by the condensation water

connection into account.

• Install the unit in a warm room (over +5°C).

• Ensure that at least 500 mm of free space is left in

front of and at least 80 mm of free space is left below

the unit for maintenance purposes.

10

FOR YOUR INFORMATION

A

B

INSTALLATION

Wall installation without

a bracket

45 kg

!

3

Check before the installation of the ventilation

unit that there are no foreign objects in the

ventilation unit or ductwork.

21

4

A = min. 25 mm, B = min. 75 mm

5

vibration-damping rubber pad

7 8

6

condensate

connection G 1/4"

internal thread

11Installation instructions for professionals

Installation of the eWind control panel

The eWind control panel (see section ‘Control system and the eWind operation panel’ on page 16) is installed in a wallmounted device box or using the surface-mounting box supplied with the accessory delivery. No more than two external

control panels can be installed in the ventilation unit.

1 2

3

5

4

6

12

7

8

OP1

9

11

10

13Installation instructions for professionals

Installation to the Modbus bus

The ventilation unit can also be controlled via the Modbus

connector X26.

Modbus specification:

• Modbus address 1 (default)

• Data transmission protocol RS485

• Modbus traffic via the motherboard’s Modbus

connector X26

• Speed 9,600, 19,200 or 115,200 bps

• 8-bit

• No parity or parity

The order of the poles in the Freeway connector is marked

in the controller board.

The Modbus registers are available on the Enervent

website at www.enervent.com.

CAUTION

Do not connect an external bus to the

motherboard before the bus has been

programmed and is compatible with the control

of the unit.

X26

Setting the Modbus parameters to the

control system

1

Simultaneously press the buttons

three times in the control panel.

2

Using buttons

c31-c32. • The meaning of each parameter is described in

section ‘Parameter list’ on page 16.

Select the parameter to be adjusted by pressing

3

button for 3 seconds.

4

Change the parameter value using buttons

and .

5

Confirm the value by pressing button

Exit the settings by simultaneously pressing

6

buttons

and , choose the parameters

and .

and

.

14

COMMISSIONING

Requirements

Operational requirements for the ventilation unit:

• Supply and exhaust air temperature below +55°C.

• Exhaust air temperature at least +10°C

• Supply air temperature for heat recovery over +5°C

• Supply air temperature over +10°C

• All foreign objects have been removed from the

ventilation system

• Both fans are running

Air flow adjustment

When the unit has been switched on, the air flows must

be adjusted to the designed values.

• The air flows are adjusted in connection with the

commissioning of the ventilation unit.

• The adjustment is made separately for both fans in

each operation mode (= at each fan speed).

Check the following during the adjustment:

• All filters are clean.

• All supply and extract air vents, the roof inlet, and the

outdoor air grilles are in place.

FOR YOUR INFORMATION

Do not cover the outdoor air grille with a

mosquito net.

To achieve optimum adjustment values, the air flows

must be measured at each duct opening. A suitable

measurement device is a thermoanemometer or

a differential pressure gauge. With the aid of the

measurement values, the air flow can be adjusted to

match the design values.

A correctly adjusted ventilation unit is quiet and provides

a good thermal economy. In addition, it also maintains

a slight negative pressure in the house. The negative

pressure prevents humidity from entering the walls and

ceiling.

Commissioning checklist

Measure Inspected Notes

The unit has been installed in accordance with the installation

instructions provided by the manufacturer.

The condensation water discharge pipe has been connected to

the water trap, and its operation has been tested.

Silencers have been installed in the supply and extract air ducts.

The terminal devices have been connected to the ductwork.

An outdoor air grille has been installed for the intake of fresh air.

NOTE: Do not cover the grille with a mosquito net. It makes

cleaning difficult.

The unit has been connected to an appropriate power supply.

The ventilation ducts have been insulated in accordance with the

ventilation plan.

The airflows are adjusted according to the ventilation plan.

15Installation instructions for professionals

Control system and the eWind operation panel

1

4

2

3

1. Mode (standard display) 2. Temperature (standard display) 3. Mode button

4. Eco button 5. Temperature button 6. Cable connection

Important information about the control

5

6

Setting the operational parameters

system

The fan speed settings for different operation modes must

The factory settings are suitable for most installations.

The fan speed settings for various operating modes are

installation specific, and they must be specified and set

separately in connection with each installation. In other

cases, the factory setting must not be changed unless

otherwise instructed in the ventilation system plan.

Make sure that all necessary information is available before

starting to adjust the settings.

be specified and set separately in connection with each

installation. The settings are described in the parameter

table.

1

Simultaneously press buttons

times.

2

Using buttons

c1-c32. • The meaning of each parameter is described in

section ‘Parameter list’ on page 16.

Select the parameter to be adjusted by pressing

3

button for 3 seconds.

and , choose the parameters

and three

16

4

Change the parameter value using buttons

and .

Confirm the value and return to the selection of

5

parameters c1–c32 by pressing button

Exit the settings by simultaneously pressing

6

buttons

and .

.

Parameter list

Parameter Description

c1 Extract fan speed, mode 1, region: 20–100%,

step: 1%

c2 Supply fan speed, mode 1, control range:

20–100%, step: 1%

c3 Extract fan speed, mode 2, control range:

20–100%, step: 1%

c4 Supply fan speed, mode 2, control range:

20–100%, step: 1%

c5 Extract fan speed, mode 3, control range:

20–100%, step: 1%

c6 Supply fan speed, mode 3, control range:

20–100%, step: 1%

c7 Extract fan speed, mode 4, control range:

20–100%, step: 1%

c8 Supply fan speed, mode 4, control range:

20–100%, step: 1%

c9 Time limit for manual boosting (mode 4),

control range: 0–4 h, step: 1 h

c10 Extract fan speed, fireplace/range hood

mode, control range: 20–100%, step: 1%

Factory

setting

36% ‘Away’ mode 102

35% ‘Away’ mode 100

56% Home mode 52

55% Home mode 51

83% Maximum power also in the removal of

80% Maximum power also in the removal of

100% Manual boosting 68

100% Manual boosting 67

2 h Setting the time limit 0 h prevents

30% 55

Note

humidity and carbon dioxide

humidity and carbon dioxide

the use of mode 4 and activates the

3-speed external control

Modbus

register

74

72

66

Field

setting

c11 Supply fan speed, fireplace/range hood

mode, control range: 20–100%, step: 1%

c12 Time limit for fireplace mode/selection of

range hood, control range: 0–15 min, step:

1 min

c13 Heat recovery defrosting, on/off Off Coil 55

c14 Maintenance reminder interval 4 or 6

months

c15 CHG/AGH pre-heating and AGH precooling,

on/off

c16 CHG/AGH outdoor temperature TE01, below

which pre-heating is used, control range:

0–10°C, step 1°C (for pre-heating)

c17 CHG/AGH pre-heating is not in use when the

outdoor air temperature (TE01) rises above

value (c16) + (c17), control range: 1–5°C, step

1°C

c18 CG cooling or CHG pre-cooling, on/off On Applies to CG and CHG heat

c19 Outdoor temperature TE01, above which

pre-cooling/cooling is allowed

c20 AGH outdoor temperature, above which the

earth duct is used, control range: 15–25°C,

step 1°C, (for pre-cooling)

50% 54

10 min Setting time limit 0 min replaces the

replace mode with the range hood

mode.

4 Register value in days 538

On Coil 58

5°C 592

1°C 593

exchangers

17°C 164

20°C 629

56

Coil 52

c21 AGH pre-cooling is not in use when the

outdoor air temperature (TE01) drops below

value (c20-c21), control range: 1–5°C, step

1°C

c22 Temperature setting for air temperature

after the electric pre-heating, control range:

–10...–20°C, step: 1°C

c23 Boosted operation for the removal of

humidity, on/off

2°C 630

–15°C 591

On Coil 19

17Installation instructions for professionals

Parameter list

Parameter Description

c24 Threshold value for summer/winter

Factory

setting

4°C

temperature,

control range –10…+10°C, step 1°C

c25 Threshold value for dehumidification,

45%

control range 10–100 %RH, step 5%

c26 Threshold value for starting

15%

dehumidification, control range: 5–30%,

humidity exceeds the 48-hour average value,

step 5%

c27 Boosted operation for the removal of carbon

Off Coil 21

dioxide, on/off

c28 Threshold value for starting the carbon

dioxide removal, control range: 600–1,200

1,000

ppm

ppm, step: 100 ppm

c29 Boosted operation for the removal of

Off Coil 24

humidity with the rotating heat exchanger,

on/off

c30 Display dimmed in the standby mode, on/off Off

c31 Modbus address of the automation

1 640

motherboard, control range: 1–99, step: 1

c32 Modbus bus speed, 1 = 9,600, 2 = 19,200, 3

2 19,200 bps 733

= 115,200

Note

The 24-hour average temperature of the

outdoor air. Above the threshold value, the

boosted operation for the removal humidity

is in the summer mode, and below the

threshold value, it is in the winter mode.

In the winter mode, the boosted operation

for the removal of humidity starts when the

humidity value exceeds the threshold value.

In the summer mode, the boosted operation

of for the removal of humidity starts when

the relative humidity exceeds the 48-hour

average value of humidity by the amount of

the threshold value.

Panel-specific setting off: dark display in the

standby mode, on: dimmed display in the

standby mode.

Modbus

register

137

69

70

76

Internal

Field

setting

18

Data display

You can view the available functions in the eWind info list on the data display.

eWind info list

Opening:

1

Simultaneously press buttons

Parameter (n1..nn) is displayed.

2

Browse the info list using buttons

and once. •

and .

Return to the standard view:

3

Simultaneously press buttons

and once.

FOR YOUR INFORMATION

If you do not press any button, the menu will

close in 5 minutes and the panel will return to the

standard view.

eWind info list

Marking Denition

n0 Standard mode is on

n1 Boosted ventilation for the removal of

humidity

n2 Boosted ventilation for the removal of carbon

dioxide

n3 Heat recovery is on

n4 Post-heating with an electric or water coil is

on

n5 Outdoor air pre-heating with CHG/AGH or an

electric pre-heater is on

n6 Supply air CG, CHG, or AGH cooling is on

n7 Cold recovery with the rotating heat

exchanger is on

n8 Ventilation boosted manually

n9 Away mode is on

n10 Dehumidification with rotor is on

n11 Defrosting is on

n12 Eco mode is on

n13 Maintenance reminder: the time remaining

until the next filter replacement in days

n14 Unit is starting

19Installation instructions for professionals

Measurement display

You can monitor temperature, humidity, heat recovery

efficiency and other measurement values in the eWind

measurement list, which is displayed on the measurement

display.

eWind measurement list

Opening:

1

Simultaneously press buttons

times. • Parameter (r1..rn) and the parameter values are

displayed.

2 Browse the parameter list up or down by pressing

button or .

Return to the standard view:

and two

1

Simultaneously press buttons

eWind measurement list

Marking in the chart

Marking Denition

r1 Outdoor air temperature, °C TE01 All models 6

r2 Supply air temperature after heat

recovery, °C

r3 Supply air temperature, °C TE10 All models 8

r4 Exhaust air temperature, °C TE30 All models 10

r5 Extract air temperature, °C TE32 All models 9

r6 Return water temperature of water-based

heating coil, °C

r7 Temperature of pre-heated outdoor air

(CHG/AGH/electric pre-heater), °C

r8 Relative humidity (RH) of exhaust air RH30 All models 13

r9 Carbon monoxide level, ppm Without an external carbon

r10 Measurement of external relative

humidity, %RH

r11 Temperature efficiency of the supply air

heat recovery, %

r12 Temperature efficiency of the exhaust air

heat recovery, %

and the connection

in the automation

motherboard

TE05 All models 7

TE45 eWind W only. Other models

TE02 Only if equipped with CHG/AGH

Note

display ‘0’.

or an electric pre-heater.

dioxide sensor (accessory), ‘- -’ is

displayed

Without an external humidity

sensor (accessory), ‘- -’ is

displayed-

All models Calculated value 29

All models Calculated value 30

and once.

Modbus

register

12

32

23

23

Commissioning documentation

• Fill in the warranty information.

• Mark the changes you have made to the factory

settings in the column Field setting in the table

‘Parameter list’ on page 16.

• Fill in the air volume measurement document.

20

FOR YOUR INFORMATION

The warranty is not valid for units with no

documented air volume measurement.

It is extremely important to record all the changes

made to the parameters. This ensures that there

are backup copies of the information in case the

automation is damaged (e.g., by a lightning strike).

Troubleshooting

Alarm Description

FILS Maintenance

reminder.

Err Sensor

malfunction

- - - - Downloading. The eWind panel is downloading

oFFE Stop mode. The ventilation

AL1 The water-

heating coil is

in danger of

freezing.

AL2 The supply

air is cold

after the

rotating heat

exchanger.

AL3 Cold supply

air.

Alarm

limit

4 or 6

months

+8°C Cold supply air. The water coil is frozen/about to

+5°C Cold supply air. The heat exchanger does not

+10°C Cold supply air. The extract fan has stopped. Replace the fan.

Symptoms Possible cause Measure Notes

It is time for the periodic

maintenance.

The sensor has short-circuited,

or there is an interruption in the

circuit.

data from the motherboard.

is off.

The external control system has

switched the ventilation unit to

stop mode.

freeze:

• The circulation pump has

stopped.

• The heat exchanger does not

rotate.

• The control valve actuator of

the water coil is faulty.

• The extract fan has stopped.

rotate:

• The drive belt is damaged.

• The drive belt skids.

• The heat exchanger motor is

damaged.

The extract filter is clogged. Replace the filter.

The ventilation has been

adjusted incorrectly/not been

adjusted at all.

The heat insulation of the ducts is

insufficient.

The fan speed of the ventilation

unit is incorrect.

Replace the filters.

Inspect the ventilation unit.

Clean, if necessary.

Check the unit for visible

damages.

Check the connections and

cables of the sensors.

Normal in connection

with start-up. In other

situations, check the eWind

connection cable.

Restart the pump.

Replace the motor or the

belt.

Replace the actuator.

Identify the cause/replace

the fan.

Replace the drive belt.

Clean or replace the belt

and the heat exchanger.

Replace the heat exchanger

motor.

Adjust the ventilation

in accordance with

the ventilation system

plan using appropriate

measurement tools.

Check the insulation

thickness of the supply and

exhaust air ducts and add

insulation, if necessary.

Always use a fan speed

specified by the ventilation

unit designer (also in the

winter).

Acknowledge by

pressing any button

for 5 seconds.

The unit will not

start until the alarm

mode has been

cleared and the

alarm has been

reset by pressing

a button in the

operation panel.

The ventilation

unit switches to

malfunction mode,

in which the fans

run at minimum

power.

The alarm is

automatically reset

when the fault is

cleared.

21Installation instructions for professionals

Alarm Description

AL4 Supply fan

malfunction.

AL5 Extract fan

malfunction.

AL6 Cold exhaust

air.

Alarm

limit

+10°C Cold supply air. Low indoor temperature. Raise the indoor

Symptoms Possible cause Measure Notes

No supply air. The supply fan has stopped. Repair or replace the supply

No exhaust air. The extract fan has stopped. Repair or replace the extract

Insufficient heat insulation of the

exhaust air duct.

The ventilation unit’s service

hatch is open.

Temperature sensor TE30 is

faulty.

fan.

fan.

temperature.

Check the insulation of the

ducts and add insulation, if

necessary.

Close the service hatch.

Repair or replace the sensor.

The unit will not

start until the alarm

mode has been

cleared and the

alarm has been

reset by pressing

a button in the

operation panel.

The ventilation

unit switches to

malfunction mode,

in which the fans

run at minimum

power.

The alarm is

automatically reset

when the fault is

cleared.

AL7 Hot supply

air.

Fire hazard.

AL8 Overheating

of the electric

post-heater

or pre-heater.

AL9 Hot exhaust

air. Fire

hazard.

+55°C Hot supply air. Fire hazard. Check for heat sources. The unit will not

There is a malfunction in the

electric post-heater.

There is a malfunction in the

actuator of the water-based postheater’s valve.

Temperature sensor TE10 is

faulty.

Hot supply air. Electric pre-heater or post-heater

does not work:

• Overheating protector has

tripped.

• The supply fan has stopped.

• The supply air filter is clogged.

• The outdoor air grille is

clogged.

• The heater’s controller board is

damaged.

• The heater is damaged.

+55°C Overheating. Fire hazard. Temperature sensor

TE30 is faulty.

Repair or replace the electric

post-heater.

Repair or replace the valve’s

actuator.

Repair or replace the

temperature sensor.

Identify the cause

for overheating and

acknowledge the error

message.

Identify the cause/replace

the fan.

Replace the filter.

Clean the grille.

Remove the possible

mosquito net.

Replace the controller

board.

Replace the heater.

Check for heat sources.

Repair or replace the

temperature sensor.

start until the alarm

mode has been

cleared and the

ventilation unit has

been restarted.

22

APPENDICES

Dimensional drawings

Technical dimensional drawing, 4-duct right-handed

23Installation instructions for professionals

Technical dimensional drawing, 4-duct left-handed

24

Technical dimensional drawing, 5-duct right-handed

25Installation instructions for professionals

Technical dimensional drawing, 5-duct left-handed

26

Electrical diagrams

Connections

Abbreviation

Colour:

BK BLACK

BN BROWN

RD RED

OG ORANGE

YE YELLOW

GN GREEN

BU BLUE

GY GREY

WH WHITE

27Installation instructions for professionals

Marking on the circuit

board

AI1

DO8

OP1

28

FIREPLACE/RANGE HOOD MODE DI6

AWAY AWAY MODE DI5

Name Denition

FP/EX

BOOST MANUAL BOOSTING DI4

ESTOP EMERGENCY STOP DI1

RETURN WATER TEMPERATURE SENSOR eWind W MODELS TE45

TE45

RETURN WATER TEMPERATURE SENSOR eWind CG MODELS TE45

TE46

PRE-HEATED OUTDOOR AIR TEMPERATURE, EXTERNAL PRE-HEATER TE02

TE02

RETURN AIR TEMPERATURE ((KOTILÄMPÖ eWind) TE02

TE20

TE10 SUPPLY AIR TEMPERATURE TE10

OUTDOOR AIR TEMPERATURE TE01

EXTERNAL HUMIDITY SENSOR AS DEFAULT (RH 0–100%). IF PARAMETER c27 IS ACTIVE, CO₂

SENSOR (200–2,000 ppm) (ACCESSORY)

PRE-HEATING ACTUATOR, CHG MODELS. COOLING ACTUATOR, CG MODELS AO6

HEATING ACTUATOR, W MODELS AO5

PRE-HEATER MODELS COOLING ON/OFF CONTROL, CG MODELS, CONDENSATE TRAY

HEATER

TE01

RH CO₂

TL01

TL50

TL45

DO8 ALARM OUTPUT A AS DEFAULT PRE-HEATING ON/OFF CONTROL, CHG –AGH, ELECTRIC

DO5 OUTDOOR AIR AND EXTRACT AIR DAMPER CONTROL (ACCESSORY) DO5

CONTROL PANEL HAS NOT BEEN INSTALLED IN THE VENTILATION UNIT

DO2 HEATING ON/OFF CONTROL eWind MODELS MAX 500-W PUMP DO2

OP1 CONTROL PANEL (1) INCLUDED IN THE DELIVERY, 10-M CABLE ALSO INCLUDED IF THE

OP2 CONTROL PANEL (ACCESSORY), 10-M CABLE INCLUDED IN THE DELIVERY OP2

EU DECLARATION OF CONFORMITY

We declare that our products follows the provisions of low voltage directive LVD 2014/35/EU, electromagnetic

compatibility directive EMC 2014/30/EU, machine directive MD 2006/42/EC, radio equipment directive RED

2014/53/EU, ROHS II directive 2011/65/EU, battery directive 2013/56/EU and waste electrical and electronic

equipment directive WEEE 2012/19/EU.

Manufacturer: Enervent Zehnder Oy

Manufacturer´s contact: Kipinätie 1, 06150 Porvoo, FINLAND,

enervent@enervent.com, www.enervent.com

Description of the product: Ventilation unit with heat recovery

Trade name of the product:

Salla eWind E CHC left, Salla eWind E (D) right, Salla eWind E (D) left,

Salla eWind E CHC (D) right, Salla eWind E CHC (D) left

The products are in conformity with the following standards:

LVD EN 60335-1:2012/A11:2014

EMC EN 61000-3-2:2014 and EN 61000-3-3:2013

EN 61000-6-1:2007 and EN 61000-6-3:2007/A1:2011/AC:2012

RED EN 300328 v2.1.1

MD EN ISO 12100:2010

ROHS EN 50581:2012

The conformity of each manufactured product is taken care according our quality descriptions.

Product is CE-marked year 2018.

Porvoo 3rd of September 2018

Enervent Oy

Tom Palmgren

Technology manager

tel. +358 207 528 800, fax +358 207 528 844

Salla eWind E right, Salla eWind E left, Salla eWind E CHC right,

EN 62233:2008/AC:2008

EN 55014-1:2006/A2:2011 and EN 55014-2:1997/A2:2008

29Installation instructions for professionals

30

31Installation instructions for professionals

Quick reference guide for the installer

<˚C

>˚C

>˚C

>˚C

<˚C

<˚C

˚C

version xx.xx.xx

x 3

> 3 sec

Parameters (c)

c1 36%

c2

c3

c4

c5

c6

c7

c8

c9

c10

c11

c12 10 min

(20–100%)

35%

(20–100%)

56%

(20–100%)

55%

(20–100%)

83%

(20–100%)

80%

(20–100%)

100% (20–100%)

(120 min)

100% (20–100%)

(120 min)

2 h

(1...4 h)

30%

(20–100%)

50%

(20–100%)

(5...15 min)

Parameters (c)

c13 oFF

c14

c15

c16

c17

c18

c19

c20

c21

c22

(on/oFF)

4

(4/6)

oFF

(on/oFF)

=> on,

TE01 < °C,

5°C (0…10°C)

=> off, TE01 >

(c16 + c17),

1°C (1…5°C)

on

on/oFF

=> on,

TE01 > °C, 17°C

=> on,

TE01 > °C,

20°C (15…25°C)

=> off, TE01 <

(c20 - c21),

2°C (1…5°C)

–15°C

(-10…-20°C)

Parameters (c)

c23

%RH

c24

c25

c26

c27

c28

c29

c30

c31 eWind

c32 Modbus 2

%RH

%RH

%CO

2

%CO

2

%RH

Modbus

%RH

48 h

on

(on/oFF)

4°C

(–10…+10°C)

45%

(10...100%RH)

=>on, 48 h %RH

+ c26,

15% (5…30%)

oFF

(on/oFF)

CO2=> on,

1,000 ppm

(600...1,200)

oFF

(on/oFF)

oFF

(on/oFF)

1

(1...99)

(1 = 9600, 2

= 19200, 3 =

115200)

x 2

%RH

˚C

˚C

RH30

%CO

%RH

2

η%

˚C

TE30

˚C

TE10

η%

TE32

TE01

˚C

TE02

Enervent Zehnder Oy

Kipinätie 1

FI-06150 Porvoo, Finland

Tel. +358 207 528 800

Fax +358 207 528 844

enervent@enervent.com

www.enervent.com

TE05

˚C

Loading...

Loading...