Page 1

Ventilation unit with heat recovery

Planning, installation and operational instructions manual

Before installing and operating this unit,

please read this manual thorougly, and retain it for future reference.

www.enervent.

PICCOLO

Enervent Piccolo

Page 2

2

TABLE OF CONTENTS

TABLE OF CONTENTS

OVERVIEW

TYPE MARKING 3

TYPE DESCRIPTION 3

FOREWORD 4

WARNING 4

OPERATING PRINCIPLE 4

DUCT HEAT INSULATION 5

KITCHEN VENTILATION 5

INSTALLATION

EQUIPMENT 5

INSTALLATION 6

DRAINING THE VENTILATION UNIT 10

USER GUIDE

STARTING THE UNIT 11

ABOUT VENTILATION 11

SUPPLY AND EXTRACT AIR CALIBRATION 12

USING AND CONTROLLING THE UNIT 13

HEAT RECOVERY DEFROSTING FUNCTION 14

MAINTENANCE

MAINTENANCE 15

BELT REPLACMENT 16

TROUBLE SHOOTING 17

TECHNICAL INFORMATION

TECHNICAL INFORMATION 17

HEAT RECOVERY EFFICIENCY RATE 18

DIMENSION DRAWINGS 19

CHARACTERISTIC CURVES 26

SOUND DATA 27

CONTROL CHART 30

WIRING DIAGRAMS 31

DECLARATION OF CONFORMITY 34

QUICK GUIDE TO THE VENTILATION UNIT AND COOKER HOOD

Copyright Enervent 2011. All rights reserved.

Page 3

3

Enervent® Piccolo EN 2011_1

OVERVIEW

TYPE MARKING

Inside the ventilation unit is a type shield. Fill in the type shields data here to have it easily available when it is needed, e.g.

when buying new lters.

This manual covers the following units:

Enervent Piccolo eco ECE-ON

Enervent Piccolo eco ECE-OFF

Enervent Liggolo eco ECE

ilmastointilaite

ventilation unit

TYYPPI/TYPE:

SRJ.NRO/SERIAL NO:

W/ V/ HZ / A:

ENERVENT OY AB

KIPINÄTIE 1 06150 PORVOO

TEL +358 (0)207 528800 FAX +358 (0) 207 528844

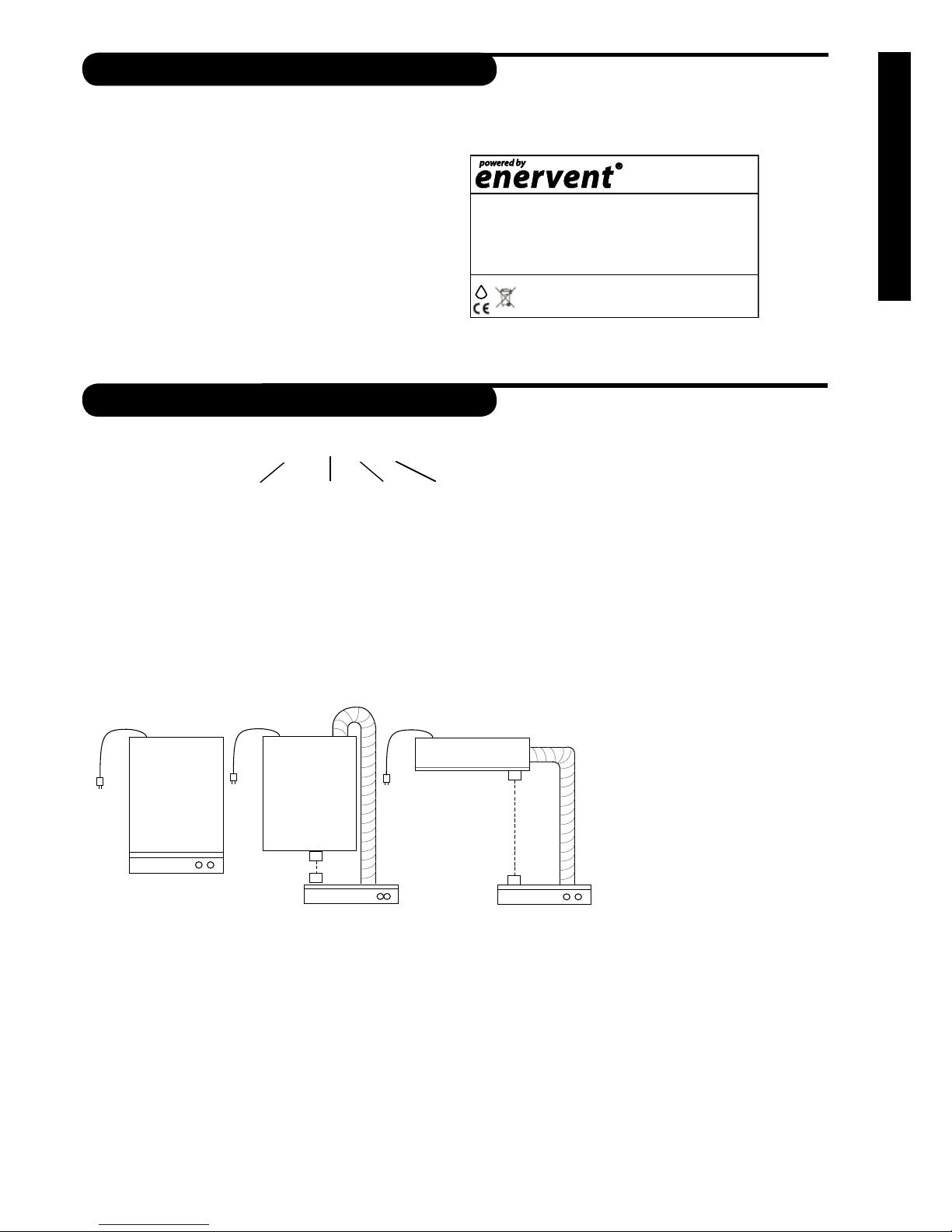

TYPE DESCRIPTION

P

P

Piccolo

ON-models

The unit is on the wall.

The cooker hood is mounted

on the ventilation unit.

Piccolo

OFF-models

Cable 8 x 1.5 mm²

The unit is on the wall.

The cooker hood and the unit are

connected with a duct.

Unit mounted hanging from the ceiling.

The cooker hood and the unit are

connected with a duct.

Liggolo

P

Cable 8 x 1.5 mm²

P

Ener vent Piccolo eco ECE-ON

Unit frame Alternating

current fans

Control

Piccolo The unit is mounted on the wall.

Liggolo A lying version of Piccolo.

eco Ventilation unit with direct current fans.

ECE Ventilation unit with ECC05 control and 800 W electrical after heater.

ON The cooker hood is mounted directly on the unit.

OFF The unit and cooker hood are connected with a duct and can hence even be installed in separate

spaces.

Installation alternative

Page 4

4

OVERVIEW

FOREWORD

All Enervent ventilation units are designed and manufactured for use all year round. In Finland the ventilation units have

been installed in houses and other spaces for over 20 years and their popularity is increasing each year. Because of the

knowledge and experience we have amassed during the years we can now manufacture more energy ecient and user

friendly ventilation units. The Enervent gr unit series is the result of a long product development. All unitsin the series are

very versatile and exible.

A unit with basic functions can be installed, by your self, with the help of this manual, but certain special functions and the

extra equipment should be connected by an electrician. We recommend that the installation is performed by a qualied

ventilation engineer.

WARNING

After opening the maintenance hatch wait two (2) minutes before starting the maintenance

work! The fans rotate for a while even after the power is cut and the ECE-model electical heatercan be searing hot. There are no user-serviceable parts inside the control panel or inside the

electrical cabinet, leave the service of these parts to a professional. It is important during troubleshooting not to turn on the power to the unit before being assured as to what the problem is.

OPERATING PRINCIPLE

The ventilation units are based on regenerative heat recovery. This is achieved with a rotating heat exchanger through

which incoming air and exhaust air ow in opposite directions. Aluminium foils within the heat exchanger transfer heat

from the exhaust air to the supply air. A characteristic of the regenerative heat exchanger is its high rate of heat recovery

(or eciency).

Enervent Piccolo and Liggolo units are linked with a cooker hood. The cooker hood is linked to the unit either directly or

with a duct. The air from the cooker hood is, with the help of the extract air fan, lead past the heat exchanger directly into

the exhaust air.

The eciency varies from 75 % to 85 %, depending on the proportion of supply air and exhaust air (the heat from the

supply air fan is taken into account). Thanks to their high eciency, the units save heating energy at the same time as they

provide excellent indoor air quality; therefore they pay themselves back in a relatively short time.

Page 5

5

Enervent® Piccolo EN 2011_1

INSTALLATION

KITCHEN VENTILATION

The general ventilation in the kitchen is taken care of with a extract air vent in the ceiling.

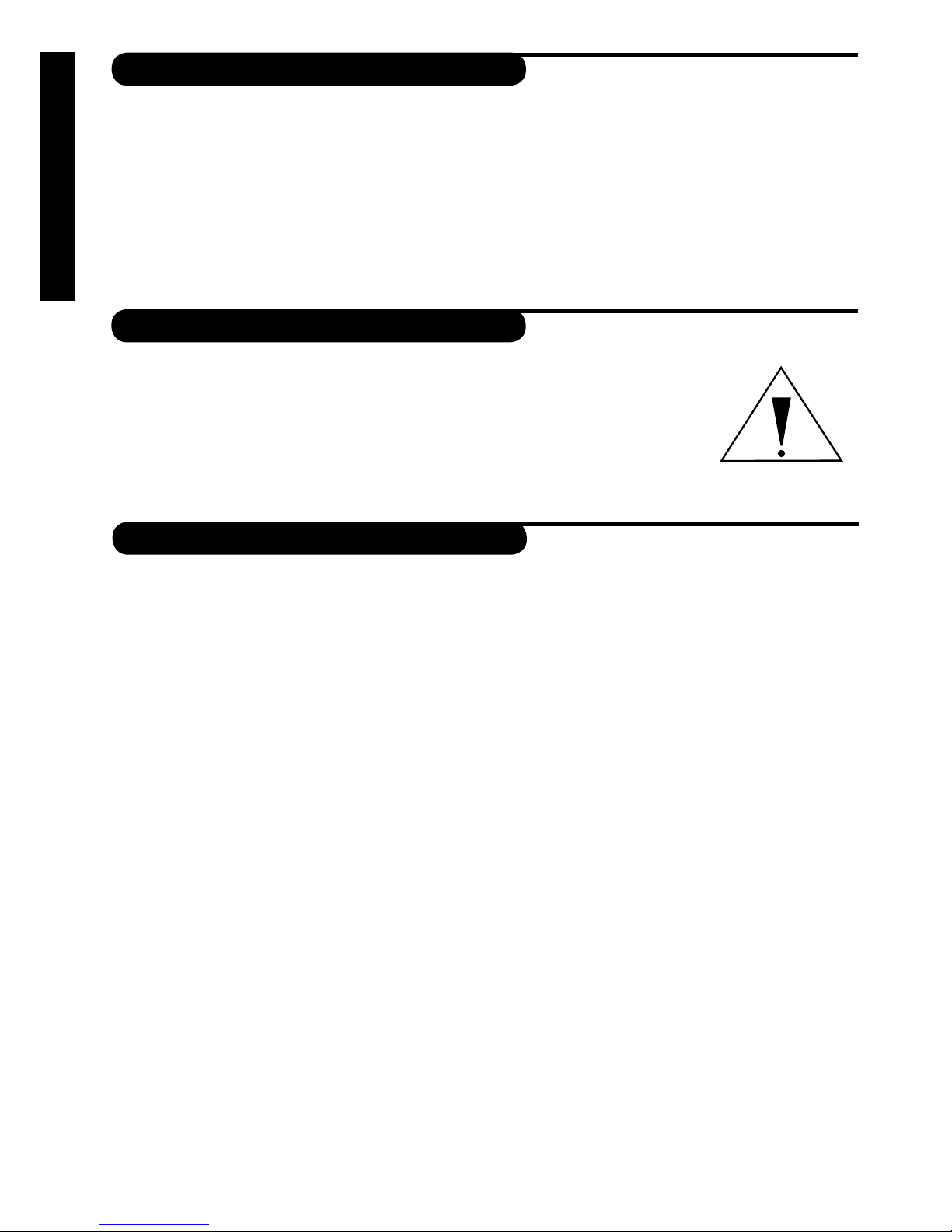

DUCT HEAT INSULATION

Examples of dierent insulation alternatives:

1. Exhaust air duct in warm spacing (indoors, no insulation).

2. Supply air duct between ventilation unit and terminal equipment.

3. Waste air and outside air duct in warm spacing (indoors).

4. Exhaust air duct in the ceiling insulation.

5. All ducts in a cold attic. Outside air and waste air ducts must not be assembled directly above the steam

barrier. Both ducts require an insulation layer of 100 mm thick mineral wool.

1.

2.

isolation 20 mm

vapour proof surface

4.

5.

isolation

100 mm

3.

isolation 80 mm

vapour proof surface

EQUIPMENT

The Enervent Piccolo (eco) ECE unit delivery includes:

1. Enervent Piccolo (eco) ECE ventilation unit

2. Attachment brackets for kitchen cabinet integration laminate

3. Standard cooker hood

The Enervent Liggolo (eco) ECE unit delivery includes:

1. Enervent Liggolo (eco) ECE ventilation unit

2. Standard cooker hood

Page 6

6

INSTALLATION

PICCOLO-MODELS:

Piccolo must be installed in a warm space (over +5°C) like a utility room or a laundry but not a garage (separate re area).

The unit can also be installed in the kitchen if the cooker hood is fastened in the unit.

If the unit is used to ventilate an area with a swimming pool, the unit must be drained. There is a drain outlet in the bottom of the unit (1/4” inner thread). At the time of delivery, the outlet is plugged.

PHASES OF INSTALLATION:

N.B.! To reduce the weight of the unit you can remove the heat recovery wheel before mounting the unit.

1. Mark and cut the holes into the ceiling.

2. Draw the ducts through the holes to the required height. The gaps between duct and steam barrier are then

sealed, with for instance ventilation tape.

3. Attach two suspension screws at an appropriate hight at a distance of 500 mm from each other. The unit has two

suspension ears. Make sure the wall material can bear the units weight. NOTE! If the cooker hood is directly at tached to the unit, the distance between the grease lter and the stove must be at least 500 mm*.

4. Lift the unit onto the wall and thighten the screws.

5. Connect the ducts to the tubes on top of the unit. It is recommended that silencers be installed to the extract

air and supply air ducts.

6. If the unit’s condensation drain is to be used, connect a pipe between the drain outlet and the nearest oor

drain or water trap of a sink. Connecting the unit directly into the sewage system is not allowed.

* NOTE! Make sure the distance satisfys the stove manufacturers and local authorities demands.

LiGGOLO-MODELS:

Liggolo must be installed in a warm space (over +5°C) like a utility room or a laundry but not a garage (separate re area).

If the unit is used to ventilate an area with a swimming pool, the unit must be drained. There is a drain outlet in the bottom of the unit (1/4” inner thread). At the time of delivery, the outlet is plugged.

PHASES OF INSTALLATION:

N.B.! To reduce the weight of the unit you can remove the heat recovery wheel before mounting the unit.

1. Mark and cut the holes into the ceiling.

2. Draw the ducts through the holes to the required height. The gaps between duct and steam barrier are then

sealed, with for instance ventilation tape.

3. Attach suspension screws at an appropriate place in the ceiling. The unit has four suspension ears. Make sure the

ceiling material can bear the units weight.

4. Lift up the unit to the ceiling and thighten the screws.

5. Connect the ducts to the tubes on top of the unit. It is recommended that silencers be installed to the extract

air and supply air ducts.

6. If the unit’s condensation drain is to be used, connect a pipe between the drain outlet and the nearest oor

drain or water trap of a sink. Connecting the unit directly into the sewage system is not allowed.

THE COOKER HOOD

Removal of the exhaust air from the cooker hood shall be done in accordance

to logal regulations. The exhaust air must not be lead into smoke canals that

are used as exhaust of cobustion gases from gas/wood stoves, wood/oil

burners.

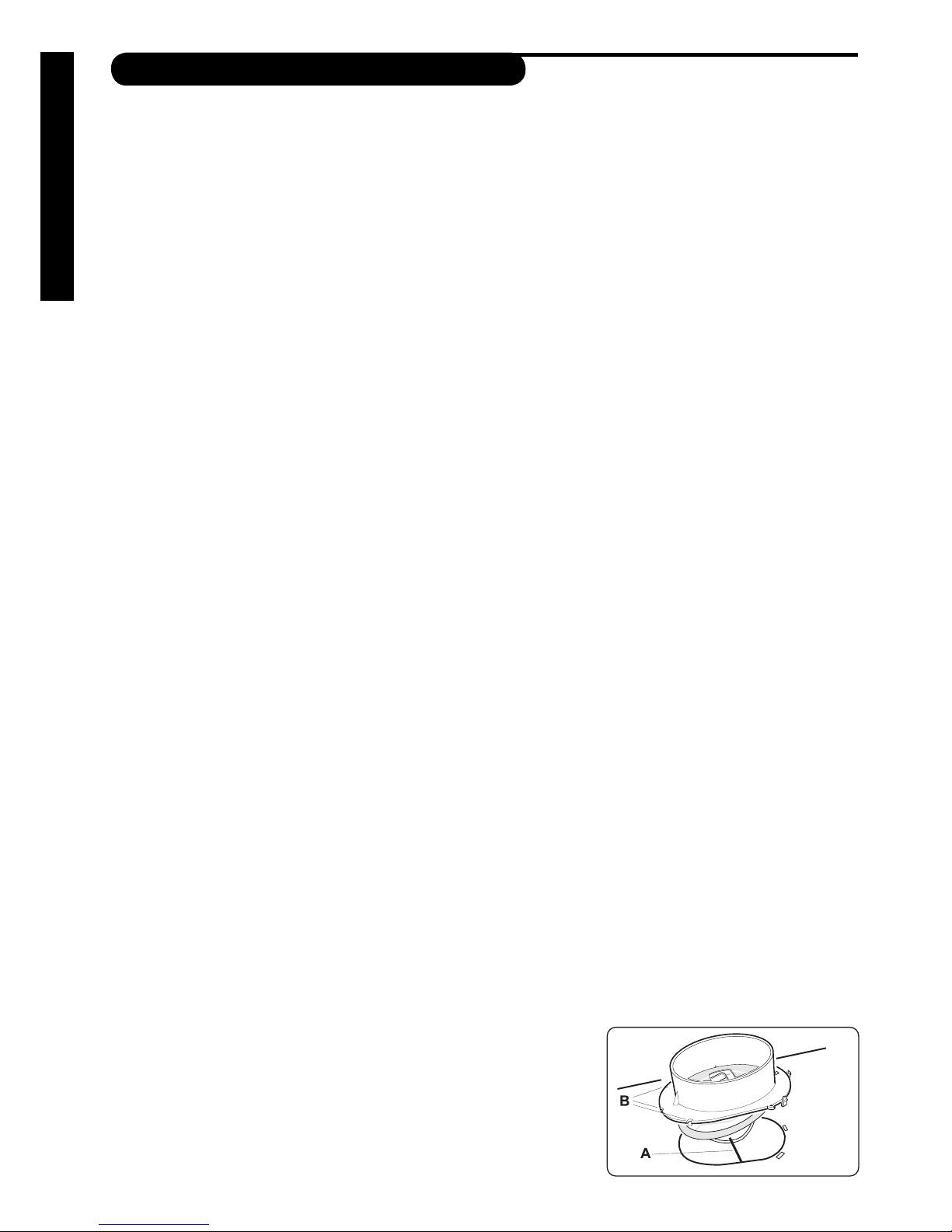

Mounting the connection cu with damper:

The connection cu is inside the cooker hood when delivered.

The damper shaft A is put in the loop beneathe the damper lid, g 1.

Make sure the clutches get beneath the sheet metal edge.

The cu will snap in place.

INSTALLATION

1

Page 7

7

Enervent® Piccolo EN 2011_1

INSTALLATION

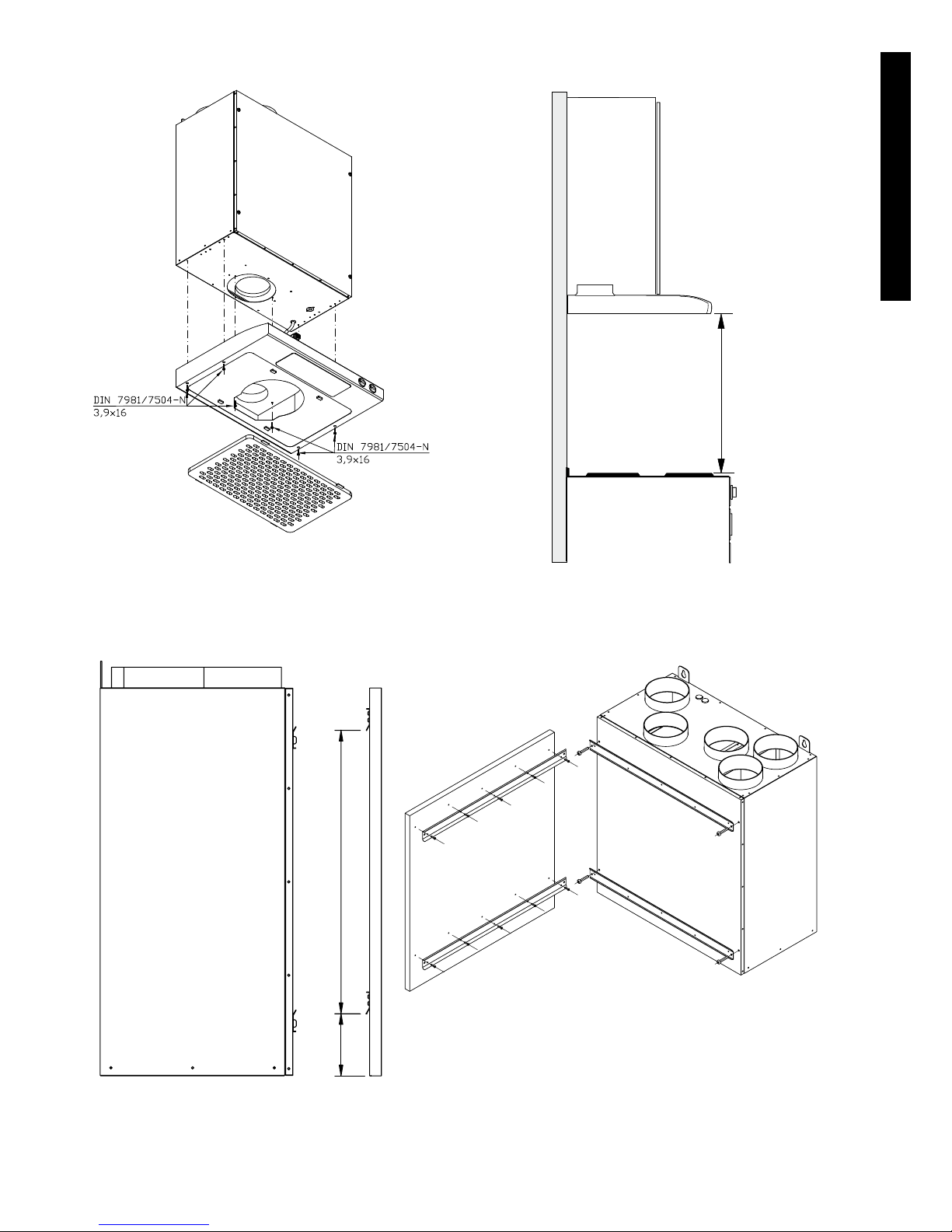

NOTE WHEN YOU INSTALL PICCOLO ON-MODELS:

500/650

101

460.25

Mounting the cabinet integration laminate:

Page 8

8

INSTALLATION

NOTE WHEN YOU INSTALL PICCOLO OFF-MODELS:

Some preparations need to be done on the cooker hood if it is not mounted on the unit.

90°

1.

2.

3.

1. Place the rubber lead through in the gap.

2. Bend the cover plate 90° along the perfora tion.

3. Place the cover plate on the hole in the

cooker hood and fasten it with the screws.

2

3

Installing the cooker hood

The cooker hood can be placed under the cup boards or embeded, g

2. Connect the cooker hood with a Ø 125 mm duct or hose. NOTE! When

using a hose, it must be installed straightened closest to the connection,

g 3.

Page 9

9

Enervent® Piccolo EN 2011_1

INSTALLATION

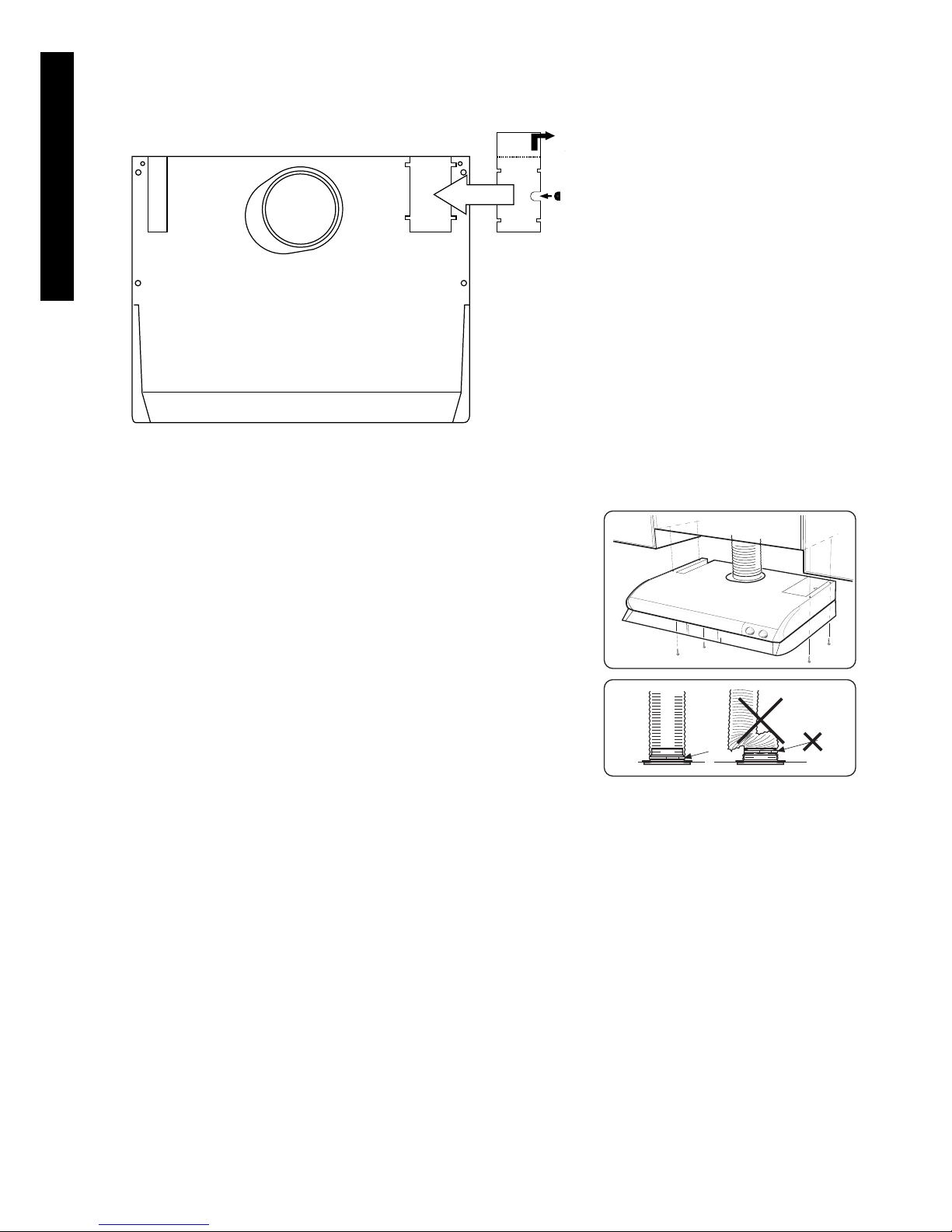

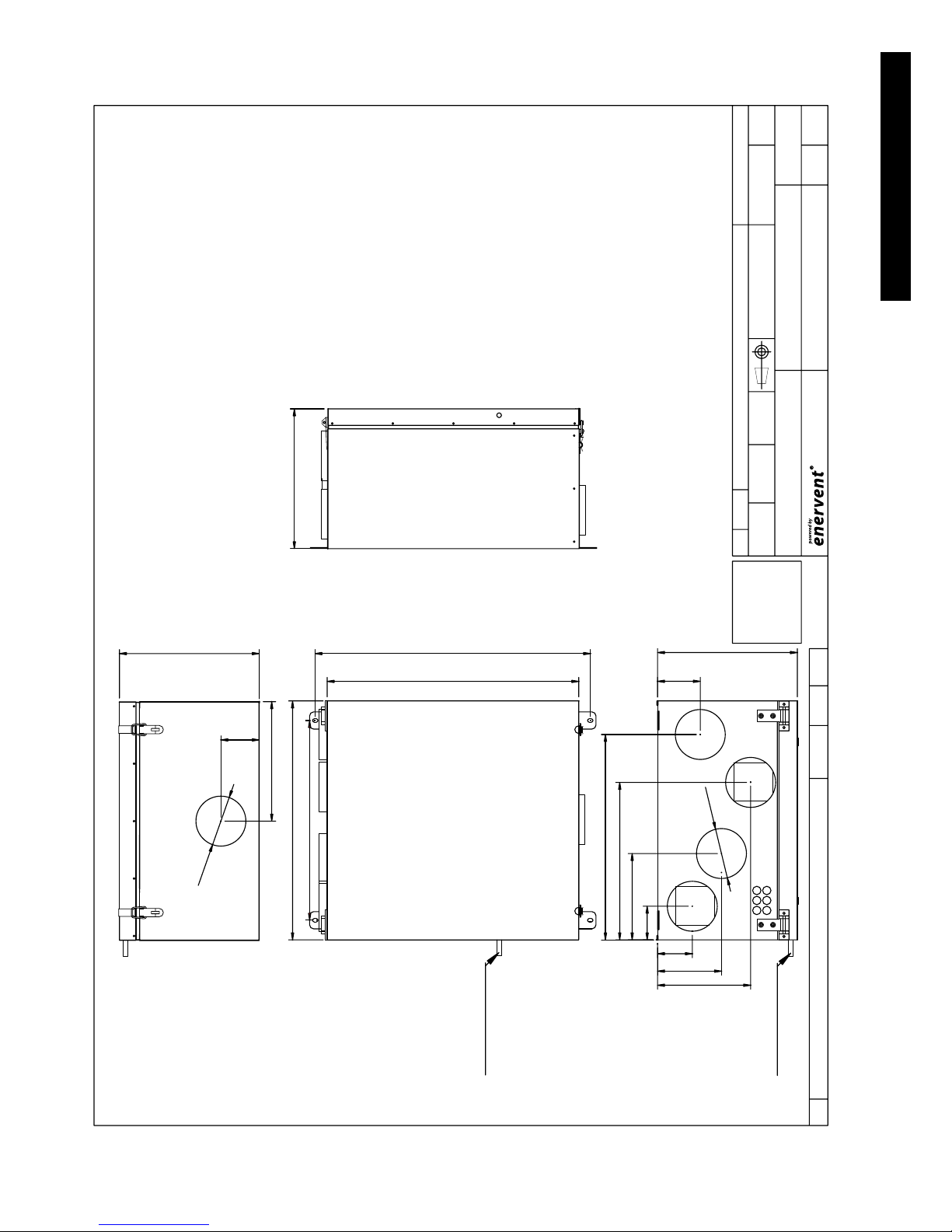

NOTE WHEN YOU INSTALL LIGGOLO MODELS:

J.T 01/10/2008 1:7

KATTOMALLI ASENNUSKUVA 002

1A

C:

Paino kg

HyvMuuttPvmMuutosNo

LehtiMuutosPiir no

Nimitys

SuhdePvmFileHyvTarkPiirt

ValmisteOsan nimitysKplOsa

EN ISO 13920-AE

YLEISTOLERANSSIT

Hitsatut rakenteet:

Koneistetut osat:

ISO 2768-MK

LIGGOLO

INSTALLATION PICTURE

E-mail: enervent@enervent.fi

Tel. 358-(0)207-528800

Fax. 358-(0)207-528844

Kipinätie1, 06150 Porvoo

DIN 571

8x60

4 pcs

Ceiling attachment

Ceiling

Foamed plastic 5mm

Rubber plate

Rubber plate +

Metal plate

J.T 01/10/2008 1: 7

KATTOMALLI ASENNUSKUVA 003

1A

C:

Paino kg

HyvMuuttPvmMuutosNo

LehtiMuutosPiir no

Nimitys

SuhdePvmFileHyvTarkPiirt

ValmisteOsan nimitysKplOsa

EN ISO 13920-AE

YLEISTOLERANSSIT

Hitsatut rakenteet:

Koneistetut osat:

ISO 2768-MK

LIGGOLO RIGHT

INSTALLATION PICTURE

E-mail: enervent@enervent.fi

Tel. 358-(0)207-528800

Fax. 358-(0)207-528844

Kipinätie1, 06150 Porvoo

Ceiling

~80mm

~45mm

Condense water drain

Page 10

10

INSTALLATION

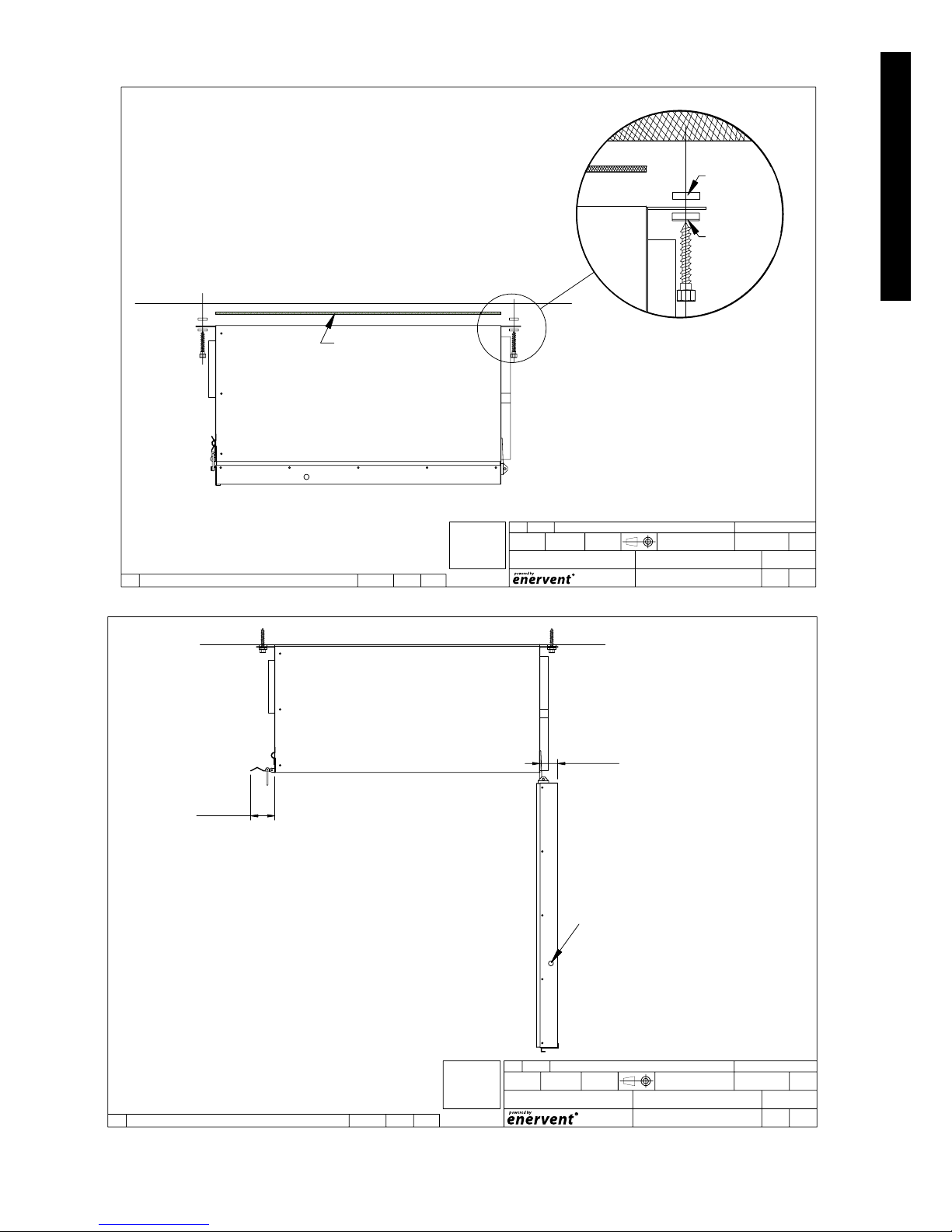

DRAINING THE VENTILATION UNIT

All Enervent Piccolo units must be drained. The condense water drain must not be directly connected to a sewer! The condense water should be led in a falling, at least Ø15 mm pipe, through a water lock to a oor drain or such. The pipe must

at all times lie lower than the bottom of the ventilation unit. There must not be any longer horizontal sections on the pipe

and there mustn’t be more than one water lock. If the unit is equipped with more than one condense water draines, each

one must have a water lock of its own.

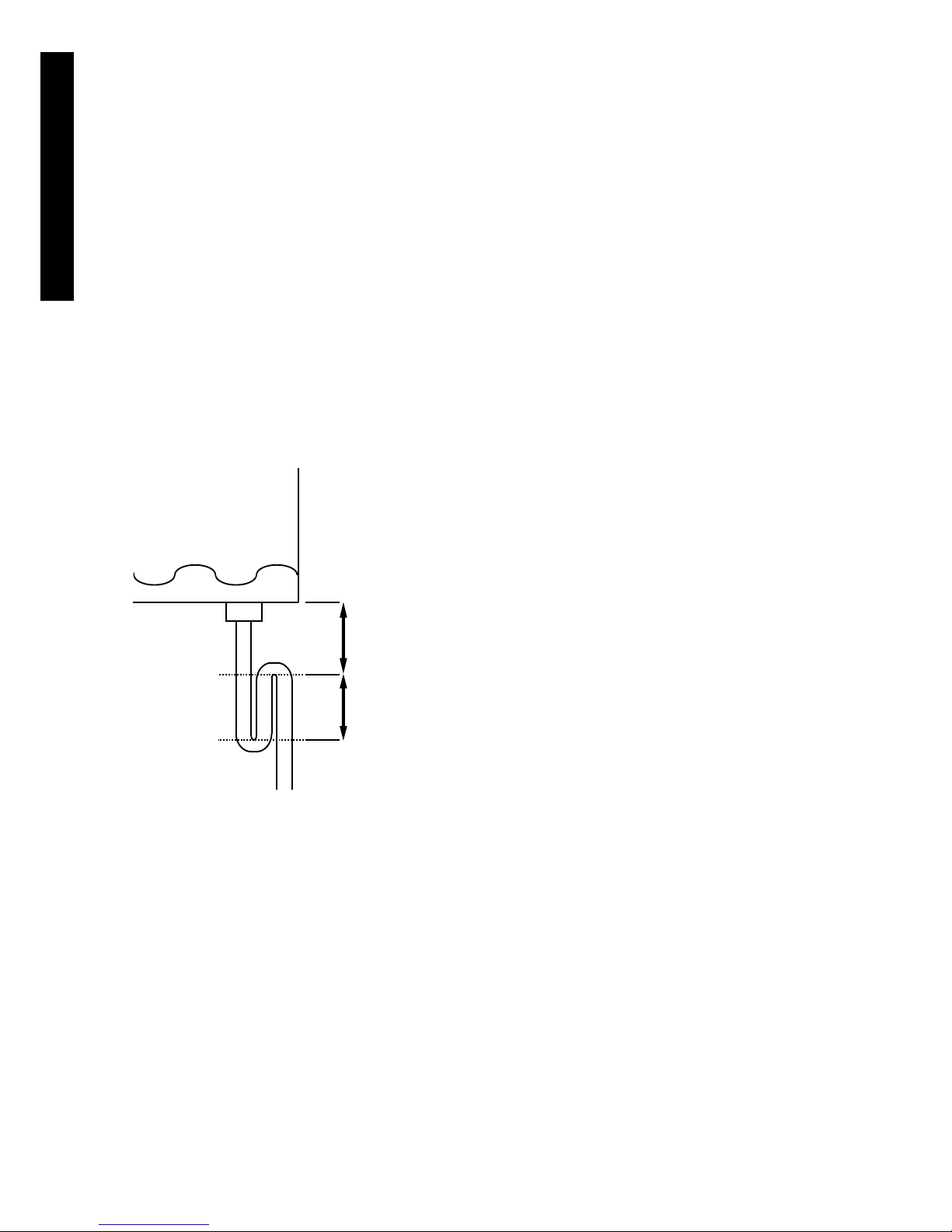

There is under pressure in the ventilation unit. We recommend a hight dierence of (A) 75 mm, or at least the under pressure divided with 10 in millimeters (i.e. 500 Pa under pressure -> 50 mm), between the unit drain and the water lock drain.

We recommend that the hight of backwater in the water lock (B) is 50 mm, or at least the under pressure divided with

20 in millimeters (i.e. 500 Pa under pressure -> 25 mm hight of backwater). Over pressure is prevailing in a duct coil. We

recommend the hight dierence (A) between the duct coil drain and the water lock drain is 25 mm. The water lock hight

of backwater (B) must be 75 mm, or at least the under pressure divided wit 10 in millimeters (i.e. 500 Pa under pressure ->

50 mm). The water lock must be lled with water before starting up the unit. The water lock might dry up if water is not

accumulated in it. If this happens, ait might get into the pipe and hinder water from entering the water lock, which might

result in an irritating ”bubbling” sound.

The size of the condense water drain is 1/4” (inner thread) in all Piccolo units.

A

B

Page 11

11

Enervent® Piccolo EN 2011_1

USER GUIDE

USER GUIDE

STARTING THE UNIT

Before the unit is ready for use the following installations should take place:

- Assemble the unit and the cooker hood as stated in the chapter Installation in this manual. Check with a water

level to make sure that the unit is level, this is crucial for the drainage to work.

- Connect the drainage outlet with its own hose to an outow supplied with a water lock.

- Install the ducts (also for the cooker hood) and the silencers.

- Assemble the terminals on to the ducts.

- Provide the outside air duct with an outside air grating (N.B! the grating must not be provided with an insect net

because it is dicult to keep clean!)

- Make the roof pass-through. We recommend the use of a factory made, insulated roof pass-through.

- Insulate the ducts as instructed.

- Provide the unit with the appropriate power supply

Open the units maintenance hatch with the key provided when all the above mentioned installation work is done. Check

that the unit is clean on the inside, that there are no spare parts inside the unit and that the lters are clean. Close the

maintenance hatch carefully.

ABOUT VENTILATION

The ventilation unit should never be switched o. It is important to always ventilate with a high enough eect! If the ventilation is insucient the humidity indoors becomes too high and condensation can appear on, for instance, all the windows. A relative humidity of 40 - 45 % indoors is recommended (room temperature of 20 - 22°C). At these levels condensation will not form and the humidity will be at a healthy level. The humidity of a room can be measured with a hygrometer.

When the humidity rises above 45 % one should increase the ventilation and when the humidity goes lower than 40 % one

should lower the ventilation.

Check regularly that the lters are not dirty! During winter the exhaust lter become dirtier more quickly than the supply

air lter. As a result of this the airow lessens, which leads to lowered humidity indoors. This also leads to lower temperatures. Check the lters each month! At each lter inspection, check that the heat exchanger is functioning correctly, meaning

check that it is rotating. Cover both the outside air intake and the waste air outtake if the unit is not to be used for a longer

period. This way you stop moist from condensing on e.g. the fans electric motors.

Page 12

12

USER GUIDE

SUPPLY AND EXTRACT AIR CALIBRATION

After the unit has been switched on its airows must be calibrated to its planned values. When making the calibration all

lters should be clean, all supply and extract air valves, the roof pass-through and the outside air grating should be in place.

The outside air grating must not be provided with an insect net. The extract air ow should be ca. 5 - 10 % higher than

the supply air ow. To achieve optimal values during calibration the airows should be measured at each duct opening.

A suitable measuring instrument would be a thermo anemometer. With the help of registered values the airow can be

regulated to achieve the projected values. A correctly calibrated ventilation unit is quiet and gives a good heat return and

it also upholds a small under-pressure in the house. The under-pressure stops humidity from entering the walls and ceiling.

To make it easier to adjust the air amount the speed (-20 %...+10 %) of the supply air fan can be adjusted with the trimmer on the main switch board. The regulation is proportional for the dierent speed positions. I.e. the regulation -10 % on

speed setting 4 (100 %) means the extract air fan runs on 100 % and the supply air fan on 90 %, on speed setting 3 (80 %)

it means the exhaust air fan runs on 80 % and the supply air fan on 72 %, on speed setting 2 (60 %) it means the exhaust

air fan runs on 60 % and the supply air fan on 54 % and on speed setting 1 (40 %) it means the extract air fan runs on 40 %

and the supply air fan on 36 %. When the exhaust and supply air fan run on the same speed the speeds are (1) 40 %, (2) 60

%, (3) 80 % and (4) 100 %. Each of the speeds can be reduced max 20 % with the switch board trimmer. There are totally 5

trimmers on the board.

eco EC(E) units main board

15

10 20

LTO TEMP

The control panels

are connected here

(in either one).

External control connections

NOTE! MORE DETAILED CIRCUIT DIAGRAMS AT THE END OF THE MANUAL.

FAN SPEED CTRL

0 %

TF

DIFF

-20 %

+10 %

S1

20 %

30 %

40 %

S2

40 %

50 %

60 %

S3

60 %

80 %

70 %

S4

80 %

90 %

100 %

TF

CTRL

PF

CTRL

The heat recovery can be turned

off only when the outside air

temperature exceed +15°C (the

value can be set on the potentiometer on the control card)

Trimmers for regulating the air amount. The

regulation is proportional for the different speed

positions. I.e. the regulation -10% on speed setting

4 (100%) means the exhaust air fan runs on 100

% and the supply air fan on 90 %. Also read the

Ch. “Adjusting the proportion of supply air and

exhaust air”.

Page 13

13

Enervent® Piccolo EN 2011_1

USER GUIDE

Supply air filter

Extract air

filter

Supply air fan

Extract air fan

Heat recovery wheel

Resetting the electrical after

heater over heating protection

R

Supply air temperature

adjustment

Cooker hood damper control (A)

Knob with two functions (B/C):

Fan speeds controlled by turning the knob

Cooker hood light on/off by pushing the knob

USING AND CONTROLLING THE UNIT

The unit is intenden for continuous use. The unit’s air ow is

regulated with the right knob on the cooker hood.

The heat recovery is automatically controlled with an outside

air thermostat which starts and stops the heat recovery according to the outside air temperature. The factory setting is

+15°C. The setting can be changed with the trimmer on the

mother board. The heat recovery is on when the temperature

is beneath +15°C and o when the temperature is over +15°C.

The electrical after heater is controlled with a supply air thermostat. The factory setting is +18°C. The setting can be changed with the knob on the heater. The heater can not be on if

the heat reccovery is o.

On the front of the cooker hood is, besides control of the fan

speed, the control for the cooker hood damper. The damper

is opened during cooking by turning the left knob (A) on the

front of the cooker hood and the desired fan speed is set with

the right knob (B). The damper shuts automatically after 60

minutes and the unit resumes normal ventilation. Normal

ventilation can also be resumed by manually shutting the

damper.

Page 14

14

USER GUIDE

HEAT RECOVERY DEFROSTING FUNCTION

The defrosting of the heat recovery is active when the outside air temperature is lower than -15°C. The temperature is

checked every other hour (with 120 minutes interval). The supply air fan stops and the exhaust air fan runs on speed 3

when the defrosting is active. The defrosting is active at the most 8 % of the time. The over pressure function over rides

the defrosting function.

The defrosting function is activated by short circuiting the defrosting pins on the main board. The defrosting is in active when

the unit leaves the factory.

PF

CTRL

15

10 20

LTO TEMP

FAN SPEED CTRL

0 %

TF

DIFF

-20 %

+10 %

S1

20 %

30 %

40 %

S2

40 %

50 %

60 %

S3

60 %

80 %

70 %

S4

80 %

90 %

100 %

TF

CTRL

Defrosting

active

J1 J2

eco ECC units (with direct current fans):

Page 15

15

Enervent® Piccolo EN 2011_1

MAINTENANCE

The ventilation unit does not require any mechanical maintenance, only changing of the lters periodically and cleaning of

the heat exchanger and fans (when needed). Cut the power supply to the unit before starting any service work (from the

main switch or by removing the service hatch of the LTR-series units). Wait for two (2) minutes before starting the maintenance work! Although the unit’s power supply is cut when the hatch is opened, the fans still rotate and the electrical coil

in ECE-model is still hot for a while.

Cleaning the heat exchanger

When changing the lters, check if the heat exchanger is dirty. If cleaning is required, remove it from the unit and carefully

wash through the air channels with a hand shower using a mild detergent, taking care not to get the motor wet. The heat

exchanger can also be cleaned by blowing through the air channels using compressed air. Do not use a pressure washer

and do not submerge the heat exchanger into water!! When restarting the unit after cleaning, check that the heat exchanger wheel can turn freely.

Cleaning the fans

When changing lters, also check the condition of the fans. If cleaning is required the fans can be removed from the unit

and cleaned with a toothbrush or compressed air.

Changing of lters

The recommended time between lters changes for the cassette lter and the bag lter is six (6) months. If class F5 baglters are used the time between lter changes can be prolonged to one (1) year, by vacuuming the lters on the inside.

Remove the old lter and put in a new one. Vacuum cleaning the inside of the device is recommended at this point. N.B!

Make sure to close the service harch carefully!

Cleaning the cooker hood

The cooker hood is wipe with a damp cloth and washing liquid. The lter should be cleaned twice a month if the use is

normal. Loosen the lter cartridge by push the lock tags in the front edge. Take the lter apart and remove the lter cloth

by loosening the lter holder, picture 1. Soak the lter cloth and lter holder in warm water mixed with washing liquid. The

lter cartridge (with the cloth) can also be washed in a dish washer. The cooker hood should be cleaned inside some times

per year. Wipe the inside with a damp cloth and washing liquid. Put the lter cartridge back in place so that it locks in place.

Changing the luminescent lamp in the cooker hood

The lamp glas is loosened by push the lock tags in the direction shown by the arrow, picture 2. The luminescent lamp is

now accessable for change (luminescent lamp socket G23).

MAINTENANCE

Picture 1 Picture 2

Page 16

16

MAINTENANCE

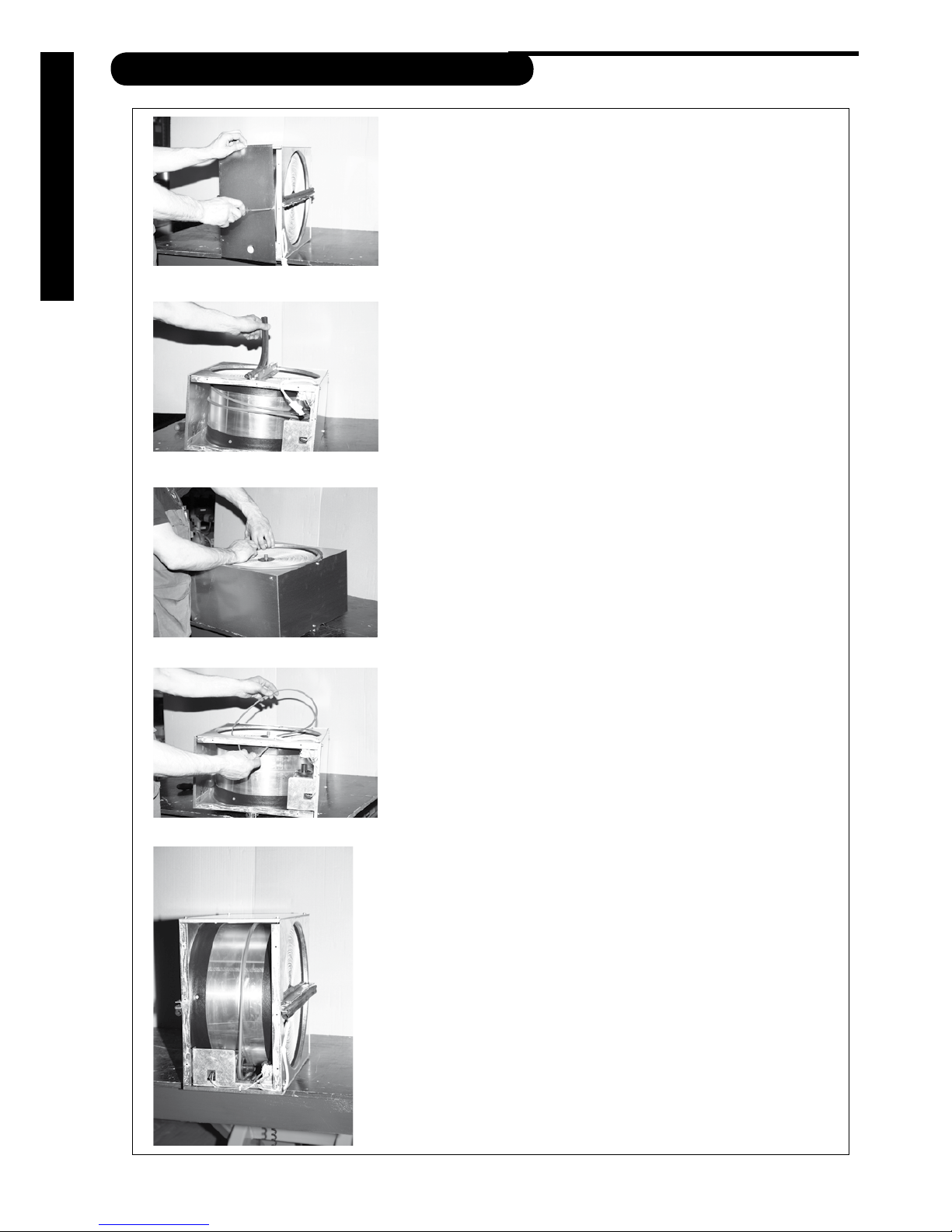

BELT REPLACEMENT

There is a spare belt in all heat exchangers. The spare belt is fixed

to the heat exchanger. In order to take the spare belt into use,

unplug the bayonet socket and remove the heat exchanger from

the ventilation unit. Open the service hatch (see below) and loosen

the spare belt from the holders. Leave the holders in the heat

exchanger. Pull the belt on to the belt holder. Close the service

hatch . Put the heat exchanger back into the ventilation unit and

connect the bayonett socket.

Follow the instructions below if there is no spare belt.

Turn of the ventilation unit by switching off the main power supply,

removing the fuse or disconnecting the wall plug.

Open the maintenance hatch.

Unplug the heat exchanger.

Pull out the heat exchanger from the ventilation unit.

Remove the lid by detaching the screws (pic 1).

pic 1

Turn the heat exchanger on to its side so that the axle is in a

vertical position. Remove the sealing strip (pic 2).

Detach the hexagonal screw and the screws in the u-beam.

Remove the u-beam.

Remove the old belt.

pic 2

Remove any possible dirt from the rotors surface and carefully

place the new belt inside the heat exchanger through outer shell

and the gasket (pic 3 and 4).

Carefully pull the belt past the gasket and rotate the rotor at the

same time. Assemble the u-beam.

Attach the beams screws and the hexagonal screw of the axle.

Put the belt on to the belt wheel and rotate the rotor away from

the motor a couple of times (pic 5).

Clean the inside of the heat exchanger.

Close the lid.

Re-assemble the heat exchanger in to the ventilation unit and

plug it in.

Turn on the ventilation unit and check that the heat exchanger is

rotating.

Close the maintenance hatch.

pic 3

pic 4

pic 5

Page 17

17

Enervent® Piccolo EN 2011_1

MAINTENANCE

TROUBLE SHOOTING

Reason Action

The heat exchanger switch is tuned o. Switch it on.

Belt of the heat exchanger broken. Replace the belt.

Belt greasy, causing slippage. Contact a service representative.

The exhaust fan has stopped. Contact a service representative.

The exhaust air lter is blocked. Change the lters.

Exhaust air valve settings incorrect. Contact a service representative.

Heat insulation of ducts inadequate. Check the insulation thickness of the supply and ex-

haust air ducts and add insulation if needed.

The after heater over heating protection has gone

o (ECE-models).

Check what the reason to the problem is and reset the

over heating protection.

SUPPLY AIR TOO COLD

REDUCED AIR FLOW

Reason Action

Filters are blocked. Change the lters.

Too small a fan speed is selected. Select higher speed.

Blockage in the fresh air grille. Clean the outer grille.

Fan wings dirty. Clean the fans.

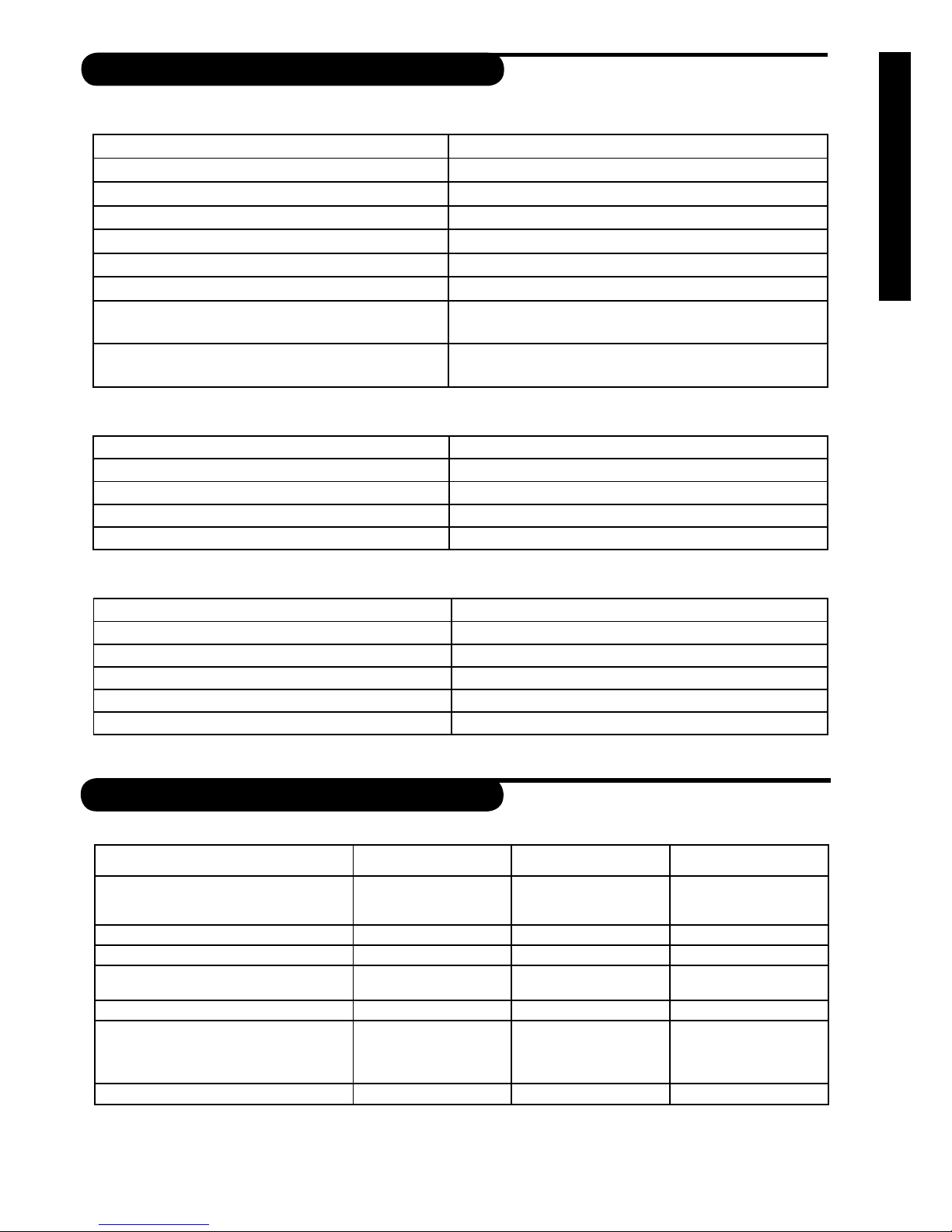

TECHNICAL INFORMATION

UNIT:

(without cooker hood)

PICCOLO eco ECE-ON PICCOLO eco ECE-OFF LIGGOLO eco ECE

Width

Depth

Hight

598 mm

320 mm

630 mm

598 mm

320 mm

700 mm

598 mm

630 mm

350 mm

Weight

46 kg 46 kg 46 kg

Duct size

Ø 125 mm Ø 125 mm Ø 125 mm

Fans supply and extract air

119 W

0,9 A

119 W

0,9 A

119 W

0,9 A

Electrical after heater

800 W 800 W 800 W

Current

Fuse

Main board glas pipe fuse 5x20 mm

230 V~, 50 Hz

10 A quick

F1 T1,6 A

230 V~, 50 Hz

10 A quick

F1 T1,6 A

230 V~, 50 Hz

10 A quick

F1 T1,6 A

Heat exchanger motor

8 W, 0.035 A 8 W, 0.035 A 8 W, 0.035 A

INCREASED OPERATING SOUND LEVEL

Reason Action

Filters blocked. Change the lters.

Outer grilles are blocked. Clean the outer grille .

Fan bearings faulty. Change bearings / contact service.

Fan wings dirty. Clean the fans.

Problem with gear/motor of the heat exchanger. Contact a service representative.

Page 18

18

TECHNICAL INFORMATION

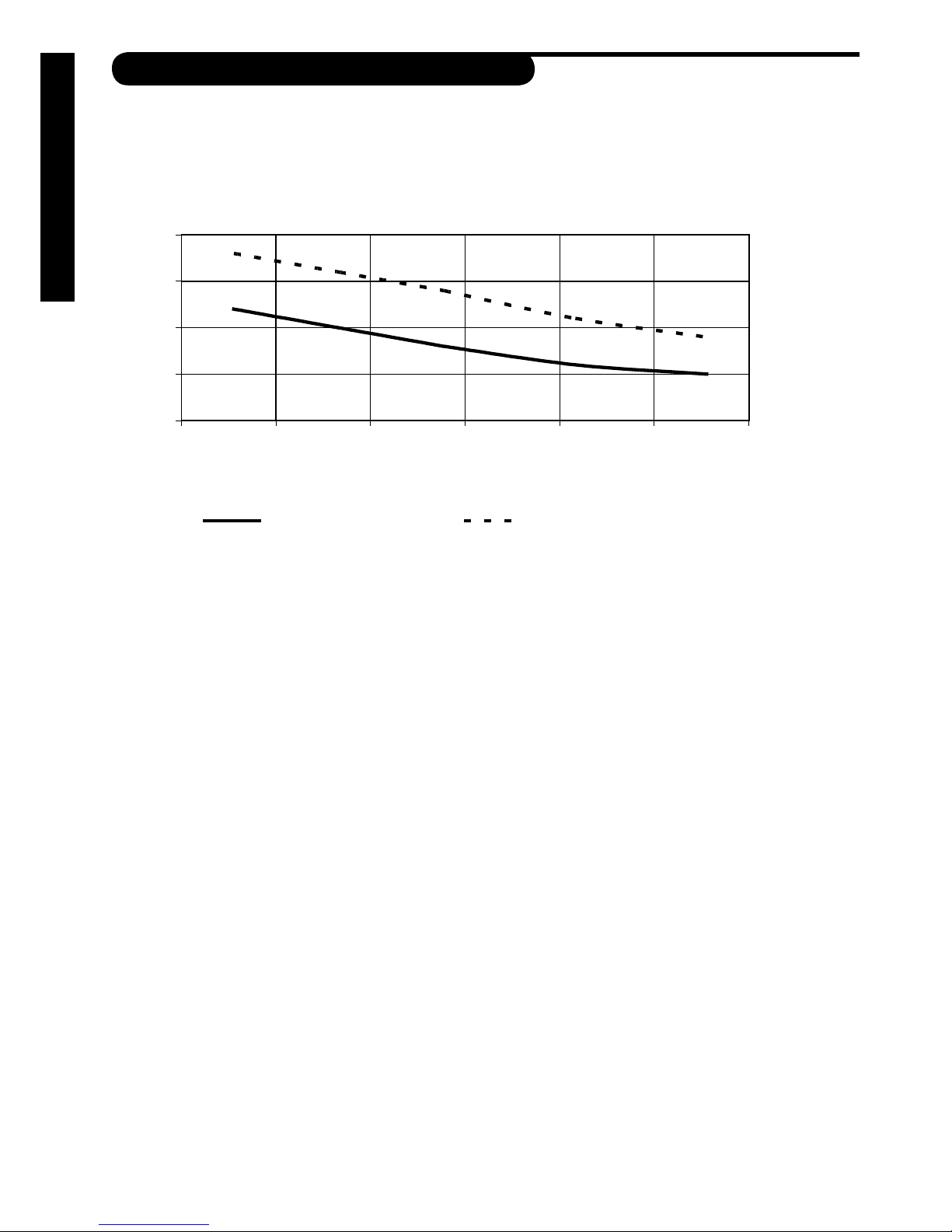

HEAT RECOVERY EFFICIENCY

ENERVENT® PICCOLO

HEAT RECOVERY TEMPERATURE EFFICIENCY

70

75

80

85

90

0 10 20 30 40 50 60

Air flow l/s

η

%

Supply/extract ratio 1.0 Supply/extract ratio 0.85

88%

82%

75%

79%

Page 19

19

Enervent® Piccolo EN 2011_1

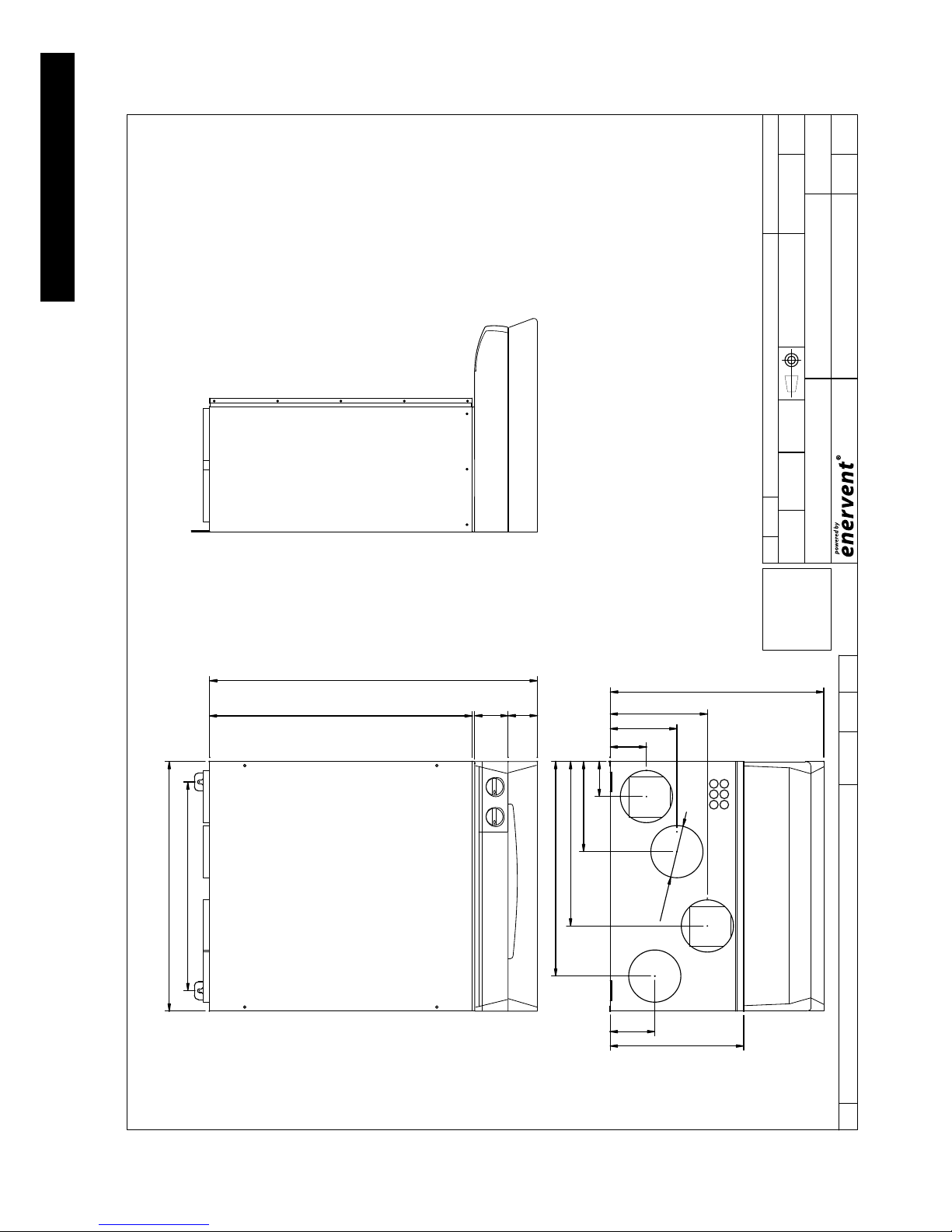

TECHNICAL INFORMATION

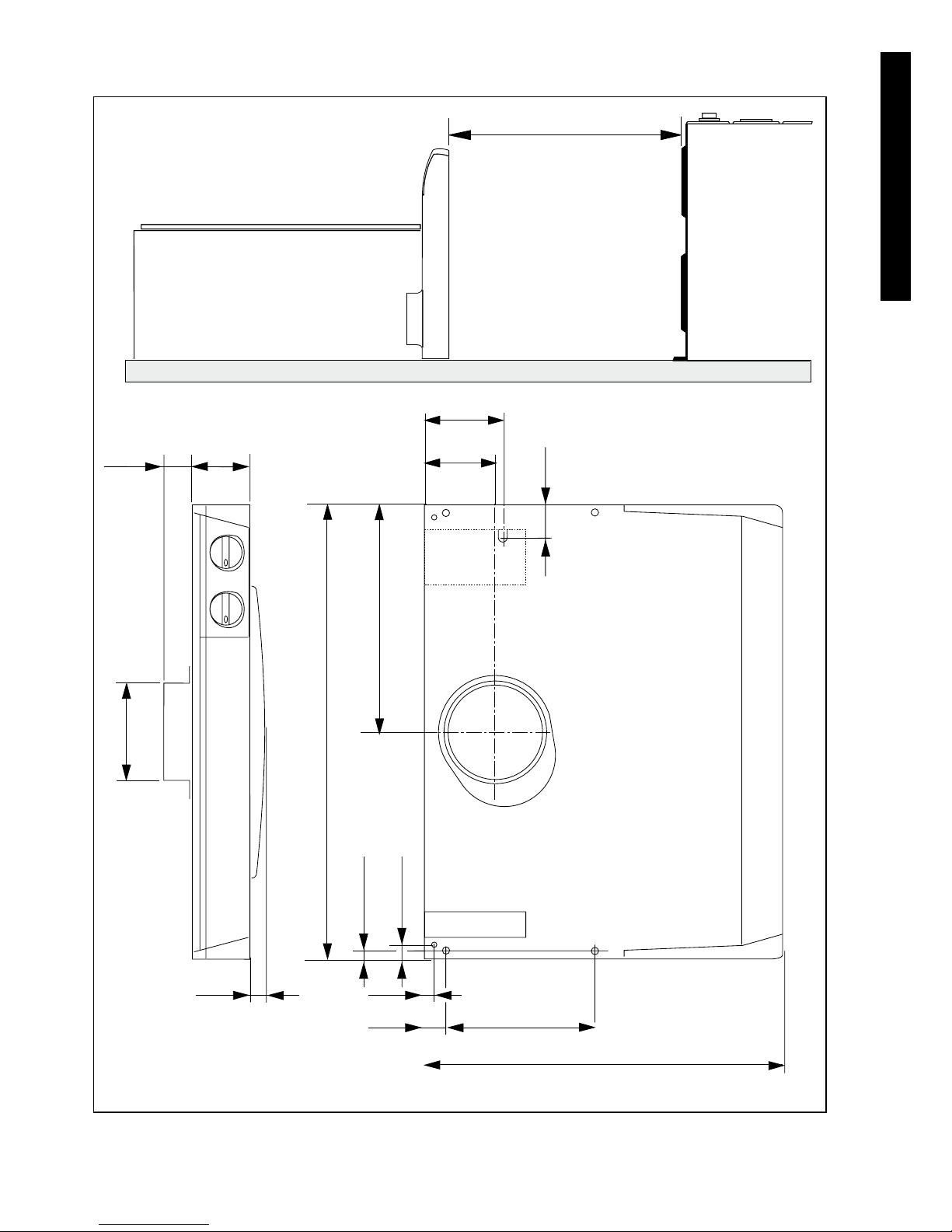

DIMENSION DRAWINGS

DIMENSION DRAWING

PICCOLO ON RIGHT

ISO 2768-MK

YLEISTOLERANSSIT

Hitsatut rakenteet:

EN ISO 13920-AE

Koneistetut osat:

Lehti

Suhde

Valmiste

Pvm

Paino kg

MuutosPiir no

Nimitys

FileHyvPiirt Tark

Osan nimitysKplOsa

HyvMuuttPvmMuutosNo

C:

E 1

71:17/08/2006J.T

785

80

630

598

500

514

320

87

394

84

160

216

233

Ø 125

107

511

EXHAUST AIR

OUTSIDE AIR

SUPPLY AIR

EXTRACT AIR

70

MH-007

E-mail: enervent@enervent.

Tel. 358-(0)207-528800

Fax. 358-(0)207-528844

Kipinätie1, 06150 Porvoo

SERVICE HATCH

Page 20

20

TECHNICAL INFORMATION

J.T 17/08/2006 1: 7

MH-008 1D

C:

No Muutos Pvm Muutt Hyv

Osa Kpl Osan nimitys

TarkPiirt Hyv File

Nimitys

Piir no Muutos

Paino kg

Pvm

Valmiste

Suhde

Lehti

EXHAUST AIR

OUTSIDE AIR

SUPPLY AIR

EXTRACT AIR

Koneistetut osat:

EN ISO 13920-AE

Hitsatut rakenteet:

YLEISTOLERANSSIT

ISO 2768-MK

PICCOLO ON LEFT

DIMENSION DRAWING

514

320

87

394

84

160

216

233

Ø 125

598

630

107

500

785

80

511

70

E-mail: enervent@enervent.

Tel. 358-(0)207-528800

Fax. 358-(0)207-528844

Kipinätie1, 06150 Porvoo

SERVICE HATCH

Page 21

21

Enervent® Piccolo EN 2011_1

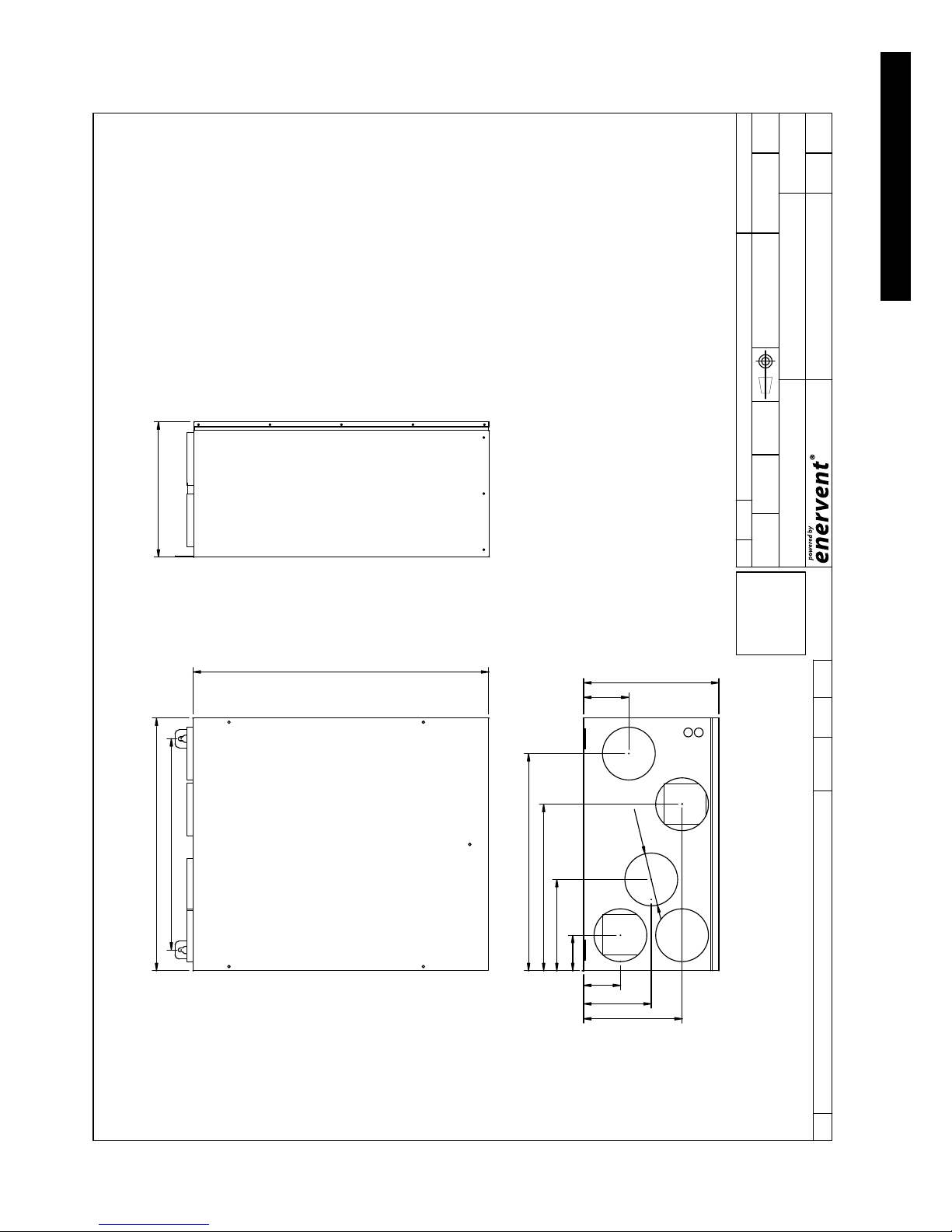

TECHNICAL INFORMATION

OUTSIDE AIR

EXTRACT AIR

SUPPLY AIR

EXHAUST AIR

500

700

598

320

J.T 17/11/2008 1: 7

MH-011 1A

U:\VAKIOT

M)\PICCOLO

Paino kg

HyvMuuttPvmMuutosNo

LehtiMuutosPiir no

Nimitys

SuhdePvmFileHyvTarkPiirt

ValmisteOsan nimitysKplOsa

EN ISO 13920-AE

YLEISTOLERANSSIT

Hitsatut rakenteet:

Koneistetut osat:

ISO 2768-MK

PICCOLO OFF RIGHT

DIMENSION DRAWING

514

320

87

394

84

160

216

233

Ø 125

107

COOKER HOOD

SERVICE HATCH

E-mail: enervent@enervent.

Tel. 358-(0)207-528800

Fax. 358-(0)207-528844

Kipinätie1, 06150 Porvoo

Page 22

22

TECHNICAL INFORMATION

J.T 17/11/2006 1: 7

MH-012 1A

Paino kg

HyvMuuttPvmMuutosNo

LehtiMuutosPiir no

Nimitys

SuhdePvmFileHyvTarkPiirt

ValmisteOsan nimitysKplOsa

OUTSIDE AIR

EN ISO 13920-AE

YLEISTOLERANSSIT

Hitsatut rakenteet:

Koneistetut osat:

ISO 2768-MK

PICCOLO OFF LEFT

DIMENSION DRAWING

514

320

87

394

84

160

216

233

320

Ø 125

EXTRACT AIR

SUPPLY AIR

EXHAUST AIR

COOKER HOOD

598

700

107

500

SERVICE HATCH

U:\VAKIOT

M)\PICCOLO

E-mail: enervent@enervent.

Tel. 358-(0)207-528800

Fax. 358-(0)207-528844

Kipinätie1, 06150 Porvoo

Page 23

23

Enervent® Piccolo EN 2011_1

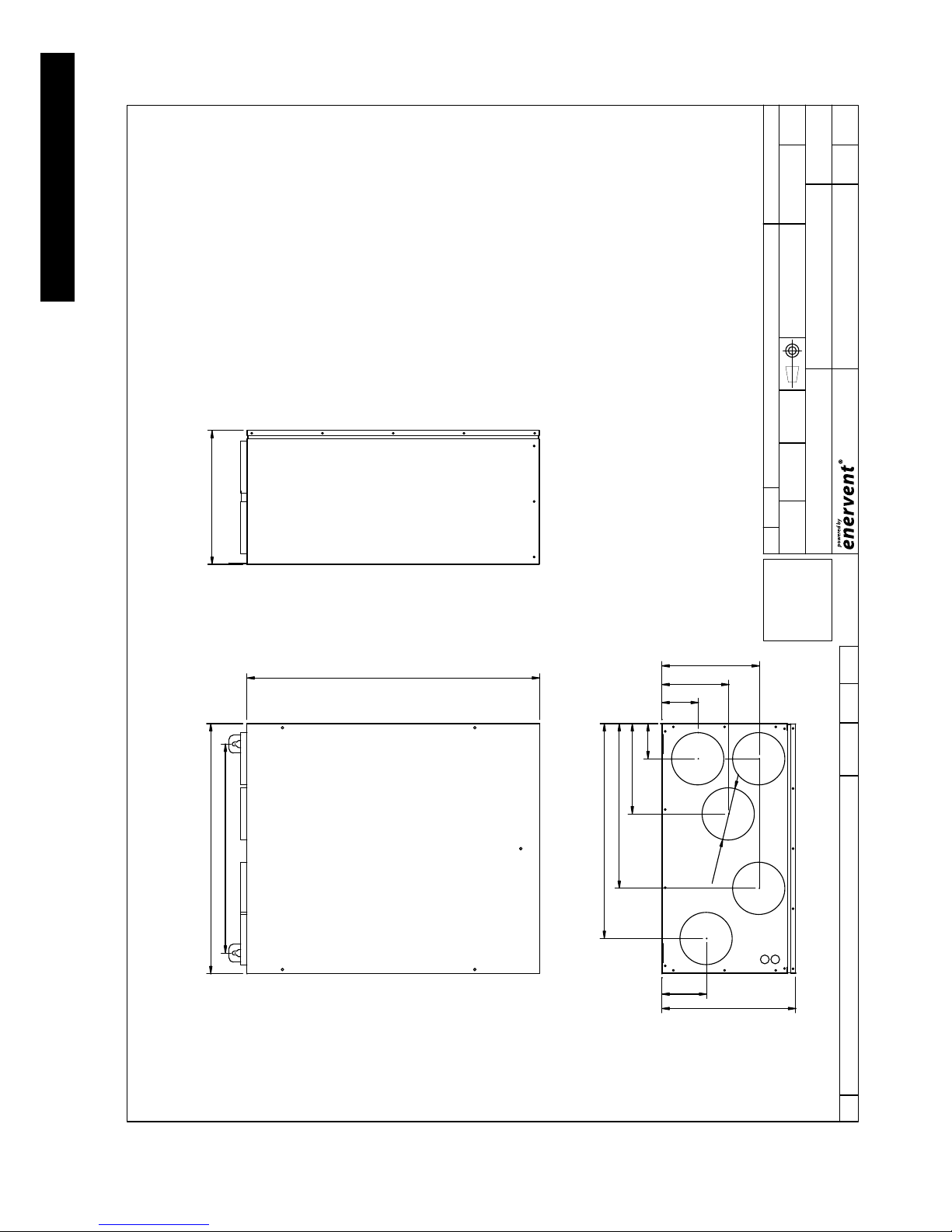

TECHNICAL INFORMATION

OUTSIDE AIR

EXTRACT AIR

SUPPLY AIR

EXHAUST AIR

COOKER

HOOD

96

299

Ø 125

350

630

598

350

J.T 02/10/2008 1: 7

1A

C:

Paino kg

HyvMuuttPvmMuutosNo

LehtiMuutosPiir no

Nimitys

SuhdePvmFileHyvTarkPiir t

ValmisteOsan nimitysKplOsa

EN ISO 13920-AE

YLEISTOLERANSSIT

Hitsatut rakenteet:

Koneistetut osat:

ISO 2768-MK

LIGGOLO RIGHT

DIMENSION DRAWING

514

350

87

394

84

160

216

233

Ø 125

107

SERVICE HATCH

500

690

E-mail: enervent@enervent.fi

Tel. 358-(0)207-528800

Fax. 358-(0)207-528844

Kipinätie1, 06150 Porvoo

KATTOMALLI 002

CONDENSE WATER DRAIN

CONDENSE WATER DRAIN

CONDENSE WATER DRAIN

Page 24

24

TECHNICAL INFORMATION

J.T 01/10/2008 1: 7

1A

C:

Paino kg

HyvMuuttPvm

MuutosNo

LehtiMuutosPiir no

Nimitys

SuhdePvmFileHyvTarkPiirt

ValmisteOsan nimitysKplOsa

OUTSIDE AIR

EN ISO 13920-AE

YLEISTOLERANSSIT

Hitsatut rakenteet:

Koneistetut osat:

ISO 2768-MK

LIGGOLO LEFT

DIMENSION DRAWING

514

350

87

394

84

160

216

233

350

Ø 125

EXTRACT AIR

SUPPLY AIR

EXHAUST AIR

598

630

350

107

COOKER HOOD

Ø 125

299

96

SERVICE HATCH

500

E-mail: enervent@enervent.fi

Tel. 358-(0)207-528800

Fax. 358-(0)207-528844

Kipinätie1, 06150 Porvoo

690

CONDENSE WATER DRAIN

CONDENSE WATER DRAIN

KATTOMALLI 001

Page 25

25

Enervent® Piccolo EN 2011_1

TECHNICAL INFORMATION

Ø 125

22

40

80

598

300

9,5

16

13

50

190

480

38

98

104

400/650

Page 26

26

TECHNICAL INFORMATION

CHARACTERISTIC CURVES

Piccolo/Liggolo ec o E CE fan power input with

F7 cassette filter in supply air and F5 bag filter in extract air

0

10

20

30

40

50

60

70

80

90

100

0 1 0 2 0 30 4 0 50 6 0 70 8 0 90

Air amount l/s

Power input W

90%

50%

100%

80%

70%

60%

40%

30%

20%

EXTRACT AIR

SUPPLY AIR

0

50

100

150

200

250

300

0 1 0 20 3 0 40 50 6 0 70 80 9 0

Air amount l/s

Available pressure P a

SUPPLY AIR

EXTRACT AIR

80 %

60 %

50 %

40 %

30 %

20 %

90 %

10 0%

70 %

Piccolo/Liggolo eco ECE supply and extract air characteristic curves with F7/F5 filter

Page 27

27

Enervent® Piccolo EN 2011_1

TECHNICAL INFORMATION

SOUND DATA

PICCOLO SOUND LEVEL IN OUTSIDE AIR DUCT

• Supply air filter F7, 281x436x29 mm (+ 3 mm)

• Extract air filter F5, 275x121-175/5

• Supply and exhaust air fan; Ebm Papst G3G146-ED23-06

Sound level in outside air duct. Heat exchanger rotating.

U(%) 2 0 % 3 0 % 4 0 % 5 0 % 6 0 % 7 0 % 8 0 % 90% 10 0 %

qv (l/s) 4 9 17 28 3 8 4 8 55 67 74

L

W6 3

, dB

L

W1 25

, dB

L

W2 50

, dB

L

W5 00

, dB

L

W1 00 0

, dB

L

W2 00 0

, dB

L

W4 00 0

, dB

L

W8 00 0

, dB

18

17

20

26

13

10

12

17

25

22

22

29

14

10

12

17

33

31

26

32

21

10

12

17

39

36

32

36

25

15

13

17

44

42

37

40

29

20

16

18

48

47

42

44

33

25

20

18

49

50

46

47

36

29

24

18

52

53

49

50

38

34

27

19

52

54

49

51

39

35

29

19

LW, dB

LWA, d B(A)

28

25

32

27

38

30

42

34

47

39

52

43

55

46

57

49

58

49

Character descript ion:

U (%) Fan spe ed settin g, V

q

V

Air fl ow, dm³/s

L

W6 3. ..8 00 0

Uni t octave e ffect ba nd

w 63 ... 80 00

O ctave b and mid f requenc y, Hz

LW Sound e f fect level, dB

LWA A - weighed so u nd effec t level, dB(A)

LpA A-weighed sound pre s sure level ( 10 m2 sound abs o rption) , dB(A)

PICCOLO SOUND LEVEL IN SUPPLY AIR DUCT

• Supply air filter F7, 281x436x29 mm (+ 3 mm)

• Extract air filter F5, 275x121-175/5

• Supply and exhaust air fan; Ebm Papst G3G146-ED23-06

Sound level in supply air duct. Heat exchanger rotating.

U(%) 2 0 % 3 0 % 4 0 % 5 0 % 6 0 % 7 0 % 8 0 % 90% 10 0 %

qv (l/s) 4 9 17 28 3 8 4 8 55 67 74

L

W6 3

, dB

L

W1 25

, dB

L

W2 50

, dB

L

W5 00

, dB

L

W1 00 0

, dB

L

W2 00 0

, dB

L

W4 00 0

, dB

L

W8 00 0

, dB

29

30

30

31

20

12

14

17

34

35

36

36

34

27

16

18

39

40

41

44

44

38

29

18

44

47

48

49

50

46

38

22

49

52

52

52

54

52

44

30

54

57

57

56

57

56

49

37

55

60

61

59

60

60

53

43

57

63

63

62

62

62

55

47

59

63

64

63

63

63

57

48

LW, dB

LWA, d B(A)

36

30

42

38

49

47

55

53

60

58

64

62

67

65

70

67

71

68

Page 28

28

TECHNICAL INFORMATION

PICCOLO SOUND LEVEL IN EXTRACT AIR DUCT

• Supply air filter F7, 281x436x29 mm (+ 3 mm)

• Extract air filter F5, 275x121-175/5

• Supply and exhaust air fan; Ebm Papst G3G146-ED23-06

Sound level in extract air duct. Heat exchanger rotating.

U(%) 2 0 % 3 0 % 4 0 % 5 0 % 6 0 % 7 0 % 8 0 % 90% 10 0 %

qv (l/s) 4 9 17 28 3 8 4 8 55 67 74

L

W6 3

, dB

L

W1 25

, dB

L

W2 50

, dB

L

W5 00

, dB

L

W1 00 0

, dB

L

W2 00 0

, dB

L

W4 00 0

, dB

L

W8 00 0

, dB

13

14

13

13

14

14

16

19

18

19

15

16

15

12

14

18

32

33

32

31

31

19

13

18

37

38

37

36

35

15

16

18

40

41

40

40

40

30

21

18

43

44

43

43

42

34

25

18

45

47

47

47

45

38

28

23

46

48

50

49

47

41

31

26

47

49

51

50

48

41

32

27

LW, dB

LWA, d B(A)

24

22

25

22

39

34

44

38

47

43

50

45

53

49

55

51

56

52

Character descript ion:

U (%) Fan spe ed settin g, V

q

V

Air fl ow, dm³/s

L

W6 3. ..8 00 0

Uni t octave e ffect ba nd

w 63 ... 80 00

O ctave b and mid f requenc y, Hz

LW Sound e f fect level, dB

LWA A - weighed so u nd effec t level, dB(A)

LpA A-weighed sound pre s sure level ( 10 m2 sound abs o rption) , dB(A)

PICCOLO SOUND LEVEL IN EXHAUST AIR DUCT

• Supply air filter F7, 281x436x29 mm (+ 3 mm)

• Extract air filter F5, 275x121-175/5

• Supply and exhaust air fan; Ebm Papst G3G146-ED23-06

Sound level in exhaust air duct. Heat exchanger rotating.

U(%) 2 0 % 3 0 % 4 0 % 5 0 % 6 0 % 7 0 % 8 0 % 90% 10 0 %

qv (l/s) 4 9 17 28 3 8 4 8 55 67 74

L

W6 3

, dB

L

W1 25

, dB

L

W2 50

, dB

L

W5 00

, dB

L

W1 00 0

, dB

L

W2 00 0

, dB

L

W4 00 0

, dB

L

W8 00 0

, dB

29

30

30

31

20

12

14

17

34

35

34

36

35

27

14

18

39

40

41

44

44

38

29

18

47

45

46

48

51

45

36

19

50

50

51

52

55

52

43

26

52

54

54

56

58

57

47

33

55

56

57

59

60

60

51

39

58

58

59

61

62

63

54

43

59

59

60

62

63

64

55

44

LW, dB

LWA, d B(A)

36

30

42

38

49

47

55

53

60

58

64

62

66

65

69

67

70

68

Page 29

29

Enervent® Piccolo EN 2011_1

TECHNICAL INFORMATION

Character descript ion:

U (%) Fan spe ed settin g, V

qV Air fl ow, dm³/s

L

W6 3. ..8 00 0

Uni t octave e ffect ba nd

w 63 ... 80 00

O ctave b and mid f requenc y, Hz

LW Sound e f fect level, dB

LWA A - weighed so u nd effec t level, dB(A)

LpA A-weighed sound pre s sure level ( 10 m2 sound abs o rption) , dB(A)

PICCOLO SOUND LEVEL IN SURROUNDING

• Supply air filter F7, 281x436x29 mm (+ 3 mm)

• Extract air filter F5, 275x121-175/5

• Supply and exhaust air fan; Ebm Papst G3G146-ED23-06

Sound level through casing, with cooker hood attached (damper shut). Heat exchanger is rotating.

U(%) 2 0 % 3 0 % 4 0 % 5 0 % 6 0 % 7 0 % 8 0 % 90% 10 0 %

qv (l/s)

Suppl y air

Extract air

10

11

17

19

25

28

33

36

42

46

47

50

51

56

60

65

64

68

L

W6 3

, dB

L

W1 25

, dB

L

W2 50

, dB

L

W5 00

, dB

L

W1 00 0

, dB

L

W2 00 0

, dB

L

W4 00 0

, dB

L

W8 00 0

, dB

31

33

24

22

16

10

13

17

37

40

30

27

21

17

15

18

42

46

36

32

26

18

15

14

46

52

41

35

30

21

13

14

51

56

44

39

33

26

17

17

52

57

46

40

34

28

18

18

53

60

49

42

35

29

20

18

55

62

52

44

38

32

23

20

57

61

53

45

38

32

24

21

LW, dB

LWA, d B(A)

LpA, dB(A)

36

24

20

43

30

26

48

35

31

53

39

35

58

43

39

59

44

40

61

47

43

63

49

45

63

49

45

Page 30

30

TECHNICAL INFORMATION

CONTROL CHARTS

FI01

FI03

LHRW

M1

TE01

INTERNAL FEED AND CONTROL SWITCHES

RK (SU)

WALL PLUG

230VAC 10 A

SILENCER

SILENCER

Q1 = SPEED

Q1

COOKER HOOD

EHC45

TS2

DIP SWITCH

MuutosNo MuuttPvm Hyv

Piirt

Osa

Osan nimitys

Tark

Kpl

Hyv

Piir no

Nimitys

File

Paino kg

Muutos

Pvm

Valmiste

Lehti

Suhde

MW

PICCOLO ECO ECE

CONTROL CHART

A

08.10.2009

Piccolo ECO ECE

SC

10

SC

30

EF

10

SF

M

30

M

ESES

+

45

TZA+

45

TZ+

ESES

Tel. 358-(0)207-528800

Kipinätie1, 06150 Porvoo

Fax. 358-(0)207-528844

E-mail: enervent@enervent.

MEASURING

ADJUSTMENT

CONTROL

STATUS

ALARM

MEASURING

ADJUSTMENT

CONTROL

STATUS

ALARM

= CABELING AND CONNECTION AT SITE (EE)

= PHYSICAL CONNECTION

= PROGRAM FUNCTION

Page 31

31

Enervent® Piccolo EN 2011_1

TECHNICAL INFORMATION

MW

PICCOLO/LIGGOLO ECO ECE

17.02.2010

M

NL

L N

NL

SF

EF

C1

T2 T1

RJ11

LTO TEMP

10-20 C

T3

AFT

HEAT

LTO

F1

S2

STOP

LTOC

COM

S1

S4

S3

OVERP

ALARM

RJ11

NC

COM

NO

L N

PFTF

CTRL CTRL

S2

FAN SPEED CTRL

S1

TF DIFF

S3

S4

-20-0 %

80-100 %

40-60 %60-80 % 20-40 %

230 VAC, 50 Hz

24 VAC

2 1 PE PE12 PE21

NNN

L

NNL

LLL

SW

L

L

IN

SW

N

N IN

PE

OUTSIDE AIR

SENSOR

CONNECTION FOR SPEED

SEE PAGE 2

CONNECTION FOR ELECTRICAL HEATER SEE PAGE 2

SUPPLY 10 A, 230 VAC

WALLPLUG SUPPLY

FOR EXTERNAL CONTROL

CONNECTIONS

POTENTIALFREE CONTACT

(MAX 35V)

SWITCH

ALARM

FREEZEALARM)

OVERPRESSURE

EXTERNAL

(FIREDANGER,

AH-E-STOP

COOLING

RECOVERY

FAULT OUTPUT

(MAX 250VAC/1A)

MOTOR

EXHAUSTFAN

MOTOR

SUPPLYFAN

MOTOR

HRW

-

+

+

1212

SF

0-10V

EF

0-10V

CONTROLCONTROL

Piccolo ECO ECE

DCC-06/ DCC-06E

ELECTRICAL CONNECTIONS

Osa Kpl Osan nimitys Valmiste

Piirt Tark Hy v File Pvm

Nimitys

Piir no

Hyv

Tel. 358-(0)207-528800

Kipinätie1, 06150 Porvoo

Fax. 358-(0)207-528844

E-mail: enervent@enervent.

WIRING DIAGRAMS

Page 32

32

TECHNICAL INFORMATION

MW 2

NL

L N

AFT

HEAT

LTO

S2

STOP

LTOC

COM

S1

S4

S3

OVERP

ALARM

NC

COM

NO

NNN

L

NNL

LLL

SW

L

L

IN

SW

N

N IN

PE

PICCOLO (ECO) ECE

17.02.2010

230 VAC, 50 Hz

24 VAC

ELECTRICAL HEATER

18°C

OVERHEATING-

PROTECTION

THERMOSTAT

IN SUPPLYAIR

MANUAL

AUTOMATIC

OVERHEATING-

PROTECTION

CONNECTOR

1 2 3

654

7 8 9

121110

YeGr

8 321 6

8 6

5123

5

47

NOT CONNECTED

Piccolo ECO ECE

ECC-05/ECC-05E or DCC-05/DCC-05E

ELECTRICAL CONNECTIONS

RANGE HOOD 251-12

Osa Kpl Osan nimitys Valmiste

Piirt Tark Hyv File Pvm Sivu

Nimitys

Piir no Muutos Lehti

Hyv

Paino kg

Tel. 358-(0)207-528800

Kipinätie1, 06150 Porvoo

Fax. 358-(0)207-528844

E-mail: enervent@enervent.

T

TZA+

2

C

T

TZ+

1

C

T

TS2

1

C

800 W

Page 33

33

Enervent® Piccolo EN 2011_1

TECHNICAL INFORMATION

MW 2

NL

L N

AFT

HEAT

LTO

S2

STOP

LTOC

COM

S1

S4

S3

OVERP

ALARM

NC

COM

NO

NNN

L

NNL

LLL

SW

L

L

IN

SW

N

N IN

PE

PICCOLO/LIGGOLO (ECO) ECE

15.11.2010

230 VAC, 50 Hz

24 VAC

ELECTRICAL HEATER

18°C

OVERHEATING-

PROTECTION

THERMOSTAT

IN SUPPLYAIR

MANUAL

AUTOMATIC

OVERHEATING-

PROTECTION

YeGr

2 631 5

86

5123

8

CONNECTOR

1 2 3

654

7 8 9

121110

YeGr

8 321 6 5

4

7

YeGr

2 631 5 8

YeGr

2 631 5 8

AP9

AP9

Connection at site

( Ex. MMO 7x1.5 S )

Piccolo ECO ECE

RANGE HOOD 250-10

ECC-05/ECC-05E or DCC-05/DCC-05E

ELECTRICAL CONNECTIONS

Osa Kpl Osan nimitys Valmiste

Piirt Tark Hy v File Pvm Sivu

Nimitys

Piir no Muutos Lehti

Hyv

Paino kg

Tel. 358-(0)207-528800

Kipinätie1, 06150 Porvoo

Fax. 358-(0)207-528844

E-mail: enervent@enervent.

T

TZA+

2

C

T

TZ+

1

C

T

TS2

1

C

81 2

6

3 5PE

81 2

6

3 5PE

800 W

Page 34

34

DECLARATION OF CONFORMITY

We declare that our products follows the provisions of low voltage directive (LVD) 2006/95/EY, EMC-directive 2004/108/

EY and machine directive (MD) 98/37/EY.

Manufacturer: Enervent Oy

Manufacturer´s contact: Kipinätie 1, 06150 PORVOO, FINLAND

tel +358 (0)207 528 800, fax +358 (0)207 528 844

enervent@enervent., www.enervent.

Description of the product: Ventilation unit with heat recovery

Trade name of the product: Enervent Piccolo eco ECE

Enervent Liggolo eco ECE

Representatives for the products in the region of EU:

Sweden: Ventener Ab, Örelidsvägen 10, 517 71 OLSFORS, SVERIGE, tel +46 735-62 00 62

Climatprodukter AB, Box 366, 184 24 ÅKERSBERGA, SVERIGE, tel +46 8 540 87515

DeliVent Ab, Markvägen 6, 43091 HÖNÖ, SVERIGE, tel +46 70 204 0809

Norway: Noram Produkter Ab, Grini Næringspark 4 A, 1361 ØSTERÅS, NORGE, tel +47 33 47 12 45

Estonia: As Comfort Ae, Jaama 1, 72712 PAIDE, EESTI, tel +372 38 49 430

Irland: Entropic Ltd., Unit 3, Block F, Maynooth Business Campus, Maynooth, Co. Kildare, IRELAND

tel +353 64 349

Germany: e4 energietechnik gmbh, Burgunderweg 2, 79232 MARCH, GERMANY, tel +49 7665 947 25 33

Austria: Inocal Wärmetechnik Gesselschaft m.b.H, Friedhofstrasse 4, 4020 LINZ, AUSTRIA,

tel +43 732 65 03 910

M-Tec Mittermayr GmbH, 4122 ARNREIT, AUSTRIA, tel +43 7282 7009-0

Poland: Iglotech S.J., ul. Toruńska 4, 82-500 KWIDZYN, PUOLA, tel +48 55 279 33 43

The products are in conformity with the following standards:

LVD EN 60 335-1 (2002) +A1 (2004), +A2 (2006), +A11 (2004), +A12 (2006)

MD EN 292-1 (1991), EN 292-2 (1991) +A1 (1995)

EMC EN 55014-1 (2006), EN 61 000-3-2 (2006) and EN 61 000-3-3 (1995).

EN 55014-2 (1997)+A1 (2002).

The conformity of each manufactured product is taken care according our ISO 9001 quality descriptions.

Porvoo 3.1.2010

Enervent Oy

Tom Palmgren

Technology Manager

DECLARATION OF CONFORMITY

Page 35

You can buy lters as well as other equipment for your Enervent ventilation unit from your local Ener-

vent dealer. Please remember to check what model your ventilation unit is before you order equipment.

Picture 1

Picture 2

MAINTENANCE OF THE VENTILATION UNIT AND COOKER HOOD

The ventilation unit does not require any mechanical maintenance, only changing of the lters pe-

riodically and cleaning of the heat exchanger and fans (when needed). Cut the power supply to the

unit before starting any service work (from the main switch or by removing the service hatch of the

LTR-series units). Wait for two (2) minutes before starting the maintenance work! Although the unit’s

power supply is cut when the hatch is opened, the fans still rotate and the electrical coil in ECE-model

is still hot for a while.

Cleaning the heat exchanger

When changing the lters, check if the heat exchanger is dirty. If cleaning is required, remove it from

the unit and carefully wash through the air channels with a hand shower using a mild detergent, taking

care not to get the motor wet. The heat exchanger can also be cleaned by blowing through the air chan-

nels using compressed air. Do not use a pressure washer and do not submerge the heat exchanger into

water!! When restarting the unit after cleaning, check that the heat exchanger wheel can turn freely.

Cleaning the fans

When changing lters, also check the condition of the fans. If cleaning is required the fans can be remo-

ved from the unit and cleaned with a toothbrush or compressed air.

Changing of lters

The recommended time between lters changes for the cassette lter and the bag lter is six (6)

months. If class F5 baglters are used the time between lter changes can be prolonged to one (1) year,

by vacuuming the lters on the inside.

Remove the old lter and put in a new one. Vacuum cleaning the inside of the device is recommended

at this point. N.B! Make sure to close the service harch carefully!

Cleaning the cooker hood

The cooker hood is wipe with a damp cloth and washing liquid. The lter should be cleaned twice a

month if the use is normal. Loosen the lter cartridge by push the lock tags in the front edge. Take the

lter apart and remove the lter cloth by loosening the lter holder, picture 1. Soak the lter cloth and

lter holder in warm water mixed with washing liquid. The lter cartridge (with the cloth) can also be

washed in a dish washer. The cooker hood should be cleaned inside some times per year. Wipe the in-

side with a damp cloth and washing liquid. Put the lter cartridge back in place so that it locks in place.

Changing the luminescent lamp in the cooker hood

The lamp glas is loosened by push the lock tags in the direction shown by the arrow, picture 2. The

luminescent lamp is now accessable for change (luminescent lamp socket G23).

Page 36

QUICK GUIDE TO THE VENTILATION UNIT AND

COOKER

GENERAL INFORMATION ABOUT VENTILATION

The basic function of the ventilation unit is to maintain good indoor air quality. When the ventilation is

planned the engineer calculates how big the air amounts need to be in order to get sucient ventila-

tion. The installer species the normal fan speed for the unit when he installes the unit and calibrates

the air ows at every terminal.

VENTILATION DICTIONARY

Outside air The fresh air ow from the outside to the ventilation unit is called outside air.

Supply air The air ow from the ventilation unit to the rooms is called supply air.

Extract air The air ow from the rooms to the ventilation unit is called exhaust air.

Exhaust air The air ow that blows out from the ventilation unit is called waste air.

Heat exchanger The heat exchanger is a component of the ventilation unit that carries heat energy

from the exhaust air ow to the supply air ow. Enervent ventilation units are

equipped with a rotating heat exchanger. The rotating heat exchanger is a wheel

made of thin metal foil, which stores the heat from the exhaust air and carries it to

the supply air. The heat exchanger prevents the warmth from the rooms from

escaping with the waste air ow.

After heating The after heating heats the supply air before it is blown into the rooms. In ECC-

units the after heating is realized with an electrical heater. All units are not equip

ped with after heating.

ECC ECC is the ventilation unit’s control. ECC is an abbreviation of Electronic Climate

Control.

USING THE VENTILATION UNIT

It is very simple to use the ventilation unit. Most of the time it needs no attention. The most important

functions are:

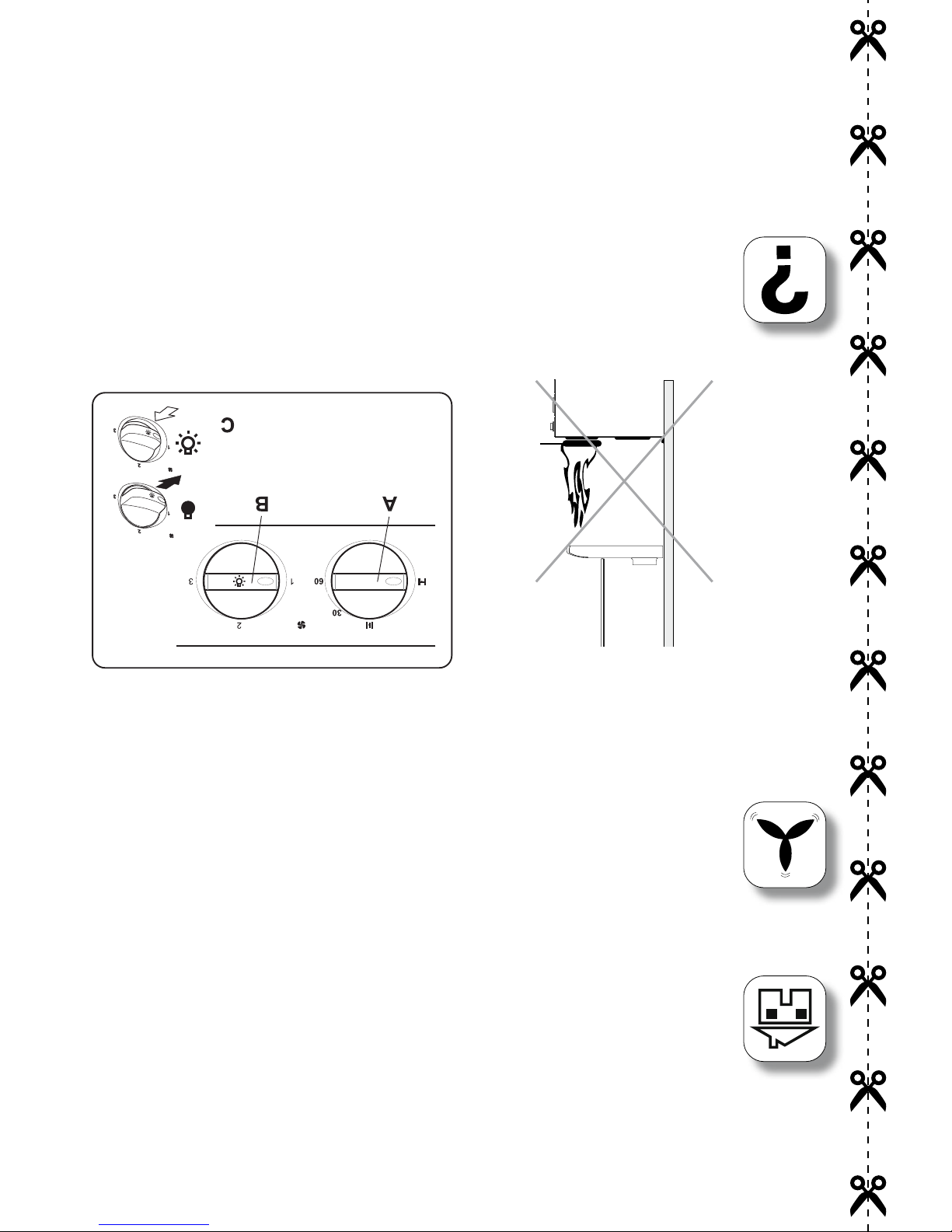

The Piccolo (eco) ECC -unit is controlled with the knobs on the cooker hood front.There is a knob for fan

speeds (B), the damper (A) and the cooker hood light (C).

There are three speeds available; normal speed, which is specied by the installer and on which the

unit runs most of the time; boosting speed which is bigger than the normal speed and is used for

temporary airing and away speed, which is used when nobody is at home.

The damper is opened during cooking (A) and the desired fan speed set (B). The damper shuts auto-

matically after 60 min and the unit resums normal ventilation . Normal ventilation can also be resumed

manually.

NOTE! It is forbidden to ambé under the cooking hood .

Loading...

Loading...