enervent Pegasos HP, Pallas HP, Pelican HP Technical Data And Additional Information To Installation Instructions

Page 1

27.12.2016

Enervent HP

Technical Data and additional

information to Enervent eAir

Installation Instructions

EN

Page 2

2

Page 3

3

Installation manual

EN

Contents

READ ME FIRST ......................................................................................................4

GENERAL ...........................................................................................................4

MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

TECHNICAL DATA ...................................................................................................5

SERVICE RECORD FOR HEAT PUMP UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

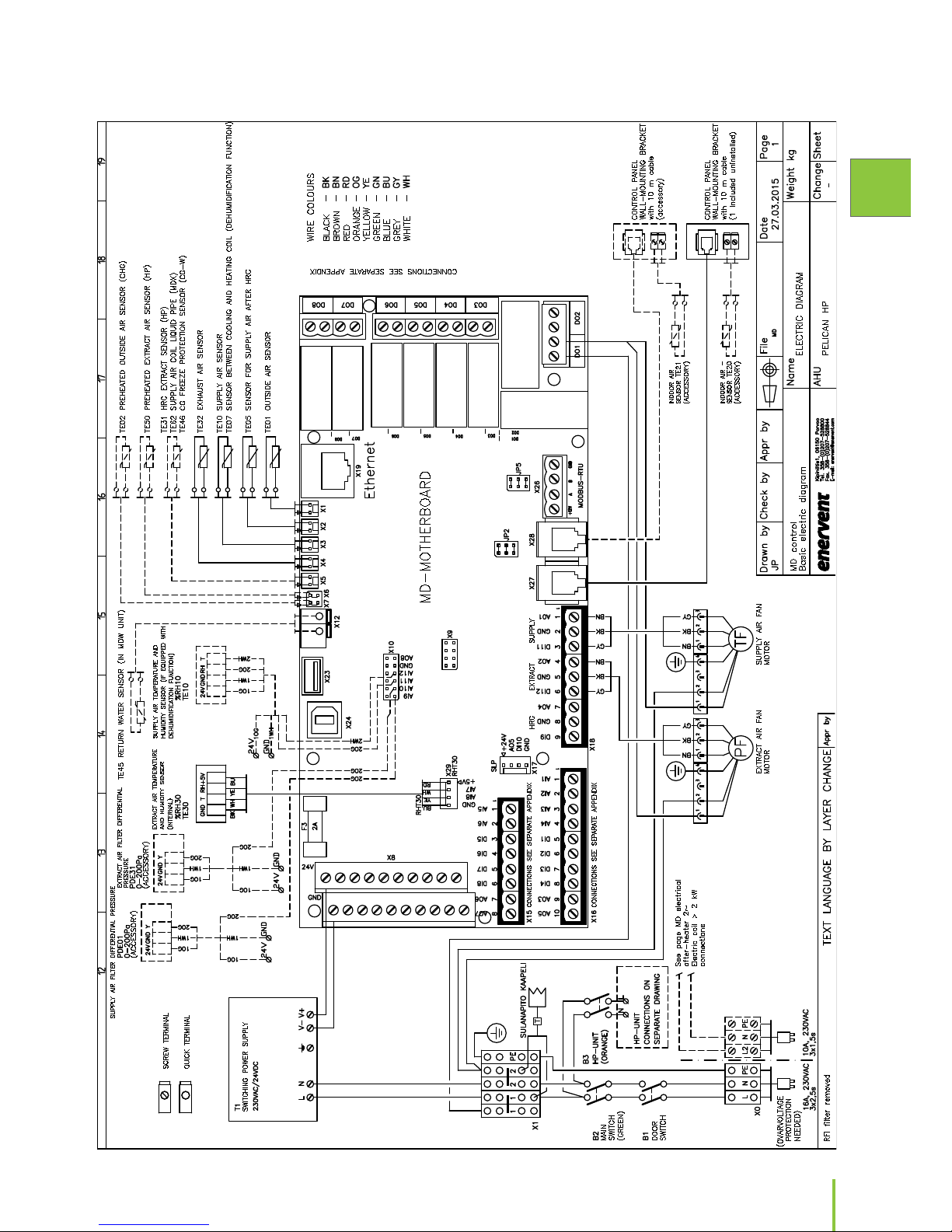

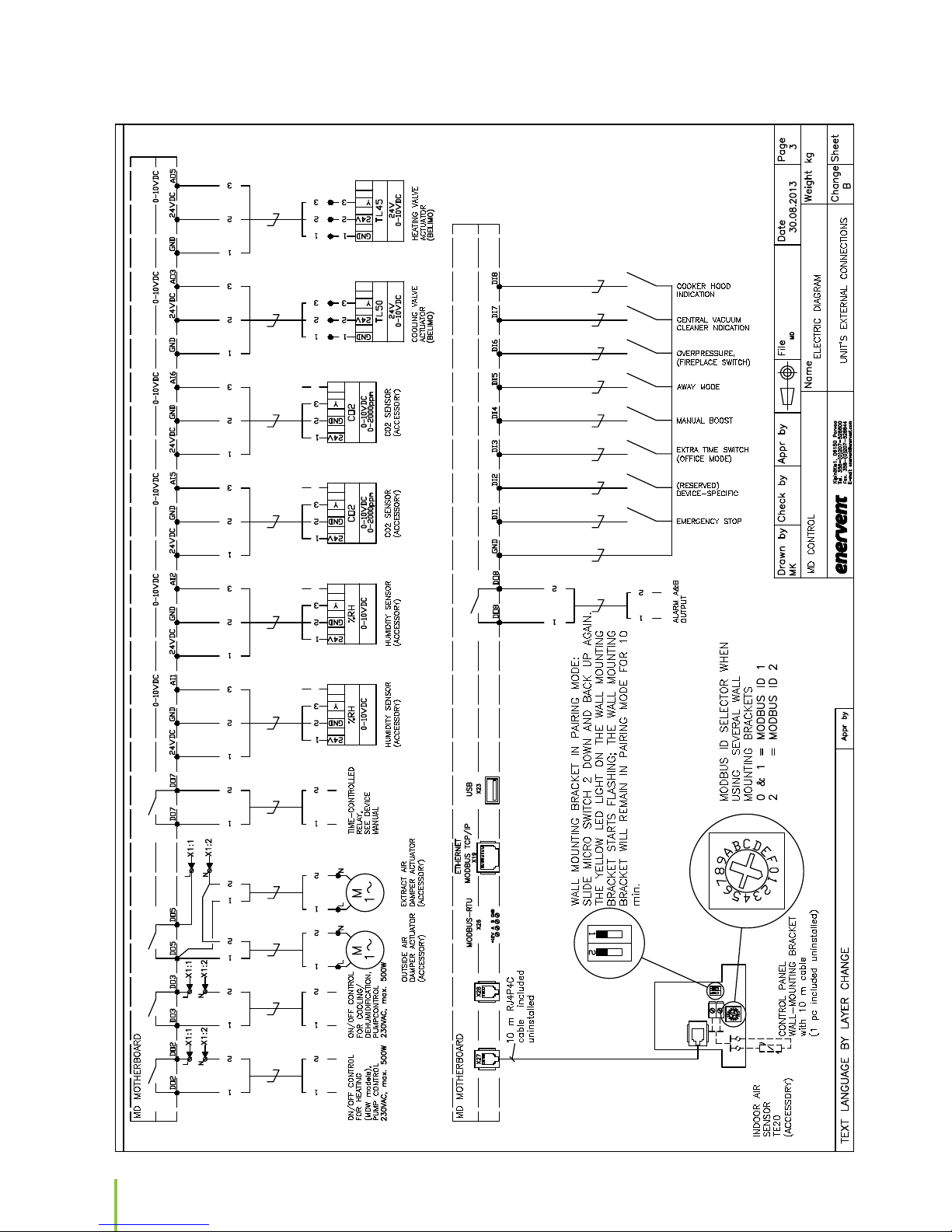

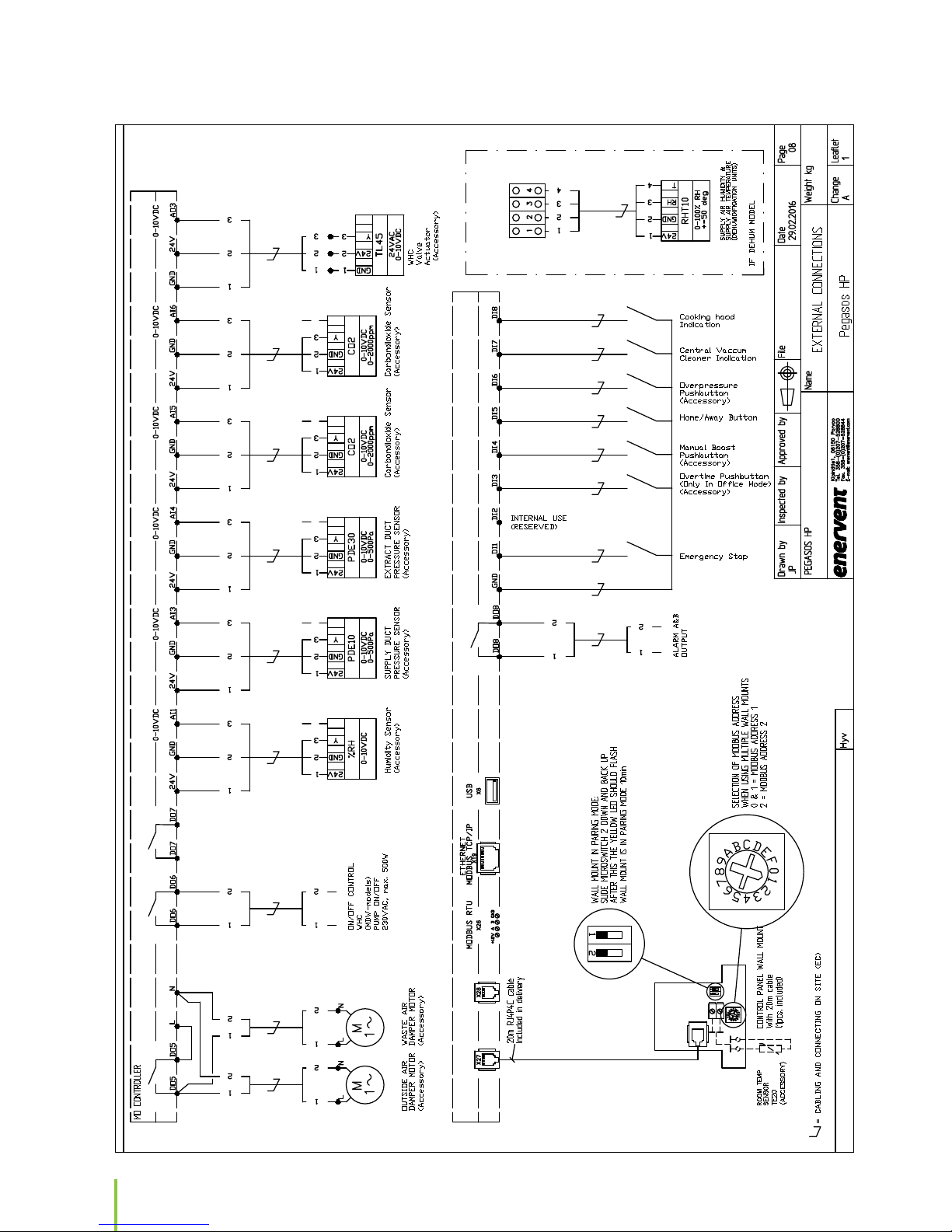

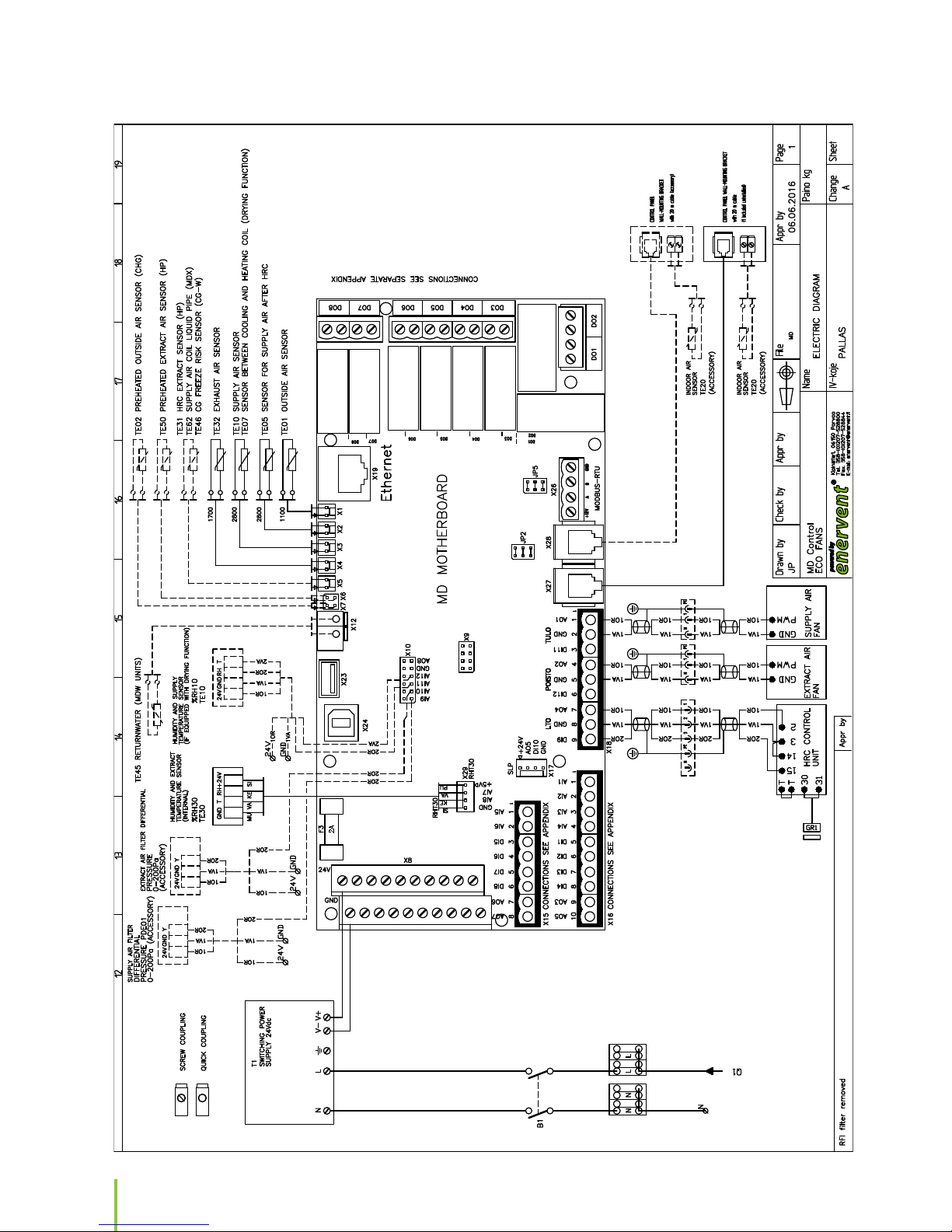

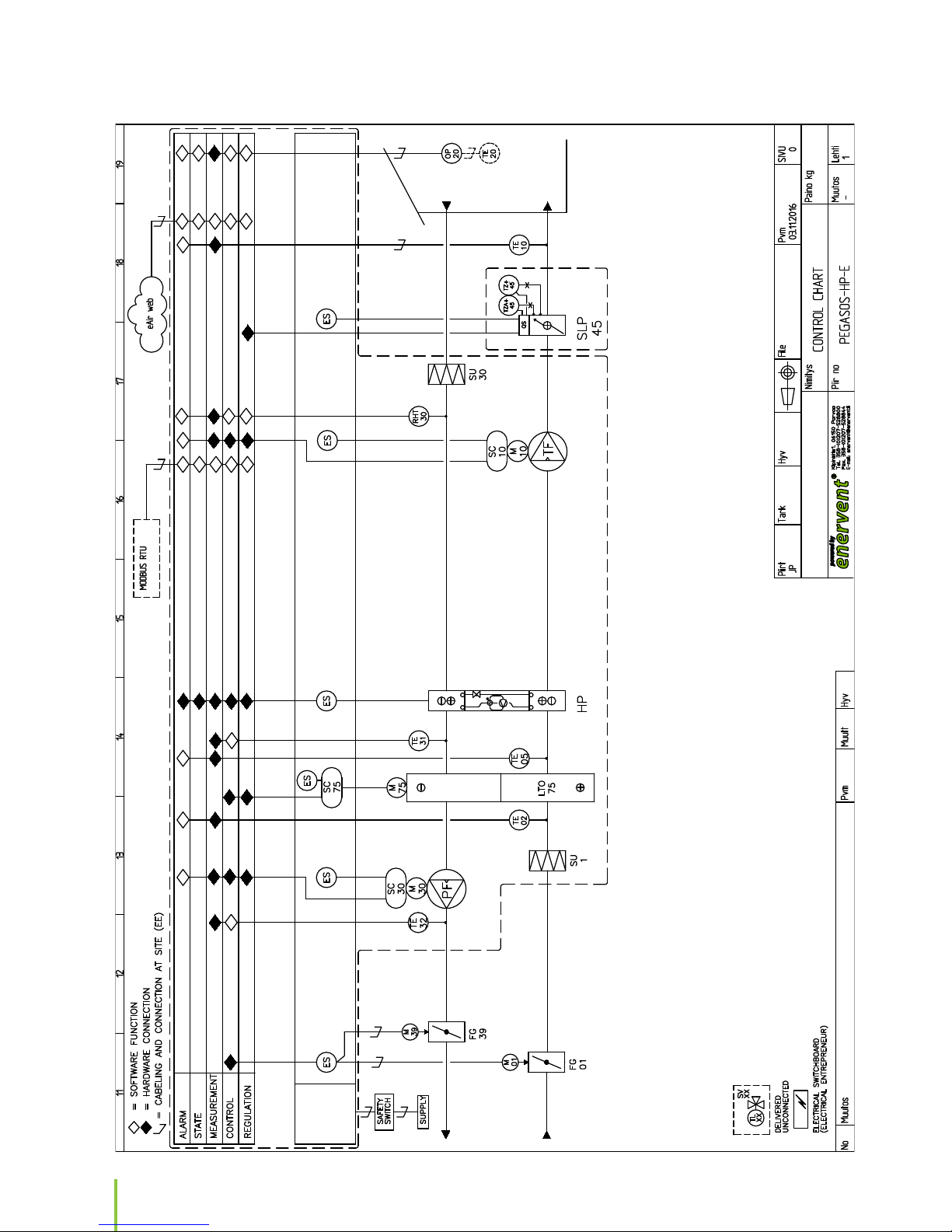

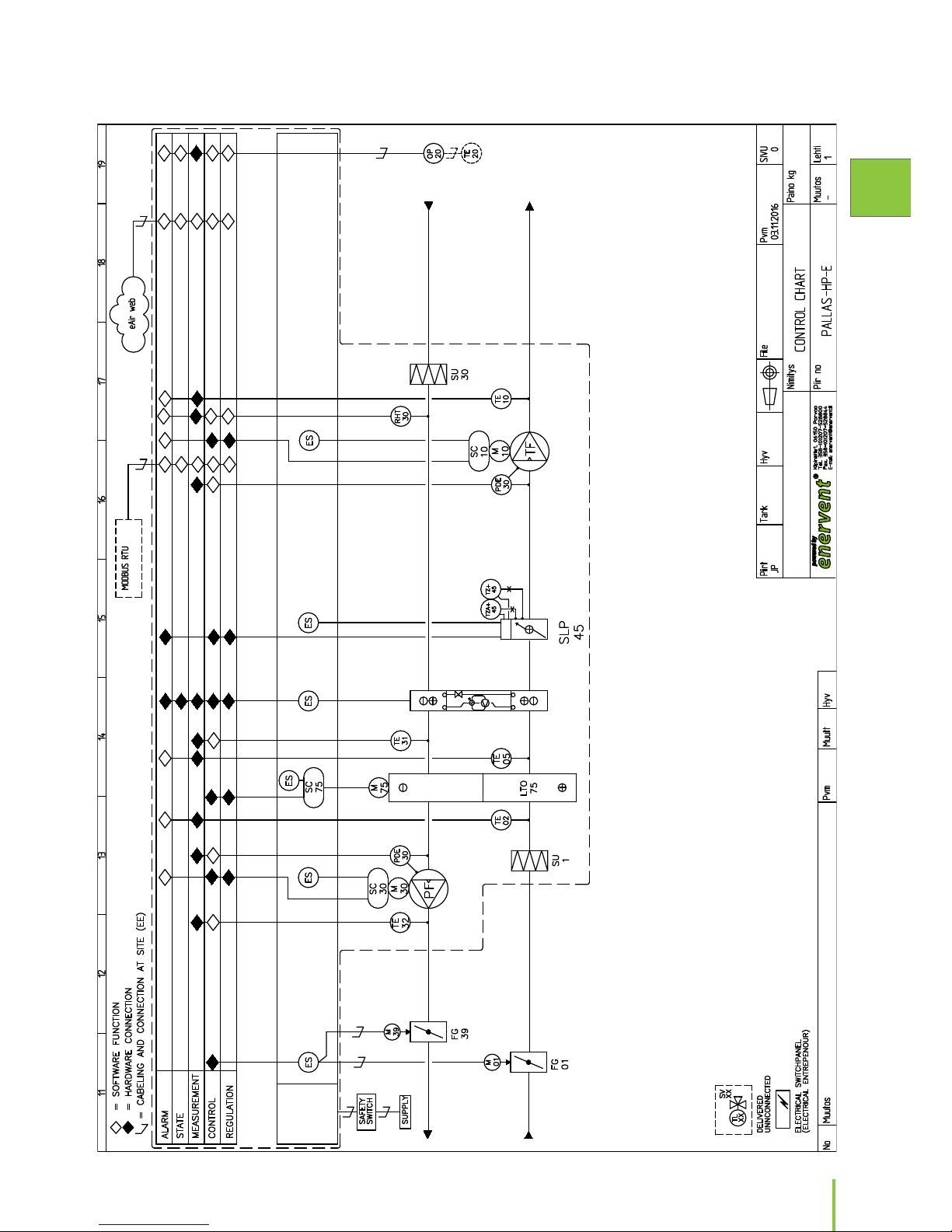

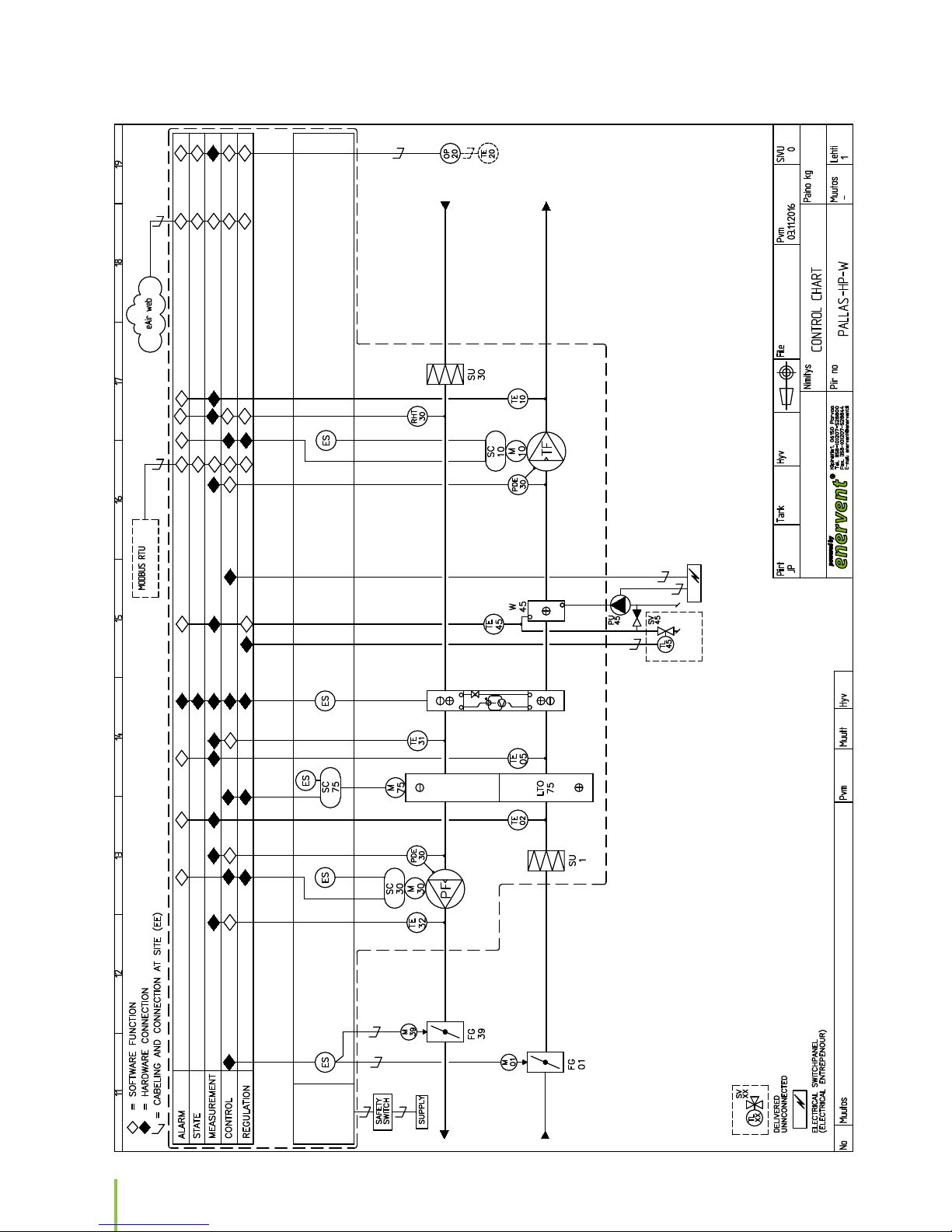

WIRING DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

CONTROL DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Page 4

4

GENERAL

Enervent Pelican HP, Pegasos HP and Pallas HP are

air handling units that consists of (among other

components) a rotating heat recovery wheel and an

extract air heat pump. Units are designed to recover

heat energy from the extract air which is blown out of

the building. Units also cool the supply air depending

the adjustments and circumstances. Units are not

designed to function as a primary heat source of the

building.

NOTE!

NOTE: For the heat pump to work properly the

extract air must be warm enough (extract air to

unit must be at least +20 °C).

Because the integrated extract-air-source heat pump

does not require a separate outdoor unit, it is also

suitable for sites where the installation of outdoor

units is restricted by regulations on façades. The unit

is suitable for both new buildings and renovation

projects.

MAINTENANCE

For maintenance see Enervent eAir Installation

instructions.

NOTE!

NOTE: The heat pump in the ventilation

unit may contain more than 2.39 kg of R410A

HFC refrigerant. The European Union's F-gas

Regulation No 517/2014 states that the

operators of equipment containing more than

2.39 kg of R410A HFC refrigerant are responsible

for maintaining a service record of such

equipment and carry out annual refrigerant

leakage checks by qualied personnel.

NOTE!

NOTE: : Ventilation units equipped with

Emerson© EC3-D73 Digital superheat controller

(concerns Pegasos and Pallas HP units) contains

a VRLA battery= valve regulated rechargeable

lead-acid battery. The battery must NOT be

disposed of with other commercial waste.

Instead, it is the user’s responsibility to pass it

to a designated collection point for the safe

recycling of batteries.

READ ME FIRST

This document is intended for everyone involved

in installation of Enervent ventilation units. The

equipment described in this manual is to be installed

by skilled persons only, according to the instructions

given in this manual, Enervent eAir Installation

Instructions, and local law and regulations. Failure to

comply with instructions in this manual and Enervent

eAir Installation Instructions will void the warranty of

the equipment, and possibly result in harm to people or

property.

The equipment described in this manual is not to be

used by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of

experience and knowledge, unless they have been

given supervision or instruction concerning use of the

equipment by a person responsible for their safety.

NOTE!

NOTE: The Unit must not be tilted more than

45° during transport.

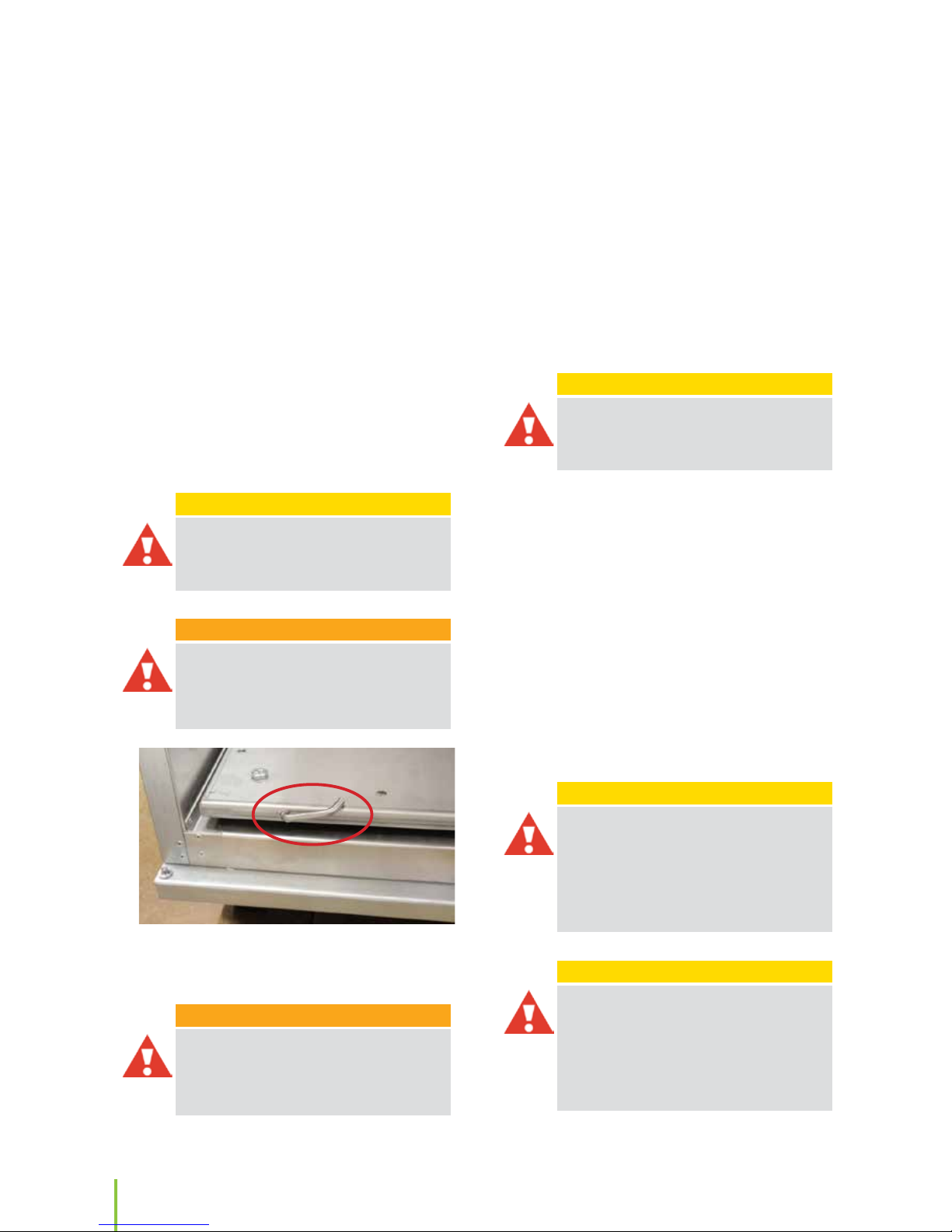

WARNING!

WARNING: Before operating the heat pump

in the Pallas HP models, remove the transport

support for the compressor mounting plate

as indicated in the picture below. Pull the rod

completely out from the compressor mounting

plate to disengage the transport support.

WARNING!

WARNING: Airow calibration must be done

before engaging the heat pump. In Pegasos and

Pallas HP eAir units the heat pump is engaged

from inside the electrical connection box: Circuit

breaker F1.

Page 5

5

Installation manual

EN

TECHNICAL DATA

For technical data see eAir Installation manual except

for following points:

Refrigerant: R410A

Refrigerant charge:

Pelican HP: 1.5 kg

Pegasos HP: 2.3 kg

Pallas HP: 5,2 kg

Compressor´s nominal input power:

Pelican HP: 0,9 kW

Pegasos HP: 4,0 kW

Pallas HP: 5,5 kW

Compressor´s oil type: POE RL32H

Compressor´s oil charge:

Pelican HP: pre-lled by component supplier.

Pegasos HP: 1,2 l

Pallas HP:1,9 l

Netto Weight of the Unit:

Pelican HP: 149,5 kg

Pegasos HP 244,6 kg

Pallas HP: 445,6 kg

Superheating control fuse (F3 Pegasos and F4 Pallas):

T2,5 A

Power supply connection:

Pelican HP: 1 x C16A /230V 1~

Pegasos HP: 3 x C16A /400V 3~

Pallas HP: 3 x C20A /400V 3~

NOTE!

NOTE: Wrong phase order will prevent the heat

pump from operating (Pegasos HP and Pallas HP

only)

Minimum allowed airow when heat pump is in

operation:

Pelican: 104 l/s (375 m³/h)

Pegasos: 120 l/s (432 m³/h)

Pallas: 200 l/s (720 m³/h)

Page 6

6

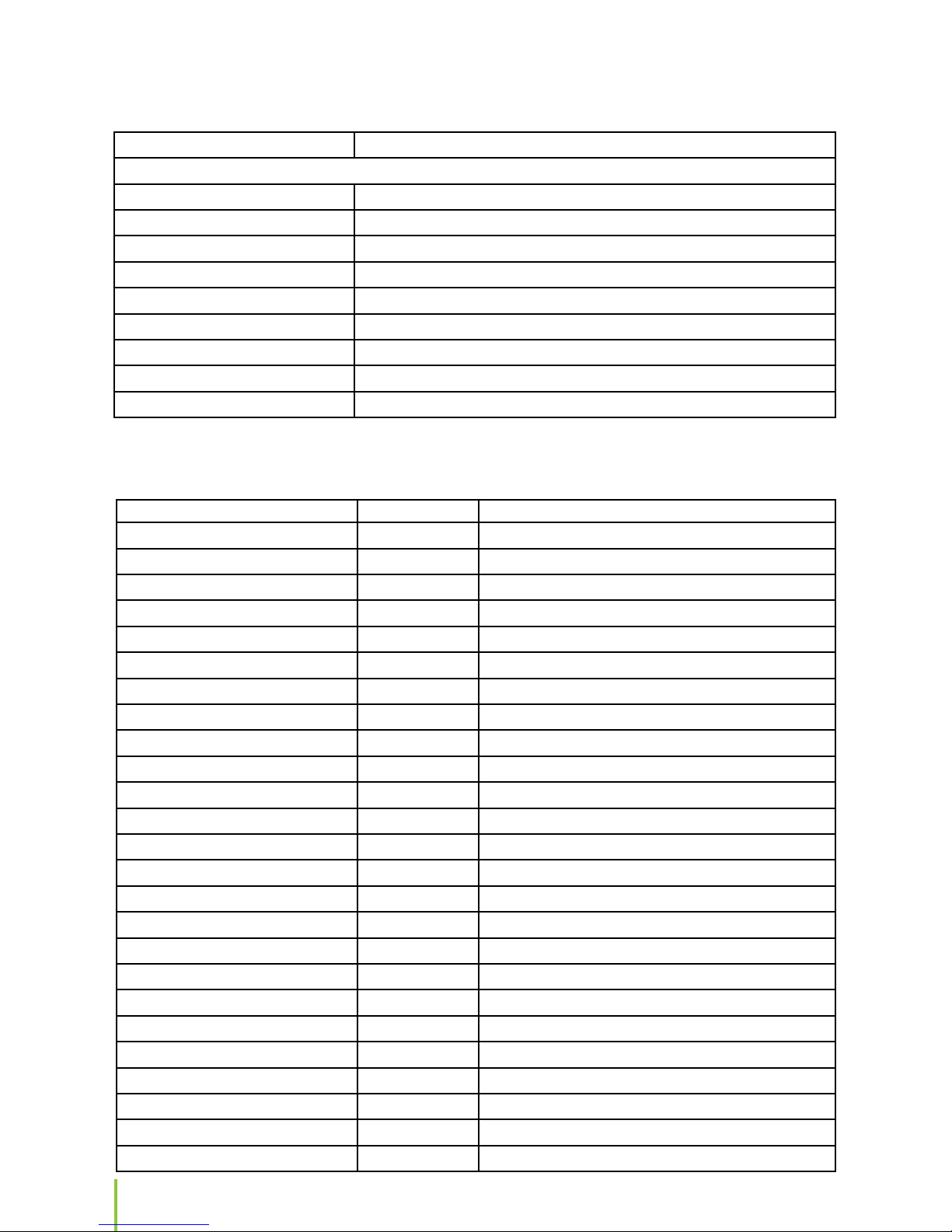

SERVICE RECORD FOR HEAT PUMP UNIT

Owner of the Heat Pump Unit:

Location of the Heat Pump Unit

Street address:

Postal Code:

City:

Country:

Unit system identication:

Unit Model:

Serial Number:

Refrigerant Type

Refrigerant amount:

Test done by: Date: Test passed: accepted/rejected

Annual refrigerant leakage test

Page 7

7

Installation manual

EN

WIRING DIAGRAMS

Page 8

8

Page 9

9

Installation manual

EN

Page 10

10

Page 11

11

Installation manual

EN

Page 12

12

Page 13

13

Installation manual

EN

Page 14

14

CONTROL DIAGRAM

Page 15

15

Installation manual

EN

MD

ELECTRICAL

CABINET

UNIT

Page 16

16

MD

ELECTRICAL

CABINET

UNIT

Page 17

17

Installation manual

EN

MD

ELECTRICAL

CABINET

UNIT

Page 18

18

ELECTRICAL

CABINET

UNIT

Page 19

19

Installation manual

EN

ELECTRICAL

CABINET

UNIT

Page 20

20

ELECTRICAL

CABINET

UNIT

Page 21

21

Installation manual

EN

Page 22

22

Page 23

23

Installation manual

EN

Page 24

Enervent Oy

Kipinätie 1, FI-06150 PORVOO

Phone: +358 207 528 800

enervent@enervent.com

www.enervent.com

Loading...

Loading...