Page 1

29.11.2017

Enervent Neo

Maintenance, Repair and Recycling manual

Page 2

2

Copyright © Enervent 2017.

Unauthorised copying and distribution is forbidden.

Page 3

3

Maintenance , Repair and Recycling manual

CONTENTS

READ FIRST ................................................................................................................ 4

TYPE PLATE ................................................................................................................ 5

SAFETY .................................................................................................................... 6

General ................................................................................................................ 6

Electrical safety ........................................................................................................ 6

UNIT MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Opening the lower service hatch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Taking the spare belt into use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Changing the heat exchanger motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Dismantling of lower part . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Cleaning the heat exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Changing the heat exchanger drive belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Dismantling of upper part . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Maintenance of fans and heater element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Cleaning of fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

TAKING UNIT INTO USE AFTER SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Reassembling the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

APPENDICES ..............................................................................................................22

Troubleshooting ......................................................................................................22

RECYCLING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Dimensional drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Dimensional drawing, left handed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Dimensional drawing, right handed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

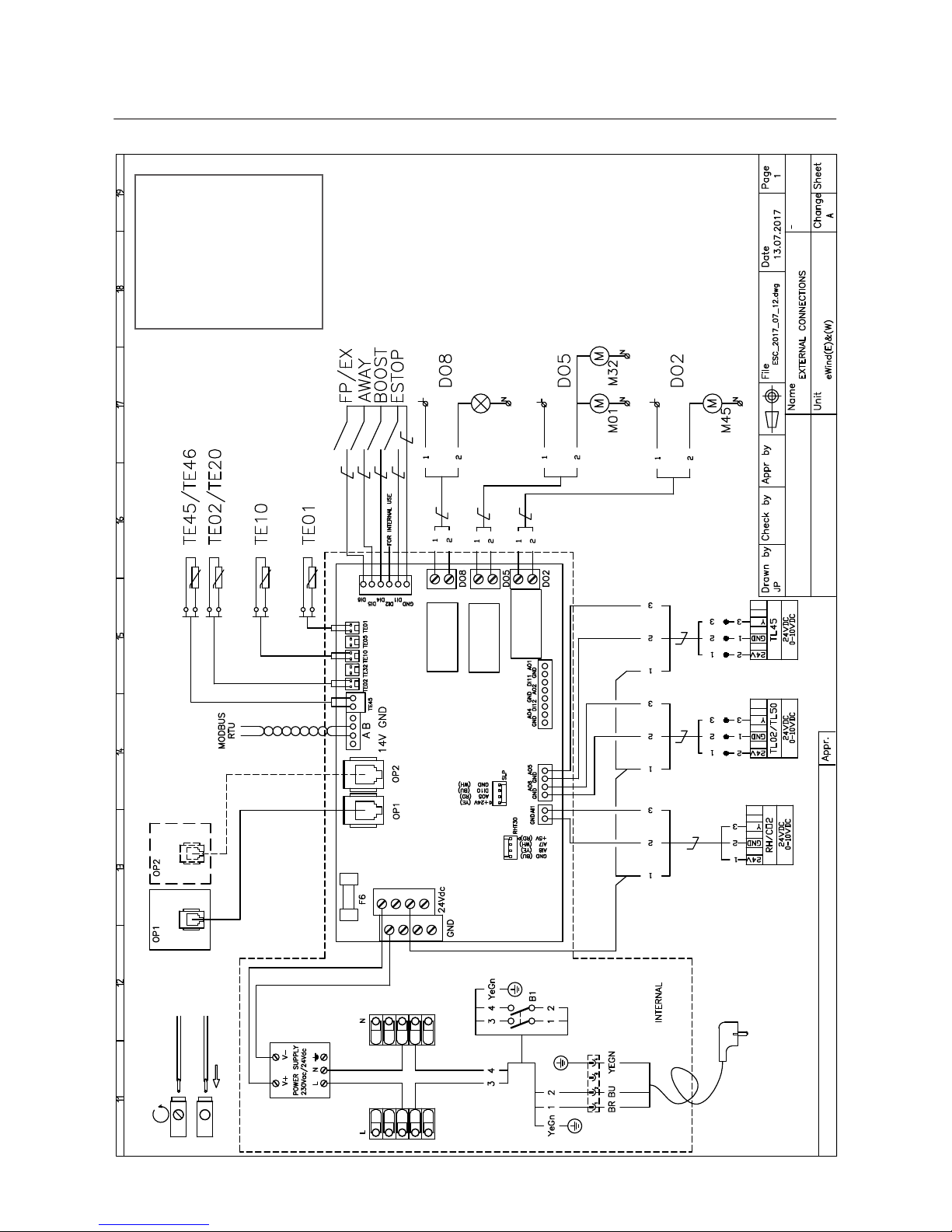

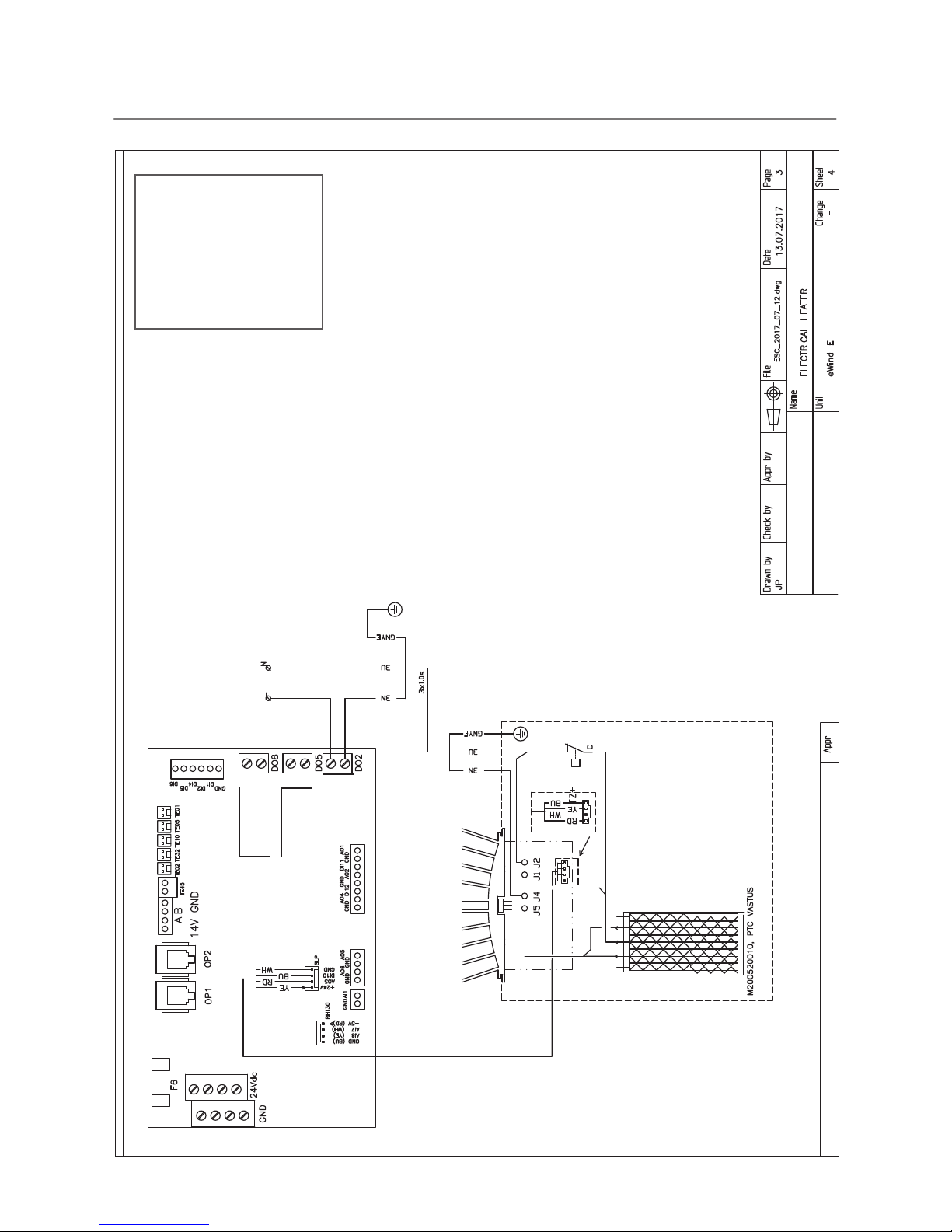

ELECTRICAL DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

External connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Internal connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Electrical heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

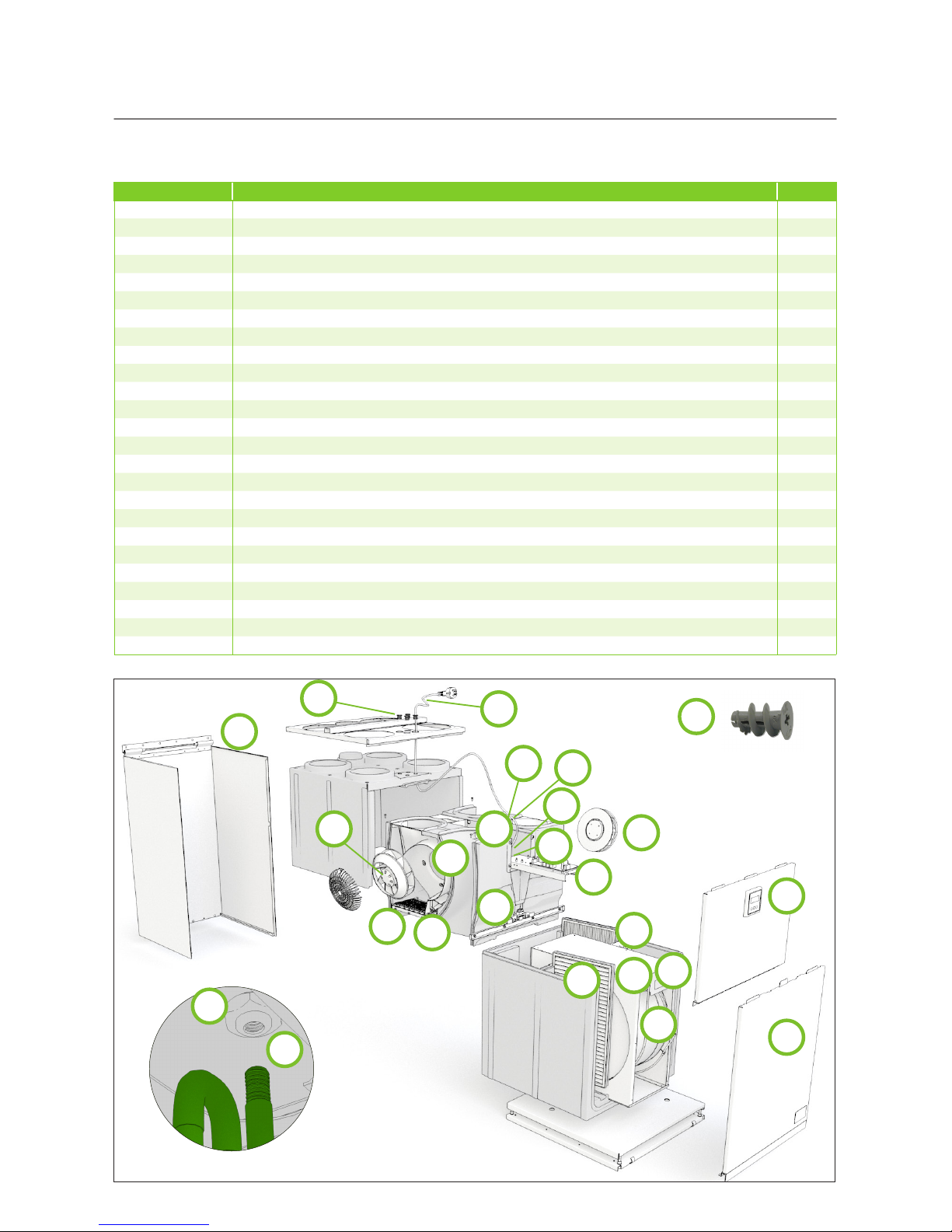

SPARE PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Page 4

4

READ FIRST

This instruction manual is intended for all people involved

in maintenance and repairing of the Enervent ventilation

units. Only professionally skilled persons may maintain

and repair the equipment described in this manual,

according to the instructions provided in this manual

and to the local laws and regulations. Failure to comply

with the instructions provided in this manual will result in

cancellation of the warranty for the equipment and may

result in harm to people or property.

The equipment described in this manual may not be

used by persons (including children) with reduced

physical, sensory or mental capacity or without sufficient

experience or knowledge, unless a person responsible for

their safety is supervising and advising in the use of the

equipment.

Page 5

5

Maintenance , Repair and Recycling manual

Should you need any technical support, refer to the type

plate for the equipment type and serial number before

contacting support.

Technical support:

www.enervent.com/contact-information/

Webshop for supplies and spareparts:

webshop.enervent.com

Service instructions and service requests:

www.enervent.com/help-center/

TYPE PLATE

ilmanvaihtolaite

ventilation unit

TYYPPI/TYPE:

W/ V/ HZ / A:

www.enervent.com

SRJ. NRO/SERIAL NO:

IP 20

Page 6

6

SAFETY

General Electrical safety

Always check that the equipment supply voltage

is switched off before opening the service hatch.

Only an authorised electrician may perform any

actions in the electrical box.

Follow the local regulations on electrical

installations.

In case of malfunction, always find out the reason

for the malfunction before starting the unit again.

Wait for two (2) minutes after switching off

the power of the unit before commencing the

maintenance. Although the power is switched

off, the fans continue running and the heating

element stays hot for a while.

Check that the unit is entirely isolated from the

mains before conducting any voltage tests,

insulation resistance measurements or other

electrical work or measurements. Such work may

damage the sensitive electrical devices.

Control devices used in the ventilation units may

cause leakage current. It may affect the operation

of the residual current devices.

All ventilation units with a control system must be

equipped with an over-voltage arrester.

DANGER DANGER

DANGER

WARNING

WARNING CAUTION

CAUTION

CAUTION

Page 7

7

Maintenance , Repair and Recycling manual

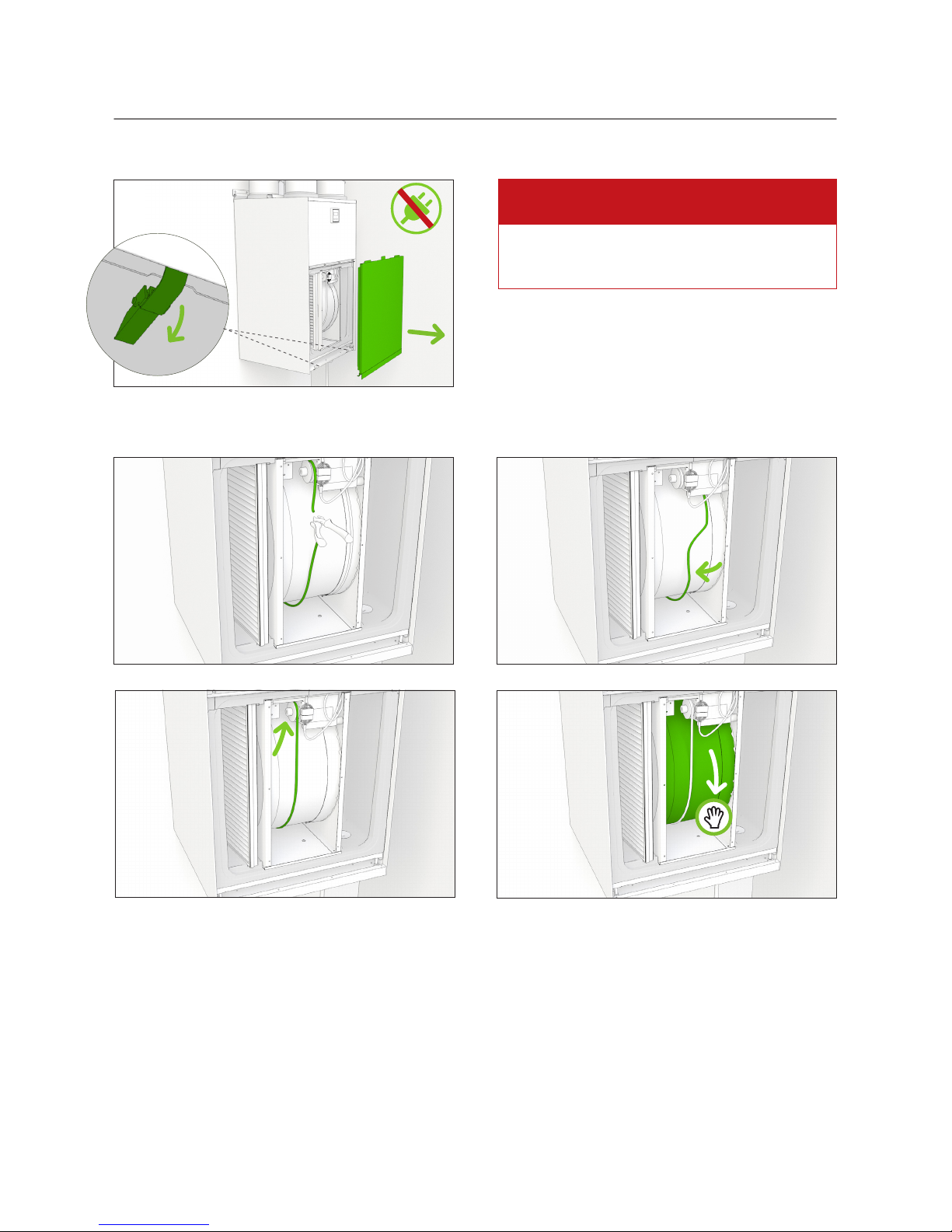

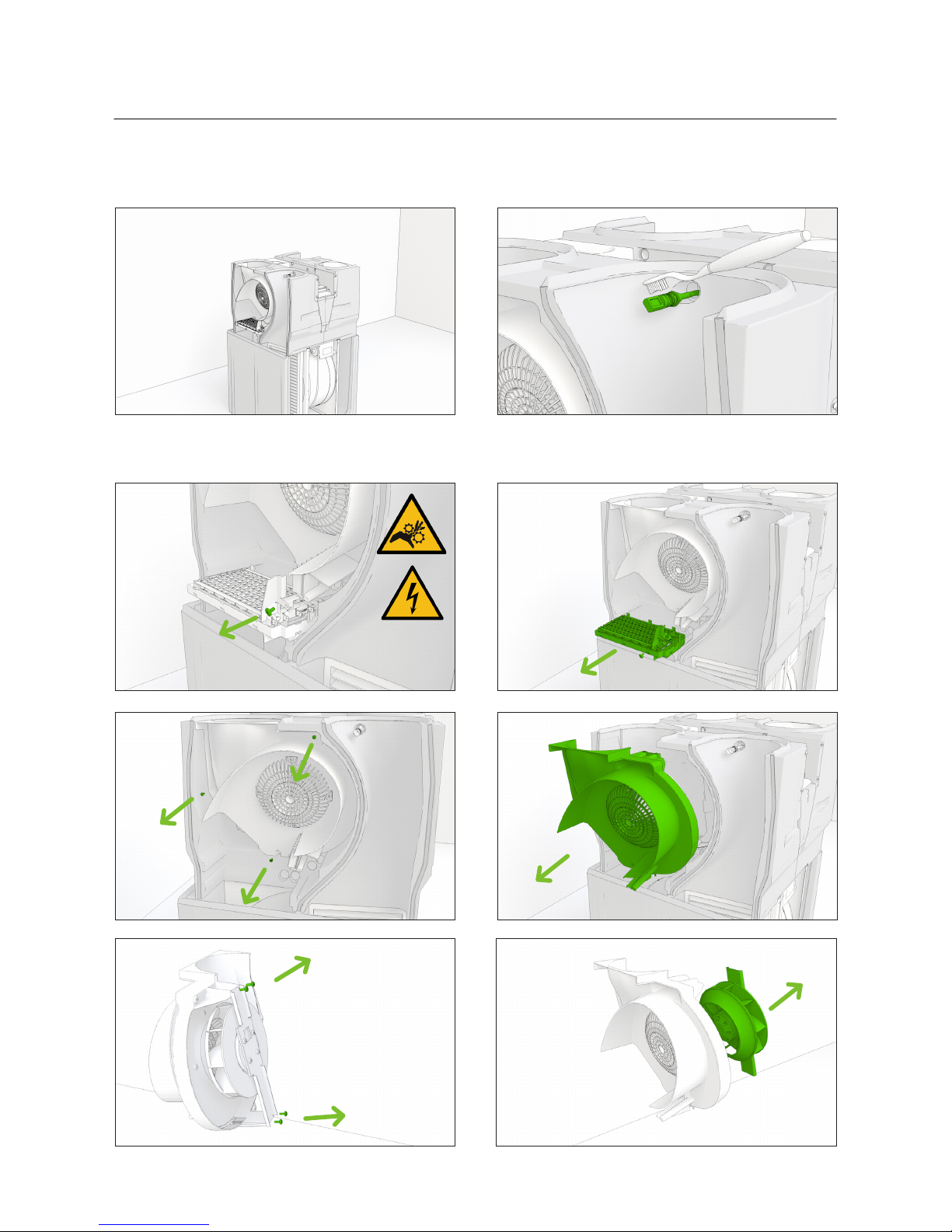

UNIT MAINTENANCE

1

Taking the spare belt into use

Opening the lower service hatch

2

4

1

3

Always check that the equipment supply voltage

is switched off before opening the service hatch.

DANGER

Page 8

8

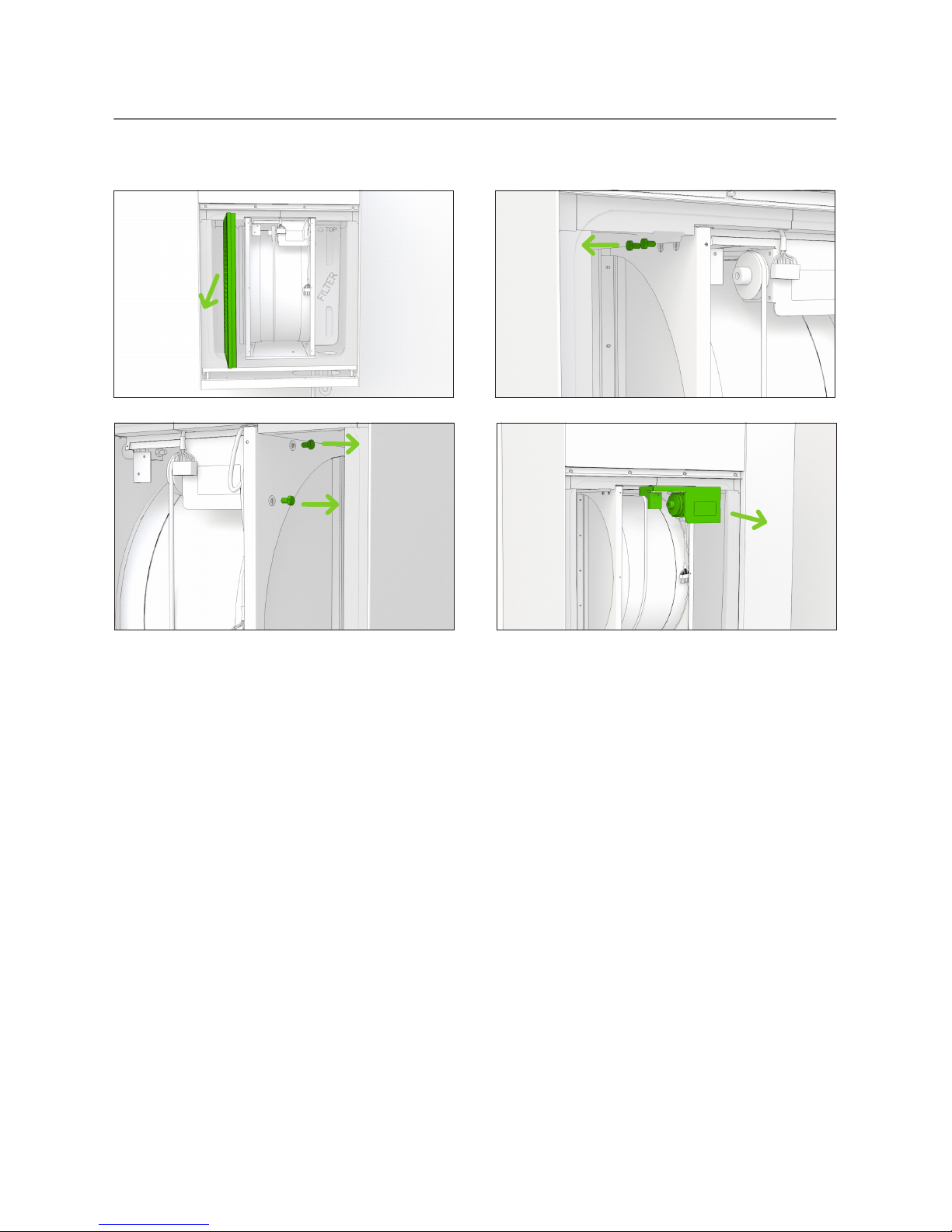

Changing the heat exchanger motor

2

4

1

3

Page 9

9

Maintenance , Repair and Recycling manual

Always check that the equipment supply voltage

is switched off before opening the service hatch.

Dismantling of lower part

Before dismantling the lower part, open the lower service hatch, see page 7 picture 1.

3

1 2

4

5b

5a

6a 6b

DANGER

Page 10

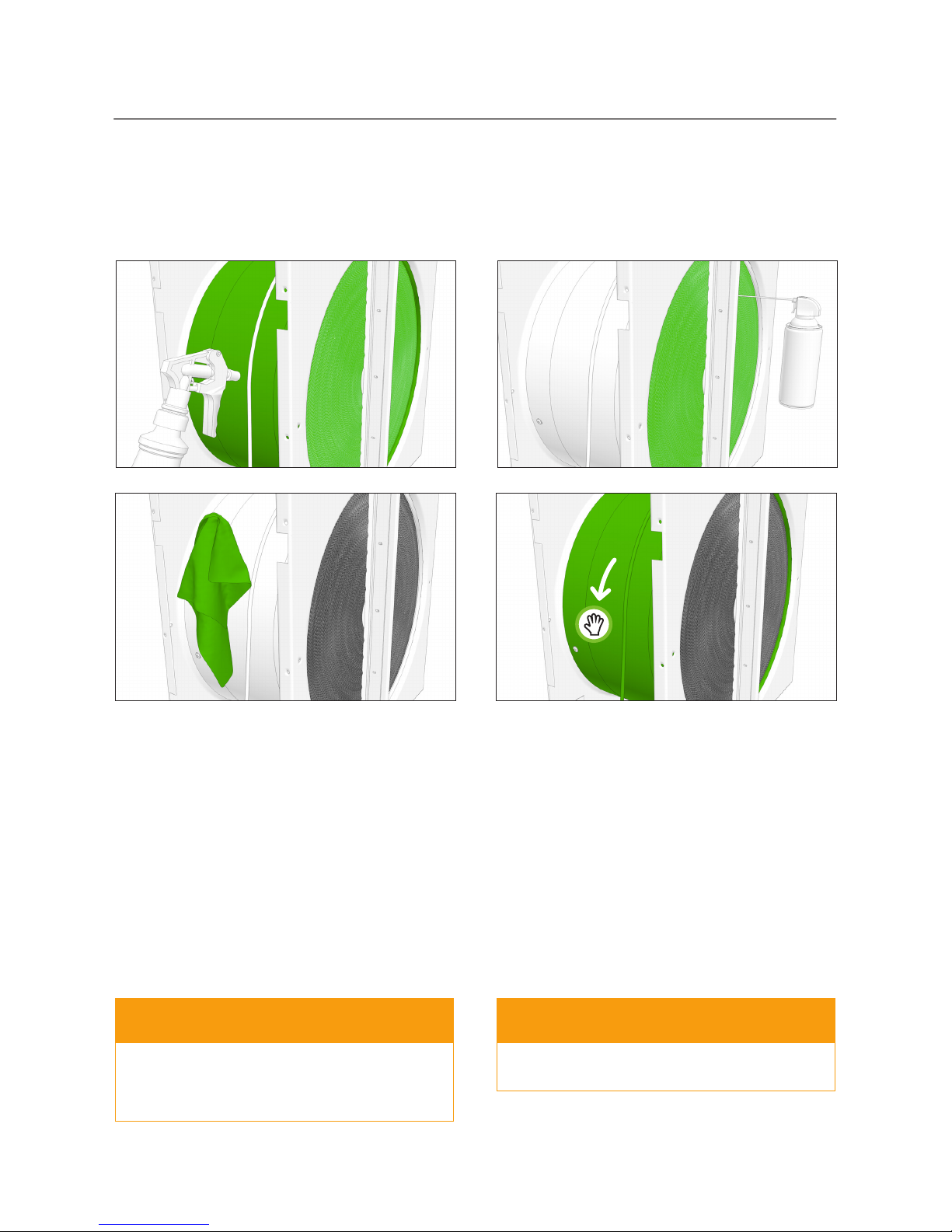

10

2

3

4

1

Check the cleanliness of the rotating heat exchanger visually when changing filters, and clean it if it looks dirty. Before

cleaning the heat exchanger, see. "Dismantling of lower part" on page. 9. The cleaning is to be performed by an authorized

service provider.

Cleaning the heat exchanger

Do not submerge the heat exchanger in water.The

electric motor inside the heat exchanger must not

get wet.

The use of a pressure washer is strictly forbidden.

WARNING WARNING

Page 11

11

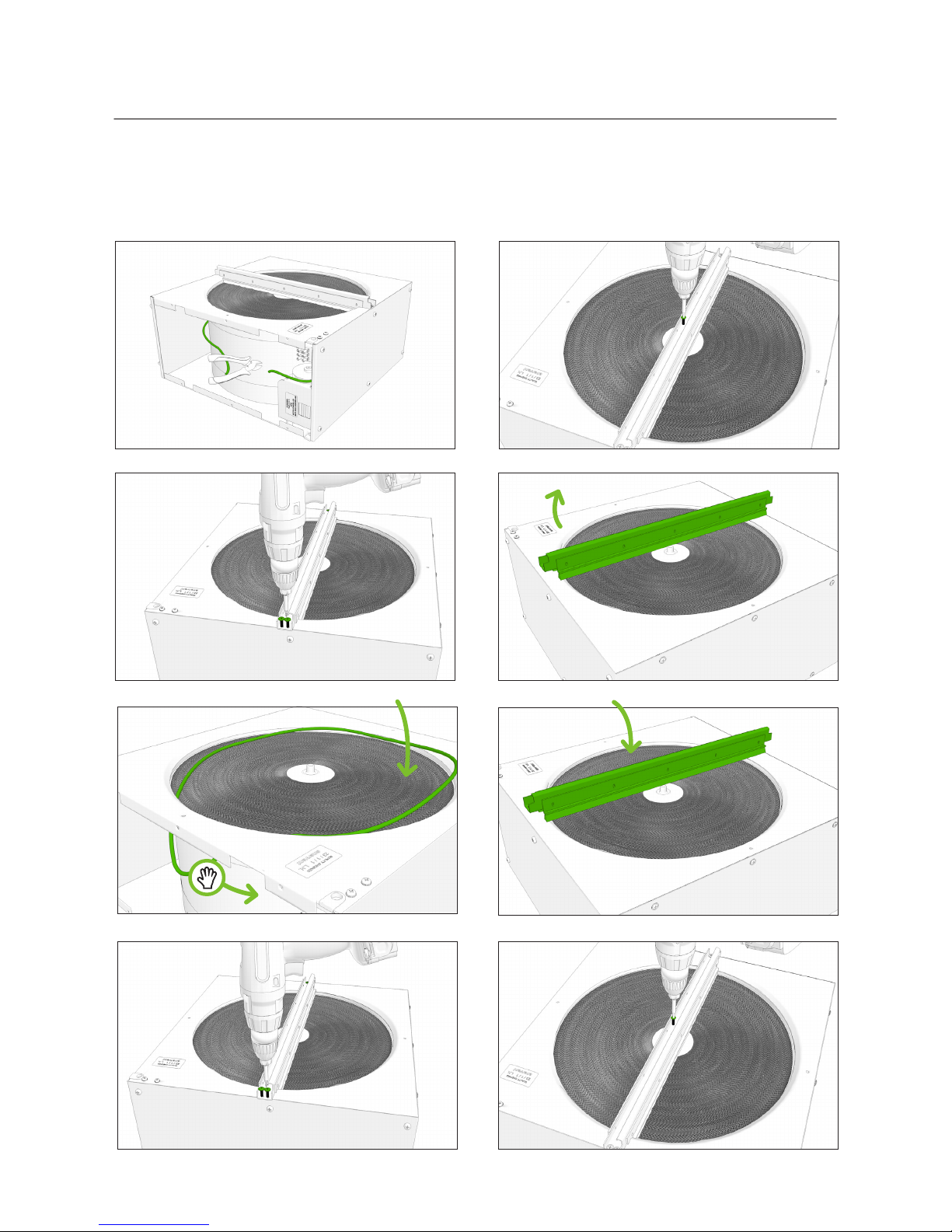

Maintenance , Repair and Recycling manual

Changing the heat exchanger drive belt

5

3

1

2

4

Before changing the belt, see. "Dismantling of lower part" on page. 9.

7

6

8

Page 12

12

10

9

11

12

13

14

Page 13

13

Maintenance , Repair and Recycling manual

Dismantling of upper part

5 6

Always check that the equipment supply voltage

is switched off before opening the service hatch.

DANGER

Only an authorized service provider may dismantle the unit

1

3 4

2

Å power cord

7

Å external sensors

Page 14

14

Maintenance of fans and heater element

Look first. "Dismantling of lower part" on page. 9..

1

2a 2b

3 4

Page 15

15

Maintenance , Repair and Recycling manual

Supply air fan

1

1

3

2

2

Cleaning of fans

4

65

Page 16

16

43

7

5

Extract air fan

1 2

Page 17

17

Maintenance , Repair and Recycling manual

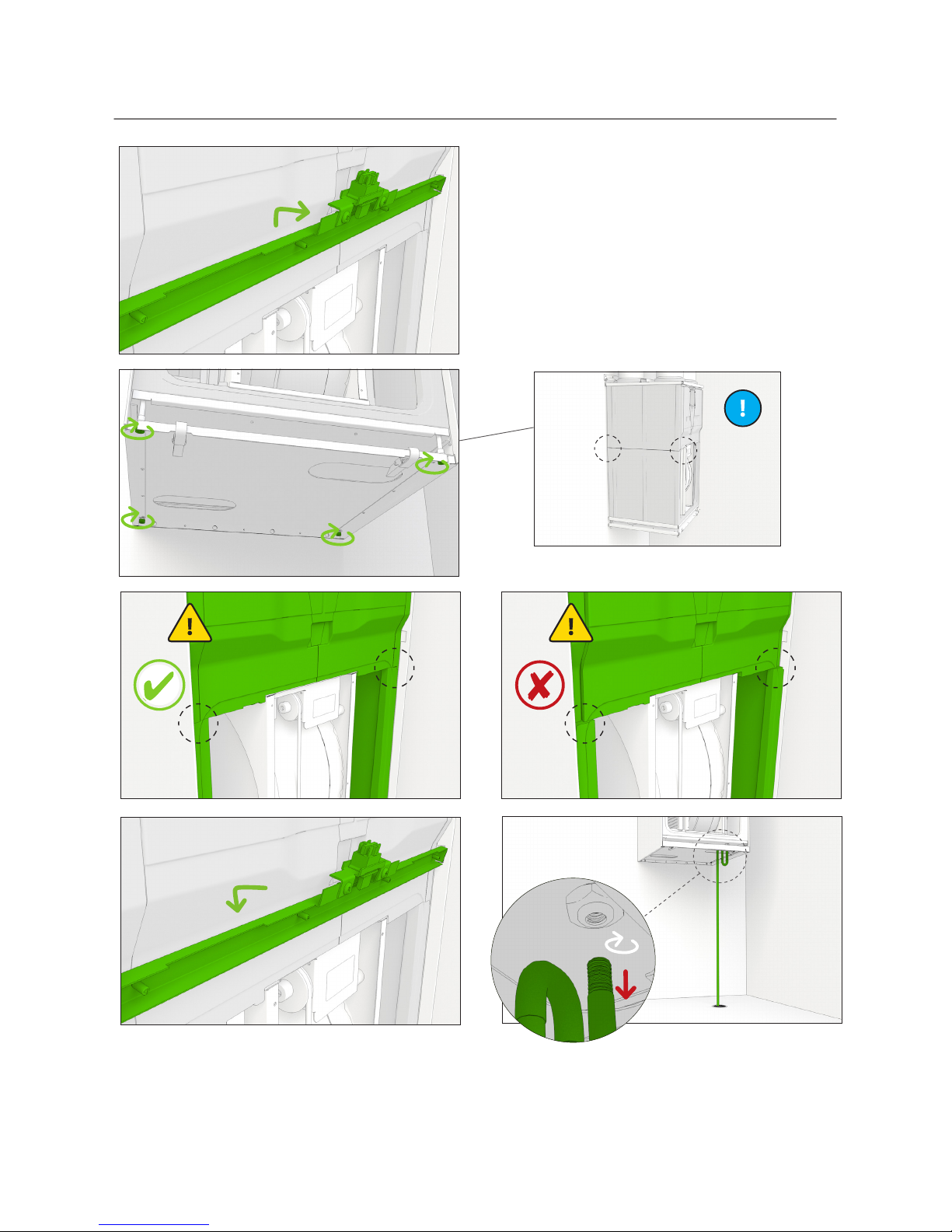

TAKING UNIT INTO USE AFTER SERVICE

2

3a 3b

4

Reassembling the unit

1

5

7

Å power cord

6

Å external sensors

silicone

Page 18

18

11 12

13

14

+2 mm 0 mm

10b10a

8

9

push all the way in 20 mm

22 mm

5 mm at a time

Page 19

19

Maintenance , Repair and Recycling manual

18

19

0 mm

0 mm

15

16

17b17a

Page 20

20

24

23

22

20

21

Page 21

21

Maintenance , Repair and Recycling manual

Page 22

22

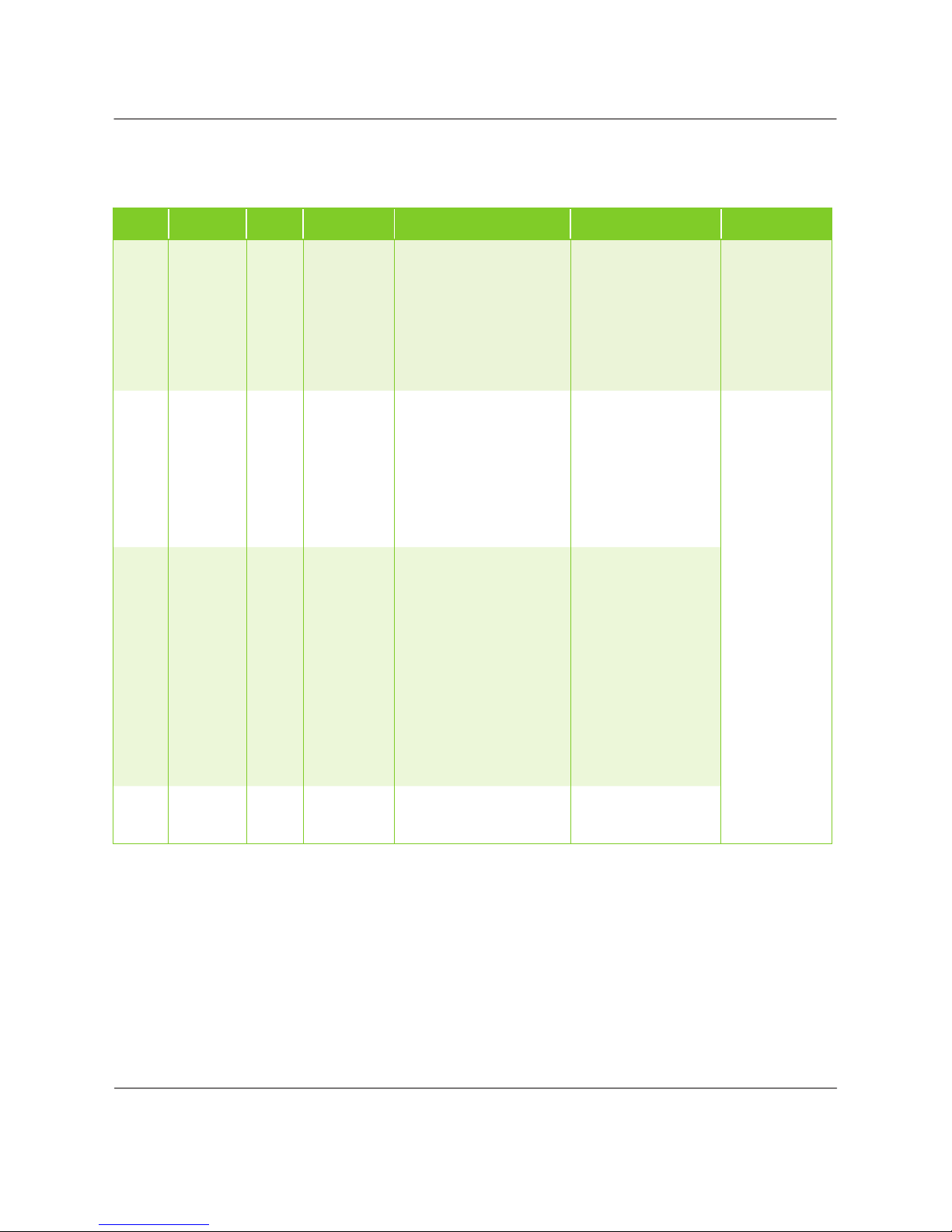

Troubleshooting

APPENDICES

Alarm Description

Alarm

limit

Symptoms Possible cause Action Notes

FILS Service

reminder.

4 or 6

months

It is time for regular maintenance. Replace the filters.

Inspect the ventilation unit.

Clean as necessary.

See if there are any damages

visible.

Acknowledge by

pressing any button

for 5 seconds.

Err Sensor

malfunction.

The sensor is in short circuit or

there is an interruption in the

circuit.

Check the connections and

cables of the sensors.

- - - - Downloading. The eWind panel downloads

data from the motherboard.

Normal during start-up. In

other situations, check the

eWind connection cable.

oFFE Stop mode. Ventilation off. External control system has

switched the ventilation unit to

stop mode.

AL1 Water heat-

ing coil is in

danger of

freezing.

+8 °C Cold supply air. The water coil is frozen/about to

freeze:

• The circulation pump has

stopped.

• The heat exchanger does not

rotate.

• The control valve actuator of

the water coil is faulty.

• The extract fan has stopped.

Restart the pump.

Replace the motor or the

belt.

Replace the actuator.

Find out the reason/replace

the fan.

The unit will not

start until the alarm

mode is cleared and

the alarm reset by

pressing a button in

the operation panel.

AL2 The supply

air is cold

after the

rotating heat

exchanger.

+5 °C Cold supply air. The heat exchanger does not

rotate:

• The drive belt is damaged.

• The drive belt skids.

• The heat exchanger motor is

damaged.

Replace the drive belt.

Clean or replace the belt or

the heat exchanger.

Replace the heat exchanger

motor.

The ventilation

unit switches to

malfunction mode,

in which the fans

operate with minimum power.

The alarm is automatically reset

when the fault is

cleared.

AL3 Cold supply

air.

+10 °C Cold supply air. The extract fan has stopped. Replace the fan.

The extract filter is clogged. Replace the filter.

The ventilation is adjusted incor-

rectly/not adjusted at all.

Adjust the ventilation as per

the ventilation system plan

with appropriate measurement tools.

The heat insulation of the ducts is

insufficient.

Check the insulation thickness of the supply and

extract air ducts and add

insulation as necessary.

The fan speed of the ventilation

unit is incorrect.

Always use a fan speed

specified by the ventilation unit designer (also in

winter).

AL4 Supply fan

malfunction.

No ventilation. The supply fan has stopped. Repair or replace the supply

fan.

The unit will not

start until the alarm

mode is cleared and

the alarm is reset by

pressing a button in

the operation panel.

AL5 Extract fan

malfunction.

No ventilation The extract fan has stopped. Repair or replace the extract

fan.

Page 23

23

Maintenance , Repair and Recycling manual

RECYCLING INSTRUCTIONS

Check the recycling instructions regarding the end-of-life of the unit on the webpage www.enervent.com.

Alarm Description

Alarm

limit

Symptoms Possible cause Action Notes

AL6 Cold extract

air.

+10 °C Cold supply air. Low indoor temperature. Raise the indoor

temperature.

Acknowledge by

pressing any button

for 5 seconds.

Insufficient heat insulation of the

extract air duct.

Check the insulation of the

ducts and add insulation as

necessary.

The ventilation unit’s service

hatch is open.

Close the service hatch

Temperature sensor TE30 is faulty. Repair or replace the sensor.

AL7 Hot supply

air.

Fire hazard.

+55 °C Hot supply air. Fire hazard. Check if there are any heat

sources.

The device will not

start until the alarm

mode is cleared and

the ventilation unit

started again.

There is a malfunction in the

electric after-heating coil.

Repair or replace the electric

after-heating coil.

There is a malfunction in the

actuator of the water-based afterheating coil’s valve.

Repair or replace the valve’s

actuator.

Temperature sensor TE10 is faulty. Repair or replace the tem-

perature sensor.

AL8 Overheating

of the electric

after-heating

or preheat

coil.

Hot supply air. Electric preheat or after-heating

coil does not work:

• Overheating protector has

tripped.

• The supply fan has stopped.

• The supply air filter is clogged.

• The outside air grille is

clogged.

• The heater controller board is

damaged.

• The heater is damaged.

Find out the reason for

overheating and reset the

error message.

Find out the reason/replace

the fan.

Replace the filter.

Clean the grille. Remove any

mosquito net.

Replace the controller

board.

Replace the heater

AL9 Hot extract

air.

Fire hazard.

+55 °C Hot extract air. Fire hazard.

Temperature sensor TE30 is faulty.

Check if there are any heat

sources.

Repair or replace the temperature sensor.

Page 24

24

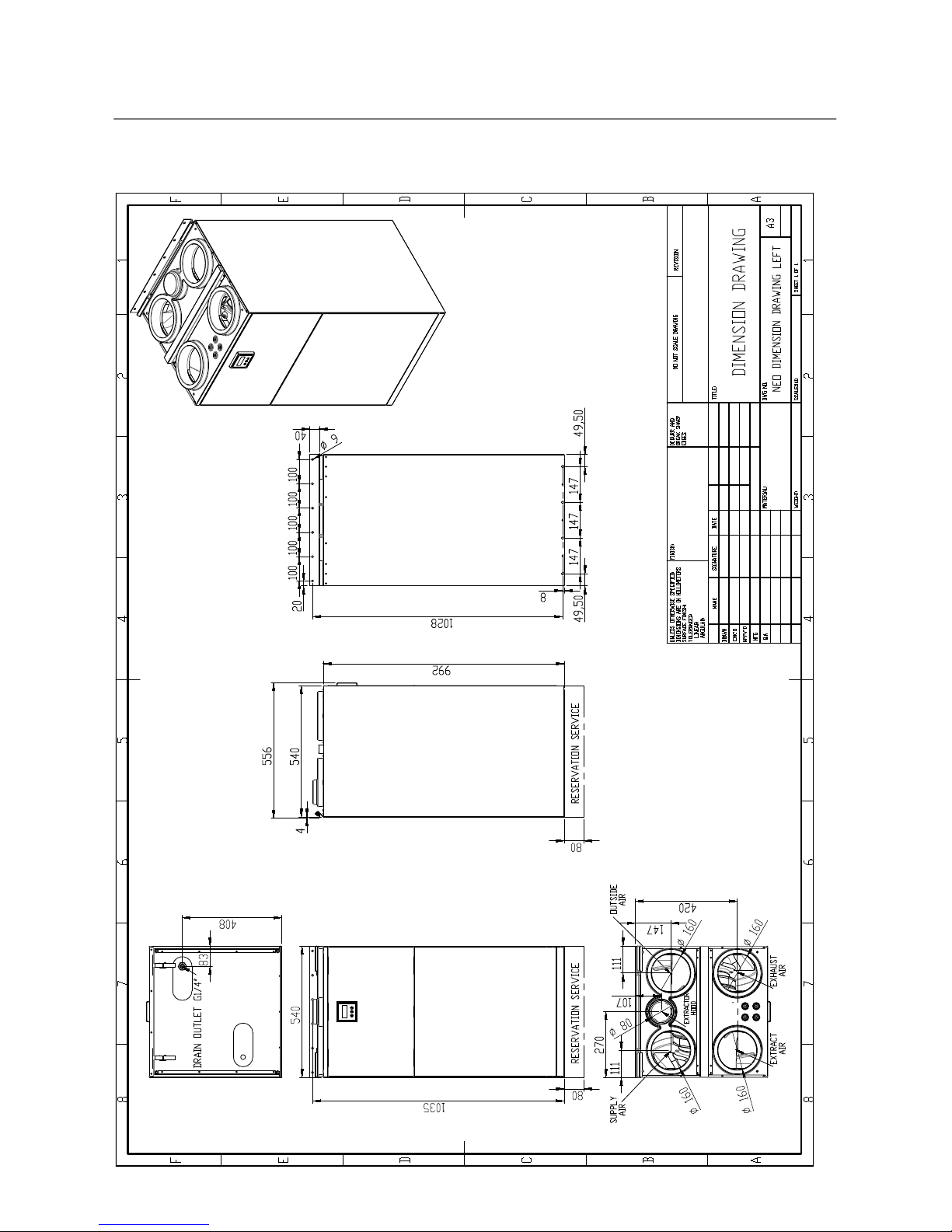

Dimensional drawings

Dimensional drawing, left handed

Page 25

25

Maintenance , Repair and Recycling manual

Dimensional drawing, right handed

Page 26

26

Electrical diagrams

External connections

WIRE COLOURS

BK BLACK

BN BROWN

RD RED

OG ORANGE

YE YELLOW

GN GREEN

BU BLUE

GY GREY

WH WHITE

Page 27

27

Maintenance , Repair and Recycling manual

Name Explanation Marking on circuit board

FP/EX

FIREPLACE/EXTRACTOR HOOD MODE

DI6

AWAY AWAY MODE DI5

BOOST MANUAL BOOST DI4

ESTOP EXTERNAL STOP DI1

TE45

RETURNWATER TEMPERATURE SENSOR eWind W UNITS

TE45

TE46

RETURNWATER TEMPERATURE SENSOR eWind CG UNITS

TE45

TE02

PREHEATED OUTSIDE AIR TEMPERATURE, EXTERNAL PREHEATER

TE02

TE20

RECIRCULATION AIR TEMPERATURE (KOTILÄMPÖ eWind)

TE02

TE10 SUPPLY AIR TEMPERATURE TE10

TE01 OUTSIDE AIR TEMPERATURE TE01

RH CO²

EXTERNAL HUMIDITY SENSOR (RH 0-100%) BY DEFAULT IF PARAMETER c27 IS ACTIVE, CO² SENSOR

(200-2000ppm) (ACCESSORY)

AI1

TL01

TL50

PREHEATER VALVE ACTUATOR -CHG MODELS COOLING VALVE ACTUATOR -CG MODELS

AO6

TL45

HEATING VALVE ACTUATOR -W MODELS

AO5

DO8 ALARM A OUTPUT BY DEFAULT PREHEATER ON/OFF CONTROL IN -CHG -AGH -ELECTRICAL

PREHEATER MODELS COOLING ON/OFF CONTROL IN -CG MODELS

DO8

DO5 OUTSIDE AIR AND EXHAUST AIR DAMPER CONTROL (ACCESSORY) DO5

DO2 HEATING ON/OFF CONTROL eWind W MODELS MAX 500W PUMP DO2

OP1 USERPANEL 1pcs. INCLUDED IN DELIVERY, 10m CABLE INCLUDED IF NOT MOUNTED ON UNIT OP1

OP2 USERPANEL (ACCESSORY) 10m CABLE INCLUDED IN DELIVERY OP2

Page 28

28

Internal connections

WIRE COLOURS

BK BLACK

BN BROWN

RD RED

OG ORANGE

YE YELLOW

GN GREEN

BU BLUE

GY GREY

WH WHITE

Page 29

29

Maintenance , Repair and Recycling manual

Name Explanation Marking on circuit board

TE45

RETURN WATER SENSOR eWind W UNITS

TE45

TE46

RETURN WATER SENSOR eWind CG UNITS

TE45

TE02

PREHEATED OUTSIDE AIR SENSOR

TE02

TE20

RETURN AIR TEMPERATURE (KOTILÄMPÖ eWind UNITS)

TE02

TE32

EXHAUST AIR TEMPERATURE SENSOR

TE32

TE10

SUPPLY AIR TEMPERATURE SENSOR

TE10

TE05

AIR TEMPERATURE AFTER THE HEAT RECOVERY HEAT EXCHANGER

TE05

TE01

OUTSIDE AIR TEMPERATURE SENSOR

TE01

RHT30

EXTRACT AIR TEMPERATURE AND HUMIDITY SENSOR(RH 0-100%)

RHT30

SF10 SUPPLY AIR FAN AO1,DI11

EF30 EXTRACT AIR FAN AO2,DI12

CF20

RETURN AIR FAN (KOTILÄMPÖ UNITS ONLY)

AO6

M75

HEAT RECOVERY HEAT EXCHANGER MOTOR

AO4

Page 30

30

Electrical heater

WIRE COLOURS

BK BLACK

BN BROWN

RD RED

OG ORANGE

YE YELLOW

GN GREEN

BU BLUE

GY GREY

WH WHITE

Page 31

31

Maintenance , Repair and Recycling manual

Product number Product name

K030160001 Neo Door 1

M070100200 Sealing strip O-sealing with fastening D=7,5 464128300 2

K930040220 Neo bulkhead door EPP 3

M900500301 52389 GK plastic plug Fischer 4

M480500015 Rubber grommet EV16 5-10 5

M360500030 Sink strainer / kondensation drain P160010501A NEO 6

M900100009 Nut DIN 934/8 ZN M20 7

K100160002 Rotating heat exchanger, stepless drive Neo 8

M140030016 Belt, PUW green,1440mm/6mm Neo 9

K120160003 Rotor motor package, stepless DC Neo 10

K140160001 Fan package, supply Neo 11

K140160002 Fan package, extract Neo 12

M680010040 Power cord 1,5m 3x1,5 including Molex and grommet 13

M710910001 eWind motherboard 14

M230110602 Humidity/temperature sensor Amphenol 600mm T9602-5-A-0.60-EV cable and connector 15

M620200011 Tufvassons switch mode power supply PSLR 24 16

M120200007 Control circuit board EM-240-M1 DC-motor 17

M230120604 EDA temperature sensor 850mm 2-nap NTC 10K sensor 850 2-pol con 18

M230120602 EDA temperature sensor 500mm 2-nap NTC 10K sensor 500 2-pol con 19

K160163001 Electrical heater Neo eWind E 20

M710600007 EDA electrical heater control circuit board Enerpoint 21

K580040003 eWind control panel Neo Package includes operating panel and 350mm cable 22

M210190142 Exchange filters F7/M5 (supply/extract) Unit size Neo 23

M03P160010022 Wall mounting bracket 24

M490300002 Switch, FA1CA22 Door switch 25

Spare parts list

Left handed

1

3

9

6

10

7

12

18

15

25

11

16

19

13

22

23

20

21

14

2

8

4

17

24

5

Page 32

Enervent Oy

Kipinätie 1

FIN-06150 Porvoo, Finland

Tel. +358 207 528 800

Fax. +358 207 528 844

enervent@enervent.com

www.enervent.com

Loading...

Loading...