Solar Pumping Inverter

User’s Manual

Preface

In order to give full play to the product performance and guarantee the safety of user and

equipment, before installation and use, please carefully read the manual.

In order to facilitate daily inspection and maintenance of inverter and understand abnormal

reason and solutions, please keep the instruction properly.

If you have any questions or special requirements during use, please contact with our

company’s product dealer or directly contact with our company’s technical service center.

If the manual contents change, we may not offer notice.

Operation Instruction of BS Series Solar Pumping Inverter Precautions

I

Contents

Precautions ................................................................................................................................ II

Chapter I Product Introduction ............................................................................................ 1

1.1 Introduction to Solar Pumping System ................................................................................ 1

1.2 Product Characteristics ........................................................................................................ 2

1.3 Inverter Specification ........................................................................................................... 3

Chapter II Installation and Wiring .......................................................................................... 7

2.1 Procurement Inspection ....................................................................................................... 7

2.2 Dimension and Weight ......................................................................................................... 7

2.3 Installation Diagram ............................................................................................................ 9

2.4 Wiring Diagram ................................................................................................................. 12

2.5 Assemble DC Connector .................................................................................................... 21

2.6 Introduction to the Wiring of Water Level Sensor ........................................................... 222

Chapter III Operation Control ............................................................................................... 23

3.1 Panel Layout and Introduction ........................................................................................... 23

3.2 Panel Operation Method .................................................................................................... 24

3.3 Work Mode ........................................................................................................................ 26

3.4 Introduction to the Procedure of Wiring and Debugging .................................................. 26

Chapter IV: Failure Diagnosis ................................................................................................ 35

4.1 Explanation and Solution for Fault Code .......................................................................... 33

Chapter V Maintenance........................................................................................................... 37

5.1 Daily Inspection and Maintenance .................................................................................... 37

5.2 Inspection and Replacement of Quick-wear Parts ............................................................. 38

5.3 Storage and Maintenance ................................................................................................... 38

Quality Assurance .................................................................................................................... 39

Warranty Card ......................................................................................................................... 42

Operation Instruction of BS Series Solar Pumping Inverter Precautions

II

Precautions

The safe operation of the product is subject to correct transportation, installation, operation,

and maintenance. Before conducting these tasks, please pay attention to relevant safety instructions.

The warnings related to safety in the manual are listed as follows:

Grounding Wire of Equipment

AC Value

DC Value

Phase

Before operating inverter, please read the instruction.

5minutes

In order to avoid electric shock, breack off machine with PV terminal and

AC terminal for at least 5 minutes, then contact the wire of machine output

terminal and input terminal

Warning: when machine works, the temperature of metal shell may be

very high.

Procurement Inspection

Warning

1. If the inverter is found to suffer damage or lack in component and part, do not

install it, or else it may cause accident!

Installation

Warning

1. In order to guarantee good effect of convection cooling, the inverter shall be

installed vertically. Keep at least 10cm space between upward side and downward

side.

Operation Instruction of BS Series Solar Pumping Inverter Precautions

III

2. Try to install it in the indoor place with ventilation opening or air interchanger. It is

forbidden to install it directly under sunshine.

3. During installation, do not discard residue of drill hole into inverter cooling find or

fan, which may affect heat dissipation.

Wiring

Danger

1. The wiring shall be conducted by qualified electric technician, or it may cause

electric shock or fire disaster.

2. Before wiring, please confirm that the input power has been cut off, or else it may

cause electric shock or fire disaster.

3. The grounding terminal must be grounded reliably, or else the inverter shell may

have electricity.

4. The solar array, motor load, and inverter model selection shall be reasonable, or

else it may damage equipment.

Warning

1. Please use specified moment of force to tighten terminal, or else it may cause fire

disaster.

2. Do not connect capacitance or phase advance LC/RC noise filter in the output end

of inverter. When the distance between inverter and motor load is over 100m, it is

advised to use output reactor.

Operation

Danger

1. Power on after confirming that the wiring is correct, or it may damage inverter or

fire disaster.

2. During electricity, do not change wiring, or else it may cause electric shock.

Operation Instruction of BS Series Solar Pumping Inverter Precautions

IV

Warning

1. Before the first operation, please adjust some control parameters according to

operation instruction. Do not alter the control parameters of inverter at random, or

else it may damage the equipment.

2. During operation, the temperature of radiator is very high. Do not touch the

radiator, or else it may scald you.

3. When height above sea level exceeds 1000m, the inverter shall be used under rated

power. If the height increases by 1500m, the output current shall decreases by 10%.

Miscellaneous

Danger

1. Assign qualified electric technician for maintenance and inspection.

2. During power-up state, do not remove the inverter. After outage, wait for 5 minutes

at least, then conduct maintenance and inspection, so as to avoid that the residual

voltage on electrolytic capacitor of major loop may cause damage to people.

3. It is forbidden to transform the inverter without authorization, or else it may

damage personnel or equipment.

4. When handling scrapped inverter, please dispose the inverter as industrial waste.

The inner electrolytic capacitor may explode during burning. Some components and

parts may generate hazardous and harmful gas during combustion.

Operation Instruction of BS Series Solar Pumping Inverter Product Introduction

1

Chapter I Product Introduction

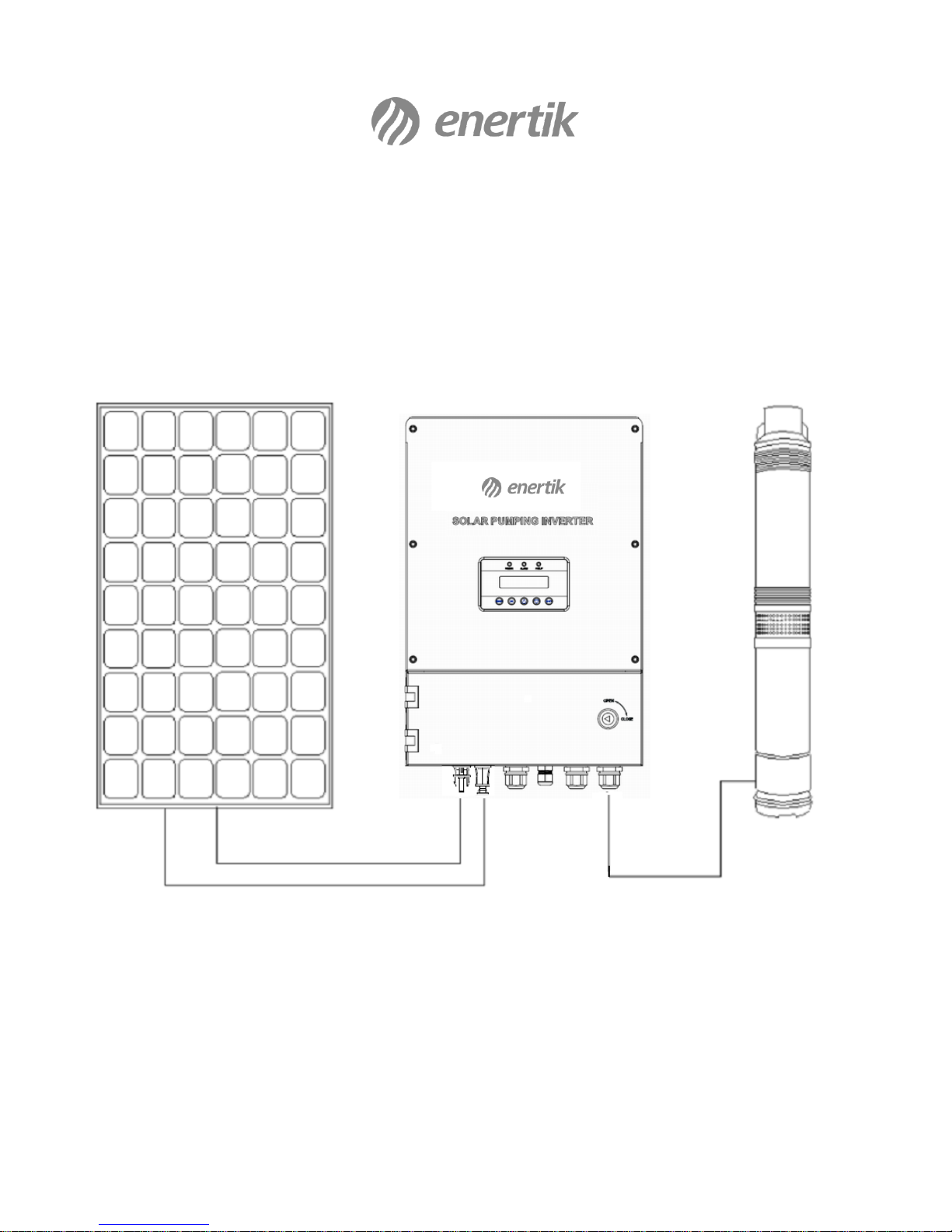

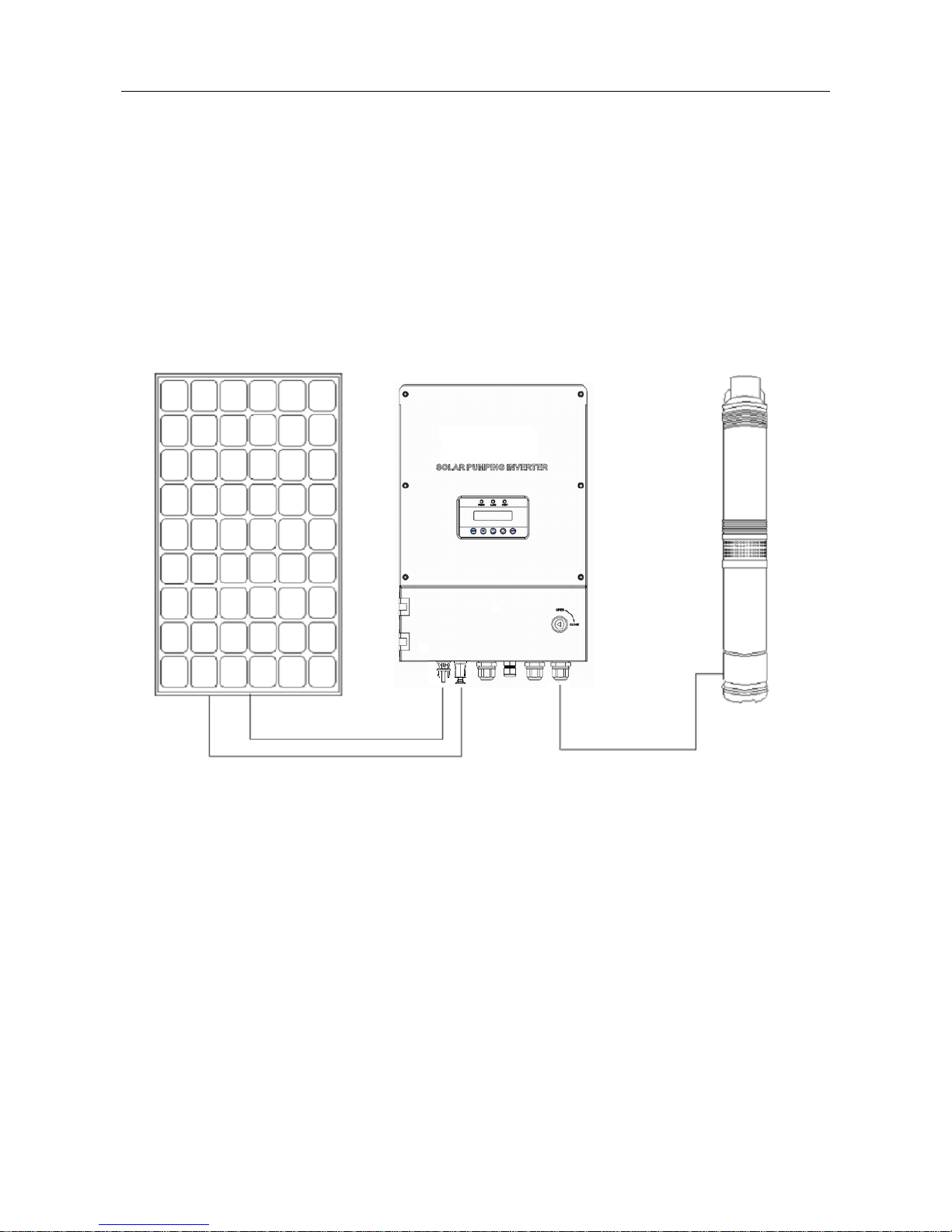

1.1 Introduction to Solar Pumping System

Solar Pumping System is widely applied in domestic water, agricultural irrigation, forestry

watering, desert control, grassland animal husbandry, island water supply, water treatment project,

etc. During recent years with the enhancement of new energy utilization, solar pumping system is

widely applied in the landscape and water spray system of municipal works, urban square, garden

sightseeing, tourist resort, hotel, and residential community. The system consists of solar cell array,

pumping inverter, and water pump(figure 1-1). Based on the design philosophy of saving water first,

the system omits energy storing device such as accumulator.

Figure 1-1 Structure of Solar Pumping System

The solar cell array is made from the series connection and parallel connection of several solar

cell modules, which absorb solar radiation energy and transform it into electric energy, so as to

supply electric power for the whole system. The pumping inverter controls and regulates the

operation of the system, transforms the direct current of solar cell array into alternating current to

drive water pump. In addition, according to the change of sunlight intensity, regulate output

frequency timely, to realize MPPT (Maximum Power Point Tracking). The water pump is driven by

three-phase AC motor. It pumps water from deep well, river, and lake, then inject water into water

storage tank/pool, or directly connect with irrigation system or fountain system, etc. According to

actual requirements of system and installation, different types of water pumps such as centrifugal

pump, axial flow pump, mixed-flow pump, or deep-well pump can be used.

DC Voltage

Three-Phase AC Voltage

Operation Instruction of BS Series Solar Pumping Inverter Product Introduction

2

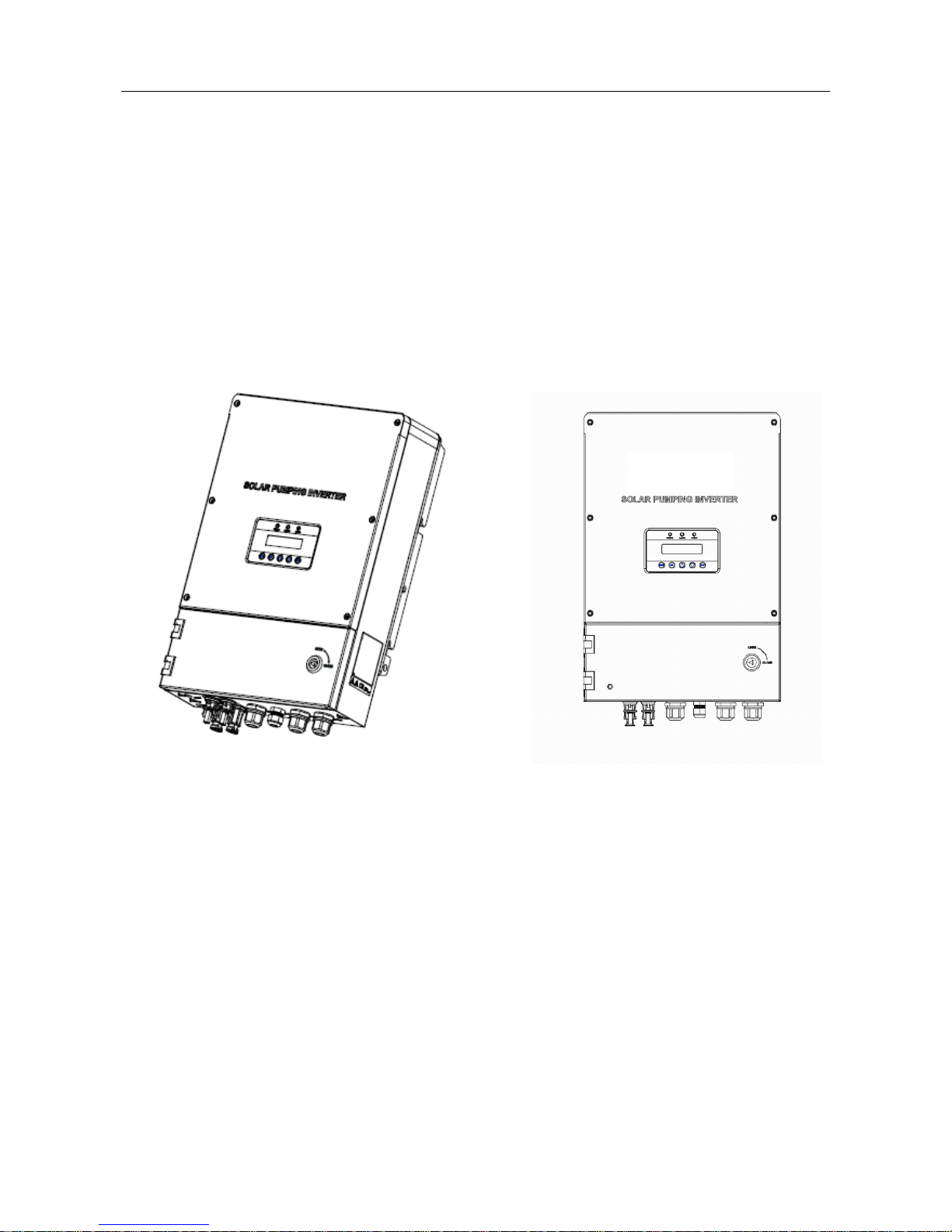

1.2 Product Characteristics

On the basis of many-year research, development, and experiment, the pumping inverter

(Figure 1-2) independently developed and produced by our company has the following advantages:

Use independently-developed dynamic VI MPPT (Maximum Power Point Tracking)

control method. The response speed is fast. Operation is stable and reliable. It solves the

following problems: tracking effect is poor when sunlight intensity rapidly; operation is not

stable; water hammer damage.

All digital control. It has complete automatic operation, data storage, and complete

protection functions.

Solar Pumping Inverter is specially designed for solar water pump. The inner structure is

more reasonable and professional.

All key parts used in solar pumping inverter are made by international famous brands. The

quality is reliable, service life is long, and quality assurance period is long.

Component

and Part

Manufacturer

Country

IGBT Module

Infineon

Germany

Electrolytic

Capacitor

NCC

Japan

EMI Filter

VAC

Germany

DSP Control

Chip

TI

America

PV Fuse

BUSSMAN

America

The shell of solar pumping inverter is thick. The design process is improved through

abrasive tool test for many times. The appearance is elegant and exquisite, model is

compact, and weight is proper.

solar pumping inverter integrates combiner box. It includes DC switch, lightning arrester,

fuse, and optional components. It greatly simplifies and facilitates equipment installation

and maintenance, but also effectively protects the equipment.

Multiple communication interfaces such as RS485/CAN/GPRS(optional), etc. User can

check or control the running status and running mode of the system in a remote place.

The design of solar pumping inverter selects electric supply or diesel generator as standby

inverter power supply, so as to meet the comprehensive requirements of water supply.

solar pumping inverter has complete operation protection mechanisms, including output

short circuit protection, IGBT module overcurrent protection,

acceleration/deceleration/constant speed overcurrent protection,

acceleration/deceleration/constant speed overvoltage protection, input

overvoltage/undervoltage protection, motor overload protection, inverter overload

Operation Instruction of BS Series Solar Pumping Inverter Product Introduction

3

protection, output side phase loss protection, inverter module overheat protection,

grounding short circuit protection, and underload (anti-dry pumping) protection.

The main circuit uses power module (PIM), and the reliability is higher.

The small-power model uses completely-new aluminum shell, LCD display operation

panel, and directly-insert connection terminal. The appearance is beautiful. The heat

dissipation effect and protective properties are good.

Upper and lower water level detection and control circuit are optional.

Protection grade IP65 (rated power is less than 22kW); temperature of service environment:

-20 ~ +60˚C.

Figure 1-2 BS Series Pumping Inverter

1.3 Inverter Specification

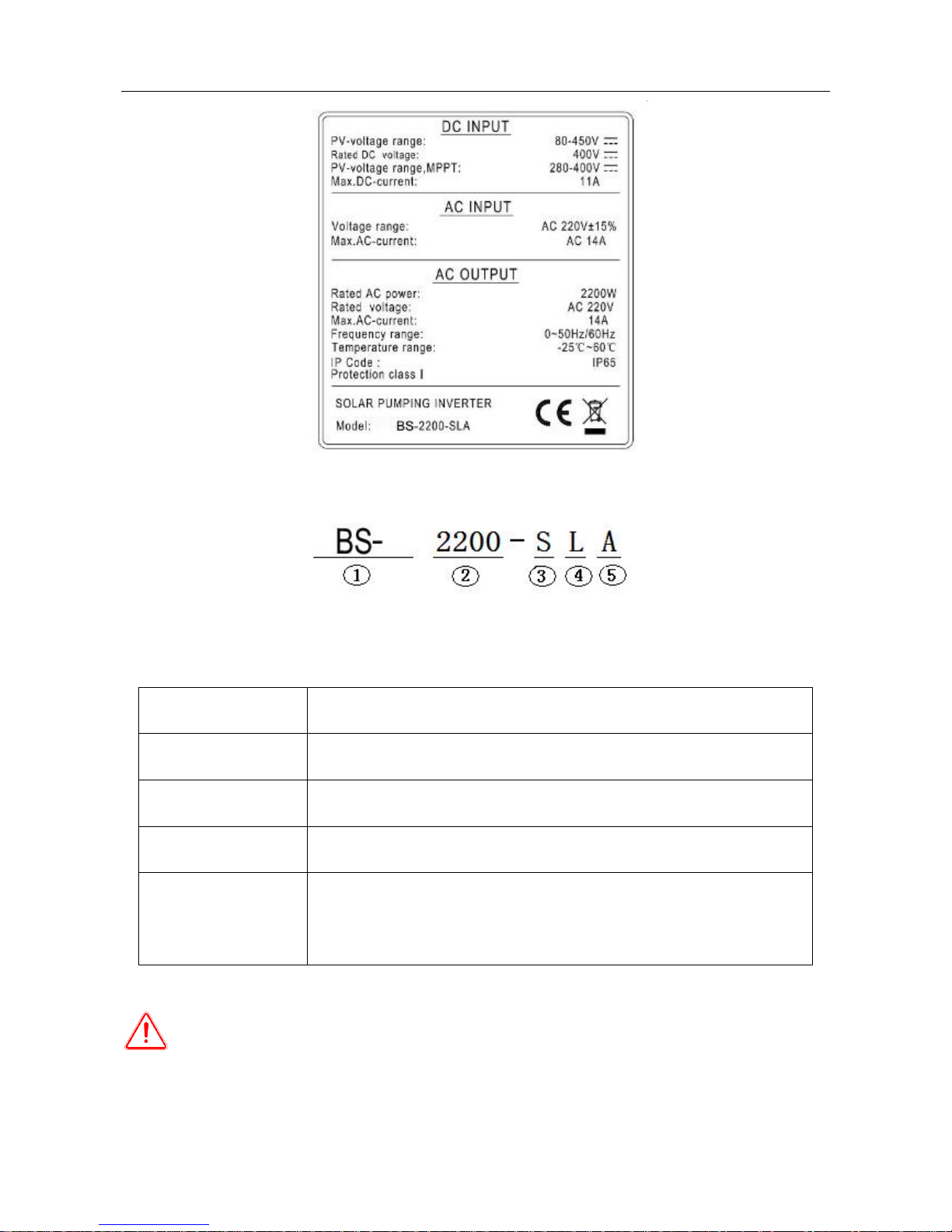

1.3.1 Introduction to Nameplate and Model

The product nameplate is located at the right lower part of inverter. The nameplate includes

important information such as product series, voltage, power grade, software version, and hardware

version. Such information provides important basis for product application, maintenance, and

after-sales service.

Operation Instruction of BS Series Solar Pumping Inverter Product Introduction

4

Figure 1-3 Introduction to Product Nameplate and Model

Identification

Introduction

1

Product Series

2

Rated Power (W) of Motor

3

Output Voltage (L: 220V None:380V)

4

A: with electric supply function None: without electric supply

function

Warning: do not rip out product nameplate label.

Operation Instruction of BS Series Solar Pumping Inverter Product Introduction

5

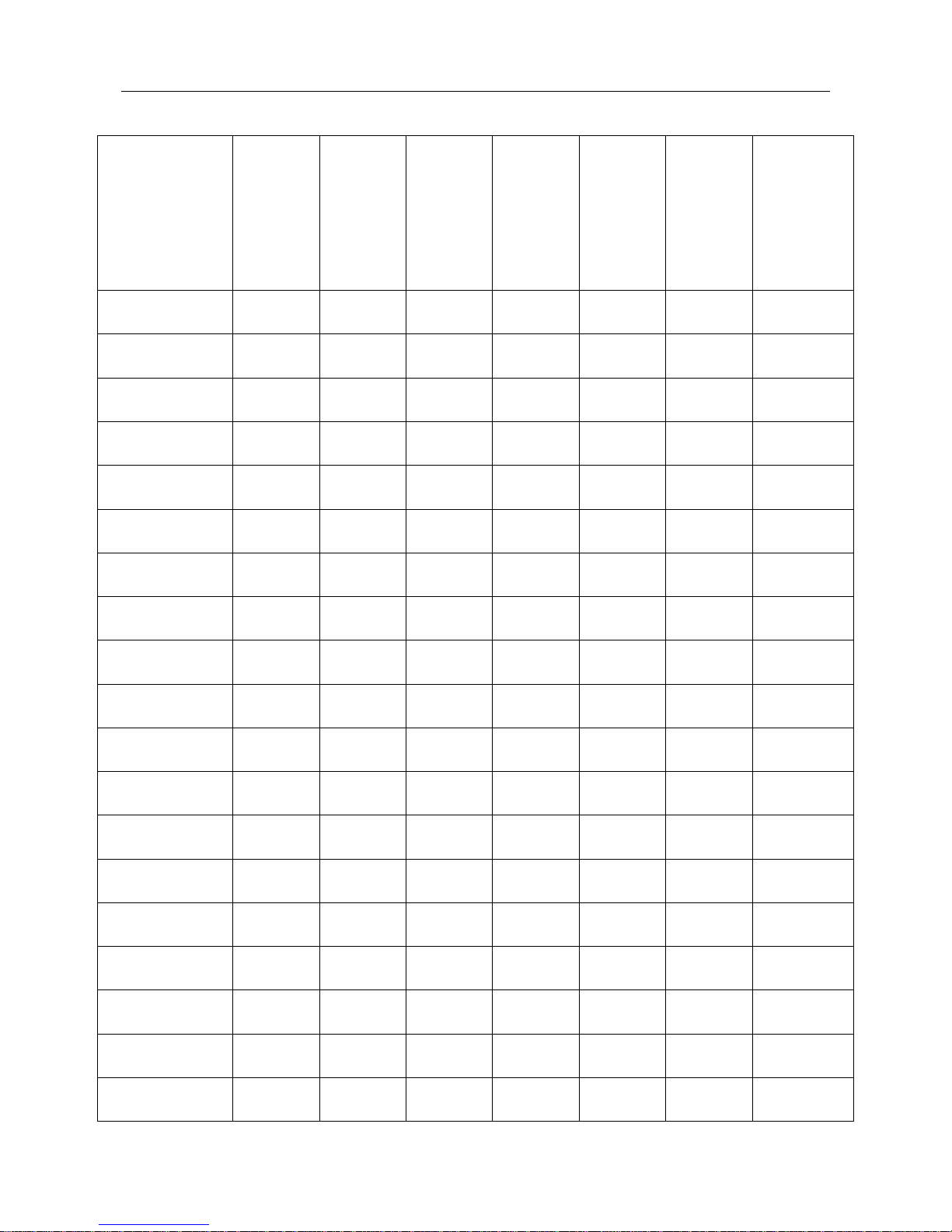

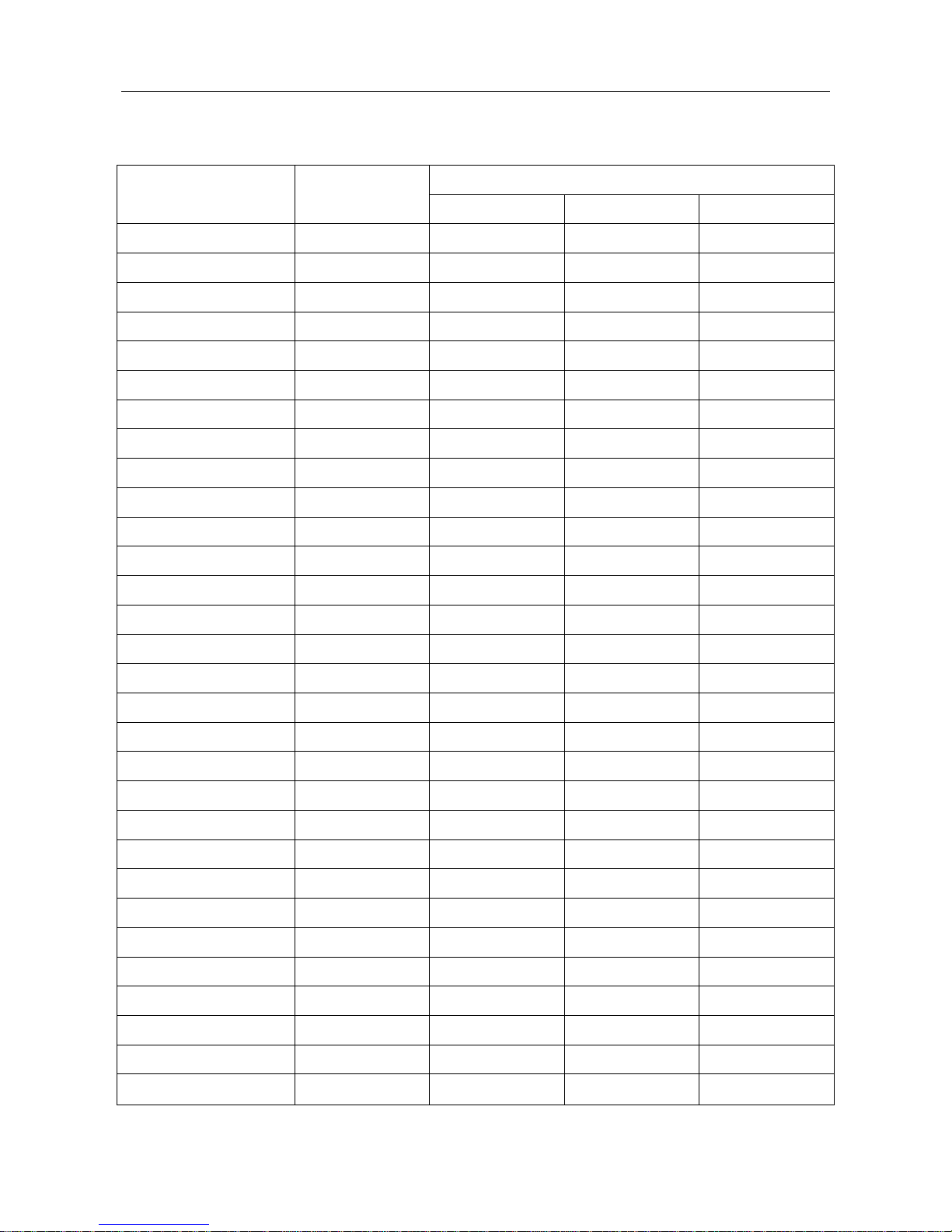

1.3.2 Product Specification and Technical Index

Model

Max.

DC input

voltage

(Vdc)

Recommen

ded MPP

voltage

(Vdc)

Start

voltage

(Vdc)

Rated

output

power(W)

Max.AC

output

current(A)

Output

frequency

(Hz)

Rated output

voltage(Vac)

BS-550-L

450

100-400

80

550

3

0-50/60

3PH 220V

BS-750-L

450

150-400

120

750

5

0-50/60

3PH 220V

BS-1100-L

450

150-400

120

1100

6

0-50/60

3PH 220V

BS-1500-L

450

200-400

120

1500

7

0-50/60

3PH 220V

BS-2200-L

450

280-400

200

2200

11

0-50/60

3PH 220V

BS-550-LA

450

100-400

80

550

3

0-50/60

3PH 220V

BS-750-LA

450

150-400

120

750

5

0-50/60

3PH 220V

BS-1100-LA

450

150-400

120

1100

6

0-50/60

3PH 220V

BS-1500-LA

450

200-400

120

1500

7

0-50/60

3PH 220V

BS-2200-LA

450

280-400

200

2200

11

0-50/60

3PH 220V

BS-3000

900

500-680

250

3000

8

0-50/60

3PH 380V

BS-4000

900

500-680

250

4000

10

0-50/60

3PH 380V

BS-5500

900

500-680

250

5500

13

0-50/60

3PH 380V

BS-7500

900

500-680

250

7500

18

0-50/60

3PH 380V

BS-9200

900

500-680

250

9200

21

0-50/60

3PH 380V

BS-11K

900

500-680

250

11000

24

0-50/60

3PH 380V

BS-13K

900

500-680

250

13000

28

0-50/60

3PH 380V

BS-15K

900

500-680

250

15000

30

0-50/60

3PH 380V

BS-18K5

900

500-680

250

18500

39

0-50/60

3PH 380V

Operation Instruction of BS Series Solar Pumping Inverter Product Introduction

6

BS-22K

900

500-680

250

22000

45

0-50/60

3PH 380V

BS-3000-A

900

500-680

250

3000

8

0-50/60

3PH 380V

BS-4000-A

900

500-680

250

4000

10

0-50/60

3PH 380V

BS-5500-A

900

500-680

250

5500

13

0-50/60

3PH 380V

BS-7500-A

900

500-680

250

7500

18

0-50/60

3PH 380V

BS-9200-A

900

500-680

250

9200

21

0-50/60

3PH 380V

BS-11K-A

900

500-680

250

11000

24

0-50/60

3PH 380V

BS-13K-A

900

500-680

250

13000

28

0-50/60

3PH 380V

BS-15K-A

900

500-680

250

15000

30

0-50/60

3PH 380V

BS-18K5-A

900

500-680

250

18500

39

0-50/60

3PH 380V

BS-22K-A

900

500-680

250

22000

45

0-50/60

3PH 380V

Warning: please select appropriate model according to solar cell array and motor load.

Warning: The input power in the above table refeBS-to multi-channel total input power. The

maximum input DC current of each group shall not exceed 15A.

Operation Instruction of BS Series Solar Pumping Inverter Installation and Wiring

7

Chapter II Installation and Wiring

2.1 Procurement Inspection

Our company has strict quality assurance system in aspects of product manufacturing,

packaging, etc. In case of abnormal condition, please contact with our company’s product dealer, or

contact with our company’s technical service center. We will provide you with solution as soon as

possible. When you get the products, please confirm the following items:

Inspection Item

Inspection Method

Whether it accords with ordered products

Inspect nameplate of product

Whether it is damaged or falls off

Check the overall appearance

Whether host computer and parts are complete

Inspect according to product checklist

Whether tightening parts such as bolt are loosened

When necessary, use screwdriver for inspection

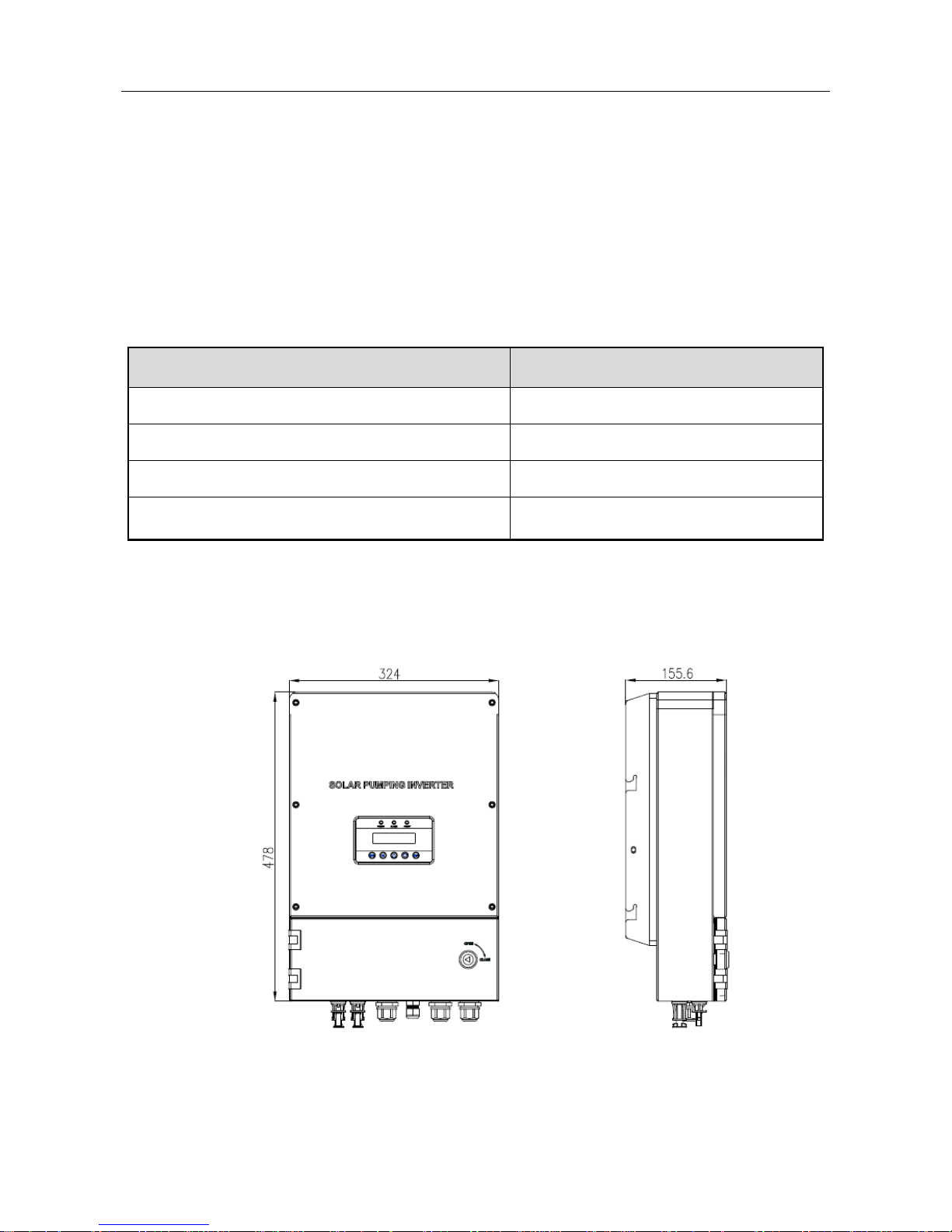

2.2 Dimension and Weight

Figure 2-1 Product Appearance and Installation Dimension

Operation Instruction of BS Series Solar Pumping Inverter Installation and Wiring

8

Product Specification Parameter:

Model

Weight(Kg)

Appearance and installation dimension (mm)

L W H

BS-550-L

5

405

297

147

BS-750-L

8

405

297

147

BS-1100-L

8

405

297

147

BS-1500-L

10

405

297

147

BS-2200-L

10

405

297

147

BS-550-LA

5

405

297

147

BS-750-LA

8

405

297

147

BS-1100-LA

8

405

297

147

BS-1500-LA

10

405

297

147

BS-2200-LA

10

405

297

147

BS-3000

14

478

325

155

BS-4000

14

478

325

155

BS-5500

15

478

325

155

BS-7500

15

563

346

148

BS-9200

15

563

346

148

BS-11K

15

563

346

148

BS-13K

16

533

405

190

BS-15K

16

533

405

190

BS-18K5

22

533

405

190

BS-22K

22

533

405

190

BS-3000-A

14

478

325

155

BS-4000-A

14

478

325

155

BS-5500-A

15

478

325

155

BS-7500-A

15

563

346

148

BS-9200-A

15

563

346

148

BS-11K-A

15

563

346

148

BS-13K-A

16

533

405

190

BS-15K-A

16

533

405

190

BS-18K5-A

22

533

405

190

BS-22K-A

22

533

405

190

Operation Instruction of BS Series Solar Pumping Inverter Installation and Wiring

9

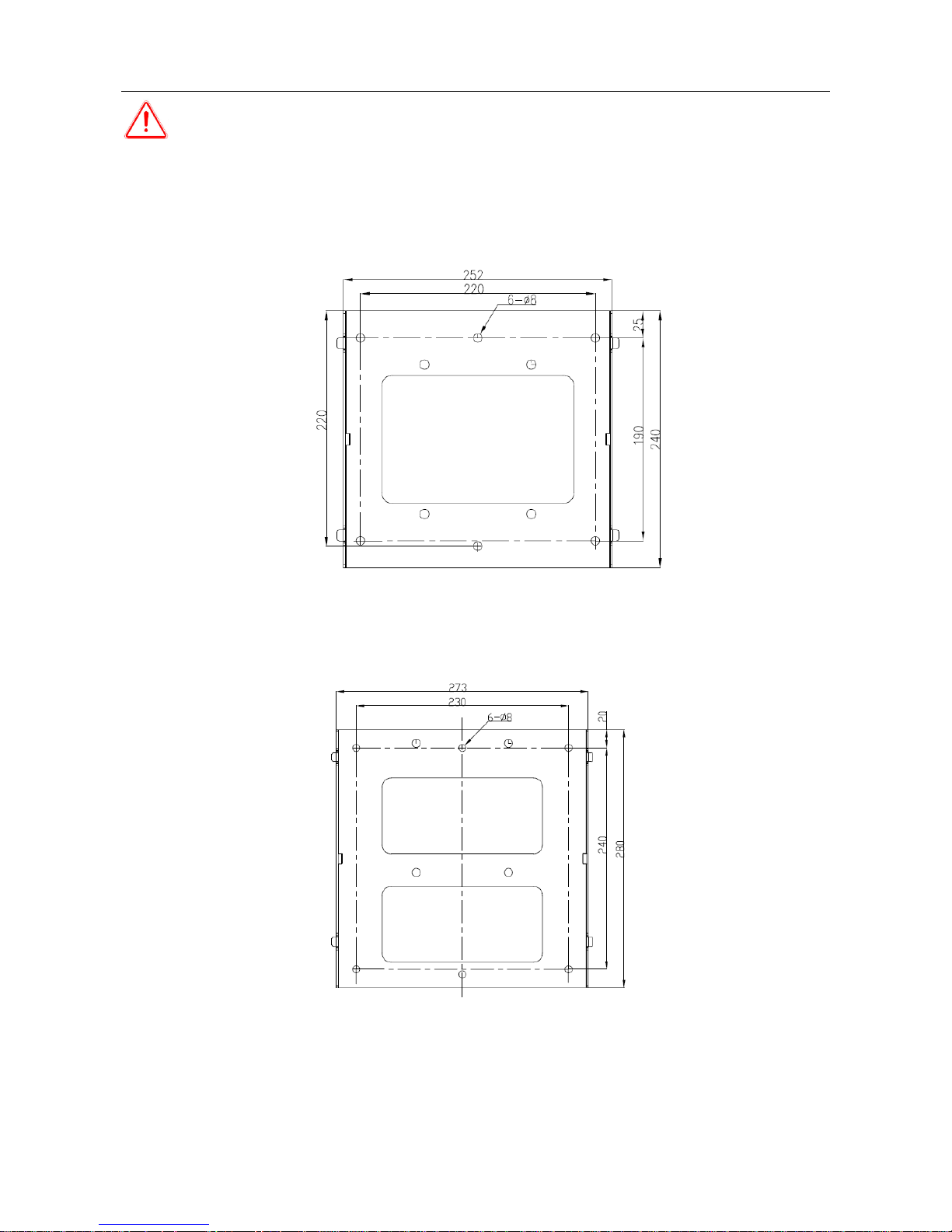

Warning: most models of BS series are hanging installation. Guarantee that the installation

backboard can bear the weight of inverter.

2.3 Installation Diagram

Figure 2-2 Installation Dimension Diagram of BS-550 to 2200

Figure 2-3 Installation Dimension Diagram of BS-3000 to 5500

Operation Instruction of BS Series Solar Pumping Inverter Installation and Wiring

10

Figure 2-4 Installation Dimension Diagram of BS-7500 to 13K

Figure 2-5 Installation Dimension Diagram of BS-15K to 22K

Operation Instruction of BS Series Solar Pumping Inverter Installation and Wiring

11

Figure 2-6 Install Safety Nut

Figure 2-7 Correct Arrangement Diagram of Inverter

Operation Instruction of BS Series Solar Pumping Inverter Installation and Wiring

12

2.4 Wiring Diagram

2.4.1 Wiring Diagram of BS-550-2200

Figure 2-8 Wiring Terminal

Figure 2-9 BS-550-L to 2200-L Wiring Diagram

PV Input Terminal

AC Input Terminal

AC Output Terminal

Water Level Terminal

Operation Instruction of BS Series Solar Pumping Inverter Installation and Wiring

13

Figure 2-10 BS-550-LA to 2200-LA Wiring Diagram

2.4.2 Wiring Diagram of BS-3000 to 5500

Figure 2-11 BS-3000 to 5500 Wiring Terminal

Operation Instruction of BS Series Solar Pumping Inverter Installation and Wiring

14

Figure 2-12 BS-3000 to 5500 Wiring Diagram

Figure 2-13 BS-3000-A to 5500-A Wiring Diagram

Operation Instruction of BS Series Solar Pumping Inverter Installation and Wiring

15

2.4.3 Wiring Diagram of BS-7500 to 13K

Figure 2-14 BS-7.5K to 13K Wiring Terminal

Figure 2-15 BS-7.5K to 13K Wiring Diagram

Operation Instruction of BS Series Solar Pumping Inverter Installation and Wiring

16

Figure 2-16 BS-7.5K-A to 13K-A Wiring Diagram

2.4.4 Wiring Diagram of BS-15K to 22K

Figure 2-17 BS-15K to 22K Wiring Terminal

Operation Instruction of BS Series Solar Pumping Inverter Installation and Wiring

17

Figure 2-18 BS-15K to 22K Wiring Diagram

Figure 2-19 BS-15K- A to 22K- A Wiring Diagram

Use key to open the lower cover of crate. There is DC switch, water level sensor connection

terminal, GPRS(optional), and AC output terminal.

Operation Instruction of BS Series Solar Pumping Inverter Installation and Wiring

18

Figure 2-20 A/O Terminal Diagram

Figure 2-21 I/O Terminal Diagram

Analog

Output

Analog

Output

Relay 1 Output

Relay 2 Output

Operation Instruction of BS Series Solar Pumping Inverter Installation and Wiring

19

Terminal Introduction

Socket

Terminal Introduction

Wiring Introduction

DC

Input

PV+

Connect with the positive pole of solar

array

PV-

Connect with the negative pole of solar

array

AC

Output

PE

Connect with protective ground wire

U

Connect with motor U phase

V

Connect with motor V phase

W

Connect with motor W phase

Water Level Sensor

Input (Switch Value)

+12V

Power supply of water level sensor

COM

Common signal grounding

S1

Auto power signal (factory settings have

been set)

S2

Water-full signal of water tower

(switching value)

S4

Water shortage signal of water

tower (switching value)

Water Level Sensor

Input (Analog Quantity)

+10V

Power supply of water level sensor

GND

Common signal ground wire

AI2

Water-full signal of water tower (analog

quantity)

AI3

Water shortage signal of water tower

(analog quantity)

RS485+

485 communication

RS485-

485 communication

CANAH

CAN communication

CANAL

CAN communication

Warning: the places of input sockets of DC positive pole and negative pole of different

models are different. Please confirm according to plug.

Warning: the signal marshalling sequence of AC output sockets of different models are

different. Please confirm according to the number on socket.

Warning: in order to guarantee that the system works normally, please select wire dimension

according to the following principle.

Operation Instruction of BS Series Solar Pumping Inverter Installation and Wiring

20

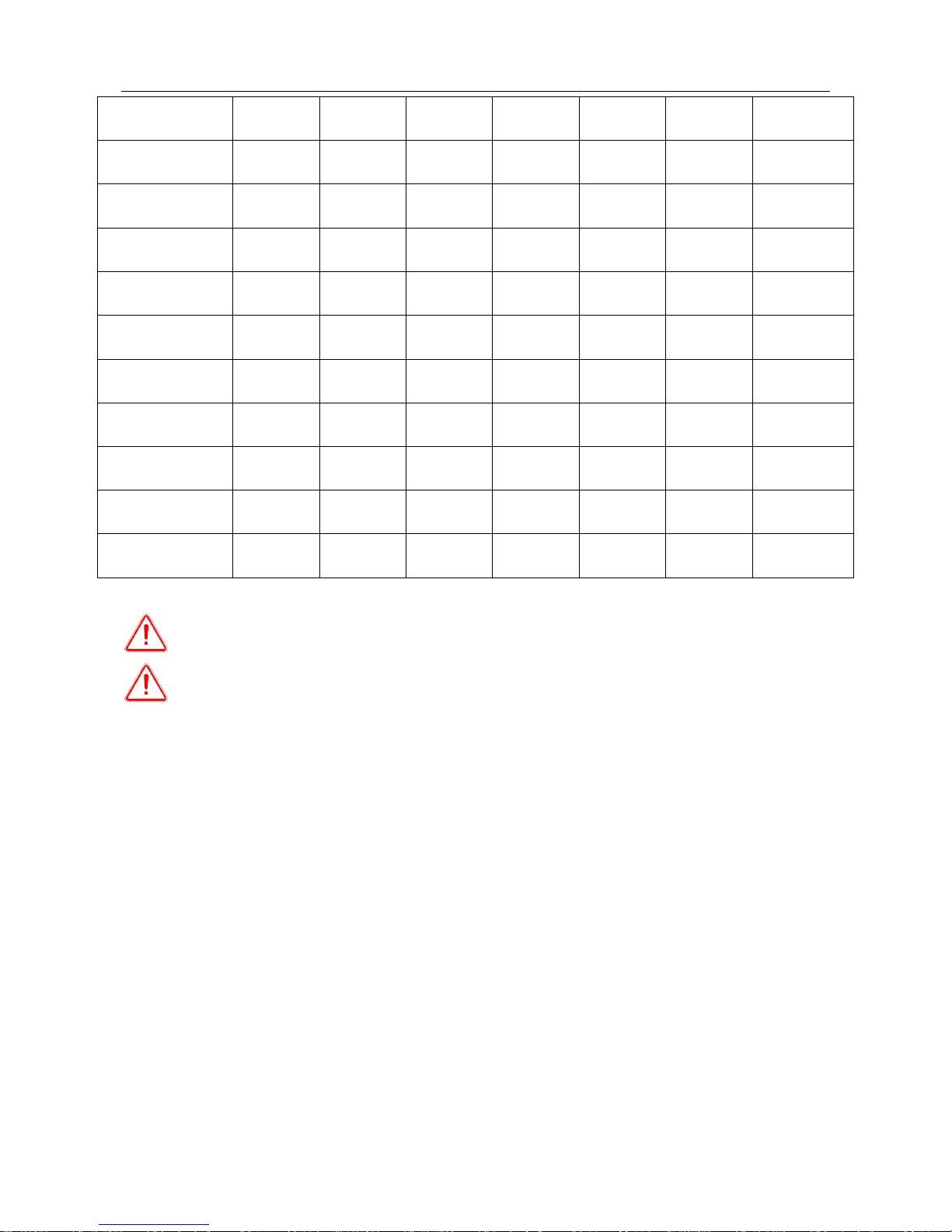

2.4.4 Recommended Diameter of Wire (mm2)

model

Recommende

d output

current(A)

Output

voltage(V)

length≤

30m

length≤

60m

length≤

90m

length≤

120m

length≤

150m

length≤

180m

length≤

210m

BS-550-L

3

1HP 230V

0.75 1 1.5

2.5

2.5

2.5

4

BS-750-L

5

3HP 220V

0.75

1.5

2.5

2.5 4 4

4

BS-1100-L

6

3HP 220V 1 1.5

2.5 4 4 4 6

BS-1500-L

7

3HP 220V 1 2.5

2.5 4 4 6 6

BS-2200-L

11

3HP 220V

1.5

2.5

2.5 6 6 6 6

BS-3000

8

3HP 380V

1.5

2.5

2.5 6 6 6 6

BS-4000

10

3HP 380V

1.5

2.5

2.5 6 6 6 6

BS-5500

13

3HP 380V

2.5

2.5 4 6 6 6

6

BS-7500

18

3HP 380V 2.5 4 6 6 10

10

BS-9200

21

3HP 380V 4 4 6

10

10

10

BS-11K

24

3HP 380V 4 6 10

10

10

16

BS-13K

28

3HP 380V 6 6 10

10

10

10

BS-15K

30

3HP 380V 6 6 10

10

16

16

BS-18K5

39

3HP 380V 6

10

10

16

16

25

BS-22K

45

3HP 380V

10

16

16

25

25

Units: mm

2

Notice: the environment temperature of the above recommended wire dimension is ≤50°C.

Notice: large-power wall-mounted model uses multiple-channel DC input. The dimension

of DC wire of each channel shall be selected according to the above table.

Operation Instruction of BS Series Solar Pumping Inverter Installation and Wiring

21

2.5 Assemble DC Connector

2.5.1 Strip the cable 6-8mm,then connect the bare wire core into core tube of connector .

Figure 2-22 DC Line connects with wiring board

2.5.2 Crimp contact barrel by using a hex crimping die.Put the contact barrel with striped cable in

the corresponding crimping notch and crimp the contact.Insert the core tube into slot of connection

until hear the voice indicating in place.

Figure 2-23

2.5.3 Insert contact cable assembly into back of the male and female connector. tight nuts according

to the opposite direction. Now wiring is finished.

Figure 2-24

2.5.4 The PV importation that will assemble a good DC conjunction machine to make an effort to

insert Inverters carries and link OK after hearing the sound of "click".

Operation Instruction of BS Series Solar Pumping Inverter Installation and Wiring

22

Warning: risk of electric shock! Before shifting solar panel, disconnect pumping inverter AC

and DC. Besides, allow 5-minute internal capacitance discharging.

2.6 Introduction to the Wiring of Water Level Sensor

Figure 2-25 Wiring Diagram of Water Level Detector

Notice: connect water level sensor 1 and detect water shortage. Respectively connect two

signal lines of sensor with S4 and COM of I/O circuit board. When water level sensor 1 detects that

the water level of well is lower than the level set by sensor, the pumping inverter will delay for 60s,

then turn off output protection pump. The water level recovers. Wait for 600s, then the pumping

inverter re-works normally.

Notice: connect water level sensor 2 to defect whether water is full. Connect two signal

lines of sensor with S2 and COM. When water level sensor 2 detects that the water level of water

tank exceeds the level set by sensor, the pumping inverter delays for 60s and turns off output; when

water level is lower than set level, wait for 120s, then pumping inverter re-starts to work normally.

DC Switch

Connect S2 and COM

Connect Three-Phase Output

Connect S4 and COM

Water Level Sensor 2

Water Pump

Water Level Sensor 1

Water Well

Impounding Reservoir

Operation Instruction of BS Series Solar Pumping Inverter Operation Control

23

Chapter III Operation Control

3.1 Panel Layout and Introduction

Solar Pumping Inverter uses LCD operation panel. The operation panel is shown in the figure,

including 3 LED lights,LCD display and 5 keys.

Figure 3-1 Keyboard Layout and Each Part Name

Indicator and Key

Name

Function Introduction

POWER

Operation

Indicator

Green

Bright: Inverter Operates

ALARM

Warning

Indicator

Yellow

Bright: warning and terminal mode

FAULT

Failure

Indicator

Red

Bright: system failure

Operation/Stop

Key

1. Press for a short time, then the inverter starts

control;

2. Press for 2s, then inverter stops control.

Operation Instruction of BS Series Solar Pumping Inverter Operation Control

24

Indicator and Key

Name

Function Introduction

Confirm/Progra

mming Key

1. Press for a short time to enter programming mode.

After altering parameter, “press for a short time” to

confirm the alteration

2. Press for 2s to return to the previous menu.

Increment Key

1. When control parameter displays state, increase

parameter number or parameter value;

2. When operation displays data state, according to

operation mode, increase output frequency or display

current operation data.

Decrement Key

1. When control parameter displays state, press for a

short time to decrease parameter number or

parameter value.

2. When operation shows data state, according to

operation mode, decrease output frequency or

display current operation data.

Shift Key

1. After entering mode of parameter editing, press

the key for a short time to conduct shifting;

2. When machine operates normally, press the key to

see the parameter of main interface.

3.2 Panel Operation Method

The operation panel display includes three modes: operation data display, control parameter

display, and historical parameter display. The default state is display state of operation data. The

default state diagram is shown as follows:

Operation

Description

Display

Initial status: Current

running data

↓

↓

Output frequency

of the inverter

Represent:50.00Hz

Set frequency of

the inverter

Represent:50.00Hz

Operation Instruction of BS Series Solar Pumping Inverter Operation Control

25

↓

↓

↓

↓

↓

Input voltage of

the inverter

Represent:542.3V

Output voltage of

the inverter

Represent:379V

Output current of

the inverter

Represent:11.1A

The relative value

of rated power

Represent:79.1%

Output frequency

of the inverter

Represent:50.00Hz

3.3 Work Mode

The inverter includes three work modes: keyboard manual mode, fully-automatic work mode,

GPRS work mode (optional). The default mode is fully-automatic work mode.

1: Keyboard manual work mode: menu S00. Setting S00.01=0. Press key

to operate. Press key for 2s, then the inverter stop working.

2: Fully-automatic work mode: menu S00. Setting S00.01=1. When sunlight is strong enough,

the inverter will automatically trace maximum power point. Under such mode, refer to inverter’s

operation parameter and DC switch to turn on/off the machine.

3: GPRS work mode (optional): menu S00. Setting S00.01=2. Under such mode, bind

Operation Instruction of BS Series Solar Pumping Inverter Operation Control

26

cellphone number. Send messages to set startup, shutdown, parameter inquiry, etc.

Warning: do not change menu S00 parameters. The default mode is fully-automatic work

mode.

3.4 Introduction to the Procedure of Wiring and Debugging

3.4.1 Procedure of Power Supply Debugging of Solar Cell

1. Conduct wiring according to system diagram and check whether wiring is correct or not.

After confirming it, turn on Q2.

Solar cell panel

Water level switch

Impounding

Reservoir

pumping

inverter

DC switch

Operation Instruction of BS Series Solar Pumping Inverter Operation Control

27

2. Conduct parameter setting for the motor

(a) Setting S00.01=0. Command code channel is keyboard manual mode instruction.

(b) Set water pump nameplate parameters: S02.01 motor rated power value; S02.02 motor rated

power value; S02.04 motor rated voltage value; S02.05 motor rated current value.

(c) After finishing parameter setting of water pump, set S00.01=1. The operation code channel is

altered as original automatic mode instruction.

See the following figure. The settings of nameplate parameters of water pump are listed as

follows (for example: 7.5KW inverter drives 5.5KW water pump):

Operation

Description

Display

Initial status:

non-historical data

display

↓

↓

↓

↓

↓

↓

Enter the main

parameter

modification interface

for long press 2s

Represent:S00 parameter group

Press OK key to enter

the branch menu

Represent:S00.00

Press UP key to view

the S00.01

Represent:S00.01

Press OK key to enter

the S00.01(the factory

set is 1)

Represent:1

Edited it to

0(controlled by

keyboard)

Represent:0

Press to save the

parameter value and

display the next code

number

Represent:S00.03

Operation Instruction of BS Series Solar Pumping Inverter Operation Control

28

Operation

Description

Display

↓

↓

↓

↓

↓

↓

↓

and

↓

↓

Return the main

parameter modification

interface for long press 2s

Represent:S00 parameter group

Long press OK for 2s to

return to the initial status

Represent:Working freq. 50.00Hz

Long press ON/OFF key

for 2s to stop the inverter.

Represent:Set freq. 50.00Hz

Enter the main

parameter

modification interface

for long press 2s

Represent:S00 parameter group

Press the UP key to

S02 group

Represent:S02 parameter group

Press OK key to enter

the S02.01

Represent:S02.01

Edited the rated

power to 5.5kW

Represent:5.5kW

Press OK turn to

S02.02

Represent:S02.02

Press UP key to S02.05

and enter

Represent:S02.05

Edited the rated

current of the pump(it

will write in pump)

e.g.11.3A

Represent:11.3A

Operation Instruction of BS Series Solar Pumping Inverter Operation Control

29

Operation

Description

Display

↓

and

↓

↓

↓

↓

↓

or

↓

↓

↓

Press to save the

parameter value

and

return to the branch

menu

Represent:S00 parameter group

Long press OK for 2s to

return to the main menu

Represent:S02 parameter group

Press DOWN key to S00

parameter group.

Represent:S00 parameter group

Press OK key to enter the

branch menu.

Represent:S00.00

Press UP or DOWN key

to view the S00.01

Represent:S00.01

Press OK key to enter

the S00.01.

Represent:0

Edited it to 1

(controlled by

terminals)

Represent:1

Press to save the

parameter value and

display the next code

number.

Represent:S00.03

Long press OK for 2s to

return to the main menu.

Represent:S00 parameter group

Long press OK for 2s to

return to the

initial

status.

Represent:50.00Hz

Operation Instruction of BS Series Solar Pumping Inverter Operation Control

30

Operation

Description

Display

↓

↓

↓

Turn off the DC switch,

waiting the LCD display off,

then turn on the DC

switch, the inverter will

auto-start to drive

pump(5.5kW)

3. After finishing all parameter settings, turn off Q2 of DC switch. After display screen is OFF for

5 minutes, turn on AC output. Then turn on DC input switch Q2. Wait for 60s. The machine will

operate automatically.

3.4.2 Procedure of Power Supply Debugging of Power Grid (Diesel Engine)

1. Conduct wiring according to systematic diagram and check whether the wiring is correct.

Operation Instruction of BS Series Solar Pumping Inverter Operation Control

31

2. Turn off Q2 switch, then turn on Q1 switch.

3. After power-on, adjust motor parameter according to Item 2 of Article 3.4.1.

4. After finishing all parameter settings, turn off Q1 of AC input switch. After display screen is

off for 5 minutes, turn on AC output switch. Then turn on Q1 of AC input switch. Wait for 60s. The

equipment will operate automatically.

5. When solar power supply is used, turn off Q1 and turn on Q2 (Attention: it is forbidden to

turn on Q1 and Q2 at the same time).

Warning: do not change inverter’s control parameters at random, or else the system may not

work normally.

3.4.3 Introduction to function parameter:

Solar cell panel

Solar

pumping

inverter

Power grid

Water level

switch

Impounding

Reservoir

DC switch

Operation Instruction of BS Series Solar Pumping Inverter Operation Control

32

SN

Name

Scope

Introduction

Factory Value

S00.01

Operation code

channel

0~2

0: keyboard operation code channel

(LED is off)

1: terminal operation code channel

(LED flickers)

2: communication operation code

channel (LED is bright)

1

S02.01

Rated power of

asynchronous

motor

0.1 ~ 3000.0

0.1 ~ 3000.0kW

Model

confirmation

S02.02

Rated frequency

of asynchronous

motor

0.01 ~ S00.03

0.01 ~ S00.03

50.00Hz

S02.04

Rated voltage of

asynchronous

motor

0 ~ 1200

0 ~ 1200V

Model

confirmation

S02.05

Rated current of

asynchronous

motor

0.8 ~ 6000

0.8 ~ 6000A

Model

confirmation

Operation Instruction of BS Series Solar Pumping Inverter Operation Control

33

Chapter IV: Failure Diagnosis

4.1 Explanation and Solution for Fault Code

BS series solar pumping inverter has complete protection. When system suffers failure, the

inverter will take protective measures: the general protective measures are to stop the output of

drive signal of motor and forbid to re-start within a certain period.

When failure or protection happens, the failure or protection needs to reset the inverter. Power

off input power supply, then power on it. If the failure is not still settled, please contact with

manufacturer to settle it.

The common failures are listed as follows:

Code

Code Description

Possible Reasons

Countermeasures

Power off

No failure

Inc over Volt

Dec over Volt

Con over Volt

Overvoltage

Input voltage is too

high

Check the voltage of solar

array

Vbus low

Undervoltage

Input voltage is too

low

Illumination

intensity is too

weak

Check the voltage of solar

array

In cover Current

Dec over Current

con over Current

Overcurrent

The load of water

pump is too large

The voltage of cell

array is too low

The motor wiring

is too long

Replace small-power water

pump load

Check the voltage of solar

array

Shorten the wiring between

inverter and motor

Overload Tel

Water pump is

overload

Load is too large

Decrease maximum operation

frequency

Operation Instruction of BS Series Solar Pumping Inverter Operation Control

34

Overload VVVF

Inverter is

overload

The inverter load is

too large

Decrease power grade of water

pump

IGBT shortcut

Module

overcurrent

Output short circuit

or grounding

Module damage

Check wiring

Seek services from

manufacturer

Inv Overtemp

Module is

over-temperatur

e

Air flue is blocked

Environment

temperature is too

high

Clean air flue or improve

ventilation

Scarce Phase Out

Output default

phase

Equipment or

circuit damage

Seek services from

manufacturer

Shortcut GND 1

Grounding

short circuit

The output line

may be connected

with ground

Curr test Fault

Current

detection failure

Seek services from

manufacturer

Lack load

Water pump

conducts

“dry-operation”

Water pump’s

connection wires

are all open circuit.

Water pump does

not match inverter.

Check water level. Check

whether the water pump wiring

condition and water pump

power meet the requirements of

inverter capacity

No Water

Water shortage

Water shortage

warning. If water is

provided, it can

recover

automatically

Water Full

Water full

When water level

decreases. It can

recover

automatically

Com Fault

Communication

failure

Device or circuit

damage

Reset

Seek services from

manufacturer

Warning: before resetting, completely find out failure reasons and eliminate the reasons. If it

fails to reset or suffers failure again, find out the reasons. The continuous resetting will damage

inverter.

Operation Instruction of BS Series Solar Pumping Inverter Operation Control

35

36

Chapter V Maintenance

5.1 Daily Inspection and Maintenance

Affected by environment temperature, humidity, vibration, and inverter internal component

aging, the inverter may suffer some potential problems during operation. In order to stably operate

the inverter for a long term, conduct periodical inspection once each year.

5.1.1 Requirements of Inspection and Maintenance

1. The inspection shall be conducted by professional technician. When necessary, cut off the

power supply of inverter.

2. Avoid leaving metal components and parts in inverter, or else it may damage the equipment.

3. The inverter has conducted electrical insulation experiment before leaving factory, so the

user needn’t conduct high-voltage insulation test.

4. If you intend to conduct insulation test on inverter, all input and output terminals must be

short circuit reliably. It is forbidden to conduct insulation test on single terminate. Please

use 500V megameter during test.

5. It is forbidden to use megameter to measure control loop.

6. When conducting insulation test on motor, remove the connecting line between motor and

inverter.

5.1.2 Key Points of Inspection and Maintenance

Please use the inverter under the environment recommended in the manual and conduct

inspection and maintenance according to the following table.

Inspection Frequency

Inspection Item

Inspection Content

Judgment Standard

Daily

Periodically

√

Operating

Environment

1.Temperature and

humidity

2. Dust and gas

1. Temperature <50°C

2. Humidity <90%, without moisture

condensation

3. No peculiar smell. No combustible or

explosive gas

√ Cooling System

1. Installation

environment

2. Radiator

1. The ventilation of installation

environment is good

2. The air flue of radiator is not blocked

√ Inverter Body

1. Vibration, temperature

rise

2. Noise

3. Wire, terminal

1. Vibration is stable and shell

temperature rise is normal

2. No abnormal noise or peculiar smell

3. Tighten the screw

√ Motor

1. Vibration, temperature

rise

2. Noise

1. Operate stably. Temperature is normal.

2. No abnormal noise

√

Input and Output

Parameter

1. Input Voltage

2. Output Current

1. Input voltage is in specified scope

2. Output current is under rated value

37

5.2 Inspection and Replacement of Quick-wear Parts

5.2.1 Filter Capacitor

The pulsating current of main loop will affect the performance of filter capacitor of aluminium

electrolysis. The affected degree and environment temperature are related to service environment.

Under normal conditions, the inverter shall change electrolytic capacitor once every 10 years. When

electrolyte of electrolytic capacitor leaks, safety valve emits, or capacitance expands, replace it

immediately.

5.2.2 Fax cooling

In BS series pumping inverter, the inverter above BS-22K has cooling fan inside. The service

life of cooling fan is about 15000 houBS-. If fan has abnormal nose or generates vibration, replace

it immediately.

5.3 Storage and Maintenance

5.3.1 Storage

After purchasing inverter, if you do not use it temporarily or decide to store it for a long time,

pay attention to the following items:

1. Avoid putting inverter on the places in which temperature is high, air is humid, or places

where there is vibration or metal dust. Guarantee good ventilation.

2. If the inverter is not used for a long term, the internal filter capacitor characteristic will

decrease. Power on twice every two years to recover the characteristics of filter capacitor.

At the same time, check the functions of inverter. During power-on, gradually increase the

voltage through DC power supply. The power-on time shall not be less than 5 hours.

5.3.2 Maintenance

The warranty period of inverter is 2 years(since production date). During warranty period, if

inverter suffers failure or damage under normal conditions, our company provides maintenance

service free of charge. After warranty period, our company also provides paid maintenance services.

During warranty period, if the failure is caused due to the following reasons, some

maintenance fees will be charged.

1. Failure caused by violation of operation manual or standards;

2. Without authorization, user repairs and transforms the inverter.

3. Failure caused by improper storage;

4. Use inverter for abnormal functions;

5. Failure caused by fire disaster, salt corrosion, gas corrosion, earthquake, windstorm,

flood, lightning, abnormal voltage, or other force majeure.

Notice: the warranty scope only refers to inverter body.

38

Quality Assurance

Warranty Policy:

Warranty period: Our company provides series solar pumping inverter with warranty period

of 24 months. The systematic components provided by our company have 12-month warranty

period.

Starting date of warranty period: the date when user gets goods from our dealer.

Warranty proof: product series number and local dealer’s shipment invoice.

Notice: if client does not provide shipment invoice and other documents, our company will use

the date which is 2 months after delivery date, as starting date of warranty period.

Scope: during warranty period, the scope and responsibility of any damage shall be appraised

by dealer and our company.

Warranty principle:

In order to provide our company final users with better services, all the dealers authorized

shall reply user’s warranty request. During warranty period, the dealer will replace all defective

products and parts in aspects of design and production.

(1) Warranty card is not sent to dealer or our company.

(2) Product change, design alteration, or component replacement is not approved by our

company.

(3) Alter, change or try to repair it. The serial number is wiped out or does not has our

company technician’s seal.

(4) Wrong installation and debugging

(5) Does not abide by proper safety regulation (CQC standards, etc.)

(6) The product is improperly stored and damaged by final user.

(7) Transportation damage. During transportation, the paint is scratched. During unloading, if

enough evidence is available, apply in insurance company as soon as possible.

(8) Fail to abide by user’s manual, installation guidance, and maintenance regulation.

(9) Incorrect use or improper operation

(10) Shortage of ventilating device

(11) The product maintenance procedure does not abide by or implement an acceptable

standard.

39

(12) Force majeure (such as lightning, over-voltage, thunderstorm, fire disaster)

If claim exceeds the power quoted in warranty principle,our company shall not undertake legal

responsibilities, including the following conditions: claim compensation due to direct or indirect

damaged caused by defective equipment; claim compensation due to the damage caused by removal

and installation; profit loss not specified in our company warranty scope.

Warranty and Claim Procedure:

Please send a simple failure description report to our company local dealer. If we agree to

replace, we will issue an equivalent replacement device according to model and year length. The

rest warranty rights will be transferred to replacing equipment. Under such condition, as your power

has been filed in our company, you will not receive a new certification. The surstitute goods will be

delivered within 2 working days. The defective equipment is to use the transportation packaging to

transport to dealer. If on-site re-installation is necessary, the end-user shall consult with dealer in

advance. All maintenance services during warranty period are free of charge.

40

Warranty Card

Client Name

Contact

Person

Client Address

Contact Tel.

Product

Specification

Procurement

Date

Equipment Code

Warranty

Date

(since

production

date)

Distribution Unit

(Seal)

Packing List

(1) Main engine quantity: One set

(2) Instruction book (including warranty card) quantity: one

(3) Patch plug of positive pole of solar cell array quantity: one

(4) Patch plug of negative pole of solar cell array quantity: one

(5) Water level sensor quantity: one (optional)

Loading...

Loading...