enertik BS-750-L, BS-550-LA, BS-1500-L, BS-750-LA, BS-1100-LA User Manual

...

Solar Pumping Inverter

User’s Manual

Preface

In order to give full play to the product performance and guarantee the safety of user and

equipment, before installation and use, please carefully read the manual.

In order to facilitate daily inspection and maintenance of inverter and understand abnormal

reason and solutions, please keep the instruction properly.

If you have any questions or special requirements during use, please contact with our

company’s product dealer or directly contact with our company’s technical service center.

If the manual contents change, we may not offer notice.

Operation Instruction of BS Series Solar Pumping Inverter Precautions

I

Contents

Precautions ................................................................................................................................ II

Chapter I Product Introduction ............................................................................................ 1

1.1 Introduction to Solar Pumping System ................................................................................ 1

1.2 Product Characteristics ........................................................................................................ 2

1.3 Inverter Specification ........................................................................................................... 3

Chapter II Installation and Wiring .......................................................................................... 7

2.1 Procurement Inspection ....................................................................................................... 7

2.2 Dimension and Weight ......................................................................................................... 7

2.3 Installation Diagram ............................................................................................................ 9

2.4 Wiring Diagram ................................................................................................................. 12

2.5 Assemble DC Connector .................................................................................................... 21

2.6 Introduction to the Wiring of Water Level Sensor ........................................................... 222

Chapter III Operation Control ............................................................................................... 23

3.1 Panel Layout and Introduction ........................................................................................... 23

3.2 Panel Operation Method .................................................................................................... 24

3.3 Work Mode ........................................................................................................................ 26

3.4 Introduction to the Procedure of Wiring and Debugging .................................................. 26

Chapter IV: Failure Diagnosis ................................................................................................ 35

4.1 Explanation and Solution for Fault Code .......................................................................... 33

Chapter V Maintenance........................................................................................................... 37

5.1 Daily Inspection and Maintenance .................................................................................... 37

5.2 Inspection and Replacement of Quick-wear Parts ............................................................. 38

5.3 Storage and Maintenance ................................................................................................... 38

Quality Assurance .................................................................................................................... 39

Warranty Card ......................................................................................................................... 42

Operation Instruction of BS Series Solar Pumping Inverter Precautions

II

Precautions

The safe operation of the product is subject to correct transportation, installation, operation,

and maintenance. Before conducting these tasks, please pay attention to relevant safety instructions.

The warnings related to safety in the manual are listed as follows:

Grounding Wire of Equipment

AC Value

DC Value

Phase

Before operating inverter, please read the instruction.

5minutes

In order to avoid electric shock, breack off machine with PV terminal and

AC terminal for at least 5 minutes, then contact the wire of machine output

terminal and input terminal

Warning: when machine works, the temperature of metal shell may be

very high.

Procurement Inspection

Warning

1. If the inverter is found to suffer damage or lack in component and part, do not

install it, or else it may cause accident!

Installation

Warning

1. In order to guarantee good effect of convection cooling, the inverter shall be

installed vertically. Keep at least 10cm space between upward side and downward

side.

Operation Instruction of BS Series Solar Pumping Inverter Precautions

III

2. Try to install it in the indoor place with ventilation opening or air interchanger. It is

forbidden to install it directly under sunshine.

3. During installation, do not discard residue of drill hole into inverter cooling find or

fan, which may affect heat dissipation.

Wiring

Danger

1. The wiring shall be conducted by qualified electric technician, or it may cause

electric shock or fire disaster.

2. Before wiring, please confirm that the input power has been cut off, or else it may

cause electric shock or fire disaster.

3. The grounding terminal must be grounded reliably, or else the inverter shell may

have electricity.

4. The solar array, motor load, and inverter model selection shall be reasonable, or

else it may damage equipment.

Warning

1. Please use specified moment of force to tighten terminal, or else it may cause fire

disaster.

2. Do not connect capacitance or phase advance LC/RC noise filter in the output end

of inverter. When the distance between inverter and motor load is over 100m, it is

advised to use output reactor.

Operation

Danger

1. Power on after confirming that the wiring is correct, or it may damage inverter or

fire disaster.

2. During electricity, do not change wiring, or else it may cause electric shock.

Operation Instruction of BS Series Solar Pumping Inverter Precautions

IV

Warning

1. Before the first operation, please adjust some control parameters according to

operation instruction. Do not alter the control parameters of inverter at random, or

else it may damage the equipment.

2. During operation, the temperature of radiator is very high. Do not touch the

radiator, or else it may scald you.

3. When height above sea level exceeds 1000m, the inverter shall be used under rated

power. If the height increases by 1500m, the output current shall decreases by 10%.

Miscellaneous

Danger

1. Assign qualified electric technician for maintenance and inspection.

2. During power-up state, do not remove the inverter. After outage, wait for 5 minutes

at least, then conduct maintenance and inspection, so as to avoid that the residual

voltage on electrolytic capacitor of major loop may cause damage to people.

3. It is forbidden to transform the inverter without authorization, or else it may

damage personnel or equipment.

4. When handling scrapped inverter, please dispose the inverter as industrial waste.

The inner electrolytic capacitor may explode during burning. Some components and

parts may generate hazardous and harmful gas during combustion.

Operation Instruction of BS Series Solar Pumping Inverter Product Introduction

1

Chapter I Product Introduction

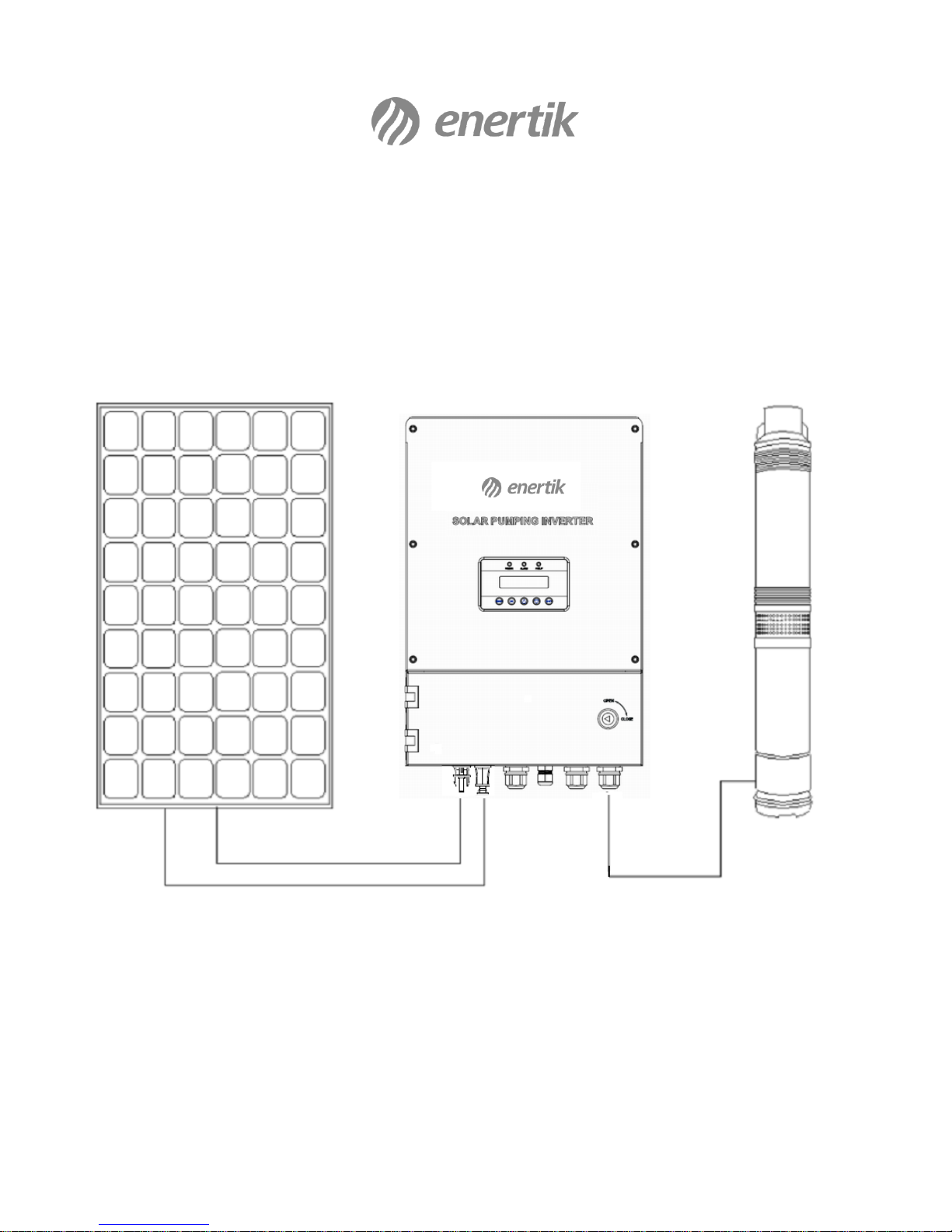

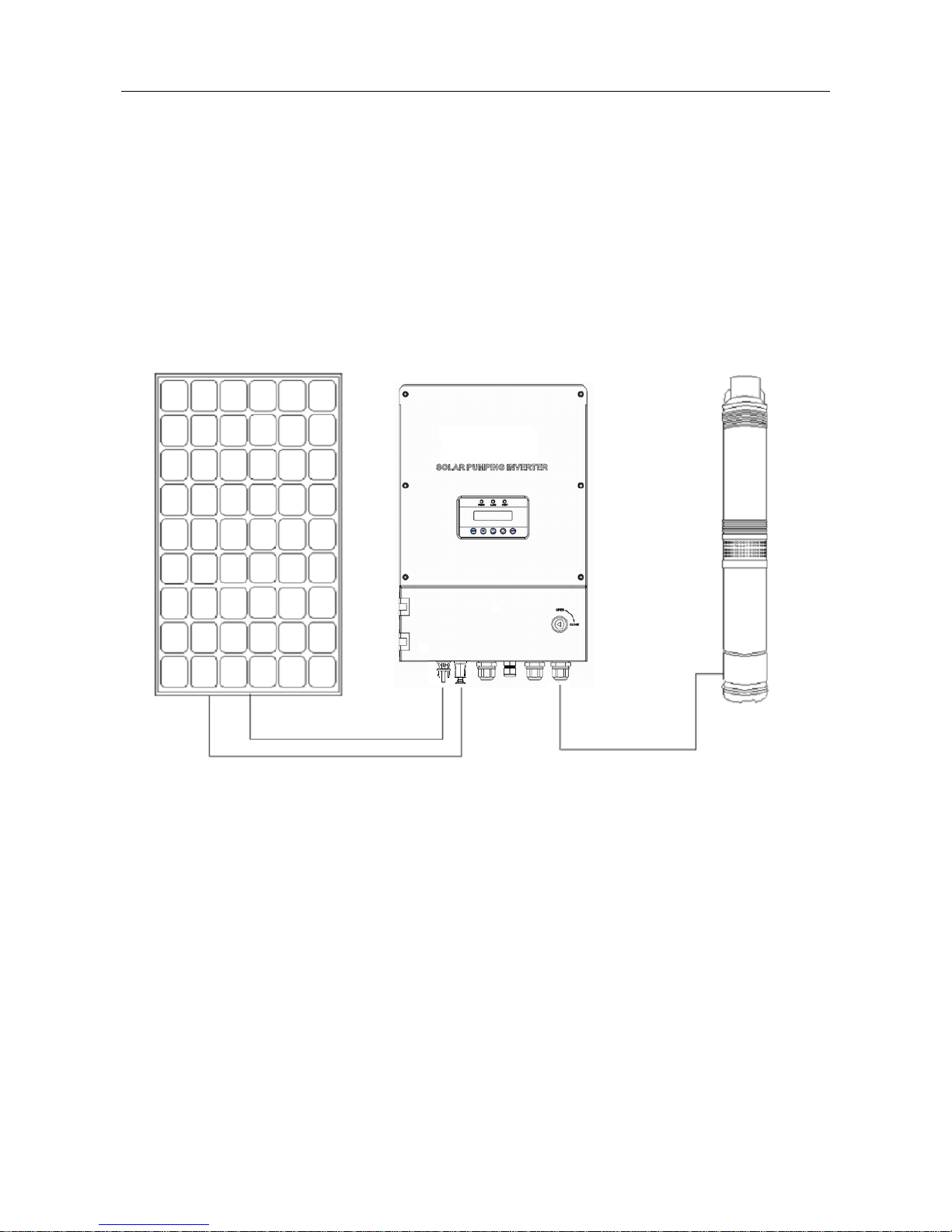

1.1 Introduction to Solar Pumping System

Solar Pumping System is widely applied in domestic water, agricultural irrigation, forestry

watering, desert control, grassland animal husbandry, island water supply, water treatment project,

etc. During recent years with the enhancement of new energy utilization, solar pumping system is

widely applied in the landscape and water spray system of municipal works, urban square, garden

sightseeing, tourist resort, hotel, and residential community. The system consists of solar cell array,

pumping inverter, and water pump(figure 1-1). Based on the design philosophy of saving water first,

the system omits energy storing device such as accumulator.

Figure 1-1 Structure of Solar Pumping System

The solar cell array is made from the series connection and parallel connection of several solar

cell modules, which absorb solar radiation energy and transform it into electric energy, so as to

supply electric power for the whole system. The pumping inverter controls and regulates the

operation of the system, transforms the direct current of solar cell array into alternating current to

drive water pump. In addition, according to the change of sunlight intensity, regulate output

frequency timely, to realize MPPT (Maximum Power Point Tracking). The water pump is driven by

three-phase AC motor. It pumps water from deep well, river, and lake, then inject water into water

storage tank/pool, or directly connect with irrigation system or fountain system, etc. According to

actual requirements of system and installation, different types of water pumps such as centrifugal

pump, axial flow pump, mixed-flow pump, or deep-well pump can be used.

DC Voltage

Three-Phase AC Voltage

Operation Instruction of BS Series Solar Pumping Inverter Product Introduction

2

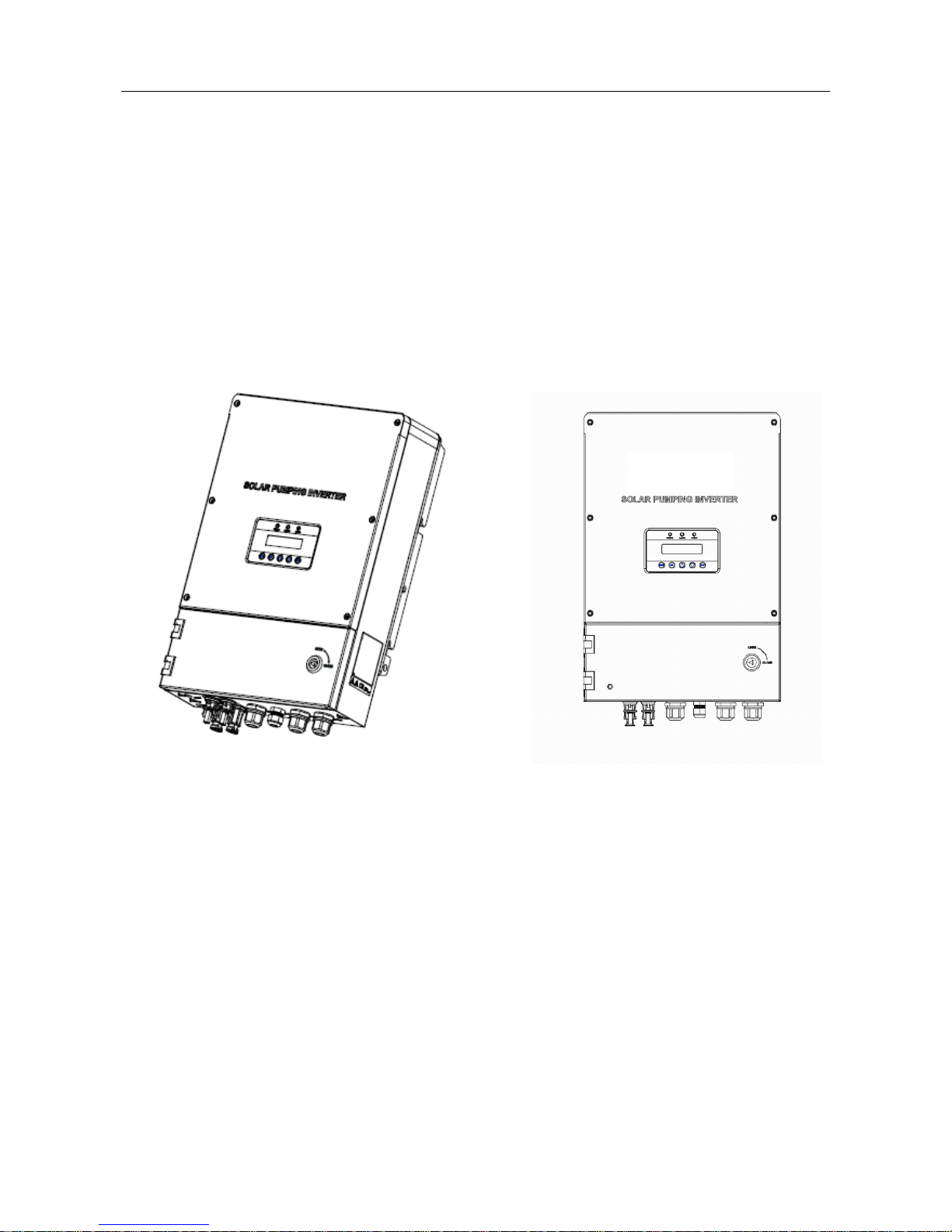

1.2 Product Characteristics

On the basis of many-year research, development, and experiment, the pumping inverter

(Figure 1-2) independently developed and produced by our company has the following advantages:

Use independently-developed dynamic VI MPPT (Maximum Power Point Tracking)

control method. The response speed is fast. Operation is stable and reliable. It solves the

following problems: tracking effect is poor when sunlight intensity rapidly; operation is not

stable; water hammer damage.

All digital control. It has complete automatic operation, data storage, and complete

protection functions.

Solar Pumping Inverter is specially designed for solar water pump. The inner structure is

more reasonable and professional.

All key parts used in solar pumping inverter are made by international famous brands. The

quality is reliable, service life is long, and quality assurance period is long.

Component

and Part

Manufacturer

Country

IGBT Module

Infineon

Germany

Electrolytic

Capacitor

NCC

Japan

EMI Filter

VAC

Germany

DSP Control

Chip

TI

America

PV Fuse

BUSSMAN

America

The shell of solar pumping inverter is thick. The design process is improved through

abrasive tool test for many times. The appearance is elegant and exquisite, model is

compact, and weight is proper.

solar pumping inverter integrates combiner box. It includes DC switch, lightning arrester,

fuse, and optional components. It greatly simplifies and facilitates equipment installation

and maintenance, but also effectively protects the equipment.

Multiple communication interfaces such as RS485/CAN/GPRS(optional), etc. User can

check or control the running status and running mode of the system in a remote place.

The design of solar pumping inverter selects electric supply or diesel generator as standby

inverter power supply, so as to meet the comprehensive requirements of water supply.

solar pumping inverter has complete operation protection mechanisms, including output

short circuit protection, IGBT module overcurrent protection,

acceleration/deceleration/constant speed overcurrent protection,

acceleration/deceleration/constant speed overvoltage protection, input

overvoltage/undervoltage protection, motor overload protection, inverter overload

Operation Instruction of BS Series Solar Pumping Inverter Product Introduction

3

protection, output side phase loss protection, inverter module overheat protection,

grounding short circuit protection, and underload (anti-dry pumping) protection.

The main circuit uses power module (PIM), and the reliability is higher.

The small-power model uses completely-new aluminum shell, LCD display operation

panel, and directly-insert connection terminal. The appearance is beautiful. The heat

dissipation effect and protective properties are good.

Upper and lower water level detection and control circuit are optional.

Protection grade IP65 (rated power is less than 22kW); temperature of service environment:

-20 ~ +60˚C.

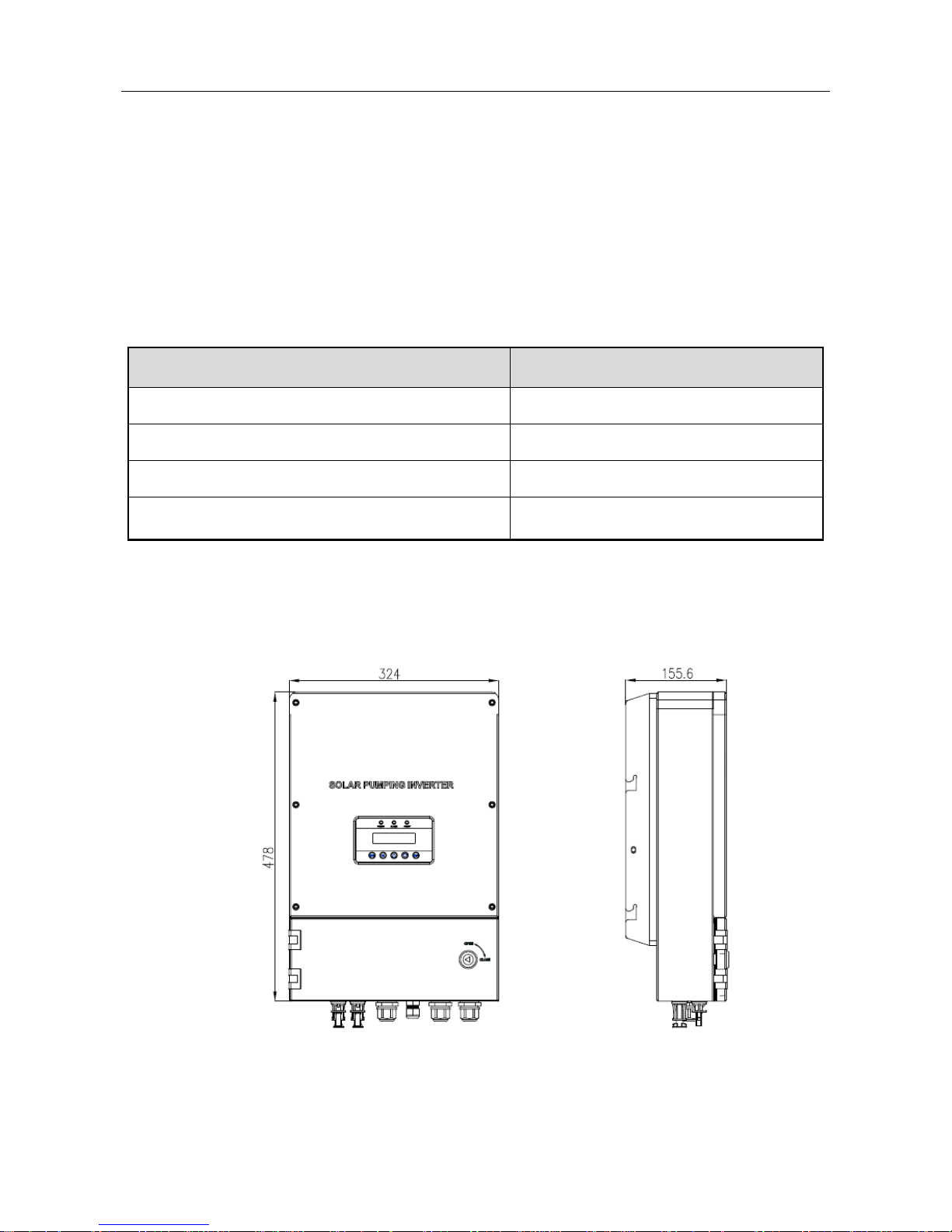

Figure 1-2 BS Series Pumping Inverter

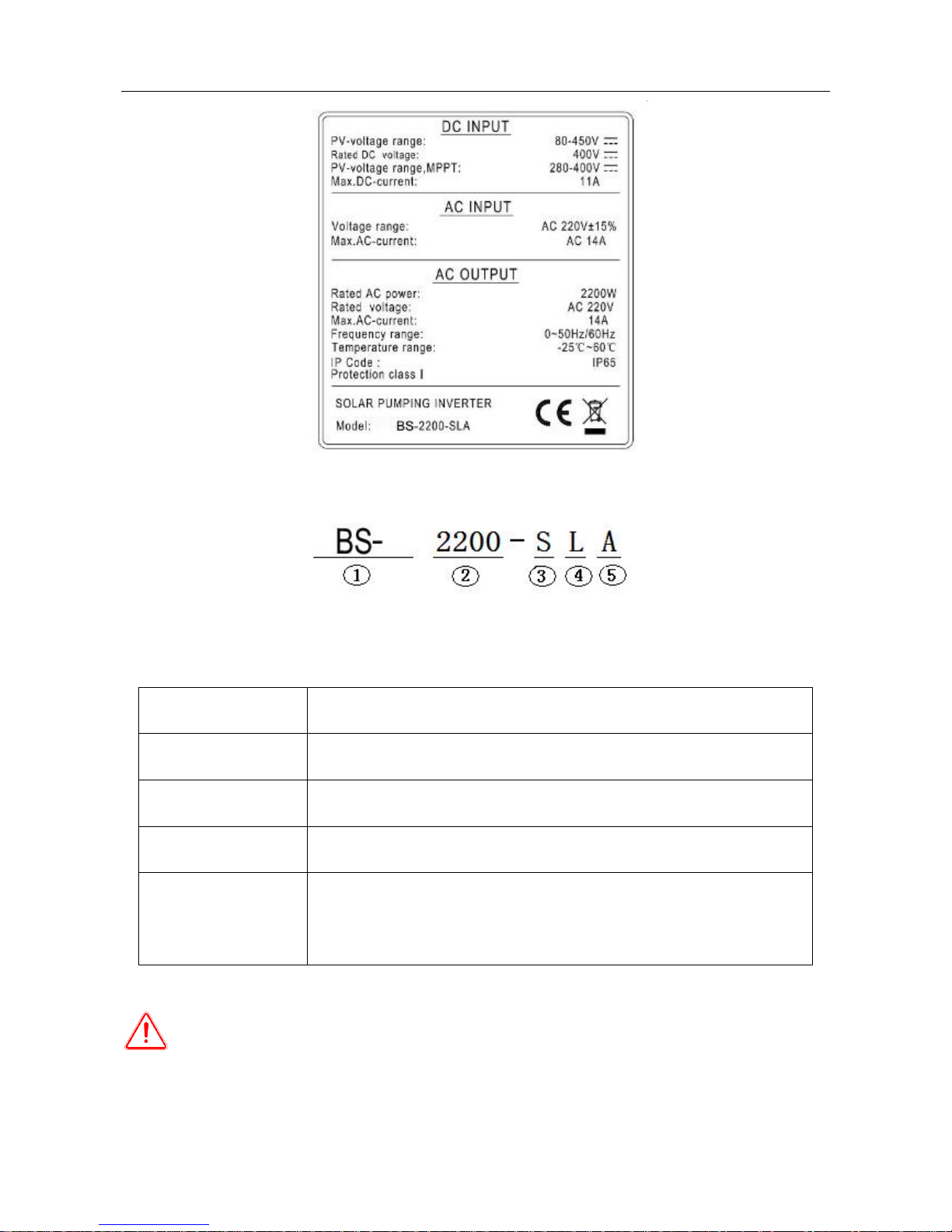

1.3 Inverter Specification

1.3.1 Introduction to Nameplate and Model

The product nameplate is located at the right lower part of inverter. The nameplate includes

important information such as product series, voltage, power grade, software version, and hardware

version. Such information provides important basis for product application, maintenance, and

after-sales service.

Operation Instruction of BS Series Solar Pumping Inverter Product Introduction

4

Figure 1-3 Introduction to Product Nameplate and Model

Identification

Introduction

1

Product Series

2

Rated Power (W) of Motor

3

Output Voltage (L: 220V None:380V)

4

A: with electric supply function None: without electric supply

function

Warning: do not rip out product nameplate label.

Operation Instruction of BS Series Solar Pumping Inverter Product Introduction

5

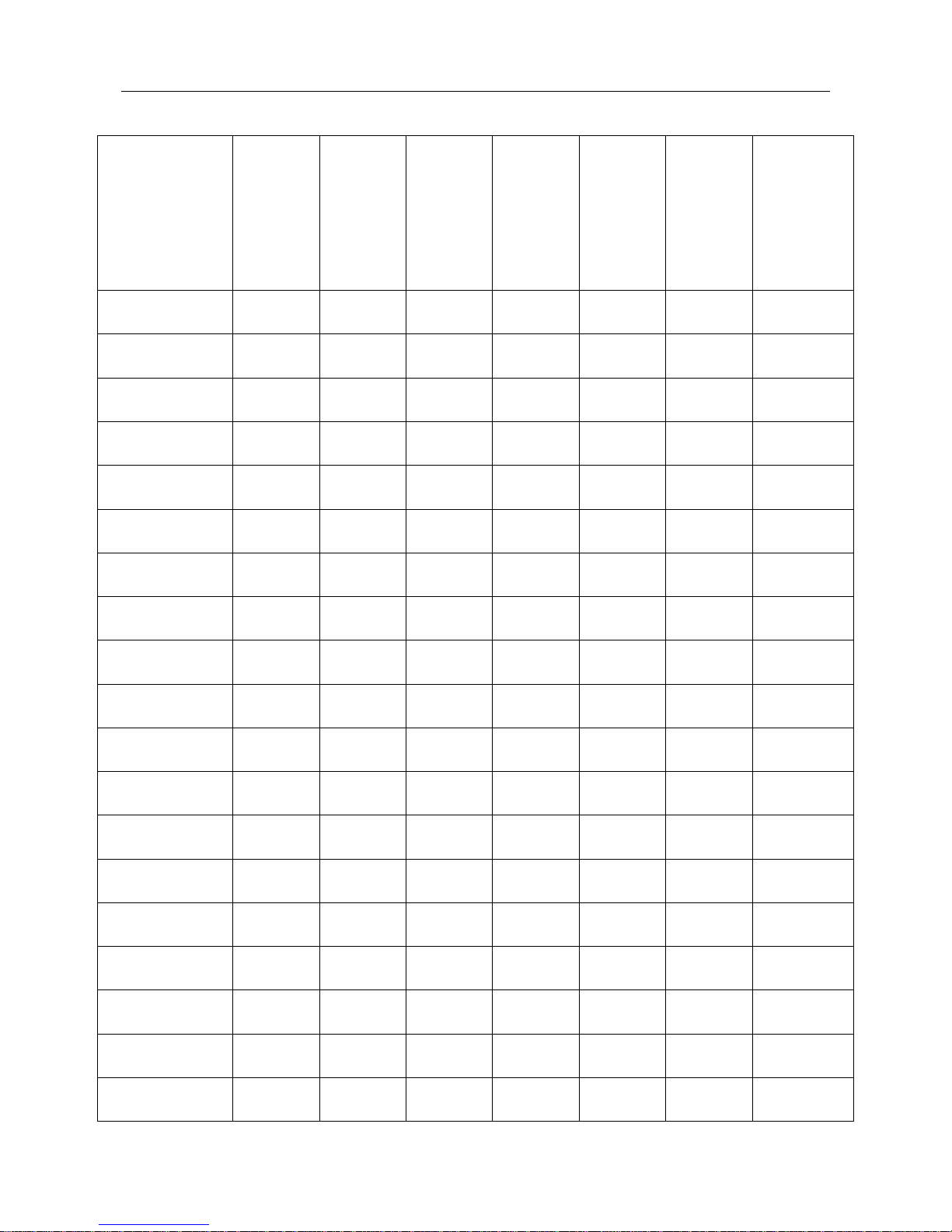

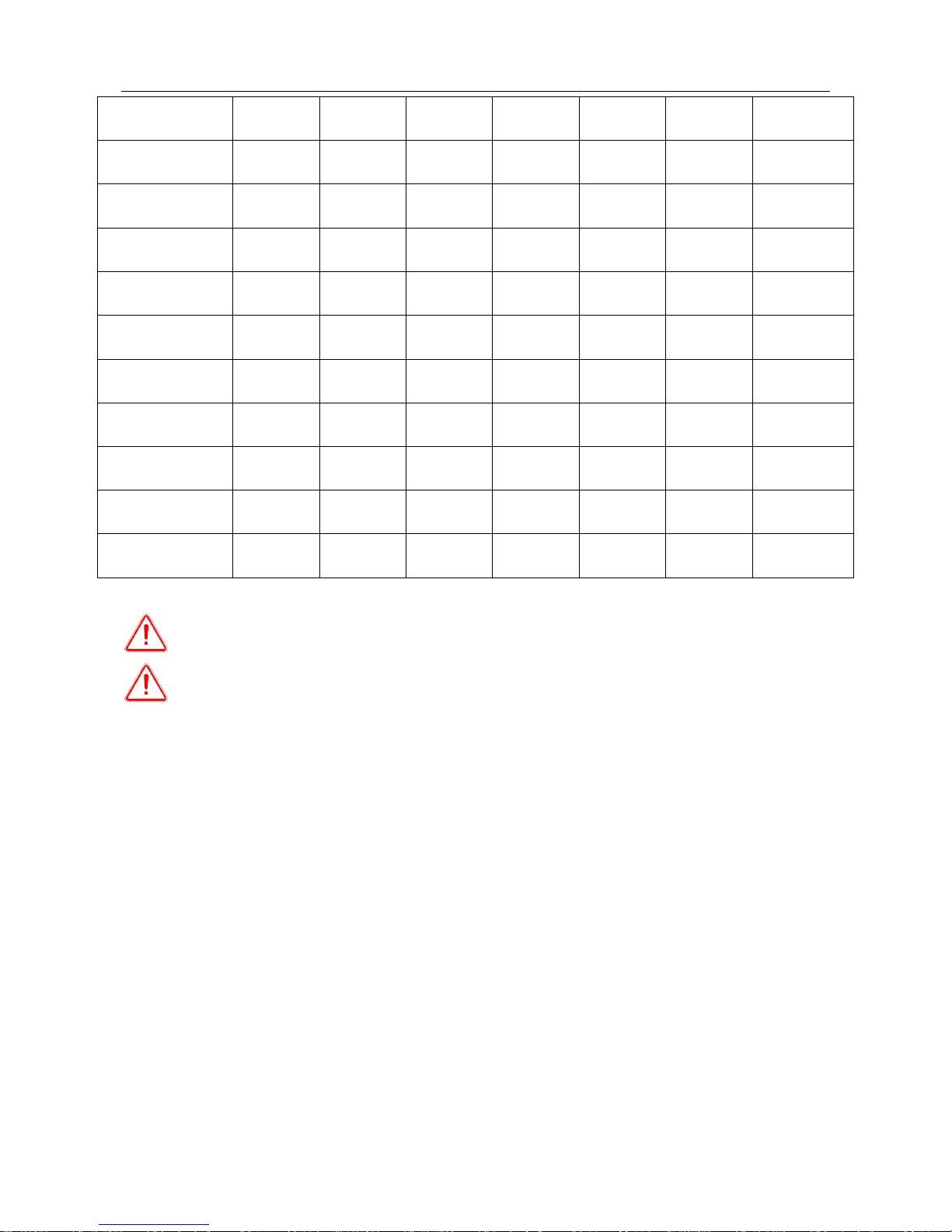

1.3.2 Product Specification and Technical Index

Model

Max.

DC input

voltage

(Vdc)

Recommen

ded MPP

voltage

(Vdc)

Start

voltage

(Vdc)

Rated

output

power(W)

Max.AC

output

current(A)

Output

frequency

(Hz)

Rated output

voltage(Vac)

BS-550-L

450

100-400

80

550

3

0-50/60

3PH 220V

BS-750-L

450

150-400

120

750

5

0-50/60

3PH 220V

BS-1100-L

450

150-400

120

1100

6

0-50/60

3PH 220V

BS-1500-L

450

200-400

120

1500

7

0-50/60

3PH 220V

BS-2200-L

450

280-400

200

2200

11

0-50/60

3PH 220V

BS-550-LA

450

100-400

80

550

3

0-50/60

3PH 220V

BS-750-LA

450

150-400

120

750

5

0-50/60

3PH 220V

BS-1100-LA

450

150-400

120

1100

6

0-50/60

3PH 220V

BS-1500-LA

450

200-400

120

1500

7

0-50/60

3PH 220V

BS-2200-LA

450

280-400

200

2200

11

0-50/60

3PH 220V

BS-3000

900

500-680

250

3000

8

0-50/60

3PH 380V

BS-4000

900

500-680

250

4000

10

0-50/60

3PH 380V

BS-5500

900

500-680

250

5500

13

0-50/60

3PH 380V

BS-7500

900

500-680

250

7500

18

0-50/60

3PH 380V

BS-9200

900

500-680

250

9200

21

0-50/60

3PH 380V

BS-11K

900

500-680

250

11000

24

0-50/60

3PH 380V

BS-13K

900

500-680

250

13000

28

0-50/60

3PH 380V

BS-15K

900

500-680

250

15000

30

0-50/60

3PH 380V

BS-18K5

900

500-680

250

18500

39

0-50/60

3PH 380V

Operation Instruction of BS Series Solar Pumping Inverter Product Introduction

6

BS-22K

900

500-680

250

22000

45

0-50/60

3PH 380V

BS-3000-A

900

500-680

250

3000

8

0-50/60

3PH 380V

BS-4000-A

900

500-680

250

4000

10

0-50/60

3PH 380V

BS-5500-A

900

500-680

250

5500

13

0-50/60

3PH 380V

BS-7500-A

900

500-680

250

7500

18

0-50/60

3PH 380V

BS-9200-A

900

500-680

250

9200

21

0-50/60

3PH 380V

BS-11K-A

900

500-680

250

11000

24

0-50/60

3PH 380V

BS-13K-A

900

500-680

250

13000

28

0-50/60

3PH 380V

BS-15K-A

900

500-680

250

15000

30

0-50/60

3PH 380V

BS-18K5-A

900

500-680

250

18500

39

0-50/60

3PH 380V

BS-22K-A

900

500-680

250

22000

45

0-50/60

3PH 380V

Warning: please select appropriate model according to solar cell array and motor load.

Warning: The input power in the above table refeBS-to multi-channel total input power. The

maximum input DC current of each group shall not exceed 15A.

Operation Instruction of BS Series Solar Pumping Inverter Installation and Wiring

7

Chapter II Installation and Wiring

2.1 Procurement Inspection

Our company has strict quality assurance system in aspects of product manufacturing,

packaging, etc. In case of abnormal condition, please contact with our company’s product dealer, or

contact with our company’s technical service center. We will provide you with solution as soon as

possible. When you get the products, please confirm the following items:

Inspection Item

Inspection Method

Whether it accords with ordered products

Inspect nameplate of product

Whether it is damaged or falls off

Check the overall appearance

Whether host computer and parts are complete

Inspect according to product checklist

Whether tightening parts such as bolt are loosened

When necessary, use screwdriver for inspection

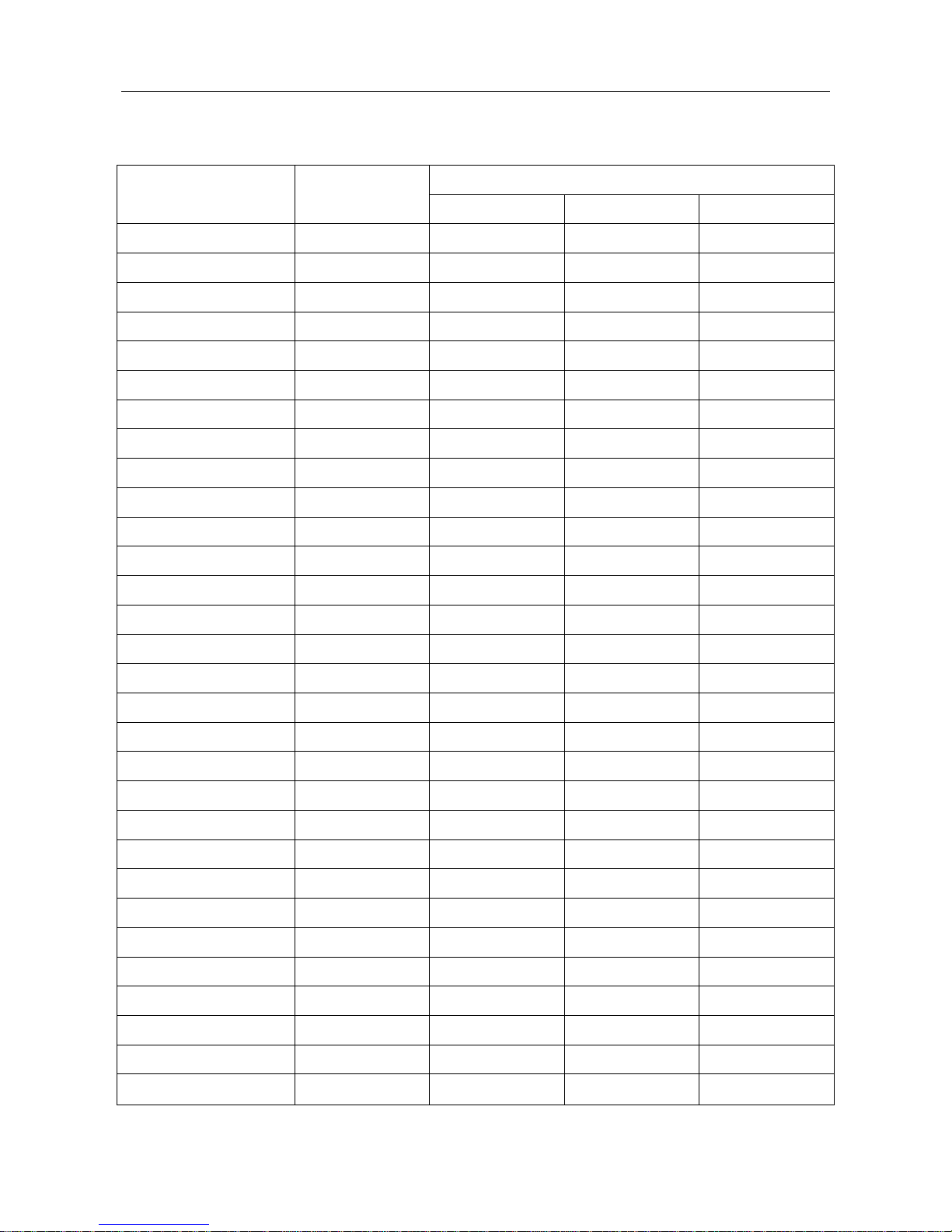

2.2 Dimension and Weight

Figure 2-1 Product Appearance and Installation Dimension

Operation Instruction of BS Series Solar Pumping Inverter Installation and Wiring

8

Product Specification Parameter:

Model

Weight(Kg)

Appearance and installation dimension (mm)

L W H

BS-550-L

5

405

297

147

BS-750-L

8

405

297

147

BS-1100-L

8

405

297

147

BS-1500-L

10

405

297

147

BS-2200-L

10

405

297

147

BS-550-LA

5

405

297

147

BS-750-LA

8

405

297

147

BS-1100-LA

8

405

297

147

BS-1500-LA

10

405

297

147

BS-2200-LA

10

405

297

147

BS-3000

14

478

325

155

BS-4000

14

478

325

155

BS-5500

15

478

325

155

BS-7500

15

563

346

148

BS-9200

15

563

346

148

BS-11K

15

563

346

148

BS-13K

16

533

405

190

BS-15K

16

533

405

190

BS-18K5

22

533

405

190

BS-22K

22

533

405

190

BS-3000-A

14

478

325

155

BS-4000-A

14

478

325

155

BS-5500-A

15

478

325

155

BS-7500-A

15

563

346

148

BS-9200-A

15

563

346

148

BS-11K-A

15

563

346

148

BS-13K-A

16

533

405

190

BS-15K-A

16

533

405

190

BS-18K5-A

22

533

405

190

BS-22K-A

22

533

405

190

Operation Instruction of BS Series Solar Pumping Inverter Installation and Wiring

9

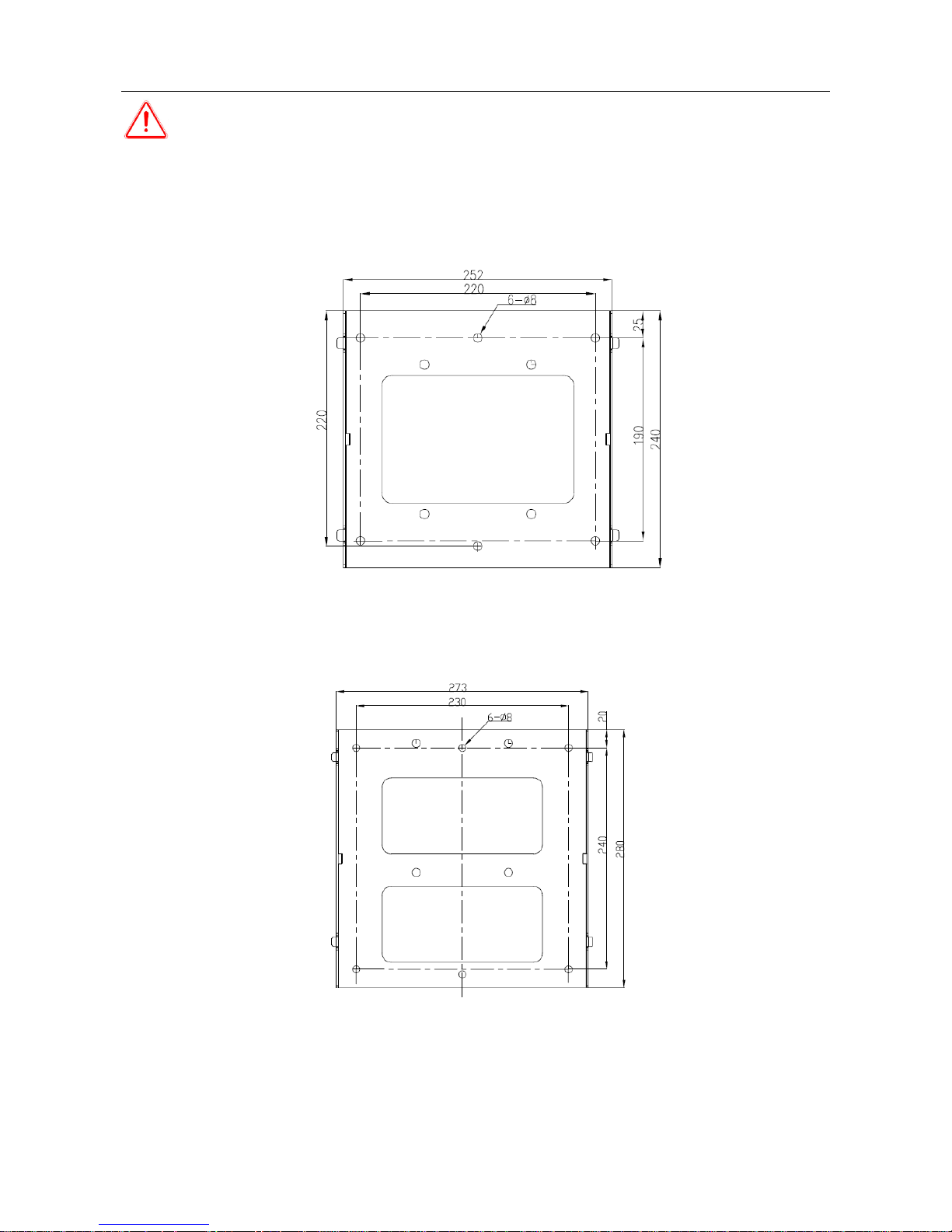

Warning: most models of BS series are hanging installation. Guarantee that the installation

backboard can bear the weight of inverter.

2.3 Installation Diagram

Figure 2-2 Installation Dimension Diagram of BS-550 to 2200

Figure 2-3 Installation Dimension Diagram of BS-3000 to 5500

Loading...

Loading...