EnerSys SBS30, SBS15, SBS60, SBS40, SBS110 Series Manual

...

Publication No: EN-SBS-PG-001 February 2003

Introduction 2

Range Summary 3

Recombination Technology 4

Construction 5

Features and Benefits 6

Battery Sizing 7-8

Performance Data 9-14

Performance Information 15-16

Installation 17

Housings 18

Charging 19-21

Maintenance 22

Introduction

2

Contents

PowerSafe SBS standby power batteries

utilise advanced pure lead, thin plate

technology to achieve exceptionally high

performance, energy density, reliability

and a long, low maintenance service life

in a wide range of applications and

operating environments. The range

includes both top and front terminal

designs for easy installation and

maintenance on racks, shelves and in

cabinets.

PowerSafe SBS combine the benefits of

high performance and long life in a

cost effective battery solution for

tele-communications, UPS, electric

utillities and engine starting

applications.

PowerSafe SBS batteries are

manufactured in ISO 9001 certified

factories.

This manual describes the

PowerSafe SBS product range, physical

characteristics and electrical

performance, and contains the basic

information for the selection, storage,

installation, operation and maintenance

of

PowerSafe SBS batteries.

Enersys has earned an international

reputation for quality and reliability

based on more than 100 years

experience in the manufacture of

batteries, and is at the forefront of new

product design to meet customers

increasing power requirements.

PowerSafe SBS batteries are designed

using proven gas recombination

technology, which removes the need

for regular water addition.

The use of gas recombination

technology for lead acid batteries has

completely changed the concept of

standby power. This technology

provides the user with the freedom to

use lead acid batteries in a wide range

of applications. The minimal level of gas

production allows battery installation in

cabinets or on stands, in offices or near

main equipment, thus maximising space

utilisation and reducing battery

accommodation and maintenance costs.

Publication No: EN-SBS-PG-001 February 2003

www.enersysinc.com

3

Range Summary

Dimensions mm (inches)

Nominal C8 to C10 to

Voltage 1.75Vpc 1.80Vpc Terminal Weight

Model (V) @ 25°C (77°F) @ 20°C (68°F) Fastener

1

Length Width Height kg (lbs)

SBS8 12 7 7 M4 F 138 (5.4) 86 (3.4) 101 (4.0) 2.7 (5.9)

SBS15 12 14 14 M6 M 200 (7.9) 77 (3.0) 140 (5.5) 5.7 (12.5)

SBS30 12 26 26 M6 M 250 (9.8) 97 (3.8) 156 (6.1) 9.5 (20.9)

HB30 12 26 26 M6 M

2

250 (9.8) 97 (3.8) 156 (6.1) 9.6 (21.1)

SBS40 12 38 38 M6 M 250 (9.8) 97 (3.8) 206 (8.1) 12.7 (28.0)

SBS60 12 51 51 M6 M 220 (8.7) 121 (4.8) 260 (10.2) 18.5 (40.7)

SBS110 6 116 115 M8 M 200 (7.9) 208 (8.2) 239 (9.4)

3

21.2 (46.6)

SBS114 4 116 115 M8 M 200 (7.9) 208 (8.2) 239 (9.4)

3

15.7 (34.5)

SBS130 6 133 132 M8 M 200 (7.9) 208 (8.2) 239 (9.4)

3

22.7 (49.9)

SBS134 4 133 132 M8 M 200 (7.9) 208 (8.2) 239 (9.4)

3

26.8 (37.0)

SBS300 2 307 310 M8 M 200 (7.9) 208 (8.2) 239 (9.4)

3

21.7 (47.7)

SBS390 2 361 360 M8 M 200 (7.9) 208 (8.2) 239 (9.4)

3

23.2 (51.0)

SBSJ13 12 12 12 M6 F 178 (7.0) 87 (3.4) 132 (5.2) 5.7 (12.6)

SBSJ16 12 15 15 M6 F 186 (7.3) 79 (3.1) 171 (6.7) 6.7 (14.8)

SBSJ30 12 26 26 M6 F 178 (7.0) 168 (6.6) 127 (5.0) 11.8 (26.0)

SBSJ40 12 39 39 M6 F 201 (7.9) 171 (6.7) 173 (6.8) 17.4 (38.2)

SBSJ70 12 64 64 M6 F 328 (12.9) 166 (6.5) 175 (6.9) 28.8 (63.4)

SBSB8

4

12 31 31 M8 F 280 (11.0) 97 (3.8) 150 (5.9)

5

10.3 (22.7)

SBSB10

4

12 34 34 M8 F 280 (11.0) 97 (3.8) 175 (6.9)

5

12.8 (28.2)

SBSB14

4

12 62 62 M8 F 280 (11.0) 97 (3.8) 256 (10.1)

5

19.1 (42.0)

SBSC11

4

12 91 92 M8 F 395 (15.6) 105 (4.1) 264 (10.4) 28.0 (61.6)

Monobloc Specifications

Notes:

1 M = male stud, F = female thread

2 supplied with wiring harness

3 dimension includes top cover

4 SBSB8, B10, B14, and C11 are available with terminals on the top face or on the front face.

For front terminals add ‘FT Adapter’ to the model number

5 SBSB8, B10 and B14 are available with a venting manifold, with a spigot at the front or back.

The manifold increases monobloc height by 9mm.

Publication No: EN-SBS-PG-001 February 2003

www.enersysinc.com

4

Recombination Technology

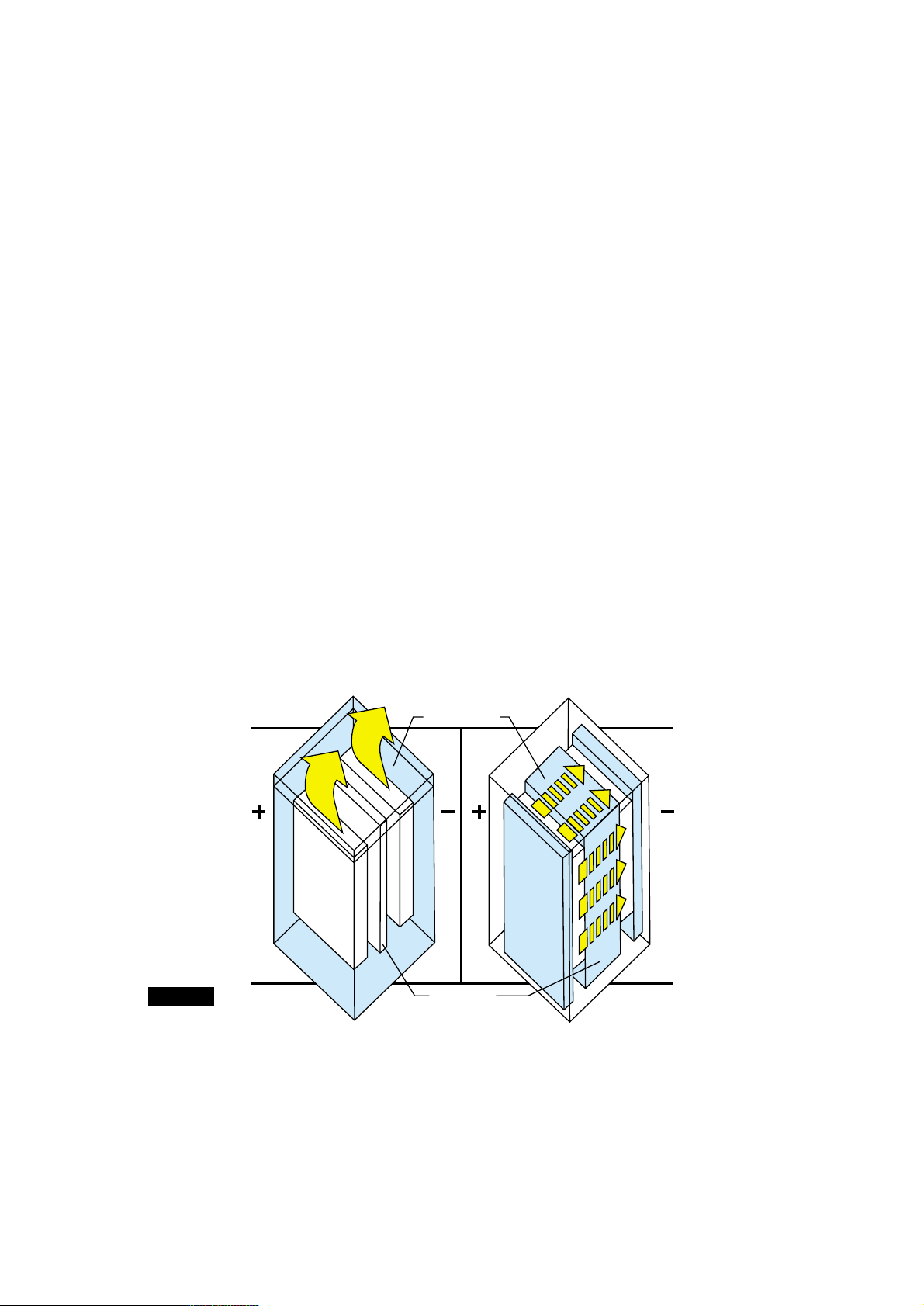

How gas recombination works

When a charge current flows through a fully charged conventional

lead acid cell, electrolysis of water occurs to produce hydrogen from

the negative electrode and oxygen from the positive electrode. This

means that water is lost from the cell and regular topping up is

needed.

However, evolution of oxygen gas and hydrogen gas does not occur

simultaneously, because the efficiency of recharge of the positive

electrode is not as good as the negative electrode. This means that

oxygen is evolved from the positive plate before hydrogen is

evolved from the negative plate.

At the same time that oxygen is evolved from the positive electrode,

a substantial amount of highly active spongy lead exists on the

negative electrode before it commences hydrogen evolution.

Therefore, provided oxygen can be transported to the negative

electrode, conditions are ideal for a rapid reaction between lead and

oxygen:

ie. This oxygen is electrochemically reduced on the negative

electrode according to the following scheme,

2e-+ 2H+ +

1/

2

O

2

➝ H

2

O

and the final product is water.

The current flowing through the negative electrode drives this

reaction instead of hydrogen generation which would occur in a

flooded cell.

This process is called gas recombination. If this process was 100%

efficient no water would be lost from the cell. By careful design of

the constituents within the cell, gas recombination up to 99% is

achieved.

Principle of the Oxygen Reduction Cycle

Electrolyte

Separator

H

2

O

2

SBS

Oxygen evolved

from positive

plate transfers

to negative and

recombines to

form water.

CONVENTIONAL

CELL

Oxygen and

hydrogen escape

to the

atmosphere

Recombination efficiency

Recombination efficiency is determined under specific conditions by

measuring the volume of hydrogen emitted from the battery and

converting this into its ampere hour equivalent. This equivalent

value is then subtracted from the total ampere hours taken by the

battery during the test period, and the remainder is the battery’s

recombination efficiency and is usually expressed as a percentage.

As recombination is never 100%, some hydrogen gas is emitted from

SBS cells and batteries through the self-regulating valve. The volume

of gas emitted is very small and for all practical purposes may

be ignored.

Figure 1

Publication No: EN-SBS-PG-001 February 2003

www.enersysinc.com

5

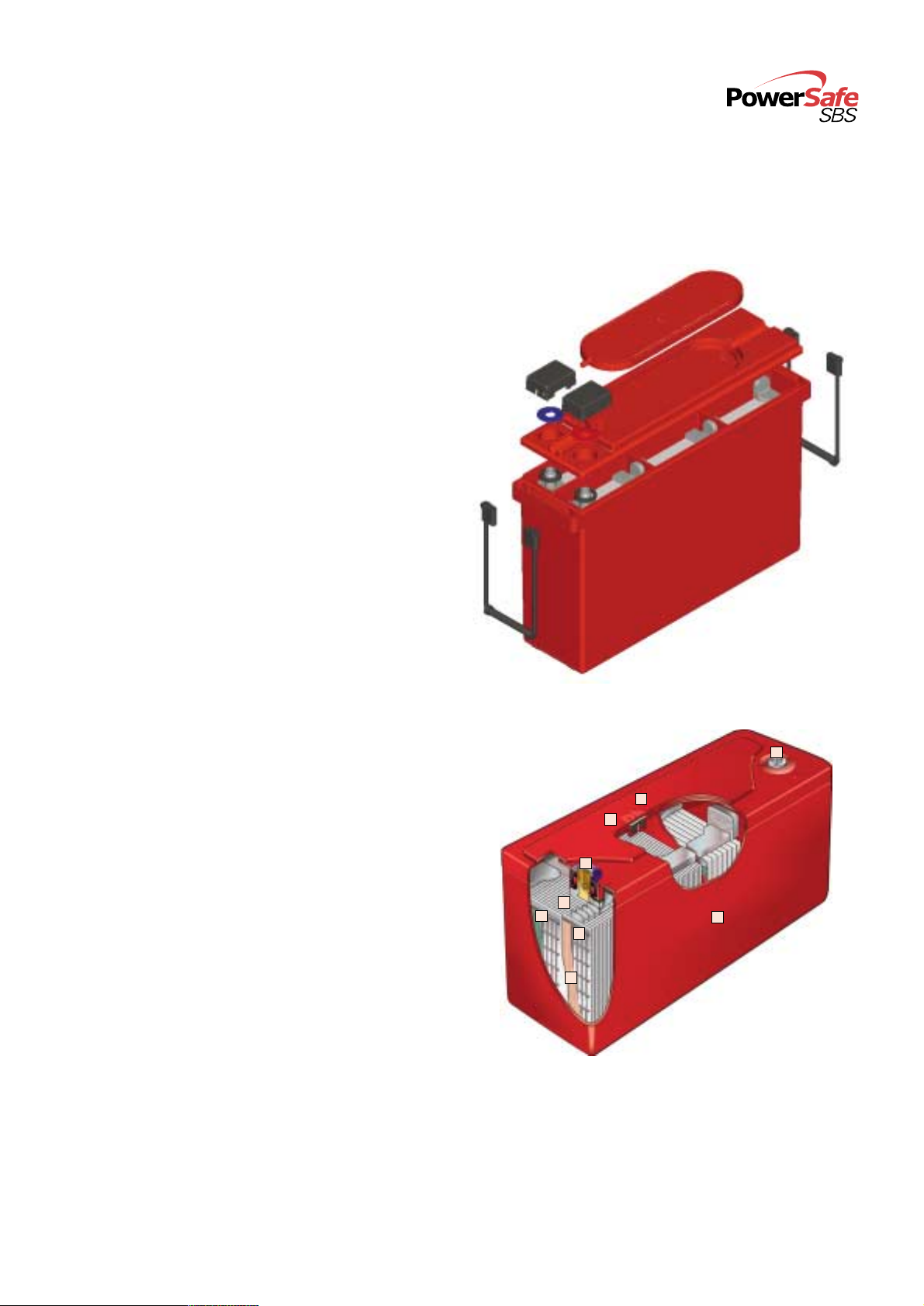

Construction

1 Terminal Posts

High conductivity post for high rate discharge.

2 Pillar Seal

Compressed rubber grommet for superior integrity.

3 Container and Lid

Heat-sealed for maximum strength. SBS cases are

made of ABS and SBS J are made of Noryl.

Both materials are flame retardant (UL94 V-0).

4 One Way Valve

Ensures no oxygen can enter the cell. Optional

remote venting systems are available. Vent adapters

and a neoprene tubing system transport gases

outside the battery compartment. This is only a

safety measure because, under normal operating

conditions, gas emission is virtually negligible.

5 Pure Lead Plates

Advanced thin grid technology and high purity

materials for high performance, efficient charging

and long life.

6 Negative Plates

Active material is balanced against the positive for

optimum performance and recombination

efficiency.

7 Flame Arrestor

The valve retaining disc also functions as a flame

Arrestor to prevent ingress of a spark or flame.

8 Separators

Separator material is resilient to scuffs and tears

to minimise risk of internal shorts caused by a

damaged separator.

9 Electrolyte

Medical grade dilute sulphuric acid is absorbed

into separator material.

2

7

8

5

9

4

1

3

6

Publication No: EN-SBS-PG-001 February 2003

www.enersysinc.com

6

Features and Benefits

Design Life

■ High purity materials give SBS batteries a long float life.

On constant voltage float charge systems the design life

expectancy is 10+ years at 25°C/77°F and 15+ years at

20°C/68°F.

Energy Density

■ The advanced thin plate pure lead technology promotes

exceptionally efficient utilisation of the active materials.

SBS energy density is typically 12 to 30 % higher than

conventional lead calcium VRLA batteries.

Operating Temperature

■ The recommended operating temperature range for

optimum life and performance is 20°C/68°F to 25°C/77°F.

■ However, SBS can be operated in the temperature range

-40°C/-40°F to 50°C/122°F, and by using the optional

metal jacket the maximum operating temperature of the

SBS J types is increased to 80°C/176°F.

■ Operation at higher or lower temperature will effect

battery life or performance respectively:

Lower capacity Optimum life Shorter life

and performance

Transportation

■ SBS products are classified as “nonspillable wet electric

storage batteries” and may be shipped by air or ground

transportation without restriction.

■ The batteries, their shipping container and external

packaging must be labelled “nonspillable” or “nonspillable

battery”.

■ SBS batteries are in compliance with:

USA 49 Code of Federal Regulations section DOT 173.159

ICAO/IATA Packaging Instruction 806 and Special

Provision A67

IMDG UN No 2800 Class 8 Exempt when securely

packaged and protected against short circuts.

Orientation

The batteries can be installed in any orientation except

upside down (vents on the bottom).

Terminal Position

■ The SBS range comprises of both top and front terminal

models, and JIS and unique SBS container sizes for

maximum battery layout flexibility.

Low Gas Emission and Remote venting

■ Under normal operating conditions, gas emission is

virtually negligible. On SBS15-60, SBS J and front terminal

models optional venting systems are available to vent gas

outside the battery compartment. The remote venting

system allows batteries to be installed in applications

where there is little ventilation.

-40°C/-40°F to 20°C/68°F to 26°C/78°F to

19°C/66°F 25°C/77°F 50°C/122°F

Publication No: EN-SBS-PG-001 February 2003

www.enersysinc.com

7

Battery capacity is affected by the discharge rate, end

voltage, temperature and age.

Battery sizing calculations should include factors for

temperature and loss of capacity over life. A battery usually

is determined to have reached end of life when its capacity

has fallen to 80% of its rated capacity.

Strings of the same SBS batteries can be connected in

parallel to obtain higher capacities.

Telecom Applications

In general, telecom applications are a constant power or

constant current load for a specified period, to a specified

end voltage. The appropriate battery model can be selected

by referring to the Discharge Tables.

EXAMPLE 1

The following information is needed:

■ Nominal system voltage

■ Minimum system voltage

■ Load (constant current or constant power)

■ Backup time

■ Temperature range

A nominal 48V system requires a constant current of 9 Amps

for 4 hours to a minimum of 42V at a minimum operating

temperature of 20°C/68°F.

Step 1. Number of cells = nominal system voltage divided

by nominal cell voltage:

48V/ 2V = 24 cells

Step 2. Cell end voltage = minimum system voltage divided

by the number of cells:

42V/ 24 cells = 1.75 volts per cell

Step 3. Correct load for temperature and ageing:

Temperature factor = 1/Factor from Temperature

Correction Chart = 1/0.978 = 1.022

Ageing factor = 100/80 = 1.25

9 amps x temperature factor x ageing factor =

9 amps x 1.022 x 1.25 = 11.5 Amps

Step 4. Refer to the constant current discharge table for an

end voltage of 1.75 Vpc, and in the 4 hour column

find the model that will provide the load current.

In this example an SBS60 will provide 11.7 amps/

4 Hrs/1.75Vpc SBS60 is a 12V six cell monobloc,

so 4 blocs are required for a 48V battery.

UPS Applications

In general, UPS systems are rated in kVA, (kilo Volt

Amperes). This is a multiplication of the output voltage in

Kilo Volts and output current in amperes. The kVA rating is

always an AC rating. The kVA rating may be converted to kW

by simply multiplying the kVA by the Power Factor (PF).

kW Rating of UPS = (kVA of UPS) x (PF of UPS)

kW Rating of UPS Battery = kVA x PF

Inverter Efficiency

EXAMPLE 2

This first example covers a basic sizing procedure with no

power factor or efficiency involvement. This procedure

details only the fundamental steps required.

In an example such as this the following information is

needed as a minimum requirement:

(i) system kilowatts

(ii) required autonomy (run time)

(iii) minimum DC voltage

(iv) maximum DC voltage

If the load is given in kVA, then the PF and inverter efficiency

values must also be known.

Therefore, for a UPS requiring the following autonomy,

Battery kW Rating: 10

Battery nominal voltage: 120

Battery end voltage: 1.67 Vpc

Battery run time: 10 minutes

Battery Sizing

Publication No: EN-SBS-PG-001 February 2003

www.enersysinc.com

8

Step 1. Number of cells needed per string

= 120 (nom.volt) /2 (nominal cell voltage)

= 60 cells

Step 2. Watts per cell required to support the load

= 10,000 (Watts) /60 (cells)

= 166.67 Watts per cell

Step 3. Refer to the constant power discharge tables for an

end voltage of 1.67 Vpc, and in the 10 minute

column find the model that can support a load of

166.67 Watts per cell.

SBS40 will provide 205 Wpc for 10 minutes.

Step 4. Calculate the number of blocs required to make up

the battery string. The number of blocs

= System Nominal Voltage/Bloc Nominal Voltage

= 120V/12V = 10 blocs.

Therefore 10 SBS40 blocs are required to make up

the battery string

EXAMPLE 3

This example is slightly more complex in that it takes into

account both the power factor and the system efficiency.

UPS kVA rating: 12.0

Inverter power factor: 0.80

Inverter efficiency: 85%

Battery nominal voltage: 120

Battery end-voltage: 1.67 Vpc

Battery run time:15 minutes

Step 1. Total power required from

battery = kVA x PF

Inverter Efficiency

= 12.000(kVA)x0.80(PF)

0.85 (Inv.eff)

= 11.294 kW

Step 2. Watts per cell required to support the load

= Total power required from battery

no. of cells

= 11.294 (kW)

60 (cells)

= 188.2 Watts per cell

Step 3. Refer to the constant power discharge tables for an

end voltage of 1.67 Vpc, and in the 15 minute

column find the model that can support a load of

188.2 Watts per cell.

SBS60 will provide 206 Wpc for 15 minutes.

Step 4. Calculate the number of blocs required to make up

the battery string. The number of blocs

= System Nominal Voltage/Bloc Nominal Voltage

= 120V/12V = 10 blocs.

Therefore 10 SBS60 blocs are required to make up

the battery string

With both of these examples, by reference to the discharge

tables, it is possible to use a parallel string system with

smaller SBS models.

These are basic examples. For split duty regimes and other

more complex sizings, contact our sales department.

Battery Sizing

Publication No: EN-SBS-PG-001 February 2003

www.enersysinc.com

Loading...

Loading...