Page 1

Installation, Operations

and Maintenance

Instructions

Publication No: EN-VX-IOM-001 February 03

Page 2

2

Important information 2

Care for your safety 2

Unpacking 2

Storage 3

Installation 3

Cell strings connected in

parallel 3

Charging 4

Discharging 4

Technical specifications of bloc 6

Typical assembly drawing 6

Battery record sheet 7

Important information

Please read this manual immediately on

receipt of the battery before commencing

unpacking and installing. Failure to comply

with these instructions will render any

warranties null and void.

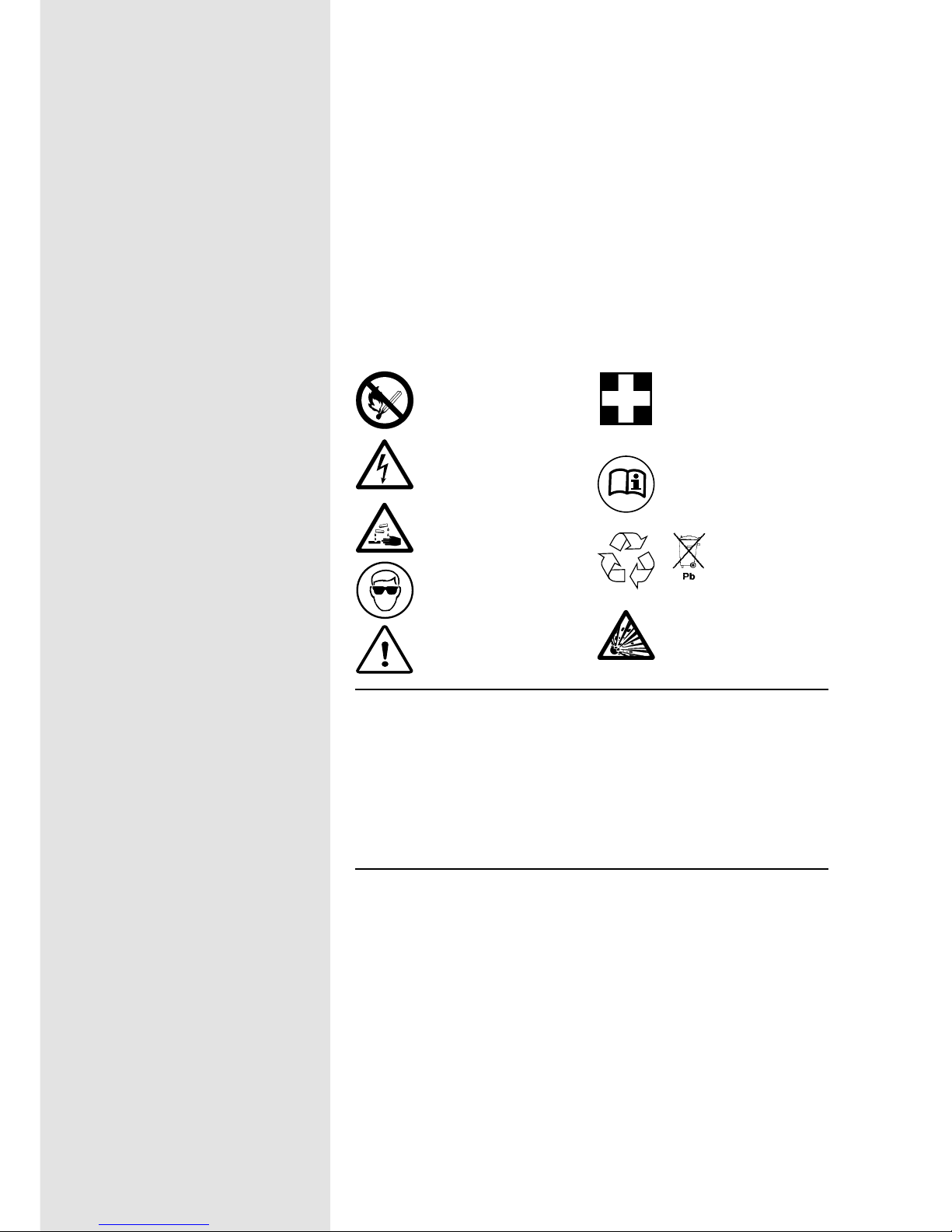

Care for your safety

No smoking, no naked flames,

no sparks

Electrolyte is corrosive

Electrical hazard

Shield eyes

Clean all acid splash in eyes or

on skin with plenty of clean

water. Then seek medical help.

Acid on clothing is to be

washed with water.

Danger

Read instructions

Risk of explosion or fire. Avoid

any short circuit. Metallic parts

under voltage on the battery, do

not place tools or items on top of

the battery.

Re-cycle scrap

batteries.

Contains lead

Unpacking

It is advisable to unpack the monoblocs

and accessories before commencing

assembly and erection and not to unpack

and erect monobloc by monobloc.

All monobloc/units should be handled

carefully as the plastic container can be

damaged or broken if dropped. Under no

circumstances should the batteries be

lifted by their terminal pillars.

All items should be carefully checked

against the accompanying advice notes to

ascertain if any are missing or damaged.

In this event contact your Enersys

representative.

Handling

PowerSafe VX batteries are

supplied in a fully charged

state and must be unpacked

carefully to avoid very high

short-circuit currents between

terminals of opposite polarity.

Keep flames away

In case of accidental

overcharge a flammable gas

may be emitted from the

safety vent.

Discharge any possible static

electricity from clothes by

touching an earth connected

part.

Tools

Use tools with insulated

handles.

Do not place or drop metal

objects on the battery.

Remove rings, wristwatch and

articles of clothing with metal

parts that may come into

contact with the battery

terminals.

Publication No: EN-VX-IOM-001 February 03

www.enersysinc.com

Page 3

3

A rigid plastic insulating cover is provided which protects the unit

terminals. These are factory fitted and there is no need to remove

them until access to the terminals is required.

Storage

Store the batteries in a dry, clean and preferably cool location.

As the batteries are supplied charged it is advised not to store

batteries without a refreshing charge for more than:

6 months at 20°C

3 months at 30°C

6 weeks at 40°C

3 weeks at 50°C

The refreshing charge needs to be at 2.27-2.30Vpc at 20°C for 48 to

96 hours. A current limit is not essential, but for optimum charge

efficiency the current output of the charger can be limited to 10%

of the 3 hour capacity rating. The need for a refreshing charge

can also be determined by measuring the open circuit voltage of

the stored battery. Refreshing charge is advised if the voltage

drops below 2.10Vpc. Failure to observe these conditions may

result in greatly reduced capacity and service life.

Temperature

Avoid placing the battery in a hot environment or in front of a

window. The battery will give the best performance and service

life when working at a temperature between 20°C and 25°C.

Operating temperatures should not exceed +45°C or fall below 30°C.

Ventilation

Under normal conditions gas release is very low and natural

ventilation is sufficient for cooling purposes and inadvertent

overcharge, enabling PowerSafe VX batteries to be used safely in

offices and with main equipment.

However care must be taken to ensure adequate ventilation when

placed in cabinets. Batteries must not be placed in sealed

cabinets.

Installation

Install batteries in a clean and dry area. PowerSafe VX products

release minimal amounts of gas during normal operation (gas

recombination efficiency ≥ 95%). Batteries must be installed in

accordance with national standards

(for instance EN 50272-2), otherwise in accordance with the

manufacturer’s instructions.

Please note that each monobloc is supplied complete with a

fastener set, i.e. nut, spring washer and plain washer. These are

fitted to the threaded stud of each terminal pillar prior to despatch

from the factory.

Enersys battery racks or cabinets are recommended when

installing the monoblocs. Assemble the rack according to

instructions. Place the battery blocs on the rack at their correct

cell centres (as indicated on the connection drawing) and arrange

the positive and the negative terminals for connection according

to the wiring diagram.

Connection of monoblocs

When all monoblocs have been placed on the stands/in the

cabinets, connect them together by means of the connecting straps

and fastener set, in sequence, pillar, connecting strap, plain washer,

spring washer and nut.

Tighten the fastener set nut(s) to a level of fastening torque of 5 ±0.5

Nm. Never use a standard spanner, use insulated tools only.

A loose connector can cause problems in charger adjustment,

erratic battery performance, possible damage to the battery

and/or personal injury.

Single solid sleeved copper strap connector type SUB5176 is used to

connect units located on the same tier of the stand (or on the same

shelf of a cabinet). A single flexible insulated cable connector is

used for inter-tier (or inter-shelf) connection which is provided when

the stand is supplied by Enersys.

Putting the terminal cover back

Insulating terminal covers have been designed to be fitted on

completion of the connecting up sequence of the battery. Where

inter-tier flexible insulated cable connectors are used, it will be

necessary to remove the corner of the cover by simply snapping it

off.

Publication No: EN-VX-IOM-001 February 03

www.enersysinc.com

Page 4

4

Cell strings connected in parallel

Using constant voltage chargers and ensuring that the

connections made between the charger and the batteries have

the same electrical resistance, no special arrangements have to

be made for batteries in parallel.

Although no special circuit arrangements are required, where the

parallel connection is made at the charger or distribution board, to

avoid out of step conditions, the bus bar run length and the area of

cross section should be designed so that the circuit resistance

value for each of the strings is equal within limits ± 5%.

Charging

Float voltage

The recommended float charge voltage is 2.28 volts per cell at

20°C.

Following a commission charge and after 6 months continuous

charge at the recommended float voltage, individual cell voltages

will stabilise within ±4.5% of the mean applied voltage.

However, immediately following commissioning and for the initial 6

months of continuous float charge, individual cell voltage values

outside the above tolerance may be observed without adverse

effect. There is no relationship between a cell’s float voltage and

its discharge capacity. Cells are perfectly capable of giving their

discharge capacity even when outside the ±4.5% range.

After 6 months service, should any individual cell or monobloc

show a continuing reduction or increase in voltage outside the

above limits over 3 successive monthly periods, Enersys should be

contacted for advice.

When the average ambient temperature deviates more than ±5ºC

from the reference temperature (20°C), it is necessary to adjust

the float voltage as follows:

Temperature Float voltage range per cell

0°C 2.33-2.36V

10°C 2.30-2.33V

20°C 2.27-2.30V

25°C 2.25-2.28V

30°C 2.24-2.27V

35°C 2.22-2.25V

40°C 2.21-2.24V

45°C 2.19-2.22V

50°C 2.18-2.21V

If the charger does not permit an adjustment of float voltage in

relation to the temperature, it is possible to set a float voltage

value according to the temperature ranges as indicated in the last

table of this publication.

Charging current

A discharged VRLA battery will accept a high recharge current,

but for those seeking a more economical charging system a

current limit of 0.08 C10 or 0.1 C3 (A) is adequate.

Fast recharge

Increasing the charge voltage to 2.40Vpc with a current limited to

0.1 C

10 or 0.125 C3 (A) can reduce recharge times. Fast charge

should be stopped after approximately 10 to 15 hours. In order to

achieve a normal service life, this charge regime must not be used

more than once per month.

Float charge ripple

Excessive ripple on the D.C. supply across a battery has the effect

of reducing life and performance.

It is therefore recommended that voltage regulation across the

system, including the load but without the battery connected,

under steady state conditions, shall be better than ±1% between

5% and 100% load.

State of charge

The battery state of charge can be determined approximately by

measuring the open circuit voltage after the battery has been at

rest for a minimum of 24 hours at 20°C.

Voltage State of charge

2.14Vpc 100%

2.10Vpc 80%

2.07Vpc 60%

2.04Vpc 40%

2.00Vpc 20%

Open circuit voltage variation with temperature is 2.5mV per 10°C.

Discharging

PowerSafe VX batteries must not be left in a discharged condition

after supplying the load but must immediately be returned to float

recharge mode.

Failure to observe these conditions may result in greatly reduced

service life.

Publication No: EN-VX-IOM-001 February 03

www.enersysinc.com

Page 5

5

Accidental deep discharging

For optimum operation the minimum voltage of the system should

be related to the duty as follows:

Duty Minimum end voltage

5 min ≤ t ≤ 1h 1.65V

1h ≤ t ≤ 5h 1.70V

5h ≤ t ≤ 8h 1.75V

8h ≤ t ≤ 20h 1.80V

In order to protect the battery it is advisable to have system

monitoring and low voltage cut-out.

Deep discharge will produce a premature deterioration of the

battery and a noticeable reduction in the life expectancy of the

battery.

The effect of temperature

- on capacity

Correction factors for capacity, according to the temperature, are

as follows:

- on life

Operation of valve regulated batteries at temperatures higher than

20°C will reduce life expectancy. Life is reduced by 50% for every

10°C rise in temperature.

Maintenance/Checks

PowerSafe VX are maintenance free, sealed, lead acid batteries

and need no water addition.

The containers and lids shall be kept dry and free from dust.

Cleaning must be carried out with a damp cotton cloth only. Check

monthly that total voltage at battery terminals is (N x 2.28 V) for a

temperature at 20°C. (N = the number of cells in the battery). Take

annual readings of the voltages of cells making up the battery.

Keep a logbook to record values, power outages, discharge tests,

etc.

An autonomy test is recommended once a year.

Technical data when charging with a constant voltage

If the charger does not permit an adjustment of the float voltage in

relation to the temperature, it is possible to set a float voltage

value and a recharging voltage value according to the

temperature ranges indicated in the table below:

Temperature Float Voltage Recharging Voltage

0°C to 10°C 2.34Vpc 2.45Vpc

10°C to 20°C 2.31Vpc 2.40Vpc

20°C to 30°C 2.28Vpc 2.35Vpc

30°C to 40°C 2.25Vpc 2.30Vpc

40°C to 50°C 2.22Vpc 2.25Vpc

Discharge 0°C 5°C 10°C 15°C 20°C 25°C 30°C 35°C 40°C 45°C 50°C

Time

5 mins to 0.80 0.86 0.91 0.96 1 1.04 1.06 1.09 1.1 1.12 1.13

59 mins

1h to 24h 0.86 0.90 0.94 0.97 1 1.03 1.05 1.06 1.07 1.08 1.09

Publication No: EN-VX-IOM-001 February 03

www.enersysinc.com

Page 6

6

3

2

1

4

Type Length Width Height Cell Weight

Centres (kg)

8VX100F 384 125 228 135 32

12VX100F 384 125 228 135 48

Technical specifications of bloc

All dimensions in millimetres

Item No. Description Cat No.

1 Fastener set M6 2 Inter-unit connector SUB5176

3 Inter-tier connector (35 mm

2

max.) -

4 Insulating terminal cover SPH0571B

Typical connection assembly

Typical assembly drawing

Publication No: EN-VX-IOM-001 February 03

www.enersysinc.com

Page 7

7

Works Order No: Customer Ref:

Installed At: Battery Type:

No. of Monoblocs: Date Installed:

Battery Float Voltage: V Ambient Temperature: °C

Battery Charging Current: A Average Vpc:

Comments:

Engineer in Charge: Date of Service:

Volts

per

cell

Volts

per

Monobloc

Volts

per

cell

Volts

per

Monobloc

Volts

per

cell

Volts

per

Monobloc

Volts

per

cell

Volts

per

Monobloc

Volts

per

cell

Volts

per

Monobloc

Volts

per

cell

Volts

per

Monobloc

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

178

179

180

181

182

183

184

185

186

187

188

189

190

191

192

193

194

195

196

197

198

Battery record sheet

Publication No: EN-VX-IOM-001 February 03

www.enersysinc.com

Page 8

Publication No: EN-VX-IOM-001 February 03 - Subject to revisions without prior notice

Global Headquarters

P.O. Box 14145 Reading,

PA 196212-4145

USA

Tel: +1-610-208-1991

+1-800-538-3627

Fax:+1-610-372-8613

EnerSys EMEA

Houtweg 26

1140 Brussels

Belgium

Tel: +32 (0)2 247 94 47

Fax:+32 (0)2 247 94 49

EnerSys Asia

No. 49, Yanshan Road

Shekou, Shenzhen

518066, China

Tel: +86-755-2689 3639

Fax:+86-755-2689 8013

Contact:

Loading...

Loading...