EnerSys PowerSafe RL Series, PowerSafe RM Series, PowerSafe RN Series, PowerSafe RH-420, PowerSafe RH Series Installation, Operating And Maintenance Instruction

Page 1

1 Publication No: EN-GAZ-Standard-IOM 001 Dec 2012

INSTALLATION, OPERATING

MAINTENANCE INSTRUCTIONS

type RL …, RM …, RN …, RH …

Battery voltage: Capacity (5 h):

T

y

pe of cell: Number of cells:

Assembled and commissioned by: Date:

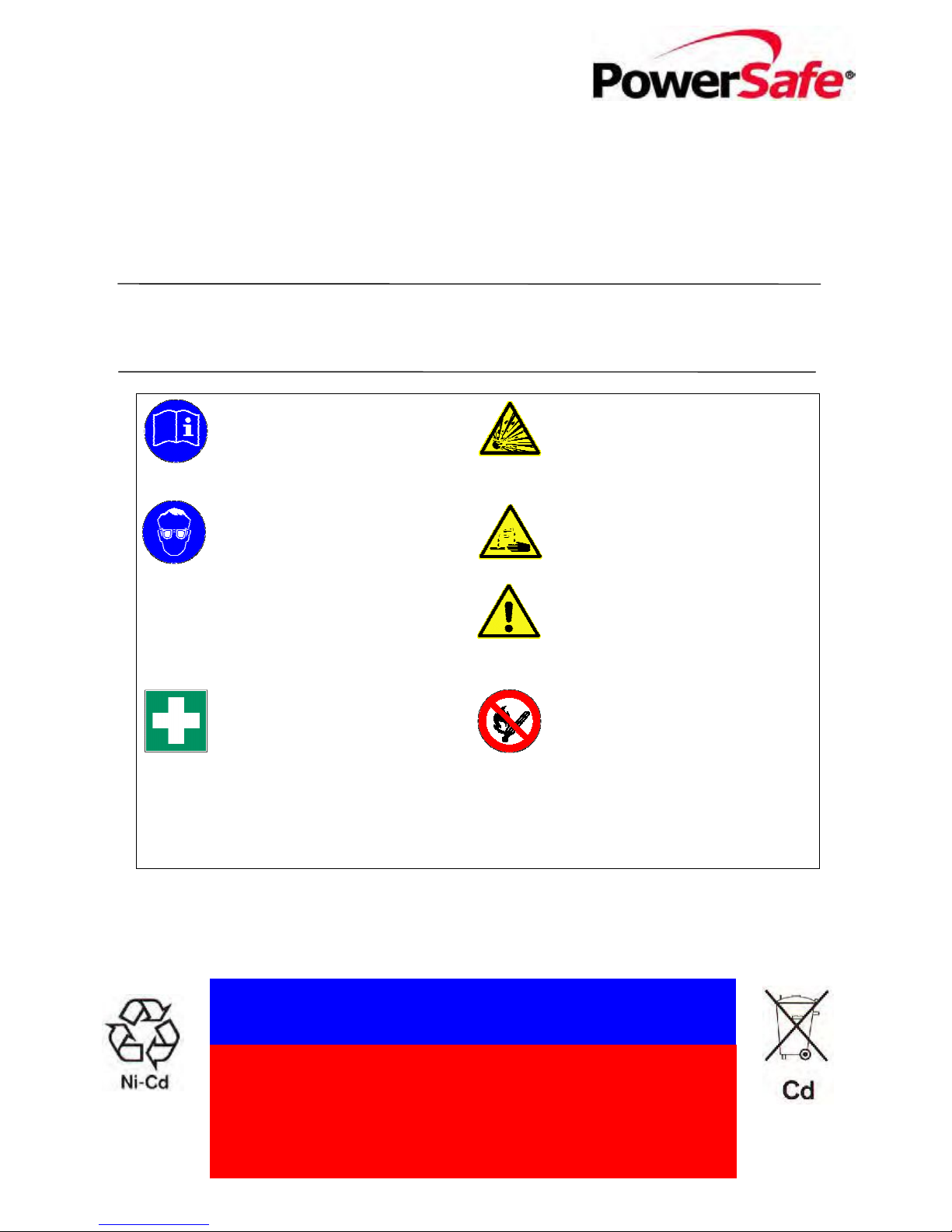

Warning!

The gases emitted during charging are explosive. The electrolyte (potassium hydroxide, KOH) is highly

co

rrosive. Exposed metal parts of the battery always conduct a voltage and are electrically active parts.

Precautions in accordance with DIN EN 50272, Part 2 have to be observed.

Observe the instructions for use and

place them visibly close to the

battery! Work only on batteries after

receiving instruction from qualified

personnel!

Warning: Risk of fire, explosion, or

burns! Avoid any short circuit!

Metallic parts under voltage on the

battery, do not place tools or items

on top of the battery!

Electrolyte is highly corrosive!

When working on batteries wear

safety glasses and protective

clothing. All metallic personal

objects, such as rings, watches,

bracelets etc. shall be removed

before starting work on the battery!

Only use insulated tools! Comply

strictly with the accident prevention

regulations and your national Health

and Safety standards as well as DIN

EN 50272, Part 1.

Cells are heavy!

Make sure they are safely

installed!

Only use suitable transport

equipment!

Electrolyte is harmful to skin and

eyes. Therefore, after an accidental

contact with the electrolyte flood the

eyes immediately with large

quantities of clean water for an

extended period of time of at least

15 minutes. In all cases, consult a

doctor immediately!

Clothing contaminated with

electrolyte should be washed in

water immediately!

No smoking! Do not allow naked

flames, embers or sparks near the

battery due to the risk of explosion

or fire!

The Installation, Operation and Handling Instructions must be strictly observed. Non-compliance

with the Maintenance and Handling Instructions, replacing with unoriginal spares, usage other

than specified, use of additives to the electrolyte and unauthorized tampering will invalidate any

entitlement to warranty.

Used batteries with this symbol are reusable products and have to be

put into a recycling system. Used batteries must be disposed of as

special waste in accordance with all standards.

WARNING!

Never use sulphuric acid or acidic

water.

Acid will damage the battery!

Page 2

2 Publication No: EN-GAZ-Standard-IOM 001 Dec 2012

1. Receiving the battery

The cells are not to be stored in

packaging, therefore, unpack the battery

immediately after arrival. Do not overturn

the package. The battery cells are

equipped with a blue plastic transport plug.

The battery can be delivered:

- Filled and charged/ the battery

is ready for installation. Replace

the transport plug with the vent

cap included in our accessories

just before use;

- Filled and discharged/ Replace

the transport plug with the vent

cap included in our accessories

just before use; or

- Unfilled and discharged/ do not

remove the transport plug until

ready to fill the battery.

The battery must not be charged with

the transport plug in the cells as this

can damage the battery.

2. Storage

The rooms provided for storing the

batteries must be clean, dry, cool (+10 °C

to 30 °C - in compliance with IEC 60623)

and well ventilated. The cells are not to be

stored in closed packaging and must not

be exposed to direct sunlight or UVradiation.

If the cells are delivered in plywood

boxes, open the boxes before storage

and remove the packing material on the

top of the cells. If the cells are delivered

on pallets remove the packing material

on the top of the cells.

2.

1 Uncharged and unfilled cells

Provided the correct storage conditions

are met then the cells and batteries can be

stored for long periods without damage if

they are deeply discharged, drained and

well sealed. It is very important that the

cells are sealed with the plastic transport

plug tightly in place. It is necessary to

check after receipt and at least every year.

Leaky plugs allow the carbon dioxide from

the atmosphere to infiltrate the cell, which

will result in carbonation of the plates. This

may influence the capacity of the battery.

2.2 Charged and filled cells/

discharged and filled cells

Filled cells can be stored for up to 12

months from the time of delivery. Storage

of filled cells at a temperature above

+30 °C results in loss of capacity of

approximately 5% per 10% year. It is very

important that the cells are sealed with the

plastic transport plugs tightly in place. In

case of loss of electrolyte during

transportation, refill the cell with distilled

water to the “MAX” mark before storage.

3. Installation

EN 50272-2:2001 “Accumulators and

battery installations, stationary battery

installations” is binding for the setting up

and operation of battery installations. For

non stationary installations specific

standards are valid.

3.1 Location

Install the battery in a dry and clean room.

Avoid direct sunlight and heat in all cases.

The battery will give the optimal

performance and maximum service life if

the ambient temperature lies between

+ 10 °C and + 30 °C.

3.2 Ventilation

During the last part of charging the battery,

gases (oxygen and hydrogen mixture) are

emitted. At normal float charge the gas

evolution is very small but some ventilation

is necessary. Special regulations for

ventilation might be required in your

area for certain applications. If no

regulations are fixed DIN EN 50272,

Part 2:2001 should be met.

3.3 Setting up

Always follow the assembly drawings,

circuit diagrams and other separate

instructions. The transport plugs have to

be replaced by the vent caps included in

the accessories. If batteries are supplied

“filled and charged” , all the electrolyte

levels should be checked and, if

necessary, topped up as described in

point 3.4.

Cell connectors and/or flexible cables

should be checked to ensure they are

tightly seated. Terminal nuts, screws and

connectors must be tightly seated. If

necessary, tighten with a torque wrench.

Torque loading for:

M10: 8 Nm

M16: 20 Nm

M20: 25 Nm

Female thread:

M 8: 20 – 25 Nm

M10: 25 – 30 Nm

The connectors and terminals should be

corrosion-protected by coating with a thin

layer of anti-corrosion grease.

3.4 Electrolyte

The electrolyte for NiCd batteries consists

of diluted caustic potash solution (specific

gravity 1.20 kg/litre ± 0.01 kg/litre) with

a lithium hydroxide component, in

accordance with IEC 60993. The caustic

potash solution is prepared in accordance

with factory regulations. The specific

gravity of the electrolyte does not allow

any conclusion to be drawn on the

charging state of the battery. It changes

only slightly during charging and

discharging and is only minimally related

to the temperature.

-

Battery delivered unfilled and

discharged/ if the electrolyte is

supplied dry, it is to be mixed to

the enclosed mixing instruction.

Remove the transport plugs from

the cell just before filling. Fill the

cells up to 20 mm above the

lower level mark “MIN”. Steel

cased cells have to be filled up to

the top edge of the plates. When

using battery racks fill cells before

installing. Only use genuine

electrolyte.

- Battery delivered filled and

charged or discharged/ check

electrolyte level. It should not be

less than 20 mm below the upper

level mark “MAX” (see 5.2).

3.5 Commissioning

A good commissioning is very important.

The following instructions are valid for

commissioning while 20 °C to 30 °C. For

different conditions please contact the

manufacturer. Charging at constant

current is preferable. If a site test is

requested it has to be carried out in

accordance with IEC 60623.

According to IEC 60623, 0.2 C5 A is also

expressed as 0.2 It A. The reference test

current It is expressed as:

It A = Cn Ah

1 h

Example:

0.2 ItA means:

20 A for a 100 Ah battery or

100 A for a 500 Ah battery

3.5.1 Commissioning with constant

current

Battery delivered unfilled and

discharged /after a period of 5 hours from

filling the electrolyte, the battery should be

charged for 15 hours at the rated charging

current 0.2 It A. Approximately 4 hour after

the end of charging, the electrolyte level

should be adjusted to the upper electrolyte

level mark “MAX” by using only genuine

electrolyte. For cells with steel cases, the

electrolyte level should be adjusted to the

maximum level according to the

“Instruction for the control of electrolyte

level”. During the charge the electrolyte

level and temperature should be

observed (see point 5.4). The

electrolyte level should never fall below

the “MIN” mark.

Battery delivered filled and discharged

/the battery should be charged for 15

hours at the rated charging current 0.2 It A.

Approximately 4 hours after the end of

charging, the electrolyte level should be

adjusted to the upper electrolyte level

mark “MAX” by using distilled or deionized

water in accordance with IEC 60993. For

cells with steel cases, the electrolyte level

should be adjusted to the maximum level

according to the “Instruction for the control

of electrolyte level”.

Page 3

3 Publication No: EN-GAZ-Standard-IOM 001 Dec 2012

During the charge the electrolyte level

and temperature should be observed

(see point 5.4). The electrolyte level

should never fall below the “MIN” mark.

Battery delivered filled and charged

and stored for more than 12 months/

the battery should be charged for 15 hours

at the rated charging current 0.2 It A.

Approximately 4 hours after the end of

charging, the electrolyte level should be

adjusted to the upper electrolyte level

mark “MAX” by using distilled or deionized

water in accordance with IEC 60993. For

cells with steel cases, the electrolyte level

should be adjusted to the maximum level

according to the “Instruction for the control

of electrolyte level”. During the charge

the electrolyte level and temperature

should be observed (see point 5.4). The

electrolyte level should never fall below

the “MIN” mark.

Battery delivered filled and charged/

a 5

hour charge at the rated charging current

0.2 It A must be carried out before putting

the battery into operation. Approximately 4

hours after the end of charging, the

electrolyte level should be adjusted to the

upper electrolyte level mark “MAX” by

using distilled or deionized water in

accordance with IEC 60993. For cells with

steel cases, the electrolyte level should be

adjusted to the maximum level according

to the “Instruction for the control of

electrolyte level”. During the charge the

electrolyte level and temperature

should be observed (see point 5.4). The

electrolyte level should never fall below

the “MIN” mark.

3.5.2 Commissioning with constant

voltage

If the charger´s maximum voltage setting

is too low to supply constant current

charging, divide the battery into two parts

that will be charged individually.

Battery delivered unfilled and

discharged / after a period of 5 hours

from filling the electrolyte, the battery

should be charged for 30 hours at the

rated charging voltage of 1.65 V/cell. The

current limit should be 0.2 It A maximum.

Approximately 4 hours after the end of

charging, the electrolyte level should be

adjusted to the upper electrolyte level

mark “MAX” by using only genuine

electrolyte. For cells with steel cases, the

electrolyte level should be adjusted to the

maximum level according to the

“Instruction for the control of electrolyte

level”. During the charge the electrolyte

level and temperature should be

observed (see point 5.4). The

electrolyte level should never fall below

the “MIN” mark.

Battery delivered filled and discharged

/

the battery should be charged for 30

hours at the rated charging voltage of 1.65

V/cell. The current limit should be 0.2 It A

maximum. Approximately 4 hours after the

end of charging, the electrolyte level

should be adjusted to the upper

electrolyte level mark “MAX” by using

distilled or deionized water in accordance

with IEC 60993. For cells with steel cases,

the electrolyte level should be adjusted to

the maximum level according to the

“Instruction for the control of electrolyte

level. During the charge the electrolyte

level and temperature should be

observed (see point 5.4). The

electrolyte level should never fall

below the “MIN” mark.

Ba

ttery delivered filled and charged

and stored for more than 12 months/

the battery should be charged for 30 hours

at the rated charging voltage of 1.65

V/cell. The current limit should be 0.2 It A

maximum. Approximately 4 hours after the

end of charging, the electrolyte level

should be adjusted to the upper electrolyte

level mark “MAX” by using distilled or

deionized water in accordance with IEC

60993. For cells with steel cases, the

electrolyte level should be adjusted to the

maximum level according to the

“Instruction for the control of electrolyte

level”. During the charge the electrolyte

level and temperature should be

observed (see point 5.4). The

electrolyte level should never fall below

the “MIN” mark.

Battery delivered filled and charged/ a

10 hour charge at the rated charging

voltage of 1.65 V/cell must be carried out

before putting the battery into operation.

The current limit should be 0.2 It A

ma

ximum. Approximately 4 hours after the

end of charging, the electrolyte level

should be adjusted to the upper electrolyte

level mark “MAX” by using distilled or

deionized water in accordance with IEC

60993. For cells with steel cases, the

electrolyte level should be adjusted to the

maximum level according to the

“Instruction for the control of electrolyte

level”. During the charge the electrolyte

level and temperature should be

observed (see point 5.4). The

electrolyte level should never fall below

the “MIN” mark.

4. Charging in Operation

4.1 Continous battery power supply

(with occasional battery discharge)

Recommended charging voltage for

ambient temperatures + 20 °C to + 25 °C.

Do not remove the vent caps during float-,

boost charge and buffer operation. The

current limit should be 0.3 It A maximum in

ge

neral.

4.

1.2 Two level charge

Floating: 1.40 – 1.42 V/cell

Boost charge: 1.55 – 1.70 V/cell

A high voltage will increase the speed and

efficiency of recharging the battery.

4.1.3 Single level charge

1.45 – 1.50 V/cell

4.2 Buffer operation

Where the load exceeds the charger

rating.

1.45 – 1.55 V/cell

5. Periodic Maintenance

The battery must be kept clean using only

water. Do not use a wire brush or solvents

of any kind. Vent caps can be rinsed in

clean water if necessary but must be dried

before using them again.

Check regularly (approximately every 6

months) that all connectors, nuts and

screws are tightly fastened. Defective vent

caps and seals should be replaced. All

metal parts of the battery should be

corrosion-protected by coating with a thin

layer of anti-corrosion grease. Do not

coat any plastic part of the battery, for

example cell cases!

Check the charging voltage. If a battery is

parallel connected it is important that the

recommended charging voltage remains

unchanged. The charging current in the

strings should also be checked to ensure it

is equal. These checks have to be carried

out once a year. High water consumption

of the battery is usually caused by

improper voltage setting of the charger.

5.

1 Equalizing charge

It is recommended to carry out an

equalizing charge once a year to maintain

capacity and to stabilize the voltage levels

of the cells. The equalizing charge can be

carried out for 15 hours at 0.2 It A or with

the boost charging stage in conformity with

the characteristic curve of the available

charging equipment. The electrolyte level

must be checked after an equalizing

charge.

In order to equalize the floating derating

effect, it is recommended to charge the

battery once a year for 15 hours at the

rated charging current 0.2 It A. Then

discharge the battery down to 1.0 V/cell

and charge again for 8 hours at the rated

charging current 0.2 It A.

Page 4

4 Publication No: EN-GAZ-Standard-IOM 001 Dec 2012

5.2 Electrolyte check an

d topping

up

Check the electrolyte level and never let

the level fall below the lower level mark

“MIN”. Use only distilled or deionized water

to top-up the cells in accordance with IEC

60993. Experience will tell the time interval

between topping-up. Refilling with

electrolyte is only permissible if spilled

electrolyte has to be replaced. If during

refilling or topping up electrolyte has been

splashed onto the cell cover or between

the cell cases, clean this off and then dry

the area.

NOTE: Once the battery has been

filled with the correct electrolyte

either at the factory or during the

battery commissioning, there is no

need to check the electrolyte

density periodically. Interpretation

of density measurements is difficult

and could lead to

misunderstandings.

5.3 Replacing of electrolyte

In most stationary applications the

electrolyte will retain its effectiveness for

the total lifetime of the battery. However,

under special battery operating conditions,

if the electrolyte is found to be carbonated,

the battery performance can be restored by

replacing the electrolyte. Only use

genuine electrolyte!

It is recommended to change the

electrolyte when reaching a carbonate

content of 75 g/litre. It is possible to test

the electrolyte in the manufacturer’s

laboratory. For this, a minimum quantity of

0.2 litres of electrolyte in a clean glass or

polyethylene container should be sent in,

paying strict attention to the valid

dangerous goods regulations. The sample

of electrolyte should be taken half an hour

after charging has ended and from several

cells of the battery. Do not take the

samples immediately after topping up. The

electrolyte sample and the cells should be

closed immediately after the electrolyte has

been taken.

CAUTION – caustic potash solution is

highly corrosive!

5.4 Electrolyte temperature

The temperature of the electrolyte should

never exceed 45 °C as higher

temperatures have a detrimental effect on

the function and duration of the cells. In the

course of charging, aim for an electrolyte

temperature of

≤ 35 °C. On exceeding

45 °C the charging should be temporarily

interrupted until the electrolyte temperature

falls down to 35 °C. The temperature

measurements are to be made on one of

the cells in the middle of the battery. Low

ambient or electrolyte temperatures down

to –25 °C do not have any detrimental

effect on the battery. They just cause a

temporary reduction in capacity.

6. Additional Warning notes

NiCd batteries must not be installed or

stored in the same room as lead acid

batteries. In addition to this, the charging

gases from lead acid batteries must be

kept away from Ni-Cd batteries by suitable

precautions such as ventilation or hermetic

isolation of the rooms. Tools for lead acid

batteries must not be used for NiCd

batteries.

Do not place electrically conductive objects

such as tools, etc. on the battery!

Risk of short circuit and fire!

No rings or metal bracelets should be worn

during the assembly of the battery – Risk

of injury!

Open the doors of the battery cabinet

during charging so that the charging gases

can escape. The charging gases from

batteries are explosive. Do not allow open

fire or ember in the vicinity of the battery!

Risk of explosion!

Caution – potassium hydroxide

(KOH) solution is highly corrosive!

Potassium hydroxide (KOH) solution is

used as electrolyte. Potassium

hydroxide (KOH) solution is a highly

corrosive liquid which can cause severe

damage to health if it comes into contact

with the eyes or the skin (risk of blinding). If

even small quantities are swallowed there

is a possibility of internal injuries.

When working with electrolyte and on

cells / batteries rubber gloves, safety

goggles with side guards and protective

clothing must always be worn!

Contact with the eyes: Flush out

immediately with abundant amounts of

water for 10 – 15 minutes. If necessary

consult an eye clinic.

Contact with the skin: Remove splashed

clothing immediately and wash the affected

skin areas with abundant amounts of

water. For any discomforts consult a

doctor.

Swallowing: Rinse out the mouth

immediately with abundant amounts of

water and keep drinking large amounts of

water. Do not provoke vomiting. Call an

emergency doctor immediately.

In the event of injuries: Rinse thoroughly

for a long period under running water.

Consult a doctor immediately.

Loading...

Loading...