Page 1

BATTERY

TM

RESERVE

POWER

APPLICATION MANUAL

Genesis®NP and NPX

Series

Page 2

TM

Genesis®NP & NPX Battery Series Application Manual

Table of contents

Introduction 2

Technical Features 3

Applications 4

Battery Construction 4

Today’s Genesis®NP Battety series is

the culmination of more than ten

decades of battery manufacturing

experience. High energy density,

leak proof construction, excellent

performance in either float or

cyclic applications and long

service life combine to make the

Genesis NP Series the most

reliable and versatile maintenance

free rechargeable sealed lead acid

batteries available.

General Specifications NP Series 5

Range Summary Layout Terminal Configurations 6

Battery Capacity Selection Charts 7

Discharge 7-9

Discharge Characteristics

Temperature Characteristics

Over-Discharge (Deep Discharge)

Storage, Self-Discharge, and Shelf Life 9

Self-Discharge

Shelf Life

Recharging Stored Batteries

Ohmic Readings 9

Charging 10-13

Constant Current Charging

Two Step Constant Voltage Charging

Charging Voltage

Initial Charge Current Limit

Refresh Charging

Temperature Compensation

Charging Efficiency

Solar Powered Charging

2 www.enersys.com

Service Life of Genesis®NP Batteries 13

Cyclic Service Life

Float Service Life

Tips & Precautions 14

Glossary 14-15

Limited Warranty 16

Publication No: US-NP-AM-003 • January 2011

Page 3

Technical Features Benefit

TM

Construction

Electrolyte Suspension System

Gas Generation

Maintenance Free Operation

Low Pressure Valve Regulated System

The construction and sealing techniques of the Genesis NP

battery guarantees leakproof operation in any position

except inverted, with no adverse effect to capacity or

service life.

All Genesis®NP batteries utilize an electrolyte suspension

system consisting of a high porosity, glass fiber material

which in conjunction with plates, totally absorb and

contain the electrolyte. No silica gels or any other

contaminants are used.

Genesis NP batteries incorporate a built-in design that

controls gas generation and induces recombination of

more than 99% of gases generated during float usage.

There is no need to check specific gravity of the electrolyte

or add water to Genesis NP batteries during float service

life. In fact, there is no provision for this type of

maintenance.

All Genesis NP batteries are equipped with safety release

valves, designed to operate between 2 and 5 psi and

automatically reseal. Hence, there is never an excessive

accumulation of gas within the battery.

Heavy Duty Grids

Cyclic Service Life

Float Service Life

Self Discharge - Shelf Life

Operating Temperature

Deep Discharge Recovery

www.enersys.com

Heavy duty lead calcium tin alloy grids provide an extra

margin of performance and service life in either float or

cyclic applications, even after repeated over discharges.

More than 1000 discharge/recharge cycles can be realized

from Genesis NP batteries, dependent on the average

depth of discharge.

Genesis NP Series batteries have an expected life span of

3 to 5 years in float service applications.

The self discharge rate of the Genesis NP series at room

temperature is approximately 3% of rated capacity per

month.

Genesis NP Batteries may be operated over a broad range

of ambient temperatures.

Genesis NP batteries recover their capacities even after

repeated deep discharges.

Publication No: US-NP-AM-003 • January 2011 3

Page 4

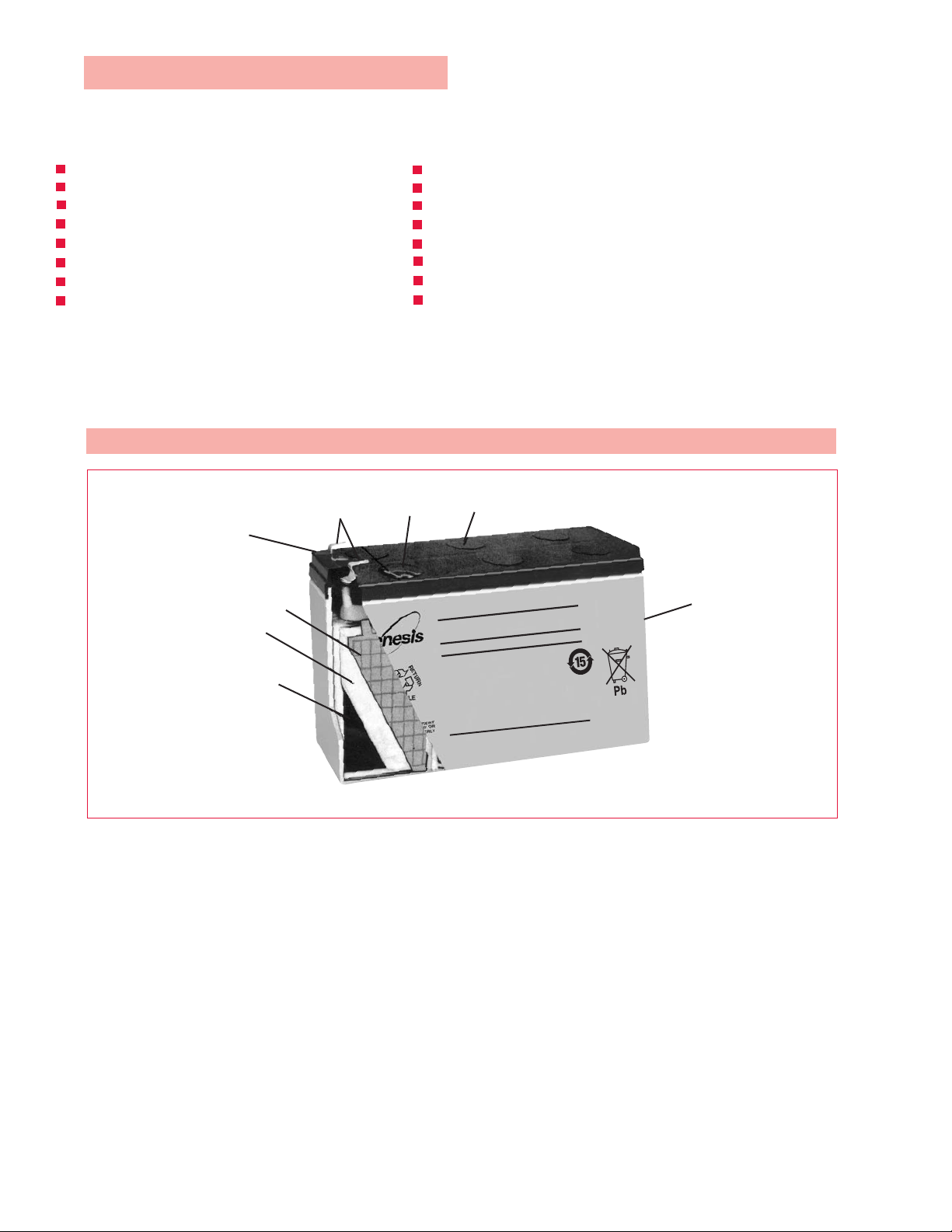

Applications

NP7-12 12V, 7.0Ah

SEALED RECHARGEABLE LEAD-ACID BATTERY

CAUTION:

• DO NOT SHORT OR PUT IN FIRE. MAY EXPLODE OR LEAK.

• USE APPROVED CHARGING METHODS.

• SHORT CIRCUIT PROTECTION REQUIRED DURING TRANSPORTATION.

• DO NOT CHARGE IN A SEALED CONTAINER.

• BATTERYPOSTS, TERMINALS, AND RELATED ACCESSORIES CONTAIN LEAD

AND LEAD COMPOUNDS, CHEMICALS KNOWN TO THE STATEOF CALIFORNIA

TO CAUSE CANCER AND REPRODUCTIVE HARM. BATTERIES ALSO CONTAIN OTHER

CHEMICALS KNOWN TO THE STATEOF CALIFORNIA TO CAUSE CANCER.

WASH HANDS AFTER HANDLING.

READING, PA 19612MADE IN VIETNAM

ENERSYS

NON-SPILLABLE

www.enersys.com

MH16464

NP712GNV

A partial list of common applications include:

Burglar and Fire Alarm

Office Machines

Cash Registers

Solar Power Devices

Telecommunications

Uninterruptable Power Supply (UPS) Equipment

Emergency Lighting

Computers

Genesis NP Battery Construction

Terminal

Sealant

Negative Plate

Absorbant

Glass

Mat

Positive Plate

Relief Valve

Audio and Video Equipment

Portable Lights

Electric Wheelchairs

Test Equipment

Geophysical Equipment

Power Tools

Surveillance Systems

Dispensing Machines

Lid

Container

NOTE:

Not recommended for use in medical equipment or devices

Not recommended for use in inverted “vents down” position

4 www.enersys.com

Publication No: US-NP-AM-003 • January 2011

Page 5

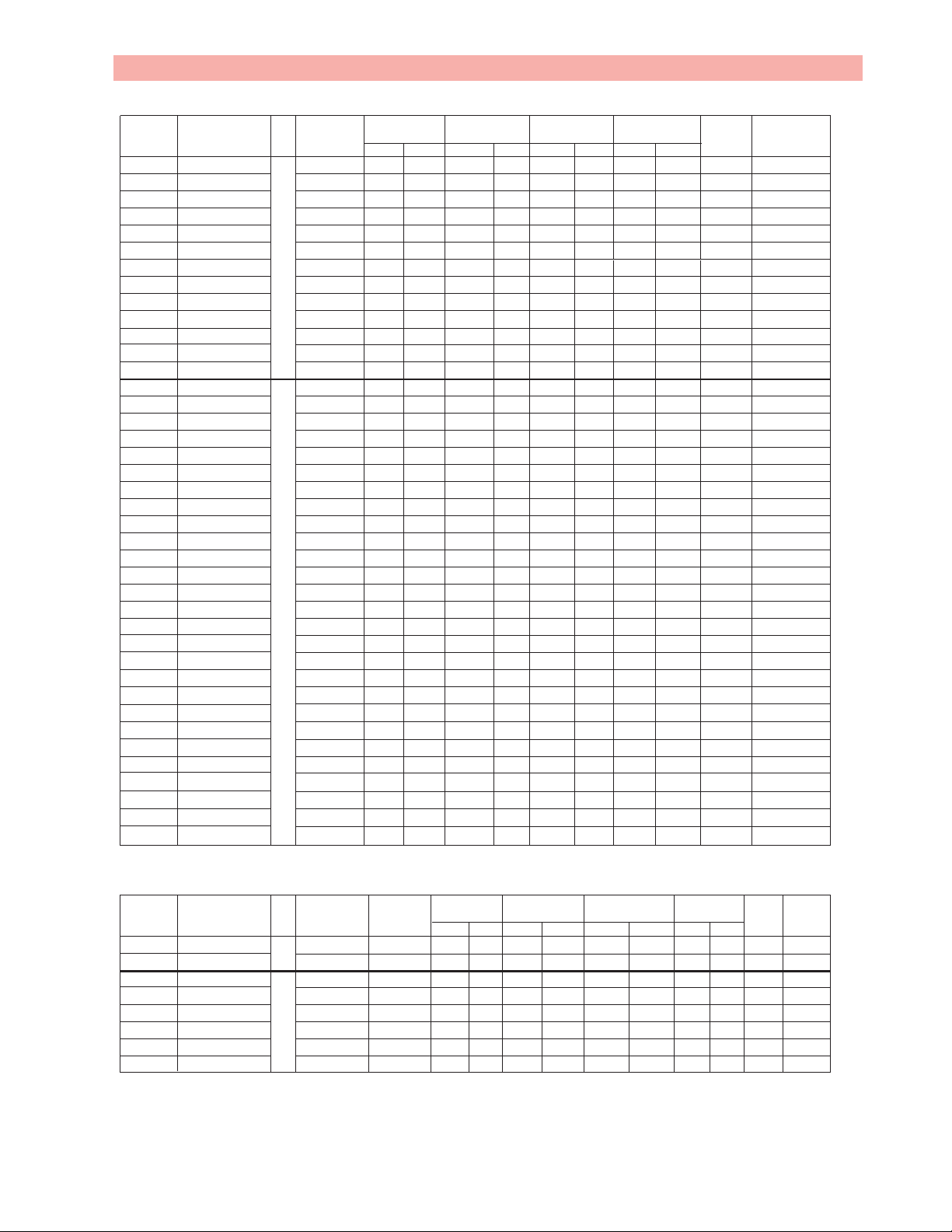

General Specifications Genesis®NP Battery Series

GENESIS®NP BATTERY SERIES

Battery

Type FR Type* Volts Capacity Length Width Incl. Terminals Layout Terminals

NP1-6 NP1-6FR 1.0 51.0 2.01 42.0 1.65 57.0 2.24 0.28 0.61 5A

NP1.2-6 NP1.2-6FR 1.2 97.0 3.82 25.0 0.98 56.0 2.20 0.30 0.67 1A

NP2.8-6 NP2.8-6FR 2.8 67.0 2.64 33.0 1.30 105.0 4.13 0.59 1.30 5 A/C

NP3-6 NP3-6FR 3.0 134.0 5.28 33.0 1.30 67.0 2.64 0.69 1.53 1A

NP3.2-6 NP3.2-6FR 3.2 66.0 2.60 33.0 1.30 104.0 4.09 0.59 1.30 5A

NP3.8-6 NP3.8-6FR 3.8 66.0 2.60 33.0 1.30 125.0 4.92 0.75 1.65 1A

NP4-6 NP4-6FR 6 4.0 70.0 2.76 47.0 1.85 105.0 4.15 0.80 1.76 5 A/C

NP4.5-6 NP4.5-6FR 4.5 70.0 2.76 47.0 1.85 105.0 4.15 0.86 1.90 5 A/C

NP5-6 NP5-6FR 5.0 70.0 2.76 47.0 1.85 105.0 4.15 0.95 2.10 5 A/C

NP7-6 NP7-6FR 7.0 151.0 5.95 33.0 1.30 100.0 3.94 1.28 2.83 1 A/C

NP8.5-6 NP8.5-6FR 8.5 98.0 3.86 56.0 2.20 118.0 4.65 1.60 3.53 9 A/C

NP10-6 NP10-6FR 10.0 151.0 5.95 50.0 1.97 101.0 3.98 1.99 4.38 1 A/C

NP12-6 NP12-6FR 12.0 151.0 5.95 50.0 1.97 101.0 3.98 2.04 4.48 1 A/C

NP0.8-12 NP0.8-12FR 0.8 96.0 3.78 25.0 0.98 61.0 2.42 0.37 0.82 7 H/I

NP1.2-12 NP1.2-12FR 1.2 97.0 3.82 48.0 1.89 56.0 2.20 0.57 1.25 3A

NP2-12 NP2-12FR 2.0 150.0 5.91 20.0 0.79 89.0 3.50 0.70 1.54 8B

NP2-12-C NP2-12-CFR 2.0 182.0 7.17 24.0 0.93 61.0 2.40 0.73 1.61 6L

NP2.3-12 NP2.3-12FR 2.3 178.0 7.01 35.0 1.38 67.0 2.64 1.02 2.15 1A

NP2.6-12 NP2.6-12FR 2.6 134.0 5.28 67.0 2.64 66.0 2.60 1.36 3.00 3A

NP2.9-12 NP2.9-12FR 2.9 79.0 3.11 56.0 2.20 105.0 4.13 1.24 2.73 1 A/C

NP3-12 NP3-12FR 3.0 132.0 5.20 33.0 1.30 105.0 4.13 1.18 2.60 1 A/C

NP3.4-12 NP3.4-12FR 3.4 134.0 5.28 67.0 2.64 67.0 2.64 1.39 3.06 3 A/C

NP4-12 NP4-12FR 4.0 90.0 3.54 70.0 2.76 107.0 4.21 1.70 3.74 1 A/C

NP4.5-12 NP4.5-12FR 4.5 90.0 3.54 70.0 2.76 107.0 4.21 1.76 3.88 1 A/C

NP5-12 NP5-12FR 5.0 90.0 3.54 70.0 2.76 107.0 4.21 1.81 4.00 1 A/C

NP7-12 NP7-12FR 7.0 151.0 5.95 65.0 2.56 100.0 3.94 2.59 5.72 4 A/C

NP12-12 NP12-12FR 12 12.0 151.0 5.95 98.0 3.86 100.0 3.94 4.06 8.95 4C

NP18-12 NP18-12FR 17.2 181.0 7.13 76.0 3.00 167.0 6.57 6.17 13.60 2 D/E

NP24-12 NP24-12FR 24.0 166.0 6.54 175.0 6.89 125.0 4.92 9.07 20.00 2 C/D/E

NP33-12 NP33-12FR 33.0 197.0 7.76 131.0 5.16 158.0* 6.22* 11.79 26.00 1 E/F

NP-35-12 NP-35-12FR 35.0 198.0 7.80 132.0 5.20 170.0 6.69 12.61 27.80 1F

NP38-12 NP38-12B 38.0 197.0 7.76 165.0 6.50 172.0 6.77 14.59 32.16 2 F/G

NP55-12 NP55-12FR 56.3 229.0 9.02 138.0 5.43 207.0

NP65-12 NP65-12FR 65.0 350.0 13.78 166.0 6.54 174.0 6.85 23.63 52.10 2 F/G

NP75-12 NP75-12FR 77.5 259.0 10.20 169.0 6.65 208.0

NP90-12 NP90-12FR 90.0 304.0 11.97 168.0 6.61 229.0 9.02

NP100-12 NP100-12FR 100.0 329.0 12.95 174.0 6.85 214.0

NP120-12 NP120-12FR 120.0 407.0 16.02 173.0 6.81 235.0 9.25 38.41 84.68 1 J/G

NP150-12 NP150-12FR 150.0 483.0 19.02 170.0 6.69 241.0 9.49 47.13 103.90 1 J/G

NP200-12 NP200-12FR 200.0 520.0 20.47 260.0 10.24 208.0 8.19 73.00 160.93 3 K/G

Nominal Overall Height

(20 hr rate - Ah)

mm. (in.) mm (in.) mm. (in.) kgs. (lbs.)

†

†

†

Weight

8.15†18.01 39.70 1 M/E

8.19†26.50 58.42 1 M/G

†

31.18 68.74 1 M/G

8.43†32.94 72.62 1 J/G

DATASAFE®NPX BATTERY SERIES

Battery W/Cell to 1.67 Nominal Overall Height

Type FR Type* Volts End Voltage Capacity Length Width Incl. Terminals Layout Terminals

NPX-35-6 NPX-35-6FR 35W/Cell 8 151.0 5.95 33.0 1.30 100.0 3.94 1.43 3.15 1 A/C

NPX-50 NPX-50FR 50W/Cell 13 151.0 5.95 50.0 1.97 100.0 3.94 2.09 4.60 1 A/C

NPX-25 NPX-25FR 23W/Cell 5 90.0 3.54 70.0 2.75 107.0 4.21 1.95 4.30 1 A/C

NPX-35 NPX-35FR 35W/Cell 8 151.0 5.95 65.0 2.56 100.0 3.94 2.75 6.06 4 A/C

NPX-80 NPX-80FR 80W/Cell 20 181.0 7.13 76.0 2.39 167.0 6.57 6.35 14.0 2 D/E

NPX-100 NPX-100FR 95W/Cell 28 166.0 6.54 125.0 4.92 175.0 6.89 9.70 21.38 2 D/E

NPX-135 NPX-135FR 135W/Cell 33 197.0 7.76 131.0 5.16 158.0†6.22 11.94 26.32 1 E/F

NPX-150 NPX-150FR 150W/Cell 40 197.0 7.76 165.0 6.50 172.0 6.77 14.29 31.50 2 F/G

FOOTNOTES:

* FR: UL94-VO, Flame Retardant Case and Cover (Oxygen index: 28)

† Height is to top cover. Overall height, including terminal is dependent on terminal configuration.

Recognized by UL File No. MH16464

NOTE: All dimensions are +/- 0.08 inches (2mm); Weights are +/- 5%

www.enersys.com

6

12

(15 Min Rate)

Weight

(20hr rate - aH) mm. (in.) mm (in.) mm. (in.) kgs. (lbs.)

TORQUE SPECIFICATIONS:

M5 Bolt: 26.6 lbf.in (3Nm) +/- 5%

M6 Bolt: 44.31 lbf.in (5Nm) +/- 5%

M5 receptacle: 35.4 lbf.in (4Nm) +/- 5%

M6 receptacle: 65 lbf.in (6.8Nm) +/- 5%

Publication No: US-NP-AM-003 • January 2011 5

Page 6

Range Summary

• LAYOUT

• TERMINAL

Faston Tab: 187

M5Threaded Receptacle

Tyco. 1-480318-0

INCH = MM INCH = MM

Faston Tab: 187

INCH = MM

M6 Bolt Fastened Terminal

INCH = MM

M8 Bolt Fastened Terminal

INCH = MM

INCH = MM

Faston Tab: 250

M6 Threaded Receptacle

M10 Bolt Fastened Terminal

INCH = MM

INCH = MM

INCH = MM

M5 Bolt Fastened Terminal

INCH = MM

JST No. VHR-2N

INCH = MM

“Camcorder” Terminal

M8 “Universal” Bolt Fastened Terminal

Terminal Continuous 1Hr. 1 Min.

Faston tab 187 16 24 48

Faston tab 250 25 38 75

Wire Lead 0.5mm^2 7 20 30

All Bolt or Receptacle 6CA

Maximum Permissable Current (Amps)

Charging

•

Standby use: Apply constant voltage charging at 2.275 volts

per cell (or 2.25–2.30VPC).

•

Cyclic use: Apply constant voltage charging at 2.40-2.50 VPC.

Initial charging current should be set at less than 0.25CA.

•

Top charge: Product in storage (ambient temperature 25°C/77°F)

requires a top charge every six months. Apply constant voltage at

2.40 volts per cell, initial charging current should be set at

less than 0.1CA for 15 to 20 hours.

Discharge

•

Stop operation when voltage has reached the minimum

permissible voltage. Recharge immediately.

•

Do not operate above 6CA or more current continuously.

6 www.enersys.com

Storage

•

Always store battery in a fully charged condition.

•

If battery is to be stored for a long period, apply a recovery

top-charge every 6 months.

•

Store batteries in a dry and cool location.

Temperature

•

Keep within ambient temperatures of –150C to +500C for both

charging and discharging.

Incorporating battery into equipment

•

Install battery in a well ventilated compartment.

•

Avoid installing battery near heated units such as a transformer.

•

House the battery in the lowest section of the equipment

enclosure or rack to prevent unnecessary battery temperature

rise.

Others

•

Avoid terminal short circuit.

•

Avoid exposure of the ABS container and cover material to PVC-based

rubber mats or spacers

•

DO NOT expose to open flame

•

WARNING - Avoid exposure of the battery to any type of

oil, solvent, detergent, petroleum-based solvent or ammonia

solution. These materials could potentially cause permanent

damage to the battery jar and cover and will void the warranty.

.

Publication No: US-NP-AM-003 • January 2011

Page 7

DISCHARGE CURRENT

MINUTES

HOURS

AT 25ºC (77ºF)

Battery Capacity Selection

Discharge

Figure 1 may be used to determine battery size (expressed in

Ampere Hours of capacity), for a specific application. To

determine the capacity of the battery, establish the discharge

current for the length of discharge time required. The point

where the current and time lines intersect is the minimum

capacity battery needed for the application. It is recommended

you also refer to Figures 3 before making your final decision.

Figure 2 is the high rate capacity selection chart for Genesis

NPX series batteries. These batteries are typically used for UPS

constant power applications under 30 minutes.

Figure 1. 20-Hour Rate Capacity Selection Chart

Discharge Characteristics

The curves shown in Figure 1, and the discharge rates shown

in Table 3 illustrate the typical discharge characteristics of

Genesis NP batteries at an ambient temperature of 25˚C

(77˚F). The symbol “C” expresses the nominal capacity of the

Genesis NP battery, measured at a 20 hour discharge rate.

®

Please refer to General Specifications to determine the

nominal capacity rating of the specific model.

The industry standard for designating the nominal capacity of

a sealed lead acid battery involves a discharge test for a given

number of hours to a final pre-set end voltage. The average

current value multiplied by the hours of discharge time

determines the capacity rating of that particular battery.

Since manufacturers vary in their rating standards, it is

always a good practice to question the rating standard.

Table 1 shows how the rated nominal capacity

decreases when the discharge load is higher than the 20

hour rate. This table should be consulted when selecting

a battery for a high discharge application.

The discharge rates depicted in Figure 2 and Table 2

reference watts per cell of the DataSafe

®

NPX series of

batteries. These batteries are designed for Uninterruptable

Power Supply (UPS) applications where high rate discharge

performance (under 30 minutes) is typical. To determine the

battery kilowatt rating required for a UPS system, refer to the

following formula: KVA rating of UPS x Power Factor (Pf)

÷ inverter efficientcy = Total Battery Kilowatts (KWB)

Temperature characteristics

At higher temperatures, the electrical capacity that can be

taken out of a battery increases. At lower temperatures, the

electrical capacity that can be taken out of a battery

decreases. Figure 4 shows the temperature effects in relation

to battery capacity.

Discharge Constant Power Watts/Cell

Figure 2. High Rate Discharge Capacity Selection Chart

Figure 4. Temperature Effects in Relation to Battery Capacity

Figure 3. Discharge Characteristic Curves: Genesis®NP Batteries

www.enersys.com

Publication No: US-NP-AM-003 • January 2011 7

Page 8

Discharge Capacity

20 Hr 10 Hr 5 Hr 3 Hr 1 Hr

NP0.8-12

0.8 0.8 0.74 0.68 0.62 0.48

NP1-6 1.0 1.0 0.93 0.85 0.78 0.60

NP1.2-6,NP1.2-12 1.2 1.2 1.1 1.0 0.9 0.7

NP2-12 2.0 2.0 1.9 1.7 1.6 1.2

NP2.3-12 2.3 2.3 2.2 2.0 1.8 1.4

NP2.6-12 2.6 2.6 2.4 2.2 2.0 1.6

NP2.8-6 2.8 2.8 2.6 2.4 2.2 1.7

NP2.9-12 2.9 2.9 2.7 2.5 2.3 1.7

NP3-6,NP3-12 3.0 3.0 2.8 2.6 2.3 1.8

NP3.2-6 3.2 3.2 3.0 2.7 2.5 1.9

NP3.4-12 3.4 3.4 3.2 2.9 2.7 2.0

NP3.8-6 3.8 3.8 3.5 3.2 3.0 2.3

NP4-6,NP4-12 4.0 4.0 3.7 3.4 3.1 2.4

NP4.5-6,NP4.5-12 4.5 4.5 4.2 3.8 3.5 2.7

NP5-6,NP5-12 5.0 5.0 4.6 4.3 3.8 3.0

NP7-6,NP7-12 7.0 7.0 6.5 6.0 5.4 4.2

NP8.5-6 8.5 8.5 7.9 7.2 6.6 5.1

NP10-6 10.0 10.0 9.3 8.5 7.7 6.0

NP12-6,NP12-12 12.0 12.0 11.2 10.2 9.2 7.2

NP18-12 17.2 17.2 16.0 14.6 13.2 10.3

NP24-12 24.0 24.0 22.3 20.4 18.5 14.4

NP33-12 33.0 33.0 30.7 28.1 25.7 19.8

NP35-12 35.0 35.0 32.6 29.8 27.3 21.0

NP38-12 38.0 38.0 35.0 32.3 29.3 22.8

NP55-12 55.0 55.0 49.5 46.8 42.9 33.0

NP65-12 65.0 65.0 60.5 55.3 50.1 39.0

NP75-12 75.0 75.0 69.8 63.8 58.5 45.0

NP90-12 90.0 90.0 83.7 76.5 70.2 54.0

NP100-12 100.0 100.0 93.0 85.0 78.0 60.0

NP120-12 120.0 120.0 111.6 102.0 93.6 72.0

NP150-12 150.0 150.0 139.5 127.5 117.0 90.0

NP200-12 200.0 200.0 186.0 170.0 156.0 120.0

20 Hr.

Cap.

(Ah)

(Ah)

0.05CA to 1.75 V/C 0.093CA to 1.75 V/C 0.17CA to 1.70 V/C 0.26CA to 1.67 V/C 0.60CA to 1.60 V/C

Type

Genesis

®

NP Battery

5 Min 10 Min 15 Min 20 Min 30 Min

NPX-25 47.0 31.0 23.0 18.8 13.8

NPX-35/NPX-35-6 68.0 44.0 35.0 28.0 21.5

NPX-50 94.0 67.0 50.0 39.0 30.0

NPX-80 155.0 104.0 80.0 65.0 42.0

NPX-100 185.0 125.0 95.0 75.0 55.0

NPX-150 285.0 200.0 150.0 120.0 90.0

Type

Genesis

®

NP Battery

0.05C 0.1C 0.2C 0.4C 0.6C 1C 2C 3C

NP0.8-12

0.8 A 0.04 0.08 0.16 0.32 0.48 0.8 1.6 2.4

NP1-6 1.0 0.05 0.10 0.20 0.40 0.60 1.0 2.0 3.0

NP1.2-12,NP1.2-6 1.2 0.06 0.12 0.24 0.48 0.72 1.2 2.4 3.6

NP2-12 2.0 0.10 0.20 0.40 0.80 1.20 2.0 4.0 6.0

NP2.3-12 2.3 0.12 0.23 0.46 0.92 1.38 2.3 4.6 6.9

NP2.6-12 2.6 0.13 0.26 0.52 1.04 1.56 2.6 5.2 7.8

NP2.8-6 2.8 0.14 0.28 0.56 1.12 1.68 2.8 5.6 8.4

NP2.9-12 2.9 0.15 0.29 0.58 1.16 1.74 2.9 5.8 8.7

NP3-6,NP3-12 3.0 0.15 0.30 0.60 1.20 1.80 3.0 6.0 9.0

NP3.2-6 3.2 0.16 0.32 0.64 1.28 1.92 3.2 6.4 9.6

NP3.4-12 3.4 0.17 0.34 0.68 1.36 2.04 3.4 6.8 10.2

NP3.8-6 3.8 0.19 0.38 0.76 1.52 2.28 3.8 7.6 11.4

NP4-6,NP4-12 4.0 0.20 0.40 0.80 1.60 2.40 4.0 8.0 12.0

NP4.5-6,NP4.5-12 4.5 0.23 0.45 0.90 1.80 2.70 4.5 9.0 13.5

NP5-6,NP5-12 5.0 0.25 0.50 1.00 2.00 3.00 5.0 10.0 15.0

NP7-6,NP7-12 7.0 0.35 0.70 1.40 2.80 4.20 7.0 14.0 21.0

NP8.5-6 8.5 0.43 0.85 1.70 3.40 5.10 8.5 17.0 25.5

NP10-6 10.0 0.50 1.00 2.00 4.00 6.00 10.0 20.0 30.0

NP12-6,NP12-12 12.0 0.60 1.20 2.40 4.80 7.20 12.0 24.0 36.0

NP18-12 17.2 0.86 1.72 3.44 6.88 10.32 17.2 34.4 51.6

NP24-12 24.0 1.20 2.40 4.80 9.60 14.40 24.0 48.0 72.0

NP33-12 33.0 1.65 3.30 6.60 13.20 19.80 33.0 66.0 99.0

NP35-12 35.0 1.75 3.50 7.00 14.00 21.00 35.0 70.0 105.0

NP38-12 38.0 1.90 3.80 7.60 15.20 22.80 38.0 76.0 114.0

NP55-12 55.0 2.75 5.50 11.00 22.00 33.00 55.0 110.0 165.0

NP65-12 65.0 3.25 6.50 13.00 26.00 39.00 65.0 130.0 195.0

NP75-12 75.0 3.75 7.50 15.00 30.00 45.00 75.0 150.0 225.0

NP90-12 90.0 4.50 9.00 18.00 36.00 54.00 90.0 180.0 270.0

NP100-12 100.0 5.00 10.00 20.00 40.00 60.00 100.0 200.0 300.0

NP120-12 120.0 6.00 12.00 24.00 48.00 72.00 120.0 240.0 360.0

NP150-12 150.0 7.50 15.00 30.00 60.00 90.00 150.0 300.0 450.0

NP200-12 200.0 10.00 20.00 40.00 80.00 120.00 200.0 400.0 600.0

20 Hr.

Cap.

(A)

Discharge Current (A)

Type

Genesis

®

NP Battery

Table 1. Discharge Current at Stipulated Discharge Rates

Table 2. NPX Watts Per Cell to 1.67 End Voltage

Table 3. Discharge Capacity at Various Discharge Rates

8 www.enersys.com

Publication No: US-NP-AM-003 • January 2011

Page 9

Over-Discharge (Deep Discharge)

The dotted line in Figure 3 indicates the lowest

recommended voltage under load, or cut-off voltage, at

various discharge rates. In general, lead acid batteries are

damaged in terms of capacity and service life if discharged

below the recommended cut-off voltages. It is generally

recognized that all lead calcium alloy grid batteries are subject

to over-discharge damage. For example, if a lead acid battery

were discharged to zero and left in either open or closed

circuit for a long period of time, severe sulfation and shorting

would occur, thus raising the internal resistance abnormally

high. In such an extreme case, the battery may not accept a

charge.

®

Genesis

NP Series batteries however, have been designed to

withstand such occasional over discharge. While it is not

recommended, Genesis NP batteries can recover their full

capacity under normal charging conditions, even when they

have been subjected to extreme over discharge.

Final discharge voltage is as shown in Table 4.

Table 4. Final Discharge Voltage

Discharge Current Final Discharge (V/Cell)

0.1C or below, or Intermittent discharge 1.75

0.17C or current close to it 1.70

0.26C or current close to it 1.67

0.6C or current close to it 1.60

From 0.6C to 3C 1.45

Current in excess of 3C 1.30

at temperatures higher than the ranges recommended, will

have no adverse effect on storage time or service life.

However, if such use continues for more than one month, the

storage time must be determined according to the new

ambient temperature.

Table 5 below shows the normal storage time or shelf life at

various ambient temperatures. Figure 6 shows open circuit

voltage vs. state of charge.

Table 5. Shelf Life at Various Temperatures

Temperature

00C ( 320F) to 200C ( 680F)

210C ( 700F) to 300C ( 860F)

310C ( 880F) to 400C (1040F)

410C (1060F) to 500C (1220F)

Shelf Life

12 months

9 months

5 months

2.5 months

When considering discharge currents exceeding 6C, consult

with an EnerSys Application Engineer.

Storage, Self-Discharge and Shelf Life

Self-Discharge

The self-discharge rate of Genesis NP batteries is approximately 3% per month when the storage temperature is

maintained at 20

with storage temperature and the remaining capacity. The

relationship between storage times at various temperatures

and remaining capacity is shown in Figure 5.

REMAINING CAPACITY

Figure 5. Self Discharge Characteristics

Shelf Life

In general, when lead acid batteries of any type are stored in a

discharged condition for extended periods of time, lead

sulfate is formed on the negative plates of the batteries. This

phenomenon is referred to as “sulfation”. Since the lead

sulfate acts as an insulator, it has a direct detrimental effect

on charge acceptance. The more advanced the sulfation, the

lower the charge acceptance. “Brief storage”, ie., a few days,

www.enersys.com

Figure 6. Open Circuit Voltage vs. State of Charge

Recharging Stored Batteries

In general, to optimize performance and service life, it is

recommended that Genesis NP batteries which are to be

stored for extended periods of time be given a supplementary

charge, commonly referred to as a “refresh charge”,

periodically. Please refer to the recommendations listed

under REFRESH CHARGING in this manual.

0

C (680F). The self-discharge rate will vary

(%)

200C

STORAGE TIME (MONTHS)

Ohmic Readings

Instruments exist from various manufacturing companies to

determine internal Ohmic measurements of cells such as

internal impedance and conductance that could be used to

assess the health of VRLA batteries. The internal impedance

(resistance) of a battery is lowest when the battery is in a fully

charged state. The internal impedance increases gradually

during discharge. Conductance is the inverse of impedance

which is measured in MHOS, also known as Siemens. The

internal Ohmic measurements of a battery consists of a

number of factors, including, but not limited to, the

temperature and state of charge of the battery, the physical

connection resistances, the ionic conductivity of the

electrolyte, and the activity of electrochemical processes

occurring at the plate surfaces. It should be understood that

neither conductance nor impedance are perfect predictors of

battery capacity.

The correct way to use ohmic readings is as a trending tool

over time to detect potentially weak or troublesome cells of a

VRLA battery string in float service. For ohmic measures that

are trended over time, insight can be provided into the

expected life of a cell. The user should establish a baseline

value for each block at the time of installation. Throughout

the battery's life, the ohmic readings should be compared

against this baseline. The most accurate health indicator is to

establish a baseline for each individual block at the time of

installation and periodically monitor ohmic readings.

Publication No: US-NP-AM-003 • January 2011

9

Page 10

Charging

Proper charging is one of the most important factors to

consider when using maintenance free sealed lead-acid

batteries. Battery performance and service life will be directly

affected by the efficiency of the charger selected. The two

charging methods are:

Constant Current Charging

Two Step Constant-Voltage Charging

Constant Current Charging

This charging method is not often utilized for sealed lead- acid

batteries, but is an effective method for charging a multiple

number of batteries at one time, and/or as an equalizing

charge to correct variances in capacity between batteries in a

group. Caution should be exercised when charging by

constant current. If the charge is continued at the same rate

for an extended period of time after the battery has reached a

fully charged state, severe overcharge may occur, resulting in

damage to the battery.

Two Step Constant Voltage Charging

Two step constant voltage charging is the recommended

method for charging a sealed lead-acid battery in a short

period of time, and maintaining the battery in a fully charged

standby or float condition,thereafter. Figure 7 illustrates the

characteristics of a two step constant voltage charger.

Figure 7. Charging Characteristics of a Two Step Constant-Voltage

The characteristics shown in Figure 7 are those of a constant

voltage, constant current charger. In the initial charging

stage, the battery is charged by constant current. The

charging voltage rises, as the charge continues, until it

reaches 2.45 volts per cell, at which point the charging mode

automatically changes to constant voltage charging. During

the constant current charging stage (A-B) the charging current

which has decreased to point B is sensed, and the charging

voltage is switched to the float level of 2.3 volts per cell from

the recovery level of 2.45 volts per cell. The switch to

constant voltage trickle charging occurs after the battery has

recovered approximately 80% of the rated capacity over a

given period of time. This charging method is one of the most

efficient. The recharge time is minimized during the initial

charging stage while the battery is protected from overcharge

by the system switching over to float charge at the switching

point B.

Charger

10 www.enersys.com

Publication No: US-NP-AM-003 • January 2011

Page 11

Charging Voltage

The charging voltage should be regulated according to the

type of service in which the battery will be used. Generally,

the following voltages are used at 25˚C (77˚F).

For standby (float) use . . . . . . . 2.25 to 2.30 volts per cell

For cyclic use . . . . . . . . . . . . . 2.35 to 2.45 volts per cell

In a constant voltage charging system, a large amount of

current will flow during the initial stage of charging, and

decrease as the charging progresses. When charging at 2.30

volts per cell, charging current at the final stage of charging

will drop to as little as 0.002CA.

Refresh Charging

Since any battery loses capacity through self-discharge, it is

recommended that “refresh charging” be applied to any battery which has been stored for a long period of time, prior to

putting the battery into service. Excepting conditions in which

storage temperatures have been abnormally high, refresh

charging is recommended within the following

parameters:

Battery Age Refresh Charging Recommendations

Charging voltage should be regulated in relation to the

ambient temperature. When the temperature is higher, the

charging voltage should be lower. When the temperature is

lower, the charging voltage should be higher. For specific

recommendations, please refer to the section on Temperature

Compensation. Similarly, capacity (measured in amperehours) attainable over time will vary in direct relation to the

ambient temperature. The capacity in a given period of time

will be larger at higher temperatures, and smaller at lower

temperatures.

Initial Charge Current Limit

A discharged battery will accept a high charging current at the

initial stage of charging. High charging current can cause

abnormal internal heating which may damage the battery.

Therefore, it is recommended that the charging current be

normally limited to 0.25CA. However, in standby use, Genesis

NP batteries are designed so that even if the charging current

is higher than the recommended limit, they will not accept

more than 2CA, and the charging current will be reduced to a

relatively small value in a very brief period of time. Therefore,

in standby use, no current limit is required.

It is recommended that a current limiting function be provided

in the charger in order to prevent charger failure due to overheating of the transformer, or other damage resulting from

mishandling, i.e., short circuiting or reversing polarity.

Within 6 months

after manufacture

Within 12 months

after manufacture

4 to 6 hours at constant current of 0.1CA, or 15 to 20

hours at constant voltage of 2.40 volts per cell.

8 to 10 hours at constant current of 0.1CA, or 20 to 24

hours at constant voltage of 2.40 volts per cell.

Genesis NP batteries must not be allowed to self-discharge to

less than 2.08 volts per cell on open circuit. To recover deeply

discharged batteries, charge them for 24 hours using a

constant voltage charger set at 2.40 volts per cell at 25˚C

(77˚F) with a maximum current of 0.15C. A 16-hour recovery

charge is possible by setting the charge voltage at 2.45 volts

per cell and a maximum current of 0.25C.

In view of the above, consideration should be given to the fact

®

that if the charging method used is constant voltage in which

the charger employs current sensing for either state of charge

indication or for reducing voltage (a two step charger), during

the initial stage of charging an over-discharged battery the

charger may give a false “full charge” indication, or may

initiate charge at a float voltage.

Temperature Compensation

As temperature rises, electrochemical activity in a battery

increases. Similarly, as temperature falls, electrochemical

activity decreases. Therefore, conversely, as temperature

rises, charging voltage should be reduced to prevent

overcharge, and increased as temperature falls to avoid

undercharge. In general, to assure optimum service life, use

of a temperature compensated charger is recommended.

The recommended compensation factor for Genesis NP

batteries is -3mV/

use). Figure 8 shows the relationship between temperatures

and charging voltages in both cyclic and

standby applications.

0

C/Cell (stand by) and -4mV/0C/Cell (cyclic

www.enersys.com

Publication No: US-NP-AM-003 • January 2011 11

Page 12

Solar Powered Charging

A battery is an indispensable component of any solar

powered system designed for demand-energy use. Since

solar cells have inherent constant voltage characteristics,

Genesis NP batteries can be charged directly from the solar

array using a simple diode regulated circuit as shown in

Figure 10.

In designing a solar system, consideration should be given to

the fact that, in addition to normal periods of darkness,

weather conditions may be such that solar energy is limited,

or virtually unavailable for long periods of time. In extreme

cases, a system may have to operate for 10 to 20 days with

little or no power available for charging. Therefore, when

selecting the correct battery for a solar application, the

capacity should be determined based upon maximum load

conditions for the maximum period of time the system may

be expected to be without adequate solar input.

Figure 8. Relationship Between Charging Voltage and Temperature

In actual use in indoor applications (50C to 400C or 410F to

1040F), it is not necessary to provide the charger with a

temperature compensation function, but it is desirable to set

the voltage at the value shown in Figure 8 which

corresponds most closely to the average ambient temperature

of the battery during service.

Any temperature compensation sensor must sense only the

temperature of the battery. Therefore, consideration should

be given to isolating the battery and temperature sensor from

other heat generating components of a system.

Charging Efficiency

The charging efficiency varies depending upon the state of

charge of the battery, temperature, and charging rate. As

shown in Figure 9, Genesis®NP batteries exhibit very high

charging efficiency, even when charged at low charging rates.

It is interesting to note that the charging efficiency of Genesis

NP sealed lead-acid batteries is superior to that of other

batteries at relatively low charge rates

.

In many instances the battery capacity will be 10 to 50 times

greater than the maximum output of the solar panels. Under

these circumstances, the maximum output of the solar array

should be dedicated to charging the battery with no loadsharing or intervening control devices of any kind.

Naturally, in cases where the output of the solar array exceeds

the capacity of the battery, and weather conditions are such

that the potential for overcharging the battery exists,

appropriate regulated charging circuitry between the solar

panels and the battery is recommended

.

Figure 9. Charging Efficiency

12 www.enersys.com

Figure 10. Block Diagram of a Solar System

Remote site, or other outdoor applications for solar systems

are commonplace. When designing a solar system for this

class of application, a great deal of consideration must be

given to environmental conditions. For example, enclosures

which may be used to house batteries and other equipment

may be subject to extremely high internal temperatures when

exposed to direct sunlight. Under those conditions, insulating

the enclosure and/or treating the surface of the enclosure with

a highly reflective, heat resistive material is recommended.In

general, when designing a solar system, consultation with the

solar panel manufacturer and battery manufacturer is

recommended

.

Publication No: US-NP-AM-003 • January 2011

Page 13

Expected Service Life of Genesis

NP Batteries

Cyclic Service Life

There are a number of factors that will effect the length

of cyclic service of a battery. The most significant are

ambient operating temperature, discharge rate, depth of

discharge, and the manner in which the battery is recharged.

Generally speaking, the most important factor is depth of

discharge. Figure 11 illustrates the effects of depth of

discharge on cyclic life.

TESTING CONDITIONS: DISCHARGE CURRENT: 0.17C AMP. (F.V. 1.7V/CELL)

(AH%)

120

100

80

60

40

20

PERCENTAGE OF CAPACITY AVAILABLE

0

200

Figure 11. Cyclic Service Life in Relation to Depth of Discharge

Genesis®NP Series

CHARGING CURRENT: 0.09C AMP.

CHARGING VOLUME: 125% OF DISCHARGED CAPACITY

AMBIENT TEMPERATURE: 20°C TO 25°C (68°F TO 77°F)

100%D.O.D.

400

50% D.O.D.

600

30% DEPTH OF DISCHARGE

800

1000

NUMBER OF CYCLES (CYCLES)

1200

1400

The relationship between the number of cycles which can be

expected, and the depth of discharge is readily apparent. In

relation to a specified discharge rate, if the application

requires a longer cyclic life than is obtainable by selecting the

battery capacity according to common practice, select a battery with larger capacity. Thus, at the specified discharge rate

over the specified time, the depth of discharge will be

shallower and cyclic service life will be longer.

Float Service Life

Genesis®NP batteries are designed to operate in standby

(float) service for approximately 3 years, based upon a normal

service condition in which float charge voltage is maintained

between 2.25 and 2.30 volts per cell in an ambient

temperature of approximately 25

0

C (770F).

In normal float service, where charging voltage is maintained

2.25 to 2.30 volts per cell, the gases generated inside Genesis

NP battery are continually recombined, and return to the

water content of the electrolyte. Therefore, electrical capacity

is not lost due to “drying up” of the electrolyte. Actually,

through the gradual and very slow corrosion of the electrodes, the battery will eventually lose capacity and come to

the end of service life. It should be noted that the corrosive

process will be accelerated by high ambient operating

temperatures and/or high charging voltage. When designing

a float service system, always consider the following:

LENGTH OF SERVICE LIFE WILL BE DIRECTLY

AFFECTED BY THE NUMBER OF DISCHARGE CYCLES,

DEPTH OF DISCHARGE, AMBIENT TEMPERATURE, AND

CHARGING VOLTAGE.

www.enersys.com

Publication No: US-NP-AM-003 • January 2011 13

Page 14

Tips and Precautions

Genesis®NP Series batteries are truly efficient maintenance free electro-chemical systems and are designed to provide years

of trouble free service. Their performance and service life can be greatly maximized by observing the following guidelines.

Heat kills batteries. Avoid installation and/or

1.

operation in close proximity to heat sources of any kind.

While the operating temperature range is -15°C to 50°C,

an ideal service life will be realized when the battery is

operated in an ambient temperature of 20°C (for cyclic

service applications, a range of 5°C to 35°C is

recommended).

2.

If the battery is to be installed in an air or water tight

container, ventilation must be provided. Batteries may

generate ignitable gases which must not be contained.

Because of this, batteries should not be installed near

spark producing equipment.

WARNING - Do NOT use any type of oil, solvent, deter-

3.

gent, petroleum- based solvent or ammonia solution to

clean the jars or covers. These materials will cause permanent damage to the battery jar and cover and will void

the warranty.

Soldering to the battery terminals is NOT recommended.

4.

If soldering is unavoidable, it must be accomplished within 3 seconds, using a maximum 100 watt soldering iron.

If installed in a heavy vibration or shock application, the

5.

battery must be securely fastened with shock absorbing

materials.

For maximum life expectancy, the R.M.S. ripple

9.

current should be regulated to no more than 0.1C (10% of

battery's rating).

Do not crush, incinerate or dismantle the battery. The

10.

electrolyte contains sulfuric acid which can cause serious

damage to eyes and skin. Should this occur, flush

profusely with water and seek medical attention.

Mixing batteries of different capacities, age and/or

11.

manufacture is not recommended. Please consult with an

application engineer if it is unavoidably necessary.

Battery life is dependent on its operating conditions.

12.

Please refer to the life curves published in this

Applications Manual. These curves represent typical

results under optimum operating conditions. Actual life

will vary greatly due to variability of these conditions. To

obtain optimum battery performance for standby service,

EnerSys recommends that within five years of use, the NP

batteries be replaced.

Observe the external appearance of the battery. If, at any

13.

time, cracks, deformation or other damage is found on the

battery case or cover, or if any leakage of the electrolyte is

observed, immediately replace the battery.

Provide free air space between batteries when more than

6.

two are grouped together. The recommended distance is

0.2" to 0.4" (5mm to 10mm).

Always wear insulated gloves when handling batteries;

7.

especially when series and parallel connecting groups of

batteries.

When batteries are connected together in a series-parallel

8.

arrangement, the inter-connecting cables must be of

equal length and resistance to insure equalization of the

load.

Note: If a battery with any irregular appearance as

stated above is used continuously, a decrease in

capacity, leak age of electrolyte, short circuits and

a potential for a smoke and/or fire incident may occur.

Glossary of Terms

Active Material The active electro-chemical materials used in the manufacture of

Ambient Temperature The average temperature seen by the battery.

Ambient Capacity

Battery

C-Rate

CA C Ampere; the C-rate of a battery measured in amperes.

Capacity Fade Loss of capacity due to inadequate recharging.

Cell

positive and negative electrodes.

The capacity from the battery based on its state of charge, rate of

discharge, and ambient temperature.

Two or more cells, series connected together. A single cell is some

times referred to as a battery.

A current rate expressed in amperes or milliamperes, in direct

relation to a battery's ampere hour rating. Ex: 6 Ah rating, 1C = 6

amps; 3C = 18 Amps; 0.05C = 300 milliamps.

The minimum unit of which a storage battery is composed. Note:

The nominal voltage of a single lead acid cell is 2.0 volts.

Closed Circuit Voltage Test

Constant Voltage Charge A method of charging batteries by applying a fixed voltage and

14 www.enersys.com

A test method in which the battery is briefly discharged at a constant

current while the voltage is measured.

allowing the current to vary. Recommended for sealed lead

acid batteries. (Also called constant potential charge).

Publication No: US-NP-AM-003 • January 2011

Page 15

Glossary of Terms (Continued)

Cutoff Voltage

Cycle

Discharge Rate

End-of-Charge Voltage

Electrolyte

Energy Density

Gas Absorption

High-Rate Discharge

Internal Impedance

Low Voltage Cutoff

Nominal Capacity

Nominal Voltage

Open Circuit Voltage The measured voltage of the cell or battery without a load attached.

Overcharge

Parallel Connection

Primary Cell

Rated Capacity

Resealable Safety Vent

Secondary Battery

Self Discharge

Separator

Series Connection

Service Life

Shelf Life

The final voltage of a cell or battery at the end of charge or discharge

A single charge and discharge of a cell or battery.

Current taken from a cell or battery and expressed as a fraction

of C (Ampere-hour rating of the cell or battery).

The voltage reached by the cell of battery at the end-of-charge,

while the charger is still attached.

Conducts ions in the cell. Lead acid batteries use a sulfuric acid

solution.

Ratio of cell or battery energy to unit weight (pound or kilogram)

or unit volume (cubic inch or cubic meter)

The ability of the negative plate to absorb oxygen gas generated

within the battery; the greater this ability, the greater the charge

current capability.

A very rapid discharge of the battery. Normally in multiples of C

(Ampere-hour rating of the cell or battery).

The resistive value of the battery to an AC current, expressed in

ohms. Normally measured at 1 khz at full charge.

A sensing device designed to end discharge at a predetermined

voltage level.

The nominal value of rated capacity. In sealed lead acid batteries,

nominal capacity is usually measured at the 20 hour rate.

The nominal value of rated voltage. In lead acid batteries, nominal

voltage is 2 volts per cell.

The continuous charging of a cell after it achieves 100% of

capacity. Battery life is reduced by prolonged over charging.

Connection of a group of batteries by inter-connecting all

terminals of the same polarity, thereby increasing the capacity of

the battery group. (Note: Differing brands and/or capacities should

not be connected together).

A cell which can be discharged only once. Example: Manganese

zinc and alkaline.

The capacity of the cell expressed in ampere hours. Commonly, a

constant current for a designated number of hours to a specified

depth of discharge at room temperature.

The safety device built into the cell to allow the release of excess

gases and prevent case rupture.

A battery which can be charged and discharged repeatedly.

Example: Lead acid and nickel cadmium batteries.

The loss of capacity of a battery while in stored or unused

condition without external drain.

The materials which separate the electrodes. In a sealed lead acid

battery, they are usually constructed of micro-porous glass fiber

and additionally serve to retain the electrolyte.

Connection of a group of batteries by interconnecting all terminals

of the opposite polarity, thereby increasing the voltage of the

battery group. (Note: The same rule applies as with parallel

connections).

Expected life of a battery expressed in the number of total cycles

or years of standby service to a designated remaining percentage

of original capacity.

The maximum period of time a battery can be stored under

specific conditions, without supplementary charging.

Standby Service A general term for an application in which the battery is

Trickle Charge Continuous charging by means of a small current designed to

Voltage Cutoff A sensing device used to terminate a charge or discharge when

www.enersys.com

maintained in a fully charged condition by trickle or float charging

and always ready for use.

compensate for self discharge in an unloaded battery

the battery reaches a predetermined voltage level.

Publication No: US-NP-AM-003 • January 2011 15

.

Page 16

Limited Warranty:

NON-SPILLABLE

GENERAL PRODUCT LIMITED WARRANTY

EnerSys Delaware Inc. (“EnerSys”) warrants Genesis® NP and DataSafe® NPX batteries against defective materials and workmanship for a

period of one (1) full year from the date the battery was manufactured.

A. If initial physical inspection identifies flaws in material or workmanship that would impair life of the battery, as defined by this warranty,

or product performance, as defined by EnerSys’ electrical and physical specification as published at the time of shipment and these flaws

are not due to transportation damage or installation abuse;

OR

B. If on initial “Acceptance Test”, as defined in IEEE Std. 1188, “IEEE Recommended Practice for Maintenance, Testing, and

Replacement of Valve Regulated Lead Acid (VRLA) Batteries for Stationary Applications”, the properly installed battery and/or

string fails to meet the published performance ratings* per EnerSys’ latest published catalog data at the time of shipment;

If EnerSys determines the battery is physically or electrically unsound due to defective materials or workmanship on the part of EnerSys,

the defective battery(s) will be repaired or replaced at the option of EnerSys without charge to the purchaser (user) for replacement

materials. However, costs of replacement installation including but not limited to equipment, travel expenses of EnerSys representatives(s),

and costs of material transportation expenses shall be borne by the purchaser (user).

* Published performance ratings. Initial capacity shall be a minimum of 90 percent of the rated string capacity upon shipment per

IEEE-1188.

EXLCUSIONS AND LIMITATIONS

1. The purchaser (user) shall give freshening charges to the battery every six (6) months for Lead-Calcium after the manufacturing date and

until final installation. Refer to the installation and maintenance instructions for maximum storage intervals.

2. At least once every six (6) months, purchaser (user) must take readings and record information per EnerSys’ installation/maintenance

instructions. These records must be maintained for warranty claim purposes. If warranty records are not kept, the warranty shall be null and

void. During the full warranty period, these records are not necessary for a claim, however, the batteries shall be operated according to the

published installation/maintenance instructions and purchase (user) shall make all reasonable efforts to substantiate the claim, including

visits to the site(s) by EnerSys representatives.

3. This warranty applies only to the original United States and Canada domestic purchaser (user) and is non-transferable internationally,

except with the expressed written consent from EnerSys headquarters in Reading, PA.

4. This warranty does not cover physical damage due to the acts of nature or man which stress the battery beyond design limits and exert

undesirable influence aside from normal wear and tear.

5. EnerSys assumes no responsibility for any work accomplished or expenses incurred except with the expressed written consent from

EnerSys headquarters in Reading, PA.

6. Movement of batteries from original point of installation shall immediately void this product warranty, except with the expressed written

consent from EnerSys headquarters in Reading, PA.

7. Any storage shall be in a dry area having an average ambient temperature of 77ºF (25ºC), or less, and in accordance with EnerSys published installation/maintenance instructions.

8. EnerSys exempts from any warranty claims any battery which has been subjected to misuse, abuse, alteration, or any battery that may

have been repaired or attempts made for repair by other than EnerSys.

9. EnerSys shall not be liable for indirect, incidental or consequential damages arising out of the sale or relating to the use of this product,

and the purchaser assumes responsibility for all personal injury and property damage resulting from the handling,

possession or use of the product. In no event shall the liability of EnerSys for any and all claims, including claims of breach of warranty or

negligence, exceed the purchase price of the product.

10. WARNING – Avoid exposure of the battery to any type of oil, solvent, detergent, petroleum-based solvent or ammonia solutions. These

materials could potentially cause permanent damage to the battery jar and cover and will void the warranty.

11. THE ABOVE WARRANTY IS IN LIEU OF ALL OTHER REMEDIES, INCLUDING BUT NOT LIMITED TO ACTIONS FOR BREACH OF

CONTRACT OR NEGLIGENCE. ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE HEREBY EXCLUDED.

* Published performance ratings. Initial capacity shall be a minimum of 90 percent of the rated string capacity upon shipment per IEEE-1188.

In the event of either A or B above, then contact your nearest EnerSys sales representative to request instructions. You will be

instructed either a) to return the equipment to an EnerSys factory or service center location, FOB Destination-Freight Prepaid, for

examination, or b) to wait until an EnerSys representative arrives at the site to inspect the equipment.

www.enersys.com

When ordering new batteries, also remember the need to properly dispose (recycle) your old

lead-acid batteries.

Most federal and state regulations require lead-acid batteries be recycled. EnerSys’ nationwide

service organization can arrange pickup, transportation, and recycling to any one of our company

affi liat ed smelters . C all 1-8 00-9 72-7 372 for more information.

EnerSys

P.O. Box 14145

Reading, PA 19612-4145

USA

Tel:+1-610-208-1991

+1-800-538-3627

EnerSys EMEA

Brussels, Belgium

Tel:+32 (0)2 247 94 47

EnerSys Asia

Guangdong, China

Tel:+86 755 2689 3639

Represented by:

Publication No: US-NP-AM-003 • January 2011 • Subject to revisions without prior notice. E.& O.E.

Printed in U.S.A.

© 2011 EnerSys. All rights reserved.

Trademarks and logos are the property

of EnerSys and its affiliates except ISO

which is not the property of EnerSys

Loading...

Loading...