Page 1

XE & EP BATTERIES

APPLICATION

MANUAL

RESERVE

POWER

Page 2

Genesis®XE & EP Application Manual

TABLE OF CONTENTS

Preface 2

Chapter 1: Introducing the Genesis

®

Battery 3

1.1 Background 3

1.2 Transportation classification 3

1.3 UL component recognition 3

1.4 Non-halogenated plastics 3

1.5 Key Genesis benefits 3

Chapter 2: Technical Information 4

2.1 Introduction 4

2.2 Choosing the right Genesis version 4

2.3 Battery life 4

2.4 Constant-power and constant-current discharge performance 5

2.5 Charging characteristics & requirements 6

2.6 Constant-voltage (CV) regime 7

2.7 Constant-current (CC) regime 7

2.8 Three-step (IUU) charge profile 8

2.9 Storage characteristics 9

2.10 Self discharge 9

2.11 Open circuit voltage (OCV) and state of charge (SOC) 10

2.12 Procedure to recover overdischarged batteries 10

Chapter 3: General Test Data 11

3.1 Introduction 11

3.2 Thermal runaway test 11

3.3 Gassing test 11

3.4 DIN standard overdischarge recovery test 12

3.5 High temperature storage recovery test 12

3.6 Altitude test 12

3.7 Accelerated float life test 12

3.8 Performance test at different temperatures 13

Chapter 4: Installation, Operation & Maintenance 13

4.1 Introduction 13

4.2 Receiving the shipment 13

4.3 Storage 13

4.4 Installation 13

4.4.1 Temperature 14

4.4.2 Ventilation 14

4.4.3 Security 14

4.4.4 Mounting 14

4.4.5 Torque 14

4.5 Parallel strings 14

4.6 Discharging 14

Appendix A: Genesis

®

XE Discharge Characteristics 15-24

Appendix B: Genesis

®

EP Discharge Characteristics 25-31

Preface

This European edition of the

Genesis Application Manual

introduces the Genesis XE range

of batteries, packaged to offer

the same superior performance

characteristics as the Genesis EP

battery in more physically

demanding applications such as

high temperature and high

vibration environments.

Appendix A offers constant

current (CC) and constant power

(CP) performance data and

graphs for the full range of

Genesis XE batteries to several

end voltages. Appendix B offers

the same information for the EP

series.

Chapter 4 offers guidelines on

the installation, operation and

maintenance of Genesis

batteries, with the goal of

maximising performance and

service life.

2

www.enersys-emea.com

Page 3

Chapter 1:

Introducing the Genesis Battery

1.1 Background

Since its introduction in the early 1990s, the Genesis

®

thin plate pure lead-tin (TPPL) battery has established

itself as a premium high performance battery suitable for

a wide range of demanding applications. Today, TPPL

technology can be found in applications as diverse as

emergency power, avionics, medical, military and

consumer equipment.

The Genesis TPPL battery is offered in either the EP or

XE version, and Table 2.2.1 shows the differences

between the two versions.

1.2 Transportation classification

Effective September 30, 1995, Genesis batteries were

classified as "nonspillable batteries", and are excepted

from the Department of Transportation’s comprehensive

packaging requirements if the following conditions are

satisfied:

(1)

The battery is protected against short circuits

and is securely packaged and

(2)

The battery and outer

packaging must be plainly and durably marked

"NONSPILLABLE" or "NONSPILLABLE BATTERY".

Genesis batteries have been tested and determined to be

in compliance with the vibration and pressure differential

tests contained in 49 CFR § 173.159(d).

Because Genesis batteries are classified as

"Nonspillable" and meet the conditions above, [from §

173.159(d)] they do not have an assigned UN number

nor do they require additional DOT hazard labelling.

1.3 UL component recognition

All Genesis batteries are recognised as UL components.

1.4 Non-halogenated plastics

As the world becomes more environmentally aware,

EnerSys

®

is striving to provide the most environmentally

friendly products possible. With this in mind, we are

proud to say that the plastics used in our Genesis

product line are non-halogenated and therefore do not

contain any of the following materials:

Polybrominated biphenyls (PBB)

Polybrominated biphenyl ethers (PBBE)

Polybrominated biphenyloxides (PBBO)

Polybrominated diphenyl ethers (PBDPE)

Polybrominated diphenyl oxides (PBDPO)

Tetrabromobisphenol-A (TBBA)

Deca-bromo biphenyl ethers (DBBPE’s).

The battery meets the non-halogenated flame retardancy

requirements of UL 94V-0 by using plastics with nonhalogenated flame retardants. Finally, the plastic material

used in the manufacturing of Genesis batteries is in full

compliance with the German Dioxin Ordinance of 1994.

1.5 Key Genesis benefits

Table 1.5.1 lists some of this battery’s features and

benefits. The Genesis battery is well suited for any

application - high rate, low rate, float or deep discharge

cycling.

Chapter 1:

Introducing the Genesis®Battery

3

www.enersys-emea.com

Feature Benefit

High volumetric and gravimetric power densities More power in less space and weight

Thin-plate design Superior high rate discharge capability

Low internal resistance Flatter voltage profile under high-rate discharge;

excellent low temperature performance

1

Negligible gassing under normal charge Safe for use in human environments such as offices and

hospitals. Must be installed in non-gastight enclosures

100% maintenance-free terminals True fit-and-forget battery

Flexible mounting orientation Battery may be installed in any position except inverted

Rugged construction Tolerant of high shock and vibration environments, especially the

XE version

Advanced manufacturing techniques High reliability and consistency

Very high purity lead-tin grid Lower corrosion rates and longer life

Non-halogenated flame retardant case and cover Meets UL 94 V-0 requirement, with an LOI >28%

Excellent high-rate recharge capability Allows >95% recharge in under an hour

Low self-discharge Longest shelf life among VRLA batteries (2 years at 25ºC)

Wide operating temperature -40ºC to +80ºC

Table 1.5.1: Key features and benefits of the Genesis battery

1 See Table 2.4.1 and Figure 2.4.1 in Section 2.4 of Chapter 2

2 The XE version of the Genesis battery may be used at 80ºC when fitted with a metal jacket

Page 4

2.3 Battery life

The life expectancy of a Genesis battery depends on the

specific application. It is expressed in terms of either

cycles or years. While life in years is self-explanatory,

a cycle refers to a sequence in which a charged battery is

discharged and then charged back up. One complete

sequence constitutes one cycle. In general, if the battery

is to be discharged frequently, cycle life rather than

calendar life is more relevant. On the other hand, if the

battery is to be used primarily as power backup, calendar

life of the battery should be considered.

In situations where one is not quite sure whether the

application is cyclic or standby (float), the following

criteria may be used to determine the application

category:

If the average time on charge between two successive

discharges is thirty (30) days, the application may be

considered to be of a standby (float) nature.

The minimum time between two successive

discharges must not be less than fourteen (14) days.

If either of these two criteria is not satisfied, the

application should be considered cyclic.

Chapter 2:

Technical Information

2.1 Introduction

We have divided this chapter into small sections

allowing you to locate the information quickly and

easily.

2.2 Choosing the right Genesis

®

version

As mentioned before, the Genesis

®

pure lead-tin

battery is available in EP and XE versions.

The EP battery is adequate under most operating

conditions.

Special application situations such as high ambient

temperature or high shock and vibration require the

XE version.

Table 2.2.1 summarises the differences between the

two versions and is designed to help you choose the

right version for your application. In this table, the

differences are highlighted in red boldfaced.

Feature Genesis®EP Genesis®XE

Technology Pure lead-tin absorbed glass mat (AGM)

Float life @ 2.27 volts per cell (Vpc) charge 10 years @ 25ºC 12 years @ 25ºC

Cycle life 400 to 80% depth of discharge (DOD)

Shock & vibration tolerance Good Better

Operating temperature range • -40ºC to +45ºC • -40ºC to +45ºC

• -40ºC to +60ºC • -40ºC to +80ºC

with metal jacket (denoted EPX) with metal jacket (denoted XEX)

Shelf life @ 25ºC 2 years from 100% charged down to 12V per block

Capacity @ 10-hr. rate 100% (reference) ≈ 95%

Weight 100% (reference) ≈ 105%

Dimensions Same footprint

Quick charge 6C to 8C charge acceptance at 25ºC

Overdischarge abuse tolerance Exceeds DIN standard for overdischarge recovery

High-rate discharge 100% (reference) ≈ 95%

Flame retardant rating V-0 rated case and cover

Case & cover colour Black Orange

Shipping Air shippable with no restrictions

Table 2.2.1: Choosing the right Genesis

®

version

Chapter 2:

Technical Information

4

www.enersys-emea.com

Page 5

While several factors affect the life of a battery, cycle life

depends primarily on the depth of discharge (DOD). At a

DOD of 80%, the Genesis

®

battery will deliver 400 cycles;

at 100% DOD, that number decreases to 320 cycles

All cycle life estimates assume adequate full recharge.

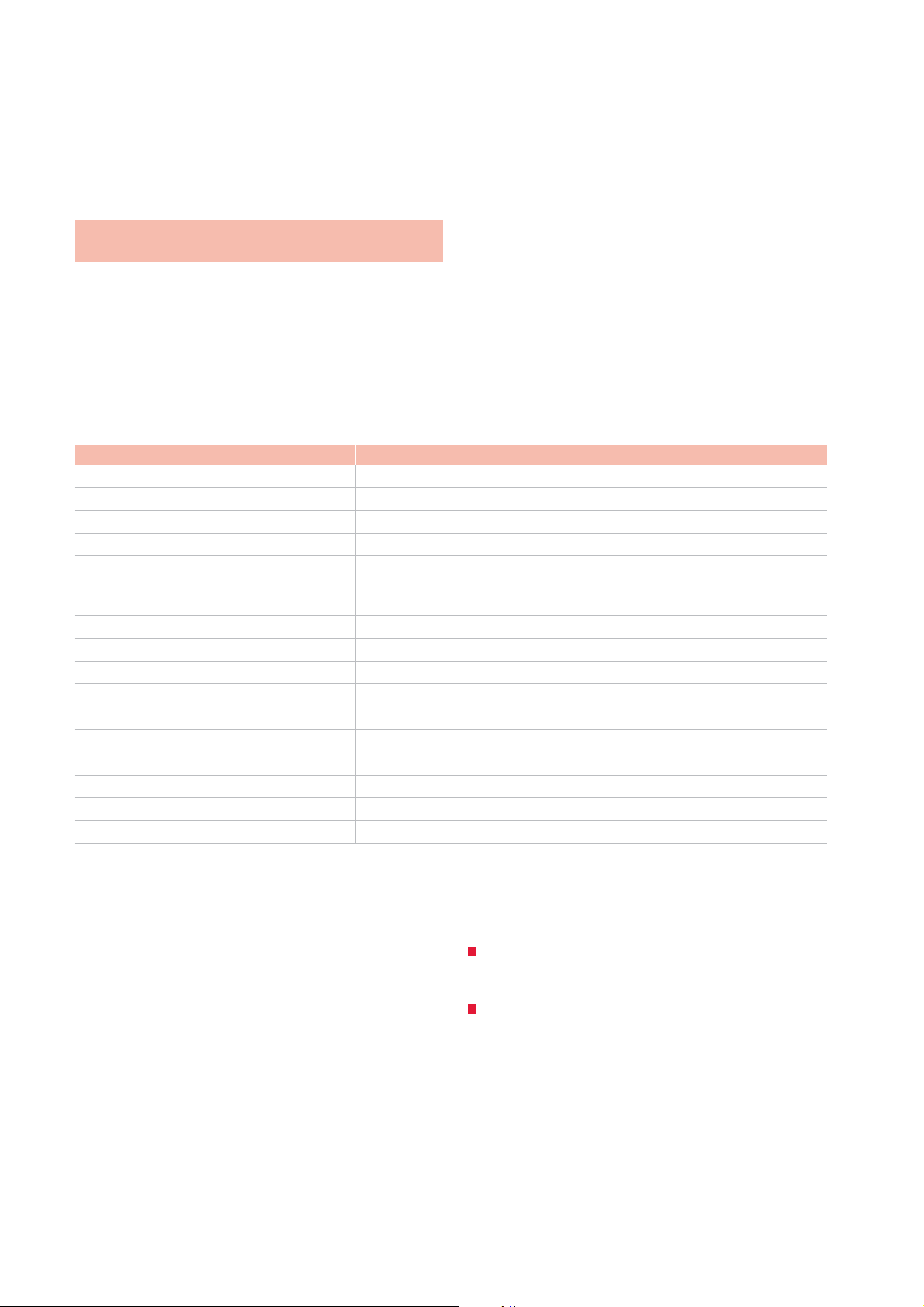

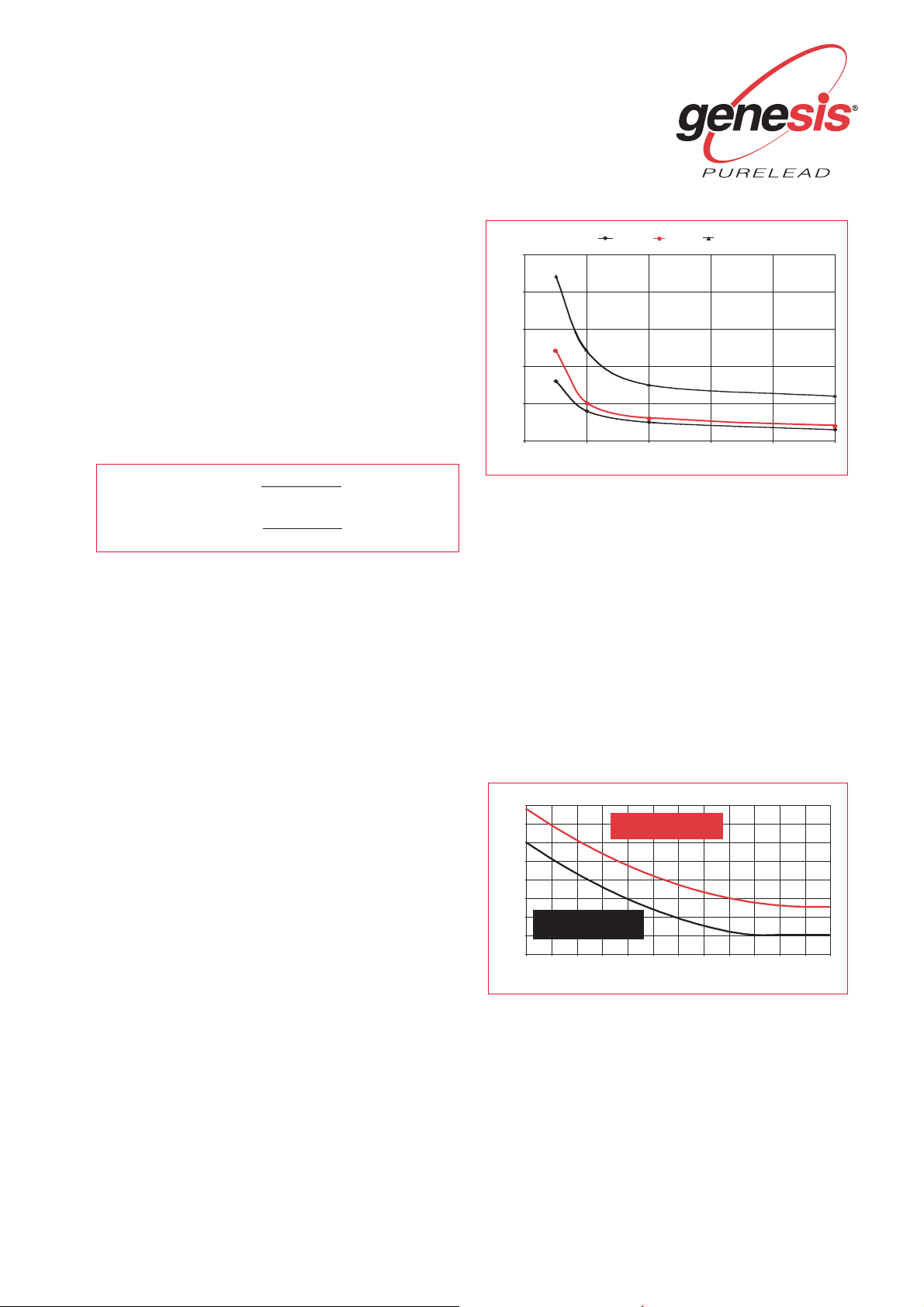

Figure 2.3.1 shows the relationship between DOD and

cycle life.

Figure 2.3.1: Cycle life and depth of discharge (DOD)

In contrast to cycle life, ambient temperature

dramatically affects float life. For roughly every 8°C rise

in ambient temperature above 25ºC, the float life of a

VRLA battery is cut in half. In other words, a 10-year

battery at 25°C) is only a 5-year battery at 33°C.

Additionally, float life is cut in half for every 100mV per

cell over the recommended float charge voltage.

The relationship between ambient temperature and

expected float life is given by the Arrhenius equation.

The equation defines the relationship between the

ambient temperature and the rate of internal positivegrid corrosion of the battery, which is the normal process

of battery aging.

A key point to note is that the temperature in question is

the battery ambient temperature. If the system is in a

25°C environment and the battery is installed next to a

power transformer where the temperature averages

32°C, then all battery calculations must be based on

32°C.

The Arrhenius equation is the theoretical foundation for

the relationship used in practice to derive the

acceleration factor for a given temperature. The equation

is shown below, in which AF is the acceleration factor

and T is the battery ambient temperature in ºC.

As an example, consider a battery in a float application

at an ambient temperature of 37ºC. Replacing T with 37

in the equation above the acceleration factor (AF) in this

case would be 2

(1.5)

or 2.83. A 10-year battery in this

situation should be expected to last only about

3.5 years (10/2.83 =3.5). Figure 2.3.2 graphically shows

the relationship between temperature and float life for

the EP and XE series batteries, assuming temperature

compensation and a reference temperature of 25ºC.

Figure 2.3.2: Battery temperature and float life

2.4 Constant-power and constant-current discharge

performance

Batteries are generally required to support either

constant-power (CP) or constant-current (CC) loads.

CP and CC discharge curves are provided in Appendix A

for Genesis

®

XE and in Appendix B for Genesis EP

batteries. The information is provided in both tabular and

graphical formats, with each curve representing the

discharge profile for a specific model to a specific end

voltage.

If intermediate run times are required, such as

watts per

battery

for 7 minutes to 1.67 volts per cell, the graphs

may be used to estimate the

watts per battery

available.

Generally speaking, most battery systems for indoor

applications are in temperature-regulated environments.

However, there are occasions when this is not the case.

This can happen when the batteries are installed in close

proximity to heat generating sources such as

transformers. In such cases, the user should know what

kind of life to expect from the batteries, since it is well

established that a battery’s overall life is sensitive to

ambient temperature.

In addition to the dependence of battery life on ambient

temperature, battery capacity also varies with

temperature. Table 2.4.1 shows the variation in battery

capacity as a function of the ambient temperature.

The capacity at 25ºC is taken as 100%.

(0.125T-3.125)

AF = 2

5

www.enersys-emea.com

1000000

Charge profile:

CV@2.45 VPC for 16 hours

100000

10000

Current limit at 1C

100

10

1

Years to 80% capacity

Genesis EP Genesis XE

Nunmber of cycles

1000

100

10

0

30

20

50

40

Depth of discharge, DOD%

60

70

90

80

100

0

20

15

30 35

25

40 45

Temperature, °C

55

60

50

65

Page 6

Temperature -20ºC 0ºC 25ºC 40ºC 55ºC

Capacity @

15 min. rate 65% 84% 100% 110% 120%

Table 2.4.1: Effect of temperature on 15-minute discharge

A graph of capacity as a function of temperature for the

Genesis

®

battery is shown in Figure 2.4.1 for various

rates of discharge.

Figure 2.4.1: Capacity as a function of temperature

Although the Genesis battery may be used, with

appropriate derating, from -40°C to 80°C, it is strongly

recommended that every effort be made to install them

in temperature-regulated environments. Metal jackets are

required for temperatures exceeding 45°C continuous.

All battery temperatures refer to the temperatures

experienced by the active materials

inside

the battery.

The time required by the active materials to reach

thermal equilibrium within the battery environment may

be considerable.

2.5 Charging characteristics & requirements

A constant-voltage (CV) regime is the preferred method

of charging these batteries, although a constant-current

(CC) charger with appropriate controls may also be used.

There is no limit on the magnitude of the charge current

during a CV charge. Because of the Genesis battery’s low

internal resistance, it is able to accept any level of inrush

current provided by a constant-voltage charger.

Note:

The following paragraphs on battery

charging have been considerably simplified for better

understanding. For example, no account has been

taken of the polarisation voltage. Second, the

battery resistance has been assumed to be static.

This is a simplifying assumption since the battery’s

internal resistance will change continuously during

the charge cycle.

This dynamism in the internal resistance occurs because

of the changing state of charge and the fact that the

temperature of the active materials within the battery is

dynamic.

Owing to these simplifications, the current magnitudes

obtained in the sample calculations are exaggerated.

However, if one remembers that assumptions have been

made and that the

mathematical steps are for illustration

only

, then the actual current values calculated become

immaterial.

It is known from basic electric-circuit theory that the

current in any circuit is directly proportional to the

voltage differential in the circuit (Ohm’s Law). Therefore,

as charging continues at a constant voltage, the charging

current decreases due to the decreasing difference

between the charger-output voltage and the batteryterminal voltage. Expressed differently, the charging

current is at its highest value at the beginning of the

charge cycle and at its lowest value at the end of the

charge cycle.

Thus, in a CV charge circuit, the battery is the current

regulating device in the circuit. It will draw only that

amount of current as necessary to reach full charge.

Once it attains 100% state of charge, it continues to draw

small currents in order to compensate for

standing/parasitic losses.

Assume that the battery under consideration has an

internal resistance of 4mΩ (0.004Ω) when fully charged.

Also, assume that it has an internal resistance of 8mΩ

(0.008Ω) when discharged to an end voltage of 10.5

volts. However, the instant the load is removed from the

battery, its voltage jumps back up to 12 volts, and this is

the initial back electromotive force (EMF) the charger

output terminals will see. The influence of this voltage

on the charge-current inrush is illustrated in the initial

and final charging magnitudes.

It is now decided to recharge the battery at a constant

voltage of 2.27 volts per cell or 13.62 volts per battery.

Further, assume that when the battery reaches a state of

full charge, the internal resistance reduces to 4mΩ and

the terminal voltage rises to 13.60V.

For illustrative

purposes, this final end-of-charge terminal voltage has

been kept deliberately slightly lower than the charging

voltage.

In reality, the charging process is dynamic. As soon as a

charging source is placed across the terminals of a

discharged battery, its voltage begins rising in an

attempt to match the charger-output voltage. Given

enough time, one would expect that the battery voltage

at some point would exactly equal the charger voltage,

thereby reducing the voltage difference in the charging

circuit to zero and thus forcing the charge current to

zero. However, this does not happen because of the

internal electrochemistry, which ensures that the battery

will keep drawing small charging currents even when

fully charged.

6

www.enersys-emea.com

10

1

0.1

Discharge time, hours

0.01

-30

-40

15 min. rate

-20

-10 0

Temperature, °C

IC rate 0.2C rate

10

30

20

40

Page 7

However, almost immediately, the battery selfdischarges, depressing its terminal voltage below the

charger voltage, thereby initiating a current flow once

again. The entire process, as outlined in the previous

paragraph, will then repeat itself.

Applying Ohm’s Law, which states that

the current in a

circuit is equal to the voltage gradient (difference) in the

circuit divided by the total resistance in the circuit

, and

substituting the various parameters’ assumed values,

we have the following charging currents. Note that all

connection resistances, such as those for cables, are

neglected for simplicity. This omission does not affect

the outcome since its influence would be the same in

both cases, neglecting changes due to electrical heating.

Initial charging current = = 202.5A

Final charging current = = 5A

This example shows how the battery acts as a current

regulator in a CV charge circuit, decreasing the current

flow in the circuit to suit its own state of charge.

Thus, even if the current limit on the charger were

250 amperes, the battery would see an inrush current of

202.5 amperes, before it tapered off and finally dropped

to its lowest value at the end of the charge cycle.

Although the 250A figure is impractical because of

prohibitive charger costs, it serves to drive home the

point that as far as the battery is concerned, a specific

current limit is not necessary for Genesis

®

batteries

under CV charging. In reality, the current limit would be

dictated by a combination of technical and economic

considerations. Note also that, in general, most other

battery manufacturers recommend current limits based

on battery capacity, usually 0.25C

10, where C10 is the

10-hour rating.

Increasing the current limit will reduce the total recharge

time, but at greater cost. The reduction in recharge time

occurs mainly up to the 90% state of charge level; the

impact on total recharge time is much less. The chargeroutput voltage exercises a much greater influence on the

total recharge time.

The question then becomes whether the reduction in the

time needed for a recharge can justify the additional

costs. In some critical applications, this may be the case,

while in other situations the added cost may not be

justifiable.

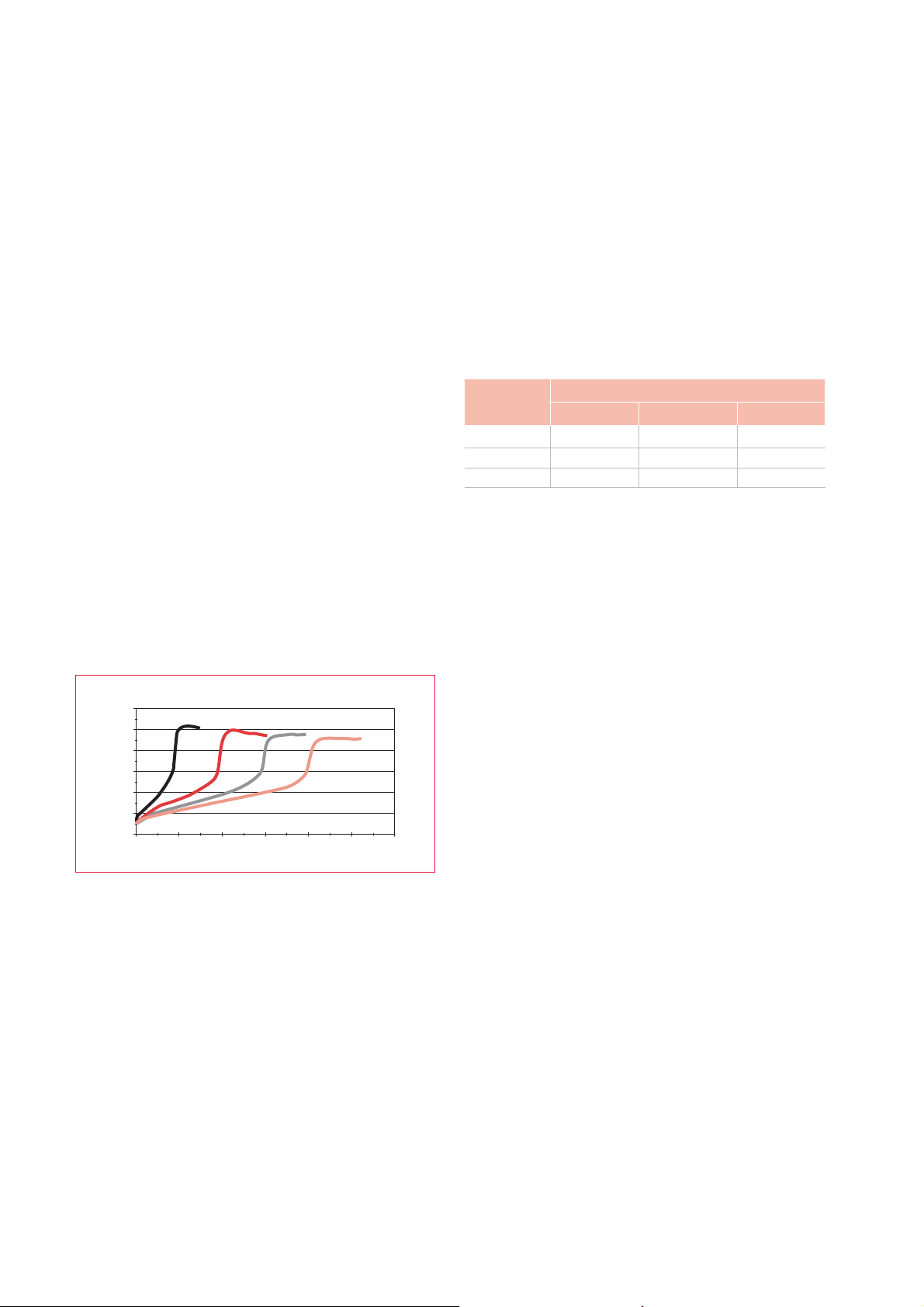

The time to recharge a battery under float charge is

shown in Figure 2.5.1. The graphs show the time taken

to reach three different states of charge. For example,

with a charge current of 0.2C

10 amps the battery will get

to 100% SOC in about 12 hours when charged at 13.62V

(2.27 Vpc).

Figure 2.5.1: Recharge times under float charge

2.6 Constant-voltage (CV) regime

In a float or standby application the CV charger should

be set at 13.5V to 13.8V at 25ºC. For a cyclic application,

the charge voltage should be set between 14.4V and 15V

at 25ºC. In both cases, the linearised temperature

compensation factor is ±24mV per battery per ºC

variation from 25ºC. The higher the temperature the

lower the charge voltage should be and vice versa.

Figure 2.6.1 shows the temperature compensation factor

for float and cyclic applications. Equations representing

the compensation curves are also shown in this figure.

Note that for both types of application there is no limit

on the inrush current. We recommend the highest

practical and economical current limit possible.

Figure 2.6.1: Temperature compensation graph

2.7 Constant-current (CC) regime

Unlike CV charging, CC charging requires the charge

current to be limited to 0.33C

10 to avoid damaging the

battery. Once 100% of previously discharged capacity

has been returned the overcharge should be continued

at a much lower rate, such as 0.002C

10, i.e., at the

500-hour rate.

13.62 - 12.00

0.008

13.62 - 13.60

0.004

7

www.enersys-emea.com

80% SOC

25

20

15

10

Time in hours at 2.27 VPC & 25°

5

0

0

0.2

Recharge current in multiple of rated capacity

90% SOC

0.4 0.6

100% SOC

0.8 1

2.90

2.80

2.70

2.60

2.50

2.40

Theoretical float (ideal)

Charge voltage, Vpc

2.30

V = 0.00004T

and 2.20VPC minium

2.20

2.10

-40

-30 -20

Theoretical cycling (ideal)

V = 0.00004T

2

- 0.006T + 2.3945

-10 0

2

- 0.006T + 2.5745

10

20

Temperature, °C

30

40

50 60

70 80

Page 8

When using a CC-charge regime, the charge current

must switch from a high (starting) rate to a low

(finishing) rate when the battery reaches 100% state of

charge. The point at which this switch occurs may be

determined by using a timer or by sensing the battery

voltage.

The timer setting can be determined by calculating the

time needed to return 105% to 110% of the amperehours drawn out. However, this method should not be

used unless the previously discharged capacity can be

reliably and consistently measured.

Alternatively, the battery-terminal voltage can be used to

trigger the transition from a high charge current to a low

charge current. As the battery charges up, its voltage

reaches a peak value and then begins to decline to the

steady-state, fully charged value. The point at which this

drop (point of inflection) begins depends on the charge

current’s magnitude, as shown in Figure 2.7.1. Since the

charge voltages in Figure 2.7.1 are on a per cell basis,

simply multiply the numbers by 6 as all Genesis

®

batteries are 12V units.

The inflection point may be used to switch the current

from a high rate (≤ 0.33C

10) to a low rate (≈0.002C10).

This is a more reliable method than amp-hour counting,

as it is independent of the previously discharged

capacity.

Figure 2.7.1: CC charging curves at 25ºC

The Genesis battery may be recharged using either a

constant-current (CC) or constant-voltage (CV) charger,

although the CV regime is the preferred method

. This

flexibility in the charging scheme is an advantage, since

it is easy for the user to replace existing batteries with

Genesis without having to alter the charging circuitry.

Because of the thin plate pure lead-tin technology used

in this battery, the internal resistance is significantly

lower than that of conventional VRLA batteries. For

example, the 26EP battery has an internal resistance of

about 5mΩ when fully charged. This compares very

favourably with a typical value of 10 to 15mΩ for

competitive products of equal capacity.

The low internal resistance helps the Genesis battery

accept large inrush currents without any harmful effects.

The heat generated by the charge current is kept at a low

level because of the very low internal resistance value.

The very high recharge efficiency of this battery also

allows high inrush currents. In tests performed on the

26Ah product, the initial current drawn by the battery

was 175 amperes. The Genesis battery may be recharged

much more rapidly than conventional VRLA batteries

because of its ability to safely accept very high currents.

Table 2.7.1 demonstrates this quick charge capability

when using a CV charge of 14.7V.

Table 2.7.1: Inrush current and charge time

This fast-charge capability is remarkable in a VRLA

battery. This feature makes the Genesis battery

competitive with a nickel-cadmium battery, which

traditionally had an advantage over lead acid batteries

due to its short charge times.

The quick charge capability of the Genesis battery makes

it particularly suitable for applications where the battery

has to be returned quickly to a high state of charge after

a discharge.

2.8 Three-step (IUU) charge profile

A three-step charge profile developed for use with the

Genesis TPPL battery is shown in Figure 2.8.1. The first

step (bulk charge) is a constant current (CC) charge with

a minimum current of 40% of the 10-hour (C

10) rating of

the battery. For example, to use this profile effectively on

the 16Ah battery, the minimum charge current must be

6.4 amps.

Bulk charge continues until the battery voltage reaches

14.7V. The charger then switches to a constant voltage

(CV) mode at 14.7V and the absorption charge phase

begins.

The charger switches to the temperature-compensated

float phase when either the current drops to 25% of the

bulk charge current (0.1C

10 amps) or the time in the

absorption phase reaches 8 hours, whichever occurs

first.

If the charger has a timer override so that the absorption

phase does not exceed 8 hours, the threshold current at

which the charger switches from absorption phase to

float phase should be reduced to 0.001C

10. This equals

16mA for the 16Ah battery discussed in the earlier

example.

If the charger does not have a timer the trigger to switch

from absorption phase to float phase should be set at

0.1C

10.

Magnitude of inrush current

Capacity

returned 0.8C

10

1.6C

10

3.1C

10

60% 44 min. 20 min. 10 min.

80% 57 min. 28 min. 14 min.

100% 1.5 hrs. 50 min. 30 min.

8

www.enersys-emea.com

Voltage Profiles at 25C

C/5

5

Constant Current Charging

C/15

C/10

10

Time (Hours)

C/20

2015

3025

Voltage

3

2.8

2.6

2.4

2.2

2

1.8

0

Page 9

Note:

The battery will not be fully charged when a

switch from absorption to float charge is made when

the current drops to 0.1C

10

. The battery will need a

minimum of 16-24 hours on float charge before it is

fully charged. The battery may be used as soon as

the switch to float is made, but repeatedly cycling it

without the necessary 16-24 hours’ on float charge

will cause premature failure of the battery.

Alternatively, the charger can stay in the absorption

phase for a fixed 8 hours. Once this absorption charge

time is over, the charger can switch to a temperaturecompensated float voltage. The advantage with this

design is a less complex circuit because it is not

necessary to monitor the charge current in the

absorption phase.

Table 2.8.1 lists the different IUU charge profile options.

A check mark indicates the feature is available in the

charger, while X indicates a charger that does not have

the feature. Note that all three designs have bulk,

absorption and float charge phases. The differences

between the three designs are limited to (a) whether a

timer is available, (b) whether the circuit monitors the

charge current and (c) the magnitude of the threshold

current, if it is used to trigger the switch from absorption

charge to float charge.

Table 2.8.1: IUU charger design options

Design 1:

The charger has a timer and a current threshold that

triggers the switch from absorption charge to float

charge. Since the timer is present, the trigger current is

set low. If the current does not drop to 0.001C

10

amps

within 8 hours on absorption charge, the timer will force

the switch to a temperature-compensated float charge.

Design 2:

The charger does not switch to a float charge based on a

preset charge current. Rather, the timer stays in the

absorption phase for 8 hours before switching to a

temperature-compensated float charge.

Design 3:

The charger has no timer. Since switching depends

solely on the charge current dropping to a set level, the

threshold is set high enough to ensure the charger will

always switch to a float charge. In this design the battery

will not be fully charged at the start of the float charge.

A minimum of 16-24 hours on float will be required to

complete the charge.

Figure 2.8.1: Three-step (IUU) charge profile

2.9 Storage characteristics

Improper storage is a common form of battery misuse.

High storage temperature and inadequate frequency of

freshening charges are examples of improper storage.

In order to better understand the various mechanisms

influencing sealed-lead batteries kept in storage, the

following paragraphs discuss in general terms several

aspects of the batteries’ storage requirements.

2.10 Self discharge

All batteries lose charge over time when kept on open

circuit. This phenomenon is termed

self-discharge

.

If the capacity loss due to self-discharge is not

compensated by recharging in a timely fashion, the

capacity loss may become irrecoverable due to

irreversible sulphation, where the active materials (PbO

2,

lead dioxide, at the positive plates and sponge lead at

the negative plates) are gradually converted into an

electroinactive form of lead sulphate, PbSO

4. If the

capacity loss associated with self-discharge is not

replenished, the battery ultimately fails because storage

is electrochemically equivalent to a very low rate of

discharge.

Storage temperature is the key factor influencing the

self-discharge rate because it plays a major role in

determining the speed at which the internal chemical

reaction proceeds. The higher the temperature, the faster

the speed of chemical reactions.

Design 1 ✓✓✓0.001C10

amps ✓

Design 2 ✓✓✓X ✓

Design 3 ✓✓X 0.10C

10

amps ✓

Feature

Bulk Absorption Timer Trigger Float

9

www.enersys-emea.com

Bulk charge

Voltage

(RED)

NOTES:

1. Charger LED stays RED in bulk charge phase (DO NOT TAKE BATTERY OFF CHARGE)

2. LED changes to ORANGE in absorption charge phase (BATTERY AT 80% STATE OF CHARGE)

3. LED changes to GREEN in float charge phase (BATTERY FULLY CHARGED)

4. Charge voltage is temperature compensated at ±24mV per battery per ºC variation from 25ºC

8-hour absorption charge

(ORANGE)

Charge voltage

Charge current

14.7V

Continuous float charge

(GREEN)

13.6V

0.4C

Amps

10 min

Page 10

Just as every 8°C rise in operating temperature cuts the

battery’s life expectancy in half, so does every 8°C

increase in ambient temperature reduce the storage life

of a battery by 50%. Conversely, a reduction in storage

temperature will have the reverse effect by increasing

the allowable storage time.

2.11 Open circuit voltage (OCV) and state of charge

(SOC)

Since most batteries are subject to some kind of storage,

it is important for the user to have some method of

accurately estimating the battery capacity after it has

been in storage.

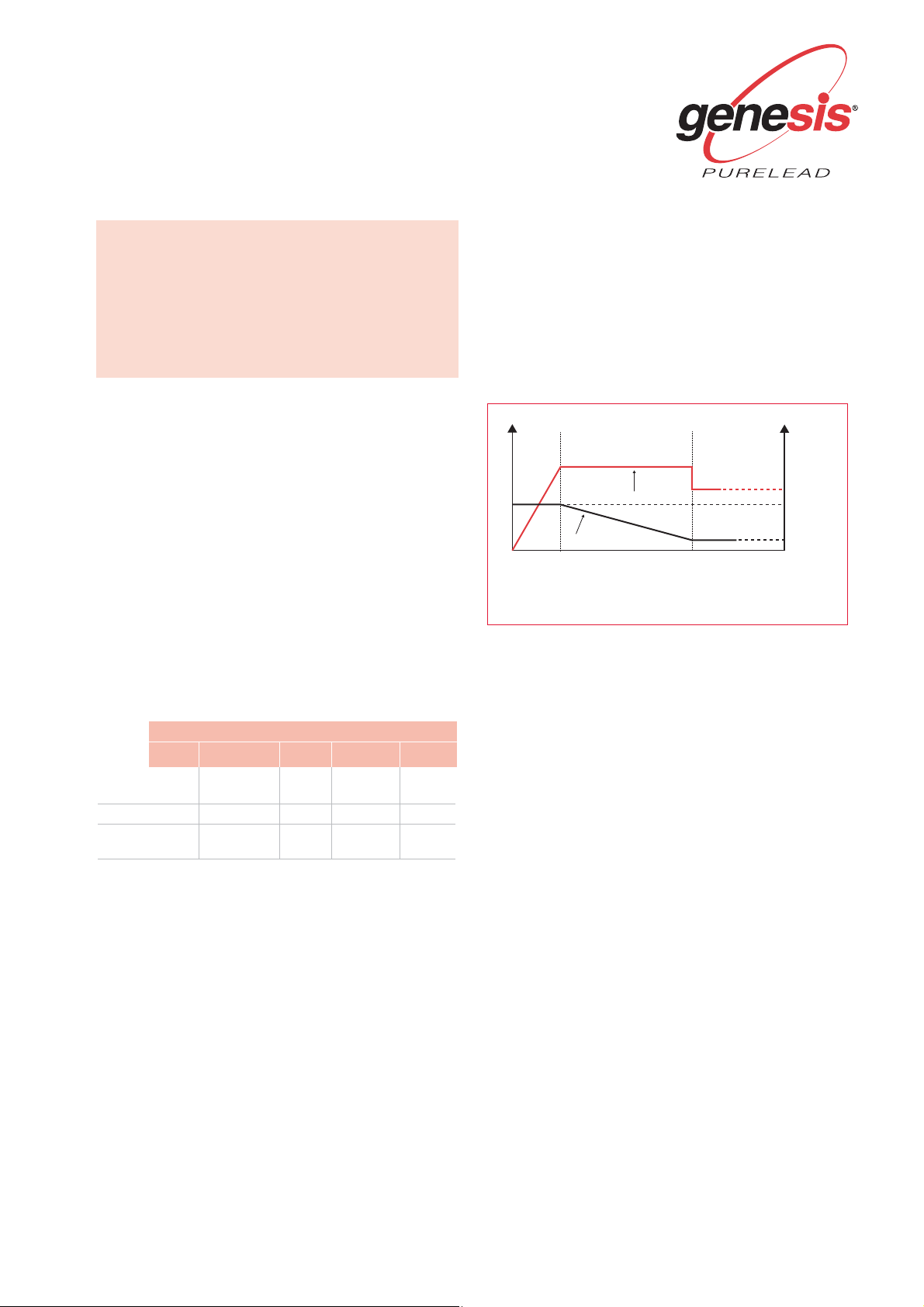

Figure 2.11.1: Open circuit voltage and state of charge

Although efforts should be made to ensure that batteries

are stored in temperature-controlled environments, a

freshening charge should be applied once every twentyfour (24) months or when the open-circuit voltage (OCV)

reading drops to 12V, whichever comes first. As shown

in Figure 2.11.1, 12V corresponds to a 35% state of

charge (SOC).

The battery may be permanently

damaged if the OCV is allowed to drop below 11.90V

.

Figure 2.11.1 shows the OCV and corresponding SOC for

a Genesis battery. An OCV of 12.84V or more indicates a

battery at 100% SOC. The figure is accurate to within

20% of the true SOC of the battery

if the battery has not

been charged OR discharged in the 24 hours preceding

the voltage measurement

. The accuracy improves to 5%

if the period of inactivity before the voltage

measurement is 5 days.

Capacity loss during storage is an important

consideration, particularly in applications where

performance loss due to storage is unacceptable.

However, knowing how much charge is remaining in the

battery at any point in its storage life is equally

important as the battery must be maintained at a

minimum charge level in order to prevent permanent

damage. Figure 2.11.2 shows the relationship between

storage time and remaining capacity at 25ºC, 45ºC and

65ºC.

Figure 2.11.2: Storage capacity at temperatures

2.12 Procedure to recover overdischarged batteries

There may be instances when a Genesis

®

battery is

overdischarged to the point where a standard charger is

unable to fully recharge the battery. In such cases, the

following procedure may help recover the affected

battery.

1. Bring the battery to room temperature (25°C).

2. Measure the OCV. Continue to step 3 if it is at least

12V; otherwise terminate the procedure and reject the

battery.

3. Charge the battery using a 0.05C

10 constant current for

24 hours. The charger should be capable of providing

a driving voltage as high as 36V. Monitor the battery

temperature;

discontinue charging if the battery

temperature rises above 45ºC

.

4. Allow the charged battery to stand on open circuit for

a minimum of 1 hour before proceeding to Step 5.

5. Perform a capacity test on the battery and record the

amp-hours delivered. The longer the discharge the

more reliable the result. This is Cycle 1.

6. Repeat steps (3) to (5). The capacity returned in step 5

is now Cycle 2. If Cycle 2 capacity is greater than Cycle

1 capacity proceed to step 7; otherwise reject the

battery.

7. Repeat steps (3) to (5) to get Cycle 3 capacity. Proceed

to step 8 if Cycle 3 capacity is equal to or more than

Cycle 2 capacity. Reject the battery if Cycle 3 capacity

is less than Cycle 2 capacity.

8. If Cycle 3 capacity equals or exceeds Cycle 2 capacity,

recharge the battery and put it back in service.

10

www.enersys-emea.com

100

90

80

70

25°C

45°C

65°C

13.0

12.8

12.6

12.4

12.2

12.0

Open circuit voltage (OCV), V

11.8

11.6

20 30 40 50 60 70 80 90 100

10

12.84V or higher indicates 100% SOC

State of Charge (SOC), %

60

50

Percent of 0.05C capacity

40

30

0

20

10

30 40

Open circuit storage time in weeks

60 70

50

Page 11

Chapter 3:

General Test Data

3.1 Introduction

This section’s purpose is to discuss actual data from

various tests conducted on Genesis

®

batteries. These

tests may be of particular interest to system designers

and application engineers. Other test results serve to

confirm the data published in the

Genesis Selection

Guide

.

Tests covered in this chapter include the following:

Thermal runaway test

Altitude test

Overdischarge recovery tests (DIN standard test and

high temperature storage test)

Accelerated float life test

Gassing test

Performance test at different temperatures

3.2 Thermal runaway test

Thermal runaway (TR) describes a situation in which the

battery is unable to maintain a steady current when

connected to a CV charger. TR can also happen when the

battery temperature increases rapidly due to inadequate

heat dissipation from the battery.

As the battery draws current, its internal temperature

rises. If the heat generated is not dissipated, the internal

reaction rate of the battery will increase, forcing the

battery to draw more current. This in turn generates

more heat. The increasing heat generation and attendant

higher current draw feed on each other which, if allowed

to escalate will trigger TR.

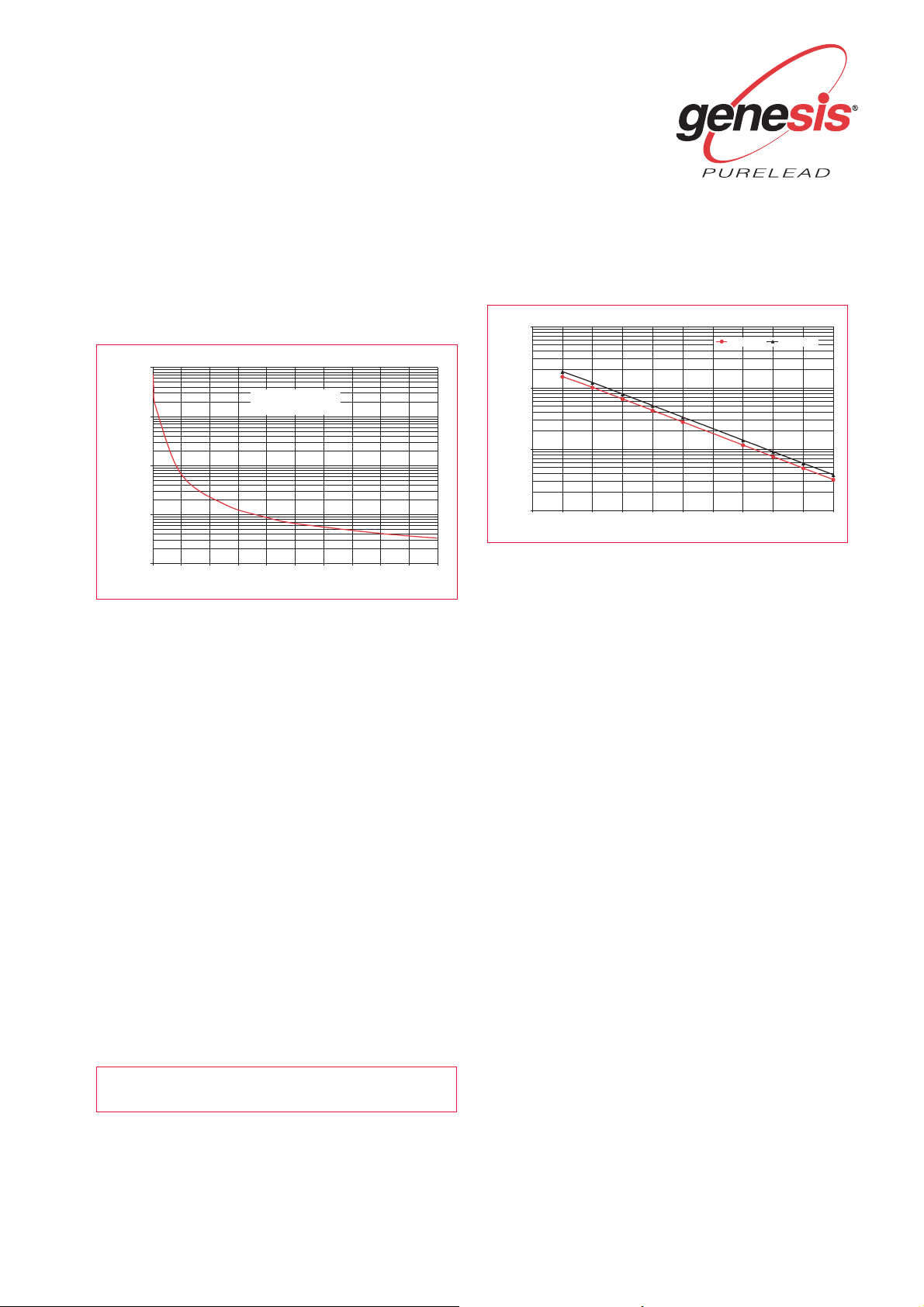

Figure 3.2.1 shows the result of TR tests conducted on a

12V, 26EP Genesis TPPL battery that had been cycled 10

times to age it. After the tenth discharge the battery was

fully charged using normal charging parameters, then

put on a gross overcharge at 15.9V (2.65 VPC) at 25ºC.

The threshold criterion for initiation of TR was set at a

charge current of 4.5 amps or a battery temperature of

60ºC. In other words, the battery was considered to be in

TR when either the charge current reached 4.5 amps or

the battery case temperature rose to 60ºC. As shown in

Figure 3.2.1 the battery reached the temperature

threshold first, after the battery had been on overcharge

for 370.9 hours, or over 15 days.

Two points are noteworthy here. First, it took over 15

days on gross overcharge (remember, the battery was

fully charged when it was placed on a 15.9V charge)

before it showed signs of going into TR. The battery

received a staggering 565.7 amp-hours (over 2,000% of

its rated capacity) during the test.

Second, there was no catastrophic failure of the battery

and its case temperature rose gradually. It took over a

week (169 hours) for the temperature to rise from 45ºC to

60ºC. The results of this test clearly show that even in the

unlikely event of a Genesis battery going into TR, its

behaviour does not raise safety issues.

Figure 3.2.1: TR test at 15.9V (2.65Vpc) charge

3.3 Gassing test

The Genesis battery is safe for use in human

environments, such as offices and hospitals. A test was

developed to determine how much hydrogen gas is

evolved under normal operating conditions. This test’s

assumption is that any weight loss suffered by the

battery can be attributed to the water lost by the battery.

Knowing the amount of water lost by the battery and the

chemical composition of water, a relatively

straightforward calculation yields the amount of emitted

hydrogen gas. Table 3.3.1 summarises the test data on a

Genesis 26Ah battery.

Table 3.3.1: Gassing test data

The oxygen evolved is recombined, while the rate of

hydrogen emission is negligible, as Table 3.3.1 shows.

Nevertheless, the battery should not be recharged in a

gas-tight container. Ventilation must always be provided

in the charging area.

Test temperature 60ºC

Charge voltage 2.30 Vpc

Duration of test

at temperature 180 days

Weight loss at 65.6 grams

end of test period = 3.65 moles (gram equiv.) H

2O

= 3.65 moles H2 and 1.82 moles O2

Gas evolved Total 122.6 litres

Duration of test

at 25ºC 2,880 days (4,147,200 minutes)

Gassing rate Total 0.03 cc/min

Hydrogen (H2): 0.02 cc/min.

Chapter 3:

General Test Data

11

www.enersys-emea.com

12V, 26Ah Pure Lead-tin VRLA

70

60

50

40

30

Temperature, °C

20

10

0

Test ends when temperature reached 60°C or current rises to 4.5A

Battery temperature at 60°C

after 370.9 hours

Total input amp-hours: 565.7

Charge current

0 50 100 150 200 250 300 350 400

Hours on charge at 2.65Vpc

7

6

5

4

3

2

1

0

Amps

Page 12

3.4 DIN standard overdischarge recovery test

This German standard test was designed to determine

the ability of batteries to recover from overdischarge

using standard chargers. In addition, the test also gives

an indication of the resistance of the battery to

permanent damage caused by sulphation, a

phenomenon that occurs when a battery is left in a

discharged condition for an extended length of time.

The test began by discharging a fully charged 26Ah

battery at the 20-hour rate to 1.70 Vpc. Following the

discharge, a 5Ω resistor was connected across the

battery terminals and left connected for 28 days. At the

end of this 28-day period, the battery was recharged at a

constant voltage of 2.25 Vpc for only 48 hours.

The battery was tested for capacity after the 48-hour

recharge, and 97% of the initial capacity was obtained.

A subsequent recharge/discharge cycle yielded a

capacity of 94% of the initial capacity. The overdischarge

test exercise is summarised in Table 3.4.1 below.

Table 3.4.1: DIN standard overdischarge recovery test

result

3.5 High temperature storage recovery test

This test demonstrates the deep discharge recovery

capability of the Genesis

®

battery. Since the test involves

storing the battery in a discharged state for 4 weeks at

50ºC it is a more difficult test than the previously

described German DIN standard test. Figure 3.5.1

summarises the test results.

Figure 3.5.1: Recovery from discharged storage at 50ºC

Both samples were discharged at the 1-hour rate to an

end of discharge voltage of 9V, then stored in a

discharged condition for 4 weeks at 50ºC.

The batteries were then charged at 14.7V with a current

limit of 0.125C

10 for the first two cycles and 1C10 for

cycles 3 through 17.

It is clear that the charge current was too low for the first

two cycles, as evident from the rapid loss in capacity.

Boosting the charge current to 1C

10 brought both

batteries back to full capacity.

3.6 Altitude test

This test was designed to prove that the Genesis battery

is capable of operating safely and without performance

loss at any altitude. Since the design of the Genesis

battery’s Bunsen valve does not rely on atmospheric

pressure to operate, the battery will operate over a wide

range of external pressure, from vacuum to as much as

100 feet under water.

These batteries have also passed the pressure

differential test required to comply with the requirements

of DOT HMR 49 Non-Hazardous Materials, International

Civil Aeronautics Organisation (ICAO) and International

Air Transport Association (IATA) Packing Instruction 806

and Special Provision A67.

In the pressure differential test, the battery is placed in

a temperature-controlled altitude chamber at 24°C.

It is then subjected to 6 hours of differential pressure at a

minimum of 88 kPa (equivalent to an altitude of 50,000

feet). The test is repeated for each of three mutually

perpendicular orientations, including the inverted

position. A visual inspection showed no acid leakage,

indicating the battery passed the test.

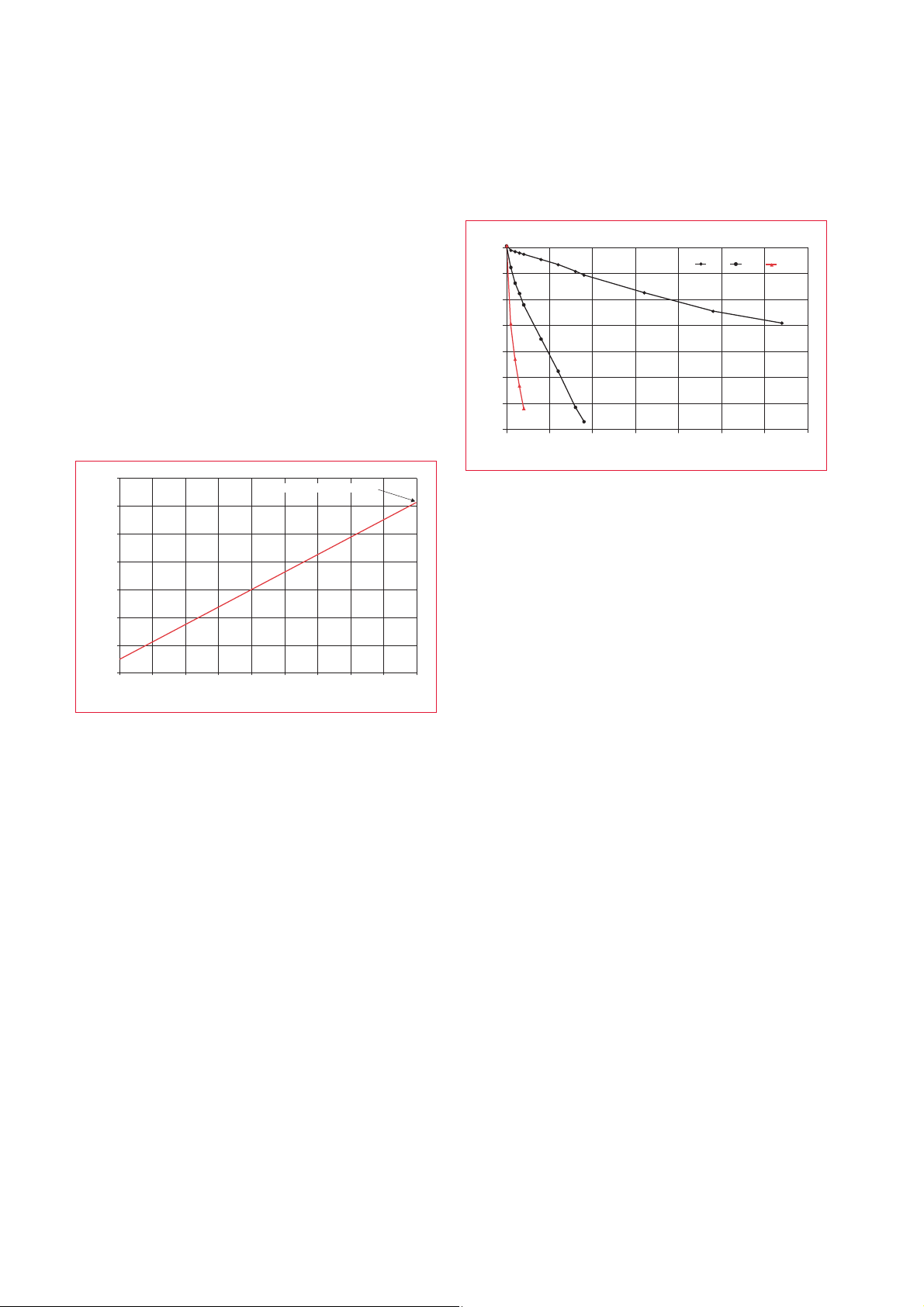

Section 3.7: Accelerated float life test

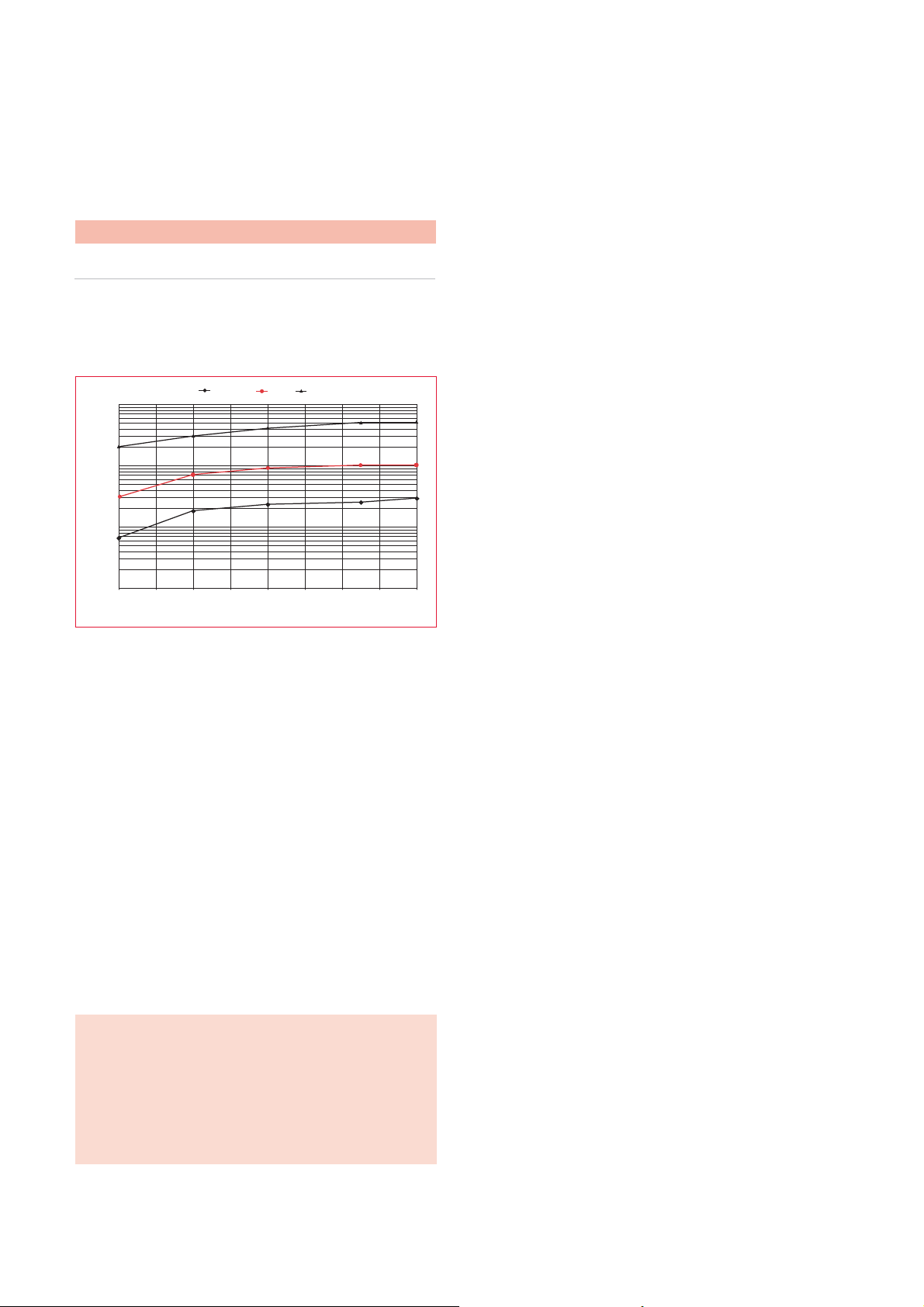

Figure 3.7.1 shows the results of accelerated float life

(AFL) tests conducted on three samples of the Genesis

16Ah battery. In AFL tests, high temperatures accelerate

the aging process of the batteries. At an AFL test

temperature of 55ºC, the acceleration factor (AF) is

13.454, which means that every day at 55ºC is

electrochemically equivalent to 13.454 days at 25ºC.

This is a conservative AF because the charge voltage

used in the test is not temperature-compensated, as it

should be. No account is taken of the accelerated aging

of the battery due to a higher-than-recommended charge

voltage.

As shown in Figure 3.7.1 the three batteries were at

109%, 108% and 110% of their rated capacity after 270

days on test at 55ºC. This is electrochemically equivalent

to 9.95

1

years on float at 25ºC. Since end of life is defined

as the failure to deliver 80% of its rated capacity, none of

these batteries is close to the end of its design life of 10

years at 25ºC.

Conditions 0.05C10 rate discharge to 1.70 Vpc

Followed by 5Ω resistor connected across battery

terminals for 28 days

Recharge 2.25 Vpc CV charge for 48 hours

Results Initial capacity: 26.8Ah

Recovered 25.9Ah (97%) on first cycle

capacity 25.3Ah (94%) on second cycle

12

www.enersys-emea.com

36

34

32

30

28

26

24

Capacity at the 1-hr rate

22

20

86 420

Cycle number

Sample 1

10

Sample 2

12

14 16 18

Page 13

Figure 3.7.1: AFL test data for Genesis®16EP batteries

Similar tests on the Genesis

®

XE batteries showed an

average float life of 454 days at 55ºC, or the equivalent of

16.7 years at 25ºC to 80% of rated capacity. These results

validate the Genesis EP and XE published design life of

10 years and 12+ years, respectively, at 25ºC to 80% of

rated capacity.

Section 3.8: Performance test at different temperatures

Figure 3.8.1 shows the effect of temperature on the

discharge performance of Genesis batteries at three rates

of discharge. The vertical broken line represents 25ºC,

and its intersections with the graphs show the 100%

capacity at the three rates of discharge.

At –40ºC, the battery will run for 2 hours at the C

5 rate

(60% of its 5-hour capacity), for 18 minutes at the C

1 rate

(30% of its 1-hour capacity) and for 4 minutes at the

15-minute rate (27% of its 15-minute capacity). These are

excellent performance numbers, considering how low

the ambient temperature is.

Figure 3.8.1: Effect of temperature on capacity

Chapter 4:

Installation, Operation & Maintenance

4.1 Introduction

This chapter is designed to provide the user with

guidelines to help get the most out these batteries.

Even though VRLA batteries do not require the addition

of water, periodic maintenance checks are strongly

recommended. These are:

Individual unit voltages

Unit-to-unit connection resistances

Ambient temperature and battery temperat

ure

A load test can be carried out once or twice a year.

The batteries must be fully charged before any capacity

test is performed.

4.2 Receiving the shipment

All batteries must be carefully inspected upon arrival for

any sign of damage during their transportation.

Use rubber gloves when handling any that are broken or

physically damaged in case of acid leakage.

4.3 Storage

All Genesis batteries must be stored in a clean and dry

location, and preferably in a temperature-controlled

environment. Although these batteries are shipped fully

charged and may be stored for up to 2 years at 25ºC

periodic checks of their open circuit voltages are

recommended. The warmer the storage environment the

more frequent the voltage checks should be.

The batteries must be given a freshening charge once

every 2 years or when the OCV drops to 12.00V,

whichever occurs earlier. The freshening charge should

be for 96 hours at 13.62V at 25ºC or until the charge

current does not vary over a 3-hour period. Alternatively,

the freshening charge can be set at 14.4V for 16 to 24

hours or until the charge current does not vary over a 3hour period.

Failure to observe these conditions may result in greatly

reduced capacity and service life. FAILURE TO CHARGE

AS NOTED VOIDS THE BATTERY’S WARRANTY.

4.4 Installation

Batteries must be installed in a clean, dry area. Genesis

batteries release negligible amounts of gas during

normal operation (gas recombination efficiency ≥99%),

making them safe for installation near main equipment

and in close proximity to humans. Batteries must be

installed in accordance with BS 6133 or EN 50272.

Genesis® 16EP/AFL/55°C/2.27 VPC

Chapter 4:

Installation, Operation & Maintenance

13

www.enersys-emea.com

C/5 (3.0A) to 10.02V/15Ah = 100%; 12Ah = 80%

21

18

Acceleration factor for 55°C:13.454

Capacities after 270 days (9.95 years at 25°C):

15

Sample 1: 16.42Ah (109%)

Sample 2: 16.22Ah (108%)

Sample 3: 16.49Ah (110%)

12

9

0 50 100 150 200 250 300

Days at Temperature

10

1

0.1

Discharge time, hours

0.01

-40

-30 -20 -10 0 10 20 30 40

15 min. rate

1 hr. rate

100% capacity at 25C

Temperature, C

5 hr. rate

10

1

0.1

Discharge time, hours

0.01

Page 14

4.4.1 Temperature

Avoid placing batteries in areas of high temperature or

in direct sunlight. The optimal temperature range for

performance and service life of the Genesis

®

battery is

20ºC to 25ºC. These batteries can, however be used at

temperatures ranging from -40ºC to 80ºC when fitted

with a metal jacket.

4.4.2 Ventilation

As stated before, under normal operating conditions

the gas emission from Genesis batteries is very low.

Natural ventilation is adequate for cooling and to

prevent buildup of hydrogen gas. This is why Genesis

batteries may be used safely in offices, hospitals and

other occupied environments.

When installing batteries in cabinets or other

enclosures, care must be taken to ensure they are not

sealed enclosures. UNDER NO CIRCUMSTANCES

SHOULD THESE BATTERIES BE CHARGED IN A

SEALED CONTAINER.

All installations and ventilation must comply with

BS 6133 or EN 50272.

4.4.3 Mounting

Check that all contact surfaces are clean before

making the interbattery connections.

Tighten the screws to the recommended torque value

using insulated tools only and follow the polarities of

individual batteries to avoid short circuits. Finally,

connect the battery end terminals.

Since the Genesis battery has all of its electrolyte

immobilised in its separators, it can be mounted on its

sides without any performance degradation.

Note: The safety standards of EN 50272.

4.4.4 Torque

The recommended terminal torque for the full range is

given in Table 4.4.5.1. A loose connector can cause

problems in charger performance, erratic battery

performance, possible damage to the battery and even

personal injuries.

Only use insulated tools when working on batteries.

Table 4.4.5.1: Terminal torque values

4.5 Parallel strings

While there are no theoretical limits on the number of

parallel battery strings, we recommend no more than

6 parallel strings per system, particularly for cyclic

applications.

4.6 Discharging

It is strongly recommended that a low voltage cutoff be

included in the battery load circuit to protect the battery

from overdischarges. The setting for end of discharge

voltage (EODV) is dependent on the rate of discharge,

as shown in Table 4.6.1. For optimum battery life, we

recommend that the battery be disconnected from the

load when the appropriate voltage is reached and put

back on charge as soon as possible after a discharge.

Table 4.6.1: Suggested battery cutoff voltages

Note:

Discharging the Genesis battery below these

low voltage cutoff levels or leaving the battery

connected to a load in a discharged state may impair

the battery’s ability to accept a charge.

Battery model Terminal torque

13EP & XE13 5.6 Nm

16EP & XE16 5.6 Nm

26EP & XE30 6.8 Nm

42EP & XE40 6.8 Nm

70EP & XE70 6.8 Nm

- XE95 6.8 Nm

Discharge rate in amps Suggested

minimum EODV

0.05C

10 (C10/20) 10.50V

0.10C10 (C10/10) 10.20V

0.20C

10 (C10/5) 10.02V

0.40C10 (C10/2.5) 9.90V

1C10 9.60V

2C

10 9.30V

>5C10 9.00V

14

www.enersys-emea.com

Page 15

Appendix A

- Genesis®XE Discharge Rates

15

www.enersys-emea.com

Figure A-1: XE13 discharge data to 9.0V at 25°C

Figure A-2: XE13 discharge data to 10.02V at 25°C

Figure A-3: XE13 discharge data to 10.5V at 25°C

2 min. 1529 149.1 5.0 50.9 764.8 25.5 283.1 9.4

5 min. 760 71.2 5.9 63.3 400.2 33.3 140.7 11.7

10 min. 460 41.7 7.1 78.2 242.3 41.2 85.2 14.5

15 min. 339 30.2 7.6 84.8 178.8 44.7 62.8 15.7

20 min. 273 24.1 7.9 90.0 143.7 47.4 50.5 16.7

30 min. 199 17.4 8.7 99.4 104.7 52.4 36.8 18.4

45 min. 144 12.5 9.4 108.0 75.9 56.9 26.7 20.0

1 hr. 114 9.8 9.8 113.6 59.9 59.9 21.0 21.0

2 hr. 64 5.4 10.9 127.1 33.5 66.9 11.8 23.5

3 hr. 44 3.8 11.4 132.9 23.3 70.0 8.2 24.6

4 hr. 34 3.0 11.8 137.0 18.0 72.2 6.3 25.4

5 hr. 28 2.4 12.0 139.7 14.7 73.6 5.2 25.9

8 hr. 18 1.6 12.6 144.3 9.5 76.0 3.3 26.7

10 hr. 15 1.3 12.7 145.5 7.7 76.7 2.7 26.9

20 hr. 7 0.7 13.2 148.0 3.9 78.0 1.4 27.4

Time Watts Amps Capacity Energy

(W) (A) (Ah) (Wh) W/litre Wh/litre W/kg Wh/kg

ENERGY AND POWER DENSITIES

2 min. 1361 128.0 4.3 45.3 680.8 22.7 252.0 8.4

5 min. 701 64.4 5.4 58.4 369.4 30.8 129.8 10.8

10 min. 443 39.6 6.7 75.2 233.2 39.6 82.0 13.9

15 min. 330 29.2 7.3 82.6 174.1 43.5 61.2 15.3

20 min. 267 23.5 7.7 88.1 140.7 46.4 49.4 16.3

30 min. 195 16.9 8.5 97.5 102.7 51.4 36.1 18.1

45 min. 141 12.2 9.1 105.7 74.2 55.7 26.1 19.6

1 hr. 111 9.6 9.6 111.2 58.6 58.6 20.6 20.6

2 hr. 62 5.3 10.6 123.4 32.5 65.0 11.4 22.8

3 hr. 43 3.7 11.1 128.7 22.6 67.8 7.9 23.8

4 hr. 33 2.9 11.5 132.3 17.4 69.7 6.1 24.5

5 hr. 27 2.3 11.7 134.8 14.2 71.0 5.0 25.0

8 hr. 17 1.5 12.1 138.9 9.1 73.2 3.2 25.7

10 hr. 14 1.2 12.4 140.6 7.4 74.1 2.6 26.0

20 hr. 7 0.7 13.0 144.3 3.8 76.0 1.3 26.7

Time Watts Amps Capacity Energy

(W) (A) (Ah) (Wh) W/litre Wh/litre W/kg Wh/kg

ENERGY AND POWER DENSITIES

2 min. 1206 111.0 3.7 40.1 603.3 20.1 223.3 7.4

5 min. 662 58.9 4.9 55.2 348.9 29.1 122.6 10.2

10 min. 429 37.3 6.3 72.9 225.9 38.4 79.4 13.5

15 min. 323 28.0 7.0 80.7 170.2 42.5 59.8 15.0

20 min. 262 22.6 7.5 86.3 137.8 45.5 48.4 16.0

30 min. 191 16.5 8.3 95.6 100.8 50.4 35.4 17.7

45 min. 138 12.0 9.0 103.8 72.9 54.7 25.6 19.2

1 hr. 109 9.4 9.4 108.7 57.3 57.3 20.1 20.1

2 hr. 60 5.2 10.4 119.3 31.4 62.9 11.0 22.1

3 hr. 41 3.6 10.9 124.2 21.8 65.5 7.7 23.0

4 hr. 32 2.8 11.3 127.4 16.8 67.1 5.9 23.6

5 hr. 26 2.3 11.5 129.6 13.7 68.3 4.8 24.0

8 hr. 17 1.5 11.9 133.5 8.8 70.4 3.1 24.7

10 hr. 14 1.2 12.1 135.1 7.1 71.2 2.5 25.0

20 hr. 7 0.6 12.8 140.6 3.7 74.1 1.3 26.0

Time Watts Amps Capacity Energy

(W) (A) (Ah) (Wh) W/litre Wh/litre W/kg Wh/kg

ENERGY AND POWER DENSITIES

Amps

10000

1000

100

10

Watts or amps per XE13 battery

1

0.1

0.01

0.1

Watts

110

Hours to 9V at 25ºC

Amps

10000

1000

100

10

Watts or amps per XE13 battery

1

0.1

0.01

0.1

Watts

110

Hours to 10.02V at 25°C (77°F)

100

100

Amps

10000

1000

100

10

Watts or amps per XE13 battery

1

0.1

0.01

0.1

Watts

110

Hours to 10.5V at 25°C (77°F)

100

Page 16

16

www.enersys-emea.com

Figure A-6: XE16 discharge data to 10.02V at 25°C

2 min. 1486 143.0 4.8 49.5 638.8 21.3 232.1 7.7

5 min. 857 78.8 6.6 71.4 368.5 30.7 133.9 11.2

10 min. 546 49.3 8.4 92.9 234.9 39.9 85.3 14.5

15 min. 412 36.7 9.2 102.9 177.0 44.2 64.3 16.1

20 min. 335 29.6 9.8 110.4 143.9 47.5 52.3 17.2

30 min. 247 21.6 10.8 123.5 106.2 53.1 38.6 19.3

45 min. 180 15.6 11.7 135.1 77.5 58.1 28.2 21.1

1 hr. 143 12.3 12.3 142.8 61.4 61.4 22.3 22.3

2 hr. 81 6.9 13.7 161.6 34.7 69.5 12.6 25.3

3 hr. 57 4.8 14.4 170.5 24.4 73.3 8.9 26.6

4 hr. 44 3.7 14.8 176.8 19.0 76.0 6.9 27.6

5 hr. 36 3.0 15.2 181.0 15.6 77.8 5.7 28.3

8 hr. 24 2.0 15.7 189.3 10.2 81.4 3.7 29.6

10 hr. 19 1.6 16.0 193.2 8.3 83.1 3.0 30.2

20 hr. 10 0.8 16.7 201.8 4.3 86.8 1.6 31.5

Time Watts Amps Capacity Energy

(W) (A) (Ah) (Wh) W/litre Wh/litre W/kg Wh/kg

ENERGY AND POWER DENSITIES

Figure A-4: XE13 discharge data to 11.1V at 25°C

Figure A-5: XE16 discharge data to 9V at 25°C

2 min. 977 87.1 2.9 32.5 488.7 16.3 180.9 6.0

5 min. 612 51.1 4.3 51.0 322.6 26.9 113.4 9.4

10 min. 410 34.0 5.8 69.7 216.0 36.7 75.9 12.9

15 min. 312 26.0 6.5 78.0 164.4 41.1 57.8 14.4

20 min. 254 21.3 7.0 83.7 133.7 44.1 47.0 15.5

30 min. 186 15.8 7.9 93.1 98.1 49.1 34.5 17.2

45 min. 133 11.4 8.6 100.1 70.3 52.7 24.7 18.5

1 hr. 105 9.1 9.1 104.9 55.3 55.3 19.4 19.4

2 hr. 57 5.1 10.1 113.4 29.9 59.7 10.5 21.0

3 hr. 39 3.5 10.6 117.2 20.6 61.8 7.2 21.7

4 hr. 30 2.7 11.0 119.8 15.8 63.1 5.5 22.2

5 hr. 24 2.2 11.2 121.3 12.8 63.9 4.5 22.5

8 hr. 16 1.5 11.6 124.7 8.2 65.7 2.9 23.1

10 hr. 13 1.2 11.8 126.6 6.7 66.7 2.3 23.4

20 hr. 7 0.6 12.4 133.3 3.5 70.2 1.2 24.7

Time Watts Amps Capacity Energy

(W) (A) (Ah) (Wh) W/litre Wh/litre W/kg Wh/kg

ENERGY AND POWER DENSITIES

2 min. 1674 170.0 5.6 55.8 720.0 24.0 261.6 8.7

5 min. 915 87.9 7.3 76.3 393.6 32.8 143.0 11.9

10 min. 566 52.0 8.8 96.2 243.4 41.4 88.4 15.0

15 min. 422 38.0 9.5 105.4 181.4 45.3 65.9 16.5

20 min. 342 30.3 10.0 112.7 146.8 48.5 53.4 17.6

30 min. 251 22.0 11.0 125.4 107.8 53.9 39.2 19.6

45 min. 183 15.8 11.8 137.5 78.8 59.1 28.6 21.5

1 hr. 145 12.4 12.4 145.3 62.5 62.5 22.7 22.7

2 hr. 82 7.0 13.9 164.1 35.3 70.6 12.8 25.6

3 hr. 58 4.9 14.7 174.7 25.0 75.1 9.1 27.3

4 hr. 45 3.8 15.3 181.4 19.5 78.0 7.1 28.3

5 hr. 37 3.1 15.6 186.2 16.0 80.1 5.8 29.1

8 hr. 24 2.1 16.4 195.2 10.5 83.9 3.8 30.5

10 hr. 20 1.7 16.7 198.7 8.5 85.4 3.1 31.0

20 hr. 10 0.9 17.3 206.7 4.4 88.9 1.6 32.3

Time Watts Amps Capacity Energy

(W) (A) (Ah) (Wh) W/litre Wh/litre W/kg Wh/kg

ENERGY AND POWER DENSITIES

Amps

10000

1000

100

10

Watts or amps per XE13 battery

1

0.01

0.1

Watts

1 10 100

Hours to 11.1V at 25°C (77°F)

Amps

10000

1000

100

10

Watts or amps per XE16 battery

1

0.1

0.01

0.1

Watts

1 10 100

Hours to 9V at 25°C (77°F)

Amps

10000

1000

100

10

Watts or amps per XE16 battery

1

0.1

0.01

0.1

Watts

1 10 100

Hours to 10.02V at 25°C (77°F)

Page 17

17

www.enersys-emea.com

Figure A-7: XE16 discharge data to 10.5V at 25°C

2 min. 1312 124.9 4.2 43.7 564.3 18.8 205.1 6.8

5 min. 799 71.8 6.0 66.5 343.4 28.6 124.8 10.4

10 min. 522 46.5 7.9 88.8 224.6 38.2 81.6 13.9

15 min. 397 35.1 8.8 99.3 170.7 42.7 62.0 15.5

20 min. 324 28.6 9.4 106.9 139.3 46.0 50.6 16.7

30 min. 240 21.0 10.5 120.1 103.3 51.6 37.5 18.8

45 min. 176 15.2 11.4 131.8 75.6 56.7 27.5 20.6

1 hr. 140 12.0 12.0 139.7 60.1 60.1 21.8 21.8

2 hr. 78 6.7 13.3 156.7 33.7 67.4 12.2 24.5

3 hr. 55 4.7 14.0 166.1 23.8 71.4 8.6 25.9

4 hr. 43 3.6 14.4 172.1 18.5 74.0 6.7 26.9

5 hr. 35 2.9 14.7 176.1 15.1 75.7 5.5 27.5

8 hr. 23 1.9 15.2 183.9 9.9 79.1 3.6 28.7

10 hr. 19 1.6 15.5 187.7 8.1 80.7 2.9 29.3

20 hr. 10 0.8 16.1 196.9 4.2 84.7 1.5 30.8

Time Watts Amps Capacity Energy

(W) (A) (Ah) (Wh) W/litre Wh/litre W/kg Wh/kg

ENERGY AND POWER DENSITIES

Figure A-8: XE16 discharge data to 11.1V at 25°C

Figure A-9: XE30 discharge data to 9V at 25°C

2 min. 1058 100.4 3.3 35.2 454.8 15.1 165.3 5.5

5 min. 721 62.1 5.2 60.0 309.9 25.8 112.6 9.4

10 min. 485 42.2 7.2 82.4 208.5 35.4 75.8 12.9

15 min. 374 32.5 8.1 93.4 160.6 40.2 58.4 14.6

20 min. 307 26.7 8.8 101.4 132.2 43.6 48.0 15.9

30 min. 230 19.9 9.9 114.7 98.7 49.3 35.9 17.9

45 min. 168 14.4 10.8 126.2 72.4 54.3 26.3 19.7

1 hr. 134 11.5 11.5 134.1 57.7 57.7 21.0 21.0

2 hr. 75 6.4 12.7 150.5 32.4 64.7 11.8 23.5

3 hr. 53 4.4 13.3 159.3 22.8 68.5 8.3 24.9

4 hr. 41 3.4 13.7 164.7 17.7 70.8 6.4 25.7

5 hr. 34 2.8 13.9 168.5 14.5 72.4 5.3 26.3

8 hr. 22 1.8 14.4 176.1 9.5 75.7 3.4 27.5

10 hr. 18 1.5 14.7 179.1 7.7 77.0 2.8 28.0

20 hr. 9 0.8 15.3 188.3 4.0 81.0 1.5 29.4

Time Watts Amps Capacity Energy

(W) (A) (Ah) (Wh) W/litre Wh/litre W/kg Wh/kg

ENERGY AND POWER DENSITIES

2 min. 2837 283.4 9.4 94.5 768.7 25.6 267.6 8.9

5 min. 1694 160.1 13.3 141.1 459.2 38.2 159.9 13.3

10 min. 1062 95.6 16.3 180.5 287.7 48.9 100.2 17.0

15 min. 793 69.8 17.4 198.2 214.8 53.7 74.8 18.7

20 min. 638 55.6 18.3 210.4 172.8 57.0 60.1 19.8

30 min. 463 39.9 20.0 231.4 125.4 62.7 43.7 21.8

45 min. 333 28.4 21.3 249.7 90.2 67.7 31.4 23.6

1 hr. 262 22.3 22.3 262.1 71.0 71.0 24.7 24.7

2 hr. 144 12.1 24.3 288.7 39.1 78.2 13.6 27.2

3 hr. 101 8.5 25.4 302.3 27.3 81.9 9.5 28.5

4 hr. 78 6.6 26.2 311.8 21.1 84.5 7.4 29.4

5 hr. 64 5.3 26.7 318.6 17.3 86.3 6.0 30.1

8 hr. 41 3.5 27.9 331.1 11.2 89.7 3.9 31.2

10 hr. 34 2.8 28.3 337.5 9.1 91.5 3.2 31.8

20 hr. 18 1.5 30.0 357.1 4.8 96.8 1.7 33.7

Time Watts Amps Capacity Energy

(W) (A) (Ah) (Wh) W/litre Wh/litre W/kg Wh/kg

ENERGY AND POWER DENSITIES

Amps

10000

1000

100

10

Watts or amps per XE16 battery

1

0.1

0.01

0.1

Watts

1 10 100

Hours to 10.5V at 25°C (77°F)

Amps

10000

1000

100

10

Watts or amps per XE16 battery

1

0.1

0.01

0.1

Watts

1 10 100

Hours to 11.1V at 25°C (77°F)

Amps

10000

1000

100

10

Watts or amps per XE30 battery

1

0.01

0.1

Watts

1 10 100

Hours to 9V at 25°C (77°F)

Page 18

18

www.enersys-emea.com

Figure A-11: XE30 discharge data to 10.5V at 25°C

Figure A-12: XE30 discharge data to 11.1V at 25°C

2 min. 2129 195.7 6.5 70.9 576.8 19.2 200.8 6.7

5 min. 1454 130.9 10.9 121.1 391.1 32.8 137.2 11.4

10 min. 972 85.5 14.5 165.3 263.4 44.8 91.7 15.6

15 min. 742 64.5 16.1 185.5 201.1 50.3 70.0 17.5

20 min. 603 52.1 17.2 198.9 163.3 53.9 56.9 18.8

30 min. 444 38.0 19.0 222.0 120.3 60.1 41.9 20.9

45 min. 321 27.3 20.5 240.8 87.0 65.2 30.3 22.7

1 hr. 253 21.4 21.4 252.7 68.5 68.5 23.8 23.8

2 hr. 139 11.7 23.4 278.8 37.8 75.5 13.2 26.3

3 hr. 97 8.1 24.3 291.2 26.3 78.9 9.2 27.5

4 hr. 75 6.2 25.0 299.5 20.3 81.2 7.1 28.3

5 hr. 61 5.1 25.4 306.3 16.6 83.0 5.8 28.9

8 hr. 40 3.3 26.4 317.4 10.8 86.0 3.7 29.9

10 hr. 32 2.7 26.9 324.0 8.8 87.8 3.1 30.6

20 hr. 17 1.4 28.7 347.3 4.7 94.1 1.6 32.8

Time Watts Amps Capacity Energy

(W) (A) (Ah) (Wh) W/litre Wh/litre W/kg Wh/kg

ENERGY AND POWER DENSITIES

2 min. 1801 160.1 5.3 60.0 487.9 16.2 169.9 5.7

5 min. 1298 113.6 9.5 108.2 351.8 29.3 122.5 10.2

10 min. 895 77.6 13.2 152.2 242.6 41.3 84.5 14.4

15 min. 698 59.6 14.9 174.4 189.0 47.3 65.8 16.5

20 min. 571 48.7 16.1 188.3 154.6 51.0 53.8 17.8

30 min. 425 36.1 18.0 212.2 115.0 57.5 40.0 20.0

45 min. 309 26.1 19.6 231.9 83.8 62.8 29.2 21.9

1 hr. 245 20.6 20.6 244.7 66.3 66.3 23.1 23.1

2 hr. 135 11.3 22.6 270.2 36.6 73.2 12.7 25.5

3 hr. 94 7.9 23.6 282.0 25.5 76.4 8.9 26.6

4 hr. 72 6.1 24.2 289.7 19.6 78.5 6.8 27.3

5 hr. 59 4.9 24.7 296.5 16.1 80.3 5.6 28.0

8 hr. 39 3.2 25.6 308.1 10.4 83.5 3.6 29.1

10 hr. 31 2.6 26.1 314.3 8.5 85.2 3.0 29.6

20 hr. 17 1.4 27.7 336.3 4.6 91.1 1.6 31.7

Time Watts Amps Capacity Energy

(W) (A) (Ah) (Wh) W/litre Wh/litre W/kg Wh/kg

ENERGY AND POWER DENSITIES

Figure A-10: XE30 discharge data to 10.02V at 25°C

2 min. 2381 224.8 7.5 79.3 645.3 21.5 224.7 7.5

5 min. 1565 142.8 11.9 130.3 424.0 35.3 147.6 12.3

10 min. 1017 90.6 15.4 172.9 275.6 46.8 95.9 16.3

15 min. 767 67.4 16.9 191.8 207.9 52.0 72.4 18.1

20 min. 622 54.2 17.9 205.4 168.6 55.7 58.7 19.4

30 min. 455 39.2 19.6 227.6 123.4 61.7 42.9 21.5

45 min. 328 28.1 21.0 245.9 88.9 66.6 30.9 23.2

1 hr. 258 21.9 21.9 258.3 70.0 70.0 24.4 24.4

2 hr. 142 11.9 23.8 283.7 38.4 76.9 13.4 26.8

3 hr. 98 8.3 24.8 294.9 26.6 79.9 9.3 27.8

4 hr. 76 6.4 25.5 304.4 20.6 82.5 7.2 28.7

5 hr. 62 5.2 25.9 309.4 16.8 83.8 5.8 29.2

8 hr. 41 3.4 27.0 323.8 11.0 87.7 3.8 30.5

10 hr. 33 2.75 27.5 330.8 9.0 89.6 3.1 31.2

20 hr. 18 1.5 29.6 354.6 4.8 96.1 1.7 33.5

Time Watts Amps Capacity Energy

(W) (A) (Ah) (Wh) W/litre Wh/litre W/kg Wh/kg

ENERGY AND POWER DENSITIES

Amps

10000

1000

100

10

Watts or amps per XE30 battery

1

0.01

0.1

Watts

1 10 100

Hours to 10.02V at 25°C (77°F)

Amps

10000

1000

100

10

Watts or amps per XE30 battery

1

0.01

0.1

Watts

1 10 100

Hours to 10.5V at 25°C (77°F)

Amps

10000

1000

100

10

Watts or amps per XE30 battery

1

0.01

0.1

Watts

1 10 100

Hours to 11.1V at 25°C (77°F)

Page 19

19

Figure A-13: XE40 discharge data to 9V at 25°C

Figure A-14: XE40 discharge data to 10.02V at 25°C

Figure A-15: XE40 discharge data to 10.5V at 25°C

2 min. 4338 436.6 14.5 144.4 777.0 25.9 269.4 9.0

5 min. 2370 226.1 18.8 197.4 424.5 35.4 147.2 12.3

10 min. 1497 136.5 23.2 254.4 268.1 45.6 93.0 15.8

15 min. 1123 100.3 25.1 280.6 201.1 50.3 69.7 17.4

20 min. 909 80.2 26.5 299.9 162.8 53.7 56.5 18.6

30 min. 665 58.0 29.0 332.3 119.1 59.5 41.3 20.6

45 min. 484 41.6 31.2 362.8 86.7 65.0 30.0 22.5

1 hr. 383 32.7 32.7 382.5 68.5 68.5 23.8 23.8

2 hr. 213 18.1 36.2 426.8 38.2 76.5 13.3 26.5

3 hr. 150 12.6 37.8 449.7 26.9 80.6 9.3 27.9

4 hr. 116 9.8 39.1 464.0 20.8 83.1 7.2 28.8

5 hr. 95 8.0 39.9 474.8 17.0 85.0 5.9 29.5

8 hr. 62 5.2 41.6 494.0 11.1 88.5 3.8 30.7

10 hr. 51 4.2 42.4 505.0 9.0 90.5 3.1 31.4

20 hr. 27 2.2 44.4 529.5 4.7 94.8 1.6 32.9

Time Watts Amps Capacity Energy

(W) (A) (Ah) (Wh) W/litre Wh/litre W/kg Wh/kg

ENERGY AND POWER DENSITIES

2 min. 3580 337.9 11.3 119.2 641.2 21.4 222.3 7.4

5 min. 2155 199.1 16.6 179.5 386.1 32.2 133.9 11.2

10 min. 1426 127.9 21.7 242.5 255.5 43.4 88.6 15.1

15 min. 1085 96.0 24.0 271.1 194.3 48.6 67.4 16.8

20 min. 884 77.5 25.6 291.6 158.3 52.2 54.9 18.1

30 min. 652 56.6 28.3 326.0 116.8 58.4 40.5 20.3

45 min. 476 40.8 30.6 356.7 85.2 63.9 29.5 22.2

1 hr. 376 32.1 32.1 376.3 67.4 67.4 23.4 23.4

2 hr. 209 17.7 35.4 418.2 37.5 74.9 13.0 26.0

3 hr. 146 12.3 36.9 438.7 26.2 78.6 9.1 27.2

4 hr. 113 9.5 37.9 451.8 20.2 80.9 7.0 28.1

5 hr. 93 7.7 38.6 462.5 16.6 82.9 5.7 28.7

8 hr. 60 5.0 40.1 481.8 10.8 86.3 3.7 29.9

10 hr. 49 4.1 40.8 490.3 8.8 87.8 3.0 30.5

20 hr. 26 2.2 43.0 518.5 4.6 92.9 1.6 32.2

Time Watts Amps Capacity Energy

(W) (A) (Ah) (Wh) W/litre Wh/litre W/kg Wh/kg

ENERGY AND POWER DENSITIES

2 min. 3232 296.4 9.9 107.6 578.9 19.3 200.7 6.7

5 min. 1987 179.6 15.0 165.5 355.9 29.6 123.4 10.3

10 min. 1350 119.4 20.3 229.4 241.7 41.1 83.8 14.2

15 min. 1010 90.9 22.7 260.0 186.3 46.6 64.6 16.2

20 min. 852 74.1 24.4 281.2 152.6 50.4 52.9 17.5

30 min. 633 54.7 27.3 316.6 113.4 56.7 39.3 19.7

45 min. 464 39.7 29.8 347.9 83.1 62.3 28.8 21.6

1 hr. 368 31.3 31.3 368.3 66.0 66.0 22.9 22.9

2 hr. 205 17.3 34.5 410.8 36.8 73.6 12.8 25.5

3 hr. 144 12.1 36.2 431.3 25.8 77.3 8.9 26.8

4 hr. 111 9.3 37.2 444.4 19.9 79.6 6.9 27.6

5 hr. 91 7.6 37.9 453.3 16.2 81.2 5.6 28.2

8 hr. 59 4.9 39.3 473.0 10.6 84.7 3.7 29.4

10 hr. 48 4.0 39.9 481.8 8.6 86.3 3.0 29.9

20 hr. 26 2.1 42.2 509.9 4.6 91.3 1.6 31.7

Time Watts Amps Capacity Energy

(W) (A) (Ah) (Wh) W/litre Wh/litre W/kg Wh/kg

ENERGY AND POWER DENSITIES

Amps

10000

1000

100

10

Watts or amps per XE40 battery

1

0.01

0.1

Watts

1 10 100

Hours to 9V at 25°C (77°F)

Amps

10000

1000

100

10

Watts or amps per XE40 battery

1

0.01

0.1

Watts

1 10 100

Hours to 10.02V at 25°C (77°F)

Amps

10000

1000

100

10

Watts or amps per XE40 battery

1

0.01

0.1

Watts

1 10 100

Hours to 10.5V at 25°C (77°F)

Page 20

20

www.enersys-emea.com

Figure A-16: XE40 discharge data to 11.1V at 25°C

2 min. 2814 249.4 8.3 93.7 504.1 16.8 174.8 5.8

5 min. 1753 153.6 12.8 146.0 314.0 26.2 108.9 9.1

10 min. 1234 106.6 18.1 209.9 221.1 37.6 76.7 13.0

15 min. 964 83.0 20.7 241.0 172.7 43.2 59.9 15.0

20 min. 802 68.5 22.6 264.5 143.6 47.4 49.8 16.4

30 min. 603 51.3 25.7 301.3 107.9 54.0 37.4 18.7

45 min. 445 37.6 28.2 333.8 79.7 59.8 27.6 20.7

1 hr. 355 29.9 29.9 354.6 63.5 63.5 22.0 22.0

2 hr. 200 16.8 33.5 399.7 35.8 71.6 12.4 24.8

3 hr. 140 11.7 35.0 420.2 25.1 75.3 8.7 26.1

4 hr. 109 9.0 36.2 434.6 19.5 77.8 6.7 27.0

5 hr. 89 7.4 36.9 444.1 15.9 79.6 5.5 27.6

8 hr. 58 4.8 38.3 461.2 10.3 82.6 3.6 28.6

10 hr. 47 3.9 38.9 469.6 8.4 84.1 2.9 29.2

20 hr. 25 2.1 41.0 495.2 4.4 88.7 1.5 30.8

Time Watts Amps Capacity Energy

(W) (A) (Ah) (Wh) W/litre Wh/litre W/kg Wh/kg

ENERGY AND POWER DENSITIES

Figure A-17: XE70 discharge data to 9V at 25°C

2 min. 6597 644.0 21.4 219.7 674.0 22.4 256.7 8.5

5 min. 4051 388.4 32.4 337.4 413.9 34.5 157.6 13.1

10 min. 2565 235.6 40.0 436.0 262.0 44.5 99.8 17.0

15 min. 1909 172.3 43.1 477.2 195.0 48.8 74.3 18.6

20 min. 1540 137.8 45.5 508.2 157.3 51.9 59.9 19.8

30 min. 1122 98.5 49.3 561.2 114.7 57.3 43.7 21.8

45 min. 804 70.0 52.5 603.1 82.2 61.6 31.3 23.5

1 hr. 627 54.7 54.6 627.2 64.1 64.1 24.4 24.4

2 hr. 342 29.6 59.2 683.4 34.9 69.8 13.3 26.6

3 hr. 235 20.5 61.4 705.9 24.0 72.1 9.2 27.5

4 hr. 181 15.7 62.6 721.8 18.4 73.7 7.0 28.1

5 hr. 146 12.8 63.8 729.0 14.9 74.5 5.7 28.4

8 hr. 93 8.2 65.7 743.5 9.5 76.0 3.6 28.9

10 hr. 75 6.7 66.6 752.0 7.7 76.8 2.9 29.3

20 hr. 38 3.5 69.3 764.3 3.9 78.1 1.5 29.7

Time Watts Amps Capacity Energy

(W) (A) (Ah) (Wh) W/litre Wh/litre W/kg Wh/kg

ENERGY AND POWER DENSITIES

Figure A-18: XE70 discharge data to 10.02V at 25°C

2 min. 5942 569.8 19.0 197.9 607.0 20.2 231.2 7.7

5 min. 3636 337.6 28.1 302.8 371.4 30.9 141.5 11.8

10 min. 2411 218.5 37.2 409.9 246.3 41.9 93.8 16.0

15 min. 1833 163.8 41.0 458.2 187.2 46.8 71.3 17.8

20 min. 1490 132.6 43.7 491.6 152.2 50.2 58.0 19.1

30 min. 1091 96.0 48.0 545.5 111.5 55.7 42.5 21.2

45 min. 786 68.6 51.4 589.1 80.2 60.2 30.6 22.9

1 hr. 615 53.6 53.6 615.4 62.9 62.9 23.9 23.9

2 hr. 333 28.9 57.8 666.1 34.0 68.1 13.0 25.9

3 hr. 229 19.9 59.6 687.5 23.4 70.2 8.9 26.8

4 hr. 175 15.2 61.0 699.7 17.9 71.5 6.8 27.2

5 hr. 142 12.4 61.8 707.6 14.5 72.3 5.5 27.5

8 hr. 90 8.0 63.6 719.0 9.2 73.5 3.5 28.0

10 hr. 73 6.5 64.5 727.6 7.4 74.3 2.8 28.3

20 hr. 37 3.4 67.9 748.4 3.8 76.5 1.5 29.1

Time Watts Amps Capacity Energy

(W) (A) (Ah) (Wh) W/litre Wh/litre W/kg Wh/kg

ENERGY AND POWER DENSITIES

Amps

10000

1000

100

10

Watts or amps per XE40 battery

1

0.01

0.1

Watts

1 10 100

Hours to 11.1V at 25°C (77°F)

Amps

10000

1000

100

10

Watts or amps per XE70 battery

1

0.01

0.1

Watts

1 10 100

Hours to 9V at 25°C (77°F)

Amps

10000

1000

100

10

Watts or amps per XE70 battery

1

0.01

0.1

Watts

1 10 100

Hours to 10.02V at 25°C (77°F)

Page 21

21

www.enersys-emea.com

Figure A-19: XE70 discharge data to 10.5V at 25°C

2 min. 5140 480.8 16.0 171.2 525.1 17.5 200.0 6.7

5 min. 3317 301.9 25.1 276.3 338.9 28.2 129.1 10.8

10 min. 2258 201.5 34.3 383.8 230.7 39.2 87.9 14.9

15 min. 1738 154.3 38.6 434.4 177.5 44.4 67.6 16.9

20 min. 1420 125.2 41.3 468.7 145.1 47.9 55.3 18.2

30 min. 1053 92.0 46.0 526.7 107.6 53.8 41.0 20.5

45 min. 761 66.3 49.7 570.4 77.7 58.3 29.6 22.2

1 hr. 600 52.1 52.1 599.9 61.3 61.3 23.3 23.3

2 hr. 327 28.4 56.7 653.8 33.4 66.8 12.7 25.4

3 hr. 225 19.6 58.7 674.6 23.0 68.9 8.7 26.2

4 hr. 172 15.0 60.2 687.5 17.6 70.2 6.7 26.7

5 hr. 139 12.2 60.7 695.3 14.2 71.0 5.4 27.1

8 hr. 89 7.8 62.6 709.2 9.1 72.5 3.4 27.6

10 hr. 72 6.4 63.5 715.3 7.3 73.1 2.8 27.8