Page 1

Installation, Operations

and Maintenance

Manual

Visit us at www.enersys.com

Page 2

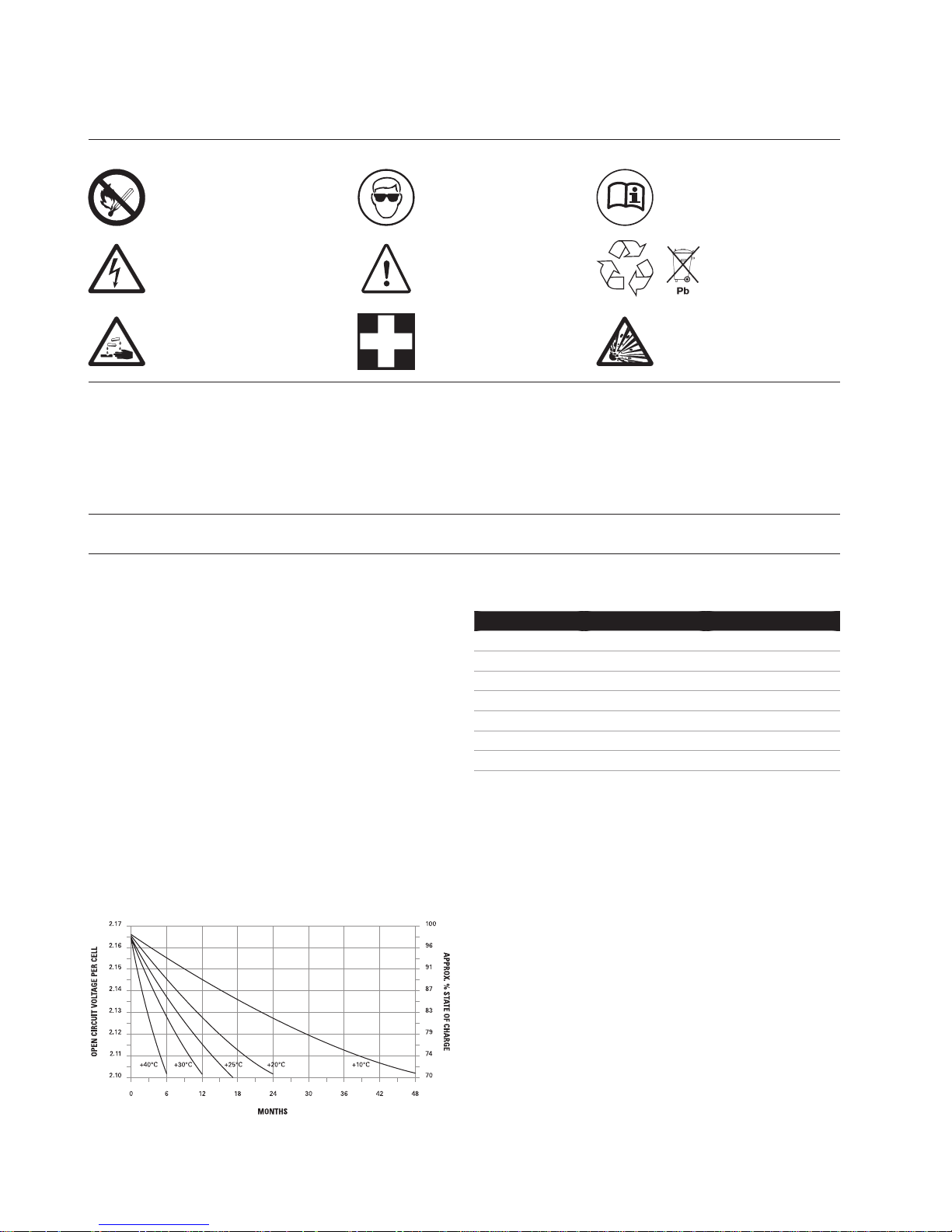

Temperature (°C / °F) Storage Time (Months)

OCV Audit Intervals (Months)

+10 / +50 48 12

+15 / +59 34 12

+20 / +68 24 12

+25 / +77 17 6

+30 / +86 12 6

+35 / +95 8.5 3

+40 / +104 6 3

Handling

DataSafe® XE batteries are supplied in a charged

condition and are capable of extremely high short

circuit currents. Take care to avoid short-circuiting

terminals of opposite polarity.

California Proposition 65 Warning - Battery posts, terminals, and related accessories contain lead and lead compounds, chemicals known to the State of California to

cause cancer and reproductive harm. Wash hands after handling.

Important

Please read this manual immediately on receipt of the battery before unpacking and installing. Failure to comply with these instructions will render any

warranties null and void.

Care for your safety

2

1. Receiving

1.1. In-Transit Damage or Short Shipments

Upon receipt of the shipment, please check that the items delivered are

undamaged and match the carrier’s Bill of Lading. Report any damage or

shortages to the carrier. EnerSys® is not responsible for shipment damage

or shortages that the receiver does not report to the carrier.

1.2. Shipment Damage or Shortages

Open the shipping containers and check the contents for damage and

against the packing slip. Immediately inform EnerSys of any damaged or

missing items. EnerSys is not responsible for damaged or missing items

after a shipment has been in storage.

2. Storage

2.1. Storage Conditions and Time

If a battery cannot be immediately installed it should be stored in a clean,

cool and dry area. During storage monoblocs lose capacity through selfdischarge. High temperatures increase the rate of self-discharge and reduce

the storage life.

The chart below shows the relationship between open-circuit voltage (OCV)

and storage time at various temperatures.

The maximum storage times before a refresh charge is required and

recommended open circuit voltage audit intervals are:

Monoblocs must be given a refresh charge when bloc voltages approach

the equivalent of 2.10 Volts per cell or when the maximum storage time is

reached, whichever occurs first.

2.2. Refresh Charge

Charge the monoblocs or strings at a constant voltage equivalent to 2.29 -

2.40Vpc with 0.1C10 current available for a period of 24 hours.

2.3. Commissioning Charge

Before commencing operation, the battery must be given a commissioning

charge. The batteries should be charged using constant voltage with a

minimum charge current of 0.1C10 with no load connected to the battery.

Either of the following methods can be used:

• Charge for 7 continuous days at the recommended float voltage of

2.29Vpc at 20˚C / 68˚F or

• Charge for 24 hours at the recommended boost charge voltage of

2.40Vpc at 20˚C / 68˚F. The battery will then be switched over to float

charging, maintaining the battery under floating voltage for 24 hours

before any discharge test.

3. Battery Location

The battery compartment/room must have adequate ventilation to limit

hydrogen accumulation to a maximum of 1% by volume of free air.

Keep flames away

Discharge any possible static electricity from clothes

by touching an earth connected part.

Tools

Use tools with insulated handles.

Do not place or drop metal objects on the battery.

Remove rings, wristwatch and articles of clothing

with metal parts that may come into contact with

the battery terminals.

No smoking, no naked flames, no

sparks

Shield eyes Read instructions

Electrical hazard Danger Re-cycle scrap batteries.

Contains lead

Electrolyte is corrosive

Clean all acid splash in eyes or on skin

with plenty of clean water.

Then seek medical help.

Acid on clothing is to be washed with

water

Warning: Risk of fire, explosion, or

burns. Do not disassemble, heat above

60ºC, or incinerate. Avoid any short

circuit. Metallic parts under voltage on

the battery, do not place tools or items

on top of the battery

Page 3

3

4. Installation

Install in a clean and dry area. DataSafe® XE batteries release minimal

amounts of gas during normal operation (gas recombination efficiency ≥

95%). They can be installed near the main equipment. Batteries must be

installed in accordance with local, national and international regulations and

manufacturer’s instructions.

n

Temperature

Avoid placing the battery in areas of high temperature or in direct sunlight.

The battery will give the best performance and service life when working at

a temperature between 20˚C (68˚F) and 25˚C (77˚F). The maximum operating

temperature range is -40˚C (-40˚F) to + 50˚C (+113˚F).

n

Ventilation

Under normal conditions gas release is very low and natural ventilation is

sufficient for cooling purposes and inadvertent overcharge, enabling DataSafe XE

batteries to be used safely in offices and with main equipment. However care

must be taken to ensure adequate ventilation when placed in cabinets. Batteries

must not be placed in sealed cabinets.

n

Security

All installation and ventilation must comply with the current local, national and

international regulations.

n

Mounting

Battery racks or cabinets, supplied by EnerSys, are recommended for proper

installation. Assemble the rack according to instructions. Place the monoblocs

on the rack and arrange the positive and the negative terminals for connection

according to the wiring diagram. Check that all contact surfaces are clean and

apply the bloc connectors and the terminal screws. Tighten the screws securely.

Follow the polarity to avoid short circuiting of blocs. Finally connect the battery

terminals. It is important that the battery is mounted firmly.

n

Installation of High Voltage Batteries

A battery consisting of 10 or more blocs connected in series presents additional

hazards and the following notes on installation should be employed.

• During installation process, limit the battery voltage by omitting interbloc connectors to give a maximum section voltage of 120V or 10 blocs.

• The omitted inter-bloc connectors should be chosen such that they are

in an easily accessible position. These connectors should only be fitted

with the load and charger isolated and when the rest of the installation

is complete.

• Never work alone on high voltage batteries.

• Always use insulated tools and wear approved high voltage insulating

gloves.

• When supplied, fit the “high voltage battery” warning labels in a

prominent position.

n

Torque

Tighten the nuts or bolts to the recommended levels of fastening torque

indicated on the product label (if applicable). A loose connector can cause

problems in charger adjustment, erratic battery performance, possible damage

to the battery and/or personal injury.

n

Blocs in Parallel Strings

When using constant voltage chargers, ensure that the connections between

the charger and the end of each string within the battery have the same

electrical resistance. Parallel strings should be limited to five strings.

5. Operation

5.1. Float Voltage

Constant voltage chargers are recommended. The charging voltage should

be set at the equivalent of 2.29Vpc at 20˚C/ (68˚F) or 2.27Vpc at 25˚C

(77˚F). The minimum charging voltage, at any temperature, is 2.21Vpc. The

recommended float voltage temperature compensation is as follows:

Due to the phenomena of gas recombination, it is not uncommon to note a

variation in individual block float voltages of 2% (or up to 5% for relatively

new batteries). However the total voltage of the battery shall be within the

limits stated above.

5.2. Charging Current

Due to the very low internal resistance DataSafe XE monoblocs will

accept very high current during recharge and there is not a need to limit

the available current. For cost and practicle purposes in float applications

where recharge time to repeat duty is not critical, the rectifier current can be

limited to the load plus 0.1C10 Amps.

5.3. Fast Recharge

In instances where the time to repeat duty is critical the charge voltage

should be set to 2.40Vpc at 20˚C (68˚F), with the rectifier current limit set to

a minimum of 0.1C10 A. Fast charge should be stopped and reverted to float

voltage after approximately 10 to 15 hours.

5.4. Periodic Boost Charge

In normal operation a periodic boost charge is not required. However, in

some cases such as when extended or repeated line power outages result

in the battery exeriencing extended periods of undercharging, a boost

charge equivalent to 2.40Vpc at 20˚C (68˚F) for a maximum of 15 hours can

be applied.

5.5. Discharging

For maximum battery life, the end of discharge voltage should be limited

to 1.60Vpc for low rate discharges or 1.50Vpc for high rate discharges

(10 minutes or less in rated duration). Failure to protect batteries from

discharges exceeding this level may impact warranty.

n

Discharged Monoblocs

DataSafe XE batteries must not be left in a discharged condition after

supplying the load, but must be immediately returned to float recharge

mode. Failure to observe these conditions may result in greatly reduced

service life and unreliability.

n

Accidental Deep Discharge

When the battery is completely discharged, the sulphuric acid is completely

absorbed and the remaining electrolyte consists only of water. At this point,

the sulphation of the plates is at its maximum, considerably increasing the

cell’s internal resistance.

Important notice: this type of deep discharge will provoke a premature

deterioration of the battery and a noticeable effect on life expectancy.

6. Maintenance

In practice, the user usually specifies the maintenance schedule based on

site criticality, location and manpower.

However, the following may be used as a suggested maintenance schedule.

• Monthly (record all readings)

Measure the battery string voltage. If necessary, adjust the float

voltage to the correct value.

• Every six months (record all readings)

- Measure the battery string voltage. If necessary, adjust the float

voltage to the correct value.

- Measure individual bloc voltages.

- Bloc to bloc connection resistance (Ohms)

- Terminal Connection Resistance (Ohms)

- Ambient temperature in the immediate environment

Inspect for contamination by dust, loose or corroded connections. If

necessary, isolate the string/bloc and clean with a damp soft cloth. Warning:

Do NOT use any type of oil, solvent, detergent, petroleum-based solvent or

ammonia solution to clean the battery containers or lids. These materials will

cause permanent damage to the battery container and lid and will invalidate

the warranty.

Keep a logbook to record values, power outages, discharge tests, etc.

An autonomy check can be carried out once or twice a year.

The above record taking is the absolute minimum to protect the warranty.

This data will be required for any warranty claim made on the battery.

Contact EnerSys if you have any questions regarding maintenance.

7. Disposal

DataSafe XE batteries are recyclable. Scrap batteries must be packaged

and transported in accordance with prevailing transportation rules and

regulations.

Scrap batteries must be disposed of in compliance with local and national

laws by a licensed or certified lead acid battery recycler.

Temperature (°C / °F)

10/50 15/59 20/68 25/77 30/86 35/95

40/104

Recommended

2.33 2.31 2.29 2.27 2.25 2.23 2.21

Minimum

2.31 2.29 2.27 2.25 2.23 2.21 2.21

Page 4

EnerSys World Headquarters

2366 Bernville Road, Reading,

PA 19605, USA

Tel: +1-610-208-1991 /

+1-800-538-3627

EnerSys EMEA

EH Europe GmbH

Baarerstrasse 18

6300 Zug

Switzerland

EnerSys Asia

152 Beach Road,

Gateway East Building #11-03,

Singapore 189721

Tel: +65 6508 1780

© 2016 EnerSys. All rights reserved. Trademarks and logos are the property of EnerSys and its affiliates unless otherwise noted.

Publication No. EN-DS-XE-IOM-001 SEE1555 - March 2016 - Subject to revisions without prior notice. E.&O.E.

Contact:

Loading...

Loading...