Page 1

Publication No: US-HX-IOM-002 - March 2004

Installation, Operation

and Maintenance

Instructions

www.enersysinc.com

Page 2

2

Publication No: US-HX-IOM-002 - March 2004

www.enersysinc.com

IMPORTANT

Please read this manual immediately on receipt of battery before

unpacking and installing. Failure to comply with these instructions will

render any warranties null and void.

CARE FOR YOUR SAFETY

Handling

DataSafe HX batteries are supplied in a fully

charged state and must be unpacked carefully to

avoid very high short-circuit currents between

terminals of opposite polarity. Use care when

handling and moving batteries. Appropriate lifting

equipment must be used.

Keep flames away

In case of accidental overcharge, a flammable

gas can leak off the safety vent.

Discharge any possible static electricity from

clothes by touching an earth connected part.

Tools

Use tools with insulated handles.

Do not place or drop metal objects on the battery.

Remove rings, wristwatch and articles of clothing

with metal parts that may come into contact with

the battery terminals.

Dispose at registered

waste handling

facility

RECEIVING THE SHIPMENT

Carefully examine the battery shipment upon arrival for any signs of transit

damage and that it agrees with the materials list or packing slip. Be very

careful not to inadvertently discard any accessories contained in the

packing material.

Batteries contain sulfuric acid in glass fiber separators.

Use rubber gloves when handling broken or damaged containers in case of

acid leakage.

STORAGE

Store DataSafe HX batteries in a dry, clean and preferably cool location.

Since the batteries are supplied charged, storage time is limited. In order to

easily charge the batteries after prolonged storage, it is advised not to store

it more than:

6 months at ambient temperature no warmer than 77°F, (25°C)

4 months at 86°F, (30°C)

2 months at 104°F, (40°C)

Give the battery a freshening charge before the end of the recommended

storage interval.

A refreshing charge shall be performed at 2.26 V/cell at 77°F (25°C) for

96 hours or until the charge current does not vary for a 3 hour period.

The necessity of a charge can also be determined by measuring the open

circuit voltage of a stored battery.

Charge is advised if the voltage drops below 2.07 V/cell.

Maximum total storage prior to installation is 2 years from date of shipment

from factory to the customer. Freshening charges are required before the

end of the storage time period or more frequently, as noted above.

Failure to observe these conditions may result in greatly reduced capacity

and service life.

FAILURE TO CHARGE AS NOTED VOIDS THE BATTERY’S WARRANTY.

INSTALLATION

Install in clean, dry area. DataSafe HX product releases minimal amounts of

gas during normal operation (gas recombination efficiency ≥ 95%). It can be

installed near the main equipment. Batteries must be installed in

accordance with local, state and federal regulations and manufacturers

instructions.

Temperature

Avoid placing the battery in areas of high temperature or in direct sunlight.

The battery will give the best performance and service life when working at

a temperature between 68°F (20°C) and 77°F (25°C). The usual operating

temperature is between -14°F (-10°C) and 113°F (+45°C). Limits are

comprised between -86°F (-30°C) and 113°F (+45°C).

Ventilation

Under normal conditions gas release is very low and natural ventilation is

sufficient for cooling purposes and inadvertent overcharge, enabling

DataSafe HX batteries to be used safely in offices and with main equipment.

However care must be taken to ensure adequate ventilation when placed in

cabinets. Batteries must not be placed in sealed cabinets.

Security

All installation and ventilation must comply with the current local, state and

federal regulations.

Mounting

EnerSys battery racks or cabinets are recommended for proper installation.

Assemble the rack according to instructions. Place the battery blocs or cells

on the rack and arrange the positive and the negative terminals for

connection according to the wiring diagram. Check that all contact surfaces

are clean and apply the bloc or cell connectors and the terminal screws.

Tighten the screws securely. Follow the polarity to avoid short circuiting of

cell groups. Finally connect the battery terminals. It is important that the

battery is mounted firmly.

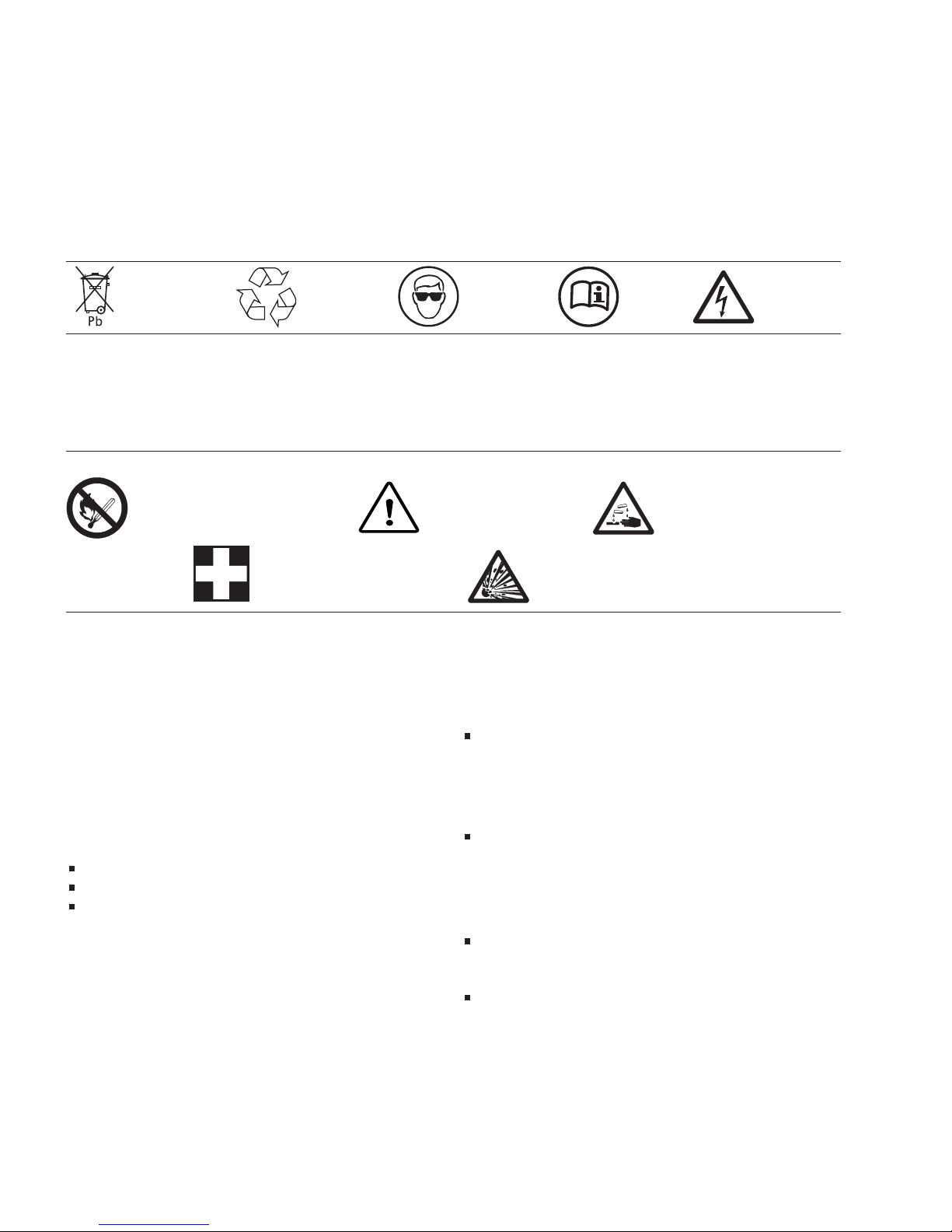

No smoking, no naked flames,

no sparks

Electrolyte is corrosive

Clean all acid splash in eyes or on

skin with plenty of clean water.

Then seek medical help. Acid on

clothing is to be washed with water.

Danger

Risk of explosion or fire. Avoid any

short circuit. Metallic parts under

voltage on the battery, do not place

tools or items on top of the battery.

Other safety precautions that need to be taken

Battery must be

recycled

Protect eyes

from electrolyte

Read

instructions

Do not charge in

sealed container

Page 3

3

Publication No: US-HX-IOM-002 - March 2004

www.enersysinc.com

Torque

The maximum torque load of intercell connector bolts is 6.8 to 10 Nm

(60 to 88 lb. in) for M6 screw. A loose connector can cause problems in

charger adjustment, erratic battery performance, possible damage to the

battery and/or personal injury. Finally, install the connector covers (optional).

CELLS IN PARALLEL STRINGS

When using constant voltage chargers, ensure that the connections

between the charger and the end of each string within the battery have the

same electrical resistance. Parallel strings must be limited to five strings.

CHARGING

Float Voltage

The float/charge voltage is 2.26 V per cell at 77°F (25°C).

When the average ambient temperature deviates more than ± 9°F (5°C)

from the reference, it is necessary to adjust the float voltage as follows :

2.37 to 2.38 Vpc at 32°F, ( 0 °C)

2.30 to 2.33 Vpc at 50°F, (10°C)

2.27 to 2.30 Vpc at 68°F, (20°C)

2.24 to 2.27 Vpc at 77°F, (25°C)

(reference T°C)

2.23 to 2.26 Vpc at 86°F, (30°C)

2.21 to 2.24 Vpc at 95°F, (35°C)

Due to the phenomena of gas recombination a difference of ± 2% (earlier in

float life ± 5% is common) for an individual cell voltage can be observed.

However the total voltage of the battery shall be within the limits stated

above.

Charging Current

The charging current is self limiting.

Fast Recharge

Occasionally (4 or 5 times a year) the battery may be recharged at 2.40 V per

cell with a current limited to the values listed in the Table 2. Fast charging

should be stopped after approx. 10 or 15 hour.

Ripple Current

Unacceptable levels of ripple current from the charger or the load can cause

permanent damage and a reduction in service life. It is recommended to

limit the continuous ripple current to the values of the Table 2 (in amperes).

State of Charge

The battery state of charge can be determined approximately by measuring

the open circuit voltage after the battery has been at rest for a minimum of

24 hours at 77°F (25°C).

DISCHARGING

End of Discharge Voltage

The end of discharge voltage must be limited to 1.60 V per cell.

A protecting system shall have to be installed to prevent deep discharge.

Discharged Cells

DataSafe HX batteries must not be left in a discharged condition after

supplying the load, but must be immediately returned to float recharge

mode.

Failure to observe these conditions may result in greatly reduced service life

and unreliability.

Accidental Deep Discharge

When the battery is completely discharged, the sulfuric acid is completely

absorbed and the remaining electrolyte consists only of water.

At this point, the sulfation of the plates is at its maximum, considerably

increasing the cell’s internal resistance.

- Important notice : this type of deep discharge will provoke a premature

deterioration of the battery and a noticeable effect on life expectancy.

The effect of temperature

- on capacity

Correction factor of the capacity, according to temperature.

MAINTENANCE/CHECKS

DataSafe HX are maintenance free, sealed, lead acid batteries and need no

water addition.

The containers and lids shall be kept dry and free from dust. Cleaning must

be done only with a damp cotton cloth. Check monthly that total voltage at

battery terminals is (N x 2.24 to 2.27 V) for a temperature of 77°F (25°C).

(N being the number of cells in the battery).

Every 12 months, read and record the following:

Individual cell or unit voltages (volts)

Cell-to-cell connection resistance (ohms)

Terminal connection resistance (ohms)

Ambient temperature in the immediate battery environment

Keep a logbook to record values, power outages, discharge tests, etc.

An autonomy check can be carried out once or twice a year.

The above record taking is the absolute minimum to protect the warranty.

This data will be required for any warranty claim made on the battery.

RECOMMENDED CURRENT LIMIT VALUES WHEN

RECHARGING WITH CONSTANT VOLTAGE

RECHARGING METHOD

41°F, ( 5 °C) 0.84

50°F, (10°C) 0.88

59°F, (15°C) 0.93

68°F, (20°C) 0.97

77°F, (25°C) 1.00

86°F, (30°C) 1.03

95°F, (35°C) 1.05

104°, (40°C) 1.07

Time of discharge 1 min to 60 mins

HX205 4.0 2.0

HX300 7.0 3.5

HX330 7.0 3.5

HX400 8.5 4.25

HX500 10.0 5.0

Type Maximum charging Max recommended rms

current (A) value of the alternating

component (A)

Table 1

Table 2

State of charge Voltage

100% 2.13 to 2.14 V/Cell

80% 2.09 to 2.11 V/Cell

60% 2.06 to 2.08 V/Cell

40% 2.02 to 2.04 V/Cell

20% 1.97 to 2.00 V/Cell

Page 4

Publication No: US-HX-IOM-002 - March 2004 - Subject to revisions without prior notice

www.enersysinc.com

Distributed by:

Printed in USA

Type Length Width CC RC A B C 1 2 3 4 5 6

HX205 8.9 5.5 5.6 9.1 2.1 1.9 9.0 866880 HRD2328 866881 HRD2328 866885 HRD2329

HX300 10.1 6.9 6.9 10.3 2.7 2.2 11.2 866881 HRD2328 866883 HRD2327 866886 HRD2330

HX330 11.9 6.9 6.9 12.1 2.7 2.5 11.2 866882 HRD2327 866883 HRD2327 866886 HRD2330

HX400 13.3 6.8 6.8 13.5 2.6 3.0 11.1 866884 HRD2327 866883 HRD2327 866886 HRD2330

HX500 13.3 6.8 6.8 13.5 2.6 3.0 11.1 866884 HRD2327 866883 HRD2327 866886 HRD2330

All measurements are in inches

INTER-UNIT CONNECTOR LAYOUT

TYPICAL LAYOUTS ON STEEL STANDS

SINGLE ROW STAND DOUBLE ROW STAND

Note! End terminal position will depend upon

number of units in row, ie. whether “ODD” or

“EVEN” number

Global Headquarters

P.O. Box 14145

Reading, PA 19612-4145 USA

Tel: +1-610-208-1991

+1-800-538-3627

Fax: +1-610-372-8613

EnerSys EMEA

Brussels, Belgium

Tel: +32 (0)2 247 94 47

EnerSys Asia

Guangdong, China

Tel: +86-755-2689 3639

Loading...

Loading...