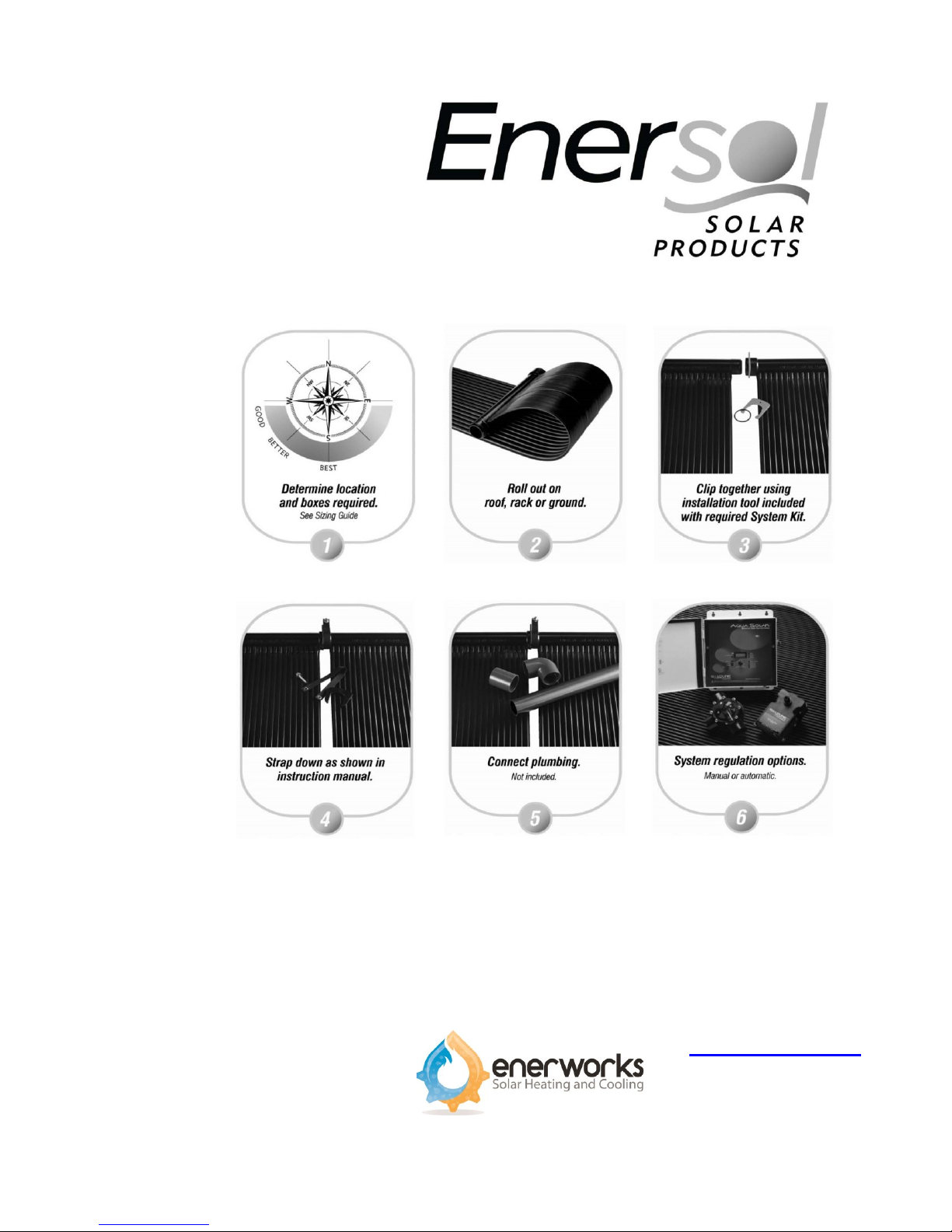

Enersol Solar Pool Heating, Solar panel Installation Manual And Owner's Manual

SOLAR PANEL

INSTALLATION GUIDE

AND OWNERS MANUAL

www.enersol.com

May, 2015

© 2015 Enerworks

Enersol Pool Panel Installation Guide – EnerWorks Inc. ©, May 2015

2 | P a g e

Enersol Pool Panel Installation Guide – EnerWorks Inc. ©, May 2015

PANEL BOX

1 section with pre attached headers

2 clips

3 lag bolts

2 O-rings

1 long strap (48”)

1 short strap (12”)

TOOLS REQUIRED

Ladder, Safety gear (safety glasses, fall arrest, and

boots), Variable speed drill, 5/16” and 3/8” socket

drivers, Level, Hacksaw, Chalk line, Utility knife,

Caulking gun, Various tools (pliers, etc.)

INSTALLATION KIT (Purchased separately – 1

per install)

1 warranty card

1 installation guide/owner’s manual

1 orange installation tool

1 tube lag bolt roof sealant

1 tube O-ring lubricant

2 end caps assembly

2 O-rings

1 Lag bolt and short strap (12”)

ADDITIONAL PARTS REQUIRED

PVC heavy bodied cement

1 ½” - 2” elbows

1 ½” - 2” tees

1 ½” – 2” pipe

pipe hold downs (1 ½” and/or 2”)

1 ½” – 2” couplers

Extra lag bolts

3-way manual valve or

Automatic controller with 3-way valve

One way check valve

1 ½” – 2” ball valve

Teflon tape

SOLAR PANEL INSTALLATION

INFORMATION

If for any reason whatsoever, the installer of this

product does not feel comfortable and/or safe do

not proceed with the installation. The installation of

this product involves walking on the roof as well as

climbing ladders. Do not attempt unless you

understand all safety procedures involved with

power tools, climbing ladders and working on roofs.

To obtain ladder safety, roof safety and power tool

safety procedures, contact your local Hardware or

Building Supply Company and State or Provincial

Worker’s Safety Board.

The installation of Enersol Solar Panels may be

performed on a low pitched (less than 12:12 or 45

degrees angle) shingle and some types of metal

roofs. If an installation varies from these types,

Enersol should be advised and asked for special

installation instructions, visit our website or contact

your roof manufacturer. For example, on a flat roof

installation, we do not advise cutting into the

roof or drilling lag bolts into the roof.

EnerWorks Inc., its agents, distributors

and sales representatives of the Enersol

solar products are in no way responsible if

safety procedures, installation instructions and

common sense are not followed, or if EnerWorks

is not consulted should an unusual problem

arise. EnerWorks assumes no liability for

installation, parts or labor. If for any reason, you

question the installation instructions, safety

procedures and/or installation locations, do not

proceed, and contact EnerWorks immediately at:

1-877-268-6502.

Remember… SAFETY FIRST!

3 | P a g e

Enersol Pool Panel Installation Guide – EnerWorks Inc. ©, May 2015

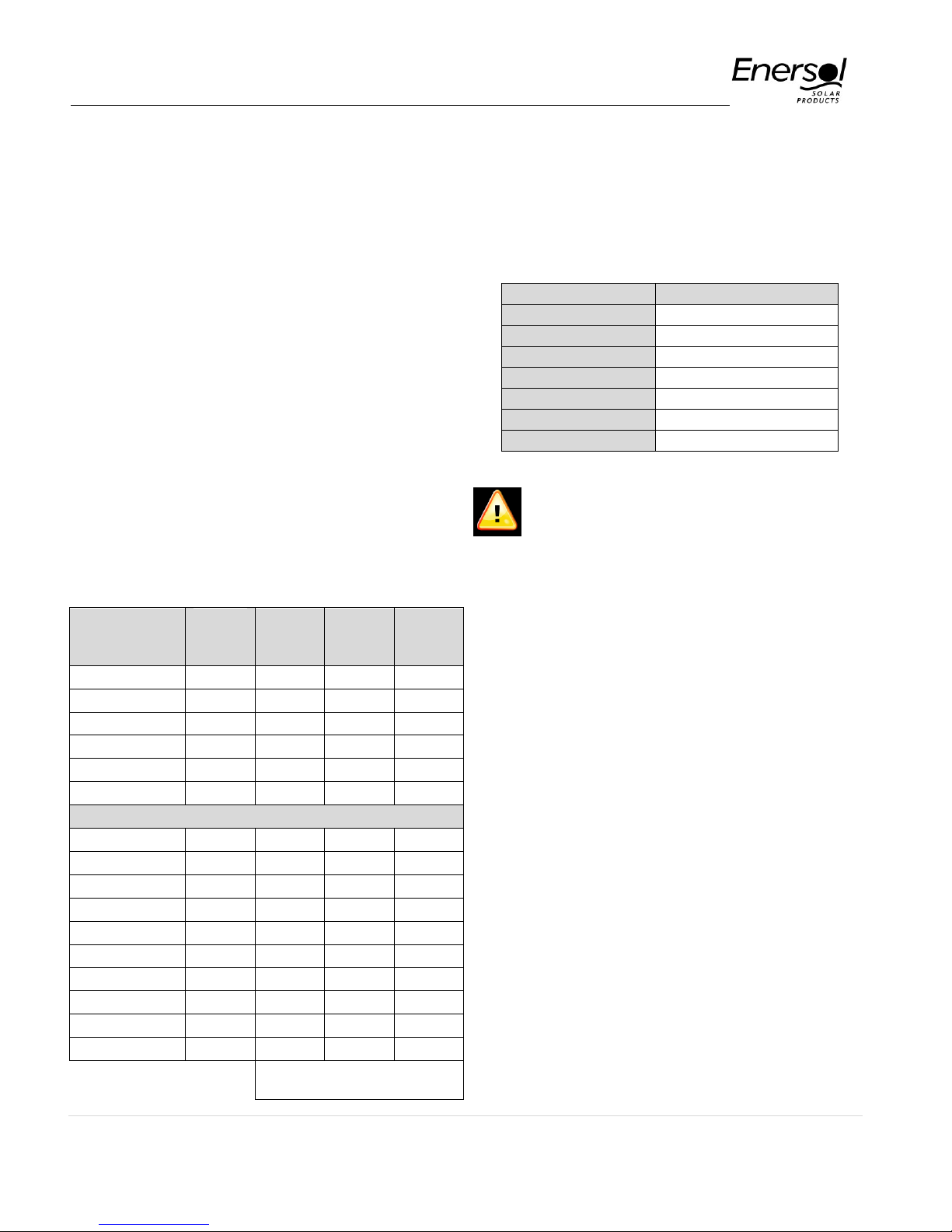

In Ground Pool

Pool

Surface

Area

1 x 8

1 x 10

1 x 12

12 x 24

288

18 - 27

14-22

12-18

14 x 28

392

25 - 37

20-29

16-25

15 x 30

450

28 - 42

23-34

19-28

16 x 32

512

32 - 48

26-38

21-32

18 x 36

648

41 - 61

32-49

27-41

20 x 40

800

50 - 75

40-60

33-50

Above Ground Pool

15' Round

177

12 - 17

12-13

12

18' Round

254

16 - 24

13-19

12-16

21' Round

346

22 - 32

17-26

14-22

24' Round

452

28 - 42

23-34

19-28

27' Round

572

36 - 54

29-43

24-36

12' x 24' Oval

257

16 - 24

13-19

11-16

14' x 28' Oval

350

22 - 33

17-26

15-22

15' x 30' Oval

402

25 - 38

20-30

17-25

16' x 32' Oval

457

28 - 43

23-34

19-28

18' x 33' Oval

524

33 - 50

26-40

22-33

Recommended number of

boxes

Panel Size

Number of Boxes / Array

4’ x 8’ (AAA074-8)

7 - 9

1’ x 8’ (AAA086-8)

28 - 36

4’ x 10’ (AAA074-10)

6 - 8

1’ x 10’ (AAA086-10)

24 - 32

4’ x 12’ (AAA074-12)

5 - 7

1’ x 12’ (AAA086-12)

20 - 28

Custom size

Consult with EnerWorks

ASSEMBLY INSTRUCTIONS

OVERVIEW

1 - Plan your system:

a) Determine the location; south is best

followed by west or east. North is not

recommended. Panels should be tilted at an

angle of 45° or less.

b) Determine the optimum number of boxes

needed. The following quick sizing guide will

help you establish the number of boxes of

solar panels required for your pool. The

lower number is for a south facing roof with

full sun. If the roof is west facing or has more

shade, you will need the larger number. The

solar rule of thumb is 50% to 75% of the pool

surface should be represented in solar panel

area. Indoor pools require 100% coverage.

If panel area exceed number of sections that can be

installed in one array (see table) panels must be split

to equally sized arrays. See typical split-array

reverse return.

For additional information in sizing the

system please see System Design

considerations or call EnerWorks for

assistance at: 1-877-268-6502.

c) Measure roof area available to be sure the

panels will fit: Panels must be positioned

vertically from eave to peak with at least 6”

space around the panels for plumbing and

workspace. Four sections of connected

headers measure 51” and rubber panel strip

width measures 48”.

d) There are several different types of roofs.

Most will accommodate the entire panel

system in a continuous row. However, some

systems may need to be split over two or

more arrays or two or more roofs. When

splitting a system, you must balance equal

sections in each array. Remember to be

conscious of the best sun exposures, and

avoid roofs with shade.

e) Check that your existing pool pump is in

good working order. Verify that pool pump is

sized accordingly and that it will not exceed

the maximum panel flow. For information on

pump size see System Design

Considerations or consult with EnerWorks

at 1-877-268-6502.

4 | P a g e

Enersol Pool Panel Installation Guide – EnerWorks Inc. ©, May 2015

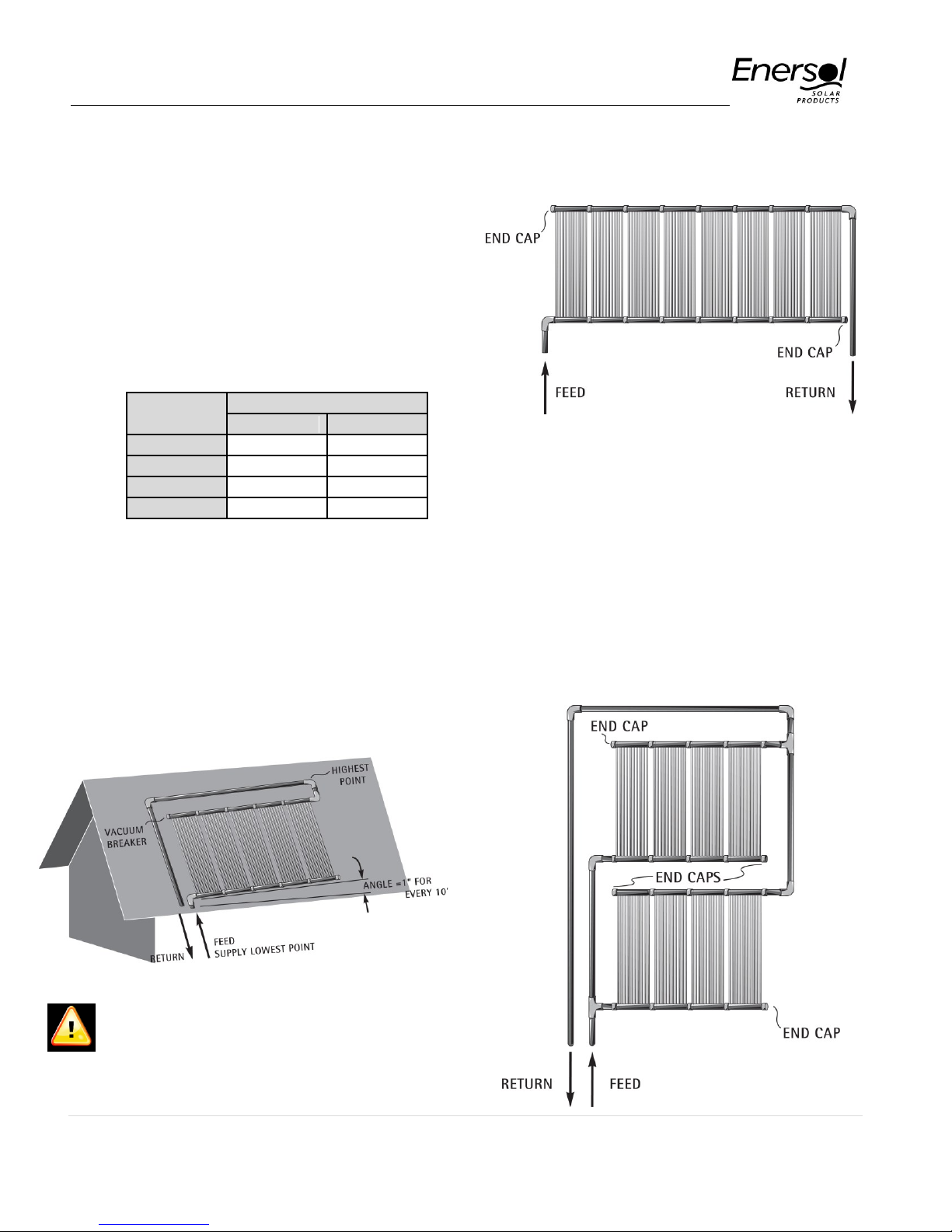

Pipe Size

Velocity

6 fps

8 fps

1-1/2"

35 gpm

50 gpm

2"

62 gpm

85 gpm

2-1/2"

90 gpm

120 gpm

3"

140 gpm

187 gpm

f) Plan for the plumbing and fittings required.

Ensure no to exceed maximum velocities

allowed on pipes when selecting pipes

diameters as per table below. See System

Design Considerations (page 13) for more

information on how to size the line set, or

consult with us at: 1-877-268-6502.

EnerWorks recommends between 6 – 8 fps

when sizing pipes for pool systems.

g) Gather all components and tools required for

the job.

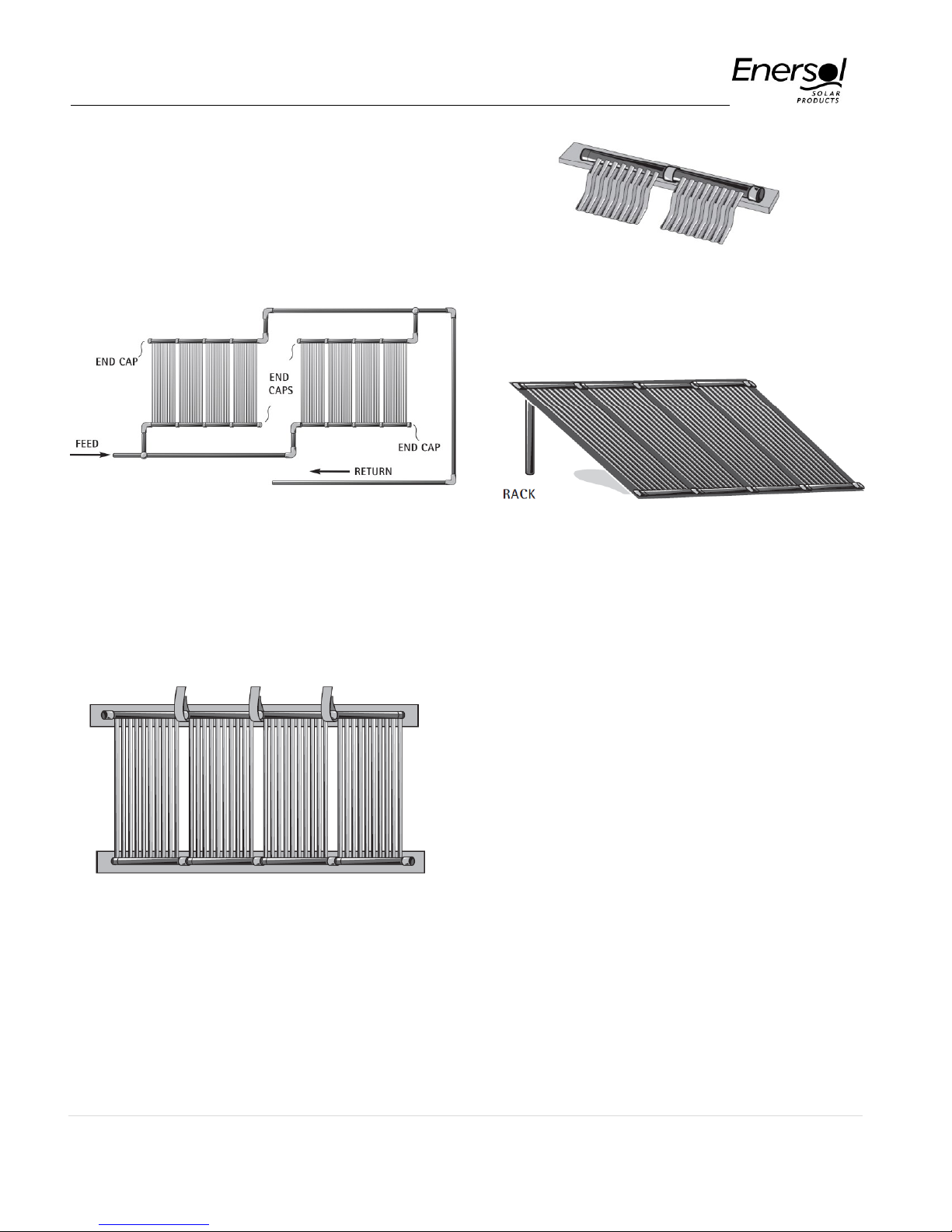

TYPICAL PITCHED ROOF MOUNT

TYPICAL PARALLEL ROOF

TYPICAL SPLIT-ARRAY REVERSE

RETURN

When installing more than the recommended

maximum number of collectors or when there is

some space limitation on the roof (i.e. a series of

small roof), the array has to be split into two or more

banks following the reverse return configuration to

ensure proper distribution of flow through the

collectors.

Important: Angle panel headers inch for

every 10 feet to drain water back to feed/supply

inlet.

5 | P a g e

Enersol Pool Panel Installation Guide – EnerWorks Inc. ©, May 2015

ASSEMBLY INSTRUCTIONS

(CONTINUED)

TYPICAL SPLIT-ARRAY REVERSE

RETURN (Horizontal array)

TYPICAL RACK MOUNT

For safety reasons do not mount panels against a

pool. Rack plywood should be mounted 45° or less.

TYPICAL FLAT ROOF MOUNT

Attach headers to 2x6” lumber on each end. 2x6”

lumber may then be attached to roof using liquid

adhesive. Ensure that the rubber is not blocking any

roof drainage.

TYPICAL METAL OR TILE STYLE ROOF

MOUNT

Attach top header to 2x6 lumber with straps

supplied, and provide a rest for the bottom headers

on 2x6 lumber (w/o strapping to allow expansion and

contraction of the rubber), lumber may then be

attached to roofing material using appropriate

method. Always consult with the roof manufacturer

for best practices.

2 - Roll out panels on roof, rack or

ground:

TYPICAL GROUND MOUNT

Support headers with 2x6” lumber. Panels may be

set on any material that will insulate them from the

earth: plywood, metal, plastic or gravel. Note: Flat

roof or ground mount panels will not gain heat if

sitting in puddles of water, always ensure proper

drainage.

a) Carry the boxes to the installation area.

b) If installing on a roof – snap a chalk line as a

guide to where the top of the panels will be

aligned. It is important to place the panels on

a slight angle on the roof. This helps purge

the air from the system when filling, and

provides drainage when draining for the

winter. Angle the panel headers 4” for every

40 feet with the slope down toward the end

that has the feed line

6 | P a g e

Loading...

Loading...