Instruction Sheet

POWERFUL SOLUTIONS. GLOBAL FORCE.

L2943 Rev. A 11/09

1.0 GENERAL SAFETY INFORMATION

Read all instructions, warnings and cautions

carefully. Follow all safety precautions to avoid

personal injury or property damage during system

operation. Enerpac cannot be responsible for damage or injury

resulting from unsafe product use, lack of maintenance or

incorrect product and/or system operation. Contact Enerpac

when in doubt as to the safety precautions and operations.

Failure to comply with the following precautionary statements

could cause equipment damage and personal injury.

A CAUTION is used to indicate correct operating or maintenance

procedures and practices to prevent damage to, or destruction

of equipment or other property.

A WARNING indicates a potential danger that requires correct

procedures or practices to avoid personal injury.

A DANGER is only used when your action or lack of action may

cause serious injury or even death.

WARNING: Read and understand the entire contents

of this manual before beginning installation or operation

of Uni-Lift® actuators and related equipment. Follow all

instructions and observe all safety precautions. Failure to

properly install or operate Uni-Lift® actuators could result in

serious personal injury or damage to equipment and/or

property.

Uni-Lift ® Mechanical Actuators

M and B Series Models

2.0 ACTUATOR SAFETY PRECAUTIONS

• Install the actuator and all related equipment in accordance

with the engineering guidelines and recommendations contained

in the Enerpac Uni-Lift® Catalog #E500 (available from your

Enerpac distributor).

• Do not exceed the actuator ratings, including design load,

travel, and input speed.

• Comply with and adhere to all applicable safety codes for

your area, such as: building codes, elevator codes, AISC Steel

Construction specifi cations, and applicable regulations and

standards (including OSHA Title 29, Chapter 1910-219 and ANSI

B15.1). Note: applicable safety codes, regulations and standards

will vary depending on country and local requirements.

• Follow standard machinery installation practices. Properly

install, align and shield all moving parts.

• Inspect, lubricate and maintain the actuator as described in

this instruction sheet. Use the actuator only for its intended

purpose.

IMPORTANT: Use of Uni-Lift® products to support or move

human cargo is not recommended. Contact Enerpac before

attempting to design a Uni-Lift® system for this application.

WARNING: Always lockout power before performing

any inspection, maintenance, lubrication, adjustment

or repair procedures on the actuator or any associated

power transmission equipment. Be absolutely certain that the

electric motor (or other prime mover) cannot be remotely or

automatically started. Make sure the load is properly supported

before the actuator brake or other holding devices are removed.

3.0 ACTUATOR MODELS

Enerpac Uni-Lift® actuators are available in two versions,

machine screw (M-Series) and ball screw (B-Series).

The M-Series actuator uses a precision rolled Acme threaded

screw that is self locking. In most applications, it will hold its

position without a brake. This type of actuator is best suited

for high load at slower speeds, applications with less frequent

cycling and if the load must be held in position when the system

is at rest.

The B-Series actuator uses ball screws to convert rotary motion

to linear movement. It requires about one-third the horsepower

of a comparable machine screw actuator. This type of actuator is

best suited when smooth, fast operation is required, and if high

cycle operation is anticipated. However, due to the effi ciency of

the ball screw, a mechanical brake must be used to stop the load

screw and to hold it in position.

IMPORTANT: Brakes are recommended for use on ANY UniLift® actuator (including M-Series models) if vibration is present.

Note: The information contained in this manual is intended for

general reference only. Appearance, features and specifi cations

will vary due to design variables, custom engineering and

optional equipment. Refer to the charts in sections 12.0 through

15.0 for an overview of available Uni-Lift® models, features and

optional accessories.

1

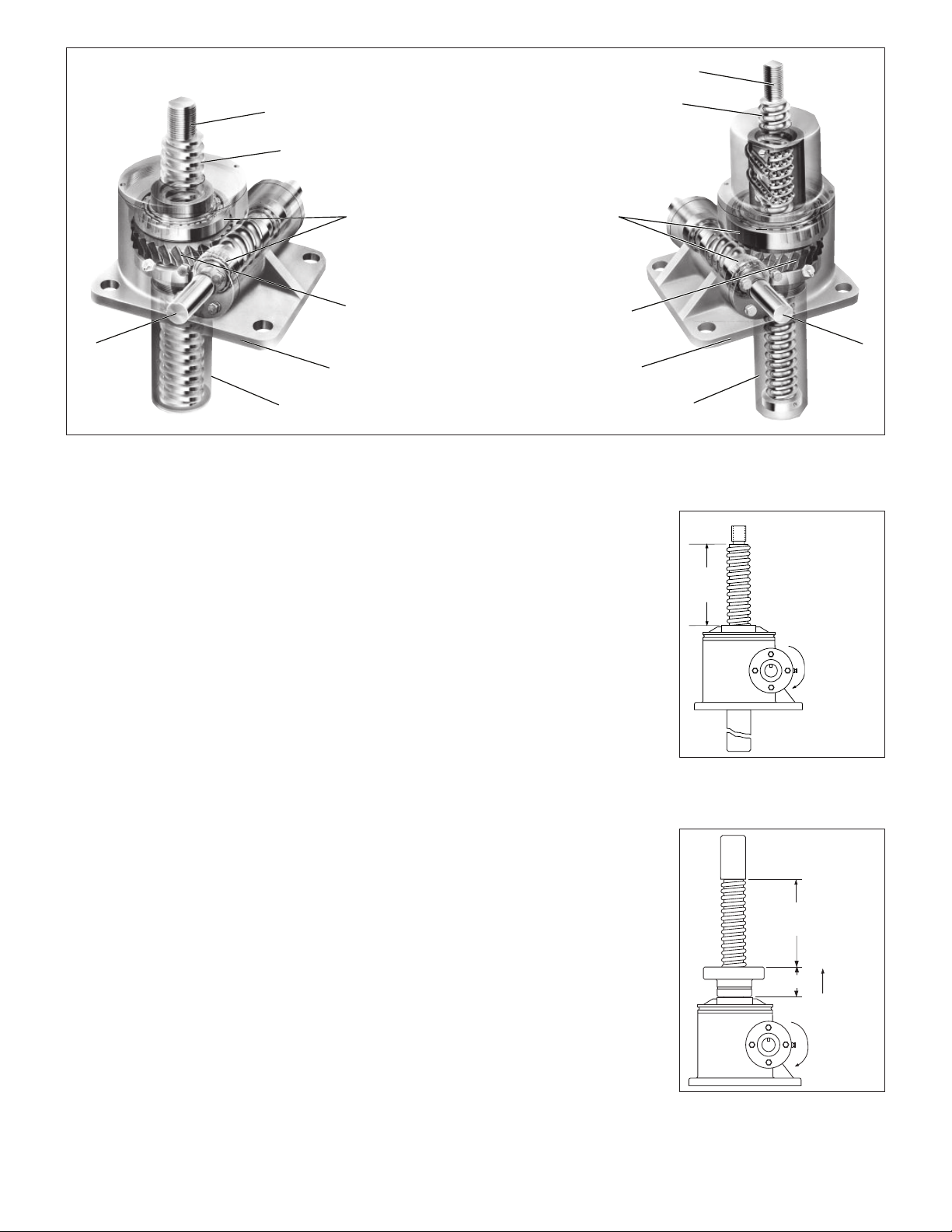

M-Series Models

1

1

2

2

3

Key:

1. Screw End

2. Load Screw

4

3. Tapered Roller Bearings

4. Driven Gear

7

5

5. Housing

6. Protective Tube

7. Input Shaft and Worm Gear

6

Figure 1, Major Features and Components

4.0 ACTUATOR FEATURES

Both M and B Series Uni-Lift® models incorporate a ground

alloy steel worm gear which drives a high tensile bronze gear

nut, accurately machined to high standards for maximum load

carrying capacity and uniformity of motion transmission. See

fi gure 1.

All shafts are mounted on heavy duty tapered roller bearings to

support the rated thrust load of the actuator while maintaining

correct gear alignment. The actuator housing is made of

aluminum or ductile iron, depending on model specifi ed.

The load screw is made of high quality steel that is ground to size

and precision rolled to form the threads. It is well proportioned

to handle the maximum load rating of the actuator. The load

screw upper end can be provided in threaded, plain, clevis or

“top plate” style, depending on model selected. Load screws

with double-clevis ends are also available as an option on some

models.

If needed, stainless steel or special alloy load screws can be

provided at additional cost. Protective bellows boots are

available as an accessory to protect the exposed portion of the

load screw, and to help keep the threads lubricated and free of

dirt.

On upright and double clevis models only, a protector tube is

furnished in order to keep the load screw threads lubricated and

free of foreign material.

Standard M and B Series actuators may be operated at a wide

range of input speeds. Units are recommended based on duty

cycle requirements and other customer supplied information.

5.0 LOAD SCREW CONFIGURATIONS

Uni-Lift® actuators are available in a choice of three different

load screw confi gurations:

1) Translating (refer to section 5.1)

2) Rotating (refer to section 5.2)

3) Keyed Translating (refer to section 5.3)

B-Series Models

3

4

5

6

5.1 Translating

Confi guration

On these actuators, the load

screw “translates” through

the unit to push or pull the

load. The load must be fi xed

to the screw and restricted

Travel

from rotation in order to

produce linear motion. See

fi gure 2.

An optional Anti-Backlash

feature is available

on selected M-Series

Translating models. This

feature automatically

compensates for normal

thread wear to reduce load

screw endplay.

5.2 Rotating Confi guration

On these actuators, the load

screw is fi xed to the driven

gear, causing the screw to

rotate. A fl ange nut travels

along the exposed length

of the load screw to push or

pull the load. The load must

be fi xed to the fl ange nut

and restricted from rotation

in order to produce linear

motion. See fi gure 3.

The plain end of the load

screw and the fl ange nut

are pre-assembled on

these units. The plain end

is designed to fi t a standard

pillow block bearing,

to provide support and

alignment for the rotating

load screw.

=

Figure 2

Flange Nut

Figure 3

7

Clockwise

Rotation

Raises Load

Travel

Motion

Clockwise

Rotation

Raises Load

2

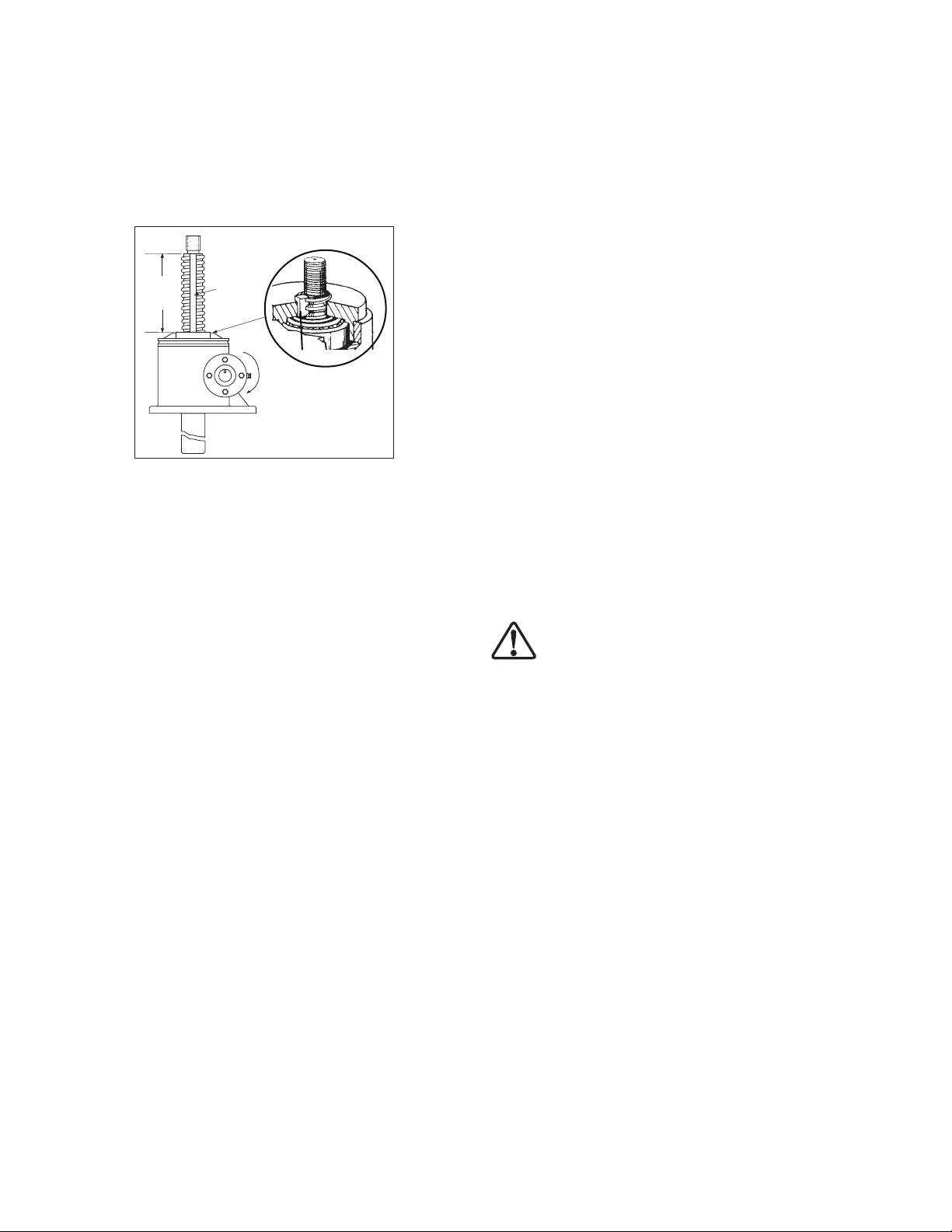

5.3 Keyed Translating Confi guration

In applications where rotation cannot be prevented externally,

a keyed design actuator is required. These models are keyed

internally to prevent rotation of the screw, so that linear motion is

produced. See fi gure 4.

Note: For keyed applications where operating loads are expected

to exceed 25 percent of rated capacity, contact Enerpac for

technical assistance. Also contact Enerpac for recommendations

if unusually long travels or high screw velocities are required.

Travel

Load Screw

Keyway

Figure 4

Key

Clockwise

Rotation

Raises Load

8.0 INSTALLATION REQUIREMENTS

1. Be certain that the rated capacity of the actuator exceeds the

maximum load that may be applied to it during use.

2. Check that the maximum allowable input speed (RPM) of the

actuator will not be exceeded.

Note: For maximum input speeds and other Uni-Lift

specifi cations, refer to the charts in sections 12.0 through 15.0

of this document.

3. Select a motor (if used) of appropriate size for your application.

For motor sizing information, refer to the Enerpac Uni-Lift®

Catalog #E500.

4. Ensure that the actuator foundation is suffi ciently rigid to

maintain correct alignment with connected machinery and

that it has suffi cient strength to support the maximum load.

5. Check that the foundation has a fl at mounting surface to

assure uniform support for the actuator. Mounting bases

should be fl at and suffi ciently strong to support the load.

6. Be sure the opening in the foundation for the protective tube

or the load screw is as small as possible, so that the unit is

supported over the greatest possible area.

7. Ensure that the method of preventing load screw or fl ange

nut (as applicable) rotation is suffi ciently strong, so that

translation will occur. Refer to the Load Screw Torque section

of the Enerpac Uni-Lift® Catalog #E500.

®

6.0 UNPACKING AND RECEIVING THE SHIPMENT

Visually inspect all components for shipping damage. Shipping

damage is not covered by warranty. If shipping damage is found,

notify carrier at once. The carrier is responsible for all repair and

replacement costs resulting from damage in shipment.

Upon delivery, take an inventory of the entire shipment to

determine if shortages exist. All shortages must be immediately

reported to Enerpac and also to the carrier.

7.0 GENERAL INFORMATION

• The customer's application design engineer is responsible

for ensuring that there are no destructive conditions which

could affect the actuator(s) and/or complementing equipment.

Conditions that may be considered destructive include, but

are not limited to: 1) excessive input speeds, 2) extreme shock

loading, 3) mechanical or thermal overloading, 4) exceeding

recommended duty cycles and 5) side loading of the load

screw.

• Each actuator in the system must be specifi ed in accordance

with the stated requirements and precautions contained in

the Enerpac Uni-Lift® Catalog #E500. All calculations and

specifi cations must be reviewed and approved by the customer's

application design engineer in advance of installation.

Note: Unless specifi ed in the sales order, the services of a fi eld

engineer are not included with the purchase of Enerpac Uni-Lift®

actuators and related equipment.

• Installation, maintenance and safety instructions must be

given to all personnel directly responsible for the installation,

maintenance and operation of the Uni-Lift® equipment.

7.1 Warranty Guidelines

• The Enerpac warranty is valid only if the actuator is operated

within the rated capacity and conditions for which the unit was

specifi cally designed.

• In the event that a malfunction of the actuator occurs within

the warranty period, the unit must be immediately removed

from service and Enerpac must be promptly informed of the

problem.

9.0 INSTALLATION AND ALIGNMENT PROCEDURES

1. Mount the actuator and check that the axis of the load screw

is parallel to the movement of the load and centered with

respect to the load. If required, shim under the actuator base

so that this condition is achieved. After re-checking that

alignment is correct, hand tighten the mounting bolts. Repeat

this step for each actuator to be installed in the system.

CAUTION: Eccentric loading and/or side loading will

result in premature wear and/or damage the actuator

and possibly other components in the system. Such

damage is not covered under the Enerpac warranty.

IMPORTANT: To help ensure proper alignment, use of laser

transits during alignment procedures is strongly recommended.

2. Install and align all power transmission equipment, including

speed reducers, mitre gearboxes, shafts and couplings.

Hand tighten mounting bolts.

3 Re-check alignment of input shaft(s) with the worm shaft(s)

of the actuator(s). This alignment is critical for proper

operation.

4. Check the entire system for any obvious indications of binding

or misalignment. Test the system alignment by rotating the

shafts by hand. Fully extend the load screw(s).

Note: When the actuator(s), shafting and gearboxes are properly

coupled together and aligned in a system, it should be possible

to rotate the shafts by hand and to fully extend the load screw(s)

when the load is not applied.

5. After checking for proper alignment, tighten all mounting bolts

and other fasteners to the proper torques. Be sure to torque

all mounting bolts evenly to avoid damaging the actuator

housing. Refer to table 1 (see next page) for torque values.

IMPORTANT: It is essential that all gearboxes and actuators be

securely bolted down to the foundation, using bolts of proper

diameter to fi t the actuator mounting holes. Bolts must be at

least S.A.E. Grade 5 or equivalent. If possible, it is recommended

that each actuator be doweled in place. Doweling will assure

exact repositioning if the component is ever removed.

3

Loading...

Loading...