Enerpac ZW3 Series, ZW4 Series, ZW5 Series Instruction Sheet

Instruction Sheet

POWERFUL SOLUTIONS. GLOBAL FORCE.

L3075 Rev. A 04/14

Index:

English:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Français:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-28

Español: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29-42

Portuguese: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43-56

Repair Parts Sheets for this product are available from the Enerpac

web site at www.enerpac.com, or from your nearest Authorized

Enerpac Service Center or Enerpac Sales office.

1.0 IMPORTANT RECEIVING INSTRUCTIONS

Visually inspect all components for shipping damage. Shipping

damage is not covered by warranty. If shipping damage is found,

notify carrier at once. The carrier is responsible for all repair and

replacement costs resulting from damage in shipment.

SAFETY FIRST

2.0 SAFETY ISSUES

Read all instructions, warnings and cautions

carefully. Follow all safety precautions to

avoid personal injury or property damage

during system operation. Enerpac cannot be responsible for

damage or injury resulting from unsafe product use, lack of

maintenance or incorrect product and/or system operation.

Contact Enerpac when in doubt as to the safety precautions and

operations. If you have never been trained on high-pressure

hydraulic safety, consult your distribution or service center for a

free Enerpac Hydraulic safety course.

Failure to comply with the following cautions and warnings could

cause equipment damage and personal injury.

A CAUTION is used to indicate correct operating or maintenance

procedures and practices to prevent damage to, or destruction of

equipment or other property.

A WARNING indicates a potential danger that requires correct

procedures or practices to avoid personal injury.

A DANGER is only used when your action or lack of action may

cause serious injury or even death.

WARNING: Wear proper personal protective gear when

operating hydraulic equipment.

WARNING: Stay clear of loads supported by hydraulics.

A cylinder, when used as a load lifting device, should

never be used as a load holding device. After the load has

been raised or lowered, it must always be blocked mechanically.

DANGER: To avoid personal injury keep hands and

feet away from cylinder and workpiece during

operation.

Pallet Coupling Pumps

Series ZW3, ZW4 and ZW5

WARNING: Do not exceed equipment ratings. Never

attempt to lift a load weighing more than the capacity of

the cylinder. Overloading causes equipment failure and

possible personal injury. The cylinders are designed for a max.

pressure of 350 bar [5,000 psi]. Do not connect a jack or cylinder

to a pump with a higher pressure rating.

DANGER: Never set the relief valve to a higher pressure

than the maximum rated pressure of the pump. Higher

settings may result in equipment damage and/or personal

injury. Do not remove relief valve.

WARNING: The system operating pressure must not

exceed the pressure rating of the lowest rated component

monitor operating pressure. It is your window to what is happening

in the system.

Sharp bends and kinks will internally damage the hose leading to

premature hose failure.

materials and packings. For optimum performance do not expose

equipment to temperatures of 65 °C [150 °F] or higher. Protect

hoses and cylinders from weld spatter.

in the system. Install pressure gauges in the system to

CAUTION: Avoid damaging hydraulic hose. Avoid sharp

bends and kinks when routing hydraulic hoses. Using a

bent or kinked hose will cause severe back-pressure.

Do not drop heavy objects on hose. A sharp impact may

cause internal damage to hose wire strands. Applying

®

pressure to a damaged hose may cause it to rupture.

IMPORTANT: Do not lift hydraulic equipment by the

hoses or swivel couplers. Use the carrying handle or other

means of safe transport.

CAUTION: Keep hydraulic equipment away from

flames and heat. Excessive heat will soften packings and

seals, resulting in fluid leaks. Heat also weakens hose

DANGER: Do not handle pressurized hoses. Escaping

oil under pressure can penetrate the skin, causing serious

injury. If oil is injected under the skin, see a doctor

immediately.

WARNING: Only use hydraulic cylinders in a coupled

system. Never use a cylinder with unconnected couplers.

If the cylinder becomes extremely overloaded, components

can fail catastrophically causing severe personal injury.

IMPORTANT: Hydraulic equipment must only be serviced

by a qualified hydraulic technician. For repair service,

contact the Authorized ENERPAC Service Center in your

area. To protect your warranty, use only ENERPAC oil.

WARNING: Immediately replace worn or damaged parts

with genuine ENERPAC parts. Standard grade parts will

break causing personal injury and property damage.

ENERPAC parts are designed to fit properly and withstand high

loads.

WARNING: Do not use electric pumps in an explosive

atmosphere. Adhere to all local and national electrical

codes. A qualified electrician must do installation and

modification.

FLOW CHARTS

WARNING: Start the pump with the valve in the neutral

position to prevent accidental cylinder operation. Keep

hands clear of moving parts and pressurized hoses.

WARNING: These pumps have internal factory adjusted

relief valves, which must not be repaired or adjusted

except by an Authorized Enerpac Service Center.

CAUTION: To prevent damage to pump electric motor,

check specifications. Use of incorrect power source will

damage the motor.

3.0 SPECIFICATIONS

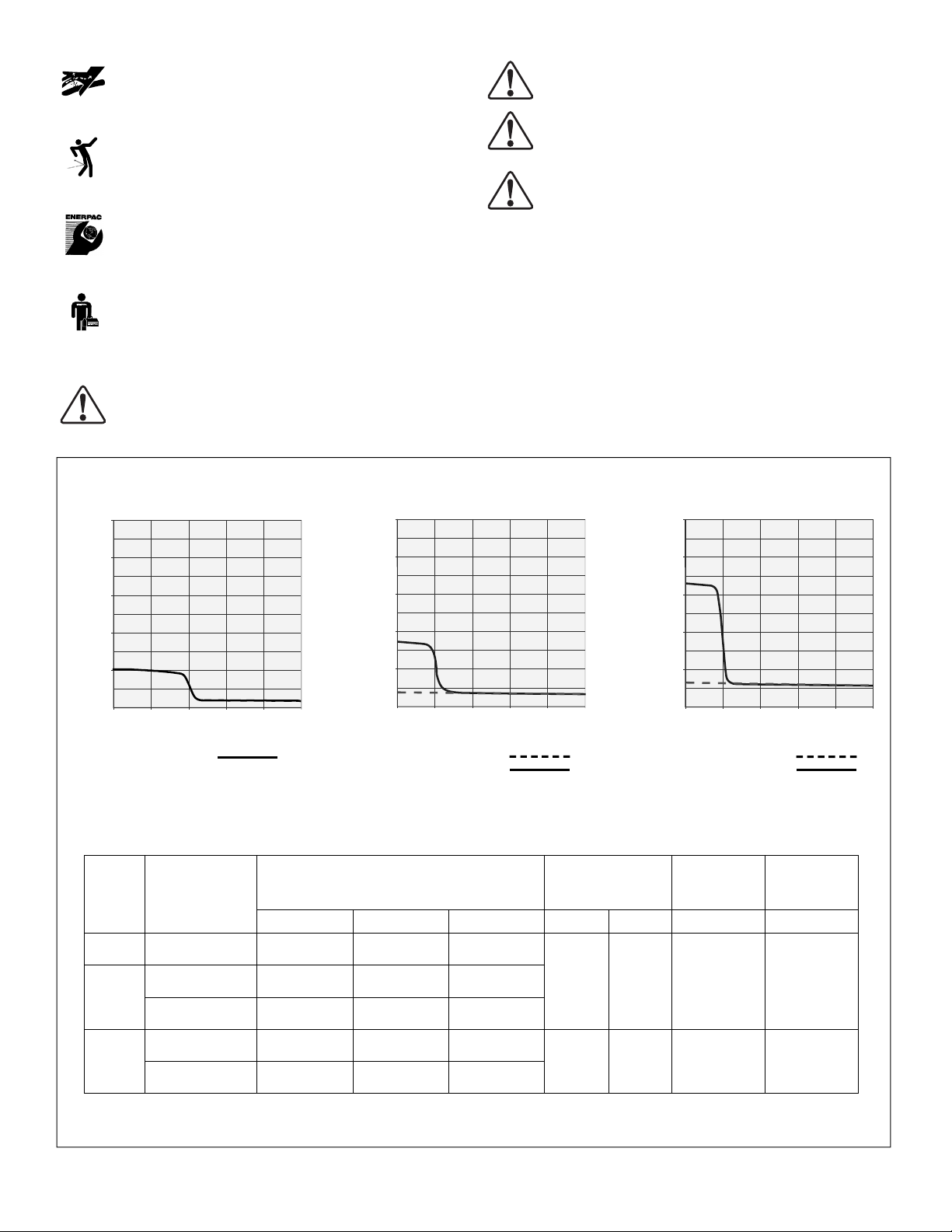

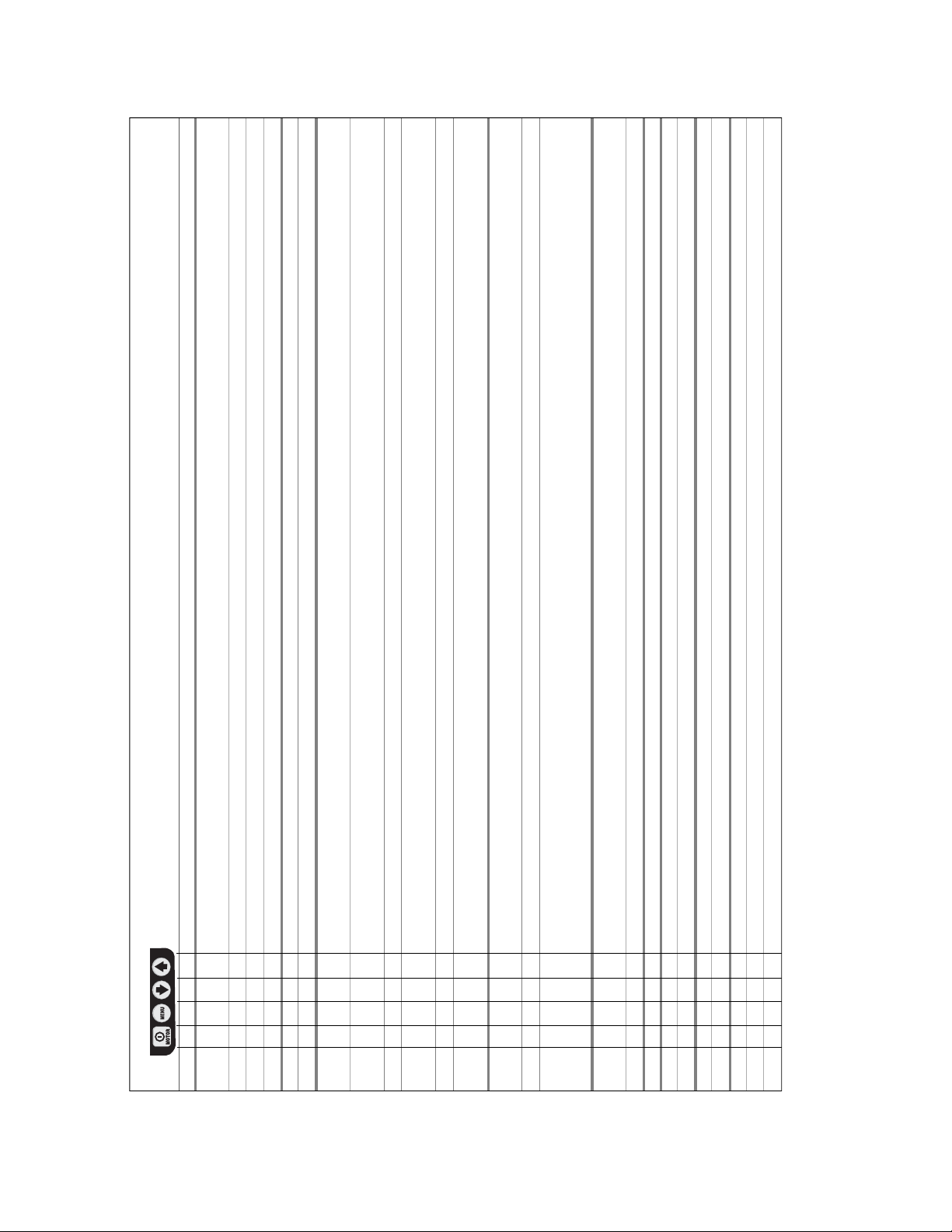

3.1 Flow Charts (see Figure 1)

3.2 Performance Charts (see Figure 1)

3.3 Electric Current Draw

(Refer to Table 4 in Section 8.0 of this manual)

ZW3 Series

1000

900

800

/min)

3

700

600

500

Oil Flow (in

400

300

200

100

0

0 1,000 2,000 3,000 4,000 5,000

1000

900

800

/min)

3

700

600

500

Oil Flow (in

400

300

200

100

0

0 1,000 2,000 3,000 4,000 5,000

Pressure (psi)

ZW3 series two-stage

ZW4 series single-stage

ZW4 series two-stage

PERFORMANCE CHART

Pump

Series

Operation Output Flow Rate

(in3/min)

100 psi 700 psi 5,000 psi hp RPM (psi) (dBA)

ZW3 Two-stage 202 190 40

ZW4 Series

Pressure (psi)

1000

900

800

/min)

3

700

600

500

Oil Flow (in

400

300

200

100

0

0 1,000 2,000 3,000 4,000 5,000

ZW5 series single-stage

ZW5 series two-stage

Motor Size Relief Valve

Adjustment

Range

ZW5 Series

Pressure (psi)

Sound

Level

Single-stage 64 63 60

ZW4

Two-stage 350 305 60

Single-stage 128 126 120

ZW5

Two-stage 650 602 120

Output flow rate is listed at 60 Hz.

Flow rate will be approximately 5/6 of these values at 50Hz.

Figure 1, Pump Specifications

1.0 1750 1,000 - 5,000 75

1.5 1750 1,000 - 5,000 75

2

B

A

B

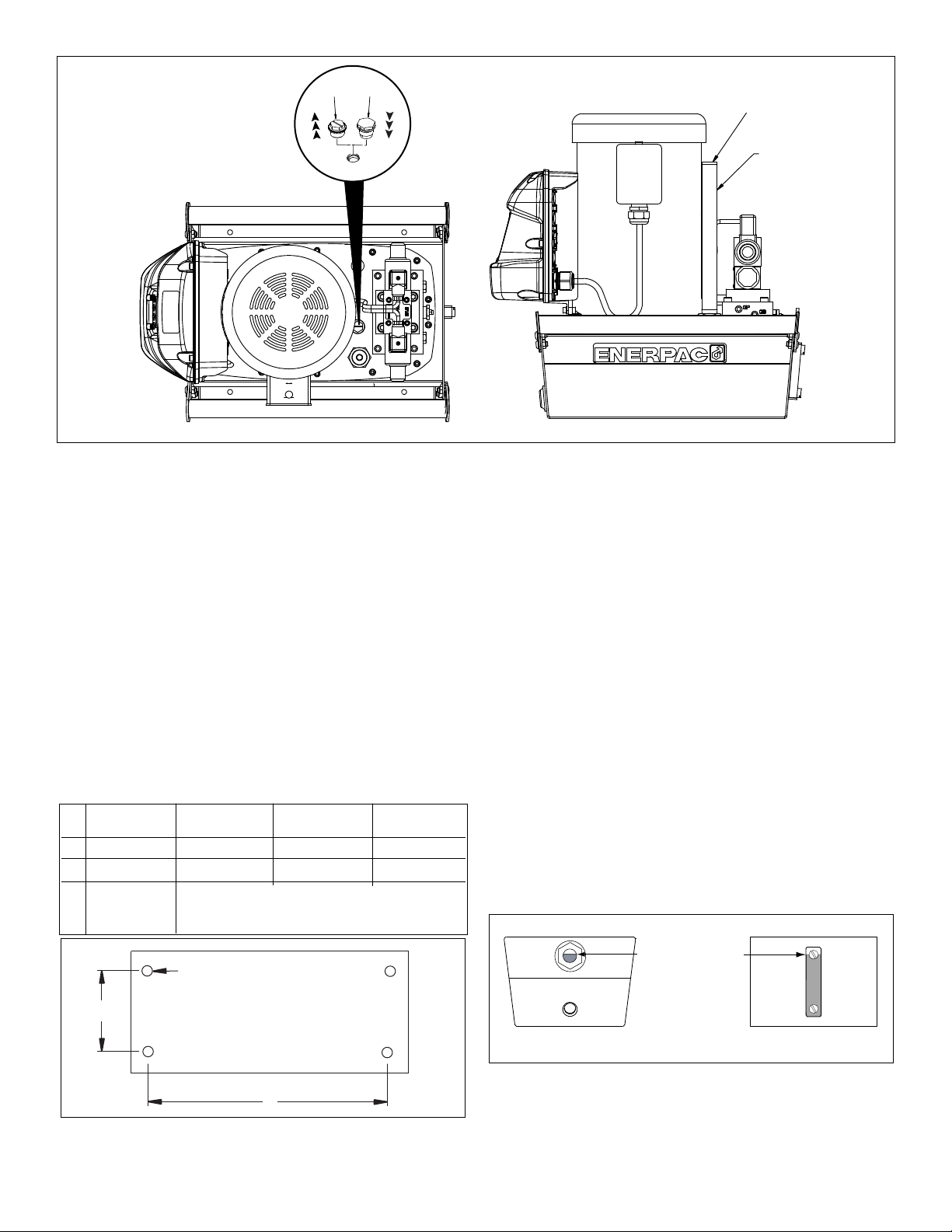

Figure 2, ZW Breather Cap Installation

C

D

4.0 INSTALLATION

Install or position the pump to ensure that air flow around the

motor and pump is unobstructed. Keep the motor clean to

ensure maximum cooling during operation.

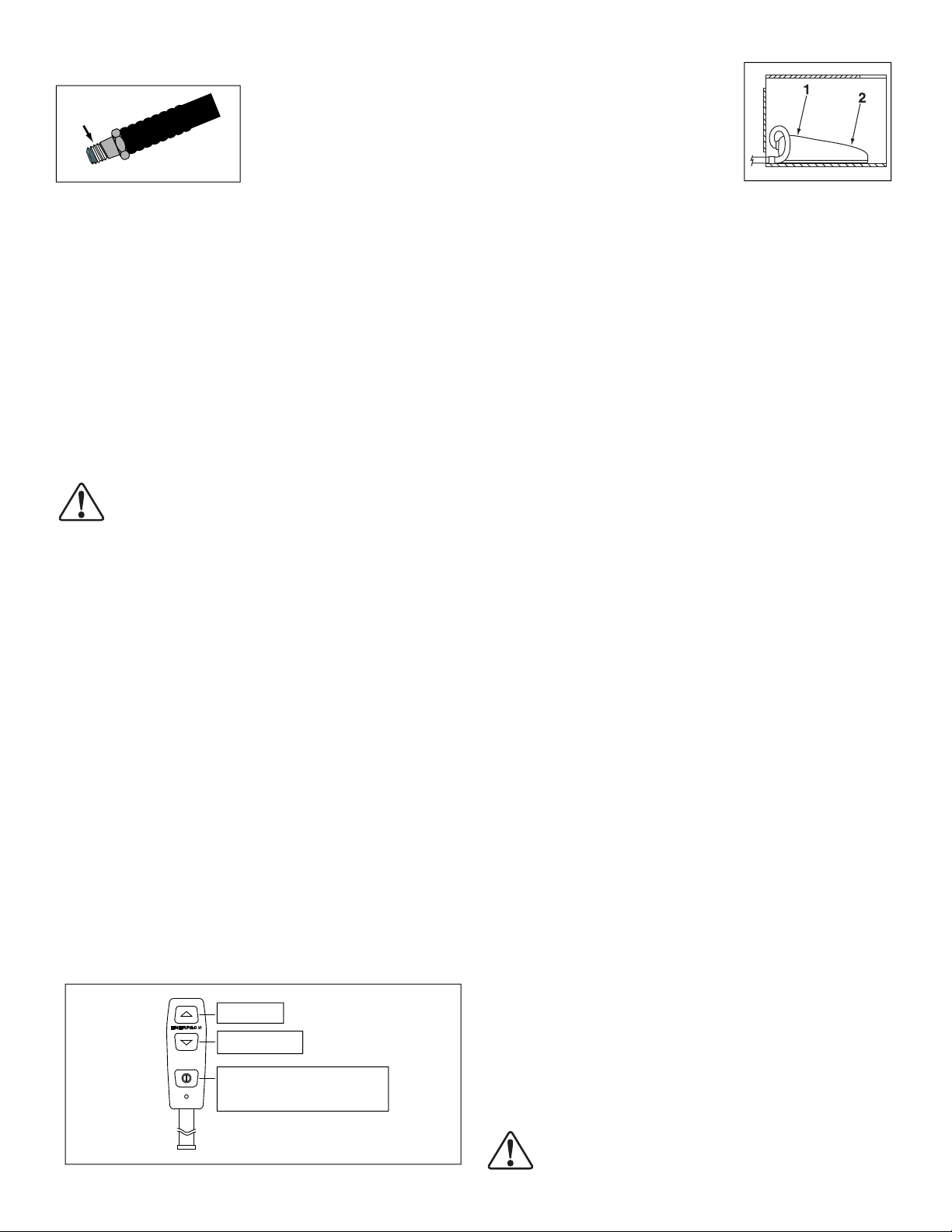

4.1 Reservoir Breather Cap (See Figure 2)

For shipping purposes, a shipping plug (A) is installed in the

breather port on the top of the reservoir. Before using replace

the shipping plug (A) with the breather cap (B).

Note: The oil fill port uses a SAE #10 plug (C). It is mounted at

the top of the fill pipe extension (D).

4.2 Pump Mounting

Refer to Figure 3 for mounting dimensions to secure the pump

to a fixed surface.

1-2 Gal. (4-8 L)

in. (mm)

A 3.75 (95) 11.0 (279) 15.6 (396) 18.9 (480)

B 9.00 (229) 12.0 (305) 12.0 (305) 12.0 (305)

tapped holes,

C

M8 x 1.25

2.5 Gal. (10 L)

in. (mm)

Ø 0.34 (8.6) diameter through holes

0.25 (6)

(Note: Reservoir viewed from below)

5 Gal. (20 L)

in. (mm)

deep

10 Gal. (40 L)

in. (mm)

4.3 Electrical Connections

THE PUMP IS FACTORY EQUIPPED WITH THE COMMON

ELECTRICAL PLUG FOR A GIVEN VOLTAGE, ALTERING

THE PLUG TYPE SHOULD ONLY BE DONE BY A QUALIFIED

ELECTRICIAN, ADHERING TO ALL APPLICABLE LOCAL AND

NATIONAL CODES.

1. The disconnect and line circuit protection to be provided by

customer. Line circuit protection to be 115% of motor full load

current at maximum pressure of application

2. For additional information, refer to pump name plate for power

rating. Also refer to Table 4 in Section 8.0 for motor current draw

information.

4.4 Oil Level

Check the pump oil level prior to start-up. If oil level is low,

remove the SAE #10 plug from the fill pipe extension and add oil

as needed (see Figure 1).

The reservoir is full when the oil level is as shown in Figure 4.

Tank is full

when oil level

is here.

10 to 40 liter4 and 8 liter

C

IMPORTANT: Add oil only when all system components are fully

A

B

Figure 3

retracted, or the system will contain more oil than the reservoir

can hold.

3

Figure 4

4.5 Hydraulic Connections

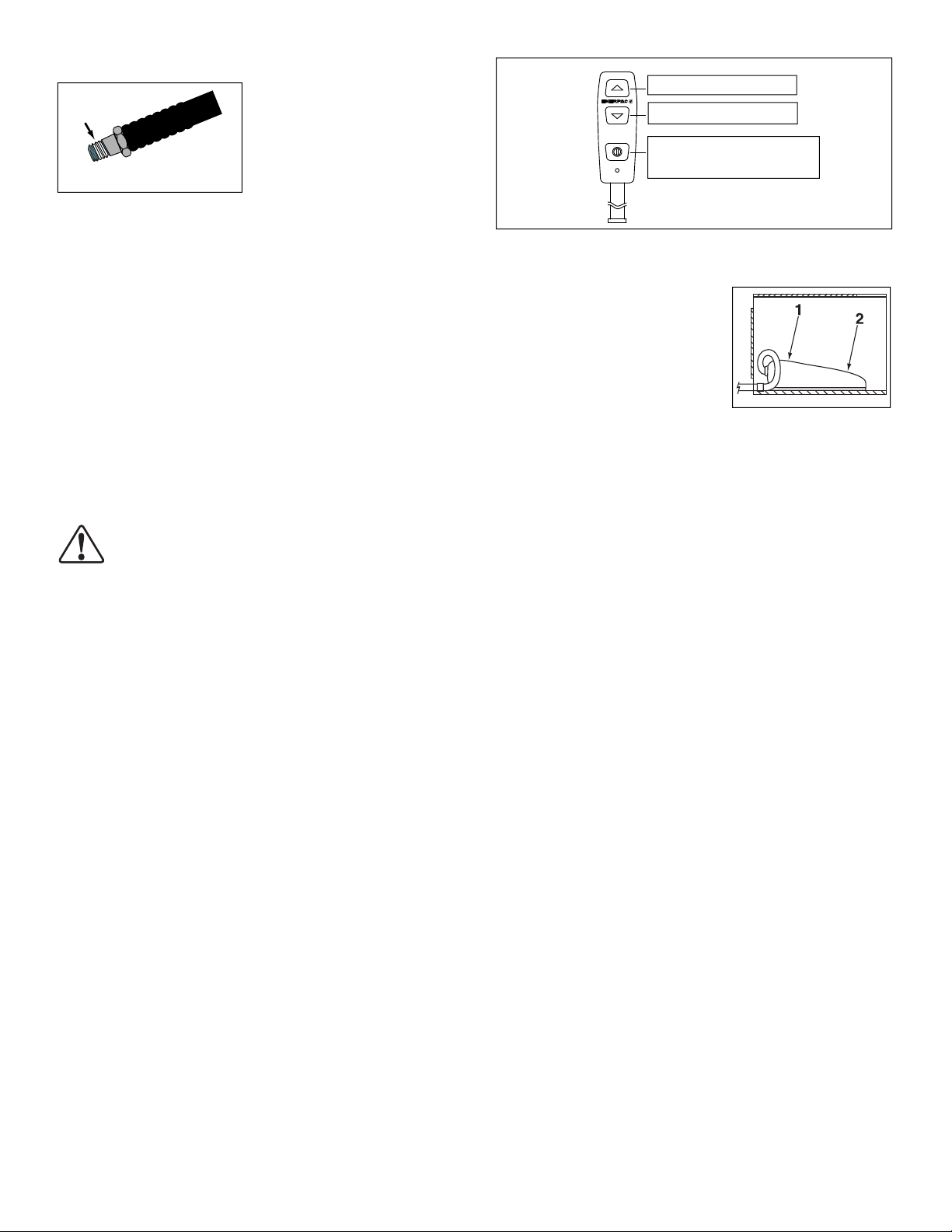

Figure 5

Apply 1-1⁄2 wraps of Teflon tape

or other suitable sealant to the

hydraulic hose fitting, leaving the

first complete thread free of tape

or sealant as shown in Figure 5.

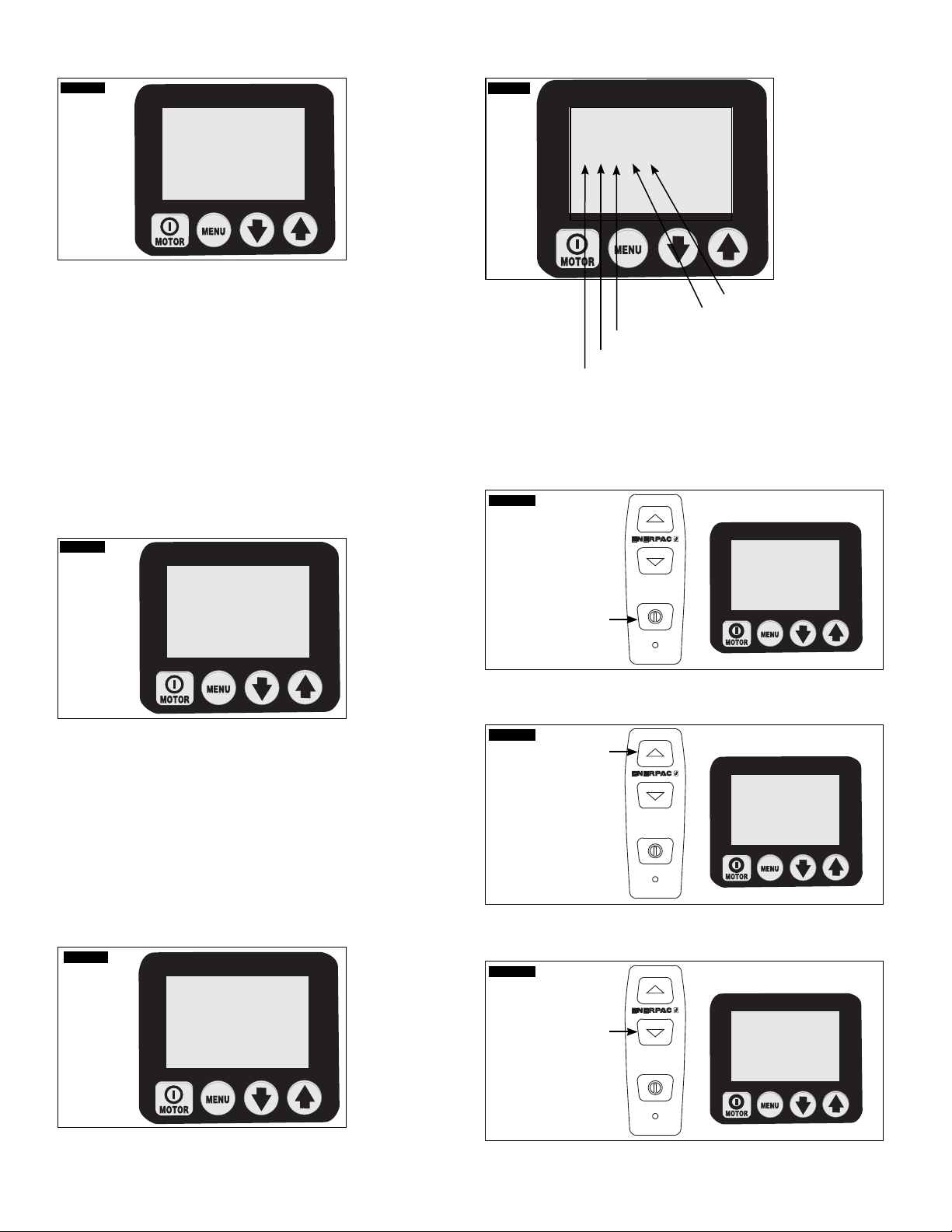

5.2 Foot Switch Option

(see Figure 7)

1. Motor On - Momentary Clamp

2. Motor On - Momentary Unclamp

Shroud On/Off = Not Used

(disabled)

Figure 7

Thread hose(s) into outlet port(s) of the valve (see valve body for

port identification).

Connect the clamp (extend) hose to valve port “A”.

Connect the unclamp (retract) hose to valve port “B”.

If desired, a pressure gauge may be installed in valve port “GA”

or “GB”.

Note: “GA” measures “A” port pressure, “GB” measures “B” port

pressure, “GP” measures pump pressure down stream of system

check. The pump pressure transducer is factory installed in the

“GP” port and must remain installed in this location to ensure

proper pump operation.

5.0 OPERATION

WARNING: Review sections 5.1-5.4 and 6.1-6.4 before

starting pump. Be sure that Dwell Mode operation and

functions are clearly understood before connecting unit

to power.

1. Check the oil level of pump and add oil if necessary.

2. Make sure the shipping plug has been removed and the

breather cap is installed. (See Section 4.1)

3. Connect unit to power. Wait until “READY” is displayed

before pressing any button on shroud or pendant. Note:

During the boot sequence, the microcontroller identifies any

button operation as a potential malfunction and prevents the

motor from starting. Reset by disconnecting power for 30

seconds.

4. For an overview of pump operation, including pendant

functions, refer to sections 5.1-5.4. For detailed LCD control

panel operation instructions, see sections 6.1-6.4.

5.1 Pendant Operation (see Figure 6)

Oil flow and motor operation are controlled by the pendant

buttons. The pump will run and the cylinder will clamp when the

pendant Up-Arrow button is pressed. The pump will run and the

cylinder will unclamp when the pendant Down-Arrow button is

pressed. Releasing either button at any time will stop the pump

and will relieve pressure in the hoses (see Fig. 6).

1. Up Arrow = Motor On - Momentary Clamp

2. Down Arrow = Motor On - Momentary Unclamp

3. On/Off = Not Used (disabled)

Shroud On/Off = Not Used (disabled)

Up Arrow

®

Down Arrow

ON / OFF

(disabled - not functional)

Figure 6

5.3 Automatic Dwell Mode Operation

The Dwell Mode feature allows the pump to react automatically at

two user-defined pressure values, “PRESR A” and “PRESR B”.

This feature can be turned on and off as desired. See the

following paragraphs for additional information. Also refer

to Section 6.2 for detailed Dwell Mode operation and setting

instructions.

1. Dwell Mode Off

The pump LCD control panel will display pressure as a

simple pressure gauge. No additional actions will be performed

regardless of PRESR A and PRESR B values.

2. Dwell Mode On

The pump will automatically de-energize the motor and valve

solenoid after the specified PRESR A or PRESR B value is

reached AND the specified dwell time (in seconds) has elapsed.

When the pump stops, pressure in hoses will drop to zero (0) so

that couplers can be disconnected from the pallet.

Note: “AUTO” is shown on the LCD screen when Dwell Mode is

turned-on. “READY” is shown when Dwell Mode is turned-off.

5.3.1 Overview of Dwell Mode

Before the PRESR A or PRESR B value is reached:

• Pendant Up-Arrow and Down-Arrow buttons will function

as described in Section 5.1.

After the PRESR A or PRESR B value is reached:

• Continuing to press and hold the Up or Down Arrow

button after the specified pressure value is reached will

activate the dwell timer. The LCD screen backlight will

begin flashing, and the pump will continue running until

the user-defined dwell time (1 to 60 seconds) has elapsed.

• To ensure proper clamping and unclamping, the Up or

Down Arrow button must remain depressed until the pump

stops.

• Releasing the Up or Down Arrow button will stop the

automatic cycle, and the LCD screen backlight will stop

flashing.

• If dwell time is set to zero (0), the pump will stop

immediately when the specified pressure value (PRESR A

or PRESR B) is reached.

Restarting the Automatic Cycle:

Releasing and depressing the pendant Up-Arrow or Down-

Arrow button will restart the automatic cycle.

IMPORTANT:

relief valve pressure setting. When Dwell Mode is ON and pendant

Up or Down Arrow button is depressed, pressure will continue to

rise to the relief valve setting even after the specified pressure value

(PRESR A or PRESR B)

when using Dwell Mode, be certain that the PRESR A and PRESR B

values are set at least 200 psi [13,7 bar] BELOW the relief valve

pressure setting.

4

Maximum system pressure is determined by the

is reached. To ensure proper operation

WARNING: Set pump to “DWELL OFF” and disconnect

electrical power to pump before working on pump or

hydraulic system.

5.4 Relief Valve Adjustment

The pump is equipped with a user-adjustable relief valve. Adjust

pressure as follows:

1. Set the pump to DWELL OFF. Refer to Section 6.2 for

instructions.

2. Install a 0-6,000 psi [0-400 bar] gauge in the “A” port (see

figure 8). Place a 3/8" pipe plug in the “B” port and torque to

25 ft-lbs [33 Nm].

3. Loosen the relief valve locknut to permit adjustment of set

screw.

4. Press and hold the Up-Arrow button on the pendant. (see

figure 6). Allow pressure to build.

5. To increase pressure: SLOWLY turn the relief valve set

screw clockwise until pressure increases to the desired

setting.

6. To decrease pressure:

a. Turn the relief valve set screw counter-clockwise

b. Press and hold the Up-Arrow button on the pendant.

(see figure 6). Allow pressure to build.

c. SLOWLY turn the relief valve set screw clockwise until

pressure increases to the desired setting.

7. When the desired pressure setting is reached, lock the set

screw with the locknut. DO NOT overtighten.

8. Release the Up-Arrow button. Check that gauge indicates

zero (0) psi.

Relief valve body

(DO NOT TURN)

Port “B” Port “A”

B

Set screw

Figure 8

A

Locknut

one turn.

6.0 OPERATION AND USE INSTRUCTIONS -

LCD CONTROL PANEL

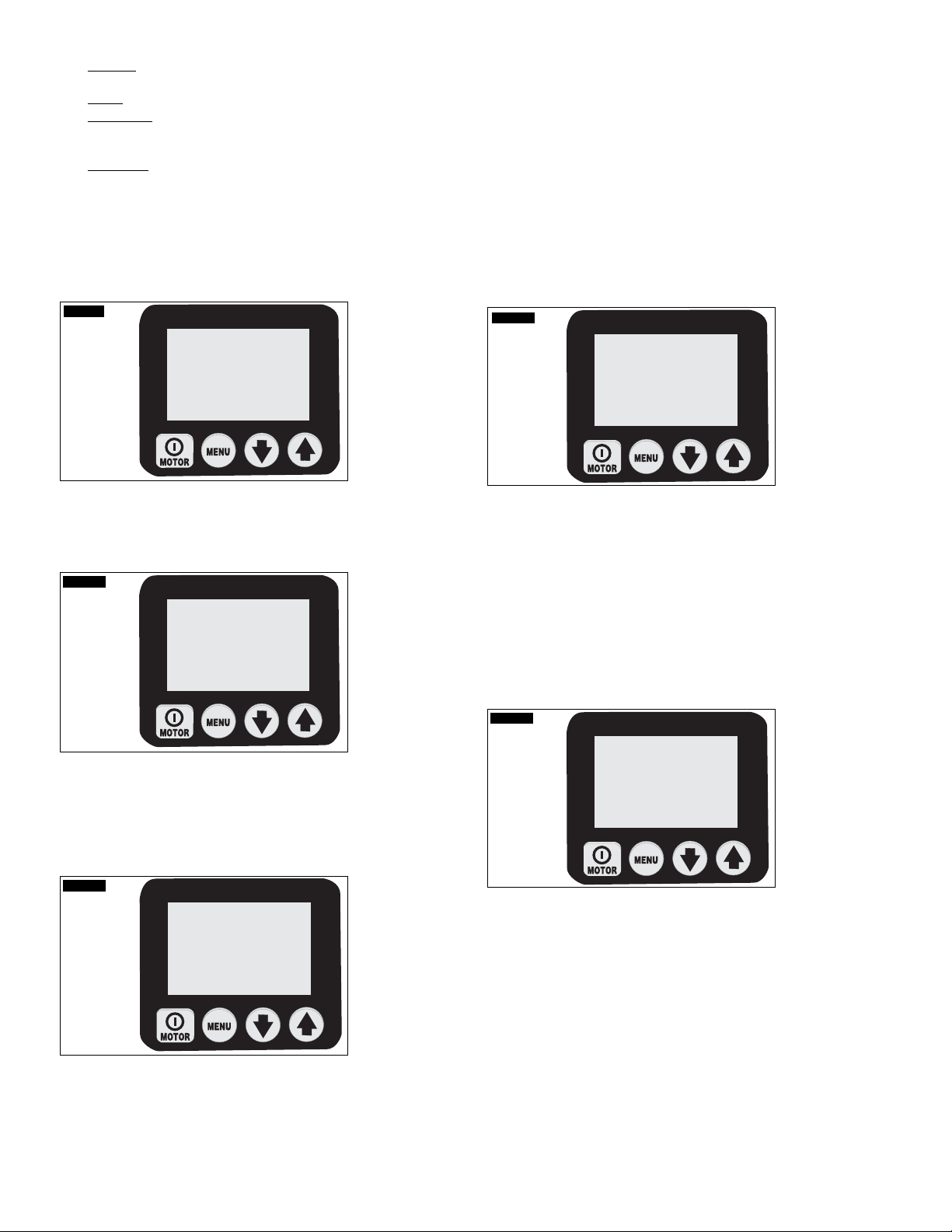

6.1 LCD Function

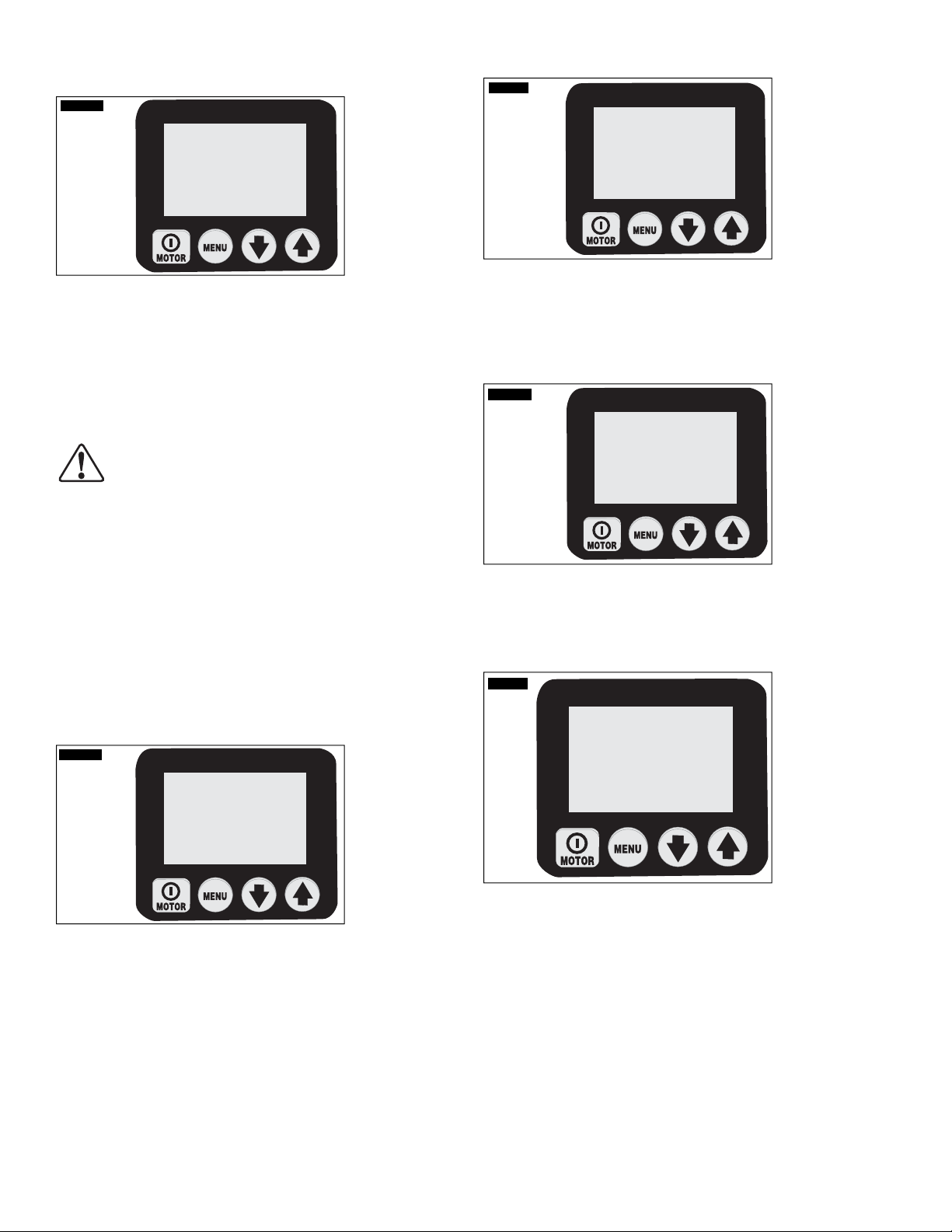

Screen 1

Number

display

SET

00000000

0000.0

HOURS CYCLES

LOW MOTOR

VOLTAGE OVERLOAD

(See Screen 1) The LCD control panel is the main interface

between the operator and the pump. By using the button

switches on the panel, the menus and functions described in the

following sections of this manual can be activated.

The backlighted LCD screen provides real time system pressure

readings. Pump fault and warning conditions are also displayed

on the screen as required.

Text display

PSI MPa

BAR

CAUTION: Make sure that the plastic overlay, that

protects the LCD screen and the button switches, is not

broken or otherwise damaged. Never punch the button

switches with a sharp or pointed instrument, use fingertips only.

Clean the overlay regularly with a damp cloth; never use

aggressive or abrasive detergents.

A. Boot Sequence

When the pump is connected to electrical power the LCD

screen will show: “FIRMWARE” 7.x for 1 second, then “Model

9” for 0.5 seconds, and then “Motor 1P/3P” for 0.5 seconds.

Additional information may appear depending on model and

installed accessories.

This is setup information about your pump that may be needed

for service. The boot sequence is finished successfully when the

text display on the LCD screen shows “READY” (sequence takes

approximately 2 seconds).

The pump microcontroller will automatically recognize the

transducer, and the current pump pressure (typically “0” psi/bar

at startup) will be shown on the LCD screen.

B. LCD Operational Buttons

The LCD control panel is equipped with four button switches:

On/Off / Menu / Down Arrow / Up Arrow

• The pump motor On/Off button is not functional for this

pump model. The pump will NOT start or stop when the

On/Off button is pressed. Motor operation is controlled by

depressing and releasing the Up-Arrow and Down-Arrow

buttons on the pendant (remote mode) or on the LCD control

panel (local mode).

• The Menu button enables the operator to step from normal

operational mode into menus. With repeated pressing the

operator steps through the various menus. Pressing the

Menu button also saves any changes made. To return to the

normal operational mode, press and hold the Menu button

for two seconds or don’t push any button for 60 seconds.

• The Down-Arrow and Up-Arrow buttons serve two purposes.

When the LCD screen shows one of the menus, the DownArrow and Up-Arrow buttons are used to step through the

menu’s options. When the pump is placed in Local Mode

(see Section 6.2

operate the B and A electric solenoids and the motor. The

pendant is non-operational in local mode.

L), the Down-Arrow and Up-Arrow buttons

C. Menus Available

The software provides the operator with a series of available

menus.

• Normal Operation – Default start-up screen. Appears

immediately after power is connected and microcontroller

has booted.

• Units – Set the pressure units to PSI / BAR / MPa, with psi

being the default setting.

• Dwell ON-OFF – Turn the Dwell Mode ON or OFF.

The additional Dwell Mode menus DWELL A, DWELL B,

PRESR A and PRESR B can be selected only when Dwell

Mode is ON.

• Motor – display the motor hour meter and on/off cycle

counter (nonresettable)

• Low Volt – display the low voltage hour-meter (nonresettable)

• Advance – display the Advance solenoid hour meter and on/

off cycle counter (nonresettable)

5

• Retract – display the Retract solenoid hour meter and on/off

cycle-counter (nonresettable)

• Local – set the pump local mode on/off

• Language – set the language of the display to English /

Spanish / French / Italian / German / Portuguese, with

English being the default setting

• Diagnose – display to show input signals from the pendant

and other electrical accessories

6.2 LCD Menus

Note: For additional information about each menu, also refer to

Table 2, Quick Reference Chart (QRC), located in Section 8.0 of

this manual.

A. Normal Operation “READY” Screen

Screen 22

Pump operation is as follows:

DWELL OFF – The motor will continue to run and the electric

valve will remain shifted until the Up or Down Arrow button on the

pendant is released (no automatic operation).

DWELL ON – the pump will automatically shut-off the motor

and de-energize the electric valve when the hydraulic pressure

reaches the operator-defined pressure limit (PRESR A or B) AND

the operator defined dwell time (DWELL A or B) has elapsed.

IMPORTANT: For automatic shut-off to occur, the pendant Up or

Down Arrow button must remain depressed (held down) until the

dwell time has completely elapsed.

D. “PRESR A” Menu

(accessible only when Dwell Mode is ON)

Screen 5

READY

0

(See Screen 2.) The READY screen indicates that the

microcontroller has booted successfully. Enter into the menus

by pressing the Menu button. See QRC step 1.

B. “UNITS” Menu

Screen 33

SET

(See Screen 3.) This screen allows the operator to set the unit

of pressure-measurement by pressing the Down (Up) Arrow

buttons. PSI, BAR, Mpa are the options with PSI being the

default. Save setting and step forward by pressing the Menu

button. See QRC step 2.

C. “DWELL ON-OFF Menu

Screen 14Screen 4

SET

DWELL

PSI

UNITS

PSI MPa

BAR

ON

SET

PRESR A

5000

(See Screen 5.) This screen allows the operator to set the PRESR A limit

for the pump. After pressure reaches this limit, the DWELL A function

will be activated and the motor / electric valve will remain energized for

the specified number of seconds. The default pressure value is 5000 psi

[344 bar].

The PRESR A value is adjusted by pressing the Up-Arrow and DownArrow buttons.

Menu button. See QRC step 3b.

E. “DWELL A” Menu

(accessible only when Dwell Mode is ON)

Screen 6

(See Screen 6.) This screen allows the operator to set the DWELL A time

in seconds. After the specified DWELL A time (0 to 60 seconds) has

elapsed, the pump will de-energize the motor / electric valve.

The DWELL A value is adjusted by pressing the Up-Arrow and DownArrow buttons. If the DWELL A time is set to zero (0) seconds, the pump

will shut-off immediately when the PRESR A limit is reached.

Save setting and step forward by pressing the

SET

DWELL A

60

PSI

(See Screen 4.) This screen allows the operator to toggle the

pump’s Dwell Mode On and Off by pressing the Down (Up)

Arrow buttons. ON or OFF are the options. Dwell Mode must be

ON to allow the operator to set the pressure and dwell settings.

Save setting (ON or OFF) and step forward by pressing the Menu

button. See QRC step 3a.

Save setting and step forward by pressing the Menu button. See

QRC step 3b.

6

F. “PRESR B” Menu

(accessible only when Dwell Mode is ON)

Screen 7

SET

PRESR B

5000

(See Screen 7.) This screen allows the operator to set the PRESR B limit

for the pump. After pressure reaches this value, the Dwell Mode feature

will be activated and the motor / electric valve will remain energized for

the specified number of seconds. The default value is 5000 psi [344 bar].

The message “Use A” will appear first. Choosing this selection will set

the PRESR B limit to the same value as PRESR A. If desired, PRESR B

can be adjusted to a different setting by pressing the Up or Down Arrow

buttons again.

CAUTION: Due to motor coast down, valve shift time,

and system oil capacitance, always set the user

adjustable relief valve 200 psi above the higher of the

two pressure values (PRESR A or PRESR B) to prevent pressure

spikes. See Section 5.4 for relief valve adjustment instructions.

PSI

H. “Motor” Menu

Screen 94

MOTOR

4.8

HOURS CYCLES

(See Screen 9.) This screen allows the operator to read the

number of hours (On/Off cycles) the motor has been operated.

Toggle between hours and cycles by pushing either the Down

or Up Arrow button. Step forward by pressing the Menu button.

See QRC step 5.

I. “Low Volt” Menu

Screen 10

LOW VOLT

.0

HOURS CYCLES

IMPORTANT: When the Dwell timer is activated, the pump will

continue to build pressure to the system relief valve setting. The

relief valve setting should be adjusted to the maximum fixture

clamping pressure, to avoid over-pressurizing any components.

Note: Maximum system pressure is mechanically limited to

approximately 5,300-5,600 PSI [366-386 bar] by an internal relief

valve located within the pump element. Setting the PRESR A or

PRESR B pressure value higher than the relief valve maximum

limit will not result in higher system pressure.

G. “DWELL B” Menu

(accessible only when Dwell Mode is ON)

Screen 8

SET

DWELL B

60

(See Screen 8.) This screen allows the operator to set the DWELL B

time in seconds. After the specified DWELL B time (0 to 60 seconds)

has elapsed, the pump will de-energize the motor / electric valve.

(See Screen 10.) This screen allows the operator to read the

number of hours the pump has been operated in low-voltage

condition. Step forward by pressing the Menu button. See QRC

step 6.

J. “Advance” Menu

Screen 11

ADVANCE

188

HOURS CYCLES

(See Screen 11.) This screen allows the operator to read the

number of hours (On/Off cycles) the Advance solenoid has been

operated. Toggle between hours and cycles by pushing either the

Down or Up Arrow buttons. Step forward by pressing the Menu

button. See QRC step 7.

The DWELL B value is adjusted by pressing the Up-Arrow and DownArrow buttons. The message “Use A” will appear first. Choosing this

selection will set the DWELL B time to the same value as DWELL A. If

desired, DWELL B can be adjusted to a different setting by pressing the

Up or Down Arrow buttons again.

If the DWELL B time is set to zero (0) seconds, the pump will shut-off

immediately when the PRESR B limit is reached.

Save setting and step forward by pressing the Menu button. See

QRC step 3b.

7

K. “Retract” Menu

Screen 12

RETRACT

334

HOURS CYCLES

(See Screen 12.) This screen allows the operator to read the

number of hours (On/Off cycles) the Retract solenoid has been

operated. Toggle between hours and cycles by pushing either

the Down or Up Arrow button. Step forward by pressing the

Menu button. See QRC step 8.

_______________________________________________________

General note for all hour and cycle displays:

HOURS DISPLAYED

- up to 9999.9 the display will show decimal hours

- between 10,000 - 99,999 whole hours will be displayed (decimal “.” is not

displayed).

- over 99,999 hours the meter starts over at 0.0 reading decimal hours

CYCLES DISPLAYED

- over 99,999 cycles the meter starts over at 0

_________________________________________________________

L. “Local” Menu

Screen 13

SET

LOCAL

N. “Diagnose” Menu

Screen 15

SET

DIAGNOSE

00001

Pendant UP ARROW Button

Pendant ON/OFF Button

(See Screen 15.) This screen allows the operator to troubleshoot

several pendant problems by displaying if the microcontroller has

received a signal from the pendant button. No signal indicates the

problem is most likely with the pendant keypad or pendant cord.

Use Local mode to operate pump until problem can be corrected.

See QRC step 11.

Screen 16

PSI

(not used)

Fan

Pendant DOWN ARROW Button

DIAGNOSE

10001

PSI

OFF

(See Screen 13.) This screen allows the operator to toggle the Local

mode ON or OFF. With Local mode ON, the shroud buttons replace

the pendant buttons as the method to operate the pump (Note:

The word “Local” replaces “READY” on the “Normal Operations”

display and the pendant buttons become deactivated).

Local mode will provide operation of the pump if the pendant

or pendant cord is damaged. Toggle Local mode ON or OFF

by pressing the Down (Up) Arrow button. Save setting and step

forward by pressing the Menu button. See QRC step 9.

Local mode OFF is the default value. Local mode ON will revert

to Local mode OFF if power is disconnected.

M. “Language” Menu

Screen 14

SET

ENGLISH

Press

(See Screen 16.) Diagnose screen with Pendant motor button

pushed.

Screen 17

Press

DIAGNOSE

01001

PSI

(See Screen

pushed.

Screen 18

17

.) Diagnose screen with Pendant Advance button

Press

DIAGNOSE

00101

PSI

(See Screen 14.) With a language shown on the text display the

operator can change the display language by pressing the Down

(Up) Arrow buttons. Save setting and step forward by pressing the

Menu button. See QRC step 10.

(See Screen 18.) Diagnose screen with Pendant Retract button pushed.

8

6.3 Fault Conditions

Any fault will shut down and prevent pump from starting.

A. Clearing a Fault Condition from the LCD

After the fault causing problem has been corrected, clear the fault

message from the LCD by disconnecting electrical power from the

pump, wait until all characters clear the LCD (~ 30 seconds), then

reconnect power.

B. Power Failure

Display: “POWER OFF”

Screen 19

POWER

OFF

(See Screen 19.) The Power Off fault is displayed when the main

power supply drops to 65% or less of nominal voltage. The pump

will automatically shut off the valves and the motor, and display

“Power Off” on the LCD. Note: Power Off is also displayed for

several seconds after the unit is disconnected from electrical

power.)

C. Button Fault

Display: “Button Fault”

Screen 20

operator must clear the fault by disconnecting and reconnecting

electrical power as described in Section 6.3A.

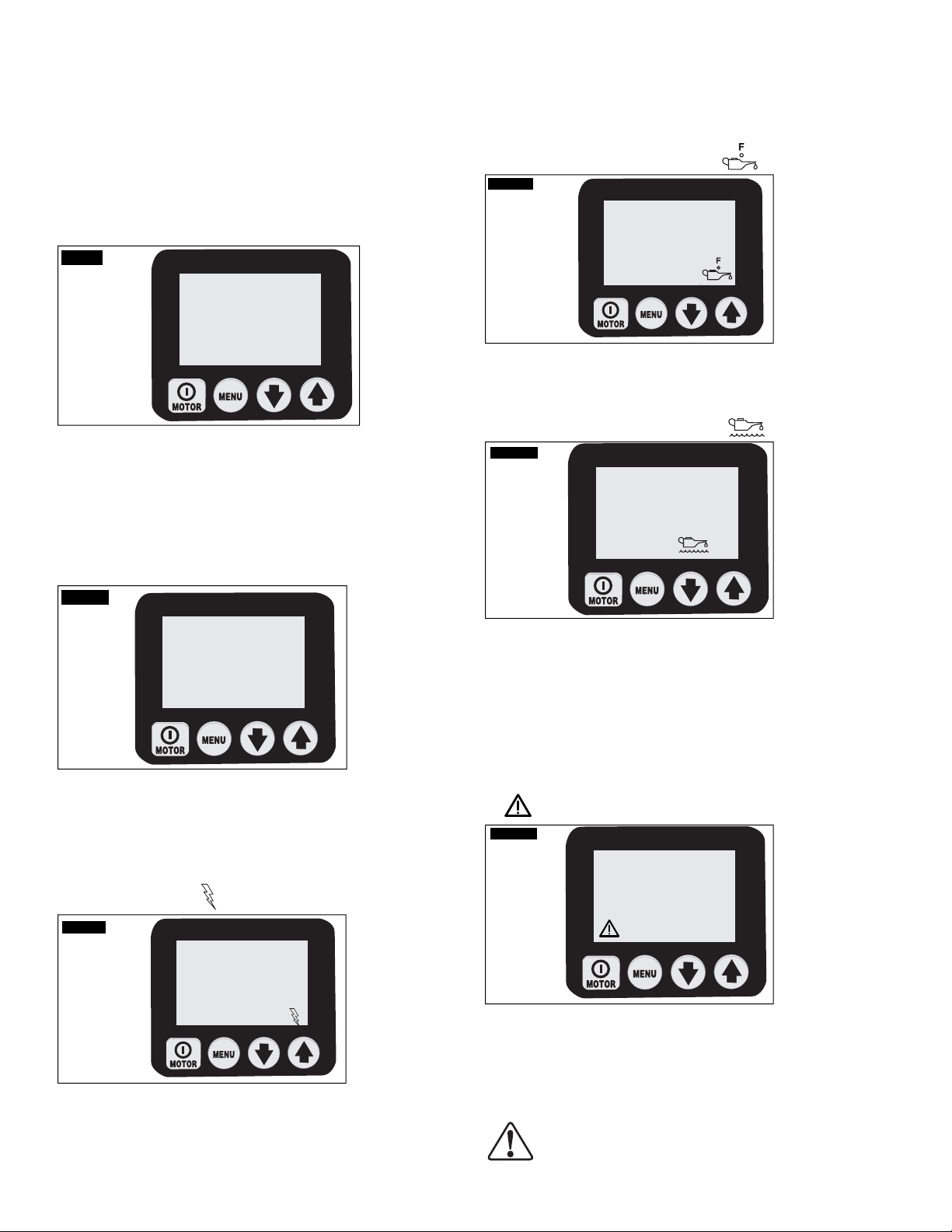

E. Oil Temperature

(requires optional level/temperature switch)

Display: “OIL TEMP FAULT”

Screen 22

OIL TEMP

FAULT

(See Screen 22.) The Oil Temperature Fault is displayed when the

temperature of the oil inside the reservoir exceeds 175 ºF (80 °C).

F. Oil Level (requires optional level/temperature switch)

Display: “OIL LEVEL FAULT”

Screen 23

OIL LEVEL

FAULT

BUTTON

FAULT

(See Screen 20.) The Button Fault is displayed when the

microcontroller detects any button press during the boot sequence

or if shroud on/off button is held in for more than 3 seconds.

D. Motor Overload

Display: “MTR OVLD FAULT”

Motor Overload

Screen 21

MTR OVLD

FAULT

MOTOR

OVERLOAD

(See Screen 21.) The Motor Overload fault is displayed when the

electric current draw exceeds the pre-set limit of the pump’s

internal circuit breaker. The circuit breaker will automatically

reset in about 2 to 3 minutes after the condition has been

corrected. However, before the pump can be restarted, the

(See Screen 23.) The Oil Level Fault is displayed when the oil level

inside the reservoir drops below 1.3" (34 mm) from bottom.

6.4 Warning Conditions

All warnings notify operator of abnormal operating condition,

however, allow pump to continue operating. Warnings will

automatically clear once issue has been resolved.

A. Low Voltage

Display: “LOW VOLT”

Low Voltage

Screen 24

LOW VOLT

LOW

VOLTAGE

(See Screen 24.) A “Low Voltage” condition is defined as an

operating condition with the main power supply is at or below

80% of nominal voltage. While running the pump under this

condition, the “Low Voltage” signal will flash on the LCD and

the Low Voltage hours will be counted and stored by the pump

microcontroller. Normal pump operation is still provided.

CAUTION: For optimized pump performance it is

recommended NOT to run the pump during a Low

Voltage condition.

9

7.0 MAINTENANCE

Frequently inspect all system components for leaks or damage.

Repair or replace damaged components. Electrical components,

for example, the power-cord, may only be repaired or replaced by

a qualified electrician, adhering to all applicable local and national

codes.

7.1 Check Oil Level

Check the pump oil level prior to start-up. If oil level is low,

remove the SAE #10 plug from the fill pipe extension and add oil

as needed (see figures 2 and 4). Always be sure cylinders are fully

retracted before adding oil to the reservoir.

7.2 Change Oil and Clean Reservoir

Enerpac HF oil is a crisp blue color. Frequently check oil condition

for contamination by comparing pump oil to new Enerpac oil. As

a general rule, completely drain and clean the reservoir every 250

hours, or more frequently if used in dirty environments.

Note: This procedure requires that you remove the pump from

the reservoir. Work on a clean bench and dispose of used oil

according to local codes.

1. Remove the drain plug and drain all oil from the reservoir.

Clean and reinstall the drain plug.

2. Unscrew the 13 bolts holding the cover plate to the reservoir

and lift the pump unit out of the reservoir. Be careful not to

damage the filter screen.

3. Thoroughly clean the reservoir and reservoir magnet (if

equipped) with a suitable cleaning agent.

4. Remove the pick-up filter screen for cleaning. (Do not pull

on the screen or the bottom of the intake to avoid possible

damage.) Clean the screen with solvent and a soft brush.

Reinstall.

5. Reassemble the pump and reservoir, installing a new reservoir

gasket.

6. Fill the reservoir with clean Enerpac hydraulic oil. The

reservoir is full when oil level is as shown in Figure 4.

7.3 Changing the Filter Element (optional)

A return line filter may be ordered as an accessory to the pump.

The filter element should be replaced every 250 hours, or more

frequently in dirty environments. The filter manifold is equipped with

a 25 psi (1.7 bar) bypass to prevent over pressure rupture if filter

plugging occurs. Filter element replacement part number is PF25.

8.0 TROUBLESHOOTING AND ADDITIONAL

REFERENCE INFORMATION

Refer to the following tables as needed:

• Table 1 (page 11) contains the pump troubleshooting guide.

• Table 2 (pages 12-13) contains a quick reference chart (QRC)

that describes the operation of the LCD control panel.

• Table 3 (page 14) contains additional information about pump

automatic operation and functions.

• Table 4 (page 14) contains detailed pump electrical current

draw information.

IMPORTANT: Only qualified hydraulic technicians should service

the pump or system components. A system failure may or may

not be the result of a pump malfunction. To determine the cause

of the problem, the complete system must be included in any

diagnostic procedure.

Note: The troubleshooting guide included in Table 1 is provided

as an aid to help diagnose and correct various possible pump

malfunctions and is intended for use only by qualified hydraulic

service personnel. For repair service, contact your nearest

Authorized Enerpac Service Center.

10

Table 1, Troubleshooting Guide

Problem Possible Cause Action*

Pump will not start Fault condition See Section 5.0, Operation and 6.3, Fault Conditions for

details

Pendant does not function Pump in local mode

Pendant damage

Motor stops under load Low voltage See Sections 6.3B and 6.4A

Electric valve will not operate No power or wrong voltage

Solenoid cable disconnected or damaged

Valve out of adjustment

Pump fails to build pressure or

less than full pressure

Pump builds full pressure, but

load does not move

Cylinder drifts back on its own External system leak

Low oil level

Relief valve set too low

External system leak

Internal leak in pump

Internal leak in valve

Internal leak in system component

Load greater than cylinder capacity at full pressure

Flow to cylinder blocked

Internal leak in a system component

Non-load holding valve used

See Section 6.2L, Local Menu

See Section 6.2N, Diagnose Menu

See authorized service center

Turn off other electric loads

Use heavier gauge extension cord

Connect to correct power source per pump name plate

Connect, repair, or replace cable

See authorized service center

Add oil per Section 4.4

Adjust per Section 5.4

Inspect and repair or replace

See authorized service center

See authorized service center

See authorized service center

Reduce load or add cylinder capacity

Check hydraulic couplers for full engagement

Inspect all hydraulic connections and replace or repair

See authorized service center

See authorized service center

Single-acting cylinder will

not return

Double-acting cylinder will not

return

Pump runs hot Advance or retract flow restricted

Pump pressure goes above

“PRESR A” or “PRESR B” value

Dwell Mode does not work

correctly

After boot-up, LCD display

shows “P switch open”

LCD display shows “FILTER” Loose jumper on power board See authorized service center.

No load on a “load return” cylinder

Return flow restricted or blocked

Valve malfunction

Cylinder return spring broken

Return flow restricted or blocked

Valve malfunction

High ambient temperature

Cylinder comes to a sudden stop (i.e., strokes out) Set user adjustable relief valve 200 psi above “PRESR A”

Pressure transducer installed in pressure port other

than “GP”

Pressure switch circuit is open See authorized service center.

Add load

Check couplers for full engagement

See authorized service center

See authorized service center

Check couplers for full engagement

See authorized service center

Check couplers for full engagement

Install heat exchanger for hydraulic oil

or “PRESR B” value to redirect excess oil flow

Move pressure transducer to “GP”

* As required during troubleshooting, refer to sections 6.2 LCD Menus, 6.3 Fault Conditions and 6.4 Warning Conditions.

11

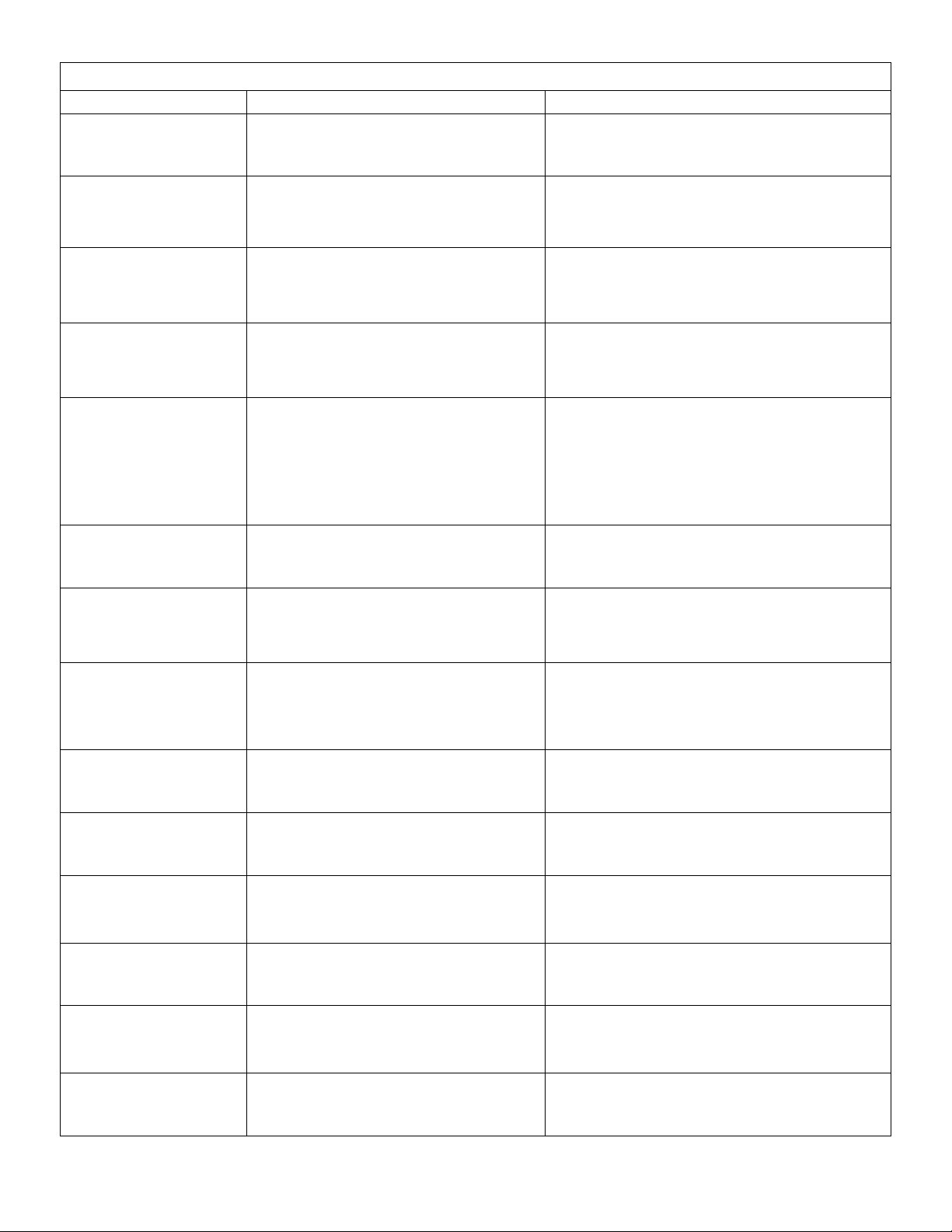

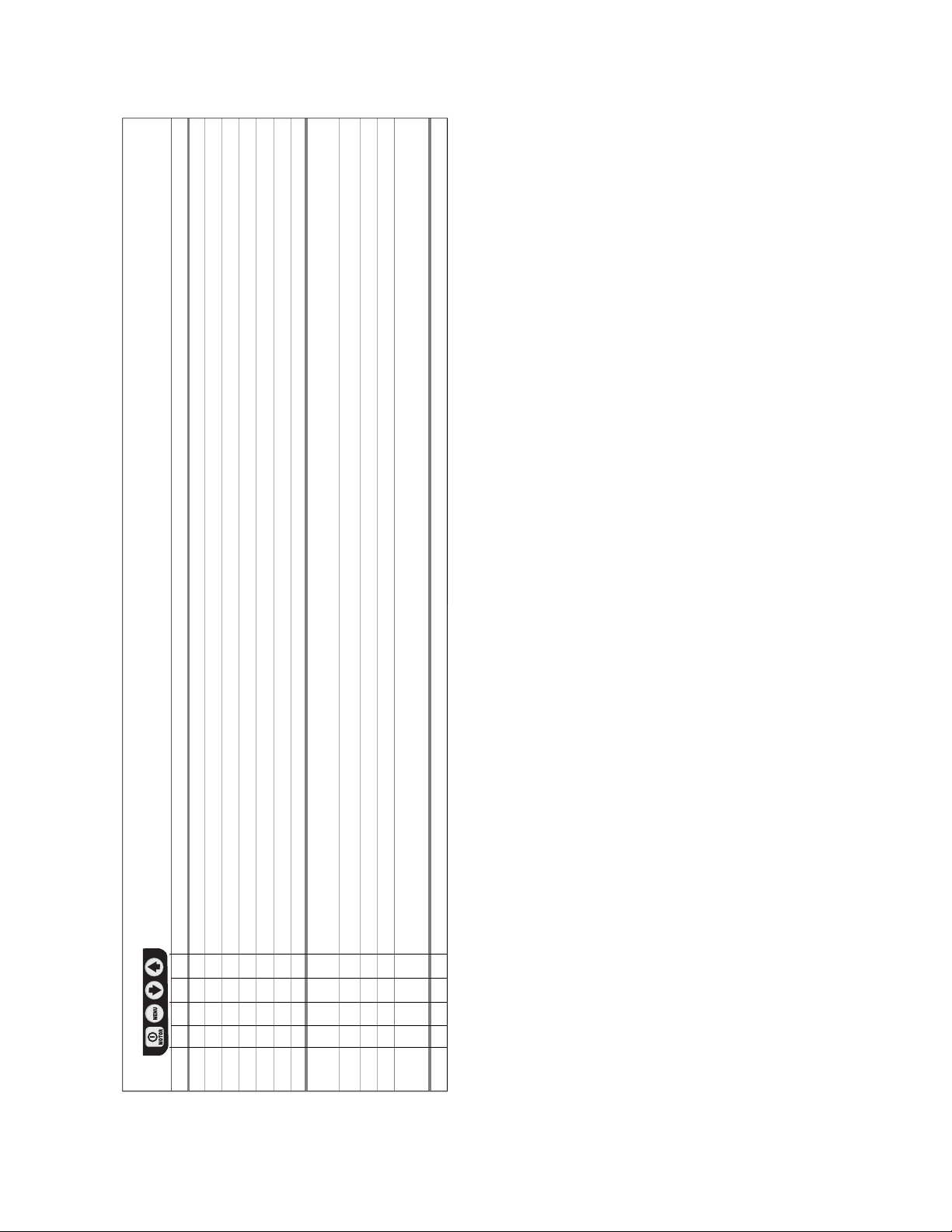

Table 2, Quick Reference Chart (QRC) • ZW Series Pallet Coupling Pumps • Firmware 7.x • Pump Program Number 9

Step Switch Text Expected reading / symbol / status Units Comments

I M t s display digital display

1 READY default reading “READY” after power on and boot sequence

2 X UNITS PSI save previous setting and step forward to select units,

default is psi

X “ BAR step through units using either the Up or

X “ MPA the Down Arrow button

X “ PSI

3a X DWELL OFF select dwell mode

X “ ON toggle between on and off by using the arrow buttons

3b X PRESR A value of “A” clamping pressure limit for Dwell Mode increase/decrease value by using the arrow-buttons

default value is 5000 PSI [344 bar]

X DWELL A value of “A” clamping dwell time for Dwell Mode increase/decrease value by using the arrow-buttons

default value is 0

X PRESR B USE A make PRESR B value same as PRESR A value

X PRESR B value of “B” clamping pressure limit for Dwell Mode increase/decrease value by using the arrow-buttons

(if USE A is not selected) default value is 0

X DWELL B USE A make DWELL B value same as DWELL A value

X DWELL B value of “B” clamping dwell time for Dwell Mode increase/decrease value by using the Arrow-buttons

(if USE A is not selected) default value is 0

4 hidden menu

X UNITS hold for 7 seconds

X X ENTRY CODE hold for 7 seconds

12

CAL PT A 0 psi start calibration process

(Note: Calibration menus are for Enerpac Authorized Service

Center use only - Pump cannot be calibrated by user)

5 X MOTOR number of hours HOURS save previous setting and step forward to select

hour-meter function

X “ number of cycles CYCLES

6 X LOW VOLT number of hours at low volt, read 0 HOURS select low-voltage check function

7 X ADVANCE number of hours HOURS select hour-meter function

X “ number of cycles CYCLES only if solenoid valve is attached

8 X RETRACT number of hours HOURS select hour meter-function

X “ number of cycles CYCLES only if solenoid valve is attached

9 X LOCAL OFF select local mode

NOTE: LCD functions shown in section 3b of Table 1 are available only when Dwell mode is ON.

X “ ON toggle between on and off

X “ OFF

Table 2, Quick Reference Chart (QRC) • ZW Series Pallet Coupling Pumps • Firmware 7.x • Pump Program Number 9 (Continued)

Step Switch Text Expected reading / symbol / status Units Comments

I M t s display digital display

10 X ENGLISH select language, default is English

X ESPANOL

X FRANCAIS step through languages using either

X ITALIANO the Up- or the Down-Arrow button

X DEUTSCH

X PORTUGUES

X ENGLISH save with Menu button

11 the digital display is expected to show processor inputs

that are “turned on”

10001 with pendant Motor-button pushed

01001 with pendant Arrow-up button pushed

00101 with pendant Arrow-down button pushed

psi psi-reading present, if pressure transducer is attached and

has been recognized during boot-up

12 X READY hold for 2 seconds to return to “READY” run mode

13

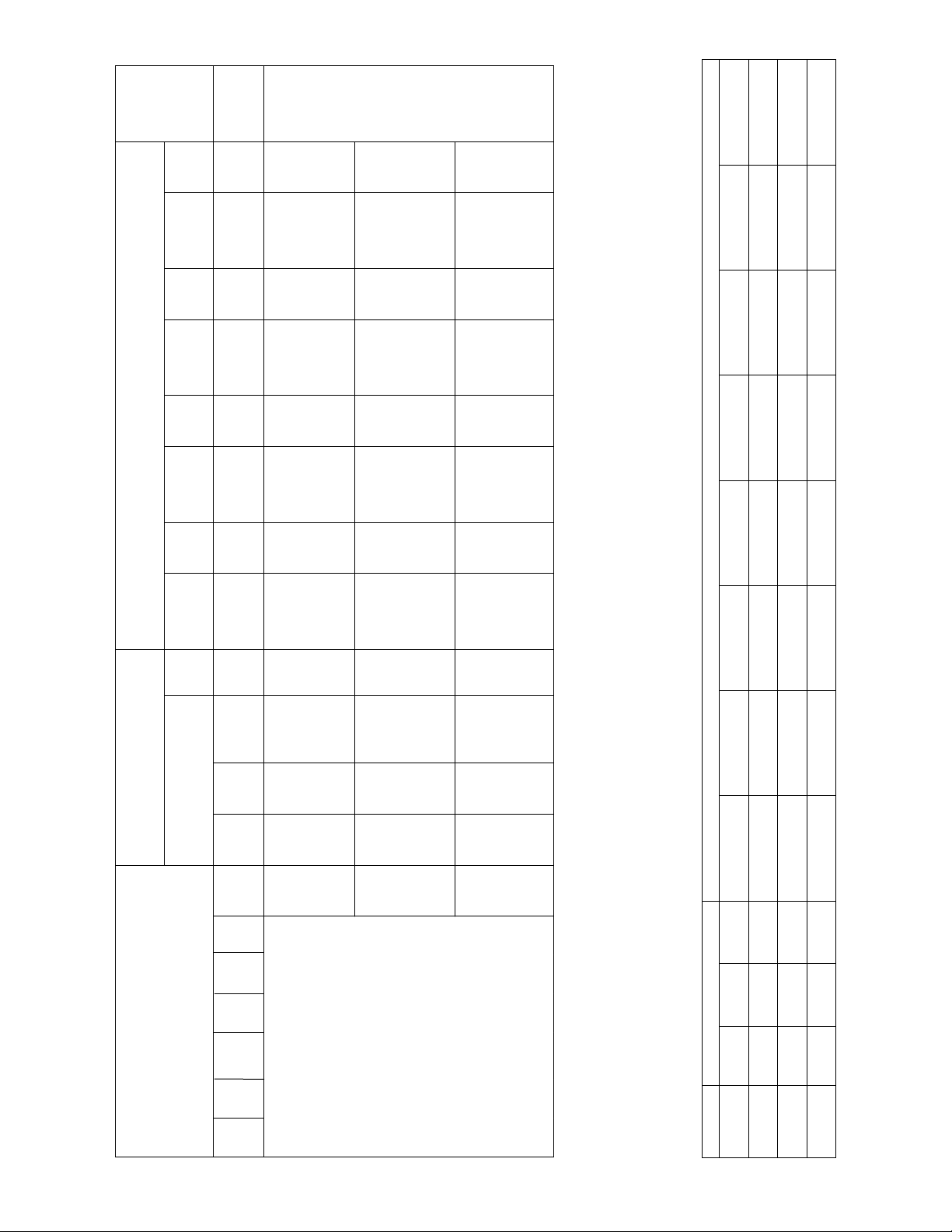

Additional

Comments

Max value

for DWELL B

DWELL B

Action when

value is reached

Rapid valve cycle

~0.5 seconds after

motor shut down

command

to release pump

pressure after

motor stops

spinning.

Maximum

pressure

mechanically

limited to 5300-

5600 PSI by

intenal relief valve.

(even if PRESR A

or PRESR B value

is set higher)

Switches off.

Unclamping stops.

Actions

Max value

for PRESR B

PRESR B

Action when

value is reached

Max value

for DWELL A

DWELL A

Action when

value is reached

Max value

for PRESR A

PRESR A

Action when

value is reached

Button

On/Off

Arrow up Motor

10,500 psi Shuts off 60 seconds

Shuts off

immediately.

If DWELL B > 0,

10,500 psi Shuts off 60 seconds If DWELL B = 0,

Shuts off

immediately.

If DWELL A = 0,

If DWELL A > 0,

disabled

off off

Continues running.

Switches off.

Clamping stops.

clamping.

Switch off to stop

Continues running.

stays on and

If DWELL A > 0,

clamping continues.

Switches off.

Stays on and

If DWELL B > 0,

Unclamping stops.

continues.

Unclamping

440V 3 PH 50/60 Hz 460-480V 3 PH 50/60 Hz 575V 3 PH 50/60 Hz

Pendant Button LCD Panel

operation mode (“READY” is displayed on LCD)

What happens when _____ button is pushed in normal

Arrow

On/Off

Item Motor

switch

na-

disabled

Pump

Motor &

Option

(on-off

Fan Motor

(if equipped)

disabled)

Solenoid A na off on na If DWELL A = 0,

Solenoid B na on off na off off If DWELL B = 0,

RPM 115V 1 PH 50/60 Hz 208-240V 1 PH 50/60 Hz 190-200V 3 PH 50/60 Hz 208-240V 3 PH 50/60 Hz 380-415V 3 PH 50/60 Hz

kW

Table 4, Electrical Current Draw • ZW Series Pallet Coupling Pumps • Firmware 7.x • Pump Program Number 9

on on na-

down

Valve Pendant Foot

Table 3, Description of Automatic Operation • ZW Series Pallet Coupling Pumps • Firmware 7.x • Pump Program Number 9

Pump Information

Pump type

Pump

Pump

code

type

No.

ZWx4xxDx VEW43 3-button

Pallet

Coupling

9

Note - 5,000 PSI (350 bar)

1 0.75 1750 13.8 6.9 5.7 4.3 2.5 2.3 2.1 2.1

ZW3

1 0.75 1750 11.2 5.6 4.8 3.6 2 1.9 1.8 1.8

ZW4

1.5 1.12 1750 15.6 7.8 6.2 4.8 2.7 2.6 2.4 2.4

ZW5

hp

Pump Series Motor Size Maximum Current Draw (in amps)

14

L3075 Rev. A 04/14

Les vues éclatées de ce produit sont disponibles sur le

site Enerpac www.enerpac.fr. Vous pouvez également les

obtenir auprès de votre réparateur agréé Enerpac ou auprès

d’Enerpac même.

1.0 INSTRUCTIONS IMPORTANTES RELATIVES

À LA RÉCEPTION

Inspecter tous les composants pour vous assurer qu’ils n’ont

subi aucun dommage en cours d’expédition. Les dommages

subis en cours de transports ne sont pas couverts par

la garantie. S’ils sont abîmés, aviser immédiatement le

transporteur, qui est responsable des frais de réparation

et de remplacement résultant de dommages en cours de

transport.

LA SÉCURITÉ AVANT TOUT !

2.0 SÉCURITÉ

Lire attentivement toutes les instructions et

mises en garde et tous les avertissements.

Suivre toutes les précautions pour éviter

d’encourir des blessures personnelles ou de provoquer des dégâts

matériels durant le fonctionnement du système. Enerpac ne peut

pas être tenue responsable de dommages ou blessures résultant

de l’utilisation risquée du produit, d’un mauvais entretien ou d’une

application incorrecte du produit et du système. En cas de doute

sur les précautions ou les applications, contacter Enerpac.

Respecter les mises en garde et avertissements suivants sous

peine de provoquer des dégâts matériels et des blessures

corporelles.

Une mise en garde ATTENTION sert à indiquer des procédures

d’utilisation et de maintenance correctes qui visent à empêcher

l’endommagement voire la destruction du matériel ou d’autres

dégâts.

Un AVERTISSEMENT indique un danger potentiel qui exige la

prise de mesures particulières visant à écarter tout risque de

blessure.

La mention DANGER n’est utilisée que lorsqu’une action ou un

acte de négligence risque de causer des blessures graves, voire

mortelles.

AVERTISSEMENT : Porter un équipement de protection

individuelle adéquat pour utiliser un appareil hydraulique.

AVERTISSEMENT : Rester à l’écart de charges

soutenues par un mécanisme hydraulique. Un vérin,

lorsqu’il est utilisé comme monte-charge, ne doit jamais

servir de support de charge. Après avoir monté ou abaissé la

charge, elle doit être bloquée par un moyen mécanique.

DANGER : Pour écarter tout risque de blessures

corporelles, maintenir les mains et les pieds à l’écart

du vérin et de la pièce à usiner durant l’utilisation.

Fiche d’instructions

Pompes d’écartement de palette

Séries ZW3, ZW4 et ZW5

AVERTISSEMENT : Ne pas dépasser les valeurs

nominales du matériel. Ne jamais essayer de soulever

une charge d’un poids supérieur à la capacité du vérin.

Une surcharge entraînera la panne du matériel et risque de

provoquer des blessures corporelles. Les vérins sont conçus

pour une pression maximale de 350 bar. Ne pas connecter de

cric ou de vérin à une pompe affichant une pression nominale

supérieure.

DANGER : Ne jamais régler la soupape de sûreté à une

pression supérieure à la pression nominale maximale de

la pompe sous peine de provoquer des dégâts matériels

et/ou des blessures corporelles. Ne pas retirer le limiteur de

pression.

AVERTISSEMENT : La pression de fonctionnement du

système ne doit pas dépasser la pression nominale du

Installer des manomètres dans le système pour surveiller la

pression de fonctionnement. Ils permettent de vérifier ce qui se

passe dans le système.

fort retour de pression. Les plis et coudes prononcés

endommageront par ailleurs l’intérieur du flexible, provoquant son

usure précoce.

endommagé risque d’entraîner sa rupture.

manière sûre.

provoquera par conséquent des fuites. La chaleur affaiblit

également les matériaux et les garnitures du flexible. Pour une

composant du système affichant la plus petite valeur.

ATTENTION : Éviter d’endommager les flexibles

hydrauliques. Éviter de les plier et de les tordre en les

mettant en place. Un flexible plié ou tordu entraînera un

Ne pas faire tomber d’objets lourds sur le flexible. Un fort

impact risque de causer des dégâts intérieurs (flexible

®

métalliques). L’application d’ une pression sur un flexible

IMPORTANT : Ne pas soulever le matériel hydraulique

en saisissant ses flexible ou ses raccords articulés.

Utiliser la poignée de transport ou procéder d’une autre

ATTENTION : Garder le matériel hydraulique à l’écart

de flammes et d’une source de chaleur. Une forte

température amollira les garnitures et les joints et

15

performance maximale, ne pas exposer le matériel à une

température supérieure ou égale à 65 °C [150 °F]. Protéger

flexibles et vérins de projections de soudure.

DANGER : Ne pas manipuler les flexibles sous pression.

L’huile sous pression qui risque de s’en échapper peut

pénétrer dans la peau et provoquer des blessures graves.

En cas d’injection d’huile sous la peau, contacter immédiatement

un médecin.

AVERTISSEMENT : Utiliser des vérins hydrauliques

uniquement dans un système couplé. Ne jamais utiliser

un vérin en présence de raccords déconnectés. La

surcharge du vérin peut avoir des effets désastreux sur ses

composants, qui peuvent causer des blessures graves.

IMPORTANT : Le matériel hydraulique doit uniquement

être réparé par un technicien hydraulique qualifié. Pour

toute réparation, contacter le centre de réparation

ENERPAC agréé le plus proche. Pour assurer la validité de la

garantie, n’utiliser que de l’huile ENERPAC.

AVERTISSEMENT : Remplacer immédiatement les

pièces usées ou endommagées par des pièces ENERPAC

authentiques. Les pièces de qualité standard se casseront

et provoqueront des blessures et des dégâts matériels. Les

pièces ENERPAC sont conçues pour s’ajuster parfaitement et

résister à de fortes charges.

ATTENTION : N’utilisez pas de pompe électrique en

atmosphère explosive. Respectez toutes les

réglementations électriques. L’installation ainsi que

toutes modifications doivent obligatoirement être effectuées par

un technicien qualifié.

ATTENTION : Démarrez la pompe avec le distributeur en

position neutre pour éviter tout mouvement accidentel

du vérin. Tenez vos mains éloignées des pièces en

mouvement et des flexibles sous pression.

ATTENTION : Ces pompes sont équipées de vannes

réglées en usine ; celles-ci ne sont réparables ou

réglables que par un centre de service agréé Enerpac.

ATTENTION : Pour éviter d’endommager le moteur

électrique de la pompe, vérifiez ses caractéristiques.

Une alimentation électrique incorrecte provoquera des

dommages au moteur.

3.0 SPÉCIFICATIONS

3.1 Diagrammes de débit (voir la figure 1)

3.2 Tableaux de rendement (voir la figure 1)

3.3 Appel de courant électrique (se reporter au Tableau

4 de la section 8.0 de ce manuel)

COURBES DE DÉBITS

16

13

10

7

Débit d’huile (l/min)

3

0

0 35028021014070

Série ZW3 à deux étages

TABLEAU DES PERFORMANCES

Série

Pompes

Série ZW3

Pression (bar)

Fonctionnement

7 bar 50 bar 350 bar kw RPM (bar) (dBA)

16

13

10

7

Débit d’huile (l/min)

3

0

0 35028021014070

Série ZW4 à un étage

Série ZW4 à deux étages

Débit nominal

l/min

ZW3 Deux étages 3,3 3,1 0,6

Un étage 1,0 1,0 1,0

ZW4

Deux étages 5,7 5,0 1,0

Un étage 2,1 2,1 2,0

ZW5

Deux étages 10,6 9,9 2,0

Série ZW4

Pression (bar)

Série ZW5

sécurité

70 - 350

Débit d’huile (l/min)

Puissance

du moteur

0,75 1750

16

13

10

7

3

0

0

Série ZW5 à un étage

Série ZW5 à deux étages

Plage de réglage

de la soupape de

1,12 1750 70 - 350

Pression (bar)

35028021014070

Niveau sonore

75

75

Le débit nominal indiqué est de 60 Hz.

Le débit atteindra approximativement 5/6 de ces valeurs à 50 Hz.

Figura 1, spécifications de la pompe

16

A

B

A

B

Figure 2, Installation du reniflard pour la série ZW

C

D

4.0 INSTALLATION

Installez ou positionnez la pompe afin de s’assurer que la

circulation d’air autour du moteur et de la pompe ne soit

pas obstruée. Gardez le moteur propre afin d’assurer un

refroidissement maximal pendant le fonctionnement.

4.1 Reniflard du réservoir (voir la figure 2)

Pour le transport, un bouchon d’expédition (A) est installé dans

l’ouverture du reniflard située sur le dessus du réservoir. Avant

d’utiliser l’appareil, remplacez le bouchon d’expédition (A) par

le reniflard (B).

Remarque : Le port de remplissage d’huile est muni d’un

bouchon SAE nº 10 (C), installé à l’extrémité de la rallonge du

tuyau de remplissage (D).

4.2 Plan de fixation

Consultez la Figure 3 pour les dimensions du support pour fixer

la pompe à une surface fixe.

4-8 L 10 L 20 L 40 L

mm mm mm mm

A 95 279 396 480

B 229 305 305 305

C M8, 12 mm Ø 8.6 diamètre à travers le trou

(6) en profondeur

C

4.3 Connexions électriques

LA POMPE A ÉTÉ MUNIE EN USINE D’UNE PRISE

ÉLECTRIQUE STANDARD NORMAL POUR UNE TENSION

DONNÉE. LA MODIFICATION DU TYPE DE PRISE DOIT

ÊTRE FAITE SEULEMENT PAR UN ÉLECTRICIEN QUALIFIÉ,

EN RESPECTANT TOUTES LES NORMES LOCALES ET

NATIONALES APPLICABLES.

1. Le sectionneur et la protection du circuit de la ligne

d’alimentation doivent être fournis par le client. La protection

pour le circuit de la ligne d’alimentation doit être établie à

115 % du débit maximal du moteur en utilisation à pression

maximale.

2. Pour obtenir de plus amples renseignements, référez-vous à

la plaque d’identification pour connaître la puissance

nominale.

Se reporter aussi au Tableau 4 de la Section 8.0 pour

l’information sur l’appel de courant du moteur.

4.4 Niveau d’huile

Vérifiez le niveau d’huile du moteur avant le démarrage. Si le

niveau d’huile est bas, retirez le bouchon SAE nº 10 de la rallonge

du tuyau de remplissage et ajouter de l’huile au besoin (voir la

figure 1).

Le réservoir est plein lorsque le niveau d’huile est au niveau

illustré dans la figure 4.

Le réservoir est

plein lorsque

l’huile a atteint

ce niveau.

(0,88 et 1,76 gal)

4 et 8 litres

10 à 40 litres

(2,20 à 8,80 gal)

Figure 4

B

Figure 3

IMPORTANT : ajoutez de l’huile seulement lorsque les

composants sont complètement rétractés, sinon le système

contiendra plus d’huile que peut en contenir le réservoir.

17

4.5 Liaisons hydrauliques

Figure 5

Appliquez 1 tour et demi de

bande Téflon ou tout autre

adhésif adéquat à l’installation

du flexible hydraulique, en

laissant le premier filet complet

sans bande ou adhésif comme

montré dans la Figure 5.

Flèche vers le haut

®

Flèche vers le bas

ON/OFF (désactivée –

hors tension)

Vissez le ou les tuyaux flexibles dans le ou les ports de sortie de

la soupape (les ports de sortie de la soupape sont identifiés sur

le corps de la soupape).

Brancher le flexible de serrage (allongé) à l’orifice de vanne “A”.

Brancher le flexible de desserrage (rétracté) à l’orifice de vanne

“B”.

Si vous le souhaitez, un manomètre peut être installé dans l’orifice

de vanne “GA” ou “GB”.

Remarque : “GA” mesure la pression de l’orifi ce “A”, “GB” mesure

la pression de l’orifi ce “B”, “GP” mesure la pression de la pompe

en aval du contrôle du système. Le transducteur de pression de la

pompe est installé en usine dans l’orifi ce “GP” et doit resté installé

à cet endroit pour garantir le bon fonctionnement de la pompe.

5.0 FONCTIONNEMENT

AVERTISSEMENT : Revoir les sections 5.1-5.4 et 6.1-

6.4 avant de démarrer la pompe. S’assurer que le mode

de fonctionnement Dwell et les fonctions sont clairement

compris avant de relier le module à une source de courant.

1. Vérifiez le niveau d’huile de la pompe et ajoutez de l’huile au

besoin.

2. Assurez-vous que le bouchon d’expédition a été retiré et que

le reniflard est bien installé. (Voir la section 4.1)

3. Branchez l’unité à l’alimentation. Attendez que l’écran

ACL affiche « PRET » avant d’appuyer sur tout bouton du

carénage ou de la télécommande. Remarque: Pendant la

séquence de démarrage, le microcontrôleur identifie toute

utilisation d’un bouton comme une défaillance potentielle

et empêche le moteur de démarrer. Pour réinitialiser le

démarrage, coupez l’alimentation de l’appareil pendant

trente

secondes.

4. Pour un aperçu du fonctionnement de la pompe, y compris

les fonctions de la télécommande, se reporter aux sections

5.1-5.4. Pour des consignes détaillées sur le fonctionnement

du panneau de commande LCD, voir sections 6.1-6.4.

5.1 Fonctionnement de la télécommande

(voir la figure 6)

Le débit d’huile et le moteur sont tous deux contrôlés par les

commandes de la télécommande. La pompe démarre et le

piston se serre lorsqu’on enfonce le bouton de flèche vers le

haut de la télécommande. La pompe démarre et le piston se

desserre lorsqu’on enfonce le bouton de flèche vers le bas

de la télécommande. Lorsqu’on relâche l’un ou l’autre de ces

boutons, la pompe s’arrête et la pression se décharge dans les

flexibles (voir la figure 6).

1. Flèche vers le haut = moteur sous tension - serrage courte

durée

2. Flèche vers le bas = moteur sous tension - desserrage

courte durée

3. On/Off – non utilisée (désactivée)

Carénage On/Off – non utilisée (désactivée)

Figure 6

5.2 Option d’interrupteur au pied

(voir la figure 7).

1. Moteur sous tension – serrage

courte durée

2. Moteur sous tension – desserrage

courte durée

Carénage On/Off = non utilisée

(désactivée)

Figure 7

5.3 Fonctionnement du mode Dwell automatique

Le mode Dwell permet à la pompe de réagir automatiquement

selon deux valeurs de pression définies par l’utilisateur, «

PRESR A » et « PRESR B ». Cette fonction peut être activée

et désactivée tel que désiré. Voir les paragraphes suivants

pour obtenir des informations supplémentaires. Référez-vous

aussi à la section 6.2 pour obtenir plus de détails concernant le

fonctionnement et le réglage du mode Dwell.

1. Mode Dwell Off

Le panneau de commande LCD de la pompe indique la pression

comme un simple manomètre. Aucune action supplémentaire ne

sera menée quelques soient les valeurs PRESR A et PRESR B.

2. Mode Dwell On

La pompe désactivera le moteur et le solénoïde de la soupape

dès que la valeur de pression PRESR A ou PRESR B spécifiée

sera atteinte et que la durée (en secondes) de la fonction

Dwell sera écoulée. Lorsque la pompe s’arrête, la pression des

flexibles tombe à zéro (0) pour que les coupleurs puissent être

déconnectés de la palette.

Remarque: « AUTO » s’affiche sur le panneau ACL lorsque le

mode Dwell est activé. « PRET » s’affiche lorsque le mode Dwell

est désactivé.

5.3.1 Aperçu du mode Dwell

Avant que la valeur PRESR A ou PRESR B soit atteinte :

• Les boutons de flèche vers le haut et de flèche vers le bas

de la télécommande fonctionnent tel qu’indiqué dans la

section 5.1.

Après que la valeur PRESR A ou PRESR B soit atteinte :

• Tenez le bouton de flèche enfoncé vers le haut ou le

bas après que la valeur de pression ait été atteinte pour

activer la minuterie de la fonction dwell. Le rétroéclairage

de l’écran ACL clignotera et la pompe continuera à

fonctionner jusqu’à la fin de la période d’exécution de la

fonction dwell définie par l’utilisateur (1 à 60 secondes).

• Afin d’assurer un serrage et un desserrage appropriés, les

boutons des flèches vers le haut et vers le bas doivent

demeurer enfoncés jusqu’à l’arrêt de la pompe.

• Le relâchement d’un de ces boutons (flèche vers le haut

ou vers le bas) arrêtera automatiquement le cycle et l’écran

ACL arrêtera de clignoter.

18

Loading...

Loading...