Page 1

1

POWERFUL SOLUTIONS. GLOBAL FORCE.

Instruction Sheet

High Tonnage Hydraulic Cylinders

HCRL-Series

L4247 Rev. A 03/18

Table of Contents:

Section Page

1.0 IMPORTANT RECEIVING INSTRUCTIONS ......1

2.0 SAFETY .................................1

3.0 CONFORMANCE TO NATIONAL AND

INTERNATIONAL STANDARDS ...............3

4.0 PRODUCT DESCRIPTION ...................3

5.0 LIFTING THE CYLINDER ....................4

6.0 SETUP ..................................4

7.0 AVOIDING SIDE LOAD ......................5

8.0 OPERATION ..............................5

9.0 INSPECTION, MAINTENANCE & STORAGE .....5

10.0 RELIEVING TRAPPED PRESSURE ...........5

11.0 TROUBLESHOOTING .....................6

12.0 PRODUCT DATA ..........................7

1.0 IMPORTANT RECEIVING INSTRUCTIONS

Visually inspect all components for shipping damage. Shipping

damage is not covered by warranty. If shipping damage is

found, notify carrier at once. The carrier is responsible for

all repair and replacement costs resulting from damage in

shipment.

2.0 SAFETY

2.1 Introduction

Read all instructions carefully. Follow all recommended safety

precautions to avoid personal injury as well as damage to the

product and/or damage to other property. Enerpac cannot be

responsible for any damage or injury from unsafe use, lack of

maintenance or incorrect operation. Do not remove warning

labels, tags, or decals. In the event any questions or concerns

arise, contact Enerpac or a local Enerpac distributor for

clarification.

If you have never been trained on high-pressure hydraulic

safety, consult your distributor or service center for information

about an Enerpac Hydraulic Safety Course.

This manual follows a system of safety alert symbols, signal

words and safety messages to warn the user of specific

hazards. Failure to comply with these warnings could result

in death or serious personal injury, as well as damage to the

equipment or other property.

The Safety Alert Symbol appears throughout this

manual. It is used to alert you to potential physical

injury hazards. Pay close attention to Safety Alert

Symbols and obey all safety messages that follow this symbol

to avoid the possibility of death or serious personal injury.

Safety Alert Symbols are used in conjunction with certain

Signal Words that call attention to safety messages or property

damage messages and designate a degree or level of hazard

seriousness. The Signal Words used in this manual are

WARNING, CAUTION and NOTICE.

WARNING

Indicates a hazardous situation that, if not

avoided, could result in death or serious

personal injury.

CAUTION

Indicates a hazardous situation that, if not

avoided, could result in minor or moderate

personal injury.

NOTICE

Indicates information considered important,

but not hazard related (e.g. messages

relating to property damage). Please note

that the Safety Alert Symbol will not be used

with this signal word.

2.2 Hydraulic Cylinder Safety Precautions

(HCRL-Series)

WARNING

Failure to observe and comply with the following

precautions could result in death or serious personal

injury. Property damage could also occur.

• Read and completely understand the safety precautions and

instructions in this manual before operating the cylinder or

preparing it for use. Always follow all safety precautions and

instructions, including those that are contained within the

procedures of this manual.

• Operating procedures will vary, depending on the system

arrangement and the specific components being used.

Always read, follow and completely understand all

manufacturer's instructions when operating pumps, valves

and all other devices used with the cylinders. Follow all

safety precautions contained in the manufacturer's manuals.

• Always wear appropriate personal protective equipment

(P.P.E.) when operating hydraulic equipment. Be sure to

wear eye protection, work gloves and protective clothing.

Page 2

2

Use of additional P.P.E. safety items such as dust mask,

non-skid safety shoes, hard hat, and hearing protection

(used as appropriate for the conditions) will reduce the

chance of personal injuries. The use of these items may also

be required by local regulations or laws.

• Do not handle pressurized hoses. Escaping oil under

pressure can penetrate the skin. If oil is injected under the

skin, see a doctor immediately.

• Do not pressurize disconnected couplers.

• Use hydraulic cylinders only in a coupled system. It is

acceptable to use a cylinder with a disconnected coupler

only if the load is mechanically supported by the cylinder

lock nut, and all hydraulic pressure is completely relieved.

• When holding loads, be certain that the lock nut is turned

down firmly against the cylinder base so that the load is

mechanically supported. Also be sure that all hydraulic

pressure is completely relieved.

• Do not remove or disable the pump relief valve.

• Do not remove or disable the cylinder relief valve (if equipped).

• The system operating pressure must not exceed the pressure

rating of the lowest rated component in the system.

• Install pressure gauge(s) in the system to monitor operating

pressure. It is your window to see what is happening in the system.

• Never set a relief valve to a higher pressure than the

maximum rated pressure of the pump and cylinder. If ratings

are dierent, relief valve setting should not exceed the

setting of the lowest rated component (pump or cylinder).

• The HCRL-Series cylinders are designed for a maximum

working pressure of 10150 psi [700 bar]. Do not connect a

pump with a higher pressure rating to these cylinders.

• Do not exceed equipment ratings. Never attempt to lift a

load weighing more than the rated capacity of the cylinder.

Overloading may cause equipment failure and possible

personal injury.

• Be sure setup is stable before lifting load. Cylinders should

be located on a firm and level surface capable of supporting

the full load.

• Where applicable, use a cylinder base plate to provide

added stability. If desired, the cylinder can be bolted to the

base plate, using the bolt holes in the bottom of the cylinder

base.

• Do not weld, drill or otherwise modify a cylinder to attach a

base plate or other support unless approved in writing by

Enerpac Engineering Department. Use only the provided

bolt holes.

• Always perform a visual inspection of the cylinder before

placing it into operation. If any problems are found, do not

use the cylinder. Have the cylinder repaired and tested

before it is returned to service.

• Never use a cylinder that is leaking oil. Do not use a cylinder

that is damaged, altered or in need of repair.

• Always lift the cylinder using a hoist, crane or other suitable

lifting device of sucient rated capacity. Use only the

supplied cylinder lifting eyes to attach the cylinder to the

lifting device. Replace any missing or damaged lifting eyes.

• Allow only trained and experienced personnel to supervise

and perform lifting and lowering procedures.

• Be certain that no persons are working on or near any

cylinders before lifting or lowering of the load begins. Alert all

personnel in advance that lifting or lowering is about to occur.

• Use suitable cribbing of rigid construction to hold loads.

• Never use a hydraulic cylinder as a shim or spacer in any

lifting or pressing application.

• Be certain that the load is centered and covers the entire

plunger saddle surface. Avoid situations where loads are not

directly centered on the plunger saddle. The load may slip or

fall, causing potential danger.

• Lift only dead weight loads. Avoid lifting live weight loads.

• Be especially careful when lifting loads such as partially filled

storage tanks, in which the center of gravity could move or

shift during lifting. Be aware that the distribution of some

loads can change quickly and without warning.

• Do not use the cylinder to lift people. Do not allow people to

be on top of the load during lifting or lowering.

• Keep all personnel clear of the work area while lifting or

lowering is in progress. To avoid personal injury, keep hands

and feet away from cylinder and load during operation.

• Maintain communication with the operator at all times during

lifting or lowering to avoid accidents. Use hand signals, twoway radios or other appropriate forms of communication (as

required by applicable laws and regulations) if the load is not

visible to the operator.

• Operate pump and valve as required to ensure that the load

is lifted and lowered evenly and at a controlled rate.

• Closely watch the load at all times during lifting and lowering.

Stop lifting or lowering immediately if the load becomes

unstable or appears to be lifting or lowering unevenly.

• Stay clear of loads supported only by hydraulics. As required,

follow the lifted load with cribbing.

• Never allow persons to work under or near the load while the

load is being supported hydraulically. After the load has been

raised or lowered, it always must be blocked mechanically

by the cylinder lock nut or via suitable cribbing.

• Always be certain that hydraulic pressure is fully relieved

and that the load is fully removed from the cylinder(s) before

disconnecting hydraulic hoses, loosening hydraulic fittings,

or performing any cylinder disassembly or repair procedures.

CAUTION

Failure to observe and comply with the following

precautions could result in minor or moderate personal

injury. Property damage could also occur.

• Be careful to avoid damaging hydraulic hoses. Avoid sharp

bends and kinks when routing hydraulic hoses. Do not

exceed the minimum bend radius specified by the hose

manufacturer. Using a bent or kinked hose will cause severe

back-pressure. Sharp bends and kinks will internally damage

the hose, leading to premature hose failure.

• Do not drop heavy objects on hoses. A sharp impact may

cause internal damage to hose wire strands. Applying

pressure to a damaged hose may cause it to rupture.

• Do not lift hydraulic equipment by the hoses or couplers.

Use the cylinder lifting eyes and appropriately rated lifting

equipment.

• Keep hydraulic equipment away from flames and heat.

Excessive heat will soften packings and seals, resulting in

fluid leaks. Heat also weakens hose materials and packings.

• For optimum performance, do not expose hydraulic

equipment to temperatures of 150˚F [65˚C] or higher. Protect

all hydraulic equipment from weld spatter.

• Immediately replace worn or damaged parts with genuine

Enerpac parts. Enerpac parts are designed to fit properly

and to withstand high loads. Non-Enerpac parts may break

or cause the product to malfunction.

NOTICE

• Hydraulic equipment must only be serviced by a qualified

hydraulic technician. For repair service, contact the Enerpac

Authorized Service Center in your area.

• To help ensure proper operation and best performance, use

of Enerpac oil is strongly recommended.

Page 3

3

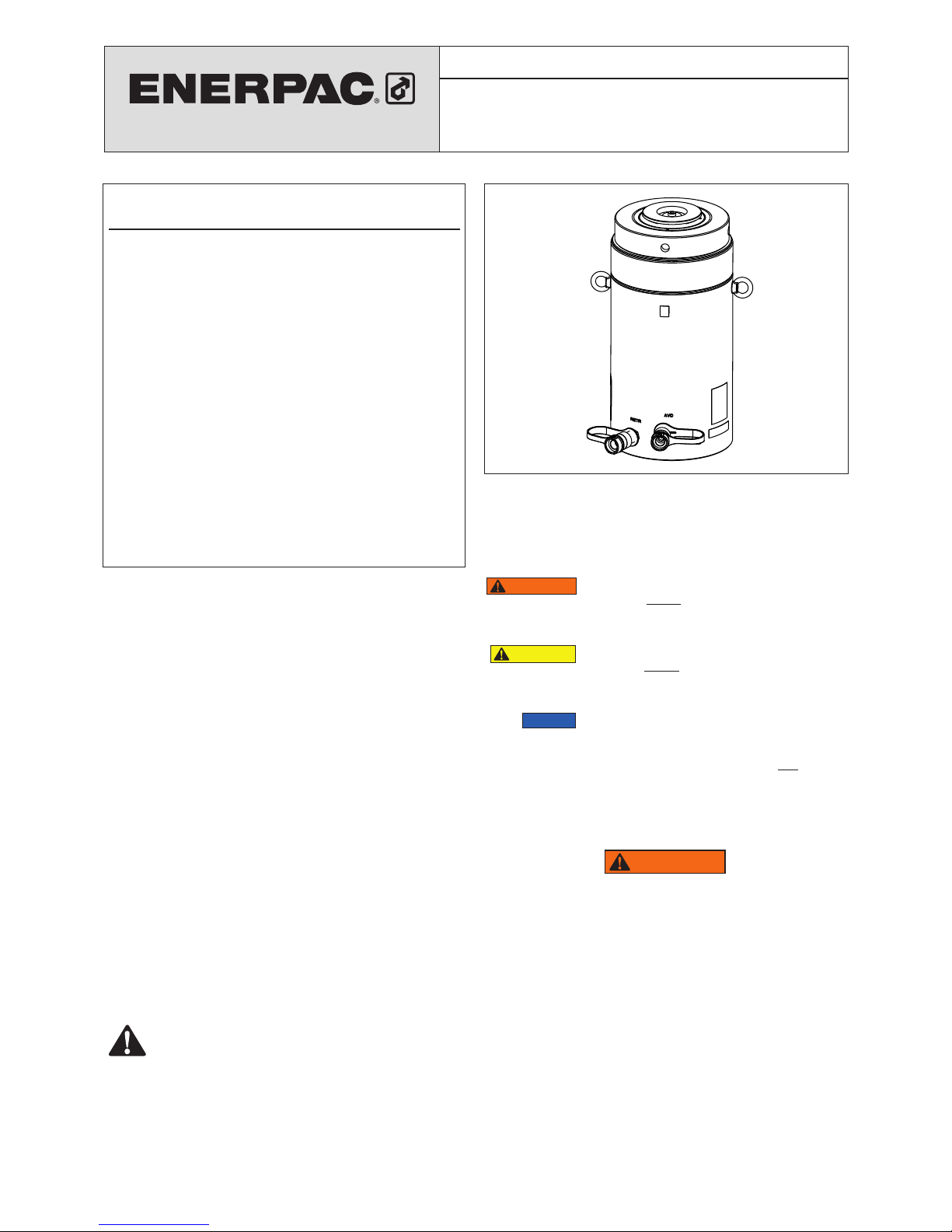

1

8

2

5

4

6

7

9

10

3

Key:

1. Tilt Saddle

2. Plunger

3. Lock Nut

4. Collar Threads

5. Cylinder Base

6. Safety Relief Valve

7. Hydraulic Coupler (advance)

3/8"-18 NPTF

8. Hydraulic Coupler (retract)

3/8"-18 NPTF

9. Lifting Eye

10. Stop Ring

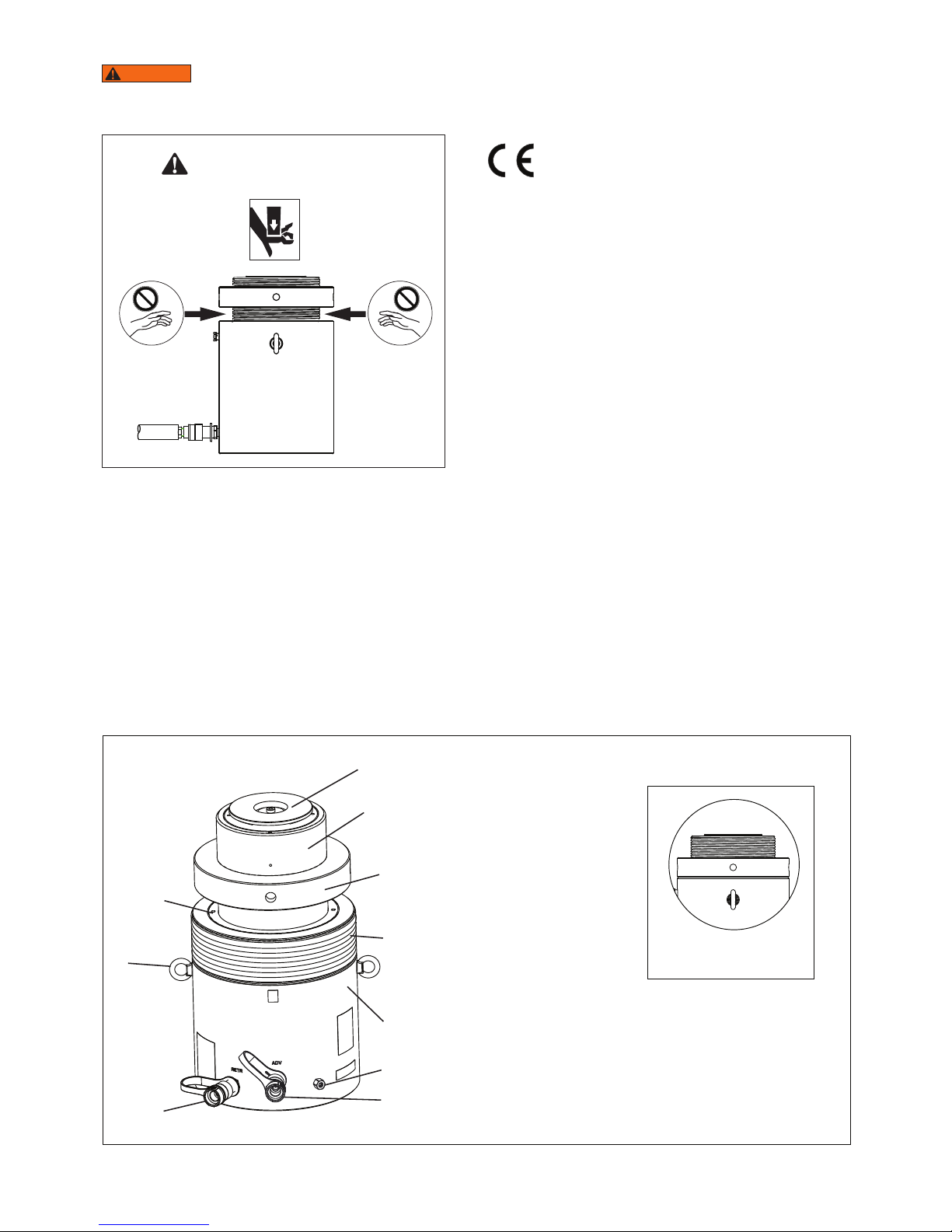

2.3 Crush and Pinch Point Hazard (HCRL-Series)

WARNING

Never reach in between the cylinder lock

nut and the top of the cylinder base. Serious personal

injury can occur if cylinder is retracted and hands, fingers

or other body parts are present in this area. See Figure 1.

CRUSH AND PINCH POINT HAZARD

Do not reach in between lock nut

and cylinder base!

Figure 1, Crush and Pinch Point Hazard

2.4 Additional Safety References

Consult the applicable industry and/or government standards

in your country or region for additional safety precautions and

work rules applicable to hydraulic cylinders, jacks and other

similar lifting equipment.

In the USA, refer to the following publications:

• Code of Federal Regulations - Title 29 Occupational Safety

and Health Standards (U.S. Government Publishing Oce,

732 North Capitol Street, NW, Washington, DC 20401-0001.

www.gpo.gov).

• ASME B30.1 Standards - Jacks (American Society of

Mechanical Engineers, Two Park Avenue, New York, NY

10016-5990. www.asme.org).

In the European Union, refer to the standards and directives

listed in the product's EU Declaration of Incorporation. A copy

of this document is packed separately with the cylinder.

3.0 CONFORMANCE TO NATIONAL AND

INTERNATIONAL STANDARDS

Enerpac declares that this product has been tested

and conforms to applicable standards and is

compatible to all CE Requirements. A copy of an EU

Declaration of Incorporation is enclosed with each shipment of

this product.

4.0 PRODUCT DESCRIPTION

Enerpac HCRL-Series cylinders are an ideal solution for a wide

variety of commercial and industrial lifting applications.

HCRL-Series cylinders are double-acting with hydraulic

advance and return. A lock nut provides mechanical load

holding capabilities.

The hydraulic return feature allows greater control during

lowering and provides positive retraction of the plunger. Note

that the HCRL-Series cylinders are not designed for pulling

applications.

Capacities range from 62 to 1196 US tons [550 to 10644 kN].

Refer to the product data markings on the cylinder base for the

capacity rating of your cylinder model.

All standard production HCRL-Series cylinders are designed

for 10150 psi [700 bar] maximum working pressure.

An integrated tilt saddle is standard equipment on all models.

Refer to Section 12 of this manual for cylinder weights, oil

volumes, dimensions and additional specifications.

Figure 2, Major Features and Components

LOCK NUT TIGHTENED

(Mechanical Load Holding)

Page 4

4

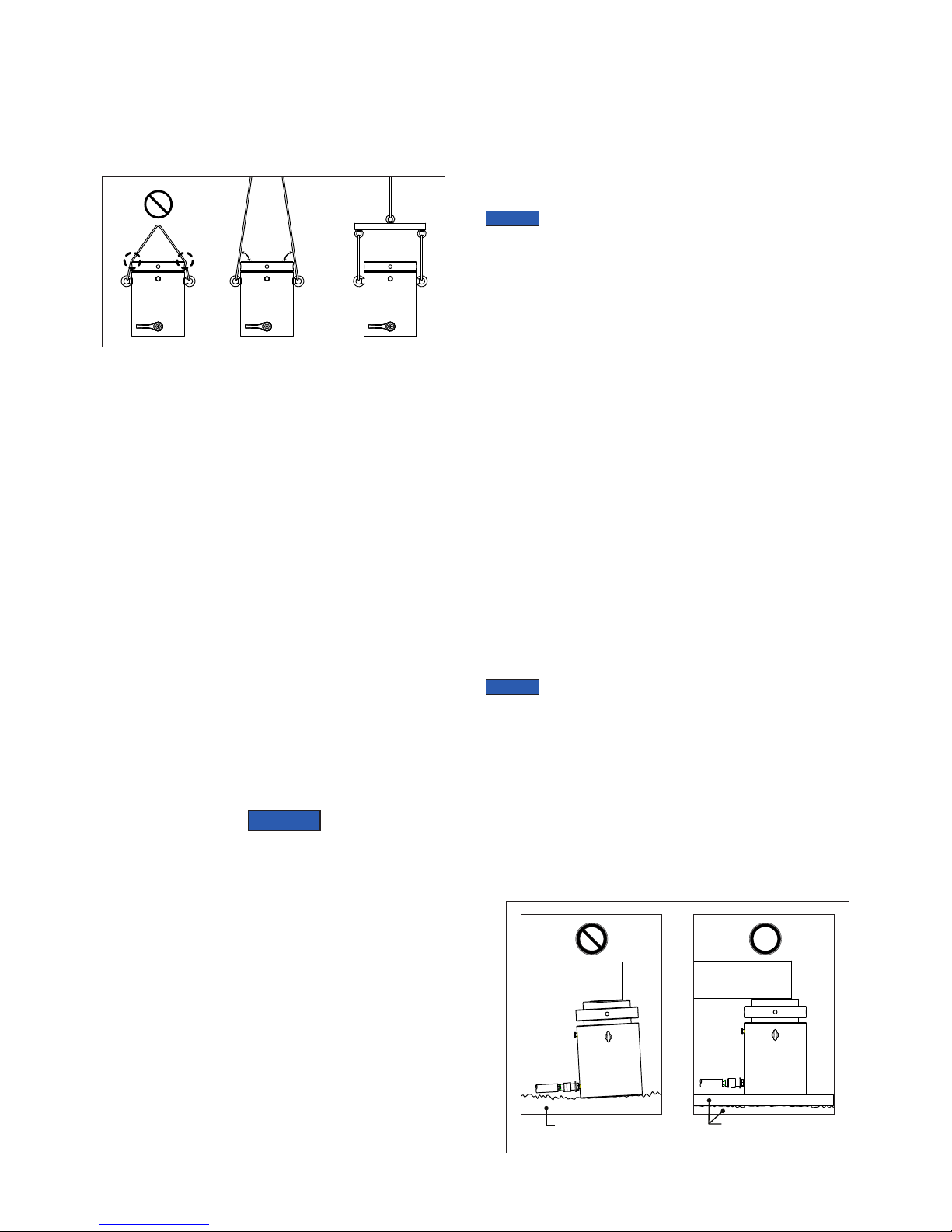

5.0 LIFTING THE CYLINDER

All HCRL-Series cylinders are equipped with TWO pre-installed

lifting eyes. Always use both lifting eyes when hoisting the

cylinder.

Lifting straps or chains must be positioned at an angle where

they will not interfere with the cylinder base. Use of a spreader

bar is recommended. See Figure 3.

Figure 3, Lifting Arrangements (typical)

OK

OK

6.0 SETUP

6.1 Hydraulic Pump Requirements

Hydraulic pumps are sold separately and are not included with

the cylinders.

A hand-operated hydraulic pump can be used to operate a

smaller HCRL-Series cylinder. However, a large size cylinder

(or a series of coupled cylinders) will typically require the use of

an electric, air or gas powered hydraulic pump.

Whichever type of pump is used, be certain that the pump

reservoir is capable of holding a sucient amount of hydraulic

oil to operate the cylinder (or set of cylinders) to full extension.

The pump must be equipped with a four-way directional control

valve. This valve may be either manual or remote operated.

The pump must also be equipped with a separate safety

pressure relief valve that opens if the system working pressure

exceeds 10150 psi [700 bar]. Verify that the pump safety relief

valve is adjusted to the proper setting before using the pump

with the cylinder(s).

6.2 Hydraulic Oil Requirements

Use of Enerpac HF Series ISO 32 hydraulic oil is recommended.

Enerpac HF oil is available at your local Enerpac Distributor or

Authorized Service Center.

NOTICE

• Failure to use the correct oil type (high-quality ISO 32

hydraulic oil) may result in damage to cylinder hydraulic

components and will void the product warranty.

• Be sure that the oil is clean. The oil cleanliness should

be maintained to a maximum level of 18/16/13 per the

ISO 4406 standard. If the oil develops a milky, cloudy or

dark appearance, it should be changed immediately.

• To avoid overfilling and possible equipment damage, add

oil to the pump reservoir only after all cylinder plungers are

completely retracted and system pressure is released.

• When using a hand-operated pump to power the cylinder(s),

it is permissible to use a high-quality brand of ISO 15

hydraulic oil. The lower oil viscosity will result in reduced

pumping eort, especially in cold weather conditions.

6.3 Hydraulic Connections

HCRL-Series cylinders are equipped with two 3/8"-18 NPTF

female couplers, one for advance side hydraulic flow and one

for retract side hydraulic flow.

Refer to Figure 2, items 7 and 8 for locations.

Be certain that all couplers are fully connected, so that hydraulic

flow is not blocked or restricted.

All hoses, fittings and other hydraulic components in the circuit

must be rated for at least 10150 psi [700 bar] operation.

NOTICE

HCRL-Series cylinders are double-acting. In both

operational modes, return oil flow (from the non-pressurized

side of the cylinder) must be directed back to the hydraulic

reservoir. Check for proper flow before placing the equipment

into operation.

6.4 Air Removal

Trapped air must be removed from the hydraulic cylinder and

hoses before placing the system into operation. If multiple

cylinders are to be used, it is recommended that air be

removed from each cylinder individually. Refer to the following

procedure:

1. Place the cylinder in the vertical position, with the base

located on a flat and level surface. Be sure that there is no

load on the plunger.

2. Verify that the lock nut is positioned at the top of the

plunger. This will allow the plunger to be fully retracted

during the air removal process.

3. Position the hydraulic pump so it is located higher than the

cylinder.

4. Fully advance and retract the plunger, being careful to avoid

pressure build-up at full extension and full retraction. Repeat

this process until plunger motion is smooth in both directions.

5. Fully retract the plunger after completing air removal

procedures. Check oil level in pump hydraulic reservoir.

Add oil if oil level is low.

6. Repeat steps 1 through 5 for all cylinders to be used in the

hydraulic circuit.

NOTICE

Refer to Section 6.2 of this document for hydraulic

oil requirements. Follow the pump manufacturer's instructions

when adding oil to the pump reservoir. To avoid overfilling, be

certain that the cylinder plunger is fully retracted before adding

any oil.

6.5 Cylinder Base Support

Be certain to provide adequate support for the cylinder base.

All HCRL-Series cylinders require a flat and stable lifting

surface that is capable of supporting the load without settling.

A steel plate or steel bars of appropriate size should be placed

between the cylinder base and the ground or other lifting

surface. See Figure 4.

OK

OK

Figure 4, Cylinder Base Support

OK

Rough and

unstable surface

Flat and stable

surface with steel plate

OK

Page 5

5

CAUTION

Use of HCRL-Series cylinders on surfaces

such as sand, mud or dirt may result in loss of load and/

or damage to cylinder.

Base mounting holes are provided on all models. Refer to

sections 12.1 and 12.2 for mounting hole locations and

dimensions. Mounting bolts are not included with the cylinder

and must be provided by the user.

7.0 AVOIDING SIDE LOAD

Plan ahead to eliminate the presence of side load forces (oset

loading) when using hydraulic cylinders. Side load can occur

as a result of one or more of the following conditions:

• An eccentric load on the plunger. • A horizontal load on a

structure. • A shifting center of gravity. • Structure and/or cylinder

misalignment. • Non-synchronized lifting actions. • Non-stable

cylinder base support.

It is understood that some side load will occur in many lifting

situations. However, the user should do everything possible to

minimize or eliminate this condition.

The possibility of side load can be reduced by ensuring that

the cylinder base is located on a flat and hard surface, capable

of supporting the cylinder and the load without settling.

To help reduce the eects of minimal side load that cannot

be eliminated, all HCRL-Series cylinders are equipped with an

integral tilt saddle. The tilt saddle helps compensate for initial

misalignment of the load and the saddle surface. It reduces

saddle edge loading, which can result in an undesirable ocenter load being applied to the plunger.

8.0 OPERATION

Operation procedures will vary, depending on hydraulic pump

type, valve configuration and other factors. For detailed

operating instructions and related information, refer to the

instruction sheet included with your pump. Also follow the

additional instructions and precautions contained in sections

8.1 and 8.2 of this manual.

If using multiple HCRL-Series cylinders: Without load, verify

that all plungers advance and retract in the same direction

when the control valve is shifted. If necessary, relieve pressure

and properly reconnect any reversed hydraulic hoses.

8.1 Operating Instructions

WARNING

To prevent serious personal injury, keep

hands, fingers and other body parts clear of pinch point

area between lock nut and cylinder base during cylinder

operation (refer to Section 2.3 for additional details). Be

certain that plunger is not moving when tightening or

loosening lock nut.

To advance: Operate pump and valve so that pressurized oil

flow is directed in a controlled rate from the pump reservoir to

the cylinder advance coupler.

To hold the load: Tighten the lock nut until it is snug against the

top edge of the cylinder base. This will mechanically prevent

the plunger from retracting when hydraulic pressure is relieved.

To loosen lock nut: Advance the plunger about 1/4 inch [6

mm] to remove any weight from the lock nut. Then, loosen the

lock nut the desired number of turns, using a tommy bar of

appropriate diameter.

To retract: Be sure that the locknut has been loosened a

sucient amount of turns, so that the plunger can be retracted

the desired amount. Then, operate pump and valve so that

pressurized oil flow is directed from the pump reservoir to

the cylinder retract coupler. Note that additional hydraulic

components may be required to control the rate at which the

plunger retracts under load.

8.2 Retract Side Safety Relief Valve

HCRL-Series cylinders include a retract side safety relief valve.

It is located near the bottom of the cylinder base. See Figure

2, item 6.

The valve is designed to relieve retract chamber pressure in

the event that hydraulic flow is directed to the advance side

of the cylinder while the retract side hose is disconnected. It is

factory set at approximately 862-896 bar [12500-13000 psi].

WARNING

Do not remove, alter or disable the retract

side safety relief valve. Do not readjust the valve setting.

Failure to observe this instruction may result in possible

catastrophic failure of the cylinder. Serious personal injury

could result.

9.0 INSPECTION, MAINTENANCE & STORAGE

• Periodically check the hydraulic system for loose

connections leaks and obvious problems. Replace any

damaged components immediately.

• Monitor the hydraulic oil temperature during operation. Do

not exceed oil temperatures above 150°F [65°C].

• Install dust caps and plugs on all hydraulic couplers after the

hydraulic hoses are disconnected from the cylinder.

• Keep all hydraulic components clean.

• Periodically check the tilt saddle for free movement. If

required, disassemble, clean and lubricate the tilt saddle.

Use white lithium grease.

• Change the hydraulic oil at the recommended interval shown

in the pump instruction sheet. Change the oil immediately if

contamination is suspected.

• Store cylinders in the vertical position, in a clean, dry and

secure location. Keep stored cylinders and hoses away from

heat and direct sunlight.

• If repairs are required, refer to the Enerpac website for the

repair parts sheet applicable to your cylinder model.

NOTICE

Hydraulic equipment must only be serviced by a

qualified hydraulic technician. For repair service, contact the

Enerpac Authorized Service Center in your area.

10.0 RELIEVING TRAPPED PRESSURE

Hydraulic pressure can sometimes become trapped within

a hydraulic cylinder. This condition can occur in both single

and double-acting cylinders, but is most likely to happen in

a double-acting cylinder that has been exposed to changing

ambient temperatures.

A common indication of trapped pressure is when mating hose

and cylinder couplers will not engage, or are unusually dicult

to engage.

If a trapped pressure condition is suspected, always use the

Enerpac model CT-604 coupler bleed tool (available from your

Enerpac distributor) to safely relieve any remaining pressure.

WARNING

Never attempt to relieve trapped hydraulic

pressure within the cylinder by loosening a coupler on the

cylinder base.

Trapped hydraulic pressure can cause a loosened coupler

to dislodge unexpectedly with great force. Serious

personal injury or death will result if the coupler becomes

a projectile and strikes persons working in the area.

A sudden escape of pressurized hydraulic oil may also

occur if a coupler is loosened while trapped hydraulic

pressure is present. Serious personal injury or death could

result if a high pressure oil stream penetrates the skin.

Use only the Enerpac CT-604 coupler bleed tool to relieve

trapped hydraulic pressure within the cylinder.

Page 6

6

WARNING

Never use a hammer and punch (or other

similar method) to unseat a coupler check ball that is under

pressure. Serious personal injury or death could result due

to the sudden and uncontrolled escape of high pressure

oil. Use only the Enerpac CT-604 coupler bleed tool to

relieve trapped pressure within the cylinder.

Troubleshooting Guide

Symptom Possible Cause Solution

1. Plunger will not

advance.

a. Directional control valve not in proper position. Shift directional control valve to proper position.

b. Coupler not fully tightened. Tighten coupler.

c. Pump oil level is low. Add oil to pump reservoir as required. See Section 6.2.

d. Pump malfunctioning. Repair or replace pump as required.

e. Cylinder load rating too low for application. Use a cylinder with a higher load rating.

f. Cylinder seals leaking. Repair or replace cylinder.

2. Plunger advances

only part way.

a. Pump oil level is low. Add oil to pump reservoir as required. See Section 6.2.

b. Coupler is not fully tightened. Tighten coupler.

c. Cylinder plunger binding. Repair or replace cylinder.

3. Plunger advances

erratically.

a. Air in hydraulic system. Remove air from hydraulic system. See Section 6.4.

b. Cylinder plunger binding. Repair or replace cylinder.

4. Plunger advances

more slowly than

normal.

a. Leaking connection. Repair leaking connection.

b. Coupler not fully tightened. Tighten coupler.

c. Pump malfunctioning. Repair or replace pump as required.

5. Plunger advances, but

will not hold.

a. Pump malfunctioning. Repair or replace pump as required.

b. Leaking connection. Repair leaking connection.

c. Incorrect system set-up. Check hose connections at pump and cylinders.

d. Cylinder seals leaking. Repair or replace cylinder.

6. Cylinder leaks oil. a. Loose connection. Tighten or repair connection.

b. Worn or damaged cylinder seals. Repair or replace cylinder.

c. Internal cylinder damage. Repair or replace cylinder.

7. Plunger will not retract

or retracts more

slowly than normal.

a. Directional control valve not in proper position. Shift directional control valve to proper position.

b. Lock nut not loosened. Loosen lock nut a sucient amount of turns.

c. Pump reservoir is overfilled. Drain oil from pump reservoir as required.

d. Improper hose connections. Check hose connections.

e. Narrow hose restricting oil flow. Replace with larger diameter hose.

f. Cylinder plunger binding and/or internal damage. Repair or replace cylinder.

8. Oil leakage from

external relief valve.

a. Coupler not fully tightened. Tighten coupler.

b. Restriction in return line. Remove restriction from return line.

c. Relief valve setting incorrect. Check relief valve setting.

d. Relief valve damaged or contaminated. Repair or replace relief valve.

11.0 TROUBLESHOOTING

Refer to the troubleshooting guide when diagnosing cylinder

operational problems. Please note that the troubleshooting

guide is not all-inclusive, and should be considered only as

an aid to help diagnose the most common possible problems.

For repair service, contact your nearest Enerpac Authorized

Service Center. As required, also refer to the troubleshooting

information provided with your hydraulic pump or power unit.

Page 7

7

U

U

X

W

H1

H2

S

0-5˚

HCRL-50-150

HCRL-200, 300

Figure 5, Dimensions - HCRL-Series

12.0 PRODUCT DATA

Refer to Sections 12.1 and 12.2 for the

dimensions applicable to your cylinder

model. Use this graphic as a reference.

Page 8

8

12.1 Dimensions, HCRL-Series (imperial)

Cylinder

Model

Number

Collapsed

Height

Extended

Height

Outside

Diameter

Cylinder Bore

Diameter

Plunger

Diameter

(threaded)

Base to

Advance

Port

Base to

Retract

Port

Saddle

Diameter

A B D E F H1 H2 J

in in in in mm in in in

HCRL-506 12.2 18.11 5.12 3.93 TR 90 x 4 1.61 1.04 3.02

HCRL-508 14.84 22.71 5.12 3.93 TR 90 x 4 1.61 1.04 3.02

HCRL-5010 16.81 26.65 5.12 3.93 TR 90 x 4 1.61 1.04 3.02

HCRL-5012 18.77 30.59 5.12 3.93 TR 90 x 4 1.61 1.04 3.02

HCRL-1006 13.62 19.52 7.28 5.51 TR 120 x 6 1.97 1.41 3.02

HCRL-1008 16.57 14,44 7.28 5.51 TR 120 x 6 1.97 1.41 3.02

HCRL-10010 18.54 28.38 7.28 5.51 TR 120 x 6 1.97 1.41 3.02

HCRL-10012 20.51 32.32 7.28 5.51 TR 120 x 6 1.97 1.41 3.02

HCRL-1506 14.13 20.03 8.74 6.69 TR 150 x 6 1.81 1.24 4.96

HCRL-1508 17.09 24.96 8.74 6.69 TR 150 x 6 1.81 1.24 4.96

HCRL-15010 19.06 28.90 8.74 6.69 TR 150 x 6 1.81 1.24 4.96

HCRL-15012 21.02 32.83 8.74 6.69 TR 150 x 6 1.81 1.24 4.96

HCRL-2006 15.70 21.61 10.24 7.87 TR 170 x 6 2.80 1.92 4.96

HCRL-2008 18.46 26.34 10.24 7.87 TR 170 x 6 2.80 1.92 4.96

HCRL-20010 20.43 30.28 10.24 7.87 TR 170 x 6 2.80 1.92 4.96

HCRL-20012 22.40 34.21 10.24 7.87 TR 170 x 6 2.80 1.92 4.96

HCRL-2506 16.38 22.28 11.42 8.66 TR 190 x 6 2.80 1.92 6.30

HCRL-2508 19.33 27.20 11.42 8.66 TR 190 x 6 2.80 1.92 6.30

HCRL-25010 21.30 31.14 11.42 8.66 TR 190 x 6 2.80 1.92 6.30

HCRL-25012 23.27 35.08 11.42 8.66 TR 190 x 6 2.80 1.92 6.30

HCRL-3006 16.57 22.48 12.40 9.45 TR 210 x 6 2.80 1.92 6.30

HCRL-3008 19.53 27.40 12.40 9.45 TR 210 x 6 2.80 1.92 6.30

HCRL-30010 21.50 31.34 12.40 9.45 TR 210 x 6 2.80 1.92 6.30

HCRL-30012 23.46 35.28 12.40 9.45 TR 210 x 6 2.80 1.92 6.30

• Refer to Figure 5 for dimensions graphic. • Imperial units of measure are used in this table (except as indicated).

• Contact Enerpac for dimensions of custom ordered cylinders not shown above.

Cylinder

Model

Number

Saddle

Protrusion

Lock Nut

Height

Base Mounting Holes Collar Thread

Bolt

Circle

Thread

Size

Minimum

Thread

Depth

Number of

Holes

Angle From

Coupler

Thread Size

Thread

Length

K S U V Z W X

in in

in mm in mm in

HCRL-506 0.57 1.02 4.13 M12 x 1.75 0.87 2 90° M130 x 2 1.65

HCRL-508 0.57 1.02 4.13 M12 x 1.75 0.87 2 90° M130 x 2 1.65

HCRL-5010 0.57 1.02 4.13 M12 x 1.75 0.87 2 90° M130 x 2 1.65

HCRL-5012 0.57 1.02 4.13 M12 x 1.75 0.87 2 90° M130 x 2 1.65

HCRL-1006 0.59 1.42 5.90 M12 x 1.75 0.87 2 90° M185 x 2 2.24

HCRL-1008 0.59 1.42 5.90 M12 x 1.75 0.87 2 90° M185 x 2 2.24

HCRL-10010 0.59 1.42 5.90 M12 x 1.75 0.87 2 90° M185 x 2 2.24

HCRL-10012 0.59 1.42 5.90 M12 x 1.75 0.87 2 90° M185 x 2 2.24

HCRL-1506 0.51 1.77 7.28 M12 x 1.75 0.87 2 90° M222 x 3 2.76

HCRL-1508 0.51 1.77 7.28 M12 x 1.75 0.87 2 90° M222 x 3 2.76

HCRL-15010 0.51 1.77 7.28 M12 x 1.75 0.87 2 90° M222 x 3 2.76

HCRL-15012 0.51 1.77 7.28 M12 x 1.75 0.87 2 90° M222 x 3 2.76

HCRL-2006 0.51 1.97 8.46 M12 x 1.75 0.87 3 60° M260 x 3 3.09

HCRL-2008 0.51 1.97 8.46 M12 x 1.75 0.87 3 60° M260 x 3 3.09

HCRL-20010 0.51 1.97 8.46 M12 x 1.75 0.87 3 60° M260 x 3 3.09

HCRL-20012 0.51 1.97 8.46 M12 x 1.75 0.87 3 60° M260 x 3 3.09

HCRL-2506 0.59 2.17 9.65 M12 x 1.75 0.87 3 60° M290 x 3 3.33

HCRL-2508 0.59 2.17 9.65 M12 x 1.75 0.87 3 60° M290 x 3 3.33

HCRL-25010 0.59 2.17 9.65 M12 x 1.75 0.87 3 60° M290 x 3 3.33

HCRL-25012 0.59 2.17 9.65 M12 x 1.75 0.87 3 60° M290 x 3 3.33

HCRL-3006 0.59 2.17 10.24 M16 x 2.00 0.98 3 60° M315 x 3 3.68

HCRL-3008 0.59 2.17 10.24 M16 x 2.00 0.98 3 60° M315 x 3 3.68

HCRL-30010 0.59 2.17 10.24 M16 x 2.00 0.98 3 60° M315 x 3 3.68

HCRL-30012 0.59 2.17 10.24 M16 x 2.00 0.98 3 60° M315 x 3 3.68

• Refer to Figure 5 for dimensions graphic. • Imperial units of measure are used in this table (except as indicated).

• Contact Enerpac for dimensions of custom ordered cylinders not shown above.

Page 9

9

12.2 Dimensions, HCRL-Series (metric)

Cylinder

Model

Number

Collapsed

Height

Extended

Height

Outside

Diameter

Cylinder Bore

Diameter

Plunger

Diameter

(threaded)

Base to

Advance

Port

Base to

Retract

Port

Saddle

Diameter

A B D E F H1 H2 J

mm mm mm mm mm mm mm mm

HCRL-506 310 460 130 100 TR 90 x 4 41 27 77

HCRL-508 377 577 130 100 TR 90 x 4 41 27 77

HCRL-5010 427 677 130 100 TR 90 x 4 41 27 77

HCRL-5012 477 777 130 100 TR 90 x 4 41 27 77

HCRL-1006 346 496 185 140 TR 120 x 6 50 36 77

HCRL-1008 421 621 185 140 TR 120 x 6 50 36 77

HCRL-10010 471 721 185 140 TR 120 x 6 50 36 77

HCRL-10012 521 821 185 140 TR 120 x 6 50 36 77

HCRL-1506 359 509 222 170 TR 150 x 6 46 32 126

HCRL-1508 434 634 222 170 TR 150 x 6 46 32 126

HCRL-15010 484 734 222 170 TR 150 x 6 46 32 126

HCRL-15012 534 834 222 170 TR 150 x 6 46 32 126

HCRL-2006 399 549 260 200 TR 170 x 6 71 49 126

HCRL-2008 469 669 260 200 TR 170 x 6 71 49 126

HCRL-20010 519 769 260 200 TR 170 x 6 71 49 126

HCRL-20012 569 869 260 200 TR 170 x 6 71 49 126

HCRL-2506 416 566 290 220 TR 190 x 6 71 49 160

HCRL-2508 491 691 290 220 TR 190 x 6 71 49 160

HCRL-25010 541 791 290 220 TR 190 x 6 71 49 160

HCRL-25012 591 891 290 220 TR 190 x 6 71 49 160

HCRL-3006 421 571 315 240 TR 210 x 6 71 49 160

HCRL-3008 496 696 315 240 TR 210 x 6 71 49 160

HCRL-30010 546 796 315 240 TR 210 x 6 71 49 160

HCRL-30012 596 896 315 240 TR 210 x 6 71 49 160

• Refer to Figure 5 for dimensions graphic. • Metric units of measure are used in this table.

• Contact Enerpac for dimensions of custom ordered cylinders not shown above.

Cylinder

Model

Number

Saddle

Protrusion

Lock Nut

Height

Base Mounting Holes Collar Thread

Bolt

Circle

Thread

Size

Minimum

Thread

Depth

Number of

Holes

Angle From

Coupler

Thread Size

Thread

Length

K S U V Z W X

mm mm

mm mm mm mm mm

HCRL-506 15 26 105 M12 x 1.75 22 2 90° M130 x 2 42

HCRL-508 15 26 105 M12 x 1.75 22 2 90° M130 x 2 42

HCRL-5010 15 26 105 M12 x 1.75 22 2 90° M130 x 2 42

HCRL-5012 15 26 105 M12 x 1.75 22 2 90° M130 x 2 42

HCRL-1006 15 36 150 M12 x 1.75 22 2 90° M185 x 2 57

HCRL-1008 15 36 150 M12 x 1.75 22 2 90° M185 x 2 57

HCRL-10010 15 36 150 M12 x 1.75 22 2 90° M185 x 2 57

HCRL-10012 15 36 150 M12 x 1.75 22 2 90° M185 x 2 57

HCRL-1506 13 45 185 M12 x 1.75 22 2 90° M222 x 3 70

HCRL-1508 13 45 185 M12 x 1.75 22 2 90° M222 x 3 70

HCRL-15010 13 45 185 M12 x 1.75 22 2 90° M222 x 3 70

HCRL-15012 13 45 185 M12 x 1.75 22 2 90° M222 x 3 70

HCRL-2006 13 50 215 M12 x 1.75 22 3 60° M260 x 3 79

HCRL-2008 13 50 215 M12 x 1.75 22 3 60° M260 x 3 79

HCRL-20010 13 50 215 M12 x 1.75 22 3 60° M260 x 3 79

HCRL-20012 13 50 215 M12 x 1.75 22 3 60° M260 x 3 79

HCRL-2506 15 55 245 M12 x 1.75 22 3 60° M290 x 3 85

HCRL-2508 15 55 245 M12 x 1.75 22 3 60° M290 x 3 85

HCRL-25010 15 55 245 M12 x 1.75 22 3 60° M290 x 3 85

HCRL-25012 15 55 245 M12 x 1.75 22 3 60° M290 x 3 85

HCRL-3006 15 55 260 M16 x 2.00 25 3 60° M315 x 3 94

HCRL-3008 15 55 260 M16 x 2.00 25 3 60° M315 x 3 94

HCRL-30010 15 55 260 M16 x 2.00 25 3 60° M315 x 3 94

HCRL-30012 15 55 260 M16 x 2.00 25 3 60° M315 x 3 94

• Refer to Figure 5 for dimensions graphic. • Metric units of measure are used in this table.

• Contact Enerpac for dimensions of custom ordered cylinders not shown above.

Page 10

10

Cylinder Model

Number

Stroke

Cylinder

Class

Maximum Capacity Eective Area Oil Capacity Weight

in mm US Ton Tonnes kN in

2

cm

2

in

3

cm

3

lb Kg

HCRL-506 5.91 150 50 53.8 48.8 478.5 10.60 68.4 62.55 1025 65 30

HCRL-508 7.87 200 50 53.8 48.8 478.5 10.60 68.4 83.42 1367 79 36

HCRL-5010 9.84 250 50 53.8 48.8 478.5 10.60 68.4 104.29 1709 88 40

HCRL-5012 11.81 300 50 53.8 48.8 478.5 10.60 68.4 125.16 2051 98 45

HCRL-1006 5.91 150 100 111.2 100.9 989.6 21,91 141.4 129.41 2121 141 64

HCRL-1008 7.87 200 100 111.2 100.9 989.6 21,91 141.4 172.54 2827 170 77

HCRL-10010 9.84 250 100 111.2 100.9 989.6 21,91 141.4 215.68 3534 188 85

HCRL-10012 11.81 300 100 111.2 100.9 989.6 21,91 141.4 258.81 4241 207 94

HCRL-1506 5.91 150 150 168.6 153.0 1500.9 33.23 214.4 196.26 3216 213 97

HCRL-1508 7.87 200 150 168.6 153.0 1500.9 33.23 214.4 261.69 4288 256 116

HCRL-15010 9.84 250 150 168.6 153.0 1500.9 33.23 214.4 327.11 5360 284 129

HCRL-15012 11.81 300 150 168.6 153.0 1500.9 33.23 214.4 392.50 6432 312 142

HCRL-2006 5.91 150 200 225.0 204.1 2001.2 44.31 285.9 261.62 4288 318 145

HCRL-2008 7.87 200 200 225.0 204.1 2001.2 44.31 285.9 348.87 5718 370 168

HCRL-20010 9.84 250 200 225.0 204.1 2001.2 44.31 285.9 436.06 7147 406 184

HCRL-20012 11.81 300 200 225.0 204.1 2001.2 44.31 285.9 523.31 8577 440 200

HCRL-2506 5.91 150 250 276.8 251.1 2463.0 54.54 351.9 322.08 5278 419 190

HCRL-2508 7.87 200 250 276.8 251.1 2463.0 54.54 351.9 429.35 7037 492 224

HCRL-25010 9.84 250 250 276.8 251.1 2463.0 54.54 351.9 536.67 8796 538 244

HCRL-25012 11.81 300 250 276.8 251.1 2463.0 54.54 351.9 644.15 10556 584 265

HCRL-3006 5.91 150 300 333.6 302.6 2968.8 65.74 424.1 388.23 6362 505 230

HCRL-3008 7.87 200 300 333.6 302.6 2968.8 65.74 424.1 517.60 8482 592 269

HCRL-30010 9.84 250 300 333.6 302.6 2968.8 65.74 424.1 647.03 10603 647 294

HCRL-30012 11.81 300 300 333.6 302.6 2968.8 65.74 424.1 776.41 12723 702 319

• Contact Enerpac for specifications of custom ordered cylinders not shown above.

12.3 Specifications, HCRL-Series

Page 11

Notes:

11

Page 12

www.enerpac.com

Loading...

Loading...