Page 1

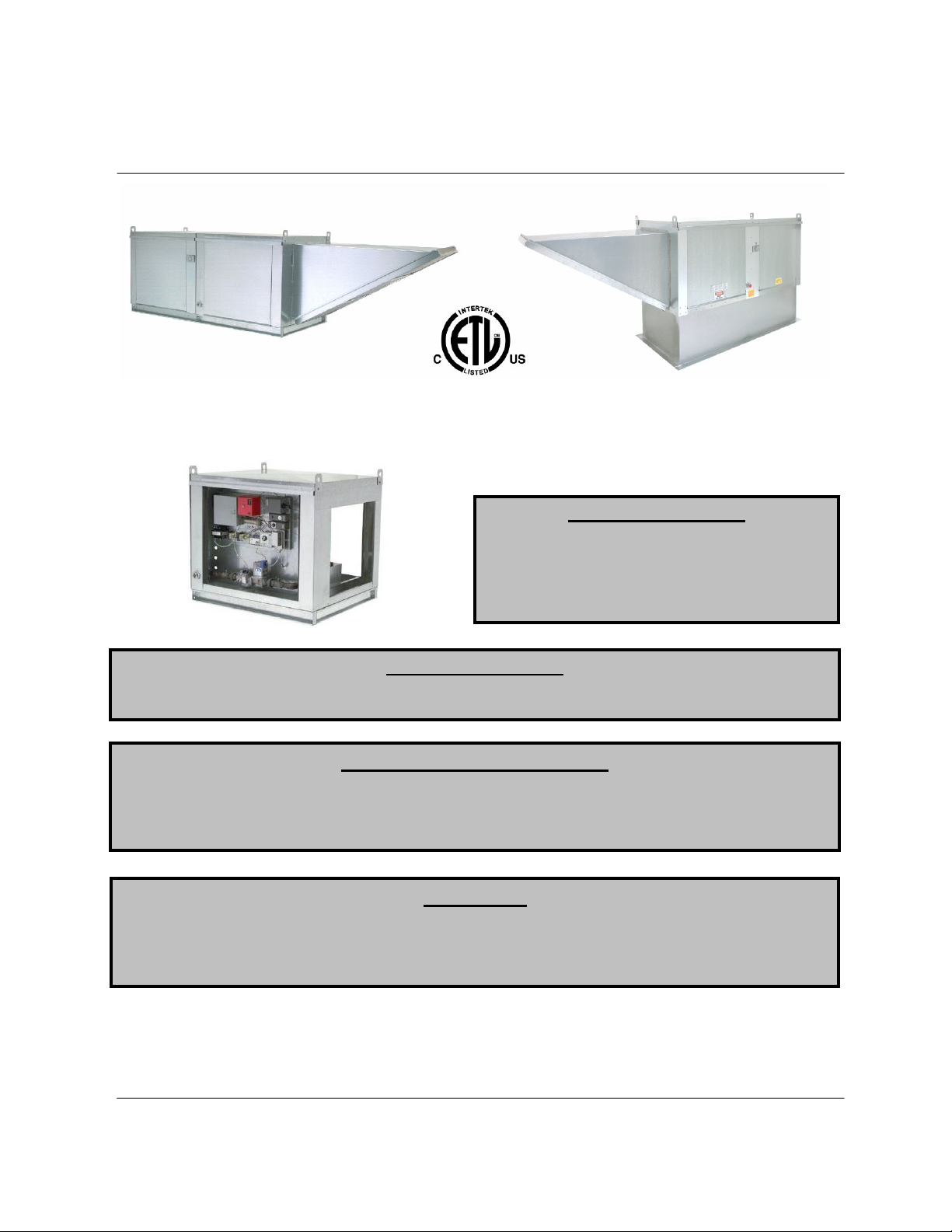

Standard and Modular Direct Fired Heaters

Installation, Operation, and Maintenance Manual

Modular Direct Fired Heater Standard Direct Fired Heater

Direct Fired Module

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

2. Don’t touch electrical switches.

3. Extinguish any open flames.

4. Immediately call your gas supplier.

FOR YOUR SAFETY

The use and storage of gasoline or other flammable vapors and liquids in open containers in the

vicinity of this appliance is hazardous.

RECEIVING AND INSPECTION

Upon receiving unit, check for any interior and exterior damage, and if found, report it

immediately to the carrier. Also check that all accessory items are accounted for and are

damage free. Turn the blower wheel by hand to verify free rotation and check the damper (if

supplied) for free operation.

WARNING!!

Improper installation, adjustment, alteration, service or maintenance can cause property

damage, injury or death. Read the installation, operating and maintenance instructions

thoroughly before installing or servicing this equipment. ALWAYS disconnect power and gas

prior to working on heater.

Save these instructions. This document is the property of the owner of this equipment and is

required for future maintenance. Leave this document with the owner when installation or

service is complete.

April 2006 Rev. 9

Page 2

TABLE OF CONTENTS

WARRANTY.................................................................................................................................................. 3

INSTALLATION............................................................................................................................................. 4

Mechanical................................................................................................................................................4

Site Preparation.................................................................................................................................... 4

Assembly ..............................................................................................................................................4

Curb and Ductwork............................................................................................................................... 4

Roof Mount Installation......................................................................................................................... 5

Installation with Exhaust Fan................................................................................................................ 5

Direct Fired Module Installation............................................................................................................6

Indoor (INLINE) Installation .................................................................................................................. 6

Heat Module Add-On Installation .........................................................................................................6

Gas ...........................................................................................................................................................7

Electrical ...................................................................................................................................................8

Motorized Intake Damper .....................................................................................................................8

Remote Control Panel ..........................................................................................................................9

Fan to Building Wiring Connection ....................................................................................................... 9

OPERATION ...............................................................................................................................................10

Start Up...................................................................................................................................................10

Special Tools Required ...................................................................................................................... 10

Start Up Procedure............................................................................................................................. 10

Pilot Adjustment..................................................................................................................................10

Main Burner Adjustment..................................................................................................................... 11

Heater Start Up Summary ..................................................................................................................12

Final Start Up Procedure.................................................................................................................... 13

Pulley Adjustment............................................................................................................................... 13

Pulley Alignment................................................................................................................................. 13

Proper Belt Tension............................................................................................................................ 13

Pulley Combination Chart................................................................................................................... 14

Sequence of Operation...........................................................................................................................15

Flame Safety Control.......................................................................................................................... 15

Air Flow Switch ................................................................................................................................... 15

Modulating Gas System ..................................................................................................................... 16

High Temperature Limit...................................................................................................................... 16

Operation Summary ........................................................................................................................... 16

Optional Remote Panel Circuit ........................................................................................................... 17

Components............................................................................................................................................18

Remote Panel Option .........................................................................................................................19

Troubleshooting ...................................................................................................................................... 20

Airflow Troubleshooting Chart ............................................................................................................ 20

Burner Troubleshooting Chart ............................................................................................................ 21

Remote Panel Troubleshooting Chart................................................................................................ 22

Troubleshooting Flowcharts ............................................................................................................... 23

MAINTENANCE ..........................................................................................................................................26

General Maintenance .............................................................................................................................26

2 weeks after startup ..............................................................................................................................27

Every 3 months....................................................................................................................................... 27

Filter Quantity Chart ........................................................................................................................... 27

Yearly......................................................................................................................................................27

Start-Up and Maintenance Documentation ............................................................................................28

Job Information...................................................................................................................................28

Heater Information.............................................................................................................................. 28

Maintenance Record .......................................................................................................................... 28

Factory Service Department............................................................................................................... 28

Page 3

WARRANTY

This equipment is warranted to be free from defects in materials and workmanship, under normal use and

service, for a period of 12 months from date of shipment. This warranty shall not apply if:

1. The equipment is not installed by a qualified installer per the MANUFACTURER’S installation

instructions shipped with the product,

2. The equipment is not installed in accordance with federal, state and local codes and regulations,

3. The equipment is misused or neglected,

4. The equipment is not operated within its published capacity,

5. The invoice is not paid within the terms of the sales agreement.

The MANUFACTURER shall not be liable for incidental and consequential losses and damages

potentially attributable to malfunctioning equipment. Should any part of the equipment prove to be

defective in material or workmanship within the 12-month warranty period, upon examination by the

MANUFACTURER, such part will be repaired or replaced by MANUFACTURER at no charge. The

BUYER shall pay all labor costs incurred in connection with such repair or replacement. Equipment shall

not be returned without MANUFACTURER’S prior authorization and all returned equipment shall be

shipped by the BUYER, freight prepaid to a destination determined by the MANUFACTURER.

3

Page 4

INSTALLATION

It is imperative that this unit is installed and operated with the designed airflow, gas, and electrical supply

in accordance with this manual. If there are any questions about any items, please call the service

department at 1-866-784-6900 for warranty and technical support issues.

Mechanical

WARNING: DO NOT RAISE VENTILATOR BY THE INTAKE HOOD, BLOWER OR

MOTOR SHAFT, OR BEARINGS – USE LIFTING LUGS PROVIDED OR A SLING

Site Preparation

1. Provide clearance around installation site to safely rig and

lift equipment into its final position. Supports must

adequately support equipment. Refer to manufacturer’s

estimated weights.

2. Consider general service and installation space when

locating unit.

3. Locate unit close to the space it will serve to reduce long,

twisted duct runs.

4. Do not allow air intake to face prevailing winds. Support

unit above ground or at roof level high enough to prevent

precipitation from being drawn into its inlet. The inlet must

also be located at least 10 feet away from any exhaust

vents. The heater inlet shall be located in accordance with the applicable building code

provisions for ventilation air. All air to the heater must be ducted from the outdoors. Recirculation

of room air is not permitted. If in doubt regarding the application, consult the manufacturer.

The top, back, and front

surfaces of this heater may not

be installed less than 6” from

combustible materials. The

heater base may be installed

on combustible surfaces.

Allow 24” minimum service

clearance on both sides of this

heater.

CLEARANCES

Assembly

Intakes and curbs are shipped unassembled. Upon unit arrival, follow the following procedure to

assemble the intake to the heater:

1. Apply silicone or weather-proof gasket on

the back side of the flanges of the intake

hood or v-bank intake.

2. Screw the flanges of the intake hood or vbank to the unit with the supplied sheet

metal screws. If the unit is a modular unit

with a v-bank or evaporative cooler section,

the v-bank or evaporative cooler will bolt to

the heater with the bolts provided.

Curb and Ductwork

This fan was specified for a specific CFM and static pressure. The ductwork attached to this unit will

significantly affect the airflow performance. Flexible ductwork and square elbows should not be used.

Also, transitions and turns in ductwork near the fan outlet will cause system effect and will drastically

increase the static pressure and reduce airflow. The chart below shows the minimum fan outlet duct

sizes and straight lengths recommended for optimal fan performance. Follow SMACNA guides and

recommendations for the remaining duct run. Fans designed for rooftop installation should be

installed on a prefabricated or factory built roof curb. Follow curb manufacturer’s instructions for proper

curb installation. The unit should be installed on a curb and/or rail elevated not less than 20” above any

surface. Be sure duct connection and fan outlet are properly aligned and sealed. Secure fan to curb

4

Page 5

through vertical portion of the ventilator base

assembly flange using a minimum of eight (8) lug

screws, anchor bolts, or other suitable fasteners (not

furnished). Shims may be required depending upon

curb installation and roofing material. Check all

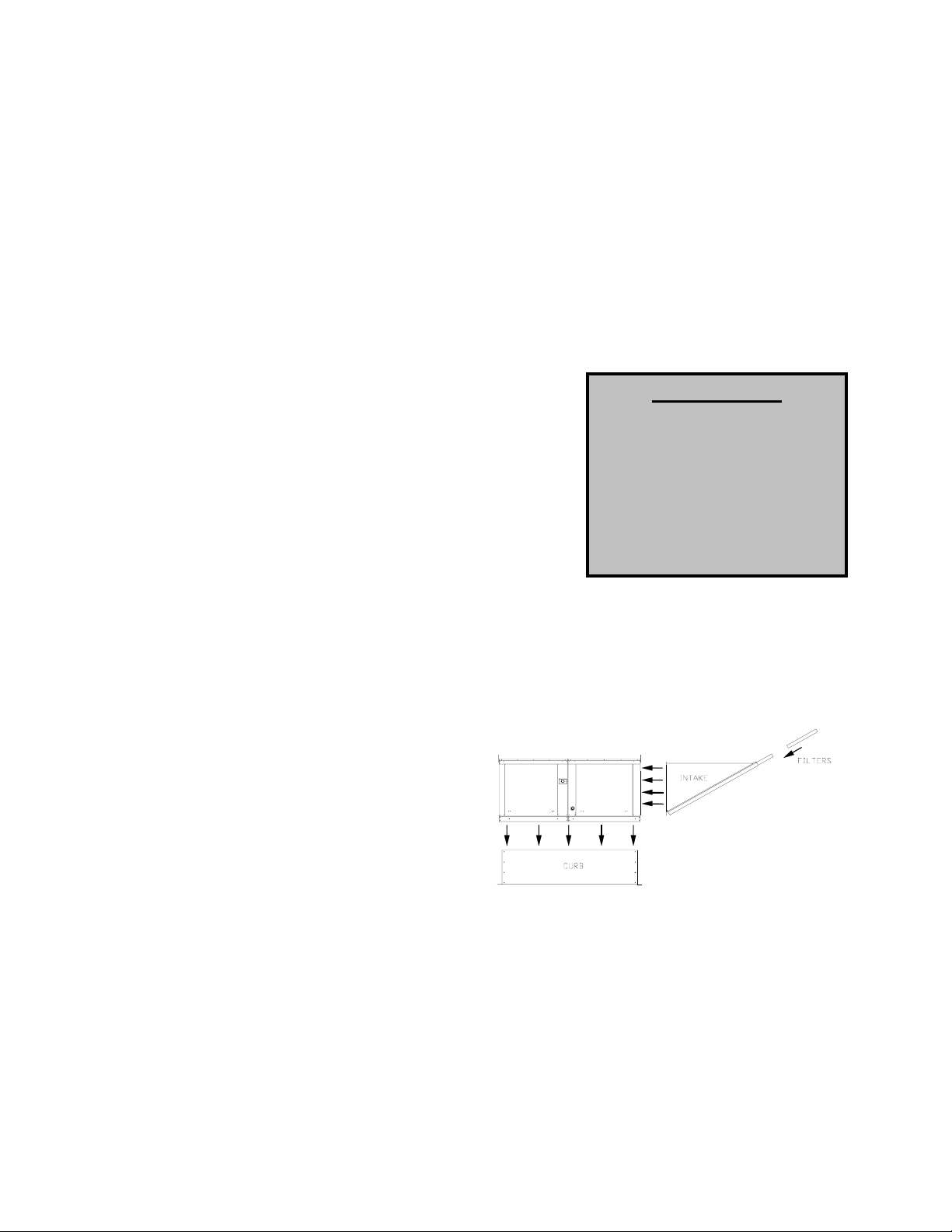

fasteners for tightness. The diagrams below show

different mechanical installation configurations.

Adequate building relief shall be provided so as to

not over pressurize the building when the heating

system is operating at its rated capacity. This can be accomplished by taking into account, through

standard engineering methods, the structure’s designed infiltration rate; by providing properly sized relief

openings; or by interlocking a powered exhaust system; or by a combination of these methods.

Heaters installed with intake ductwork must be purged to replace at least four air changes of the volume

of the intake duct.

If the failure or malfunction of this heater creates a hazard to other fuel burning equipment in the building

(e.g. when the heater is providing make up air to a boiler room), the unit is to be interlocked to open inlet

air dampers or other such devices.

Units being installed in airplane hangars should be installed in accordance with the Standard for Aircraft

Hangars, ANSI/NFPA 409. Units being installed in public garages should be installed in accordance

with the Standard for Parking Structures, ANSI/NFPA 88A, or the Standard for Repair Garages,

ANSI/NFPA 88B, and with CAN/CGA B149 Installation Codes.

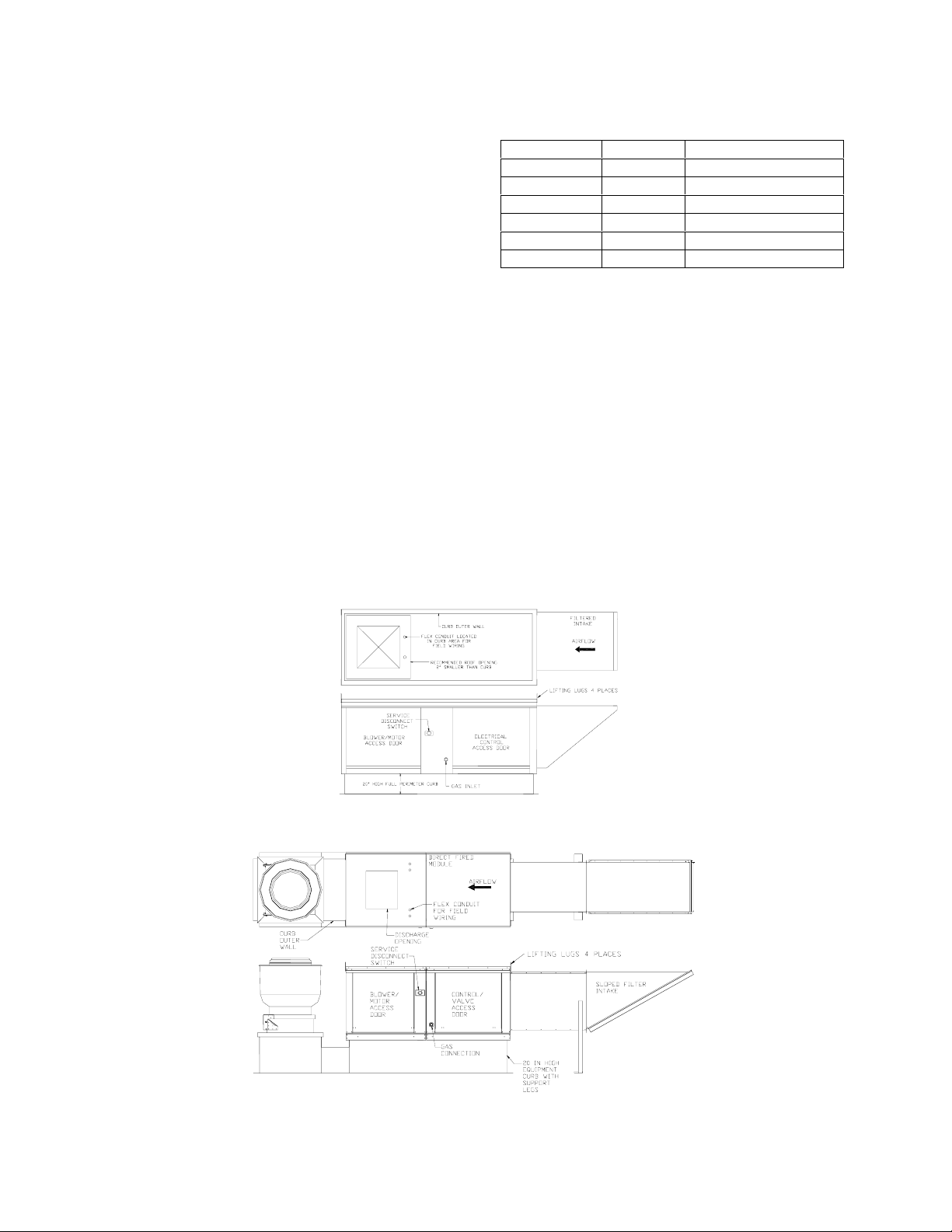

Recommended Supply Ductwork Sizes

Blower Size Duct Size Straight Duct Length

10 14 x 14 48 in.

12 16 x 16 54 in.

15 20 x 20 72 in.

18 24 x 24 86 in.

20 26 x 26 108 in.

25 32 x 32 168 in.

Roof Mount Installation

Installation with Exhaust Fan

5

Page 6

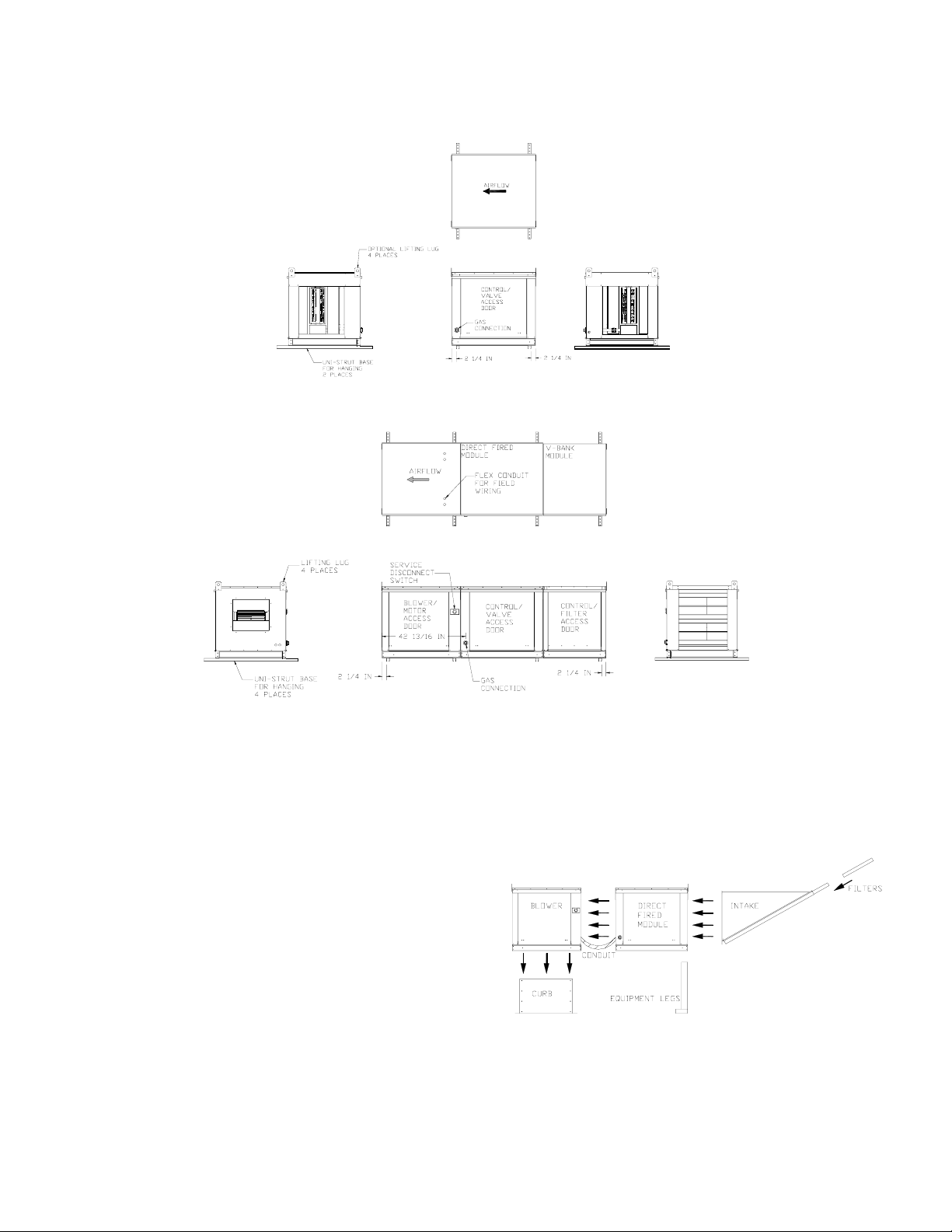

Direct Fired Module Installation

Indoor (INLINE) Installation

Heat Module Add-On Installation

Modular heat units shipped to add heat onto existing blower only applications require field mechanical

and wiring installation.

1. Remove existing filter intake and lifting lugs from blower section intake side.

2. Attach heat module to blower intake using the provided sheet metal screws and bolts. Tighten

screws and bolts securely to compress the

gasket between the heat module and the

blower module.

3. Support and level the end of the heat module

(end opposite the blower) with the provided

equipment legs/rails.

4. Attach the filter hood to the intake side of the

heater module.

5. Drill a hole in the discharge of the blower large

enough to insert the Maxitrol mixing tube and

discharge sensor (if provided). Install the Maxitrol mixing tube in the proper airflow direction. The

airflow direction is labeled on the Maxitrol mixing tube.

6. Wire the sensor as indicated on the supplied wiring schematic. Run all wiring within metal

conduit. Supply 120V AC to terminals 1 and N in the direct fired module.

7. Follow the start up instructions located in this manual.

6

Page 7

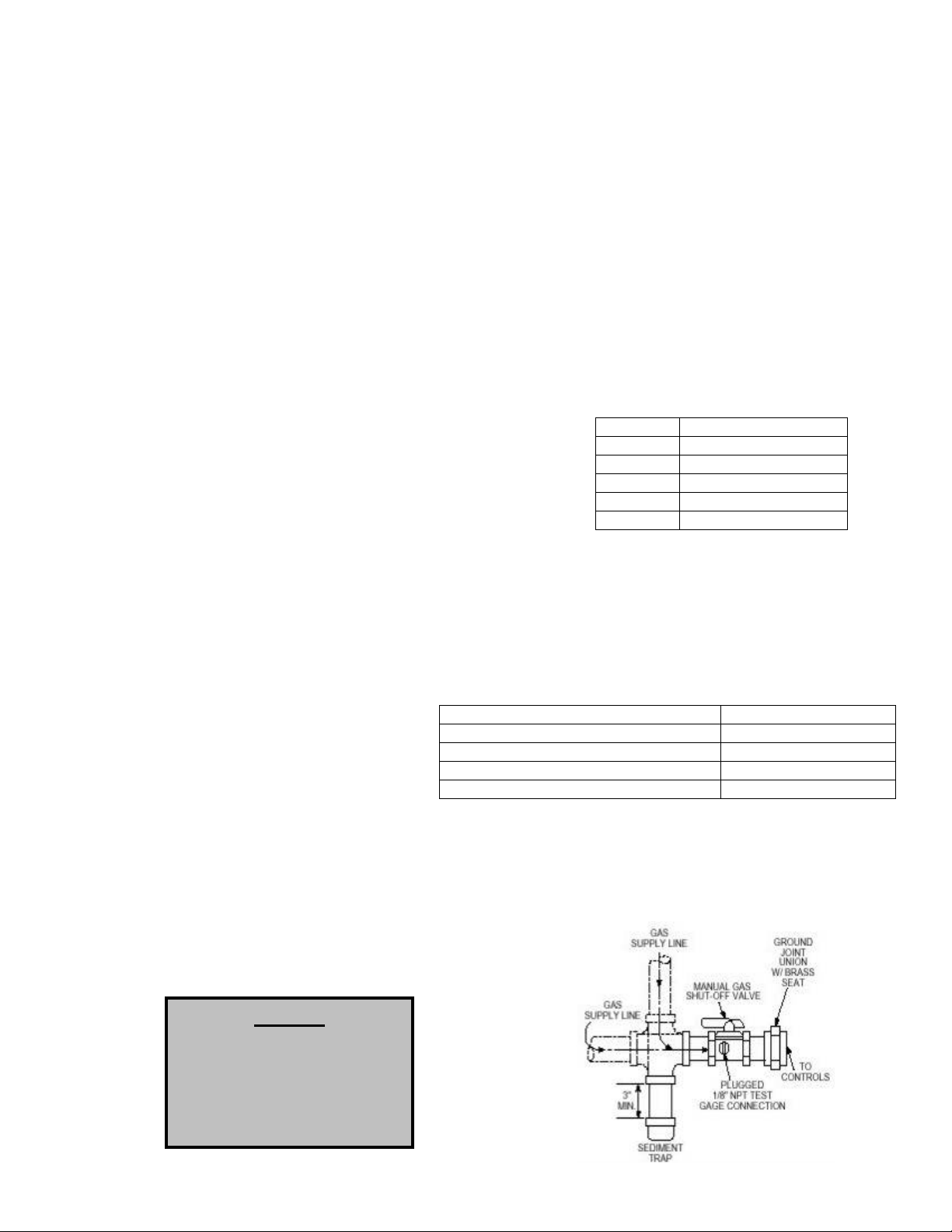

Gas

Installation of gas piping must conform with local building codes, or in the absence of local codes, with the

National Fuel Gas Code, ANSI Z223.1 (NFPA 54) – latest edition. In Canada, installation must be in

accordance with CAN/CGA-B149.1 for natural gas units and CAN/CGA-B149.2 for propane units.

WARNING: INLET GAS PRESSURE MUST NOT EXCEED PRESSURE INDICATED

ON NAMEPLATE. SEE UNIT NAMEPLATE FOR PROPER GAS SUPPLY

PRESSURE AND GAS TYPE.

1. Always disconnect power before working on or near a heater. Lock and tag the disconnect

switch or breaker to prevent accidental power up.

2. Piping to the unit should conform with local and national requirements for type and volume of gas

handled, and pressure drop allowed in the line. Refer to the Gas Engineer’s Handbook for gas

line capacities.

3. The incoming pipe near the heater should be sized to

match the connection on the outside of the unit. Unit inlet

sizes are shown in the table to the right. Avoid multiple

taps in the gas supply so the unit has a steady supply of

gas at all times.

4. Install a ground joint union with brass seat and a manual

shut-off valve external to the unit casing, as shown below,

adjacent to the unit for emergency shut-off and easy

servicing of controls.

5. Provide a sediment trap, as shown below, before each

unit and where low spots in the pipe line cannot be avoided.

6. Blow out the gas line to remove debris before making connections. Purge line to remove air

before attempting to start unit. Purging of air from gas lines should be performed as described in

ANSI Z223.1-latest edition “National Fuel Gas Code”, or in Canada in CAN/CGA-B149.

7. All field gas piping must be pressure/leak tested prior to unit operation. Use a non-corrosive

bubble forming solution or equivalent

for leak testing. The heater and its

individual shut-off valve must be

disconnected from the gas supply

piping system during any pressure

testing of that system at test

pressures in excess of ½ psi. The

heater must be isolated from the gas

supply piping system by closing its

individual manual shutoff valve

during any pressure testing of the gas supply piping system at test pressures equal to or less

than ½ psi.

8. This unit requires a constant 7 in. w.c. minimum

natural gas supply, when the unit is operating at

maximum gas flow. If the gas supply exceeds 14 in.

w.c. (5 psi. for sizes 4-5 housings) it will damage the

internal valve components, and if it is below 7 in.

w.c., the heater may not perform to specifications.

Max. Manifold Pressure - Natural Gas 5 in. w.c. maximum

Max. Manifold Pressure - Propane 2.5 in. w.c. maximum

Gas Pressure Type Gas Pressure

Size 1-3 Inlet Pressure 7 in. w.c. – 14 in. w.c.

Size 4-5 Inlet Pressure 7 in. w.c. – 5 psi.

Gas Connection Sizes

Unit Size Gas Pipe Size (NPT)

Size 1 ¾”

Size 2 1”

Size 3 1”

Size 4 1-1/4”

Size 5 1-1/2”

Gas Pressure Table

Gas Connection Diagram

NOTICE

Refer to the heater rating

plate for determining the

minimum gas supply

pressure for obtaining the

maximum gas capacity for

which this heater is specified.

7

Page 8

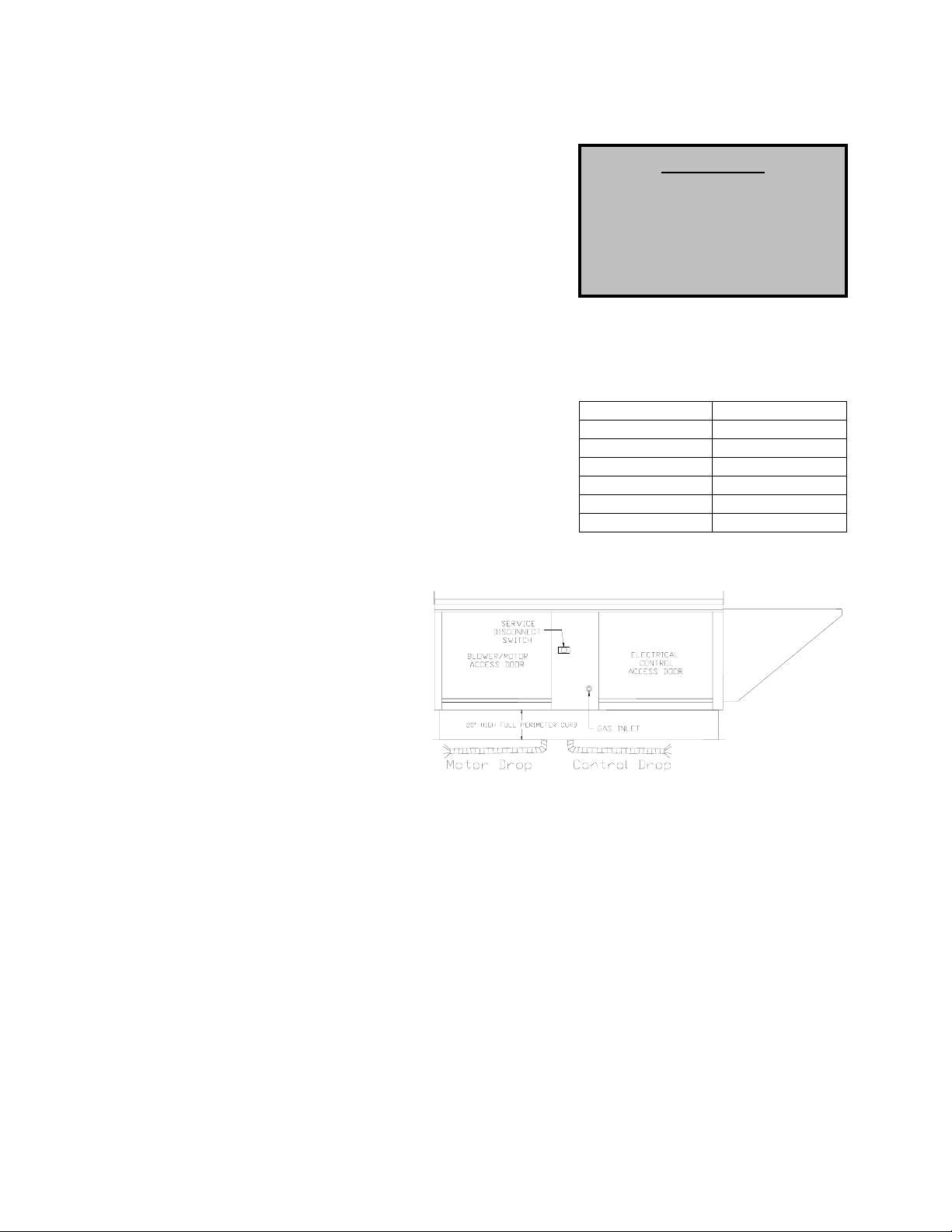

Electrical

Before connecting power to the heater, read and understand this

entire section of this document. As-built wiring diagrams are

furnished with each fan by the factory, and are attached to the

door of the unit.

Electrical wiring and connections should be done in accordance

with local ordnances and the National Electric Code,

ANSI/NFPA70. Be sure the voltage and phase of the power

supply and the wire amperage capacity is in accordance with the

motor nameplate. For additional safety information refer to AMCA publication 410-96, Recommended

Safety Practices for Users and Installers of Industrial and Commercial Fans.

Disconnect power before

installing or servicing fan. High

voltage electrical input is

needed for this equipment. This

work should be performed by a

qualified electrician.

WARNING!!

1. Always disconnect power before working on or near a

heater. Lock and tag the disconnect switch or breaker to

prevent accidental power up.

2. An electrical drop containing the motor power wiring is

shipped with every fan. The electrical drop should be

brought through one of the conduit openings located in

the base of the unit, run through the curb, and connected

to a junction box inside the building.

3. A dedicated branch circuit should supply the motor circuit

with short circuit protection according to the National

Electric Code. This dedicated branch should be run to the junction box mentioned above and

connected as shown in a following

illustration labeled “Fan to Building

Wiring Connection”.

4. Make certain that the power source

is compatible with the

requirements of your equipment.

The heater nameplate identifies

the proper phase and voltage of

the motor.

5. Units shipped with an optional

remote panel have two electrical

circuit drops. It is important to run

the motor wires in a separate conduit from the remote control wiring. The DC wires from the unit

temperature controller, located in the control drop, should either be shielded cable or be run in a

separate conduit.

6. Before connecting heater to the building power source, verify power line wiring is de-energized.

7. Secure the power cables to prevent contact with sharp objects.

8. Do not kink power cable and never allow the cable to come in contact with oil, grease, hot

surfaces or chemicals.

9. Before powering up the heater, check fan wheel for free rotation and make sure that the interior of

the heater is free of loose debris or shipping materials.

10. If any of the original wire supplied with the heater must be replaced, it must be replaced with type

TW wire or equivalent.

Copper Wire Ampacity

Wire Size AWG Maximum Amps

14 20

12 25

10 30

8 40

6 55

4 70

Motorized Intake Damper

On units shipped with the optional motorized intake damper, a power transformer is supplied with the unit

if the main incoming voltage is greater than 120V. The damper motor is automatically energized when

the main disconnect switch is in the ON position. No external wiring to the damper motor is required.

8

Page 9

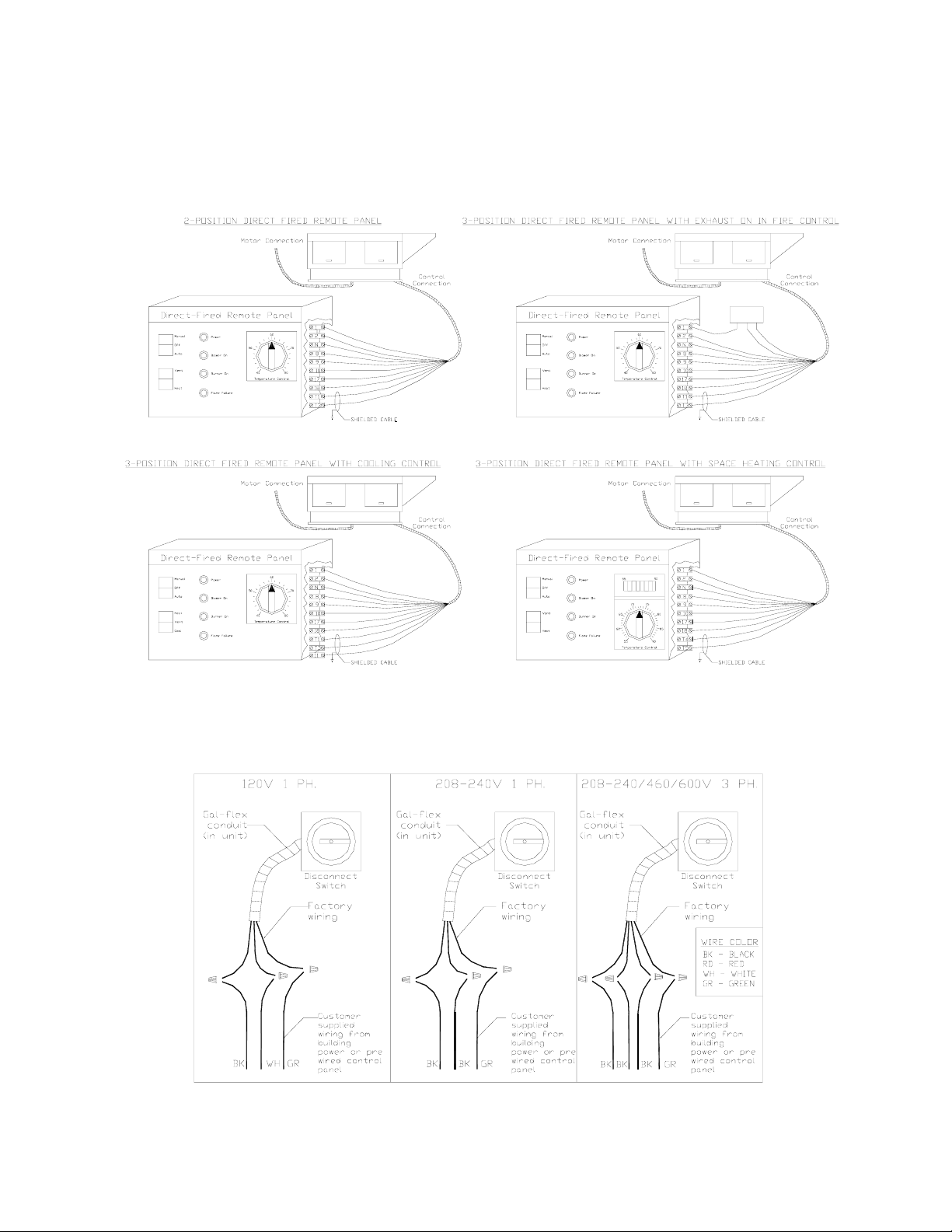

Remote Control Panel

On units shipped with the optional remote control panel, an electrical drop containing the panel wiring is

provided with the heater. There is a terminal strip inside the remote panel that matches the terminals in

the heater unit. The remote panel should be wired as shown below.

Fire System

Microswitch

C

NC

NO

BK

BK

OR

WH

GY

BR

RD

PK

YW

RD

BK

BK

OR

WH

GY

BR

RD

PK

YW

RD

BK

PR

1

E

BK

OR

WH

GY

BR

RD

PK

YW

RD

BK

BL

Fan to Building Wiring Connection

BK

OR

WH

GY

BR

RD

PK

YW

RD

BK

9

Page 10

OPERATION

Prior to starting up or operating the heater, check all fasteners for tightness. In particular, check the set

screw in the wheel hub, bearings and the fan sheaves (pulleys). With power and gas to the heater OFF or

prior to connecting ventilator to power, turn the fan wheel by hand to be sure it is not striking the inlet or

any obstacles. Re-center if necessary.

Start Up

Special Tools Required

• AC Voltage Meter

• Tachometer

• Standard Hand Tools

Start Up Procedure

1. Check all electrical connections for tightness and continuity.

2. Check pulley alignment and belt tension as described below.

3. Inspect the condition of the intake damper and damper linkage, if provided.

4. Inspect the air-stream for obstructions and install intake filters if missing.

5. Compare the supplied motor voltage with the fan’s nameplate motor voltage. If this does not

match, correct the problem.

6. Start the fan up, by turning the external disconnect to the ON position, and shut it OFF

immediately to check rotation of the wheel with the directional arrow on the blower scroll.

Reversed rotation will result in poor air performance, motor overloading and possible burnout.

For units equipped with a single-phase motor check the motor wiring diagram to change rotation.

For 3-phase motors, any two power leads can be interchanged to reverse motor direction.

7. When the fan is started up, observe the operation and check for any unusual noises.

• Amperage Meter

• Manometer

• Differential Pressure Gauge

Pilot Adjustment

1. Restart the fan and check the gas supply pressure at the inlet

gas tap upstream of all electronic valves. The inlet pressure

should be 7 in. - 14 in. w.c. ( 7 in. w.c. – 5 psi on Size 4-5

heaters). If the inlet pressure is too high, install an additional

pressure regulator external to the unit.

2. Open the field installed manual gas shut-off valve and the

manual main gas valve on the combination gas control valve.

3. Call for heat with the intake air thermostat (turn set-point to

temperature above outside air) and allow the pilot to light. If the

pilot does not light, purge the pilot line. If air purging is

required, disconnect the pilot line at the outlet of the pilot valve.

4. Check the pilot flame voltage at the Flame Safety Control

interface test jacks. A weak pilot flame can be caused by low

gas pressure, or a dirty pilot orifice. To adjust the pilot flame,

remove the cap from the pilot adjustment screw on the

combination gas valve. Increase the pilot gas flow by turning

the screw counter-clockwise. Decrease the pilot gas flow by

turning the screw clockwise. The pilot DC voltage should read

12 VDC minimum and should typically be 15 VDC.

5. Once the pilot has been established, open the main manual gas

shut-off valve downstream of the electronic valves. Check to

make sure that the main gas valve opens, and gas flows to the

burner.

Pilot Assembly

10

Page 11

Main Burner Adjustment

1. Once the pilot has been properly established, the

manifold gas pressure or temperature rise should be

adjusted to jobsite conditions. The gas pressure

regulator (integral to the combination gas control on size

1-3 heaters and located in the modulating valve on size

4-5 heaters) is adjusted at the factory for average gas

Mod Valve Voltage Summary

Volts DC Firing Mode

0 to 5 VDC Low Fire

5 to 15 VDC Modulation

15 to 20 VDC High Fire

conditions. It is important that the gas be supplied to the burner in accordance with the input

rating on the rating plate.

2. Create a high fire call for heat. This should be done with the blower on and all gas controls on.

High fire can be achieved by removing the wire at terminal #4 (remove wires #2 and #4 for

Maxitrol 44 systems) from the Maxitrol 14 amplifier.

3. The manifold pressure should be checked

at the pressure tap downstream of the

Average Manifold Pressure vs. Firing Rate/Ft. of Burner

6.00

modulating valve. The graph to the right

indicates the proper manifold pressure for

the desired amount of BTUs per foot of

burner. For natural gas systems, the high

fire manifold pressure should not exceed 5

in. w.c. For propane gas, the high fire

manifold pressure should not exceed 2.5

in. w.c. Another method of checking high

fire is to measure the temperature rise of

the unit. The temperature rise should be

set to design conditions and typically is

minimum 70°F.

4. Remove the cap from the combination gas

valve regulator adjustment (size 1-3) or

5.00

4.00

3.00

2.00

1.00

Manifold Pressure (in. w.c.)

0.00

-1.00

0 100000 200000 300000 400000 500000 600000

Natural Gas Propane Gas

Firing Rate (BTU/Hr/Ft. of Burner)

the cap from the MR212 valve (size 4-5).

Using the regulator pressure adjusting screw, adjust the high fire manifold pressure to 5 in. w.c.

maximum for natural gas and 2.5 in. w.c. maximum for propane gas. High fire should be set to

generate the desired temperature rise. If the high fire screw is at the end of its adjustment and

more pressure is needed, then adjust the main building gas pressure regulator spring (located

external to the unit) to achieve the proper manifold pressure. Turning the regulator screw

clockwise will increase pressure and counter-clockwise will decrease pressure. Remember -

The high fire DC voltage should read 12 VDC minimum and should typically be 15 VDC on

the Flame Safety Controller test jacks.

5. Reconnect the wire on the Maxitrol 14 amplifier at terminal #4 (wires #2 and #4 for Maxitrol 44).

6. The low fire manifold pressure must now be set. Low fire can be achieved

by removing the wire at terminal #5 from the Maxitrol 14 amplifier (remove

#8 for Maxitrol 44). Check the low fire flame signal to ensure that the DC

voltage is 12 VDC minimum on the Flame Safety Controller test jacks.

Maxitrol MR212 Low

Fire Bypass Screw

7. Using the bypass screw (located on the side of the M511 and M611 valves,

and under the cap of the MR212 valve), adjust low the low fire manifold

pressure until there is a very thin flame along the entire length of the burner.

No dark spots should be seen in the burner. The burner may be observed

through the view-port located on the external wall of the heater. Replace

the cap to the Maxitrol valve and restore all of the original wiring on the

Maxitrol amplifier and gas components.

8. A final gas leak check shall be performed to verify the gas-tightness of the

Maxitrol M511 and M611

Low Fire Bypass Screw

heater’s components and piping under normal operating conditions. This

can be done by measuring the gas pressure at the ¼” gas plug just

downstream of the modulating valve.

11

Page 12

Heater Start Up Summary

Is incoming gas pressure

7"-14"?

No

(7"-5 psi. for size 4-5 units)

Yes

Adjust

incoming gas

pressure.

Adjust pilot flame.

Lock unit into

high fire.

Does high fire produce

at least a 70°F temp

rise and produce the

correct manifold

pressure?

Yes

Lock unit into low fire.

Does thin flame fill

entire burner length?

Yes

Burner start up

complete.

No

Adjust high fire

No

Adjust low

fire.

Setting incoming pressure:

Presure must be measured at first "T" in

supply gas line before the first gas valve.

Adjusting the pilot:

The pilot DC signal should be 12 VDC

minimum.

Adjusting high fire:

High fire manifold pressure should be 5"

maximum for natural gas and 2.5"

maximum for propane. High fire should

produce at least a 70°F temperature rise.

Remove wire #4 from the Maxitrol 14

amplifier (#2 and #4 for Maxitrol 44).

This will drive the valve into its full open

position. Adjust high fire with the

regulator inside the unit. Turn clockwise

to increase temperature rise. Ensure that

DC flame signal is minimum 12 VDC.

Replace the wires on the Maxitrol

Amplifier.

Adjusting low fire:

Remove wire #5 from the Maxitrol 14

amplifier (#8 for Maxitrol 44). This will

drive the valv e into its lowest position.

Adjust the low fire by turning the low fire

bypass screw on the side of teh

modulating valve for M511 and M611

models. For MR212 valves, the low and

high fire are both under the valve cov er.

Refer to the included Maxitrol literature

for more detailed inf ormation. Ensure

that DC flame signal is minimum 12 VDC

and that the enite length of burner is filled

with a thin flame.

12

Page 13

Final Start Up Procedure

1. With the air and burner systems in full operation and all ducts attached, measure the system

airflow. Motor sheave (pulley) is variable pitch, and allows for an increase or decrease of the fan

RPM to adjust the airflow, as shown in the illustration below. For your convenience, a RPM chart

is included in the following pages.

2. Once the proper airflow is achieved, measure and record the fan speed with a reliable

tachometer. Caution - Excessive speed will result in motor overloading or bearing failure.

Do not set fan RPMs higher than specified in the maximum RPM chart. See the

troubleshooting guide for more information.

3. Measure and record the voltage and amperage to the motor and compare with the motor

nameplate to determine if the motor is operating under safe load condition.

4. Once the rpm of the ventilator has been properly set, disconnect power and recheck belt tension

and pulley alignment as described below.

Maximum RPM and HP Chart

Blower Size Maximum RPM Maximum HP

10” 1800 2

12” 1500 3

15” 1400 5

18” 1200 5

20” 1000 10

25” 900 20

Pulley Adjustment Illustration

Pulley Adjustment

The adjustable motor pulley is factory set for the RPM specified.

Speed can be increased by closing or decreased by opening the

adjustable motor sheave. Two groove variable pitch pulleys must

be adjusted an equal number of turns open or closed. Any

increase in speed represents a substantial increase in

horsepower required by the unit. Motor amperage should always

be checked to avoid serious damage to the motor when the

speed is varied. Always torque setscrews according to the

setscrew torque chart.

Pulley Alignment

Setscrew Torque

Thread Size Torque (IN/Lb)

No. 10 33

1/4” 80

5/16” 156

3/8” 275

7/17” 384

1/2” 600

Proper Belt Tension

13

Page 14

Pulley Combination Chart

Motor RPM 1725

1/3 to 1-1/2 HP MOTOR PULLEY Dd1 Dd2 Pd1 Pd2

AX BELTS 1VL34 1.9 2.9 2 3

BLOWER PULLEY DATUM DIAMETER PITCH DIAMETER 5 4 1/2 4 3 1/2 3 2 1/2 2 1 1/2 1 1/2 0

AK114 11 11.2 308 323 339 354 370 385 400 416 431 447 462

1/3 to 2 HP MOTOR PULLEY Dd1 Dd2 Pd1 Pd2

AX BELTS 1VL40 2.4 3.4 2.6 3 .6

BLOWER PULLEY DATUM DIAMETER PITCH DIAMETER 5 4 1/2 4 3 1/2 3 2 1/2 2 1 1/2 1 1/2 0

AK114 11 11.2 400 416 431 447 462 477 493 508 524 539 554

AK94 9 9.2 488 506 525 544 563 581 600 619 638 656 675

AK79 7.5 7.7 582 605 627 650 672 694 717 739 762 784 806

AK66 6.2 6.4 701 728 755 782 809 836 863 889 916 943 970

AK54 5 5.2 863 896 929 962 995 1028 1062 1095 1128 1161 1194

AK46 4.2 4.4 1019 1059 1098 1137 1176 1215 1255 1294 1333 1372 1411

AK39 3.5 3.7 1212 1259 1305 1352 1399 1445 1492 1539 1585 1632 1678

AK32 3 3.2 1402 1455 1509 1563 1617 1671 1725 1779 1833 1887 1941

3 to 5 HP MOTOR PULLEY Dd1 Dd2 Pd1 Pd2

BX BELTS 2VP42 2.9 3.9 3 4

BLOWER PULLEY DATUM DIAMETER PITCH DIAMETER 6 5 1/2 5 4 1/2 4 3 1/2 3 2 1/2 2 1 1/2 1 1/2 0

2BK160H 15.4 15.7 330 339 348 357 366 375 385 394 403 412 421 430 439

2BK140H 13.4 13.7 378 388 399 409 420 430 441 451 462 472 483 493 504

2BK120H 11.4 11.7 442 455 467 479 491 504 516 528 541 553 565 577 590

2BK110H 10.4 10.7 484 497 511 524 537 551 564 578 591 605 618 631 645

2BK100H 9.4 9.7 534 548 563 578 593 608 622 637 652 667 682 697 711

2BK90H 8.4 8.7 595 611 628 644 661 677 694 710 727 744 760 777 793

2BK80H 7.4 7.7 672 691 709 728 747 765 784 803 821 840 859 877 896

2BK70H 6.4 6.7 772 794 815 837 858 880 901 923 944 965 987 1008 1030

10 - 20 IN. BLOWER**

2BK60H 5.4 5.7 908 933 958 984 1009 1034 1059 1084 1110 1135 1160 1185 1211

2BK55H 4.9 5.2 995 1023 1050 1078 1106 1133 1161 1189 1216 1244 1272 1299 1327

2BK50H 4.4 4.7 1101 1132 1162 1193 1223 1254 1285 1315 1346 1376 1407 1438 1468

7-1/2 to 10 HP MOTOR PULLEY Dd1 Dd2 Pd1 Pd2

BX BELTS 2VP60 4.3 5.5 4.7 5.9

BLOWER PULLEY DATUM DIAMETER PITCH DIAMETER 6 5 1/2 5 4 1/2 4 3 1/2 3 2 1/2 2 1 1/2 1 1/2 0

2BK160H 15.4 15.7 516 527 538 549 560 571 582 593 604 615 626 637 648

2BK140H 13.4 13.7 592 604 617 630 642 655 667 680 693 705 718 730 743

2BK120H 11.4 11.7 693 708 722 737 752 767 781 796 811 826 840 855 870

2BK110H 10.4 10.7 758 774 790 806 822 838 854 871 887 903 919 935 951

2BK100H 9.4 9.7 836 854 871 889 907 925 943 960 978 996 1014 1031 1049

2BK90H 8.4 8.7 932 952 972 991 1011 1031 1051 1071 1091 1110 1130 1150 1170

2BK80H 7.4 7.7 1053 1075 1098 1120 1143 1165 1187 1210 1232 1255 1277 1299 1322

3 to 5 HP MOTOR PULLEY Dd1 Dd2 Pd1 Pd2

BX BELTS 2VP42 2.9 3.9 3 4

BLOWER PULLEY DATUM DIAMETER PITCH DIAMETER 6 5 1/2 5 4 1/2 4 3 1/2 3 2 1/2 2 1 1/2 1 1/2 0

2B5V278 27.8 28.1 184 189 194 200 205 210 215 220 225 230 235 240 246

2B5V250 25 25.3 205 210 216 222 227 233 239 244 250 256 261 267 273

2B5V234 23.4 23.7 218 224 230 237 243 249 255 261 267 273 279 285 291

2B5V200 20 20.3 255 262 269 276 283 290 297 304 312 319 326 333 340

2B5V184 18.4 18.7 277 284 292 300 307 315 323 331 338 346 354 361 369

2B5V160 16 16.3 317 326 335 344 353 362 370 379 388 397 406 414 423

2B5V154 15.4 15.7 330 339 348 357 366 375 385 394 403 412 421 430 439

2B5V136 12.6 12.9 401 412 423 435 446 457 468 479 490 501 513 524 535

2B5V124 12.4 12.7 407 419 430 441 453 464 475 487 498 509 521 532 543

2B5V110 11 11.3 458 471 483 496 509 522 534 547 560 572 585 598 611

7-1/2 to 10 HP MOTOR PULLEY Dd1 Dd2 Pd1 Pd2

BX BELTS 2VP60 4.3 5.5 4.7 5.9

BLOWER PULLEY DATUM DIAMETER PITCH DIAMETER 6 5 1/2 5 4 1/2 4 3 1/2 3 2 1/2 2 1 1/2 1 1/2 0

2B5V278 27.8 28.1 289 295 301 307 313 319 325 331 338 344 350 356 362

2B5V250 25 25.3 320 327 334 341 348 355 361 368 375 382 389 395 402

2B5V234 23.4 23.7 342 349 357 364 371 378 386 393 400 408 415 422 429

2B5V200 20 20.3 399 408 416 425 433 442 450 459 467 476 484 493 501

2B5V184 18.4 18.7 434 443 452 461 470 480 489 498 507 517 526 535 544

2B5V160 16 16.3 497 508 519 529 540 550 561 571 582 593 603 614 624

2B5V154 15.4 15.7 516 527 538 549 560 571 582 593 604 615 626 637 648

25 IN. BLOWER

2B5V136 12.6 12.9 628 642 655 669 682 695 709 722 735 749 762 776 789

2B5V124 12.4 12.7 638 652 666 679 693 706 720 733 747 761 774 788 801

2B5V110 11 11.3 717 733 748 763 779 794 809 824 840 855 870 885 901

15 to 20 HP MOTOR PULLEY Dd1 Dd2 Pd1 Pd2

BX BELTS 2VP75 5.8 7 6.2 7.4

BLOWER PULLEY DATUM DIAMETER PITCH DIAMETER 6 5 1/2 5 4 1/2 4 3 1/2 3 2 1/2 2 1 1/2 1 1/2 0

2B5V278 27.8 28.1 381 387 393 399 405 411 417 424 430 436 442 448 454

2B5V250 25 25.3 423 430 436 443 450 457 464 470 477 484 491 498 505

2B5V234 23.4 23.7 451 459 466 473 480 488 495 502 509 517 524 531 539

2B5V200 20 20.3 527 535 544 552 561 569 578 586 595 603 612 620 629

2B5V184 18.4 18.7 572 581 590 600 609 618 627 636 646 655 664 673 683

2B5V160 16 16.3 656 667 677 688 698 709 720 730 741 751 762 773 783

2B5V154 15.4 15.7 681 692 703 714 725 736 747 758 769 780 791 802 813

2B5V136 12.6 12.9 829 842 856 869 883 896 909 923 936 949 963 976 990

** 2HP Motors on 20 IN Blowers use 2VP42 Pulleys

Open Closed

Open Closed

Open Closed

Open Closed

Open Closed

Open Closed

Open Closed

TURNS ON MOTOR PUL LEY

TURNS ON MOTOR PUL LEY

TURNS ON MOTOR P ULLEY

TURNS ON MOTOR P ULLEY

TURNS ON MOTOR P ULLEY

TURNS ON MOTOR P ULLEY

TURNS ON MOTOR P ULLEY

14

Page 15

Sequence of Operation

The direct-fired heater is most easily understood when broken down into smaller individual systems.

There are two main systems, a make-up air fan and a heater. The make-up air fan consists of a blower

and motor. The heater may be further broken down into two control systems, the Flame Safety Control

(FSC) and the Modulating Gas System (MGS). The burner mixes air with the gas (Natural or LP) which

heats the air.

Flame Safety Control

The first system to understand is the Flame Safety Control. The FSC

is there only to monitor the flame, NOT to control temperature. The

FSC uses a flame rectification sensor mounted on the pilot assembly

to detect the presence of flame in the burner. Flame strength and

presence can be measured at the FSC by reading the rectified flame

signal. This is done by removing the FSC cover and using a DC

voltage meter in the test jacks. Flame is present when the DC voltage

reads between 6 and 18 VDC. Ideal flame intensity produces a signal

of 12 VDC or greater. The FSC is also wired into an airflow switch,

which tells it whether there is proper airflow through the unit (not just

any airflow, but proper

.15 in. w.c. to .65 in. w.c. differential pressure drop across the

burner. When the airflow through the heater produces a pressure

drop in this range, the FSC indicates so by illuminating the AIRFLOW

LED. The FSC controls the opening of the redundant solenoid gas

valves and the operation of the spark igniter to initiate a pilot flame

upon start-up.

The OPR CTRL LED indicates that there is power to the FSC. Next,

the AIRFLOW LED will come on if there is proper airflow through the

unit. Third, the unit will pause to purge any gasses or combustible vapors before attempting flame

ignition. Then, there is a Pilot Trial For Ignition (PTFI) and the PTFI LED comes on. During PTFI, the FSC

opens the pilot gas valve and allows gas to flow to the pilot assembly. At the same moment, the spark

igniter is started, causing the spark to ignite the pilot gas. When the flamerod sensor detects the flame, it

turns on the FLAME LED, turns off the PTFI LED, and powers the modulating gas system. This is the

normal operating mode. The FSC continues to monitor the flame and airflow. Once this occurs, the unit is

in a main flame cycle and thus powers the main gas valve and the modulating gas system. This is the

normal operating mode. The FSC continues to monitor the flame and airflow. The last LED on the FSC is

the ALARM LED. This will turn on when the FSC determines an unsafe condition has occurred, and will

not allow the unit to recycle for heat until it has been properly reset. Anytime the FSC has gone into

“Alarm” mode, the problem must be diagnosed and corrected to avoid future lockouts after resetting. To

begin troubleshooting, or to reset the FSC, shut down power to the heater and restart the heater. This

will clear the alarm from the flame safety.

airflow). Proper airflow occurs when there is a

Flame Safety Controller

DC Flame Signal

DC Voltage Flame Status

0 to 5 VDC No Flame

6 to 11 VDC Weak Flame

12 to 18 VDC Strong Flame

Air Flow Switch

There are both high and low airflow switches contained within one housing

measuring the pressure drop across the burner. This is to insure that there is

proper airflow (.15 in. w.c. to .65 in. w.c.) across the burner and proper

combustion at all times. Both switches are wired in series and have single pole

double throw (one common contact, one normally open contact, and one normally

closed contact) switches that are ‘switched’ by air pressure. There are two airflow

tubes in the heater, located near the burner and profile plate assembly (profile

plates surround the burner and control air into the burner section). In the case of

clogged filters, blocked intake, excessive duct static pressure, or a broken belt, the

correct burner differential pressure may not be achieved, not allowing the low

15

Air Flow Switch

Page 16

airflow switch to close. The high airflow switch protects against profile plate failures that cause excessive

airflow through the burner. In the event that the pressure drop across the burner is not in the range of the

airflow switch, gas flow to the burner is stopped by the Flame Safety Control.

The graphs below illustrate the approximate cfm going through the unit vs. the differential pressure

measured by the airflow switch. Simply measure the differential profile pressure drop at the airflow tubes

in the unit and match that value up to the matching unit curve below. This will show the cfms traveling

through the burner and will indicate proper airflow or airflow problems (too much or not enough). If the

pressure drop is outside of the .15” to .65” range, the blower rpm should be adjusted to fix airflow.

10000

CFM

9000

8000

7000

6000

5000

4000

3000

2000

1000

Size 1-3 Heater CFM vs. Burner Profile Pressure

Size 1

Size 2

Size 3

0

0.15 0.2 0.25 0.3 0.35 0.4 0. 45 0.5 0.55 0.6 0.65

Burne r Differe ntial Profile Pressure (in. w.c.)

25000

23000

21000

19000

17000

15000

CFM

13000

11000

9000

7000

5000

3000

Size 4-5 Heater CFM vs. Burner Profile Pressure

Size 4

Size 5

0.15 0.2 0.25 0.3 0. 35 0.4 0.45 0.5 0.55 0. 6 0. 65

Burne r Differe ntial Profile P ressure (in . w.c.)

Modulating Gas System

The second system, the Maxitrol modulating gas system, consists of a

temperature selector dial, a discharge air sensor, an amplifier, and a

modulating gas valve. The two types of Maxitrol systems used are the Maxitrol

14 series or the Maxitrol 44 series. The Maxitrol 14 utilizes a discharge air

sensor and modulates the Maxitrol gas valve to provide discharge air to match

the selected temperature on the temperature selector. The Maxitrol 44 utilizes a

room temperature sensor to control room temperature as well as a discharge air

sensor in order to control the discharge air temperature. The modulating gas

valve controls the amount of gas flow to the burner based on the temperature

rise needed. When the modulating gas valve is all the way open and achieving

the maximum BTUs and temperature rise of the unit, it is called “high fire”.

Maxitrol 14

Amplifier

High Temperature Limit

One of the back up safety device is the high temperature limit switch.

This switch is a mechanical thermostat that measures the temperature

inside the unit downstream of the burner. If the factory-set temperature

of 170°F is exceeded, it will signal the FSC to turn off the burner. This

requires a manual reset of the high temperature limit. This insures that

the discharge does not exceed 185°F.

Operation Summary

With the blower already running and the airflow switch proven;

9 The outside air temperature falls below the setting of intake air thermostat

or

9 The optional remote panel is set to “Manual” and “Heat” mode

• The FSC in energized and the following occurs;

9 FSC indicates that it has power by illuminating the OPR CTRL LED

9 FSC verifies proper Airflow

16

High Temperature Limit

Page 17

9 Begins Pilot Trial For Ignition and turns on PTFI LED

9 The pilot gas solenoid valve is opened, the spark igniter begins sparking, and the flamerod

sensor watches for flame initiation

9 When flame is established, the FLAME LED is illuminated and main valve opens and the

FSC powers the Maxitrol system and gas flow begins modulating

9 The FSC monitors the flame while the Maxitrol system adjusts to the selected temperature

• The Maxitrol system checks the discharge air temperature (and the room temperature for the Maxitrol

44) and regulates the gas going to the burner to satisfy the temperature setting. The Maxitrol system

will modulate the main burner gas from 100% down to 5% as needed.

Optional Remote Panel Circuit

Power

Supply From

Heater

"Auto"

Power is Sent to

Heater to Open

Damper (if

provid ed) and

Star t Blow er

"Blower On"

Light

On

"Power " LightOnOff

Panel is

Powered

Blower Switch

Off

Stat has Detected

Low Tem peratu re

No Power to

Panel

Position

(3-Position Panels Only)

Damper is not

Open or Freeze-

Operat ion

"Off"

"Manual"

Nothing Happens

No Power is Sent

to Heat er

Power is Sent to

Heater to Open

Damper (if

provid ed) and

Star t Blow er

"Blower On"

Light

On

Off

Damper is not

Open or FreezeStat has Detected

Low Tem peratu re

Oper ation

Nothing Happens

Intake Air is

War mer Than

Ther mostat

Set-Point

Intak e Air is C ooler T han

Ther most at Set -Poin t

Heat C irc uit is E nergi zed

"Burner On" Light Illuminates with

"Flame Failure" Light illuminates

if p roper flam e is not est ablished

Intake Air

Thermstat is

Powere d

proper fl ame.

Blower Oper ates

Cooling Circuit is

Energized

"Cool "

Position

(if provided)

Temperature

Control Switch

Position

Heat C irc uit is E nergi zed

"Burner On" Light Illuminates with

proper flame.

"Flame Failure" Light illuminates

if proper fl ame is n ot establi shed

Position

"Heat "

"Vent"

Blower Oper ates

Heat D oes not

Oper ate

17

Page 18

Components

The following image and list outlines the typical direct fired heater components and their functions.

2

8

3

4

9

6

7

5

5

6

1

10

18

11

12

13

14

15

16

17

19

23

20

21

22

1. Gas Inlet – Main gas supply connection

2. Motor Starter – Contactor with overload protection to start and protect motor.

3. Freeze-Stat Thermostat (Optional) – De-energizes blower motor if the discharge air

temperature falls below the set point.

4. Cooling Interlock Relay (Optional) – Energizes power to cooling circuit on call for cooling.

5. Inlet Gas Pressure Tap – Inlet gas pressure should be measured here.

6. Combination Gas Valve - A combination of redundant solenoid valves, pilot valve and gas

regulator built into one unit.

7. Pilot Tubing – Pilot tube connection to combination gas valve.

8. Manual Reset High Temperature Limit – Safety device that prevents the heater from

overheating.

9. Maxitrol Modulating Amplifier - Regulates temperature by modulating gas valve

10. Power Transformer – Installed when motor voltage > 120V. Used to provide 120V service to

controls.

11. Circuit Breaker – Protects electrical components from high current spikes.

12. Terminal Strip – Central location to terminate control wiring. Should be used for troubleshooting.

13. Control Transformer – 120V primary; 24V secondary control transformer.

14. Low Pressure Airflow Probe – Measures profile pressure downstream of burner.

15. High Pressure Airflow Probe – Measures profile pressure upstream of burner.

16. Modulating Gas Valve – Modulates gas flow to burner to provide proper air temperature.

17. Manifold Gas Pressure Tap – Manifold gas pressure should be measured here.

18. Flame Safety Control – Initiates and monitors flame.

19. Airflow Switch – A safety device insuring proper air flow during burner operation.

20. Ignition Transformer – Produces high voltage spark to ignite flame.

21. Intake Air Thermostat – De-energize heating circuit when intake air exceeds set-point.

22. Damper Actuator – Motor containing end switch that opens intake damper.

23. Manual Gas Shut-Off Valve Allows gas flow to burner to be shut off to leak test gas train

18

Page 19

Remote Panel Option

The Remote Panel is a device used to control the operation of the heater from a remote location. This

unit is available in both a “2 Position” or “3 Position” configuration and with or without a cooling output. It

also will accommodate both the Maxitrol discharge temperature dial and the Maxitrol space sensing

Selectrastat. It is important to understand the following Remote Panel controls and uses:

1

3

4

2

FLAME

FAILURE

CLOGGED

FILTER

1. Manual/Off/Auto Switch - Used to control blower operation and tempering mode of unit. The

AUTO position allows the unit to “decide”, through the use of the intake air thermostat, whether or

not heating is needed. The MANUAL position allows the user to control whether or not heat is

needed. The OFF position will turn the blower off when a “3 Position” remote panel is ordered.

The OFF position will disable all temperature controls when a “2 Position” remote panel is

ordered and fan power is then controlled by the pre-wire package only.

2. Heat/Vent Switch – This switch is powered when the Manual/Off/Auto switch is in the MANUAL

position. It is used to control the tempering mode of the unit. The VENT position will prevent the

burner from operating and the heater will deliver untempered air. The HEAT position will force

the burner on and the unit will heat the incoming air. This switch becomes a Heat/Vent/Cool

switch when the cooling interlock is ordered. This option provides a 120V cooling output from the

remote panel.

3. Lights- Displays the current status of unit features. The light definitions are as follows:

POWER - Illuminated when there is power to Remote Panel.

BLOWER ON - Illuminated when the blower motor is powered.

BURNER ON - Illuminates after pilot flame has established and main valve is powered.

FLAME FAILURE - Illuminated when the Flame Safety Control is in Alarm mode.

CLOGGED FILTER – (Optional) Illuminated when the Intake Filters are Dirty.

4. Temperature Control – Controls the discharge temperature of a standard unit. The temperature

dial is replaced with Maxitrol Selectrastat in Space Heating applications and is used to control the

space temperature.

19

Page 20

Troubleshooting

The following tables list causes and corrective actions for possible problems with direct fired heater units.

Review these lists prior to consulting manufacturer.

Airflow Troubleshooting Chart

Problem Potential Cause Corrective Action

Fan Inoperative

Motor Overload

Insufficient Airflow

Excessive Airflow

Excessive Vibration and Noise

Blown fuse or open circuit breaker Replace fuse or reset circuit breaker

and check amps

Disconnect switch in “Off” position Turn to “On” position

Motor wired incorrectly Check motor wiring to wiring diagram

located on fan motor

Broken fan belt Replace belt

Motor starter overloaded Reset starter and check amps

Remote panel set to “Off” Position Set Remote Panel to “Manual” or

“Auto” Position

Fan rotating in the wrong direction Be sure fan is rotating in the direction

shown on rotation label

Fan speed is too high Reduce fan RPM

Motor wired incorrectly Check motor wiring to wiring diagram

located on fan motor

Overload in starter set too low Set overload to motor FLA value

Motor HP too low Determine if HP is sufficient for job

Duct static pressure lower than design Reduce fan RPM

Fan rotating in the wrong direction Be sure fan is rotating in the direction

shown on rotation label

Poor outlet conditions There should be a straight clear duct

at the outlet

Intake damper not fully open Inspect damper linkage and replace

damper motor if needed

Duct static pressure higher than

design

Blower speed too low Increase fan RPM. Do not overload

Supply grills or registers closed Open and adjust

Dirty or clogged filters Clean and/or replace

Belt slippage Adjust belt tension

Blower speed to high Reduce fan RPM

Filters not installed Install filters

Duct static pressure lower than design Reduce fan RPM

Misaligned pulleys Align pulleys

Damaged or unbalanced wheel Replace wheel

Fan is operating in the unstable region

of the fan curve

Bearings need lubrication or

replacement

Fan speed is too high Reduce fan RPM

Belts too loose, worn or oily Inspect and replace if needed

Improve ductwork to eliminate or

reduce duct losses

motor

Refer to performance curve for fan

Lubricate or replace

20

Page 21

Burner Troubleshooting Chart

Problem Potential Cause Corrective Action

Pilot Does Not Light/Stay Lit

Main Burner Does Not Light

(Pilot is Lit)

Not Enough Heat

Too Much Heat

Main gas if off Open main gas valve

Air in gas line Purge gas line

Dirt in pilot orifice Clean orifice with compressed air

Gas pressure out of range Adjust to proper gas pressure

Pilot valve is off Turn pilot valve on

Pilot orifice fitting leak Tighten pilot orifice

Excessive drafts Re-direct draft away from unit

Safety device has cut power Check limits and airflow switch

Dirty flame sensor Clean flame sensor

Remote panel in “Vent” mode Change to “Heat” mode

No spark at igniter Check wiring, sensor, and ignition

controller. Check spark gap as shown

below.

Defective valve Replace combination valve

Loose valve wiring Check wiring to valve

Defective pilot sensor Replace pilot sensor

Shut off valve closed Open shut off valve

Defective flame safety controller Replace flame safety controller

Pilot fails as main gas valves open

and main gas begins to flow

Main gas pressure too low Increase main gas pressure – do not

Too much airflow Decrease airflow if possible

Burner undersized Check design conditions

Gas controls not wired properly Check wiring

Thermostat setting too low Increase thermostat setting

Thermostat malfunction Check/replace thermostat

Unit locked into low fire Check wiring

Defective modulating gas valve Check/replace modulating valve

Thermostat setting too high Decrease thermostat setting

Unit locked into high fire Check wiring

Thermostat wired incorrectly Check thermostat wiring

Plug the first burner port next to the

pilot gas tube with burner cement

exceed 14 in. w.c. inlet pressure (5 psi.

on size 4-5 heater)

Proper Spark Gap

21

Page 22

Remote Panel Troubleshooting Chart

Light Indication Condition Possible Cause

No Lights Power not available to Remote Panel

POWER Light Only

POWER Light and

BLOWER ON Light

POWER Light and

BLOWER ON Light and

BURNER ON Light

CLOGGED FILTER Light On

(Optional)

FLAME FAILURE Light On Flame Safety Alarm Activated

Proper unit Off Operation No problem

No power to motor starter

Proper Ventilation Operation No Problem

No Power to Flame Safety Controller

Improper Airflow

Proper Heating Operation No Problem

Filters Clogged Filters Dirty or Need Replacement

No Flame Detected during Pilot

Establishment Period

Bad voltage to unit

Main disconnect in “OFF” Position

Circuit breaker tripped

Bad main transformer

Manual/Off/Auto Switch in “Off” Position

(3 Position Remote Panels Only)

Improper damper function

Low Temperature Thermostat Timed

Out (Option)

Manual/Off/Auto Switch in “Off” Position

(2 Position Remote Panels Only)

Heat/Vent Switch in “Vent” Position

Gas Pressure Switch Tripped (option)

High Temperature Limit Thermostat

Tripped

Manual/Off/Auto Switch in “Auto”

Position and Intake Air Thermostat not

Satisfied

Insufficient Airflow

Excessive Airflow

Bad airflow switch

Problem with air probes

Problem with airflow tubing

Broken Belt

Combination Valve in “Off” Position

(Unit Sizes 1-3)

Stuck Closed Gas Valve

No or Low Gas Pressure

Bad Spark Electrode

Bad Ignition Transformer

Flames Sensor Malfunction

Clogged Pilot Orifices

22

Page 23

Nothing

Happens

Is Overload

tripped on

starter?

NO

Is Freeze-Stat

open?

NO

Is end switch on

Motoriz ed

Damper closed?

Reset & measure FLA

YES

of motor. Is it higher

YES

NO

Troubleshooting Flowcharts

than rating?

Adjust or

Replace

Adjust or

Replace

actuator

YES

Adjust

or

change

Pulley

Blower runs

but there is

no heat

Is the air flow LED

on Flame Saftey

illuminated?

Is outside air cooler than

intake air thermostat

YES

setting?

YES

Is High Temp.

Limit Tripped?

NO

Is there a

Remote Panel

Installed?

YES

Is Remote set to

"Heat"

YES

Refer to Flame

Safety Guide

NO

YES

NO

NO

Adjust pulley to

achieve proper

NO

economizer

Check wiring

"Manual" and

"Heat" mode.

airflow.

Proper

operation

Reset

Set Remote

Panel to

Burner lights but

heater stays in

Low Fire

Is there voltage on

Terminal #17

Yes

Are all valves

powered and open?

Yes

With wires 3 & 4

removed from the

Maxitrol Amplifier, is

there 9.5K to 11K

Ohms between the

wires?

Yes

Remove Terminal #4

from the Maxitrol

Amplifier. Does the

heater go into High Fire?

Yes

With wires 1 & 2

removed from the

Maxitrol Amplifier, is

there 9.5K to 11K Ohms

between the wires?

No

Replace

FSC

No

Check valve wiring

or open valves

Replace

No

Discharge Air

Sensor

Is there a short or open

No

circuit in Modulating

Valve? Should be 45-55

Ohms (60-80 on MR212)

No

Replace

Amplifier

Replace the

No

Temperature

Selector

Yes

Replace

Modulating

Valve

Burner lights but heater

stays in High Fire

Is there a jumper between

terminals 2 & 3 on the

Maxitrol Amplifier?

Yes

Is there a short circuit in

the Remote Temperature

Selector or wiring?

No

Is there an open circuit in

the Discharge Air Sensor

or wiring?

No

Is Plunger in the

Modulating Valve jammed?

Inspect and clean. It

should operate freely in

the sleeve.

No

Foreign object holding

valve open. Remove

bottom plate and inspect

valve and seat. Clean or

replace valve.

No

Yes

Yes

Install

Jumper

Repair short or

replace

Temperature

Selector

Repair Circu it or

replace the

Discharge Air

Sensor

23

Page 24

Flame Safety Service Guide

(Airflow LED may or may not be illuminated)

24

Page 25

Flame Safety Service Guide (continued)

(Airflow LED may or may not be illuminated)

25

Page 26

MAINTENANCE

To guarantee trouble free operation of this heater, the manufacturer suggests following these guidelines.

Most problems associated with fan failures are directly related to poor service and maintenance.

Please record any maintenance or service performed on this fan in the documentation section located at

the end of this manual.

WARNING: DO NOT ATTEMPT MAINTENANCE ON THE HEATER UNTIL THE

ELECTRICAL SUPPLY HAS BEEN COMPLETELY DISCONNECTED AND THE

MAIN GAS SUPPLY VALVE HAS BEEN TURNED OFF.

General Maintenance

1. Fan inlet and approaches to ventilator should be kept clean and free from any obstruction.

2. Motors are normally permanently lubricated. Check bearings periodically. If they have grease

fittings lubricate each season. Use caution when lubricating bearings, wipe the fittings clean, the

unit should be rotated by hand while lubricating. Caution: Use care when touching the exterior

of an operating motor. Motors normally run hot and may be hot enough to be painful or

cause injury.

3. All fasteners should be checked for tightness each time maintenance checks are preformed prior

to restarting unit.

4. Blowers require very little attention when moving clean air. Occasionally oil and dust may

accumulate causing imbalance. If the fan is installed in a corrosive or dirty atmosphere,

periodically inspect and clean the wheel, inlet and other moving parts to ensure smooth and safe

operation.

Re-Setting Of The Unit

If the flame safety control is locked out (alarm light on), reset the unit by:

1. Turn OFF Power to the unit.

2. Turn Power to the unit back ON.

Emergency shutdown of unit

To shut down the unit in the event of an emergency do the following:

1. Turn power OFF to the unit from main building disconnect.

2. Turn the external disconnect switch to the OFF position.

3. CLOSE the inlet gas valve located on the heater.

Prolonged shutdown of the unit

For prolonged shutdown the following steps should be done:

1. Turn the external disconnect switch to the OFF position.

2. CLOSE the inlet gas valve located on the heater.

To re-start the unit the following steps should be done:

1. Turn the external disconnect switch to the ON position.

2. OPEN the inlet gas valve located on the heater.

26

Page 27

2 weeks after startup

1. Belt tension should be checked after the first 2 weeks of fan operation. Belts tend to stretch and

settle into pulleys after an initial start-up sequence. Do not tension belts by changing the

setting of the motor pulley, this will change the fan speed and may damage the motor. To retension belts, turn the power to the fan motor OFF. Loosen the fasteners that hold the blower

scroll plate to the blower. Rotate the motor to the left or right to adjust the belt tension. Belt

tension should be adjusted to allow 1/64” of deflection per inch of belt span. Exercise extreme

care when adjusting V-belts as not to misalign pulleys. Any misalignment will cause a sharp

reduction in belt life and produce squeaky noises. Over-tightening will cause excessive belt and

bearing wear as well as noise. Too little tension will cause slippage at startup and uneven wear.

Whenever belts are removed or installed, never force belts over pulleys without loosening

motor first to relieve belt tension. When replacing belts, use the same type as supplied by the

manufacturer. On units shipped with double groove pulleys, matched belts should always be

used.

2. All fasteners should be checked for tightness each time maintenance checks are preformed prior

to restarting unit.

Every 3 months

1. Belt tension should be checked quarterly. See instructions in the previous maintenance section.

Over-tightening will cause excessive bearing wear and noise. Too little tension will cause

slippage at startup and uneven wear.

2. Filters need to be cleaned and/or replaced quarterly, and more often in severe conditions.

Washable filters can be washed in warm soapy water. When re-installing filters, be sure to install

with the airflow in the correct direction as indicated on the filter.

Filter Quantity Chart

Intake 16” x 20” 20” x 25”

Size 1 Sloped 3

Size 2 Sloped 3

Size 3 Sloped 6

Size 4 Sloped 10

Size 5 Sloped 8

Size 1 V-Bank 3

Size 2 V-Bank 8

Size 3 V-Bank 8

Size 4 V-Bank 15

Size 5 V-Bank 12

Yearly

1. Inspect bearings for wear and deterioration. Replace if necessary.

2. Inspect belt wear and replace torn or worn belts.

3. Inspect bolts and set screws for tightness. Tighten as necessary.

4. Inspect motor for cleanliness. Clean exterior surfaces only. Remove dust and

grease from the motor housing to ensure proper motor cooling. Remove dirt

and grease from the wheel and housing to prevent imbalance and damage.

5. Check for gas leaks and repair if present.

6. Clean flame sensor by rubbing with steel wool to remove any rust build-up,

7. Clean burner with a wire brush and insure burner ports are free of debris.

Then wipe the burner with a clean rag.

Burner Orifice

Drill Size

Orifice Drill Size

Gas Port 31

Air Port 43

27

Page 28

Start-Up and Maintenance Documentation

START-UP AND MEASUREMENTS SHOULD BE PERFORMED AFTER THE SYSTEM HAS BEEN

AIR BALANCED AND WITH THE HEAT ON (Warranty will be void without completion of this form)

Job Information

Job Name Service Company

Address Address

City City

State State

Zip Zip

Phone Number Phone Number

Fax Number Fax Number

Contact Contact

Purchase Date Start-Up Date

Heater Information

Refer to the start-up procedure in this manual to complete this section.

Name Plate and Unit Information

Model Number

Serial Number

Motor Volts

Motor Hertz

Motor Phase

Motor FLA

Motor HP

Blower Pulley

Motor Pulley

Belt Number

Gas Type

Min. Btu/Hr

Max. Btu/Hr

**If measured amps exceed the FLA rating on the nameplate, fan RPM must be reduced to decrease the

measured amps below the nameplate FLA rating.

Field Measured Information

Motor Voltage

Motor Amperage**

RPM

Burner Differential Pressure in. w.c.

Pilot Flame Signal VDC

Low Fire Flame Signal VDC

High Fire Flame Signal VDC

Gas Type

High Fire Inlet Gas Pressure in. w.c.

Low Fire Manifold Gas Pressure in. w.c.

High Fire Manifold Gas Pressure in. w.c.

Thermostat Set-Point

Temperature Control

Airflow Direction

Discharge

Space

Correct

Incorrect

Maintenance Record

Date Service Performed

Factory Service Department

Phone: 1-866-784-6900

Fax: 1-919-554-9374

28 April 2006 Rev. 9

Loading...

Loading...