Page 1

INSTALLATION

MANUAL

SPLIT-SYSTEM

(AIR COOLED)

EVAPORATOR BLOWER

CONTENTS

GENERAL....................................4

REPLACEMENTPARTS........................4

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INDOOR PRODUCT NOMENCLATURE . . . . . . . . . . . . 5

UNITINSTALLATION..........................11

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

See the following page for a complete Table of Contents.

MODELS: LB300

LB360

LB480

LB600

NOTES, CAUTIONS AND WARNINGS

Installer should pay particular attention to the words:

NOTE, CAUTION, and WARNING. Notes

clarify or makethe installation easier. Cautions

prevent equipment damage. Warnings

installer that personal injury and/or equipment damage

may result if installation procedure is not handled properly.

CAUTION: READ ALL SAFETY GUIDES BEFORE YOU

BEGIN TO INSTALL YOUR UNIT.

SAVE THIS MANUAL

are intended to

are given to

are given to alert

035-18496-000-C-1102

Page 2

TABLE OF CONTENTS

035-18496-000-C-1102

GENERAL ......................................4

NOTES, CAUTIONS AND WARNINGS . . . . . . . . . . . . . . . .4

REPLACEMENTPARTS...........................4

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

LIMITATIONS..................................4

INDOOR PRODUCT NOMENCLATURE . . . . . . . . . . . . . . .5

BLOWERMOTORMOUNTINGLOCATIONS.........7

LA300/LB360/LB480MOTORMOUNTING............7

LB600MOTORMOUNTING .......................7

MOTORMOUNTARRANGEMENTS ...............8

LA300/LB360/LB480 MOTOR ARRANGEMENTS . . . . . . 8

ADDITIONAL M OTOR ARRANGMENTS FOR

LA300/LB360/LB480 ............................8

LB600MOTORARRANGEMENTS..................9

RE-LOCATING THE LB600 MOTOR MOUNT ING PLATE 9

ALTERNATEPOSITIONONE......................9

ALTERNATEPOSITIONTWO .....................9

ALTERNATEPOSITIONTHREE ...................9

AIRDISCHARGECONVERSION ..................9

LA360/LB360/LB480 AIRDISCHARGE ..............9

LB600AIRDISCHARGE .........................11

UNITINSTALLATION ............................11

LOCATION...................................11

RIGGING ....................................11

CLEARANCES................................11

MOUNTING ..................................12

DUCT CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . .15

INSULATION ..................................15

SUPPLY AIR DUCTS . . . . . . . . . . . . . . . . . . . . . . . . . . .15

RETURN AIR DUCT ANGLES . . . . . . . . . . . . . . . . . . . . 16

DRAINCONNECTIONS .........................16

REFRIGERANTMAINS.........................16

EVAPORATORSECTIONPIPING .................17

EXPANSION VALVE BULB INSTALLATION . . . . . . . . .17

LA300........................................17

LB360/LB480/LB600 ............................17

LIQUIDLINESOLENOIDS .......................17

PUMPOUT ...................................18

BEARING ALIGNMENT: LB600 . . . . . . . . . . . . . . . . . . .18

AIR SYSTEM ADJUSTMENT . . . . . . . . . . . . . . . . . . . .18

TWINBELTDRIVEADJUSTMENT................18

ELECTRICALCONNECTIONS ...................19

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

LIST OF FIGURES

Fig.# Pg.#

1 LA300 AND LB360/LB480 FACTORY MOTOR

MOUNTINGPOSITION ........................7

2 LB600 FACTORY MOTOR MOUNTING POSITION . .7

3 LB600MOTORMOUNTPLATE..................7

4 LA300/LB360/LB480MOTOR LOCATION A . . . . . . . . 8

5 LA300/LB360/LB480MOTOR ARRANGEMENTS . . . .8

6 VERTICAL AIRFLOW ARRANGEMENTS . . . . . . . . . 10

7 HORIZONTAL AIRFLOW ARRANGEMENTS . . . . . .10

8 LB600AIRFLOWARRANGEMENTS.............11

9 DETAILS FOR SECURING BOTTOM MOUNTING

SUPPORTS ................................13

10 LA300/LB480/LB360 WEIGHT DISTRIBUTION . . . .13

11 LB600 WEIGHT DISTRIBUTION WITH SUSPENSION

APPLICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

12 DETAILS FOR SECURING SUSPENSION

CHANNELS ................................15

13 SUGGESTED METHOD FOR CONNECTING

DUCTWORK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

14 RECOMMENDEDDRAINPIPING ...............16

15 LB600 CENTER BEARING . . . . . . . . . . . . . . . . . . . . . 18

16 DOUBLEGROOVEPULLEY ...................18

17 UNIT DIMENSIONS - LA300, LB360, LB480 . . . . . . .22

18 25TONLIQUIDLINESOLENOIDWIRING ........22

19 30, 40 & 50 TON LIQUID LINE SOLENOID

WIRING....................................22

20 LA300PIPINGCONNECTIONS.................23

21 LB360PIPINGCONNECTIONS.................23

22 LB480PIPINGCONNECTIONS.................23

23 UNITDIMENSIONS ..........................24

24 LB600 PIPING CONNECTIONS - END PANEL

DETAIL ....................................24

25 HOLE LOCATION FOR PRESSURE DROP

READING ..................................25

26 25-TON PRESSURE DROP VS. CFM ACROSS

INDOORCOIL ..............................26

27 30-TON - PRESSURE DROP VS. CFM ACROSS

INDOORCOIL ..............................26

28 40 TON - PRESSURE DROP VS. CFM ACROSS

INDOORCOIL(DOMESTIC) ...................27

29 50 TON - PRESSURE DROP VS. CFM ACROSS

INDOORCOIL ..............................27

30 INDOOR UNIT WIRING DIAGRAM LB360,

480&600 ..................................28

31 INDOORWIRINGDIAGRAMLA300 .............29

2 UnitaryProductsGroup

Page 3

035-18496-000-C-1102

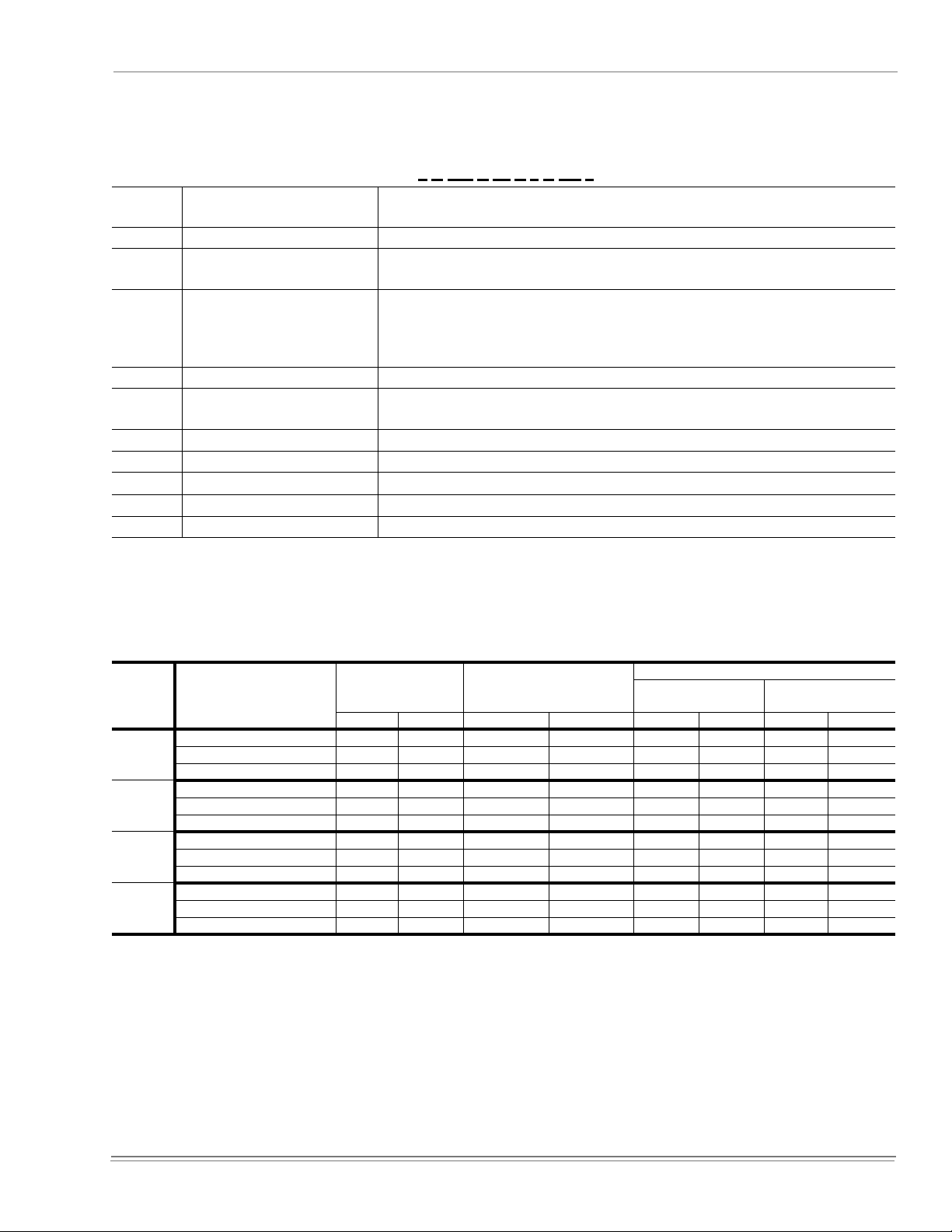

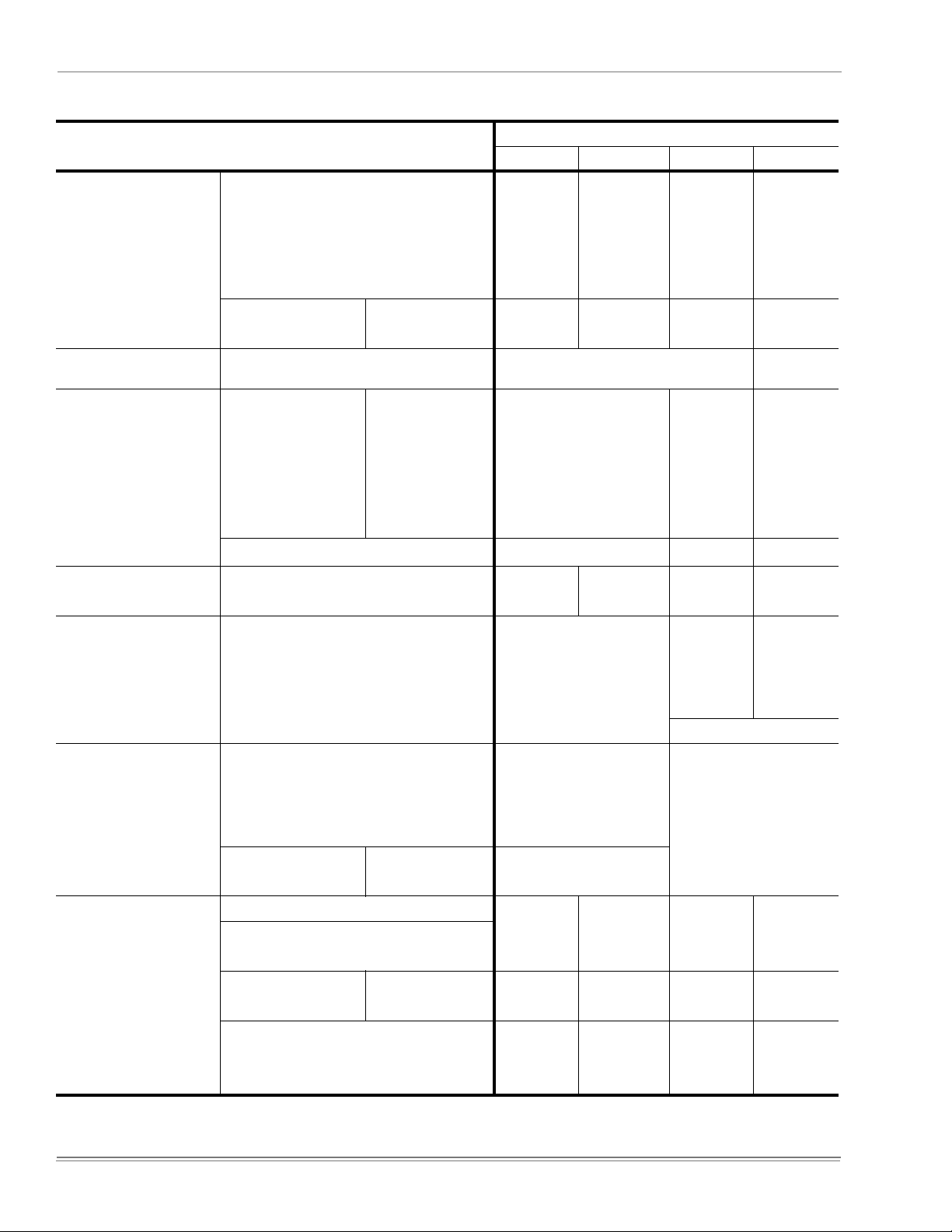

LIST OF TABLES

Tbl.# Pg.#

1 UNIT APPLICATION DATA . . . . . . . . . . . . . . . . . . . . . 5

2 PHYSICALDATA .............................6

3 UNITMOUNTINGDIMENSIONS ................12

4 CORNERWEIGHTS..........................12

5 ACCESSORY OPERATING WEIGHT DISTRIBUTION

(LBS)......................................12

6 ELECTRICALDATA ..........................19

7 MOTOROVERLOADELEMENTS ...............19

8 UNITDRIVEDATA...........................20

Tbl.#

9 UNITBLOWERMOTORDATA .................20

10 FANPEFORMANCEDATA-25TON ............21

11 FANPEFORMANCEDATA-30TON ............21

12 FANPERFORMANCEDATA-40TON...........21

13 FANPERFORMANCEDATA-50TON...........21

14 UNIT DIMENSIONS - LA300, LB360, LB480 . . . . . . . 22

15 UNITCONNECTIONSIZES....................23

Pg.#

Unitary Products Group 3

Page 4

035-18496-000-C-1102

GENERAL

The LA and LB evaporator units are designedfor use with the

HA/HB Series condensing units.Units are designed to match

up with LA/LB series Evaporator Blowers to meet ASHRAE

90.1 standards.

Each unit consists of a coil section and a blower section that

are factory assembled and shipped as shown in figures 3 and

4. These sections may be rearranged in the field for other air

discharge patterns. See figures 7, 8 and 9.

The LA and LB evaporator units have 24 volt normally closed

solenoid valves to match the 24-volt control circuits of the

Simplicity

HB360, HB480 and HB600 condensing units.

TM

control board in the HA300 as well as the

NOTES, CAUTIONS AND WARNINGS

Installer should pay particular attention to the words: NOTE,

CAUTION and WARNING. Notes

make installation easier. Cautions

equipment damage. Warnings

personal injury and/or equipment damage may result if installation procedure is not handled properly.

are intended to clarify or

are given to prevent

are given to alert installer that

REPLACEMENT PARTS

Refer to parts manual for complete listing of replacement

parts on this equipment. The above forms and all other forms

referenced on this instruction may be ordered from;

Standard Register

2101 W. Tecumseh Road

Norman, OK 73069

Telephone : (877) 318-9675

Toll Free Fax: (877) 379-7920

INSPECTION

As soon as a unit is received, it should be inspected for possible damage during transit. If damage is evident, the extent of

the damage should be noted on the carrier's freight bill. A

separate request for inspection by the carrier's agent should

be made in writing.

LIMITATIONS

This unit must be installed in accordance with all national and

local safety codes. If no local codes apply, installation must

conform to the appropriate national code. The unit is

designed to meet National Safety Code Standards. If

components are to be added to a unit to meet local codes,

they are to be installed at the dealer's and/or the customer's

expense. See Table1 for unit application data.

4 UnitaryProductsGroup

Page 5

035-18496-000-C-1102

INDOOR PRODUCT NOMENCLATURE

L A 300 C 00 A 6 A AA 1

Model #

300

AA Additional Options AA = None

Model Number

Description

Options

L Product Category L = Air Handling Unit

A Product Identifier

Nominal Cooling

Capacity

MBH

A = R-22 Standard Efficiency 2-Pipe

B = R-22 Standard Efficiency 4-Pipe

300 = 25 Ton

360 = 30 Ton

480 = 40 Ton

600 = 50 Ton

C Heat Type C = Cooling Only

Nominal Heating

00

Capacity

00 = No Heat Installed

A Airflow Options A=None

6 Voltage 5 = 575-3-60 6 = 208/230-460-3-60

A Installation Options A=None

1 Product Generation 1 = First Generation 2 = Second Generation

NOTE: LB600 Indoor Unit matches with both HB480

and HB600 Outdoor Condensing Units for

maximum efficiency.

TABLE 1: UNIT APPLICATION DATA

Entering Air Temperature Degrees °F

Model Power Supply Voltage

208/230-3-60 187 253 8,000 12,000 65/57 95/72 40 77

LA300

LB360

LB480

LB600

*.

Heating Min/Max temperatures apply to steam and hot water coils. NOTE: Do not apply steam to hot water coils.

460-3-60 414 506 8,000 12,000 65/57 95/72 40 77

575-3-60 540 630 8,000 12,000 65/57 95/72 40 77

208/230-3-60 187 253 10,000 14, 000 65/57 95/72 40 77

460-3-60 414 506 10,000 14,000 65/57 95/72 40 77

575-3-60 540 630 10,000 14,000 65/57 95/72 40 77

208/230-3-60 187 253 12,800 19, 200 65/57 95/72 40 77

460-3-60 414 506 12,800 19,200 65/57 95/72 40 77

575-3-60 540 630 12,800 19,200 65/57 95/72 40 77

208/230-3-60 187 253 16,000 24, 000 65/57 95/72 40 77

460-3-60 414 506 16,000 24,000 65/57 95/72 40 77

575-3-60 540 630 16,000 24,000 65/57 95/72 40 77

VoltageVariation Supply Air Range CFM

Min. Max. Min. Max. Min. Max. Min. Max.

Cooling

DB/WB

Heating DB

*

Unitary Products Group 5

Page 6

TABLE 2: PHYSICAL DATA

DESCRIPTION

Rows Deep X Rows High 4 x 40 4 x 40 4 x 50 4 x 62

Finned Length, Inches 93 93 96 96

EVAPORATOR

COIL

CENTRIFUGAL

BLOWERS (2 PER UNIT)

FILTERS (THROWAWAY)

OPERATING CHARGE

(LBS R-22)

DRAINABLE HOT WATER

COIL ACCESSORY

NON-FREEZE, STEAM

DISTRIBUTING COIL

ACCESSORY

COMPONENT WEIGHT

Face Area, Feet

Tube (copper) OD, Inches 3/8 3/8 3/8 3/8

Fins (Aluminum) per 1 inch 16 16 16 16

Piping Connections,

Inches

Diameter X Width, Inches (Forward Curved) 18 x 18 20 x 18

Size and Quantity Per

Model, Inches

Total Face A rea / feet

System 1 49.65 30.08 37.83 46.59

System 2 - 30.08 37.83 46.59

Tube (copper) OD, Inches 1/2 1/2 1/2

Rows Deep 2 2 2

Fins (Aluminum) per 1 inch 12 12 8

Face Area, Feet

Connections (Supply & Return), Inches 1 3/8 OD (Copper) 1 5/8 OD (Copper)

Tube (copper) OD, inches 1 (Outside) 5/8 (Inside)

Rows Deep 1

Fins (Aluminum) per 1 inch 8

Face Area, feet

Connection, (Brass )

Inches (NPTE)

Basic Unit (Less Motor & Drive) 980 980 1260 1474

Shipping Weight (lbs) 1180 1180 1510 Operating Weight (lbs) 1125 1146 1426 1640

Accessories

Blower Motor (1750 RPM)

035-18496-000-C-1102

MODEL

LA300 LB360 LB480 LB600

2

Liquid, Inches 7/8 7/8 7/8 7/8

Suction, Inches 2 1/8 1 1/8 1 3/8 2 1/8

16 x 20 x 2 - 6 20 x 20 x 2 - 3 20 x 22 x 2 - - 16 x 25 x 2 - - 6

20 x 25 x 2 10 6 3

25 x 25 x 2 - - 6

2

2

2

Inlet 2

Outlet 1-1/2

Hot Water C oil 150 150 190 190

Steam Coil 160 160 - -

25.8 25.8 33.3 41.3

34.7 42.6 53.1

21.2 27.2 27.2

18.2

N/A

117(5hp) 117 (5hp) - -

120 (7.5hp) 120 (7.5hp) 120 (7.5hp) 141 (10hp)

- 141 (10hp) 141 (10hp) 217 (15hp)

6 UnitaryProductsGroup

Page 7

035-18496-000-C-1102

a

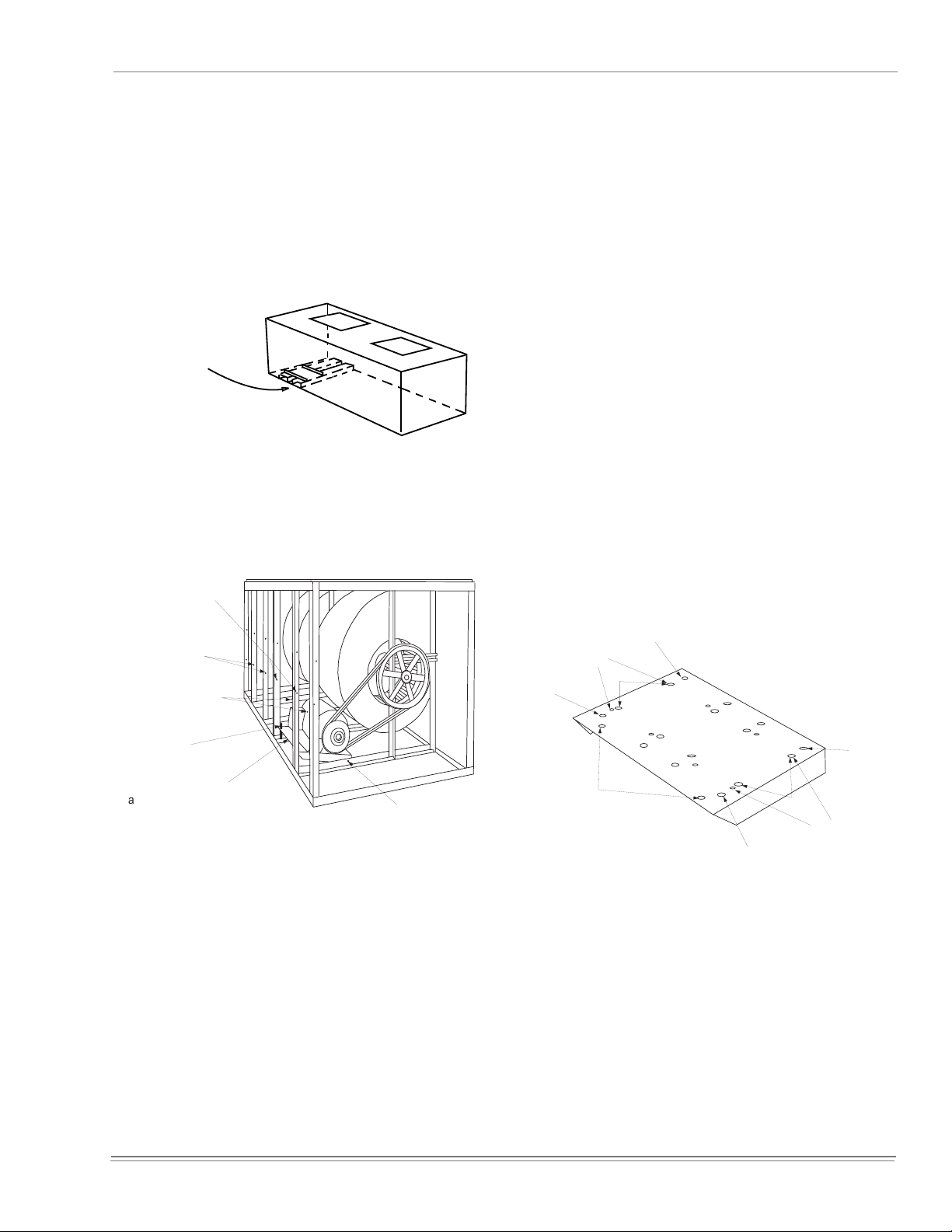

BLOWER MOTOR MOUNTING LOCATIONS

Unitsareshippedfrom the factory less motor and drives. The

blower motor and drive packages are ordered and shipped

separatelyfor field mounting. However, the units are shipped

with the motor mounting assembly installed as shown in

1 for the LA300, LB360, LB480 and 2 for the LB600.

MOTOR MOUNTING

CHANNELS AND

MOUNTING PLATE

ARE ALWAYS

SHIPPED IN THIS

LOCATION.

FIGURE 1 - LA300 AN LB360/LB480 FACTORY

MOTOR MOUNTING POSITION

NOTE: The 5HP motors are not inherently protected.

A lte rn a tiv e P o s itio n

1 F o r P iv o t B o lts

Alternate

Position 3

F o r P iv o t B o lts

A lte rn a tiv e P o s itio n

2 F o r P iv o t B o lts

LA300/LB360/LB480 MOTOR MOUNTING

The LA300, LB360 and LB480 ship from the factory with a

motor mounting adapter plate for use with the 7.5 and 10 HP

motors. If a 5 HP motor is used,the adapter is not necessary

and should be removed and discarded.

LB600 MOTOR MOUNTING

The motor mounting plate will accommodate a 10 or 15 HP

motor. One set of boltholes is provided on each end of the

motor mounting plate for either motor. The motor mounting

plate can be raised or lowered to any position on the adjustment screws to adjust the belt tension for the various pulley

settings to cover the complete range of blower speeds.

The physical size of the 15HP motor reducesthe adjustment

range of the motor mounting plate. To maximize this amount

of adjustment, one set of boltholesis provided near the

adjustment screws on each end of the motor mounting plate

(refer to 4).

For some motor/blower wheel arrangements,however, the

motor cannot be mounted in these bolt holes because the

motor terminal box would interfere with one of the blower section panels. To make these motor/blower wheel arrangements possible, a second set of boltholes is provided near

the pivot bolts on each end of the motor mounting plate.

15 H P

10 H P

15 H P

15 H P

Adjustm ent

S c re w (2 )

M otor M ounting P late

(S tandard Location

s Shipped)

P iv o t B o lt (2 )

FIGURE 2 - LB600 FACTORY MOTOR MOUNTING

POSITION

Adjustm ent

Screw Holes

15 H P

15 H P

15 H P

10 H P

FIGURE 3 - LB600 MOTOR MOUNT PLATE

The motors used withthe evaporator blower are 3-phaseand

can drive the blower wheels from either end of the blower

section. Reversing the direction of rotation can be accomplished by changing the connection of the power supply wiring at the motor terminal box.

NOTE: The 7.5-15 HP blower motors have solid bases

and are not inherently protected. For proper

operation, these motors require overload

heater elements. Please see curent product

price pages for overloads.

Unitary Products Group 7

The 15 HP drive package requires two different lengths of

belts to vary the blower wheel RPM over the complete range

of rated conditions. When the motor is mounted near the

adjustment screws, the two lengths of belt are interchangeable except for the higher and lower limits of blower wheel

RPM. When the m otor is mounted near the pivot bolts, the

shorter length of belt is recommended for the higher blower

wheel Rpm's and the longer length of belt is recommended

for the lower blower wheel Rpm's. See Page 7 for the recommended blower motor locations.

Page 8

035-18496-000-C-1102

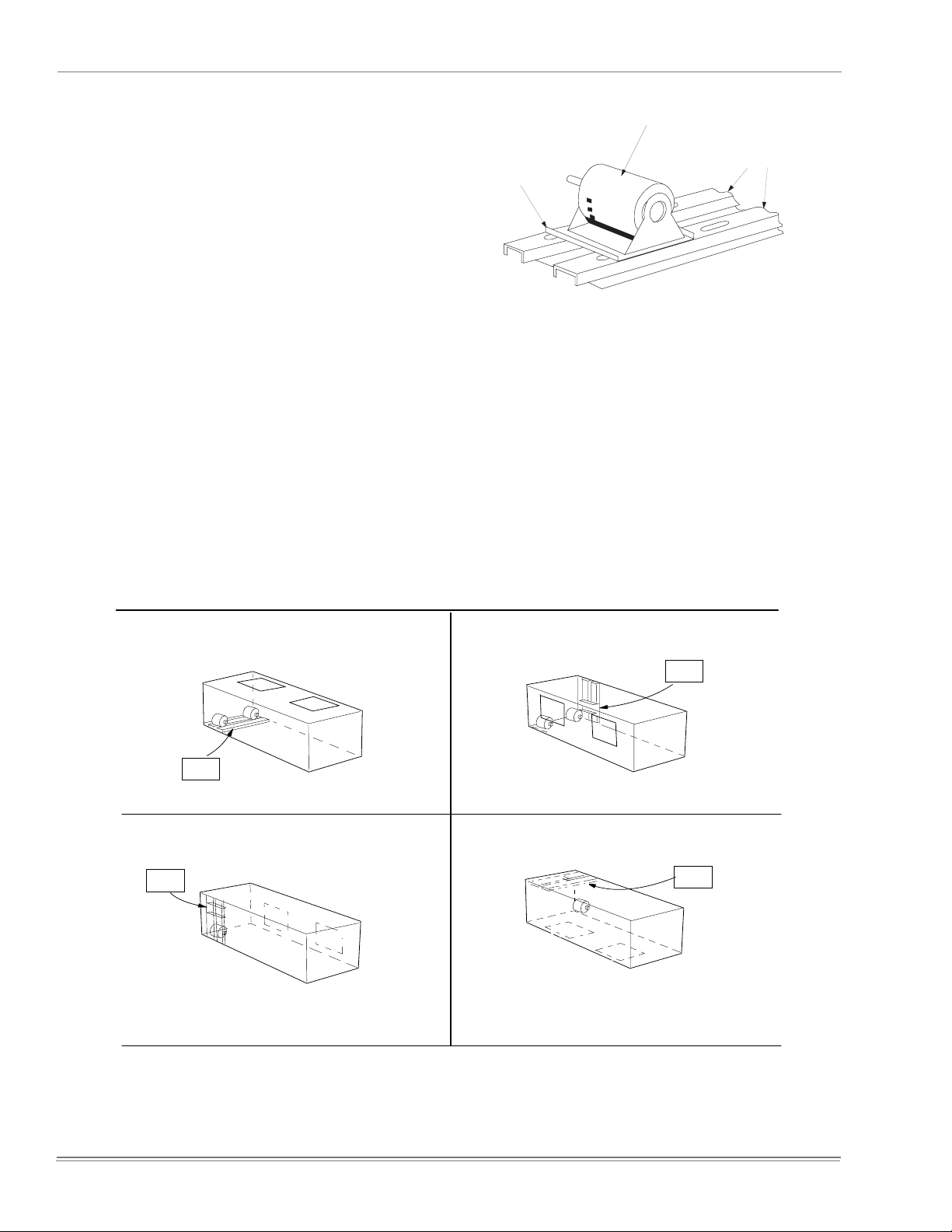

MOTOR MOUNT ARRANGEMENTS

The motor mounting arrangement can be changed to allow

motor access based on the airflow arrangement required.

The recommended motor location for each blower arrangement is as follows.

LA300/LB360/LB480 MOTOR ARRANGEMENTS

The LA300, LB360 and LB480 units are shipped with the

motor mount in locationA as shownin 4. If this is the desired

position, the motor mounting assembly is already in the correct position and the motor and drive package can be

installedwithout modifications.

ADDITIONAL MOTOR ARRANGMENTS FOR LA300/

LB360/LB480

Move the entire motor amounting assembly (both the mounting plate and the channels) so that the mountingplate will be

in the correct location.

1. Rotate the motor mounting plate 180 degrees on the

mountingchannels.(For locations B, andD only! Do not

rotate the plate for location C or E.)

MOTOR

MOTOR

MOTOR

MOUNTING

MOUNTING

CHANNELS

PLATE

FIGURE 4 - LA300/LB360/LB480 MOTOR

LOCATION A

2. Install the motor and drive package.

NOTE: The blower section must be lifted off the evap-

orator section to gain access to the mounting

channel fasteners. Since these sections have

to be repositioned for the arrangements 2

through 10 and 12 of 6, the motor mounting

assembly should be relocated before the two

sectionsare rejoined.

ARRANGEMENT 1, 4, 8 OR 11

B

A

SEE

NOTES

ARRANGEMENT 3, 5 OR 10

SEE

NOTES

E

NOTE: Since the motor mounting assembly cannot be

secured to the panel with the blower openings,

the motor cannot be installed in either of the

normally recommended bottom positions.

FIGURE 5 - LA300/LB360/LB480 MOTOR ARRANGEMENTS

ARRANGEMENT 2, 6 OR 7

D

C

ARRANGEMENT 9 OR 12

C

SEE

NOTES

SEE

NOTES

8 UnitaryProductsGroup

Page 9

035-18496-000-C-1102

LB600 MOTOR ARRANGEMENTS

The LB600 unit is shipped with the motor mount in the standard location as shown in 2.

If this is the desired position, the motor mounting assembly is

already in the correct position and the motor and drive package can be installed without modifications.

RE-LOCATING THE LB600 MOTOR MOUNTING PLATE

The motor mounting plate can bere-locatedin three alternate

positions:

ALTERNATE POSITION ONE

For locating motor mounting plate in alternate position one,

see 3 and re-locate as follows:

1. Remove pivot bolts from the mounting plate.

2. Remove the mounting plate from the adjustment screws.

3. Rotate mounting plate 180.

4. With pivot bolts removed in Step 1 fasten the mounting

plate to alternate position No. one.

5. Fasten mounting plate to the adjustment screws.

ALTERNATE POSITION TWO

The motor mounting plate, the pivot bolts and the adjustment

screws can be m oved intoa position similar to the one shown

as standard in 3 but under the other blower scroll. The framework under each blower scroll has the same bolthole

arrangement.

ALTERNATE POSITION THREE

The motor mounting plate, the pivot bolts and the adjustment

screws can be moved into a position similar to the one

detailed in alternate position one but behind the other blower

scroll. The framework behind each blower scroll has the

same bolthole arrangement.

AIR DISCHARGE CONVERSION

LA360/LB360/LB480 AIR DISCHARGE

The LA300 LB360 and LB480 units are shipped for upflow

operation, but may be converted for any of the illustrated air

discharge patterns shown in 7 and 8. C onvert as follows:

1. Remove the panels from the blower section.

2. Remove the Phillips machine screws located inside casing corner angles that hold the coil and blower sections

together.

3. Rotate the blower section for the desired air discharge

pattern.

NOTE: Before proceeding to step 4, see the section

on the blower motor mounting locations and

mount the blower motor in the desired position.

4. If accessory heating coils are used, mount heating coil

between cooling coil and blower sections. Screw fastening locations are the same for all sections and heating

accessories. If heating coils are not used, fasten coil

section to blower section with machine screws removed

in step 2.

5. Before replacingpanels, see duct connectionsand drain

connections.

6. Replace panels.

Unitary Products Group 9

Page 10

035-18496-000-C-1102

1

BLOWER

AIR

AIR

EVAPORATOR

COIL

AIR

2

AIR

**

AIR

AIR

4

AIR

AIR

5

**

FIGURE 6 - VERTICAL AIRFLOW ARRANGEMENTS

78

VERTICAL ARRANGEMENTS

AIR

AIR

AIR

3

AIR

*

6

* IF REQUIRED, SOME AIR CAN

BE BROUGHT THROUGH THE

BOTTOM OF THE EVAPORATOR

SECTION.

AIR

*

9

AIR

AIR

AIR

10

AIR

AIR

FIGURE 7 - HORIZONTAL AIRFLOW ARRANGEMENTS

AIR

11

AIR

AIR

AIR

12

AIR

AIR

10 UnitaryProductsGroup

Page 11

035-18496-000-C-1102

LB600 AIR DISCHARGE

The LB600 blower and coil section are shipped separately

and must be joined in the field. The blower section can be

mounted either above the coil for a vertical positioning or

beside the coil for horizontal positioning. Both vertical and

horizontal positions can be arranged for upward, downward,

or horizontal air discharge.

1

2

3

54

NOTE: Ductwork should never be used to support the

blower section. Refer to duct connection for

more information

UNIT INSTALLATION

LOCATION

The evaporator blowers are not designed for outdoor installation. They must be located inside the building structure,

either inside or outside the conditioned space where they are

protected from rain and other such moisture.

The unit should be located as close to the condensing unit as

practical and positioned to minimize bends in the refrigerant

piping.

Units being installed vertically or horizontally can be set

directly on a floor or platform, or supported by metal or

wooden beams.

Units being installed horizontally (LA300, LB360 & LB480

only) can be suspended from above as shown in figure 12.

Refer to form 035-18501-000 for more information on the

installationof the suspension accessory and for the individual

load on each hanger rod.

6

7

FIGURE 8 - LB600 AIRFLOW ARRANGEMENTS

The coil section and the blower section may be assembled

together as shown in 8. All arrangements may be by rearranging the panels as shown.

When arranged vertically (8, arrangements 1 through 3), the

LB600 can be set directly on any floor or platform that is

capable of supporting its weight.

When arranged horizontally (8, arrangements 4 through 7),

the evaporator coil section can be set directly on the floor, but

a 9" support is required under the blower section to stabilize

the unit. The support should extend the full width of the

blower section and be located under the edge away from the

evaporator coil section. If the unit does not have to be

secured to the platform, the 9" support will not have to be

bolted to either the blower section or the floor.

The evaporator blower arrangement 7 shown in 8 is not recommended for bottom support due to interference with the

ductwork connection.

RIGGING

Caremustbetakenwhenmovingtheunit. Donotremove

any packaging until the unit is near the place of installation.

SPREADER BARS SHOULD BE USED BETWEEN THE

SLINGS TO PREVENT CRUSHING THE UNIT FRAME OR

PANELS. When preparing to move the unit, always determine the center of gravity of the unit in order to equally distribute the weight. Rig the unit by attaching chain or cable

slings around the bottom skid. A lift truck may be used to

raise a unit to a suspended location. Refer to Table 2 for the

total unit operating weight.

CLEARANCES

A 25-inch clearance is required on the end with the piping

connections and the supply air blower motor to properly service and maintain the unit and to replace the filters.

Some clearance will also be required for the duct and power

wire connections. A clearance equal to the unit width is

required on one end of the unit if the blower shaft or evaporator coil is to be replaced without moving the unit.

Unitary Products Group 11

Page 12

TABLE 3: UNIT MOUNTING DIMENSIONS

035-18496-000-C-1102

LA/LB

UNIT

300

360

480

AX BX CX

69-1/4 49-1/16 26-5/8

69-1/4 49-1/16 26-5/8

84 50-9/16 34

DIMENSIONS, INCHES

MOUNTING

The evaporator blower may be suspended from the joists with

isolation type hangers or hooks. Suspension accessory

1HH0403, which includes three suspension channels and

hardware, may be ordered separately. The channels extend

TABLE 4: CORNER WEIGHTS

UNIT-

MODEL

LA300 1180 1125

LB360 1180 1146

LB480 1510 1426

LB600 - 1640

Unit Weight (Lbs.)

across the evaporator coil section, the heating coil section (if

included) and the blower section. Each channel is to be

bolted to each section as shown in 9.

Configuration ABCDShipping Operation

HORIZONTAL 276 317 285 247

VERTICAL 262 301 301 262

HORIZONTAL 281 323 290 252

VERTICAL 266 307 307 266

HORIZONTAL 348 414 361 303

VERTICAL 292 348 427 359

HORIZONTAL 451 386 370 433

VERTICAL 484 414 342 400

TABLE 5: ACCESSORY OPERATING WEIGHT DISTRIBUTION (LBS)

ACCESSORY

†

BASE

HOT WATER COIL

STEAM COIL 1 ROW

*.

These weights should be added to each point load (W1 through W6) in table 5.

†.

This accessory can only be applied on units installed in the vertical position.

LA300 LB360 LB480 LB600

25 25 30 45

35 35 45 35

30 30 35 50

*

12 UnitaryProductsGroup

Page 13

035-18496-000-C-1102

NOTE: The following illustration shows how the channels

should be secured to the unit using the hardware

provided with the suspension accessory.

(2) 9/16 HOLES FOR 1/2

HANGER RODS

SUSPENSION

CHANNEL

5/16 NUT,

FLATWASHER

3/8 NUT (USED

AS SPACER)

3

LOCKWASHER,

FLATWASHER

UNIT PANEL

5/16 BOLT,

FLAT-WASHER

SIDE

PANEL

UNIT ANGLE

FIGURE 9 - DETAILS FOR SECURING BOTTOM MOUNTING SUPPORTS

D

AX

AX

A

3

1-1/2

EVAP. C OIL

HOR IZONTAL

LE U 360 O R 480

UN IT S U S PE ND ED

FR OM ABOVE

T he s ame c hannels ca n be us ed in e ither pos ition. W he n us ed to

1

support at ve rtical u nit, the se c hannels s hould be c ut to ma tch the

bottom dimens ion of the e vapora tor coil s ection.

T he s uspens ion cha nnels h ave two s ets o f mounting holes to

ac commodate horizontal u nits with or without a he ating coil. O n

2

a h orizontal unit without a h eating coil, th e s uspens ion cha nnels

will extend 3 " beyond both e nds of the unit.

3

S E CT ION

BX

VERTICAL LA300, LB360, LB480

UNIT SUPPORTED FROM BELOW

BX

C

HE AT ING C OIL

SUSPENSION

ANGLE S

2

A

1

B

BLOWER

S E CT ION

5/16 NUT,

D

BLOWER

S E CT ION

BX

B

EVAP.

COIL

S E CT ION

4

CX

BX

C

T he s ame c hannels can b e us ed to s upport a horiz ontal, fl oor-

3

mounted unit from be low.

After these bottom c hannels are c ut per Note 1 , a new h ole will h ave

4

to be d rilled a t the cut e nd if the unit is to be m ounted on is olators.

FIGURE 10 - LA300/LB480/LB360 WEIGHT DISTRIBUTION

Unitary Products Group 13

Page 14

D = 295 LB S .

035-18496-000-C-1102

E = 300 LB S .

SUSPENSION

CHANNELS

A = 275 LB S .

B=280 LB S .

2

1

C =285 LB S.

2

1

2

1

2

F=310 LB S .

AIR

IN

BLOW ER SECTION

HEATING COIL (ACCESSO R Y)

EVAPORATOR CO IL SECTIO N

FIGURE 11 - LB600 WEIGHT DISTRIBUTION WITH SUSPENSION APPLICATION

The weights for the LB600 shown in 11 include only the evaporator coil section, the blower section with a 10HP motor and

the suspension accessory. Add the weights listed for a horizontal arrangement in Table 4 to determine the weight distribution of the unit with accessories. See 12 for details on

connecting the center channel to the unit at points one and

two.

The weights are located 5" from both ends of each suspension channel.

When arranged horizontally (see 8) the LB600 evaporator

blower can be suspended from overhead joists with hanger

rods using the suspension accessory.

The suspension channels require no drilling or cutting. Each

channel has enough holes in its bottom flange for:

1. Four bolted connections to the evaporator coil section.

(Only two are used on the outside supports)

3. Four bolted connections to the blowersection. (Only two

are used on the outside supports)

See 12 for the bolted connection in detail.

When the heating section is not included, each channel will

extend 3" beyond the front and the rear of the unit. Boltholes

inthebottomflangeofeachchannelwillstillalignwiththe

holes provided in the top framework of the evaporator coil

section and the blower section.

For both outsidechannels and for the 1" locations on thecenter channel, the bolted connections are to be made where the

top sheet metal panels are attached to the unit framework.

The ¼" screws and cage nuts must be removed and may be

discarded. For the 2" locations on the center channel, the

bolted connections are to be made through the knockouts in

the top sheet metal panels. 5/16" cage nuts are provided in

the unit framework under these knockout locations. Note that

these cage nuts are part of the basic unit. They are not supplied with the suspension accessory.

2. One bolted connection to the heating coil section.

Refer to 11 as well as Table 3 and Table 4 for mounting

details and unit weight distribution.

14 UnitaryProductsGroup

Page 15

035-18496-000-C-1102

SUSPENSIO N CH ANN EL

5/16-18" HE X NU T

OUTSIDE CHANN EL

9/16" H O LE FO R 1/2" H A N G ER R O D

(2 P E R C H A N N E L )

5/16-18" HE X NU T

LOCK W ASHER

SPACER (3/8" LONG )

SID E PAN EL

C E N TE R C H A N N E L (Location "1" Figure 6)

SUSPENSIO N CH ANN EL

5/16-18" HE X NU T

TOP PANEL

CENTER FRAME

OF UNIT SECTIONS

(2 1 /8 " X 3 /8 " )

M AC H IN E SC R E W (5/16-18 X 1-1/2 LG )

C E N TE R C H A N N E L (Location "2" in Figure 6)

SUSPENSIO N CH ANN EL

9/16" FLA T W AS H E R

TOP PANEL

CENTER FRAME

OF UNIT SECTIONS

(2 1 /8 " X 3 /8 " )

5/16-18" CA G E NU T

9/16" FLA T W AS H E R

TOP PANEL

9/16" FLA T W AS H E R

M AC H IN E SC R E W (5/16-18 X 1-1/2 LG )

OUTER FRAME OF UNIT SECTION

(1 -3/4 " X 1 -3/4 ")

9/16" H O LE FO R 1/2" H A N G ER R O D

(2 P E R C H A N N E L )

5/16-18" HE X NU T

LOCK W ASHER

9/16" FLA T W AS H E R

SPACER (3/8" LONG )

TOP PANEL

9/16" FLA T W AS H E R

9/16" H O LE FO R 1/2" H A N G ER R O D

(2 P E R C H A N N E L )

M AC H IN E SC R E W (5/16-18 X 1-1/2 LG )

LOCK W ASHER

9/16" FLA T W AS H E R

SPACER (1/2" LONG )

TOP PANEL

FIGURE 12 - DETAILS FOR SECURING SUSPENSION CHANNELS

DUCT CONNECTIONS

Ductwork should always be suspended with hangers or supported by legs. It should never be fastened directly to the

building structure.

Allow clearance around ducts for safety in the handling of

heated air and for insulation when required.

INSULATION

Ductwork insulation should meet the following criteria:

Be used when ducts pass through an unconditioned space in

the cooling season or through an unheated space during the

heating season.

Unitary Products Group 15

Include a vapor barrier around the outside to prevent the

absorption of moisture.

Be no less than 2 inches thick with the weatherproof coating

when applied to ducts exposed to outdoor conditions.

SUPPLY AIR DUCTS

See 13 for suggested method of connecting supply air ductwork. Non-flammable material collars should be used to minimize the transmission of noise and/or vibration.

Page 16

(

)

NON-FLAMMABLE

COLLAR

24"

AIR

OUTLET

BLOWER

GASKETS

BY INSTALLER

DUCT

FLANGED DUCT

CONNECTION

(FIELD

FABRICATED)

FIGURE 13 - SUGGESTED METHOD FOR CONNECTING DUCTWORK

035-18496-000-C-1102

DUCT

TRANSITION

RETURN AIR DUCT ANGLES

Return air duct angles are shipped turned in. They are

intended to be unscrewed and turned for connection of ductwork. The return air grille accessory attaches in the same

manner as the panels.

DRAIN CONNECTIONS

All drain lines MUST be trapped and located so they will not

be exposed to freezing temperatures.

The evaporator blower has 7/8" OD steel condensate stub at

each end of a single drain pan. Both ends are closed with

plastic caps. A plastic or rubber ell can be used. (Field supplied) Attach the ell to the desired end and run a full size 7/8"

drain line to the nearest drain facility. Seal the cap at the

unused end with suitable mastic.

Drain piping should be constructed as shown in 14. The 3inch dimension must equal or exceed the negative static

pressure developed by the supply air blowers. If it does not,

the condensate will not drain properly and may overflow the

drain pan. The trap must be at least 2-inches deep to maintain a water seal under all operating conditions, especially

when the blowers are starting.

FIGURE 14 - RECOMMENDED DRAIN PIPING

REFRIGERANT MAINS

Hard drawn copper tubing should be used where no appreciable amount of bending around pipes or other obstructions

is necessary. Use long radius ells wherever possible. If soft

copper is used, care should be taken to avoid sharp bends

that may cause a restriction.

Where refrigerant lines pass through a wall, pack fiberglass

insulation and a sealing material such as permagum around

the refrigerant lines to reduce vibration and to retain some

flexibility in the lines.

16 UnitaryProductsGroup

Page 17

035-18496-000-C-1102

Suitable hangers, brackets or clamps should support the

refrigerant lines.

Braze all copper-to-copper joints with Silfos-5 or equivalent

brazing material. Do not use soft solder.

Never braze or solder the liquid and suction lines together.

The complete suction line should be insulated with no less

than ½" Armaflex or equivalent.

If it is desirable to tape or wire the liquid and suctions lines

together for support purposes, they must be completely insulatedfromeachother.

EVAPORATOR SECTION PIPING

The units are shipped with a holding charge of R-22. The

connections are terminatedwith a copper disc brazed over

the ends.

Before starting installation of the mains, be sure the unit has

not developed a leak in transit by connecting a pressure

gauge to the service access port. If pressure still exits, the

circuit may be considered leak free. If pressure does not

exist, the unit must be evacuated along with the field installed

refrigerant piping.

NOTE: To minimize the possibility of system failure

due to dirt and moisture, a filter-drier must be

installed in each liquid line as close to the

evaporator as possible. Filter-driers are not

supplied with the evaporator blowers. They

are supplied with the matching HA/HB series

condensing units.

The temperature required to make or break a brazed joint is

sufficiently high to cause oxidation of the copper unless an

inert atmosphere is provided.

The liquid, suction and drain connectionsinside the unit must

be piped to the outside. Refer to 17 and 23 for unit dimensions or the locations and the dimensions of the access

openings in the unit panel.

Remove the evaporatorholding charge and any caps or discs

on the liquid and suction connections that will not permit a

free flow of nitrogen.

Connect a supplyof dry nitrogen through a reducing regulator

to an access valve or charging tail. Choose a procedure that

will allow nitrogen to flow continuously through the system

and reach all jointsto be brazed.

Begin the refrigerant main piping by installing the liquid line

from the condensing unit to the evaporator liquid connection,

maintaining a flow of nitrogen during all brazing operations.

The filter drier and sight glass must be located in this line,

close to the evaporator. Make the suction line connection at

the evaporator and run the line to the condensing unit.

After puncturing the sealing caps with a small drill bit,

unbraze the condensing unit suction disc and connect the

line. Maintainaflowofnitrogenthroughtheliquidlinetothe

evaporator, through the evaporator, back to the condensing

unit and out the suction connection and service port.

NOTE: Size the suction line outside the evaporator

casing per the line sizing information provided

in the condensing unit instruction form 03518499-000.

EXPANSION VALVE BULB INSTALLATION

LA300

The bulbs for the thermal expansionvalve on theblower units

are not factory-installed in its final location; it's only temporarily taped for shipment. They must be fastened in a 4

o'clock and 8 o'clock position to the common suction l ine out

of the evaporator coil after piping connections are made. Use

the bulb clamps from the bag taped to the suction connection

inside the blower unit.

LB360/LB480/LB600

The bulbs for the thermal expansionvalve on theblower units

are not factory-installed in its final location; it's only temporarily taped for shipment. The bulbs for system one must be

fastened in a 4 o'clock and 8 o'clock position to the system

one suction line of system one leaving the evaporator coil

after piping connections are made. Repeat the procedure for

system two, locating the bulbs in a 4 o'clock and 8 o'clock

position to the system two suction line. Use the bulb clamps

from the bag taped to the suction connection inside the

blower unit.

NOTE: Ensure the TXV bulbs are not crossed

between systems. Undesirable performance

and possible compressor damage may occur.

LIQUID LINE SOLENOIDS

The unit is shipped with factory installed, normally closed, liquid line solenoid valves. When the solenoid coil is energized

with a 24-volt signal, the valve will open.

During brazing operations, the valves should be placed in the

OPEN position by removing the stem cap with a 9/16”

wrench, then rotating the exposed valve stem inward

(CLOCKWISE), approximately 10-12 full turns (from the fully

CLOSED position), using a 4” adjustable wrench.

The valve stems should be returned to the CLOSED

(COUNTER-CLOCKWISE) position prior to the unit’soperation. The “Pump-out” procedure is detailed in the following

section.

The sequence of operation applies to the HA/HB condensing

units and LA/LB air handlers when applied as a matched system. Non-matched systems will have to be field wired to operate in a similar fashion as described on page 19.

NOTE: See Liquid Line Solenoid Wiring on page 22.

Unitary Products Group 17

Page 18

PUMP OUT

The pump out function is a standard feature on the 25 to 50

ton systems. The pump out circuit is activated each time the

first and third compressor stage is called for by the thermostat. As such, it’sa“Pump Out On Start Up” design. A normally closed solenoid valve (POS1, 2, 3 or 4) is placed in the

liquid line, just prior to expansion valve.

When cooling is not being called for by the thermostat, the

pump out solenoid (POS) is not energized, so it’sinthe

closed position. When the Simplicity™ control receives a call

for cooling, it energizes a compressor. With the POS being

closed, it causes the pressure on the low side of the system

to begin falling.

When the low pressure switch (LPS) opens, the control board

energizes its on-board pump out relay, providing a 24 vac

output to an external relaly used to energized the pump out

solenoid. The refrigeration circuit being controlled is not in

normal operating mode.

035-18496-000-C-1102

BEARING C OLLAR

SET SC REW

BEARING

C O LLA R

BLOW ER

SHAFT

SHIM

SHAFT

RO TATION

BOLT "B" BOLT "B"

BEARING SU PPOR T ANG LE

BOLT "A"

BEARING

BEARING

C O LLA R

REM O VAL

HOLE

FIGURE 15 - LB600 CENTER BEARING

AIR SYSTEM ADJUSTMENT

Refer to Tables 7-11 on pages 19-20 to adjust the air system.

If the low pressure switch is already open on a call for cooling, the pump out relay is energized immediately. If the LPS

does not open after 5 minutes, the pump out relay is energized.

BEARING ALIGNMENT: LB600

Before the supply air blowerdrive is installed,turn the blower

assemblyby hand several times. If it doesn't rotate freely, the

center bearing may have been knocked out of alignment during shipping and/or rigging. To realign, refer to 15 and the following instructions:

1. Loosen the bearing collar set screw.

2. With a drift pin in the bearing collar removal hole, loosen

the bearing collar by tapping the drift pin in the direction

opposite to the shaft rotation.

3. Loosen bolts "A" and "B".

4. Remove the shim.

NOTE: The bearing support angle must be horizontal

to the unit and below the bearing.

5. Tighten bolts "B" without the shim.

6. Tighten bolts "A".

7. With a drift pin in the bearing collar removal hole, tighten

the bearing collar by tapping the drift pin once in the

direction of the shaft rotation.

TWIN BELT DRIVE ADJUSTMENT

Check to see if both belts drive at the same speed. Do this

by making a mark across both belts. Turn the drive several

revolutions by hand. If mark has not separated, the belts are

traveling at the same speed.

Twingroove blower motor pulleys should be installed with the

shaft set screw (A) towards the motor (see 16).

B

A

C

B

E

D

C

STATIONARY WEB

FIGURE 16 - DOUBLE GROOVE PULLEY

If necessary to align pulleys, the housing of the twin groove

motor pulley may extend 25% of its length beyond end of

motor shaft.

8. Tighten the bearing collar set screw.

9. Loosen bolts "B"

10. Raise the blower shaft and re-install the shim between

Always align twin groove pulleys using the stationary web.

The blower motor pulleys are adjustable by half turns. Select

required RPM from table 5 and adjust pulley.

the bearing and the bearing support angle.

11. Tighten bolts "B".

18 UnitaryProductsGroup

Page 19

035-18496-000-C-1102

Check belt tension. Drive packages are supplied with fiberglass belts that must be properly tensioned at installation

because they do not stretch. The belt should deflect 3/16"

per foot of belt span with a 2 or 3-pound force. Alignment of

the resilient motor mount can be corrected by adjustment at

the slots on the end opposite the pulleys.

ELECTRICAL CONNECTIONS

The electric box ships complete with motor starter, transformers, relays and terminal block for making field connections.

Remember: One air handlers with factory installed pump out

solenoids, wires to the solenoid must be field connected.

Refer to Figures 30 & 31 for Indoor Unit Wiring Diagrams.

Install a power supply to meet the requirements listed in

table 6.

Provide a disconnect switch and fusing as required.

Install interconnecting control wiring between condensing

section, evaporator blower and room thermostat.

Starters are shipped without overloads. These must be

ordered separately to match the selected motor used in the

air handler. See unit’s Technical Guide or price page for correct overload.

NOTE: For the 10HP 200/208-volt motors, install the

power wiring to the supply air blower through

the starter.

TABLE 6: ELECTRICAL DATA

UNIT

MODEL

LA300

LB360

LB480

LB600

HP FLA

5

7.5

5.0

7.5

10

7.5

10

10

15

VOLTAGE

(3PH-60HZ)

16.7 208 21 35

15.2 230 19 30

7.6 460 10 15

6.1 575 8 15

24.2 208 30 50

22 230 28 45

11 460 14 20

9 575 11 20

16.7 208 21 35

15.2 230 19 30

7.6 460 10 15

6.1 575 8 15

24.2 208 30 50

22 230 28 45

11 460 14 20

9 575 11 20

30.8 208 39 60

28 230 35 60

14 460 18 30

11 575 14 20

24.2 208 30 50

22 230 28 45

11 460 14 20

9 575 11 20

30.8 208 39 60

28 230 35 60

14 460 18 30

11 575 14 20

30.8 208 39 60

28 230 35 60

14 460 18 30

11 575 14 20

46.2 208 58 100

42 230 53 90

21 460 26 45

17 575 21 35

MIN

CIRCUIT

AMPACITY

MAX.

FUSE

SIZE

(Amps)

TABLE 7: MOTOR OVERLOAD ELEMENTS

*

MOTOR HP VOLTAGE MODEL NUMBER

208 2MP04704600

5

230 2MP04704600

460 2MP04704900

575 2MP04705000

208 2MP04703700

7.5

230 2MP04704500

460 2MP04704300

575 2MP04704000

208 2MP04701600

10

230 2MP04704100

460 2MP04704200

575 2MP04704300

208 2MP04704400

15

230 2MP04701700

460 2MP04704500

575 2MP04704600

*.

These units are equipped from the factory with a correctly sized motor starter; overload elements are not

factory supplied. Three elements required per unit.

Unitary Products Group 19

Page 20

035-18496-000-C-1102

TABLE 8: UNIT DRIVE DATA

UNIT MODEL

LA300

LB360

LB480 1LD0409 607 - 776 4.3 - 5.5 1 3/8 12.4 1 3/16 2 85.1 B84

LB600 1LD0411 692 - 833 4.8 - 6.0 1 3/8 12.4 1 3/16 2 78.6 B78

DRIVE KIT

MODEL

NUMBER

1LD0440 600 - 750 4.0 - 5.0 1 1/8 12.0 1 3/16 2 63.3 A62

1LD0407 700 - 850 4.2 - 5.2 1 3/8 11.0 1 3/16 2 63.3 A62

1LD0442 780 - 940 5.3 - 6.3 1 3/8 12.0 1 3/16 2 63.3 A62

1LD0415 636 - 795 4.0 - 5.0 1 3/8 11.0 1 3/16 2 63.3 A62

1LD0407 668 - 827 4.2 - 5.2 1 3/8 11.0 1 3/16 2 63.3 A62

1LD0408 827 - 986 5.3 - 6.3 1 3/8 11.0 1 3/16 2 59.7 A59

1LD0410 776 - 917 5.4 - 6.6 1 3/8 12.4 1 3/16 2 86.8 B85

1LD0412 762 - 931 5.4 - 6.6 1 5/8 12.4 1 3/16 2 76.8 B75

BLOWER

RPM

RANGE

ADJUSTABLEMOTOR PULLEY FIXED BLOWER PULLEY BELTS

PITCH DIA.

(IN.)

BORE

(IN.)

PITCH DIA.

(IN.)

BORE

(IN.)

QTY.

PITCH

LENGTH

(IN.)

TABLE 9: UNIT BLOWER MOTOR DATA

UNIT MODEL HP MOTOR KIT MODEL NUMBER FRAME SIZE

2LR04605023

LA300

LB360

LB480

LB600

7.5

5.0

7.5

10

7.5

10

10

15

5

2LR04605032 208/230/460

2LR04605158 575

2LP04607133

2LP04607158 575

2LR04605023

2LR04605032 208/230/460

2LR04605158 575

2LP04607133

2LP04607158 575

2LP04610133

2LP04610158 575

2LP04607133

2LP04607158 575

2LP04610133

2LP04610158 575

2LP04610133

2LP04610158 575

2LP04615133

2LP04615158 575

184

213

184

213

215

213

215

215

254

VOLTAGE

(3PH-60-HZ)

208/230/460

208/230/460

208/230/460

208/230/460

208/230/460

208/230/460

208/230/460

208/230/460

208/230/460

DESIGNATION

MAINTENANCE

Filters must be cleaned or replaced as often as necessary to

assure good airflow and filtering action.

To remove filters through the sides of the unit, remove either

the solid sidepanel on the piping end, or the larger side panel

on the end opposite the piping.

To remove the filters from the front of the unit, loosen 2

screws and raise the top filter retainer. The upper filters can

20 UnitaryProductsGroup

be lifted over the center filter lip. Three wing nuts are provided under the center filter retainer. Remove these and a

part of the center filter support, givingaccess to the bottom filters.

Drain pan(s) should be inspected regularly to assure proper

drainage.

The evaporator blower bearings and blower motor bearings

are permanently lubricated.

Page 21

035-18496-000-C-1102

TABLE 10: FAN PEFORMANCE DATA - 25 TON

CFM

RPM

8,000 9,000 10,000 11,000 12,000

SP BHP kW SP BHP kW SP BHP kW SP BHP kW SP BHP kW

600 - - - 0.30 2.5 2.3 0.20 3.1 2.9 0.02 3.6 3.4 - - 635 0.56 2.4 2.3 0.43 2.7 2.6 0.31 3.3 3.1 0.13 3.8 3.5 - - 700 0.80 3.0 2.8 0.68 3.3 3.1 0.54 3.7 3.5 0.38 4.2 3.9 0.20 4.8 4.5

775 1.12 3.7 3.4 1.00 4.0 3.7 0.85 4.4 4.1 0.70 4.8 4.5 0.54 5.3 5.0

800 1.23 3.9 3.7 1.11 4.3 4.0 0.97 4.7 4.4 0.82 5.1 4.8 0.66 5.6 5.2

875 1.60 4.8 4.5 1.48 5.1 4.8 1.34 5.6 5.2 1.19 6.0 5.7 1.04 6.6 6.2

900 1.73 5.1 4.8 1.61 5.5 5.1 1.47 5.9 5.5 1.33 6.4 6.0 1.17 7.0 6.5

940 1.95 5.6 5.2 1.82 6.0 5.6 1.70 6.5 6.1 - - - - - -

TABLE11:FANPEFORMANCEDATA-30TON

CFM

RPM

600 0.38 2.8 2.4 0.23 3.3 2.9 0.06 3.9 3.4 - - - - - 635 0.52 3.1 2.7 0.37 3.7 3.2 0.21 4.3 3.7 0.03 4.9 4.2 - - 700 0.77 3.8 3.3 0.64 4.4 3.8 0.49 5.0 4.3 0.33 5.6 4.8 0.17 6.3 5.4

775 1.11 4.7 4.1 0.99 5.3 4.6 0.85 5.9 5.1 0.70 6.5 5.6 0.55 7.2 6.2

800 1.20 4.9 4.2 1.08 5.5 4.8 0.94 6.2 5.4 0.79 6.9 6.0 0.64 7.6 6.6

875 1.54 5.9 5.1 1.42 6.5 5.6 1.29 7.1 6.1 1.16 7.8 6.7 1.03 8.6 7.4

900 1.65 6.2 5.4 1.54 6.8 5.9 1.41 7.4 6.4 1.28 8.1 7.0 1.16 8.9 7.7

970 2.00 7.2 6.2 1.88 7.8 6.7 1.76 8.5 7.3 1.65 9.2 7.9 1.54 10.0 8.6

1000 2.15 7.6 6.6 2.03 8.2 7.1 1.92 8.8 7.6 1.81 9.5 8.2 1.71 10.4 9.0

10,000 11,000 12,000 13,000 14,000

SP BHP kW SP BHP kW SP BHP kW SP BHP kW SP BHP kW

TABLE 12: FAN PERFORMANCE DATA - 40 TON

CFM

RPM

600 0.84 6.0 5.2 0.63 7.2 6.2 0.40 8.4 7.2 0.13 9.7 8.4 - - 660 1.19 7.3 6.3 1.00 8.5 7.3 0.78 9.8 8.5 0.50 11.2 9.7 0.19 12.7 11.0

700 1.42 8.2 7.1 1.25 9.4 8.1 1.03 10.7 9.2 0.75 12.2 10.5 0.45 13.7 11.8

760 1.78 9.5 8.2 1.63 10.8 9.3 1.43 12.3 10.6 1.16 13.8 11.9 0.86 15.6 13.5

800 2.02 10.4 9.0 1.89 11.8 10.2 1.69 13.3 11.5 1.43 14.9 12.9 1.14 16.9 14.6

900 2.62 12.8 11.0 2.53 14.5 12.5 2.40 16.0 13.8 - - - - - 930 2.80 13.5 11.6 2.72 15.3 13.2 - - - - - - - - -

12,800 14,400 16,000 17,600 19,200

SP BHP kW SP BHP kW SP BHP kW SP BHP kW SP BHP kW

TABLE 13: FAN PERFORMANCE DATA - 50 TON

CFM

RPM

600 0.82 6.0 5.2 0.59 7.2 6.2 0.35 8.4 7.2 0.08 9.7 8.4 - - 660 1.17 7.3 6.3 0.96 8.5 7.3 0.73 9.8 8.5 0.45 11.2 9.7 0.14 12.7 11.0

700 1.40 8.2 7.1 1.21 9.4 8.1 0.98 10.7 9.2 0.70 12.2 10.5 0.40 13.7 11.8

760 1.76 9.5 8.2 1.59 10.8 9.3 1.38 12.3 10.6 1.11 13.8 11.9 0.81 15.6 13.5

800 2.00 10.4 9.0 1.85 11.8 10.2 1.64 13.3 11.5 1.38 14.9 12.9 1.09 16.9 14.6

900 2.60 12.8 11.0 2.49 14.5 12.5 2.35 16.0 13.8 - - - - - 930 2.78 13.5 11.6 2.68 15.3 13.2 - - - - - - - - -

16,000 18,000 20,000 22,000 24,000

SP BHP kW SP BHP kW SP BHP kW SP BHP kW SP BHP kW

Unitary Products Group 21

Page 22

C

EVAPORATOR

COIL SECTION

035-18496-000-C-1102

7/8 KNOCKOUTS FOR POWER

AND CONTROL WIRING

AIR

OUT

M

K

L

AIR

OUT

5/8

5/8

K

AIR

J

BLOWER

IN

AIR

IN

SECTION

G

H

KNOCKOUT

FOR

LIQUID

PIPING

KNOCKOUT

FOR

SUCTION

PIPING

F

D

LESS

BOTTOM

E

{

PANEL

D

See detailed drawings for piping

KNOCKOUT

FOR

DRAIN

PIPING

B

A

5/8 PANEL

and drain connections

on following pages.

D

5/8 BOTTOM

PANEL

FIGURE 17 - UNIT DIMENSIONS - LA300, LB360, LB480

TABLE 14: UNIT DIMENSIONS - LA300, LB360, LB480

MODEL

LA300

LB360

LB480

A BCDEFGH J KLM

100-1/8 95-5/8 33-1/4 36-5/8 74 2-1/2 18-7/8 16-1/2 15-13/16 21-7/8 18 22-9/16

100-1/8 95-5/8 33-1/4 36-5/8 74 2-1/2 18-7/8 16-1/2 15-13/16 21-7/8 18 22-9/16

103-1/8 95-5/8 40-5/8 44 88-5/8 2-1/2 18-7/8 23-7/8 20-11/16 21-7/8 18 22-11/16

FIGURE 18 - 25 TON LIQUID LINE SOLENOID

WIRING

FIGURE 19 - 30, 40 & 50 TON LIQUID LINE

SOLENOID WIRING

22 UnitaryProductsGroup

Page 23

035-18496-000-C-1102

SUCTION

LIQUID

SUCTION

SYS. #2

LIQUID

SYS. #1

LIQUID

SYS. #2

FIGURE 20 - LA300 PIPING CONNECTIONS

LIQUID (SYS. #1)

LIQUID (SYS. #2)

SUCTION

(SYS. #1)

SUCTION

(SYS. #2)

SYS. #1

FIGURE 22 - LB480 PIPING CONNECTIONS

TABLE 15: UNIT CONNECTION SIZES

Connection Entry

LA300 LB360 LB480 LB600 + M2CX600

Suction Line Sys # 1 2-1/8 1-1/8 1-3/8 2-1/8

Suction Line Sys # 2 N/A 1-1/8 1-3/8 2-1/8

Liquid Line Sys # 1 7/8 7/8 7/8 7/8

Liquid Line Sys # 2 N/A 7/8 7/8 7/8

Power Wiring 7/8 (2) 7/8 (2) 7/8 (2) 1-3/8

Control Wiring 7/8 (2) 7/8 (2) 7/8 (2) 7/8 (2)

Connection Size

FIGURE 21 - LB360 PIPING CONNECTIONS

Unitary Products Group 23

Page 24

035-18496-000-C-1102

FIGURE 23 - UNIT DIMENSIONS

Condensate

Drain

10.1"

23.86"

3.0"

Liquid

Line

Sys. #1

Liquid

Line

Sys. #2

3.0"

2.1"

6.7"

6.0"

4.7"

4.0"

3.8"

13.5"

24.0"

13.5"

SUCTION

LINE

SYS. #2

SUCTION

LINE

SYS. #1

FIGURE 24 - LB600 PIPING CONNECTIONS - END PANEL DETAIL

24 UnitaryProductsGroup

Page 25

035-18496-000-C-1102

To check the supply air CFM after the initial balancing has been completed:

1. Drill two (2) 5/16-inch holes in the side panel as shown in

Figure 24.

2. Insert at least 8 inches of 1/4 inch tubing into each of

these holes for sufficient penetration into the airflow on

both sides of the evaporator coil.

3. Using an inclined manometer, determine the pressure

drop across a dry evaporator coil. Since the moisture on

an evaporator coil may vary greatly, measuring the pressure drop across the wet coil under field conditions

would be inaccurate. To assure a dry coil, the refrigerant

system should be de-activated while the test is being

run.

4. Knowing the pressure drop across a dry coil, the actual

CFM through the unit can be determinedfrom the curves

shown in Figures 25-28.

If the CFM is above or below the specified value, the supply

air motor pulley may have to be readjusted. After one hour of

operation, check the belt and pulleys for tightness and alignment.

After readings have been obtained, remove the tubes and

seal up the drilled holes in the side panel. 5/16 inch dot plugs

(P/N 029-12880) are available through normal York parts

ordering procedures.

25"

7"

5/16"

HOLE

EVAPORATOR

COIL

22

"

5/16"

HOLE

14"

FILTERS

COIL SECTION

FIGURE 25 - HOLE LOCATION FOR PRESSURE

DROP READING

Failure to properly adjust the total system air

quantity can result in extensive blower damage.

Unitary Products Group 25

Page 26

25-ton

Pressure Drop Across Indoor Coil

1.00

0.90

0.80

0.70

0.60

0.50

I.W.C.

0.40

0.30

0.20

0.10

0.00

7000 8000 9000 10000 11000 12000 13000

035-18496-000-C-1102

CFM

FIGURE 26 - 25-TON PRESSURE DROP VS. CFM ACROSS INDOOR COIL

30-ton

Pressure Drop Across Indoor Coil

0.70

0.60

0.50

0.40

I.W.C.

0.30

0.20

0.10

0.00

9000 10000 11000 12000 13000 14000 15000

CFM

FIGURE 27 - 30-TON - PRESSURE DROP VS. CFM ACROSS INDOOR COIL

26 UnitaryProductsGroup

Page 27

035-18496-000-C-1102

0.70

0.60

0.50

0.40

I.W.C.

0.30

0.20

0.10

0.00

40-ton

Pressure Drop A cross Indoor Coil

12000 14000 16000 18000 20000

CFM

FIGURE 28 - 40 TON - PRESSURE DROP VS. CFM ACROSS INDOOR COIL (DOMESTIC)

50-ton

Pressure Drop Across Indoor Coil

0.70

0.60

0.50

0.40

I.W.C.

0.30

0.20

0.10

0.00

15000 17000 19000 21000 23000 25000

CFM

FIGURE 29 - 50 TON - PRESSURE DROP VS. CFM ACROSS INDOOR COIL

Unitary Products Group 27

Page 28

035-18496-000-C-1102

FIGURE 30 - INDOOR UNIT WIRING DIAGRAM LB360, 480 & 600

28 UnitaryProductsGroup

Page 29

035-18496-000-C-1102

FIGURE 31 - INDOOR WIRING DIAGRAM LA300

Unitary Products Group 29

Page 30

035-18496-000-C-1102

30 UnitaryProductsGroup

Page 31

035-18496-000-C-1102

Unitary Products Group 31

Page 32

Subject to change without notice. Printed in U.S.A. 035-18496-000-C-1102

Copyright © by Unitary Products Group 2002. All rights reserved. Supersedes: 035-18496-000-B-0302

Unitary 5005 Norman

Products York OK

Group Drive 73069

Loading...

Loading...