Energy Tech Laboratories DSH User Manual

Model DSH

Ceiling Mounted Ducted R-410A

New Release

Air Conditioning Units

CEILING MOUNTED DUCTED R-410A

AIR CONDITIONING UNITS

INSTALLATION INSTRUCTIONS

Form 145.32-IOM1 (908)

IMPORTANT!

READ BEFORE PROCEEDING!

GENERAL SAFETY GUIDELINES

FORM 145.32-IOM1 (908)

This equipment is a relatively complicated apparatus.

During installation, operation, maintenance or service,

individuals may be exposed to certain components or

conditions including, but not limited to: refrigerants, oils,

materials under pressure, rotating components, and

both high and low voltage. Each of these items has the

potential, if misused or handled improperly, to cause

bodily injury or death. It is the obligation and responsibility of operating/service personnel to identify and

recognize these inherent hazards, protect themselves,

and proceed safely in completing their tasks. Failure to

comply with any of these requirements could result in

serious damage to the equipment and the property in

SAFETY SYMBOLS

The following symbols are used in this document to alert the reader to areas of potential hazard:

DANGER indicates an imminently haz-

ardous situation which, if not avoided,

will result in death or serious injury.

which it is situated, as well as severe personal injury or

death to themselves and people at the site.

This document is intended for use by owner-authorized

operating/service personnel. It is expected that this

individual possesses independent training that will enable them to perform their assigned tasks properly and

safely. It is essential that, prior to performing any task

on this equipment, this individual shall have read and

understood this document and any referenced materials.

This individual shall also be familiar with and comply with

all applicable governmental standards and regulations

pertaining to the task in question.

CAUTION identies a hazard which could

lead to damage to the machine, damage

to other equipment and/or environmental pollution. Usually an instruction will

be given, together with a brief explanation.

WARNING indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

All wiring must be in accordance with published specications and must be performed ONLY

by qualied service personnel. Johnson Controls will not be responsible for damages/problems

resulting from improper connections to the controls or application of improper control signals.

Failure to follow this will void the manufacturer’s warranty and cause serious damage to property or injury to persons.

2

NOTE is used to highlight additional information which may be helpful to you.

JOHNSON CONTROLS

CHANGEABILITY OF THIS DOCUMENT

FORM 145.32-IOM1 (908)

In complying with Johnson Controls policy for continuous product improvement, the information contained

in this document is subject to change without notice.

While Johnson Controls makes no commitment to update or provide current information automatically to the

manual owner, that information, if applicable, can be

obtained by contacting the nearest Johnson Controls

service ofce.

It is the responsibility of operating/service personnel as

to the applicability of these documents to the equipment

in question. If there is any question in the mind of operating/service personnel as to the applicability of these

documents, then, prior to working on the equipment, they

should verify with the owner whether the equipment has

been modied and if current literature is available.

TABLE OF CONTENTS

SAFETY SYMBOLS .......................................................................................................................2

CHANGEABILITY OF THIS DOCUMENT .....................................................................................3

TABLE OF CONTENTS .................................................................................................................3

GENERAL INFORMATION ...........................................................................................................4

PRE-INSTALLATION INSPECTION OF EQUIPMENT .................................................................6

RIGGING .................................................................................................................................................6

INSTALLATION .............................................................................................................................6

UNIT MOUNTING ...................................................................................................................................7

SEPARATION OF UNITS .......................................................................................................................8

INTERCONNECTING REFRIGERANT TUBING - SPLIT INSTALLATION ...........................................8

DUCTWORK ............................................................................................................................... 11

LOUVER SIZING GUIDELINES ........................................................................................................... 11

ELECTRICAL WIRING ................................................................................................................12

PACKAGED UNIT .......................................................................................................................12

SPLIT SYSTEM ...........................................................................................................................12

MOTOR AND PULLEY DATA ...............................................................................................................14

BLOWER SPEED ADJUSTMENT .......................................................................................................14

START-UP AND OPERATION ....................................................................................................15

REFRIGERANT CHARGES ..................................................................................................................15

PRESSURE SWITCH SETTINGS .........................................................................................................15

MAINTENANCE / SERVICE .......................................................................................................17

FILTERS ................................................................................................................................................17

EVAPORATOR AND CONDENSER COILS .........................................................................................17

BLOWERS ............................................................................................................................................17

DRIVE BELTS .......................................................................................................................................17

REFRIGERANT CIRCUIT(S) ................................................................................................................17

COMFORT ALERT™ DIAGNOSTICS ........................................................................................18

LED DESCRIPTION ..............................................................................................................................18

INTERPRETING THE DIAGNOSTIC LEDS .........................................................................................18

INSTALLATION VERIFICATION .................................................................................................21

JOHNSON CONTROLS

3

GENERAL INFORMATION

FORM 145.32-IOM1 (908)

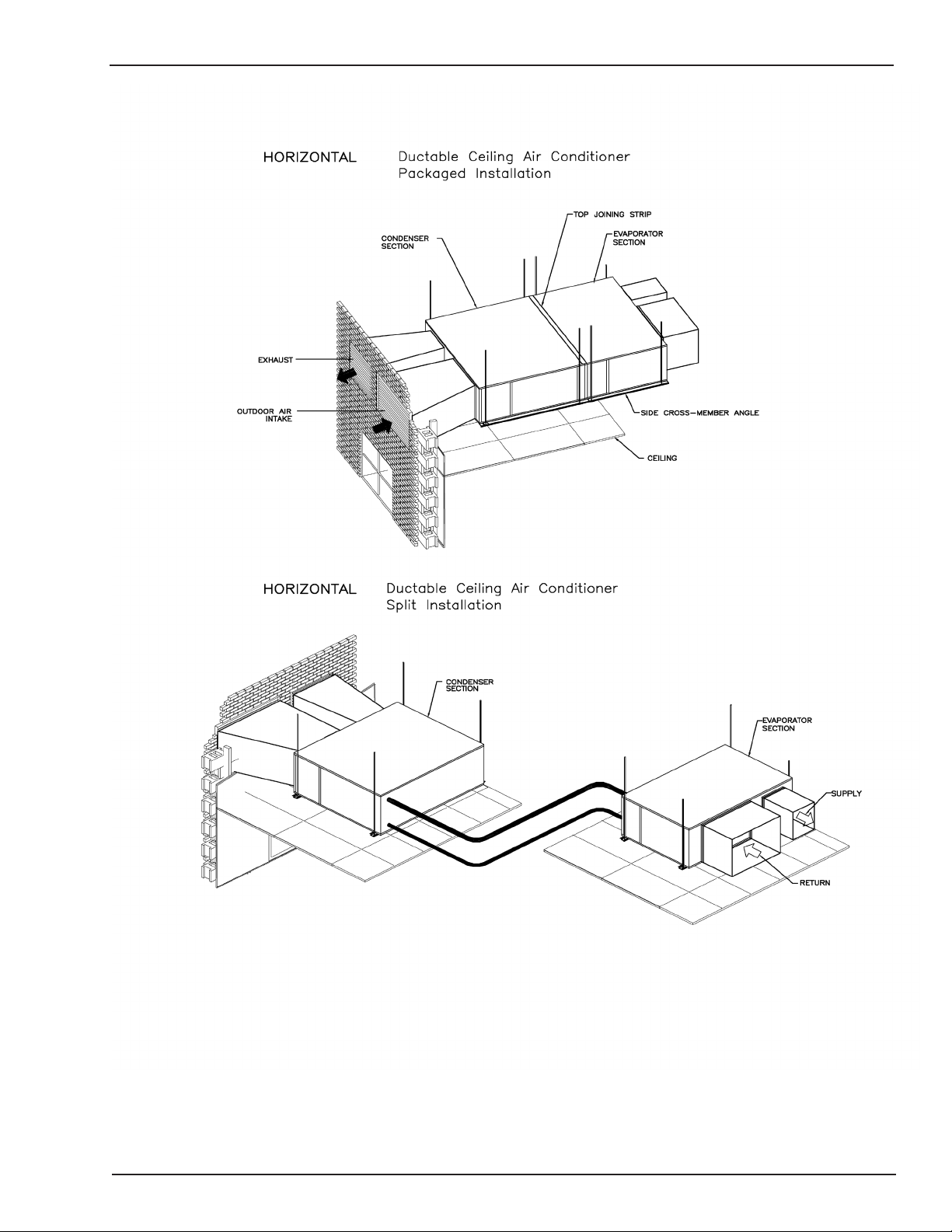

Our units are designed to meet the ever-changing

(unique) installation requirements of today’s market. The

horizontal conguration is unitized for single package

or split installation. Low prole design allows the unit to

be installed on the oor or suspended from the ceiling.

All unit components are securely mounted inside the

heavy gauge “Galvalume” sheet metal cabinet. All units

are lined with a 1/2 in. thick – 21lb density acoustical

insulation to ensure the quietest operation. All models

are shipped with medium-efciency 2-in. thick throwaway lters. Multi-position lter rack is external to the

cabinet.

Unit can be turned on its side for short periods of time,

which allows passage through standard door sizes.

Removal of the cross supports on the top and sides will

convert packaged unit into a split system, allowing the

condensing section to be installed remotely from the

evaporator section.

Horizontal units 2, 3, 4 & 5 ton models have a single

refrigerant circuit conguration. All models are equipped

with an adjustable thermal expansion valve (with external equalizer), one valve per circuit. Each refrigerant

circuit is also equipped with a liquid line lter drier, sight

glass/moisture indicator and easy access service gauge

ports. All 2-5 ton models are shipped as factory-charged

unitized packages. The 2-5 ton units include refrigerant

line shut-off valves to allow the units to be eld split.

Installation time is minimized with all models. When planning an installation consider power supply, thermostat,

condensate drain line, duct run, servicing allowances,

and load points. A remote thermostat control device is

eld supplied and installed to control the units operation.

Each refrigerant circuit is equipped with auto-reset high

pressure and low pressure switches. Each circuit is constantly monitored by ComfortAlert module. By monitoring

and analyzing data from the Copeland Scroll compressor

and the thermostat demand, the module can accurately

detect the cause of electrical and system related failures

and protect the compressor. A ashing LED indicator

communicates the ALERT code and guides the service

technician more quickly and accurately to the root cause

of a problem. Control circuit is 24-volt operation with

oversized transformer. Optional anti-short circuit timers

can be eld/factory installed.

Service access doors are equipped with handles and

are located on all sides of the unit to allow easy servicing of all components. Service access doors are factory

shipped with knock-outs allowing gauge lines to be

installed and pressure readings to be taken while the

machine is operating. In addition there is a removable

panel on the access door so visual observation of the

sight glass is possible without removing the access door.

All units are equipped with centrifugal blowers combined

with variable pitch adjustable pulleys. Forward curved

double width and inlet centrifugal blowers are used for

condenser & evaporator air movement. All models em-

ploy a draw-through air ow system. All blower wheels

are galvanized steel, with solid steel shafts and are

equipped with permanently lubricated ball bearings. Vbelt driven blowers are used in all models; RPM can be

adjusted through the variable pitch motor sheave.

ONLY QUALIFIED PERSONNEL SHOULD

PERFORM INSTALLATION AND SERVICE OF THIS EQUIPMENT.

High efciency scroll compressors are used in all models, mounted on durable rubber isolator pads reducing

vibration and noise while operating. Large evaporator

and condenser coil face areas reduce noise levels, air

pressure drops and minimize potential for condensate

blow off. All models are equipped with copper tube and

rippled aluminum plate n coils.

Units will operate reliably at an outdoor ambient down

to 60 deg F.

4

JOHNSON CONTROLS

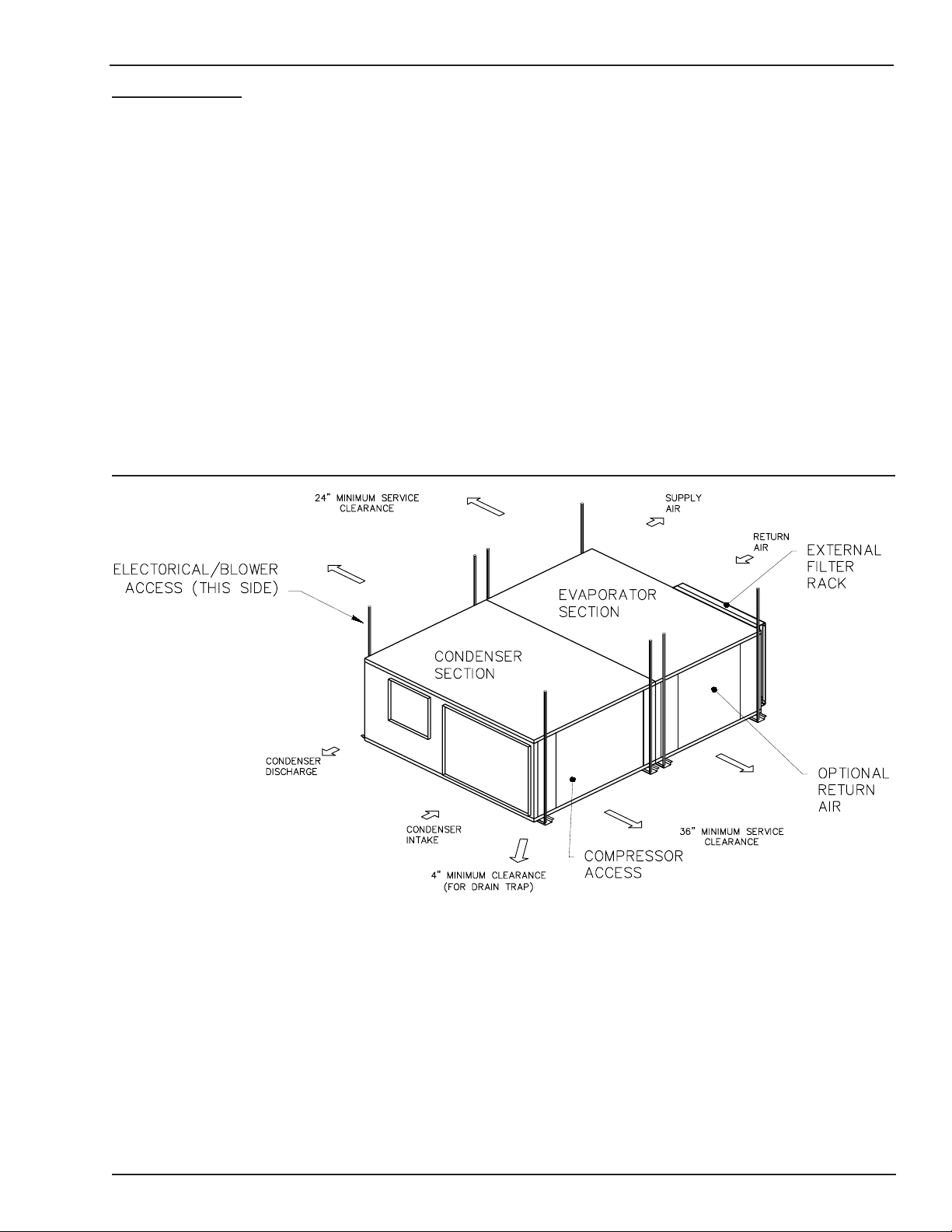

TYPICAL INSTALLATION DRAWING

FORM 145.32-IOM1 (908)

JOHNSON CONTROLS

5

FORM 145.32-IOM1 (908)

PRE-INSTALLATION INSPECTION OF EQUIPMENT

All units are factory tested to ensure safe operation

and quality assembly. Units are packaged and sealed

on shipping skids and shipped in rst class condition.

Torn and broken packaging, scratched or dented panels

should be reported to carrier immediately. An internal

inspection of each unit should be performed prior to

installation. Remove all access doors and check for

visual defects that can occur during transport. Any problems found internally should be reported to carrier and

manufacturer immediately. Refrigerant circuit should be

checked to ensure no leaks have occurred during shipment. Install gauge set on high and low pressure ports

to conrm pressure has been maintained and no leaks

have occurred during shipment. Repair any damage

prior to installation to ensure safe operation.

Record any unit damage on the Bill of

Lading and report to carrier and factory

immediately. Shipping and handling

damages are not warranty items.

RIGGING

Prior to mounting unit, check individual

unit weights (pages 7-8) and verify lifting

capacity of lifting equipment exceeds

weight of units by safe margins. Failure

to do so may result in unit damage, per-

sonal injury or even death.

INSTALLATION

Lock all electrical power supply switches in the off position before installing

the unit. Failure to disconnect power

supply may result in electrical shock or

even death.

Location - To ensure unit operates at maximum efciencies, choose a dry indoor area where the temperature

is controlled between 50 deg F and 115 deg F. Consideration of surrounding areas should be taken when

choosing a location to install the unit. Common vibration

and sound levels associated with commercial equipment

may be objectionable to people or equipment.

Failure to allow adequate space between

units may result in poor unit performance and possible unit failure.

Refer to typical installation diagram (Page #5).

Install thermostats, air supplies and returns so that each

unit will operate only on individual unit control. To assure

fast drainage of condensate run-off, unit can be slightly

pitched in the same direction as drain pan outlet.

To ensure safe installation of the unit when ceiling mount

application is specied, estimate the approximate center

of gravity of the unit. The conguration of internal com-

ponents for each unit is different and weight is unevenly

distributed.

Determine the actual center of gravity of

the unit by performing a test lift. Lifting

an unbalanced unit can cause personal

injury or even death.

6

JOHNSON CONTROLS

UNIT MOUNTING

FORM 145.32-IOM1 (908)

The 2 through 5 ton unit consist of an evaporator and

condenser module. These two modules are rigidly attached by a joining strip across the top of the two cabinet,

and two long side cross-member angles which bridge the

mounting channels on the bottom of the unit. These units

may be eld split to allow for passage through doors,

elevators, hallways, etc. Alternatively, the units may be

installed as a split system after separation.

Units may be either hung, or oor mounted. If unit is to

be hung, use all mounting points indicated - regardless

if unit is installed as a package or split system (See unit

dimension drawings). Use of 1/2in. dia hanger rods is

recommended. Ensure the attachment point of the rods

to the building structure is sufcient to support the unit

weight. In order to ensure efcient condensate drain-

age, the unit may be pitched towards the evaporator

end of the unit.

A minimum of 4-in. clearance is required under the unit to

allow for trapping of the evaporator condensate drain.

Floor mounted units should be secured on a solid, level

pad. The use of isolating vibro-pads at several points

under the bottom mounting channels is recommended.

Ensure that provision is made for clearance to install a

trap on the condensate drain outlet.

JOHNSON CONTROLS

7

FORM 145.32-IOM1 (908)

SEPARATION OF UNITS

The 2 through 5 ton units are provided with refrigerant

shut-off valves to allow the evaporator and condenser

sections to be eld split - without the necessity of reclaiming the entire unit refrigerant charge.

The evaporator and condenser sections may be separated by performing the following procedure:

1. Close all refrigerant shut-off valves, on both suction

and liquid lines. There are four valves in a single

compressor model, and a total of eight valves in the

dual compressor models. Valves are not a backseating design. Caps are wrench tight. Remove

caps and turn stem clockwise to seat in the closed

position.

2. Use the valve access ports to reclaim the refrigerant

trapped in the lines between the pairs of shut-off

valves.

3. Cut the refrigerant line sections between the pairs of

shut-off valves. It is recommended to make this out

where accessibility is greatest - in the condensing

section of the unit. This will allow best access for

reconnection, or attachment of an extended line

set in the case of a split system.

4. Remove the interconnecting wiring between the

evaporator and condenser electrical panel. Disconnect the wire terminations in the condenser

electrical panel, and pull the excess wire into the

evaporator panel.

5. Remove the threaded wire bushing connecting the

two electrical panels.

INTERCONNECTING REFRIGERANT TUBING

- SPLIT INSTALLATION

After the evaporator and condenser sections have been

mounted, the interconnecting refrigerant tubing can be

fabricated. Line sizing recommendations shown in the

accompanying table are suitable for most applications.

Consult sales ofce for applications outside the specied guidelines.

Route refrigerant tubing for minimum linear length, and

minimum number of bends and ttings. Use long radius

elbows for all 90-degree bends, except oil traps. Traps

should be constructed from short radius street elbows,

in order to keep the trap as small as possible. All brazing

should be done using a 2 to 8 psig dry nitrogen purge

owing through the pipe being brazed.

Once the brazing operation of refrigeration lines is com-

pleted, the eld-brazed connections must be checked for

leaks. Pressurize the system through the shut-off valve

ports with dry nitrogen to a minimum of 400 psig. Use

soap bubbles or alternate methods of leak-checking all

eld brazed joints. After completion of the leak check,

evacuate the interconnecting lines to hold a 350-micron

vacuum. If gauge pressure rises above 500 microns in

one minute, then evacuation is incomplete or the system

has a leak.

Additional refrigerant (R-410A) must be added to the

system due to the extended refrigerant lines. Calculate

the amount of additional refrigerant required as follows:

1. 5/16 in OD liquid line - add 0.40 oz per linear foot

2. 3/8 in OD liquid line - add 0.60 oz per linear foot

3. 1/2 in OD liquid line - add 1.20 oz per linear foot

4. 5/8 in OD liquid line - add 1.80 oz per linear foot

6. Remove the unit top-joining strip; take care to remove only those screws which attaches the joining

strip to the evaporator and condenser cabinets.

7. Remove the two side cross-member angles.

8. Carefully pull the evaporator section away from the

condenser section. Take care not to damage the

short lengths of refrigerant tubing extending into

the condenser section.

The separated evaporator and condenser modules may

now be individually moved to the proposed installation

site for re-assembly, or separately located for split applications.

8

JOHNSON CONTROLS

Loading...

Loading...