OPERATING INSTRUCTIONS

FOR

K2™

CONDENSING HIGH EFFICIENCY

DIRECT VENT

GAS - FIRED HOT WATER BOILER

9700609

As an ENERGY STAR

STAR® guidelines for energy efciency established by the United States Environmental Protection Agency (EPA).

®

Partner, U.S. Boiler Company has determined that the K2™ Series meets the ENERGY

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause property damage,

injury, or loss of life. For assistance or additional information, consult a qualied installer, service agency or the

gas supplier. This boiler requires a special venting system. Read these instructions carefully before installing.

105337-02 - 9/14

Price - $5.00

1

IMPORTANT INFORMATION - READ CAREFULLY

NOTE: The equipment shall be installed in accordance with those installation regulations enforced in the area where the

installation is to be made. These regulations shall be carefully followed in all cases. Authorities having jurisdiction

shall be consulted before installations are made.

All wiring on boilers installed in the USA shall be made in accordance with the National Electrical Code and/or local

regulations.

All wiring on boilers installed in Canada shall be made in accordance with the Canadian Electrical Code and/or local

regulations.

The City of New York requires a Licensed Master Plumber supervise the installation of this product.

The Massachusetts Board of Plumbers and Gas Fitters has approved the K2™ Series boiler. See the Massachusetts Board of

Plumbers and Gas Fitters website, http://license.reg.state.ma.us/pubLic/pl_products/pb_pre_form.asp for the latest Approval

Code or ask your local Sales Representative.

The Commonwealth of Massachusetts requires this product to be installed by a Licensed Plumber or Gas Fitter.

The following terms are used throughout this manual to bring attention to the presence of hazards of various risk levels,

or to important information concerning product life.

DANGER

Indicates an imminently hazardous situation

which, if not avoided, will result in death, serious

injury or substantial property damage.

Indicates a potentially hazardous situation which,

if not avoided, may result in moderate or minor

injury or property damage.

CAUTION

NOTICE

WARNING

Indicates a potentially hazardous situation which,

if not avoided, could result in death, serious injury

or substantial property damage.

Indicates special instructions on installation,

operation, or maintenance which are important

but not related to personal injury hazards.

DANGER

Explosion Hazard. DO NOT store or use gasoline or other ammable vapors or liquids in the vicinity of this

or any other appliance.

If you smell gas vapors, NO NOT try to operate any appliance - DO NOT touch any electrical switch or use

any phone in the building. Immediately, call the gas supplier from a remotely located phone. Follow the gas

supplier’s instructions or if the supplier is unavailable, contact the re department.

2

105337-02 - 9/14

WARNING

Asphyxiation Hazard. This boiler requires regular maintenance and service to operate safely. Follow

the instructions contained in this manual.

Improper installation, adjustment, alteration, service or maintenance can cause property damage,

personal injury or loss of life. Read and understand the entire manual before attempting installation,

start-up operation, or service. Installation and service must be performed only by an experienced,

skilled, and knowledgeable installer or service agency.

This boiler must be properly vented.

This boiler needs fresh air for safe operation and must be installed so there are provisions for

adequate combustion and ventilation air.

Asphyxiation Hazard. The interior of the venting system must be inspected and cleaned before the

start of the heating season and should be inspected periodically throughout the heating season for

any obstructions. A clean and unobstructed venting system is necessary to allow noxious fumes

that could cause injury or loss of life to vent safely and will contribute toward maintaining the boiler’s

efciency.

Installation is not complete unless a safety relief valve is installed into the tapping located on left

side of appliance or the supply piping. - See the Water Piping and Trim Section of the K2 Installation

manual for details.

This boiler is supplied with safety devices which may cause the boiler to shut down and not re-start

without service. If damage due to frozen pipes is a possibility, the heating system should not be left

unattended in cold weather; or appropriate safeguards and alarms should be installed on the heating

system to prevent damage if the boiler is inoperative.

Burn Hazard. This boiler contains very hot water under high pressure. Do not unscrew any pipe

ttings nor attempt to disconnect any components of this boiler without positively assuring the water

is cool and has no pressure. Always wear protective clothing and equipment when installing, starting

up or servicing this boiler to prevent scald injuries. Do not rely on the pressure and temperature

gauges to determine the temperature and pressure of the boiler. This boiler contains components

which become very hot when the boiler is operating. Do not touch any components unless they are

cool.

Respiratory Hazard. Boiler materials of construction, products of combustion and the fuel contain

alumina, silica, heavy metals, carbon monoxide, nitrogen oxides, aldehydes and/or other toxic or

harmful substances which can cause death or serious injury and which are known to the state of

California to cause cancer, birth defects and other reproductive harm. Always use proper safety

clothing, respirators and equipment when servicing or working nearby the appliance.

Failure to follow all instructions in the proper order can cause personal injury or death. Read all

instructions, including all those contained in component manufacturers manuals which are provided

with the boiler before installing, starting up, operating, maintaining or servicing.

All cover plates, enclosures and guards must be in place at all times.

105337-02 - 9/14

3

Table of Contents

I. Operation 5

II. Troubleshooting 26

4

105337-02 - 9/14

I. Operation (A. Overview)

180 F

Boiler 1

Energy Save On

Max Efficiency On

Standby

i

Status

Help

Adjust

Detail

A. Overview

1. Sage 2.1 Controller

The Sage 2.1 Controller (Control) contains features and

capabilities which help improve heating system operation,

and efciency. By including unique capabilities, the Control

can do more, with less eld wiring, and fewer aftermarket

controls and components – improving the operation of both

new and replacement boiler installations.

2. Advanced Touch Screen Display

Home Screen

Boiler status and setup selections are available from an

easy to use, dual color, LCD Touch Screen Display. Over

one hundred helpful information screens are provide to

explain status information and setup functions. In the event

of a fault condition the user is guided by “blinking” touch

buttons to Help screens that explain the problem cause and

corrective action. Operation evaluation and problem-solving

is enhanced by historical capability including graphic trends,

lockout history records as well as boiler and circulator cycle

counts and run time hours.

3. Advanced Modulating Control

The Control modulates the boiler input by varying the fan

speed. As the fan speed increases, so does the amount of

fuel gas drawn into the blower. As a result, a fairly constant

air-fuel ratio is maintained across all inputs. The Control

determines the input needed by looking at both current and

recent differences between the measured temperature and

the setpoint temperature. As the measured temperature

approaches the setpoint temperature, the fan will slow

down and the input will drop. The Control also utilizes

boiler return water and ue gas temperatures to adjust fan

speed.

4. Built-in Safety Control

The Control includes safety controls designed to ensure safe

and reliable operation. In addition to ame safety controls

the Control includes supply water temperature, differential

water temperature, and stack temperature safety limits and

stepped modulation responses. Boiler modulation is adjusted

when required to help avoid loss of boiler operation due

to exceeding limits. Additionally, the Control accepts the

eld installation of optional auxiliary safety limits.

5. Outdoor Air Reset

When selected the modulation rate setpoint is automatically

adjusted based on outside air temperature, time of day and

length of demand (boost) settings. Outdoor air “reset”

setpoint saves fuel by adjusting the water temperature of a

heating boiler lower as the outside air temperature increases.

105337-02 - 9/14

6. Warm Weather Shutdown (WWSD)

Some boilers are used primarily for heating buildings,

and the boilers can be automatically shutdown when

the outdoor air temperature is warm. When outside air

temperature is above the WWSD setpoint, this function

will shut down the boiler, boiler and system pump.

7. Domestic Hot Water Priority (DHWP)

Some boilers are used primarily for building space heating,

but also provide heat for the domestic hot water users.

When the outdoor temperature is warm, the outdoor reset

setpoint may drop lower than a desirable domestic hot

water temperature. Also, often it is required to quickly

recover the indirect water heater. When DHWP is

enabled, heating circulators are stopped, the domestic

circulator is started and the domestic hot water setpoint is

established in response to a domestic hot water demand.

Priority protection is provided to allow the heating loop

to be serviced again in the event of an excessively long

domestic hot water call for heat.

8. Energy Management System (EMS) Interface

The control accepts a 4-20mAdc input from the EMS

system for either direct modulation rate or setpoint.

A factory congured RS485 Modbus interface is available

for Energy Management System (EMS)monitoring

when not used for Multiple Boiler Sequencer Peer-ToPeer Network. Consult factory for points list or if this

interface must be used in addition to the boiler Peer-toPeer Network.

9. Circulator Control

The Control may be used to sequence the domestic hot

water, boiler and system circulators. Service rated relay

outputs are wired to a line voltage terminal block for easy

eld connection. Simple parameter selections allow all

three pumps to respond properly to various hydronic

piping arrangements including either a boiler or primary

piped indirect water heater. Circulators are automatically

run for a 20 second exercise period after not being used

for longer than 7 days. Circulator exercise helps prevent

pump rotor seizing.

10. Multiple Boiler Sequencer Peer-To-Peer Network

The Control includes state-of-the-art modulating lead-

lag sequencer for up to eight (8) boilers capable of auto

rotation, outdoor reset and peer-to-peer communication.

The peer-peer network is truly “plug and play”.

Communication is activated by simply connecting a RJ45

ethernet cable between boilers. The Control provides

precise boiler coordination by sequencing boilers based

on both header water temperature and boiler modulation

rate. For example, the lead boiler can be congured to

start a lag boiler after operating at 50% modulation rate for

longer than an adjustable time. The boilers are modulated

in “unison” (parallel) modulation rate to ensure even heat

distribution.

5

I. Operation B. Supply Water Temperature Regulation (contineud)

B. Supply Water Temperature Regulation

1. Priority Demand

The Control accepts a call for heat (demand) from

multiple places and responds according to it’s “Priority”.

When more than 1 demand is present the higher priority

demand is used to determine active boiler settings. For

example, when Domestic Hot Water (DHW) has priority

the setpoint, “Diff Above”, “Diff Below” and pump

settings are taken from DHW selections. Active “Priority”

is displayed on the “Boiler Status” screen.

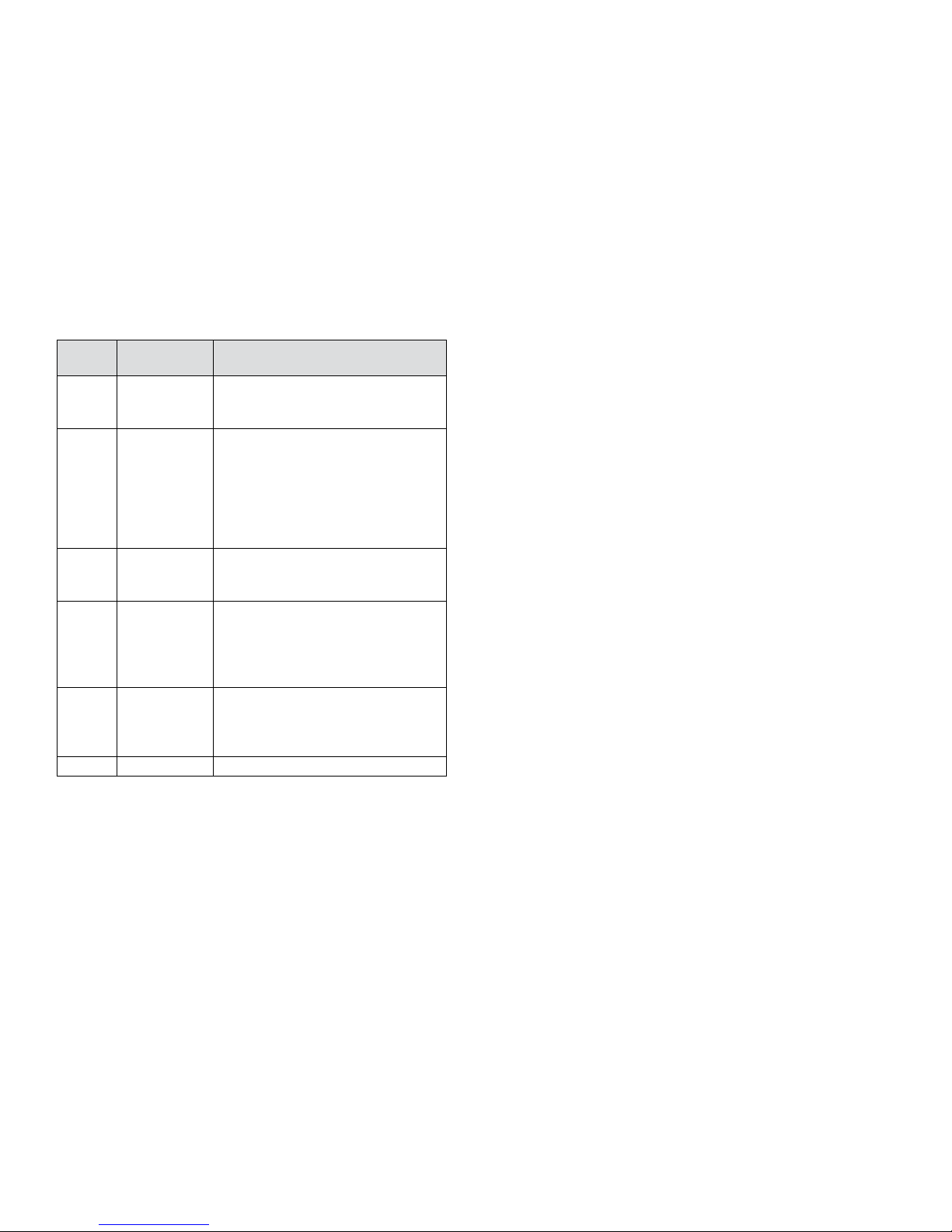

Table 1: Order of Priority

Priority

2nd Domestic Hot

Status Screen

Display

1st Sequencer

Control

Water

3rd Central Heat Central Heat call for heat is on and

4th Frost

Protection

5th Warm

Weather

Shutdown

(WWSD)

6th Standby There is no demand detected.

Boiler Responding to:

The boiler is connected to the peerto-peer network. The boiler accepts

demand from the Sequencer Master.

DHW call for heat is on and selected

as the priority demand. DHW is

always higher priority than Central

Heat. It also has higher priority than

the Sequencer Control when DHW

priority is “enabled” and “Boiler Piped”

IWH is selected.

there is no DHW demand or DHW

priority time has expired.

Frost Protection is active and there is

no other call for heat. Frost protection

will be a higher priority than Sequencer

Control if the Sequence Master has

no active call for heat.

WWSD is active and the boiler will

not respond to central heat demands.

DHW demand is not blocked by

WWSD.

2. Setpoint Purpose

The Control starts and stops the boiler and modulates

the boiler input from minimum (MBH) to maximum

(MBH) in order to heat water up to the active setpoint.

The setpoint is determined by the priority (Central Heat

or Domestic Hot Water) and as described in the following

paragraphs.

3. Central Heat Setpoint

Upon a Central Heat call for heat the setpoint is either

the user entered Central Heat Setpoint or is automatically

adjusted by a thermostat’s “Sleep” or “Away” modes and/

or Outdoor Air Reset or a Energy Management System

(EMS) supplied 4-20mAdc setpoint.

4. Outdoor Air Reset

If an outdoor temperature sensor is connected to the boiler

and Outdoor Reset is enabled, the Central Heat setpoint

will automatically adjust downwards as the outdoor

temperature increases. When the water temperature is

properly matched to heating needs there is minimal chance

of room air temperature overshoot. Excessive heat is

not sent to the room heating elements by “overheated”

(supply water temperature maintained too high a setting)

water. Reset control saves energy by reducing room

over heating, reducing boiler temperature & increasing

combustion efciency and reducing standby losses as a

boiler and system piping cool down to ambient following

room over heating.

5. Boost Time

When the Central Heat Setpoint is decreased by Outdoor

Air Reset settings the Boost function can be enabled to

increase the setpoint in the event that central heat demand

is not satised for longer than the Boost Time minutes. The

Boost feature increases the operating temperature setpoint

by 10°F (5.6°C) every 20 minutes (eld adjustable) the

central heat demand is not satised. This process will

continue until heat demand is satised (indoor air is at

desired temperature). Once the heat demand is satised,

the operating setpoint reverts to the value determined by

the Outdoor Air Reset settings. If Boost Time is zero,

then the boost function is not used.

6. Domestic Hot Water (DHW) Setpoint

Upon a DHW call for heat the setpoint is either the user

entered DHW setpoint or the Thermostat’s “Sleep” or

“Away” DHW setpoint. The optimal value of this setpoint

is established based on the requirements of the indirect

water heater.

7. Domestic Hot Water Priority (DHWP)

When domestic hot water priority is selected and there

is a DHW call for heat, the system pump will be turned

off (when “System Pump Run Pump for” parameter is

set for “Central Heat Optional Priority”) and the DHW

pump will be turned on. Additionally, if outdoor reset

is active, the active setpoint is adjusted to the DHW

Setpoint. Priority protection is provided to ensure central

heat supply in the case of excessively long DHW call for

heat.

8. “Setback” Setpoints

User adjustable Thermostat “Sleep” or “Away” Setback

Setpoints are provided for both Central Heat and

DHW demands. The Setback setpoint is used when the

EnviraCOM thermostat is in “leave” or “sleep” modes.

When setback is “on” the thermostat setback setpoint shifts

the reset curve to save energy while the home is in reduced

room temperature mode. The Honeywell VisionPro IAQ

(part number TH9421C1004) is a “setback” EnviraCOM

enabled thermostat.

6

105337-02 - 9/14

I. Operation C. Boiler Protection Features (continued)

C. Boiler Protection Features

1. Supply Water Temperature High Limit

The control is equipped with internal operating

control and high limit features. The control monitors

a dual element temperature sensor that is mounted in

the supply water manifold and provides UL353 and

UL1998 internal safety algorithms. If supply water

temperature increases above the active setpoint plus

diff above, default 187°F (86°C) (maximum setting

200°F (93°C) the boiler is cycled off. If the temperature

exceeds 210°F (98.9°C), a manual reset hard lockout

results.

If the boiler is responding to the internal Multiple Boiler

Control Sequencer or an External EMS demand and

the supply water temperature increases above 190°F

(87.7°C) the control begins to reduce the blower

maximum speed setting and if the temperature increases

to 200°F (93°C) a forced recycle results. Additionally,

if the supply temperature rises faster than the degrees

Fahrenheit per second limit a soft lockout is activated.

2. High Differential Temperature Limit

The Control monitors the temperature difference

between the return and supply sensors. If this difference

exceeds 43°F (23.9°C) the control begins to reduce the

maximum blower speed. If temperature difference

exceeds 53°F (29.4°C) a forced boiler recycle results.

If the temperature difference exceeds 63°F (35°C) the

control will shut the unit down. The unit will restart

automatically once the temperature difference has

decreased and the minimum off time has expired.

3. Return Temperature Higher Than Supply

Temperature (Inversion Limit)

The Control monitors the supply and return temperature

sensors. If the return water temperature exceeds the

supply water temperature for longer than a limit time

delay the Control shuts down the boiler and delays

restart. If the inverted temperature is detected more

than ve times the boiler manual reset Hard Lockout is

set. This condition is the result of incorrectly attaching

the supply and return piping.

4. External Limit

An external limit control can be installed on the low

voltage terminal strip. Be sure to remove the jumper

when adding an external limit control to the system. If

the external limit opens, the boiler will shut down and

an open limit indication and error code is provided. If

the limit installed is a manual reset type, it will need

to be reset before the boiler will operate.

5. Boiler Mounted Limit Devices

The control monitors individual limit devices: ow

switch, thermal fuse and sump pressure switch. If any of

these limits open the boiler will shut down and an open

limit indication is provided. Additionally, the control

monitors an air proving switch. During the boiler start

sequence the control requires the air proving switch to

be in the “open” position before the blower starts and

in the “closed” position after the blower starts. If the

air proving switch is not in the required position the

start sequence is halted or the boiler is shut down and

the open limit indication is provided.

6. Stack High Limit

The Control monitors the ue gas temperature sensor

located in the vent connector. If the ue temperature

exceeds 194°F (90°C), the control begins to reduce

the maximum blower speed. If the ue temperature

exceeds 204°F (96°C), a forced boiler recycle results.

If the ue temperature exceeds 214°F (101°C), the

control activates a manual reset Hard Lockout.

7. Ignition Failure

The Control monitors ignition using a burner mounted

ame sensor. In the event of an ignition failure, the

control retries 5 times and then goes into soft lockout

for one hour.

8. Central Heating System Frost Protection

When enabled, Frost Protection starts the boiler and

system pump and res the boiler when low outside air

and low supply water temperatures are sensed. The

Control provides the following control action when

frost protection is enabled:

Table 2: Frost Protection

Device

Started

Boiler & System

Pump

Boiler Supply Water < 38°F (3.3°C) Supply Water > 50°F (10°C)

Outside Air < -22°F (-30C)

Supply Water < 45°F (7.2°C)

FROST PROTECTION NOTE

The Control helps provide freeze protection for the boiler

water. Boiler ue gas condensate drain is not protected from

freezing. Since the Control only controls the system and

boiler circulators individual zones are not protected. It is

recommended that the boiler be installed in a location that is

not exposed to freezing temperatures.

Start

Temperatures

Stop

Temperatures

Outside Air > -18°F (-28°C)

Supply Water > 50°F (10°C)

105337-02 - 9/14

7

I. Operation D. Multiple Boiler Control Sequencer (continued)

D. Multiple Boiler Control Sequencer

1. “Plug & Play” Multiple Boiler Control Sequencer

When multiple boilers are installed, the Control’s

Sequencer may be used to coordinate and optimize

the operation of up to eight (8) boilers. Boilers are

connected into a “network” by simply “plugging in”

standard ethernet cables into each boiler’s “Boiler-ToBoiler Communication” RJ45 connection.

2. Sequencer Master

A single Control is parameter selected to be the Sequencer

Master. The call for heat, outdoor and header sensors,

and common pumps are wired to the Sequencer Master

“enabled” Control.

3. Lead/Slave Sequencing & Equalized Run Time

One boiler is a “Lead” boiler and the remaining networked

boilers are “Slaves”. When demand is increasing, the

Lead boiler is the rst to start and the Slave boilers are

started in sequential order (1,2,3,…) until the demand

is satised. When demand is decreasing, the boilers are

stopped in reverse order with the Lead boiler stopped

last (…,3,2,1). To equalize the run time the sequencer

automatically rotates the Lead boiler after 24 hours of

run time.

4. Improved Availability

The following features help improve the heat availability:

a. Backup Header Sensor: In the event of a header sensor

failure the lead boiler’s supply sensor is used by the

Sequence Master to control ring rate. This feature

allows continued coordinated sequencer control even

after a header sensor failure.

b. “Stand Alone” Operation Upon Sequence Master

Failure: If the Sequence Master Control is powered

down or disabled or if communication is lost

between boilers, individual boilers may be setup

to automatically resume control as a “stand alone”

boiler.

c. Slave Boiler Rate Adjustment: Each slave boiler

continues to monitor supply, return and ue gas

temperatures and modies the Sequence Master’s

ring rate demand to help avoid individual boiler

faults, minimize boiler cycling and provide heat to

the building efciently.

d. Slave Boiler Status Monitoring: The Sequence Master

monitors slave boiler lockout status and automatically

skip over disabled boilers when starting a new slave

boiler.

5. Customized Sequences

Normally, boilers are started and stopped in numerical

order. However, custom sequences may be established

to optimize the heat delivery. For example, in order to

minimize boiler cycling, a large boiler may be selected

to run rst during winter months and then selected to

run last for the remainder of the year.

8

6. Multiple Demands

The Sequence Master responds to Central Heat, DHW

and frost protection demands similar to the stand alone

boiler. For example, when selected and DHW priority

is active, the sequence master uses DHW setpoint, “Diff

Above”, “Diff Below” and pump settings.

7. Shared or Isolated DHW Demand

When the Indirect Water Heater (IWH) parameter is set

to “Primary Piped” the Sequence Master sequences all

required boilers to satisfy the DHW setpoint (default

180°F (82.2°C). When “Boiler Piped” is selected only

the individual slave boiler, with the wired DHW demand

and pump, res to satisfy the DHW setpoint.

8. DHW Two boiler Start

When the Indirect Water Heater (IWH) parameter is set to

“Primary Piped” and the DHW Two Boiler Start parameter

is set to “Enabled” two boilers are started without delay

in response to a DHW call for heat. This feature allows

rapid recovery of large IWH’s and multiple IWH’s.

9. Optimized Boiler Modulation

Boiler ring rate is managed to increase smoothly as

boilers are started. For example, when a second boiler is

started the initial ring rate is 100%/2 or 50%, when the

third boiler is started the ring rate starts at 200%/3 or

66%. After the initial start, the Sequence Master develops

a unison ring rate demand based on it’s setpoint and

sensed header temperature.

10. Innovative Condensing Boiler Control

During low loads, the Sequence Master limits ring rates

to a ‘Base Load Common Rate” to ensure modulating

condensing boiler peak operating efciency. Lower ring

rates boost efciency by helping increase the amount of

ue gas water vapor condensation. The Control maintains

a “Base Load Common Rate” until the last lag boiler is

started. At this point, the “Base Load Common Rate” is

released to allow boilers to modulated as required to meet

heat load.

11. Advanced Boiler Sequencing

After there is a Call For Heat input, both header water

temperature and boiler ring rate percent are used to start

and stop the networked boilers. The control starts and stops

boilers when the water temperature is outside the user

selected “Diff Above” and “Diff Below” settings. Also,

in order to minimize temperature deviations, the control

adjusts the number of boilers running based on the ring

rate. This combination allows the boilers to anticipate

slow load changes before they disrupt water temperature

yet still respond quickly to sudden load changes. These

special sequencer features help reduce energy wasting

system temperature swings and the resulting unnecessary

boiler cycling.

12. Stop All Boilers

All boilers are stopped without delay if the Call for Heat

input is removed or if the header temperature is higher

than 195°F (90.6°C) (eld adjustable).

105337-02 - 9/14

X. Operation E. Boiler Sequence Of Operation (continued)

E. Multiple Boiler Control Sequencer

1. Normal Operation

Table 3: Boiler Sequence of Operation

Status Screen Display Description

<

Priority:

Standby

Status:

Standby

Priority:

Central Heat

Status:

(burner Off, circulator(s) Off)

Boiler is not ring and there is no call for heat, priority equals standby. The boiler

is ready to respond to a call for heat.

(burner Off, circulator(s) On)

Boiler is not ring. There is a Central Heat call for heat and the Supply temperature

is greater than setpoint minus the “Diff Below”.

Standby

When supply temperature drops burner demand continues with following Status

Priority:

Central Heat

Status:

Prepurge

shown:

Safe Startup: Flame circuit is tested.

Drive purge: The blower is driven to the fan purge speed.

Prepurge: After the blower reaches the fan purge speed setting the 10

second combustion chamber purge is conducted.

Priority:

Central Heat

Status:

Direct

ignition

i

Boiler 1

Supply

Setpoint

Rate

Priority:

Status:

132 F

140 F

100%

Central Heat

Running

Central Heat

>

Priority:

Status:

Running

After purge time is complete the following Status is shown:

Drive light-off: The blower is driven to light-off rate.

Pre-Ignition Test: After the blower reaches light-off rate a safety relay test is

conducted.

Pre-ignition: Spark is energized and it is conrmed that no ame is present

Direct Ignition: Spark and Main fuel valve are energized.

(burner On, circulator(s) On)

After ame is proven the sequence continues with run stabilization and low

re hold time. Once the eld adjustable low re hold time is completed normal

boiler operation begins, modulation rate depending on temperature and setpoint

selections.

i

<

Boiler 1

Supply

Setpoint

Rate

Priority:

Status:

132 F

180 F

100%

Domestic Hot Water

Running

105337-02 - 9/14

>

Priority:

Domestic

Hot Water

Status:

Running

Priority:

Standby

Status:

Post-purge

Priority:

Standby

Status:

Standby

Delay

Priority:

Standby

Status:

Lockout

If the Central Heat call for heat is active and a Domestic Hot Water (DHW) call for

heat received the DHW demand becomes the “priority” and the modulation rate,

setpoint, “Diff Above” and “Diff Below” are based on DHW settings.

(burner Off, circulator(s) Off)

If there is no call for heat the main fuel valve is closed and the blower is driven

to the fan post-purge speed. After the blower reaches the fan post-purge speed

setting the 29 second combustion chamber purge is conducted.

Standby delay status is entered when a delay is needed before allowing the burner

control to be available. For example, when Anti-Short Cycle time is selected

Standby delay is entered after the Central Heat call for heat ends. Select “Help”

button from the “Home Screen” to determine the cause of the Standby Delay.

A lockout status is entered to prevent the boiler from running due to a detected

problem. Select “Help” button from the “Home Screen” to determine the cause of

the Lockout. The last 10 Lockouts are recorded in the Lockout History.

9

I. Operation E. Boiler Sequence Of Operation (continued)

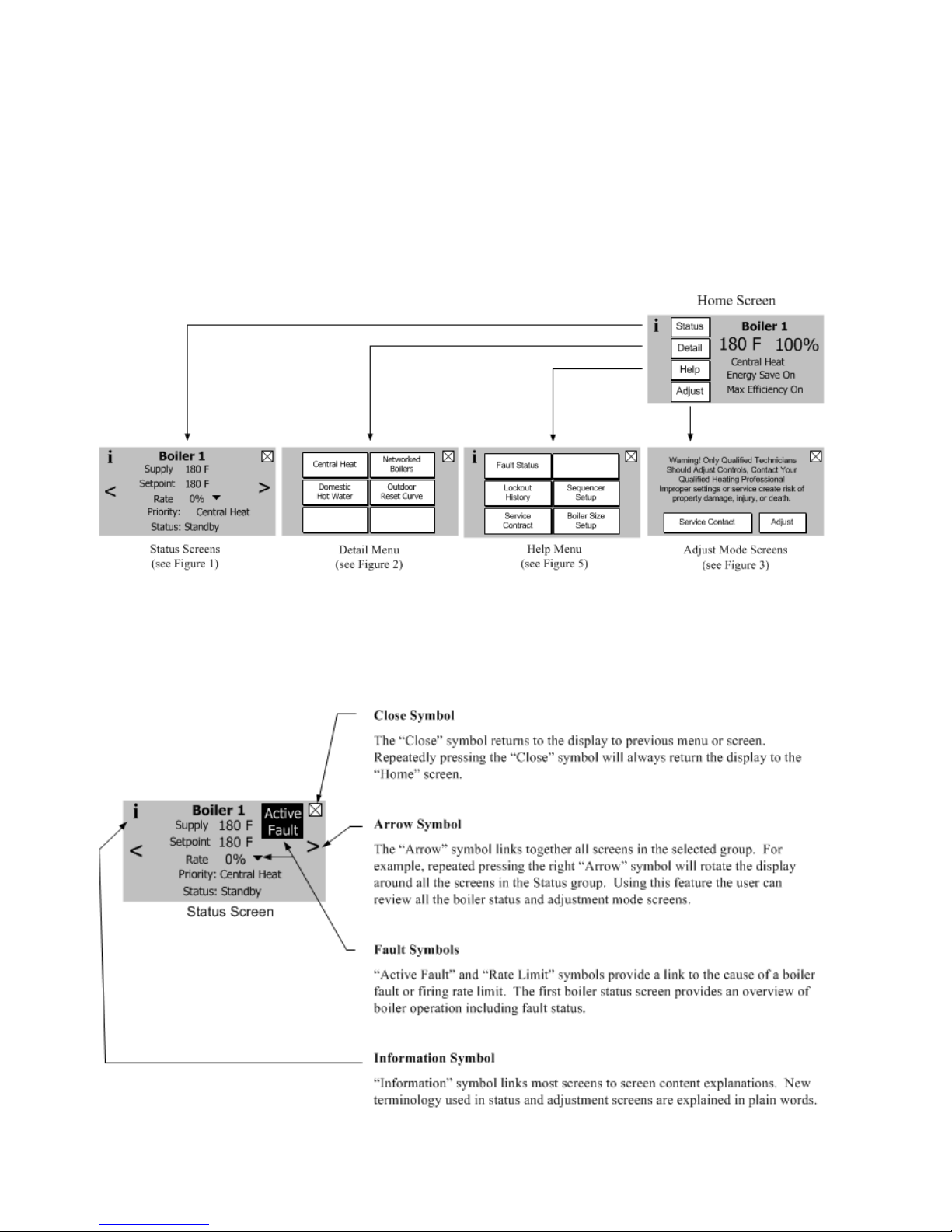

2. Using The Display

The Control includes a touch screen LCD display. The user monitors and adjusts boiler operation by selecting screen

navigation “buttons” and symbols. Navigation features are shown below.

The “Home Screen” and menu selections are shown below. When no selection is made, while viewing any screen, the

display reverts to the “Home Screen” after 4 minutes. The “Home Screen” displays boiler temperature, boiler status and

Efciency Information. “Energy Save On” indication appears when the outdoor reset or setback features have lowered the

Central Heat Setpoint based on outside air temperature measurement or time of day. “Max Efciency On” appears when

the boiler return temperature has been reduced low enough to allow energy saving ue gas condensation.

Home Screen

The Home Screen Menu Buttons connect the displays four main display groups; Status, Detail,

Help and Adjustment Screens.

10

105337-02 - 9/14

I. Operation F. Viewing Boiler Status (continued)

F. Viewing Boiler Status

1. Status Screens

Boiler Status screens are the primary boiler monitoring screens. The user may simply “walk” though boiler

operation by repeatedly selecting the right or left “arrow” symbol. These screens are accessed by selected the

“Status” button from the “Home” screen.

Figure 1: Status Screens

105337-02 - 9/14

11

1. Status Screens (continued)

Central Heat

On Point - 7 F

Setpoint

Off Point +

5 F

Firing Rate 22%

Setpoint: Outdoor Reset

i

180 F

180 F

Supply

Outdoor Reset

Outside Air

W

a

t

e

r

180

130

110

0 70

i

Setpoint 164 F

Outside Air 16 F

Status: Enabled

I. Operation F. Viewing Boiler Status (continued)

Data Logging

Real time graphic trends allow users to observe process

changes over time providing valuable diagnostic

information. For example, ame current performance

over start up periods and varying loads can be an indication

of gas supply issues. Additionally, supply and return

temperature dual pen trends brings a focused look at

heat exchanger and pump performance. For example,

studying a differential temperature trend may indicate

pump speed settings need to be changed.

Pump Status/Cycles

i

System On 98

Boiler On 23

DHW Off 0

Frost Protection On Exercise On

><

Pumping is a major part of any hydronic system. This screen

provides the status of the boiler’s demand to connected

pumps as well as the status of Frost Protection and pump

Exercise functions.

Cycles and Hours

Boiler cycles and hours are used to monitor the

boilers overall compatibility to the heating load.

Excessive cycling compared to run time hours

may be an indication of pumping, boiler sizing or

adjustment issues.

Heat Demand

i

Central Heat On

Domestic Hot Water Off

Sequence Master Off

Frost Protection Off

><

This screen provides the status of the boiler’s 4 possible

heat demands. When demand is off the Control has not

detected the call-for-heat.

2. Detail Screens

Detail screens are accessed by selected the

“Detail” button from the “Home” screen and

provide in depth operating parameter status

such as “On Point”, “Off Point” and Setpoint

Source information.

Detail screens are provided for Central Heat

(shown), DHW and Sequencer demands.

12

Outdoor Reset saves energy and improves home comfort

by adjusting boiler water temperature . This screen

presents the active reset curve. The curve shows the

relationship between outside air and outdoor reset

setpoint. The curve shown is adjustable by entering the

display’s adjust mode.

Figure 1: Detail Screens

105337-02 - 9/14

I. Operation F. Viewing Boiler Status (continued)

3. Multiple Boiler Sequencer Screens

When the Sequence Master is enabled the following screens are available:

105337-02 - 9/14

13

I. Operation G. Changing Adjustable Parameters (continued)

G. Changing Adjustable Parameters

1. Entering Adjust Mode

The Control is factory programmed

to include basic modulating boiler

functionality. These settings are password

protected to discourage unauthorized or

accidental changes to settings. User login is

required to view or adjust these settings:

- Press the “Adjust” button on the “Home”

screen.

- Press the “Adjust” button on the Adjust

Mode screen or Press “Service Contact”

for service provider contact information.

- Press “Login” button to access password

screen.

- Press 5-digit display to open a keypad.

Enter the password (Installer Password

is 86) and press the return arrow to close

the keypad. Press the “Save” button.

- Press the “Adjust” button to enter

Adjustment mode.

Figure 2: Adjust Mode Screens

2. Adjusting Parameters

Editing parameters is accomplished as follows:

i

<

Accept Value

Press the button to confirm

newly edited value.

The value modified with the

increase and decrease buttons is

not accepted unless this button is

also pressed

Edit Value

Press the buttons to edit a

value. While editing a value it will blink

until it has been accepted or cancelled. A

value is also cancelled by leaving the

screen without accepting the value.

Central Heat

CH Setpoint

F

180

Value to be edited

(blinks while editing)

>

Cancel edit

Press the button to cancel

newly edited value and go back

to the original

14

105337-02 - 9/14

I. Operation G. Changing Adjustable Parameters (continued)

Pump

Setup

- More -

Manual

Control

Contractor

Setup

System

Setup

Modulation

Setup

Outdoor

Reset

Remote

4-20mA

Central

Heat

Domestic

Hot Water

Sequence

Master

Sequence

Slave

System

Setup

2. Adjusting Parameters (continued)

From the “Home” screen select the Adjust button to access the adjustment mode screens show below (if required, refer to

the previous page to review how to enter Adjustment mode):

The following pages describe

the Control’s adjustable parameters.

Parameters are presented in the order

they appear on the Control’s Display,

from top to bottom and, left to right

“Press”

Factory

Setting

Fahrenheit

4 0-14

8 0-14

Wired

Enabled Enable/Disable

0 Secs 0-900 Secs

Disabled Enable/Disable

70°F 0-100°F

Fahrenheit,

Not Installed,

Wireless

Range /

Choices

Celsius

Wired

button to access the following parameters:

Parameter and Description

Temperature Units

The Temperature Units parameter determines whether temperature is represented in units of

Fahrenheit or Celsius degrees.

Display Brightness

Display brightness is adjustable from 0 to 14.

Display Contrast

Display contrast is adjustable from 0 to 14.

Outdoor Sensor Source

Not Installed Outdoor Sensor is not connected to the boiler, the sensor is not monitored for faults.

Wired Outdoor Sensor is installed directly on the boiler terminal Strip-TB2.

Wireless Outdoor sensor is installed and wireless.

Frost Protection

Disable Frost Protection is not used.

Enable Boiler and system circulators start and boiler res when low outside air, supply and

return temperatures are sensed as follows:

Anti-Short Cycle Time

Anti-short cycle is a tool that helps prevent excessive cycling resulting from a fast cycling

Thermostat or Zone valves. It provides a minimum delay time before the next burner cycle. DHW

demand is serviced immediately, without any delay.

Warm Weather Shutdown Enable

Disable Warm Weather Shutdown (WWSD) is not used.

Enable The boiler will not be allowed to start in response to a central heat call for heat if the

outside temperature is greater than the WWSD setpoint. WWSD is initiated as soon

as outside air temperature is above WWSD Setpoint. The control does not require

call for heat to be satised.

The boiler will still start in response to a Domestic Hot Water call for heat.

Warm Weather Shutdown Setpoint

The Warm Weather Shutdown (WWSD) Setpoint used to shutdown the boiler when enabled by the

“WWSD Enable” parameter.

Device

Started

Boiler & System Outside Air < -22°F (-30°C) Outside Air > -18°F (-28°C)

Start

Temperatures

Stop

Temperatures

105337-02 - 9/14

15

Modulation

Setup

I. Operation G. Changing Adjustable Parameters (continued)

2. Adjusting Parameters (continued)

WARNING

Asphyxiation Hazard. Boiler type is factory set and must match the boiler model. Only change the boiler

type setting if you are installing a new or replacement Control. The boiler type setting determines minimum

and maximum blower speeds. Incorrect boiler type can cause hazardous burner conditions and improper

operation that may result in PROPERTY LOSS, PHYSICAL INJURY OR DEATH.

“Press”

Factory

Setting

See Table

4

See Table

4

See Table

4

See Table

4

See Table

4

button to access the following parameters:

Range / Choices Parameter and Description

Boiler Type

Boiler Size Setup

To verify the boiler size selection, a qualied technician should do the following:

1. Check boiler’s label for actual boiler size.

See Table 4

Minimum to

Maximum

Modulation

Minimum to

Maximum

Modulation

Minimum

- 100 to

Maximum

See Table 4

2. Set “Boiler Type” to match actual boiler size.

3. Select “Conrm”.

The Boiler Type parameter changes the minimum and maximum modulation settings. This

parameter is intended to allow a user to set the parameters in a spare part Control to a particular

boiler type.

Central Heat Maximum Modulation

This parameter denes the highest modulation rate the Control will go to during a central heat call

for heat. If the rated input of the installed home radiation is less than the maximum output of the

boiler, change the Central Heat Maximum Modulation (fan speed) setting to limit the boiler output

accordingly.

Domestic Hot Water (DHW) Max Modulation

This parameter denes the highest modulation rate the Control will go to during a Domestic Hot

Water call for heat. If the rated input of the indirect water heater is less than the maximum output

of the boiler, change the DHW Maximum Modulation (fan speed) setting to limit the boiler output

accordingly.

Minimum Modulation

This parameter is the lowest modulation rate the Control will go to during any call for heat.

Lightoff Rate

This is the blower speed during ignition and ame stabilization periods.

Table 4: Parameters Changed Using the Boiler Type Parameter Selections:

Control Repair Part P/N 105439-01

Altitude 0 - 2000 Ft.

Boiler Type K2-80-02 K2-100-02 K2-120-02 K2-150-02 K2-180-02

Maximum Modulation Rate (RPM) 5100 5500 5100 5400 6000

Minimum Modulation Rate (RPM) 1600 1650 1600 2000 1800

Absolute Maximum Modulation Rate (RPM) 5400 6900 5700 6300 6700

Minimum Light-off Rate (RPM) 3500 3500 3500 3500 3500

Maximum Light-off Rate (RPM) 4000 4000 4000 4000 4000

NOTE: Maximum Modulation Rates are designed for 100% nameplate rate at 0°F (-18°C) combustion air. Contact factory before

attempting to increase the Maximum Modulation Rate.

16

105337-02 - 9/14

Pump Setup

I. Operation G. Changing Adjustable Parameters (continued)

“Press”

Factory Setting Range / Choices Parameter and Description

Central Heat,

Optional Priority

Any Demand

Primary

Loop Pipe

IWH

button to access the following parameters:

System Pump run pump for:

Activates the system pump output according to selected function.

Never,

Any Demand,

Central Heat,

No Priority,

Central Heat,

Optional Priority

Any Demand

Never,

Primary Loop

Piped IWH,

Never: Pump is disabled and not shown on status screen.

Any Demand: Pump Runs during any call for heat.

Central Heat, No Priority: Pump Runs during central heat and frost protection call for

heat. Pump does not start for a DHW call for heat and

continues to run during Domestic Hot Water Priority.

Central heat, Optional

Priority: Pump Runs during central heat and frost protection call for

heat. Pump does not start for a DHW call for heat and will be

forced off if there is a DHW call for heat and Domestic Hot

Water Priority is active.

Boiler Pump run pump for:

Activates the boiler pump output according to selected function. This feaature is not

adjustable.

Any Demand: Pump Runs during any call for heat.

Domestic Pump run pump for:

Activates the Domestic pump output according to selected function.

Never: Pump is disabled and not shown on status screen.

Primary Loop Piped IWH: Pump Runs during domestic hot water call for

heat. Domestic Hot Water Priority enable/disable

does not affect pump operation.

Example Pump Parameter selections:

Single boiler with no Indirect Water Heater

Parameter Selection:

System pump = “Central Heat,

Optional Priority”

Boiler pump = “any demand”

DHW pump = “never”

Explanation:

This piping arrangement only

services central heat. When

there is any demand both

boiler and system pumps turn

on.

105337-02 - 9/14

17

I. Operation G. Changing Adjustable Parameters (continued)

Example Pump Parameter selections (continued):

Single boiler Indirect Water Heater (IWH)Piped to Primary, Optional Domestic Hot Water Priority.

Parameter Selections:

System Pump = “Central Heat,

Optional Priority”

Boiler Pump = “any demand”

DHW Pump = “Primary Loop Piped IWH”

DHW Priority Enable is optional

Explanation:

This piping arrangement permits the

system pump to run or not run when

there is a domestic hot water call for heat.

Domestic hot water priority is optional.

It is permissible for the domestic and

system pumps to run at the same time.

The boiler pump must run for every call

for heat.

Multiple Boilers with Boiler Piped IWH, System and DHW Wired to Master

Wiring locations:

Thermostat X

DHW call for heat X

System pump X

DHW pump X

Boiler Pump X X

Sequencer Master Parameter Selections:

Sequencer Master Enabled

Indirect Water

Heater

Pump Parameter Selections:

System Pump =

Boiler Pump = Any demand

DHW Pump = “Primary Piped” Never

Sequencer

Master

(Boiler 1)

“Boiler Piped”

Central Heat,

No Priority

Boiler 2

Never

Any

demand

Explanation:

When call for Domestic Hot Water is received the DHW pump is turned on and the boiler pump is turned on. However, the system

pumps may run to satisfy a central heat demand that is being satised by a different slave. The central heat demand is ignored by

Slave 1 until the domestic hot water demand is ended.

18

105337-02 - 9/14

I. Operation G. Changing Adjustable Parameters (continued)

Example Pump Parameter selections (continued):

Multiple boilers IWH Piped to Primary, Optional Domestic Hot Water Priority

Sequencer Master

(Boiler 1)

Wiring locations:

Thermostat X

DHW call for heat X

System pump X

DHW pump X

Boiler Pump X X

Sequencer Master Parameter Selections:

Sequencer Master Enabled

Indirect Water

Heater

Pump Parameter Selections:

System Pump =

Boiler Pump = Any demand

DHW Pump =

Explanation:

This piping arrangement permits the system pump to run or not run when there is a domestic hot water call for heat. Domestic hot water

priority is optional. It is permissible for the domestic and system pumps to run at the same time. The boiler pump must run for every call for

heat.

“Primary Piped”

Central Heat,

Optional Priority

Primary Loop

Piped IWH

Boiler 2

Never

Any

demand

Never

Multiple Boilers, IWH piped to primary, system pump required to run for any call for heat

Sequencer Master

(Boiler 1)

Wiring locations:

Thermostat X

DHW call for heat X

System pump X

DHW pump X

Boiler Pump X X

Sequencer Master Parameter Selections:

Sequencer Master Enabled

Indirect Water

Heater

Pump Parameter Selections:

System Pump = Any demand Never

Boiler Pump = Any demand Any demand

DHW Pump =

Explanation:

This piping arrangement requires the system pump to be running for any calls for heat. Also the boiler pump must run for any call for heat.

“Primary Piped”

Primary Loop

Piped IWH

Boiler 2

Never

105337-02 - 9/14

19

Contractor

Setup

I. Operation G. Changing Adjustable Parameters (continued)

Manual

Control

“Press”

button to access the following parameters:

i

<

Use Up and DOWN Arrows for More

Exit Screen without Saving

Contractor Name

Press box to input contractor information.

Bill Smith

Save

Press SAVE button to store revisions.

Enter Contractor Information

Bill Smith

2

3

1

A

4

B

C

D

Clear Entire Field

Backspace

Save Field and Exit

5

For Service Contact:

Bill Smith

>

12 Victory Lane

Plainview, New York

516 123-4567

Example Screen

8

7

8

6

7

CL

ES

BS

R

C

Factory Setting Range / Choices Parameter and Description

Contractor Name User dened Contractor Name

Address Line 1 User dened Contractor Address Line 1

Address Line 2 User dened Contractor Address Line 2

Phone User dened Contractor Phone

“Press”

button to access the following screen:

The Manual Speed Control speed screen allows the technician to set ring rate at low or high speed for combustion testing.

Manual Speed Control

i

0 RPM 0%

Status Auto

press to change mode

High

Low

Auto

Selecting “Low” or “High”

locks (manual mode) firing

rate at min or max Rate %.

After combustion testing select

“Auto” to return the boiler to

NOTE

normal operation.

“Press” “Low” to select

manual firing rate control

and Minimum firing rate %

20

“Press” “High” to select

manual firing rate control

and Central Heat

Maximum firing rate %

Press “Auto”

to return

firing rate to

Automatic

Mode

105337-02 - 9/14

“Press”

Central

Heat

I. Operation G. Changing Adjustable Parameters (continued)

button to access the following parameters:

Factory

Setting

180°F

(82.2°C)

170°F

(76.7°C)

7°F

(3.9°C)

5°F

(2.8°C)

120

seconds

Range / Choices Parameter and Description

60°F to 190°F

(16°C to 87.8°C)

60°F to 190°F

(16°C to 87.8°C)

(1.1°C to 5.6°C)

(1.1°C to 14°C)

3 1 to 5

0 to 300 seconds

2°F to 10°F

2°F to 25°F

Central Heat Setpoint

Target temperature for the central heat priority. Value also used by the outdoor air reset function.

Central Heat Thermostat “Sleep” or “Away” Setback Setpoint

Thermostat setback setpoint is used when the EnviraCOM thermostat is in “leave” or “sleep”

modes and sensed at E-COM terminals D, R, and C. When setback is “on” the thermostat setback

setpoint shifts the reset curve to save energy while home is in a reduced room temperature mode.

The reset curve is shifted by the difference between the High Boiler Water Temperature and the

Thermostat Setback Setpoint. Honeywell VisionPro IAQ part number TH9421C1004 is a “setback”

EnviraCOM enabled thermostat. When connected, it allows boiler water setback cost savings.

Central Heat Diff Above

The boiler stops when the water temperature rises ‘Diff Above’ degrees above the setpoint.

Central Heat Diff Below

The boiler starts when the water temperature drops ‘Diff Below’ degrees below the setpoint.

Response Speed

This parameter adjusts the Central Heat temperature controller Proportion Integral Derivative

(PID) values. Higher values cause a larger ring rate change for each degree of temperature

change. If set too high ring rate “overshoots” required value, increases to high re causing the

temperature to exceed the “Diff Above” setpoint and cycle the boiler unnecessarily. Lower values

cause a smaller ring rate change for each degree of temperature change. If set too low, the ring

rate response will be sluggish and temperature will wander away from setpoint.

Low Fire Hold Time

“Low Fire Hold Time” is the number of seconds the control will wait at low re modulation rate

before being released to modulate. After ignition and ame stabilization periods the ring rate is

held at low re for “Low Fire Hold Time”. This delay allows heat to travel out to the system and

provide system feedback prior to the control modulating ring rate.

Supply

Sensor

Supply Sensor,

Header Sensor

Modulation Sensor

Heat Demand may respond to the boiler’s Supply Temperature or Header Temperature sensors.

When Header Sensor is selected the boiler is red in response to the sensor wired to Header

Sensor Low Voltage Terminal Block Terminals.

105337-02 - 9/14

21

Domestic

Hot Water

I. Operation G. Changing Adjustable Parameters (continued)

“Press”

Factory

Setting

170°F

(76.7°C)

160°F

(71.1°C)

7°F

(3.9°C)

5°F

(2.8°C)

10

seconds

Enable Enable Disable

Range / Choices Parameter and Description

60°F to 190°F

(16°C to 87.8°C)

60°F to 190°F

(16°C to 87.8°C)

(1.1°C to 5.6°C)

(1.1°C to 14°C)

3 1 to 5

0 to 300 seconds

30 to 120 Minutes

button to access the following parameters:

2°F to 10°F

2°F to 25°F

Domestic Hot Water Setpoint

The Domestic Hot Water (DHW) Setpoint parameter is used to create a minimum boiler water

temperature setpoint that is used when DHW heat demand is “on”.

When the DHW heat demand is not “on” (the contact is open or not wired) this setpoint is ignored.

Domestic Hot Water Thermostat “Sleep” or “Away” Setback Setpoint

Thermostat setback setpoint is used when the EnviraCOM thermostat is in “leave” or “sleep”

modes and sensed at E-COM terminals D, R, and C. When setback is “on” the thermostat

setback setpoint shifts the DHW setpoint to lower the DHW temperature and to save energy

while home is in a reduced room temperature mode.

Domestic Hot Water Diff Above

The boiler stops when the water temperature rises ‘Diff Above’ degrees above the setpoint.

Domestic Hot Water Diff Below

The boiler starts when the water temperature drops ‘Diff Below’ degrees below the setpoint.

Response Speed

This parameter adjusts the Domestic Hot Water temperature controller Proportion Integral

Derivative (PID) values. Higher values cause a larger ring rate change for each degree of

temperature change. If set too high ring rate “overshoots” required value, increases to high re

causing the temperature to exceed the “Diff Above” setpoint and cycle the boiler unnecessarily.

Lower values cause a smaller ring rate change for each degree of temperature change. If set

too low, the ring rate response will be sluggish and temperature will wander away from setpoint.

Low Fire Hold Time

“Low Fire Hold Time” is the number of seconds the control will wait at low re modulation rate

before being released to modulate. After ignition and ame stabilization periods the ring rate is

held at low re for “Low Fire Hold Time”. This delay allows heat to travel out to the indirect water

heater and provide feedback prior to the control modulating ring rate

Domestic Hot Water Priority (DHWP)

When Domestic Hot Water Priority is Enabled and Domestic Hot Water (DHW) heat demand is

“on” the DHW demand will take “Priority” over home heating demand. When the System and

Boiler pumps are congured as “Central Heat (off DHW priority)” or “Central Heat, Optional

Priority” then they will be forced “off” during DHW Priority. Priority protection time is provided to

end DHWP in the event of a failed or excessive long DHW demand.

Priority Time

When DHWP is Enabled the Priority Time Parameter appears and is adjustable.

.

22

105337-02 - 9/14

I. Operation G. Changing Adjustable Parameters (continued)

Outdoor

Reset

“Press”

Factory

Setting

Enabled Enable Disable

0°F

(-18°C)

70°F

(21.1°C)

110°F

(43.3°C)

130°F

(54.4°C)

20 Minutes

Range / Choices Parameter and Description

(-40°C to 37.8°C)

(21.1°C to 87.8°C)

(26.7°C to 87.8°C)

button to access the following parameters:

-40°F to 100°F

32°F to 100°F

(0°C to 37.8°C)

70°F to 190°F

80°F to 190°F

0-1800 Seconds

(0-30 Minutes)

Outdoor Reset Enable

If an outdoor sensor is installed and Outdoor Reset is Enabled, the boiler will automatically

adjust the heating zone set point temperature based on the outdoor reset curve in Figure

2. The maximum set point is dened by the Central Heat Setpoint [factory set to 180°F

(82.2°C)] when the outdoor temperature is 0°F (-18°C) or below. The minimum set point

temperature shown is 130°F (54.4°C) [adjustable as low as 80°F (26.7°C)] when the

outdoor temperature is 50°F (10°C) or above. As the outdoor temperature falls the supply

water target temperature increases. For example, if the outdoor air temperature is 30°F,

(-1.1°C) the set point temperature for the supply water is 150°F (65.6°C).

Disable Do Not Calculate setpoint based on outdoor temperature

Enable Calculate the temperature setpoint based on outdoor temperature using a reset

curve dened by Low Outdoor Temp, High Outdoor Temp, Low Boiler Water

Temp, Min Boiler Temp and Central Heat Setpoint and Boost Time parameters.

Low Outdoor Temperature

The Low Outdoor Temperature parameter is also called “Outdoor Design Temperature”.

This parameter is the outdoor temperature used in the heat loss calculation. It is typically

set to the coldest outdoor temperature.

High Outdoor Temperature

The High Outdoor Temperature parameter is the outdoor temperature at which the Low

Boiler Water Temperature is supplied. This parameter is typically set to the desired building

temperature.

Low Boiler Water Temperature

The Low Boiler Water Temperature parameter is the operating setpoint when the High

Outdoor Temperature is measured. If the home feels cool during warm outdoor conditions,

the Low Boiler Water Temperature parameter should be increased.

Minimum Boiler Temperature

The Minimum Boiler Temperature parameter sets a low limit for the Reset setpoint. Set this

parameter to the lowest supply water temperature that will provide enough heat for the type

radiation used to function properly. Always consider the type of radiation when adjusting

this parameter.

Boost Time

When the Central Heat Setpoint is decreased by Outdoor Reset settings, the Boost Time

parameter is used to increase the operating setpoint when the home heat demand is not

satised after the Boost Time setting is exceeded. When heat demand has been “on”

continuously for longer than the Boost Time parameter the operating setpoint is increased

by 10°F (5.6°C). The highest operating setpoint from Boost Time is current Central Heat

Setpoint minus the Central Heat “Diff Above” setting. A setting of 0 seconds disables this

feature.

105337-02 - 9/14

23

Outdoor Air Temperature

-20 105-15 -10 -5

0

110

454020 25 30 35 55 60 65

70

15 50

145

115

150

120

140

135

130

125

155

190

160

195

165

185

180

175

170

200

Boost Maximum Off Point

= Central Heat Setpoint

minus Diff Above

Low Boiler Water Temp

Default = 110 F

High Outside Air Temp

Default = 70 F

10 F

Hot Water Setpoint

Minimum Water Temperature

Default = 130 F

TOD Setback Setpoint

Default = 170 F

Central Heat Setpoint

Low Outside Air Temp

=180 F & 0 F

Default Outdoor Air Reset Setpoint

(Shown Bold)

Default Boost Outdoor Air Reset Setpoint

(Shown with thin lines, typical)

(Reset setpoint increased by 10 F every

20 minutes that demand is not satisfied.

Boost Time is field selectable

between 0 to 30 minutes)

75

I. Operation G. Changing Adjustable Parameters (continued)

Central Heat

Setpoint

180°F to 190°F

(82.2°C to 87.8°C)

160°F to 190°F

(71.1°C to 87.8°C)

130°F to 160°F

(54.4°C to 71.1°C)

24

Figure 4: Outdoor Reset Curve

Heating Element Type

Fan Coil

Convection

Baseboard

Fin Tube

Convective

Radiant

Baseboard

Central Heat

Setpoint

100°F to 140°F

In Slab Radiant High

(37.8°C to 60°C)

130°F to 160°F

(54.4°C to 71.1°C)

140°F to 160°F

(60°C to 71.1°C)

Heating Element Type

Mass Radiant

Staple-up Radiant

Low Mass Radiant

Radiators

105337-02 - 9/14

I. Operation G. Changing Adjustable Parameters (continued)

Sequence

Master

Sequence

Slave

“Press” button to access the following parameters:

Factory

Setting

Local

Local

130°F

(54.4°C)

180°F

(82.2°C)

* Only visible when Central Heat Setpoint Source is set to 4-20mA.

Range /

Choices

Local,

4-20mA

Local,

4-20mA

80°F (26.7°C) -

Central Heat

Setpoint

80°F (26.7°C) -

Central Heat

Setpoint

Central Heat Modulation Source

This parameter enables the 4-20mA input to control ring rate and the thermostat input to control boiler on/off

demand directly without using the internal setpoint. The 4-20mA selection is used to enable a remote multiple boiler

controller to control the Sage2.1 Control:

Local: 4-20mA Input on Terminal 9 & 10 is ignored.

4-20mA 4-20mA Input on Terminal 9 & 10 is used to control ring Rate % directly.

Central Heat Setpoint Source

Sets the remote (Energy Management System) control mode as follows:

Local: Local setpoint and modulation rate is used. 4-20mA input on Terminal 9 & 10 is ignored.

4-20mA 4-20mA Input on Terminal 9 & 10 is used as the temperature setpoint. The following two

parameters may be used to adjust the signal range.

Central Heat 4-20mAdc Setup, 4 mA Water Temperature*

Sets the Central Heat Temperature Setpoint corresponding to 4mA for signal input on terminal 9 & 10. Current

below 4mA is considered invalid, (failed or incorrect wired input).

Central Heat 4-20mAdc Setup, 20 mA Water Temperature*

Sets the Central Heat Temperature Setpoint corresponding to 20mA for signal input on terminal 9 & 10. Current

above 20mA is considered invalid, (failed or incorrect wired input).

Parameter and Description

“Press”

Factory

Setting

Disable

Boiler

Piped

Disabled

180 Secs 120 - 1200 Secs

195°F

(90.6°C)

70% 50% - 100%

3 1-5

Range / Choices Parameter and Description

Enable,

Disable

Boiler Piped,

Primary Piped

Enable,

Disable

Central Heat

Setpoint,

195°F (90.6°C)

button to access the following parameters:

Master Enable/Disable

The Sequencer Master Enable/Disable is used to “turn on” the Multiple Boiler Controller. Warning! enable

ONLY one Sequence Master.

Indirect Water Heater (IWH)

Boiler Piped Sequencer to respond to an Isolated DHW demand that is piped to a single boiler. The

individual boiler goes on “Leave” from the Sequencer Master and goes to DHW Service.

Primary Piped The Sequence Master responds to the DHW Call For Heat. This allows one or more

boilers to provide heat to the IWH.

DHW Two Boiler Start

The Sequencer to immediately start two boilers for a DHW call for heat. Used when DHW is the largest

demand. Only visible when primary piped IWH is selected.

Boiler Start Delay

Slave boiler time delay after header temperature has dropped below the setpoint minus “Diff below” setpoint.

Longer time delay will prevent nuisance starts due to short temperature swings.

Stop All Boilers Setpoint

When this temperature is reached all boilers are stopped. This setpoint allows the Sequencer to respond to

rapid load increases.

Base Load Common Rate

To maximize condensing boiler efciency, the ring rate is limited to an adjustable value. Boilers are kept at

or below this ring rate as long as the boilers can handle the load. After last available boiler has started, the

modulation rate limit is released up to 100%.

Response Speed

This parameter adjusts the Sequence Master temperature controller Proportion Integral Derivative (PID)

values. Higher values cause a larger ring rate change for each degree of temperature change. If set too

high ring rate “overshoots” required value, increases to high re causing the temperature to exceed the “Diff

Above” setpoint and cycle the boiler unnecessarily. Lower values cause a smaller ring rate change for each

degree of temperature change. If set too low, the ring rate response will be sluggish and temperature will

wander away from setpoint.

“Press”

Factory

Setting

None 1-8

Normal

Range / Choices Parameter and Description

Use Boiler First,

Normal,

Use Boiler Last

button to access the following parameters:

Boiler Address

Each boiler must be given a unique address. When ”Normal” slave selection order is used, the boiler address

is used by the Master Sequencer as the boiler start order. The boiler address is also the Modbus Address

when a Energy Management System is connected.

Slave Selection Order

“Use Boiler First”; places the Slave in the lead permanently.

”Normal”; ring order follows boiler number (1,2,3,..) order.

”Use Boiler Last”; places the slave last in the ring order.

105337-02 - 9/14

25

II. Troubleshooting

WARNING

Electrical Shock Hazard. Turn off power to boiler before working on wiring.

A. Troubleshooting problems where no error code is displayed.

Condition Possible Cause

Boiler not responding to call for heat, “Status” and

“Priority” show “Standby”.

Boiler not responding to a call for heat, “Status”

shows “Standby” and “Priority” shows Central Heat

or Domestic Hot Water.

Boiler Running but System or Boiler Circulator is

not running

Home is cold during mild weather days • Increase Low Boiler Water Temperature parameter 5°F (2.8°C) per day.

Home is cold during cold weather days • Increase High Boiler Water Temperature parameter 5°F (2.8°C) per day

B. Display Faults:

Faults are investigated by selecting the “Help” button from the “Home” screen. When a fault is active the “Help” button ashes

and the home screen turns a red color. Continue to select ashing buttons to be directed to the Fault cause.

Boiler is not seeing call for heat. Check thermostat or zone wiring for loose connection,

miswiring, or defective thermostat/zone control.

Boiler is not ring, temperature is greater than setpoint. Water ow through boiler primary

loop non-existent or too low.

• Check wiring for loose connection, miswiring.

• When there is a Domestic Hot Water Heat Request the System or Boiler pumps will be

forced “off” when there “Run Pump for” parameter is set to “Central heat, off DHW

demand” or “Central Heat, Optional Priority”. This has been set to allow all of the heat

to be provided for fast indirect water heater recovery. After one hour of “priority

protection” or the end of the Domestic Hot Water Heat Request the system and boiler

pumps will be free to run.

Home Screen

Status

i

Detail

Standby

Help

Energy Save On

Max Efficiency On

Adjust

Boiler

024 F

**00FF

Communication

Fault

Sensor

Fault

i

Lockout

History

Service

Contract

Active Faults

Sequencer

Boiler Size

Help Screen

Indication Condition Possible Cause

Display Completely Dark

Fan off, LWCO lights off, no green power

light on Control

Display Completely Dark, Fan running No 24Vac

Blinking Green power light on Control Control

Display Completely Dark but Boiler res No 5 Vdc

**00FF display lost

ER0011 Adjustment

No 120Vac Power

at Boiler

Power to Control

Fault

Power to Display

communication

with control

Mode Password

Timeout

Setup

Setup

Figure 5: Help Menu

Check breaker and wiring between breaker panel and boiler.

- Blown high voltage fuse, Replacement Fuse Kit, part number 105349-01.

- Loose 120Vac connection wiring between boiler J-Box and transformer

- Loose 24 Vac connection wiring between transformer and Control.

- Blown low voltage fuse, Replacement Fuse Kit, part number 105349-01.

- The green light is connected to internal power supply. The power supply

is repeatedly starting and stopping (not normal) making the light ash. The

microprocessors are not running.

- Try disconnecting all terminals except 24VAC to power the Control. The

green light should be steady. If it is not, then the control is defective. If steady,

start plugging in all the connectors while watching the green light.

When faulty wiring reconnected, green light will begin to ash.

- Loose 5 Vdc connection wiring between display and Control

- Defective Display or Control.

- Loose or defective display harness

- Defective Display

- Defective Control

- The Control and Display are NOT defective. The password has timed out.

Simply cycle power to the Display to restore operation.

i

Soft Lockout

Limit String

Rate Limit

(Hold)

Status

Status

Active Fault Screen

Lockout

Hard

Sensor

Status

Reset

26

105337-02 - 9/14

II. Troubleshooting (contined)

Sequencer

Setup

Boiler Size

Setup

C. Help Screen Faults

Indication Condition Possible Cause

This alarm is active if the slave boiler has lost communication with the Sequence Master. Check

the following:

- RJ 45 peer-to-peer network disconnected

- Sequencer Master was Enabled and then Disabled

- Master’s Boiler has been powered down.

- To clear fault restore communication or cycle power

Boiler size setting may not match actual boiler size.

The Boiler size setting determines min, max and light-off blower speeds. Incorrect boiler size can

cause hazardous burner conditions and improper operation that may result in PROPERTY LOSS,

PHYSICAL INJURY, OR DEATH.

Refer to page 16 for boiler size setting instructions.

Flashing

Flashing

Sequencer

Setup

Fault

Boiler

Size

Fault

D. Help Screen Diagnostic Features

Indication Possible Cause

Lockout History is stored in a rst-in, rst-out basis. Each History le is stored with boiler run hour of when the

lockout occurred.

For Service Contact:

CONTRACTOR NAME

CONTRACTOR ADDRESS 1

CONTRACTOR ADDRESS 2

PHONE NUMBER

The “When happened” and “Current” provide:

- “Current” is the run hour and status the boiler just nished.

- “When happened” is the run hour and status when the lockout occurred.

The user is given the contact information of the responsible service provider. Refer to page 20 for data entry

instructions.

WARNING!

E. Active Fault Screen Faults

Indication Condition Possible Cause

The Limit String Status screen shows the safety limit status. A contact icon, either “open” or

Limit String Status

Limit String Status

i

Limits Flow Switch

Air Proving Switch

Sensor Status

i

Supply Sensor 180 F Normal

Return Sensor 768 F Shorted

Stack Sensor 024 F Open

Outdoor Sensor 45 F Normal

Header Sensor None

4-20mA Input 4 mA Normal

Rate Limit

Rate Limits

i

Active Rate Limiter:

High Stack Temp Rate Limit

Active Rate Override:

Burner Control Rate Override

Limit String

Fault

Sensor

Fault

High Stack

Temperature

Rate Limit

“closed”, graphically represents each safety limit. The “closed” contact icon is steady; the “open”

contact icon is blinking. For example, the screen shown to the left illustrates a “closed” Limit

contact and an “open’ Flow Switch and Air Proving Switch Limit contacts.

NOTE: Since the limit string items are wired in series, all limits downstream of the “open” limit will

also appear on the screen as “open” (blinking) icons regardless of whether or not they are actually

open. The Air Proving Switch is wired independent to all other limits.

The Sensor Status screen shows the status of all sensors. Possible states include:

None: Feature requiring this sensor has not been selected.

Normal: Sensor is working normally.

Shorted: Sensor is shorted or is defective.

Open: There is a break in the wiring between the Control and the sensor or the sensor is

defective

Out of Range: Sensor is defective or is being subjected to electrical noise.

Unreliable: Sensor is defective or is being subjected to electrical noise.

When a sensor fails “opened” or “shorted” the value is changed to reverse video (background

black and value white) “024” or “768” respectively to indicate that there is a fault with the sensor.

The following messages appear when the ring rate is limited or reduced to help avoid a lockout.

Refer to lockout section for potential corrective action.

- High Stack Temperature Limit

- High Supply Temperature Limit

- High Differential Temperature Limit

The following messages appear as part of a normal start and stop sequence:

- Minimum Modulate (normal start/stop sequence)

- Forced Modulation (normal start/stop sequence)

- Burner Control Rate (normal start/stop sequence)

- Manual Firing Rate ( User selection)

- Low Fire Hold (user selection)

105337-02 - 9/14

27

II. Troubleshooting (contined)

F. Troubleshooting problems where a Soft Lockout Code is displayed. When a soft lockout occurs, the

boiler will shut down, the display will turn red and the “Help” button will “blink”. Select the “blinking” “Help” button to

determine the cause of the soft lockout. The boiler will automatically restart once the condition that caused the lockout is

corrected.

Soft Lockout Codes Displayed

Lockout

Number

1

Anti Short Cycle

2

Boiler Safety Limit

Open

3

Boiler Safety Limit

Open

7

Return sensor

(10 KOhms) fault

8

Supply sensor

(10 KOhms) fault

9

DHW sensor fault

10

Stack sensor

(10 KOhms) fault

11

Ignition failure

Condition Possible Cause

Minimum time between starts has not been

reached. Normal delay used to avoid

excessive cycles.