Energy Saving Products Hi-Velocity RCM-I Series, Hi-Velocity RCM-I-70, Hi-Velocity RCM-I-100 Installation Manual

Small Duct High Velocity Heating, Cooling and Home Comfort Systems

RCM-I Refrigerant Module

Installation Manual

For use with HVS-36 & HVS-60 Variable Speed Heat Pumps

Includes:

Service/Access Ports

L-Mounting Brackets

Double Sided Mounting Tape

Carry-Over Screen

RCM-I-70 (2.5-3 Tons)

RCM-I-100 (3.5-5 Tons)

Manufactured By

Module-RCM-I-Refrigerant-Module-Installation-050519

www.hi-velocity.com

Module RCM-I

RCM-I Installation

Refrigerant Modules (RCM-I)

The RCM-I cooling coil comes as a module and must be

installed in the horizontal position on the return air side of the

fan coil. RCM-I modules come with two L mounting brackets,

two access ports, carry-over screen and additional components

for air sealing.

RCM-I modules can be used on any R-410A condenser if

R-410A refrigerant components are used. All Energy Saving

Products R-Series modules come standard with R-410A

refrigerant components.

This module is for use with HVS-36 and HVS-60 Inverter

Heat Pump Condensing Units. It does not come with thermal

expansion valve, as there are internal EXVs inside the Heat

Pump. When installing the RCM-I Modules, DO NOT INSTALL

WITH TXVs.

The module will come with access ports that will need to

be installed to read refrigerant pressures/temperatures at the

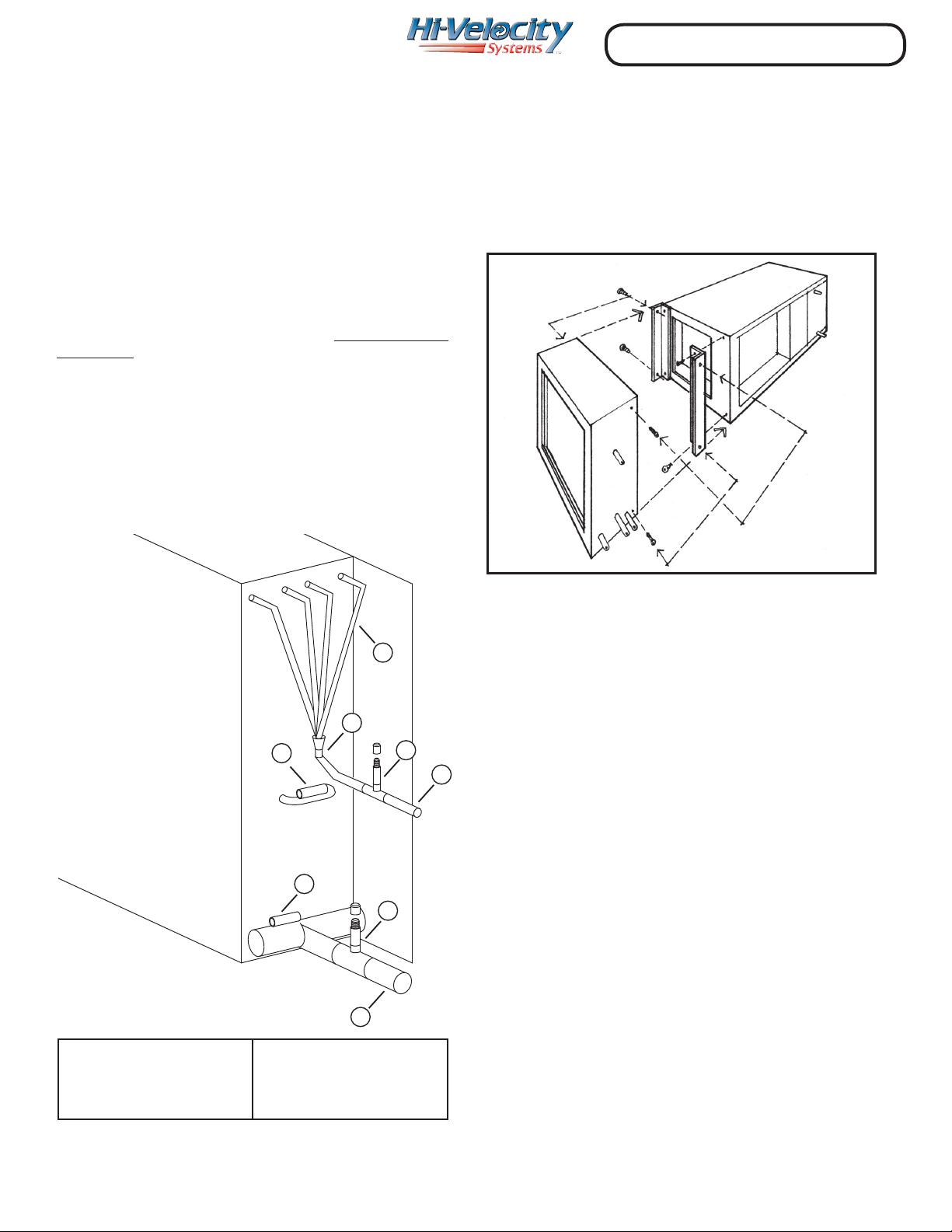

Evaporator (RCM-I). Fig. 01 shows approximate installation

locations for these components.

RCM-I Modules were designed to be used with the HVS36 and HVS-60 Heat Pumps but can be used on any R-410A

Condensing Unit, as long as a TXV is installed as well. All Energy

Saving Products cooling modules come standard with R-410A

refrigerant components.

Mounting Brackets

Mounting the cooling coil to the fan coil can be done with

the L brackets supplied (Fig. 02), ensure that no screws puncture

the drain pan or coil. Page 8 has the dimensions of the cooling

modules.

Fig. 02 - Mounting brackets

Fig. 01 - Coil Assembly

1) Liquid line

2) High side access port

3) Refrigerant distributor

4) Distributor tubes

4

3

7

7

5) Suction line

6) Low side access port

7) Suction line temperature port

8) Middle coil temperature port

2

6

5

Access Ports

When refrigerant lines are connected to the RCM-I coil, high

and low side access ports must be connected as well. (Fig. 01 reference 2 & 6) With the use of a tee and reducer this process is

simplied. The access ports are required for system startup and

for future trouble shooting or service. When reading refrigerant

pressures/temperatures, always read them at the evaporator

1

access ports.

Note: 7 & 8 coil temperature ports are explained in Module HVS - Heat Pump Manual

Module RCM-I - RCM-I Coil Installation (2/8)

www.hi-velocity.com

Module RCM-I

RCM-I Installation

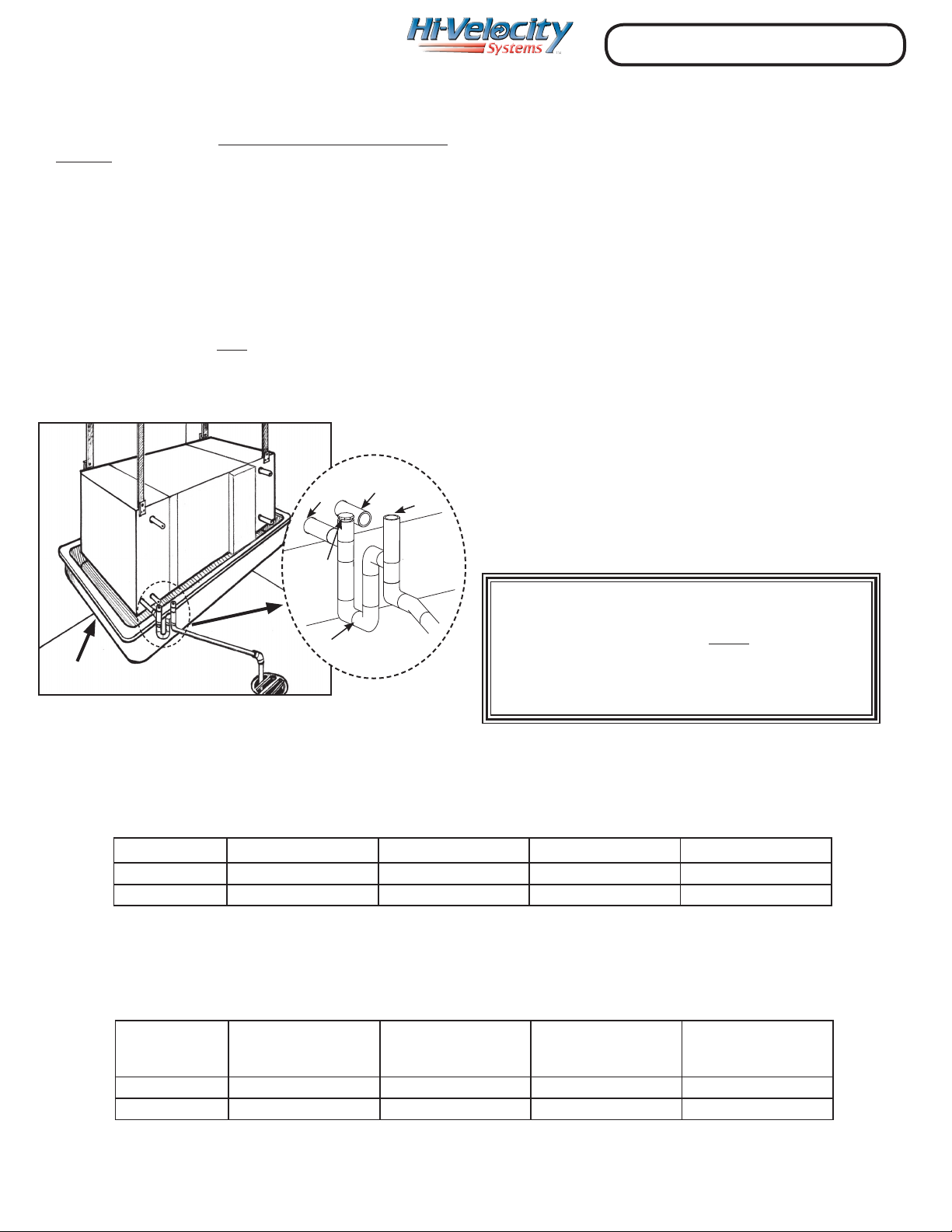

P - Trap

The condensate drain must have a minimum 3” P-Trap

installed (Fig. 03), and run at a slope of ¼” per foot in the

direction of the drain. All RCM-I modules come with a ¾” male

CPVC primary outlet and a ¾” secondary outlet. When installing

the P-Trap it must be installed on the primary outlet. It is good

practice to install a tee and a cap right above the P-Trap to act as

a clean out, in the event of the drain line being plugged. If a vent

is to be installed, it must be on the drain side of the P-Trap, and

must comply with all local building code requirements. If code

requires a secondary drain line, run the secondary line using the

same method. Otherwise, having it drain into a secondary drain

pan is acceptable. If the coil is located above a nished area,

a secondary drain pan must be installed. An equipment

stand/riser or rubber equipment mat may be necessary to

elevate the module o of the ground to allow for the P-Trap.

Secondary

Drain

Vent

Clean

Out

Primary

Drain

Pipe Sizing

Refer to charts below and Module HVS - Variable Speed Heat

Pump Manual for pipe sizing.

Piping the RCM-I

Only refrigerant grade pipe and ttings are to be used with

the RCM-I Module. Plumbing ttings may contain wax or other

contaminants which are detrimental to the proper operation of

the system. Insulate the suction line with a minumum of 3/8”

insulation. For inverter heat pump applications, insulating both

suction and liquid lines is mandatory. In high heat areas, a

minimum of 1/2” insulation may be needed. Support the pipe

every 5 feet, or whatever local code states.

Run the pipes in the most direct route possible, taking into

account structural integrity, building details and local building

codes. Minimum refrigerant pipe length is 16ft (6m). If going less

than 16 ft, coil the additional copper pipe up in horizontal loops

to ensure proper oil return. If the evaporator is located above

the condenser, slope any horizontal runs toward the condenser.

If the condenser is located above the evaporator, a P-trap must

be installed at the bottom of the vertical riser. For long vertical

risers, additional P-traps must be installed for every twenty feet.

Lines running over 213’ (65m) are not recommended.

Secondary Drain Pan

Table 02 - Minimum pipe sizes (up to 98’), factory charge and additional refrigerant required

P-Trap

Important: Return Air must be ltered

before entering the cooling module.

Fig. 03 - P-Trap, Secondary Drain Pan

Pipe Sizing

Table 01 - Minimum pipe sizes, maximum length and maximum lift

Model Liquid Line Suction Line Maximum Length Maximum Lift

HVS-36 3/8” (9.5 mm) 5/8” (15.9 mm) 213.25’ (65 m) 98.4’ (30 m)

HVS-60 3/8” (9.5 mm) 3/4” (19 mm) 213.25’ (65 m) 98.4’ (30 m)

The HVS Variable Speed Heat Pump comes with a factory charge. Additional charge will only be needed on line sets

longer than 49 ft. (See Table 02 below)

Add extra refrigerant

Model Liquid Line Suction Line Factory Charge (kg)

HVS-36 3/8” (9.5 mm) 5/8” (15.9 mm) 6.75 lbs (3.06 kg) 1 oz/ 3.3 ft

HVS-60 3/8” (9.5 mm) 3/4” (19 mm) 10.15 lbs (4.6 kg) 1 oz/ 3.3 ft

for line sets

over 49 ft (15 m)

Module RCM-I - RCM-I Coil Installation (3/8)

Loading...

Loading...