Energy Save AWH9-V5+, AWH13-V5+, AWH20-V5+, AWH11-V5+ User Manual

User manualUser manual

Direct-Current Frequency Conversion Heater

AWH9/11/13/20-V5+

★Before operating this product,please read the instruction carefully and

keep this manual for future use!

1.Before use

Catalogue

1.1 List of accessories

1.2 Symbol description

1.3 Safety precautions

1.4 Features and advantages

1.5 Specifications

1.6 Part name

1.7 Working principle

1.8 Water pump

2.Installation

2.1 Installation

2.2 Installation precautions

2.3 Installation of indoor unit

Outdoor installation

2.4

2.5 Wiring

2.6 Connection of refrigerant pipe

Installation of air purging valve

2.7

2.8 Water pipe connection

2.9 Air purging

2.10 Test run

methods

3

3

3

6

7

9

11

12

13

16

17

18

19

27

33

34

35

36

3.Useage

3.1 Introduction of operation panel

Parameter Setting Overview

3.2

Basic Operation

3.3

Advanced Setting

3.4

Failure code

3.5

3.6 Error code

4.Maintenance

4.1 Introduction of maintenance

4.2 Cleaning of water filter

4.3 Cleaning of plate heat exchanger

4.4

Gas charging

4.5 Condenser coil

4.6

Service of outdoor unit

4.7

Trouble shooting

5.Appendix

5.1 Outlines and dimensions

5.2 Exploded view

5.3 Wiring diagram

37

39

44

56

67

68

78

78

78

79

80

80

84

86

89

95

-2-

1.BEFORE USE

Attention

Thank you for choosing the product. In order to operate this product well and to prevent accidents

due to misoperation, please read carefully this user manual before carrying out any installation or

operation. Please pay special attention to the warning, prohibition and attention instructions. We will

continuously upgrade this user manual for better service !

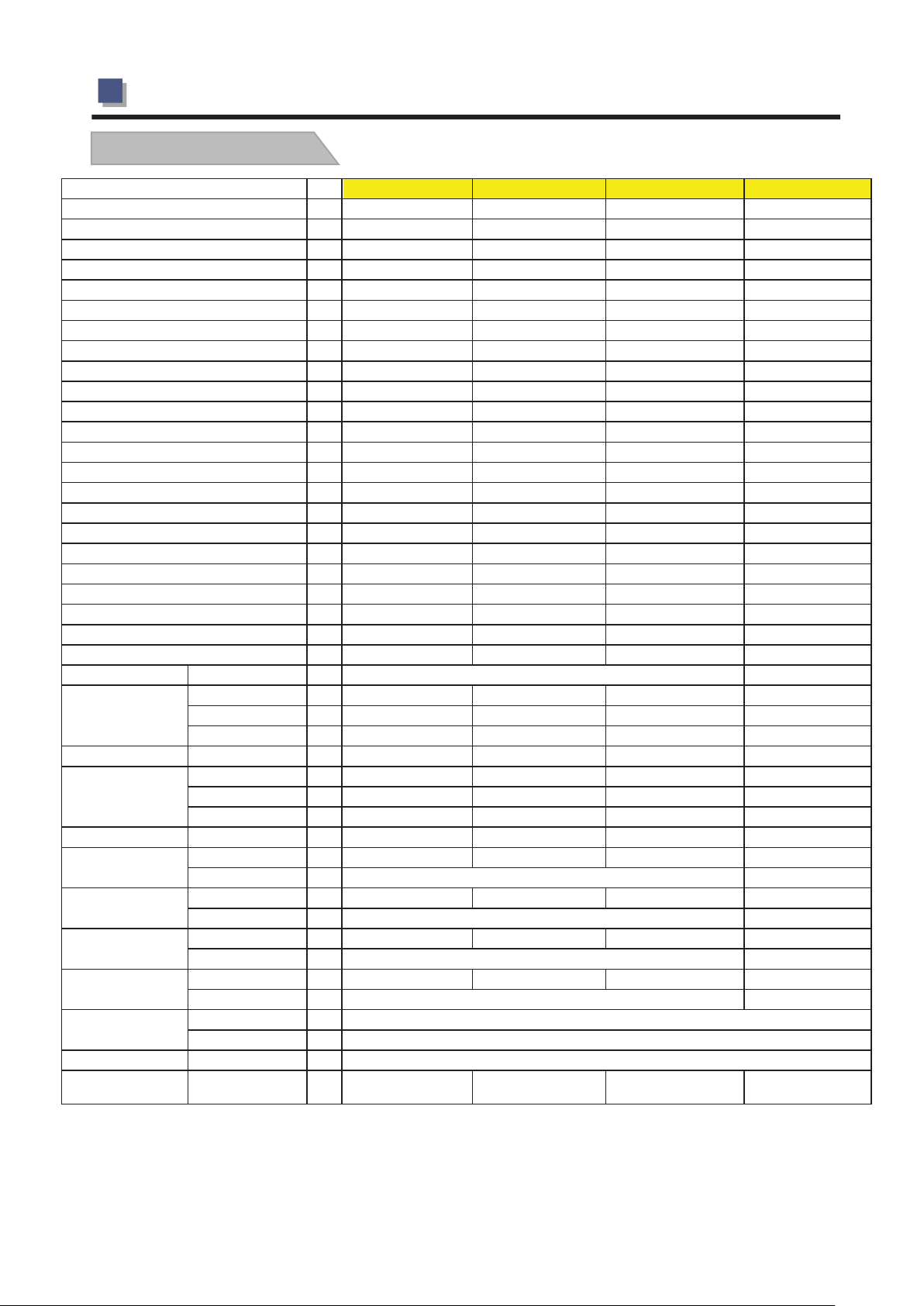

1.1 List of accessories

The accessories below are delivered together with the product .

Please check in time. If there is any shortage or damage, please contact local distributor.

Name

Sealing ring

Expansion bolt

Screw

5m extention cable for sensor TH/TC/TW

12m extention cable for sensor TR

Plastic casing for sensor TR

Plastic casing for sensor TR

User manual

Copper pipe connected to pressure release valve

Mounting plate

Pressure release valve

Copper nut

Connector for pressure release valve

13m signal cable between indoor and outdoor unit

Quantity

2

2

12

3

1

1

1

1

1

1

1

1

1

1

1.2 Symbol description

The following symbols are very important. Please be sure to understand their meaning, which concerns

the product and your personal safety.

1.3 Safety precautions

CautionWarning

This appliance is not intended for use by persons, including children, with

reduced physical, sensory or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety. Children should

be supervised to ensure that they do not play with the appliance.

Prohibition

-3-

1.BEFORE USE

User Ma nual

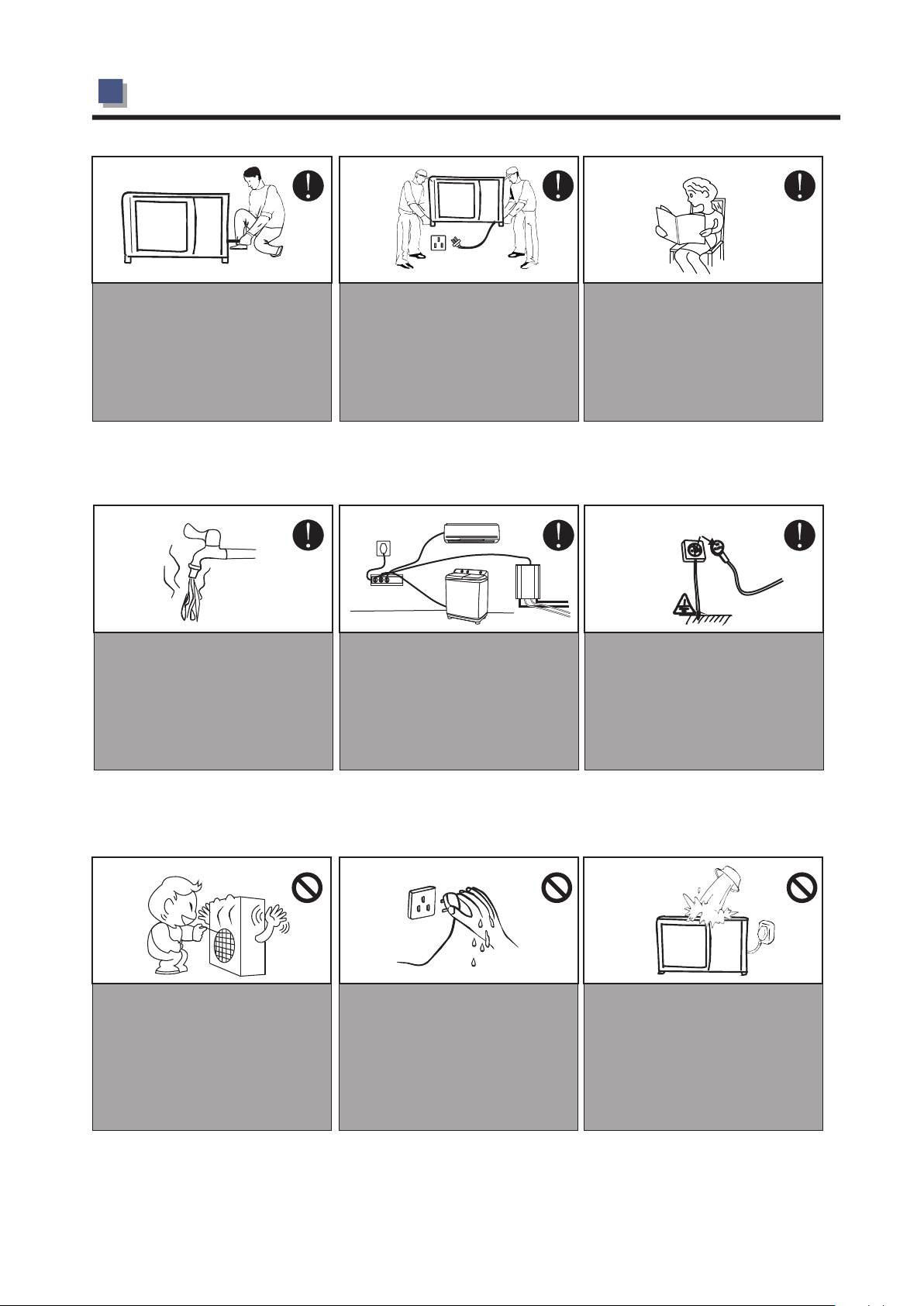

The installation, dismantlement and

maintenance of the unit must be

performed by qualified personnel.

It is forbidden to do any changes to

the structure of the unit. Otherwise

injury of person or unit damage

might happen.

Before taking shower, please always

add a mixture valve before water tap

and set it to proper temperature.

Make sure the power supply to the

heat pump unit is off before any

operations are done on the unit.

Use a dedicated socket for this unit,

otherwise malfunction may occur.

Be sure to read this manual before

use.

Ground wire

The power supply to the unit must

be grounded.

Do not touch the air outlet grill when

fan motor is running.

Do not touch the power plug with

wet hands.Never pull out the pulg

by pulling the power cable.

-4-

Water or any kind of liquid is

strictly forbidden to be poured into

the product, or may cause creepage

or breakdown of the product.

1.BEFORE USE

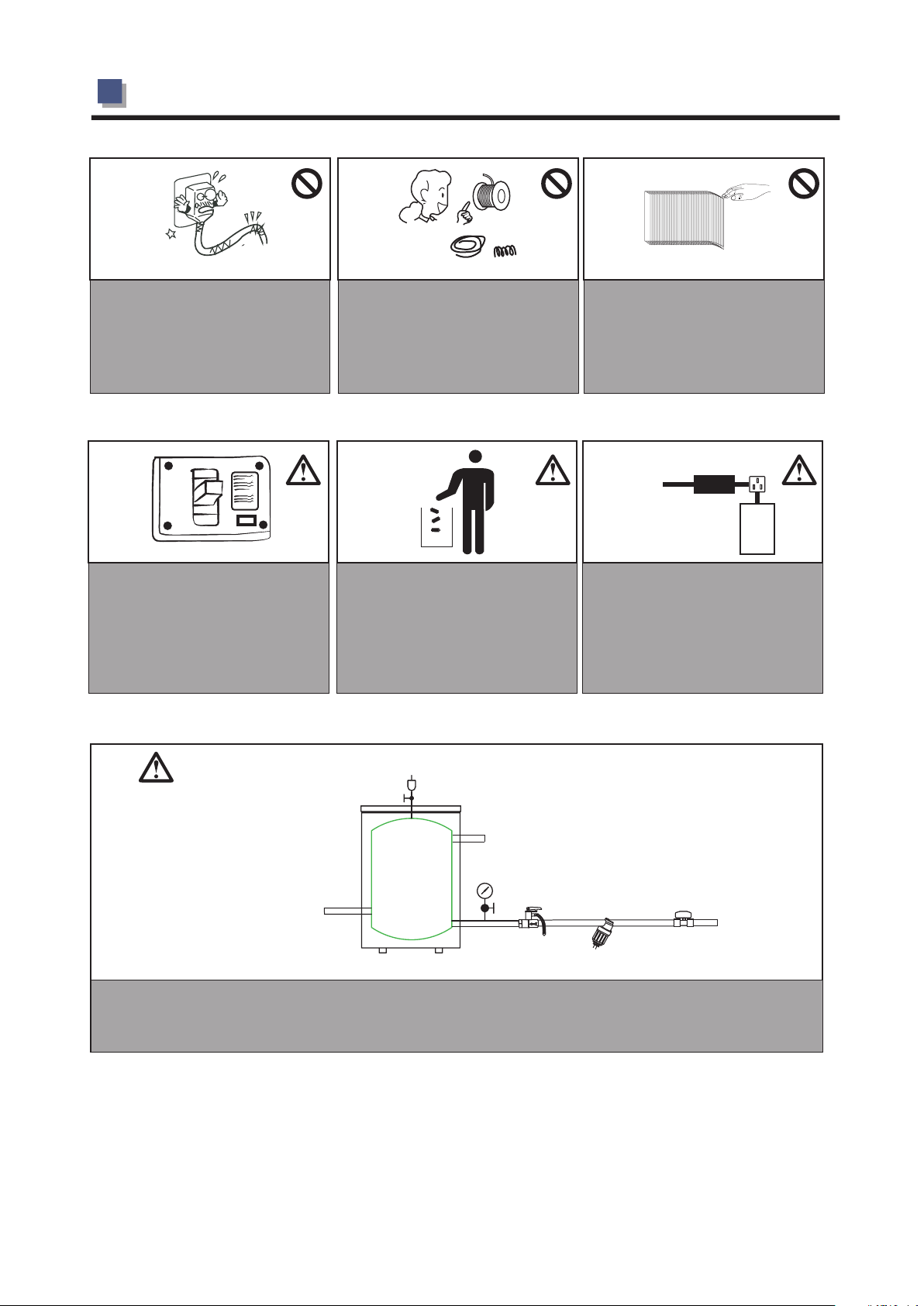

Steel

Copper

Fuse

When the power cord gets loose or is

damaged, always get a qualified

person to fix it.

ON

OFF

It is mandatory to use a suitable

circuit breaker for the heat pump and

make sure the power supply to the

heater corresponds to the

specifications. Otherwise the unit

might be damaged.

Please select the correct fuse or

breaker as per recommended.

Steel wire or copper wire cannot

be taken as substitute for fuse or

breaker. Otherwise, damag ed

maybe caused.

Disposal of Scrap Batteries --Please discard the batteries as sorted

municipal waste at the accessible

collection point.

Be aware finger might be hurt by

the fin of the coil.

Main

Power Cable

Installation of a residual current

device (RCD) having a rated

residual operating current not

exceeding 30 mA is advisable.

RCD

Indoor

unit

System water filling

T/P valve

Connect to heating/cooling system

Buffer tank

Connect to heat pump

One way valve

Filter

1. It's suggested to use pure water for filling the system.

2. If use city water for filling, please soften the water and add a filter.

Note: After filling, the system of water system should be 0.15~0.6MPa.

City water inlet

-5-

1.BEFORE USE

1.4 Features and advantaged

This unit using the latest DC inverter techology.It can adjust its working frequency,so to give out

★

its output according to the loading.It can work down to -25℃ with good COP.

★ The unit is designed with easy installation that no refrigerant charging or copper pipe brazing is

required

on site.It can be widely used in house and villa.

★ The unit is with environment-friendly refrigerant R410A,which also provides one of the highest

energy effciency ratings in the industry.Output of the compressor and therefore the energy input

requirements are constantly monitored and adjusted at the most optimum level for the given

indoor and outdoor environmental conditions,and the user’s desired demands from the system.

★ Microprocessor control system contains several enhanced software features to make the

operation of the system most advantageous and pleasing,under varying environmental conditionds.

★ Special vibration absorbers on the compressor allow operation of the system with ultra low noise.

★ Microprocessor is programmed to allow operation under wide range of input voltages from

160V-260V and soft starting with lower current draw at each compressor start-up.

★ Auto-restart function keeps all settings in memory and automatically resumes the operation

after a power failure.

★ Compressor crankcase heater and bottom plate heater are available as options for extreme cold

conditions,enabling the unit to work in very low ambient temperatures with much lessened defrost

frequencies,Both these optional heaters are electronically controlled based on the outdoor ambient

temperatures and a sophisticated logic.

★ Programmable timer function provides unattended operation of the system.

★ Acrylic coated enhanced aluminum fins on the coil heat exchanger extends the fin life against

corrosion and allows easier rainwater wash-down as well as faster defrosts.

★ Copper tubing in all heat exchangers are made by the latest developments in the technology of

inner grooved tubing by extending the area of heat exchange in a more compact coil,therefore

increasing the operational efficiency.

-6-

1.BEFORE USE

1.5 Specifications

Model AWH9 -V5+ AWH11 -V5+ AWH1 3 -V5+ AWH2 0 -V5+

Power Supply - Refrig eran t

Max. Heatin g Capaci ty

(1)

C.O.P

Heatin g Capaci ty Min./M ax.

Heatin g Power Input Min./M ax.

C.O.P Min./M ax.

Max. Heatin g Capaci ty

(2)

C.O.P

Heatin g Capaci ty Min./M ax.

Heatin g power input Min./M ax.

C.O.P Min./M ax.

Max. Coolin g Capaci ty

(3)

E.E.R

Coolin g Capaci ty Min./M ax.

Coolin g Power Input Min./M ax.

E.E.R Min./M ax.

Max. Coolin g Capaci ty

(4)

E.E.R

Coolin g Capaci ty Min./M ax.

Coolin g Power Input Min./M ax.

E.E.R Min./M ax.

(1)

(1)

(1)

(1)

(2)

(2)

(2)

(2)

(3)

(3)

(3)

(3)

(4)

(4)

(4)

(4)

Pdesig n W 6 047. 00

SCOP W/W 3.99

Compre ssor Type - Quanti ty/S ystem Twin Rotary / 1 Twin Rotary / 2

Quanti ty 1 1 2 2

Fan

Airflo w

Rated power W 76 7 6 76 x2 76x2

Noise Level Indoor /Out door dB(A ) 43/62 45/65 46/ 65 35/ 66

Wate r Side Heat

Exchan ger

Type Plate Heat Exchan ger Plate Heat Exchan ger Pl ate Heat Exchan ger Pla te Heat Exchan ger

Wate r Pressu re Drop kPa 23 23 26 35

Piping Connec tion Inch G1" G1" G1" G1 "

Allowa ble Wate r Flow Min. /Rated ./Ma x. L/S

Net Dimens ion

(L×D×H)

Packin g Dimens ion

(L×D×H)

Net Weig ht

Packin g Weig ht

Ambien t Temp . range

Outdoo r Unit mm 934X35 4X75 3 104 4X414X7 63 1124X46 0X1195 92 0X4 12X1 440

Indoor Unit mm 580X38 0X25 6.7 530X27 5X83 5

Outdoo r Unit mm 990X44 0X81 0 114 0X49 0X810 116 0X4 90X1 355 1005X5 05X1 570

Indoor Unit mm 695X45 0X31 5 620X35 0X90 5

Outdoo r Unit Kg 62. 5 7 5 113 100

Indoor Unit K g 23 39

Outdoo r Unit K g 72 .5 80 12 3 115

Indoor Unit Kg 28 42

Heatin g -25~45

Coolin g 0~55

Inlet water temp. range 10~50

Refrig eran t piping

dimens ions

Note:(1) Hea ting cond itio n: water i nlet /outlet te mper atur e: 30 /35 , Ambie nt temperatur e: DB 7 /WB 6 ;

( 2) He atin g c ondi tion: wa ter inl et/outl et tem pera ture: 40 /45 , Ambi ent tempe ratu re: DB 7 / WB 6 ;

( 3) Co olin g c ondi tion : wat er in let/ outlet temperatur e: 23 /18 , Amb ient temperatur e: DB35 /WB24 ;

( 4) Co olin g c ondi tion : wat er inlet/outl et temperat ure: 12 /7 , Am bien t tempera ture : DB3 5 /WB 24 ;

( 5) Th e spe cificat ions are subject to ch ange wi thout prior notice. Fo r act ual specificat ions of unit, please re fer to the s tickers on th e un it.

V/H z/Ph

220 - 240 /50/1 - R410A 220 - 240 /50/1 - R410A 220 - 240 /50/1 - R410A 220 -24 0/50/1 - R410A

kW 1 0.10

W/W 4.03

kW 4.33 / 10.10 4.67/11 .5 4.2/12 .6 8.6 6/20 .2

W 975/215 3 915/30 29 926/30 72 1950/4 300

11.5 12.6 20.2

3.82 3.89 4.03

W/W 4.02 / 4.65 3.82/5 .05 3.89/4 .77 4.02/4.6 5

kW 9.53

W/W 3.17

kW 4. 19 / 9.53 4.14/1 0.7 3.7 6/11.50 8 .38/ 19.06

W 1230/ 2990 1218 /362 4 1267 /3723 24 60/5 980

10.7 11.5 19.06

2.95 3.08 3.15

W/W 3.12 / 3.55 2.95/3 .56 2.9 7/3.28 3.15/3 .55

kW 6.84

W/W 2.09

kW 4. 10/ 6.84 4.33/9 .2 4. 29/10.3 7 5. 22/1 2.6

9.2 10.3 12 .6

2.68 3.29 2. 09

W 123 0 / 3280 993/346 5 957/ 3156 2460/6 650

W/W 2.09/3 .32 2.685/4 .11 3.29/4 .63 2. 09/3 .32

kW 5.05

W/W 1.58

kW 2. 34 / 5.05 2. 17/6.74 2. 34/7 .91 4. 68/10.1

6.74 7.9 10.1

2.15 2.63 1. 66

W 1 080/ 3200 924/31 32 100 0/3012 2 160/ 6400

W/W 1.58 / 2.40 2.15/ 3.0 2.33/3 .12 1. 66/2.4

8262 9556 13103

3.92 3.9 3.73

0.3

0.52 / 0.62

/

0.3

0.61 / 0.73 0.48 /0.79 /0.95

/

3

m / h

3000 3100 4200 3000x2

0.43 / 0.51

0.3

/

℃

℃

℃

Inch 3/8''~ 1/2' '

3/8''~ 1/2' ' 3 /8'' ~1/2'' 3/ 8''~ 5/8''

℃ ℃ ℃ ℃

℃ ℃ ℃ ℃

℃ ℃ ℃ ℃

℃ ℃ ℃ ℃

-7-

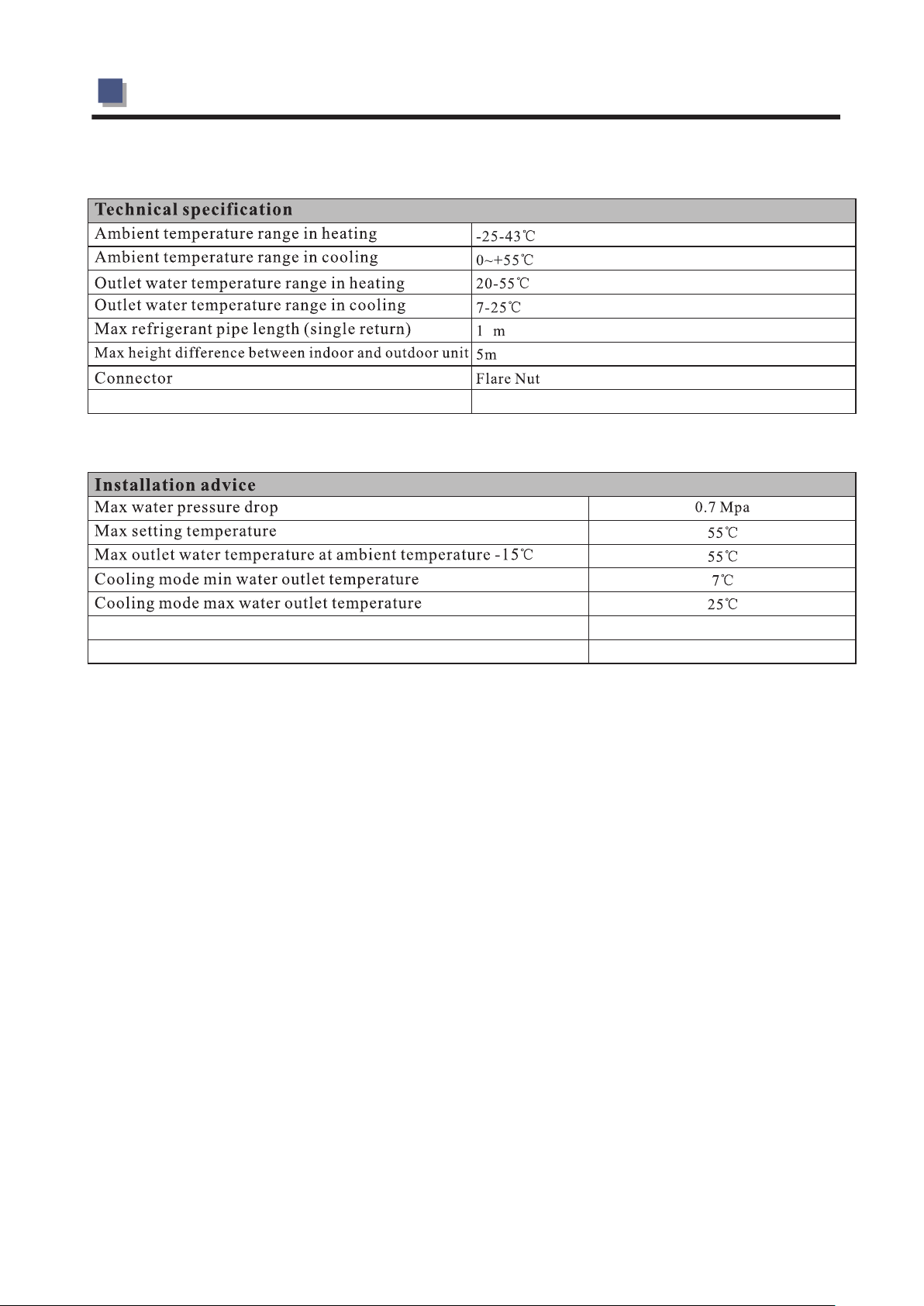

1.BEFORE USE

2

Safety valve release pressure

Minimum water inlet temperature in heating or hot water mode

Minimum water volume for a buffer tank

2.5 bar

23℃

60L

-8-

1.BEFORE USE

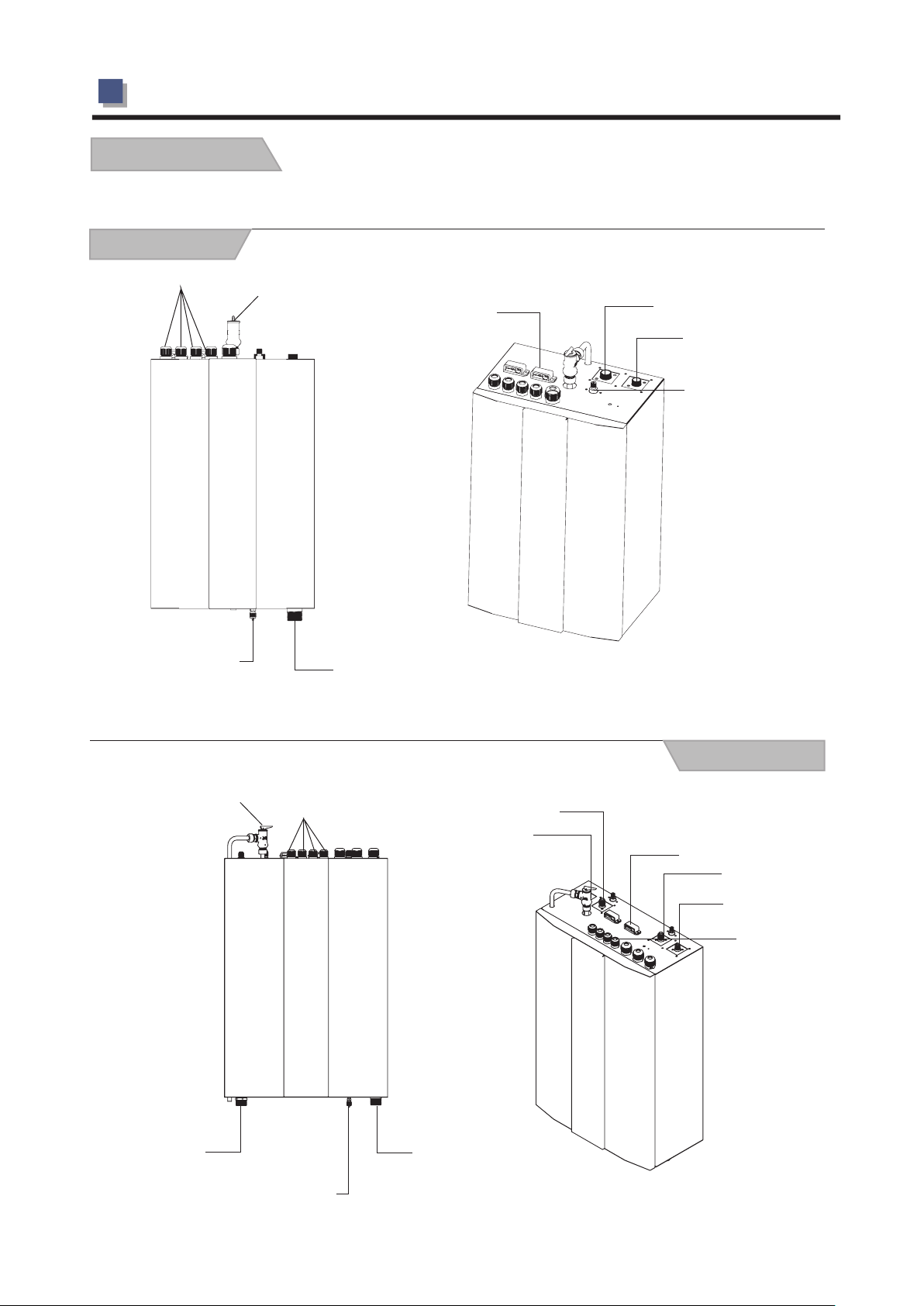

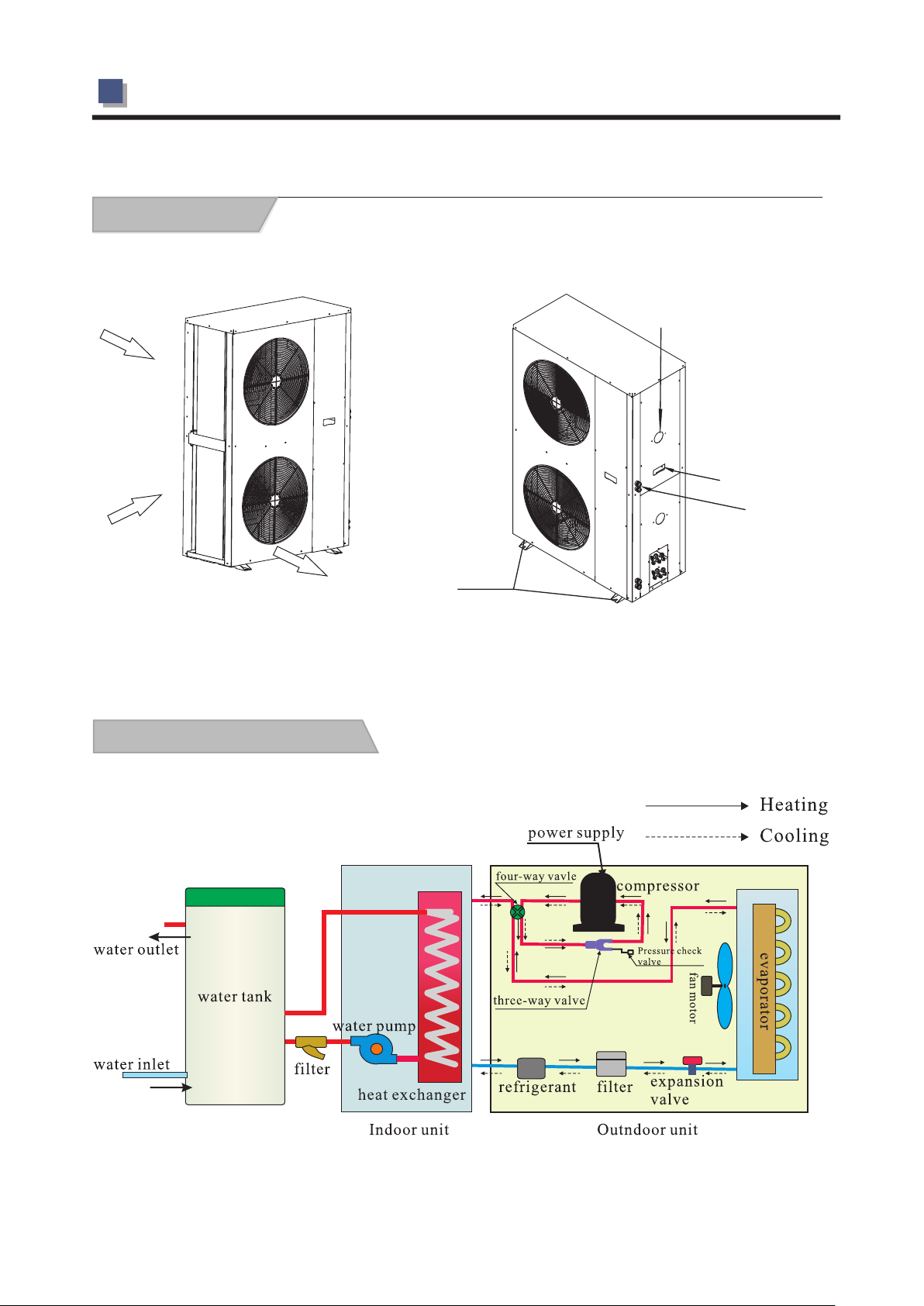

1.6 Part name

AWH9/11/13-V5+

Indoor

Cable Fixture

Needle valve for drain

Pressure release valve

Pipe Connector

Wire clip

1/2〞Connector

3/8〞Connector

Service valve

AWH20-V5+

Pressure release valve

Pipe Connector

Needle valve for drain

Cable Fixture

Indoor

1/2〞Connector

3/8〞Connector

Wire clip

1/2〞Connector

3/8〞Connector

Service valve

Pipe Connector

-9-

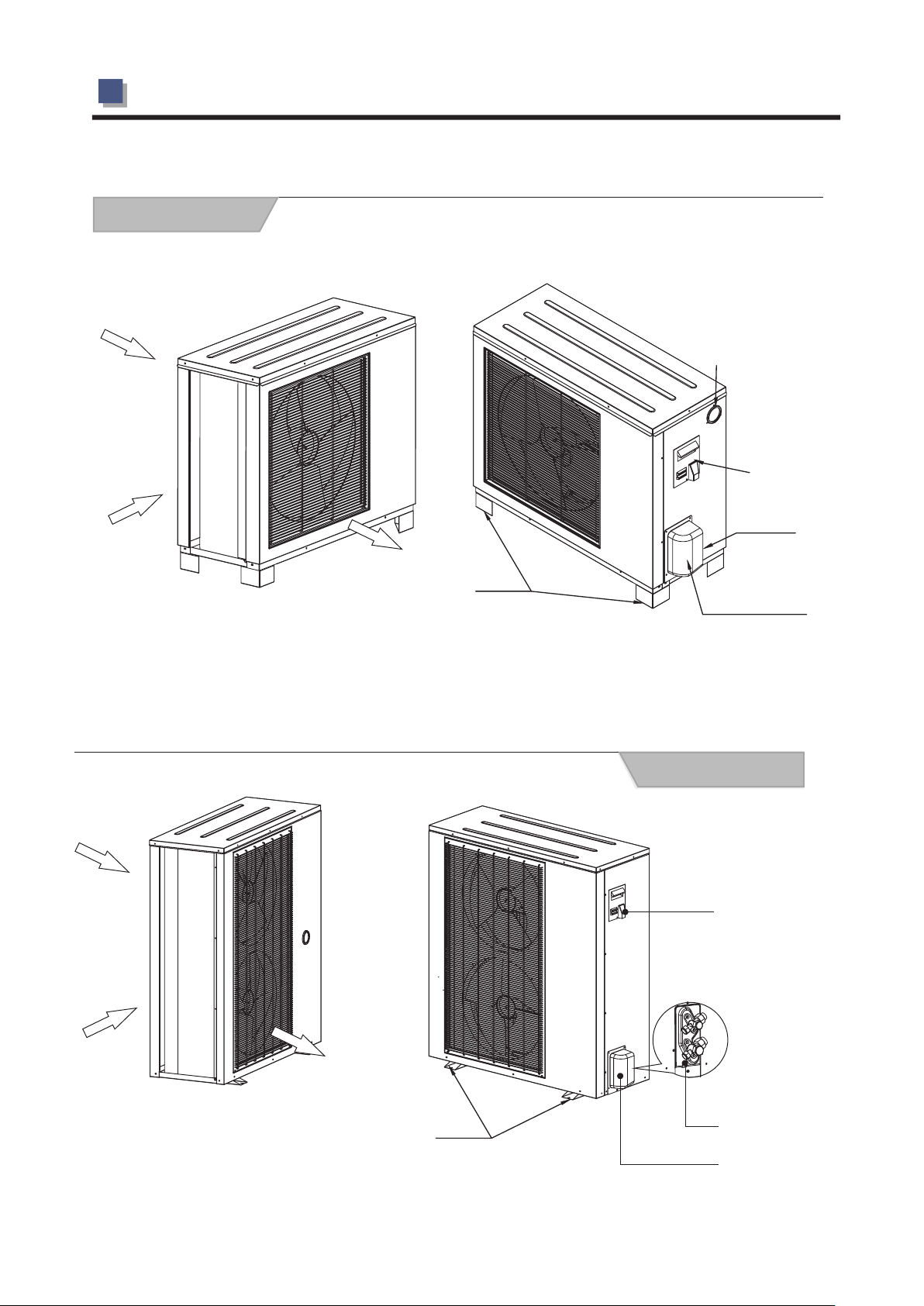

1.BEFORE USE

AW9/11-V5+

Outdoor

Air intlet

Air intlet

Pressure gauge

Handle

Pipe

Connector

AW13-V5+

Intlet

Outlet

Feet

Valve cover

Outdoor

Handle

Intlet

Outlet

Feet

-10-

Refrigerant connector

Valve cover

1.BEFORE USE

AWH20-V5+

Outdoor

Air intlet

Air intlet

Pressure gauge

Handle

Cable gland

1.7 Working principle

Outlet

Feet

-11-

1.BEFORE USE

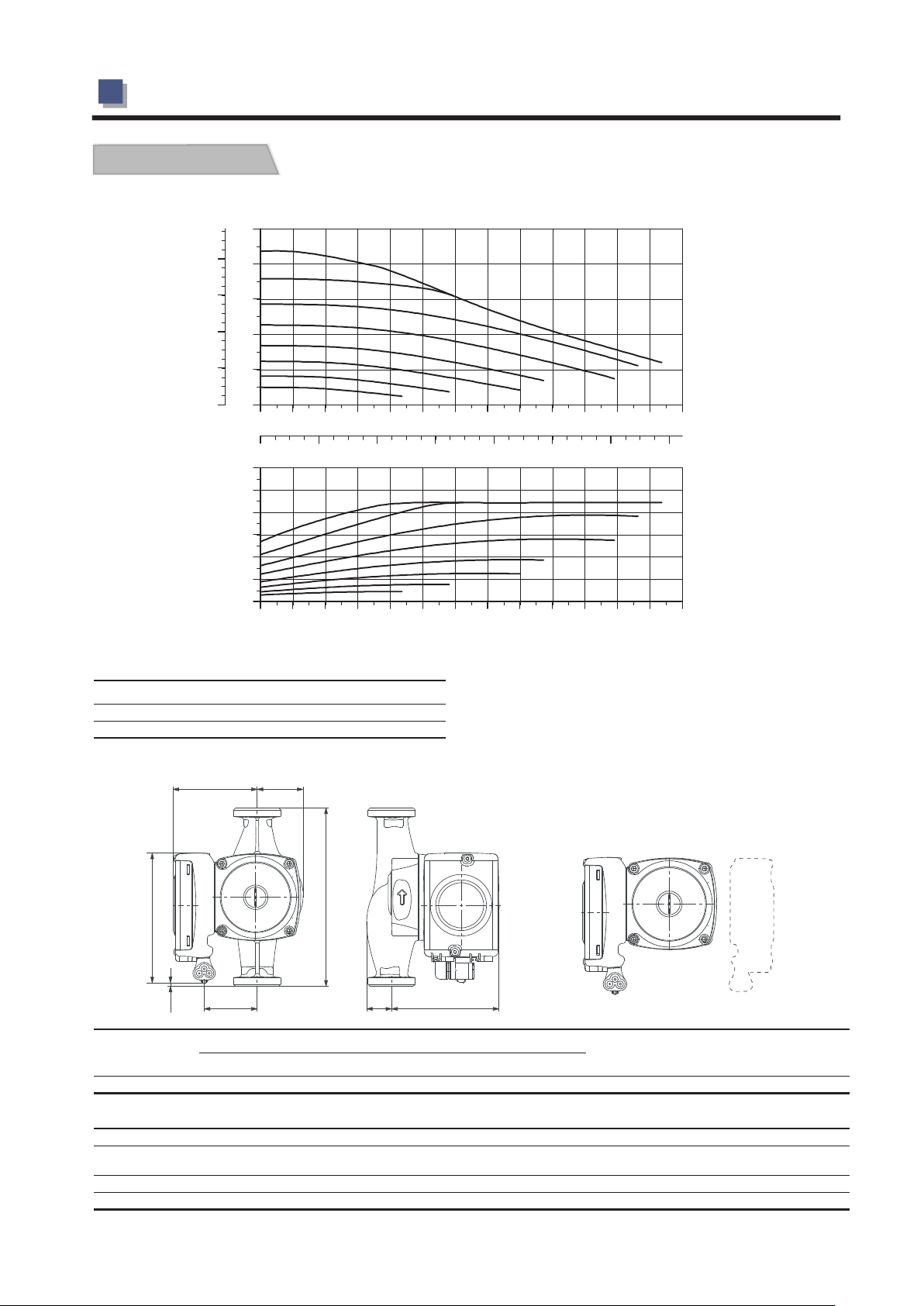

1.8 Water pump

UPM GEO 25-85 180,1X230V,50/60Hz

p

[kPa]

H

[m]

80

8

60

6

40

4

20

2

0 0

P1

0.4

0.0

0.0 0 .2

0.8

1.2

0.4

1.6

2.0

2.4 2.8

0.6

[W]

100

80

60

40

20

0

0.0

0.4

0.8

1.2

1.6

2.0

2.4 2.8

2.4 4.4

Electrical data,1X230V,50Hz

Speed P1 [W] I1/1 [A]

Min.

Max.

5.7

87

0.06

0.71

Dimensional sketches and position of control box

B3

B4

3.2 3.6 4 .0 4 .4

0.8

1.0

3.2 3.6 4 .0 4 .4

1.2

3

Q [m h]

Q [l/s]

3

Q [m h]

EEI

≤

0.23

L3

L1

L2

Pump t ype

UPM GEO 25-85 180 3.5 131 95 50 64 38 102 G11/2 2.59 160

B5

L1 L2 L3 B3 B4 B5 H1 H2

Technical data

System pressure :

Minimum inlet pressure:

Liquid temperat ure:

Motor protectio n: Overload protecti

Max. 1.0 MPa

0.05MPa (0.5 bar) at 95℃ liquid

temperature

-10

℃ to + 95 ℃ (TF 95)

H1

Dimensions [mm ]

( bar) Enclosure class: IPX4D10

on Approvals and marking: VDE, CE

H2

Connection

Insulation class:

Equipm ent class: I

Net weight

H

[kg]

Quantity per

pallet

-12-

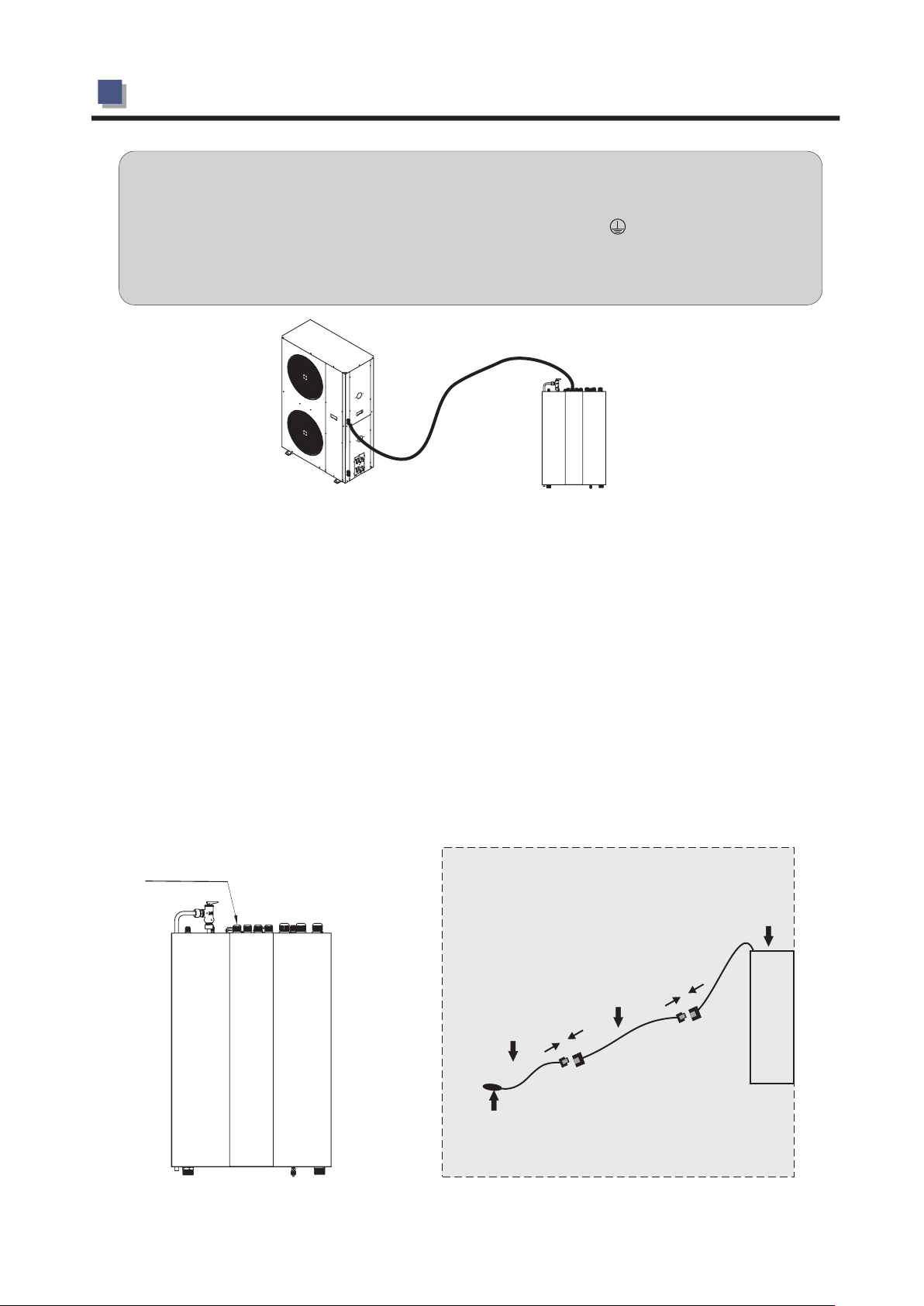

2.INSTALLATION

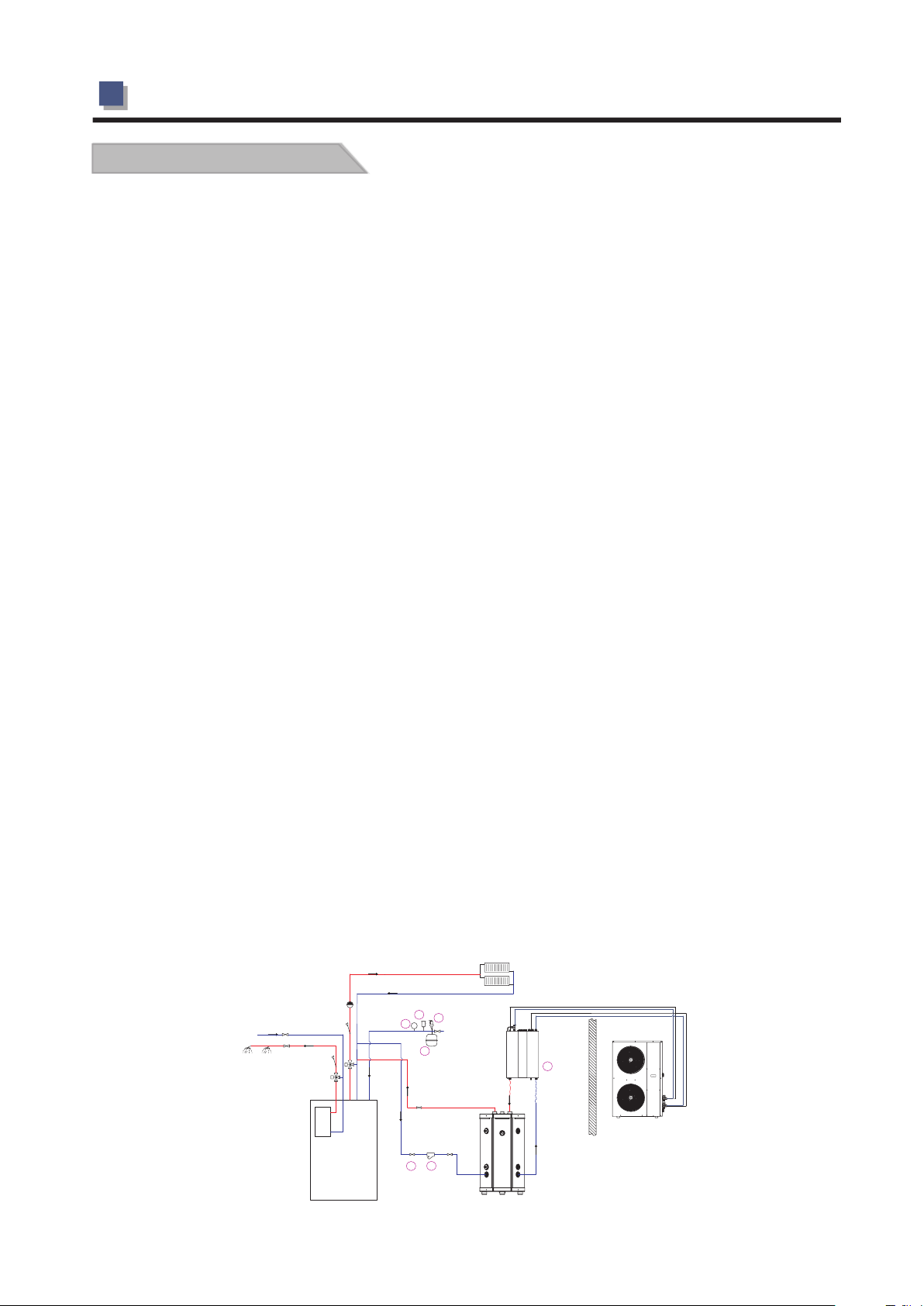

2.1 Installation methods

Please observe

All drawings contains buffer tank , since this is normally used for better temperature balance form

heat pump and heating / cooling system . The sensors are therefore placed in the buffer tank . If you

don't have buffer tank in your system , the sensors needs to be put directly on the water lines . Make

sure that you get good readings by only connecting the sensors to cop per pip es or similar .

Installation drawing of unit connected directly to hea ting sy stem. (not all installers use buffer tan k).

a. With ex terna l water pump, add by pass between turn and return line between indoor unit and external

circulation pump

b. Witho ut exte rnal water pump, an adjustable bypass (ball valve) is required to ensure flow for heat pump

if thermostat close the flow in the heating system.

c. External circulation pump needs to be connecte d to indo or unit w ater pump terminal (P0)

Minimum piping dimensions required.

a. ≤ 6kW heat pump output, minimum 22 mm copper piping or similar

b. ≤ 13 kW heat pump output, minimum 28 mm copper piping or similar. For 13 kW heat pump 35 mm

copper can be required if it is much fittings and angles.

c. ≤ 20 kW heat pump output, minimum 35 mm copper piping or similar.

Please be aware of

All the sensors are put on the indoor unit . Please adjust the position o f senso rs acco rding to your

real application .

All sensors ( TW , TH and TC ) needs to be connected to the PCB to avoid failure codes , event hey

are not in use in your application .

Make sure to insulate the pipes and sensors if sensors are put direct ly on the w ater lines .

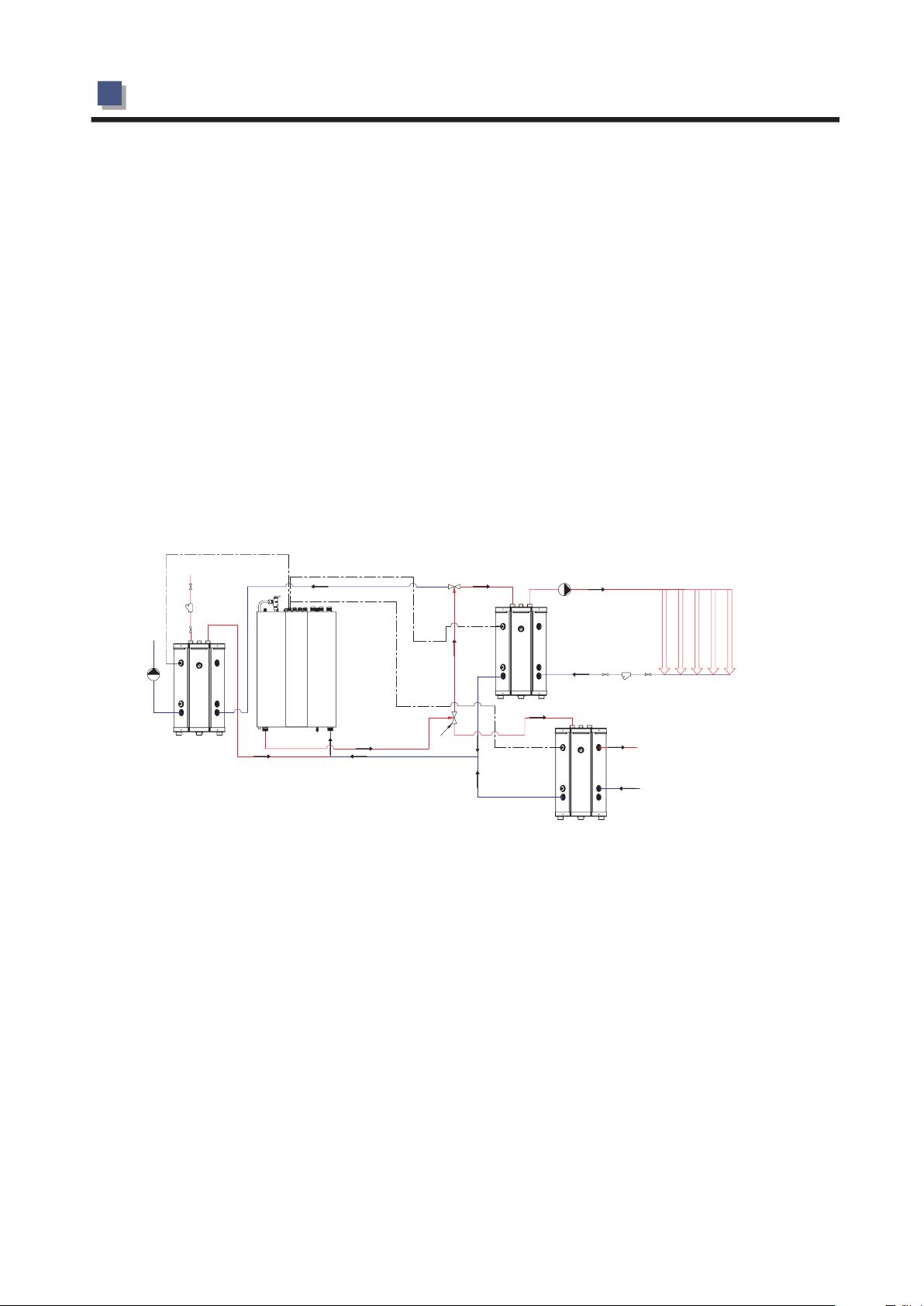

Application 1

For space heating

In this application heat pump is connected on the ret urn lin e of the heating system . The unit can be

controlled by fixed or variable water temperatu re ( curv e , based o n ambient temperature ) .

This heat pump has no internal back up , so an existing heating so urce li ke oil burner etc . needs to

be connected as back up . The installation also demand s that th e backup source have a working

controller to control the supply temperature to the heat ing sys tem . When the heating deman d

exceeds the heat pump capacity , the backup source au tomat ically starts supporting the heat pump .

This means the heat pump curve or temperature controller s hould b e set slightly above the existing

heating source controller . Then heat pump will always have the priority .

All sensors ( TW , TH and TC ) needs to be connected, even they have no function for the chosen

application. Locate water temperature senso rs on ret urn lin e if no buffer tank is installed. Mak e sure

the sensors have good contact with the pipe, and insulate th e pipes a nd sens ors.

Radiator

4

11

9

tap water

hot water supply

P

7

Indoor unit

6

Flexible

pipe 50cm

Buffer

tank

Outdoor unit

Oil fired boiler

2

1

-13-

2.INSTALLATION

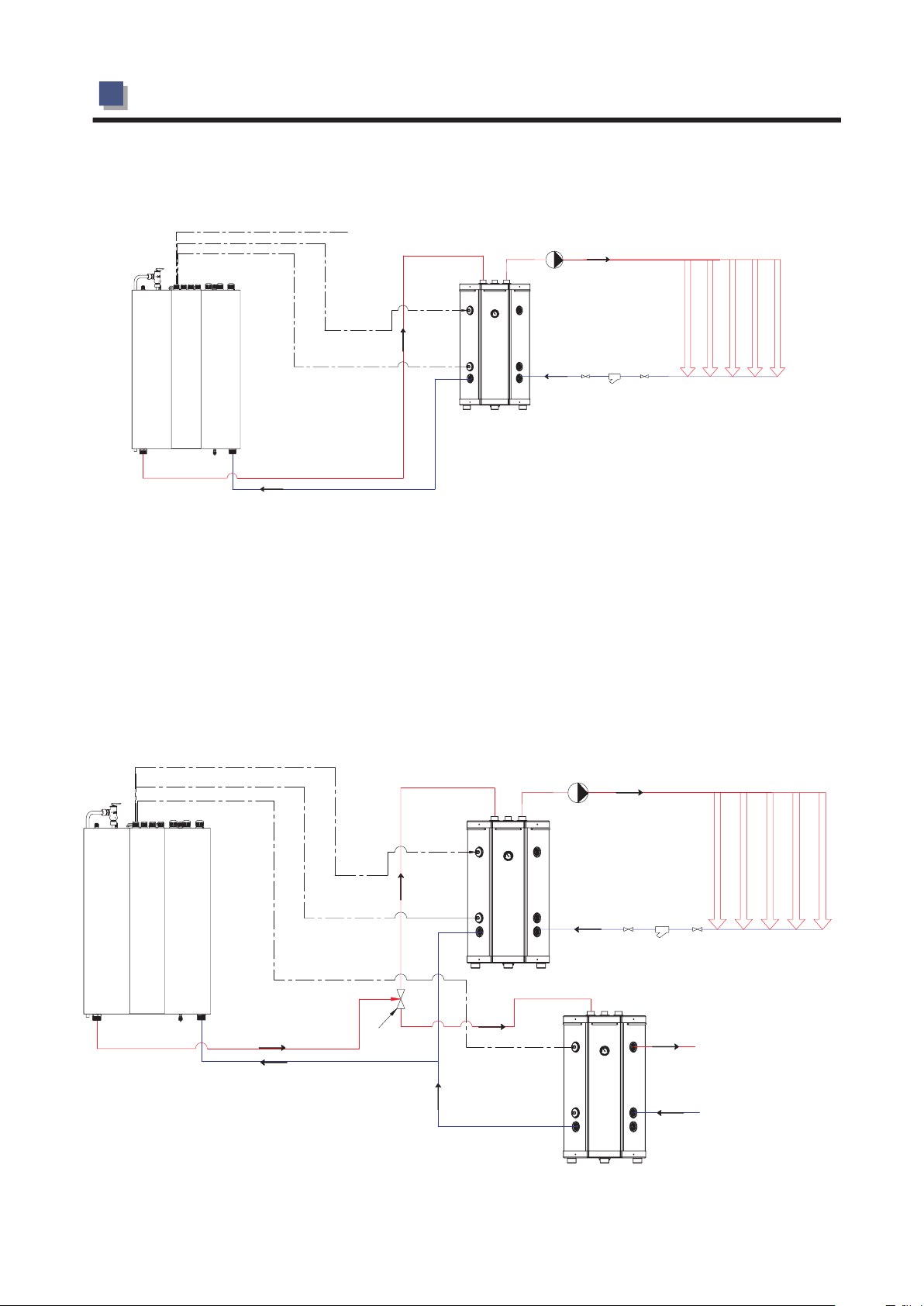

Application 2

for space heating/cooling

TW

TH

TC

Pump

Buffer

tank

Heating/Cooling

system

Place the TH (heating) sensor in the sensor pocket in the upper part of the buffer tank.

Place the TC (cooling) sensor in the sensor pocket in the lower part of the buffer tank.

If your system don' t contain a buffer tank, TH and TC sensor needs to be put directly

on the water lines. For more stable running of the heat pump, we suggest to place the

sensors on the return line and adjust the heating curve or cooling temperature accordingly

to fit the normal Delta T for your heating/ cooling system.

Heat pump setting temperature is now controlled at the actual location of these sensors.

Application 3

for space heating/cooling+hot water

Changing

valve

TH

TC

TW

Pump

Bufer

tank

Heating/Cooling

system

Hot water outlet(heated

through coils in this

drawing)

City water inlet

-14-

2.INSTALLATION

This application needs a changing valve (accessories) to change the water direction according

to the set temperature for heating/cooling and hot water. Place the TH (heating) sensor in the

sensor pocket in the upper part of the buffer tank. Place the TC (cooling) sensor in the sensor

pocket in the lower part of the buffer tank. If your system don't contain a buffer tank, TH and

TC sensor needs to be put directly on the water lines. For more stable running of the heat pump,

we suggest to place the sensors on the return line and adjust the heating curve or cooling

temperature accordingly to fit the normal Delta T for your heating/cooling system.

Heat pump setting temperature is now controlled at the actual location of these sensors.

Place the TW (hot water) sensor in the upper or lower part of your accumulating water tank.

Hot water is in this system now heated through coils in the water volume. Heat pump can also

be connected to coils in a hot water storage tank (water heater). If so, it is required to have an

electric heater to increase the water temperature to 60 degrees once every week, which is

above the heat pump maximum outlet temperature of 52 degrees.

Observe: Never mix heating/cooling water and hot water.

Application 4

for space heating+cooling+hot water

TC

To fan coils

Buffer tank

Cooling

Changing

valve

TH

Pump

Buffer tank

Heating

TW

Heating system

Hot water outlet (heated

through coils in this

drawing)

City water inlet

This application needs a 2 changing valves (accessories) to change the water direction

according to the set temperature for heating, cooling and hot water. Place the TH

(heating) sensor in the sensor pocket in the upper part of the heater buffer tank. Place

the TC (cooling) sensor in the sensor pocket in the upper part of the cooling buffer tank.

If your system don' t contain buffer tanks, TH and TC sensor needs to be put directly

on the water lines. For more stable running of the heat pump, we suggest to place the

sensors on the return line and adjust the heating curve or cooling temperature

accordingly to fit the normal Delta T for your heating/cooling system.

Heat pump setting temperature is now controlled at the actual location of these sensors

.

Place the TW (hot water) sensor in the upper or lower part of your accumulating water

tank. Hot water is in this system now heated through coils in the water volume. Heat

pump can also be connected to coils in a hot water storage tank (water heater). If so,

it is required to have an electric heater to increase the water temperature to 60 degrees

once every week, which is above the heat pump maximum outlet temperature of 52

degrees.

Observe: Never mix heating/cooling water and hot water.

-15-

2.INSTALLATION

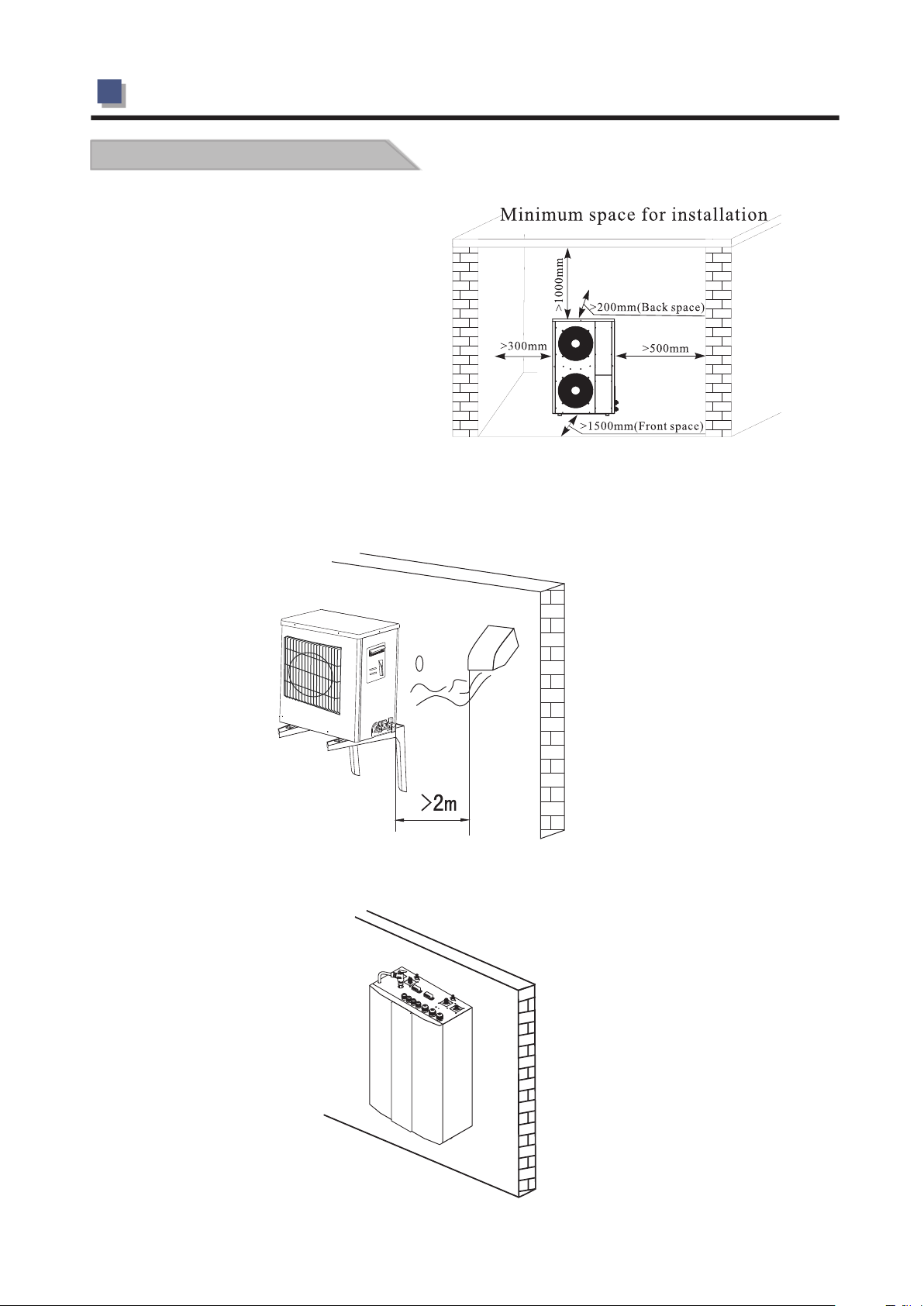

2.2 Installation precautions

1.The installation,dismantlement

and maintenance of the heat pump

must be performed by qualified

personnel.

2.The unit must be installed outdoors

in an area with sufficient clearance to

provide free air citculation through

the coil.Please refer to the following

figure to choose the right place for

the unit.

3.The outdoor unit should be placed at least 2M away from the ventilation outlet of kitchen,to keep

the unit clean.

4.The indoor unit should be hung on the wall with the water connectors downwards.

-16-

2.INSTALLATION

5.All the hot water pipe and water connections

should be insulated,to reduce the energy loss.

6. A mesh filter must be installed in front of the water

inlet of the unit and water tank, for keeping the

water quality and collecting impurity contained

in the water. Take care to keep the water filter

Water inlet

mesh towards the bottom. Check valve is

recommended to be installed at both sides of the

filter, so as to clean or change the filter in a easier way.

7.Shield the unit from direct sunshine,rain or snow,

but never cover the unit which will cause the bad

ventilation.

8. Install the unit and water tank close to each other as much as possible to reduce the distance

between them,so to reduce the energy loss

9.The unit should be free from corrosive and moisture surrounding.Otherwise the lifetime of the

unit might be shortened.

Filter

2.3 Installation of indoor unit

For the installation of the indoor unit, please refers to the followings:

1.Mark out the positions of the unit bracket on the wall.

2.Drill the holes on the wall.

3.Fix unit bracket with expansion bolts on the wall.

4.Then hand the indoor unit on the bracket.

1

Note:You must choose very firm wall for installation otherwise the bolts may get loose and

cause unit damage!

(refer fig.2)

(refer fig.4)

2

(refer fig.1)

(refer fig.3)

3

4

-17-

2.INSTALLATION

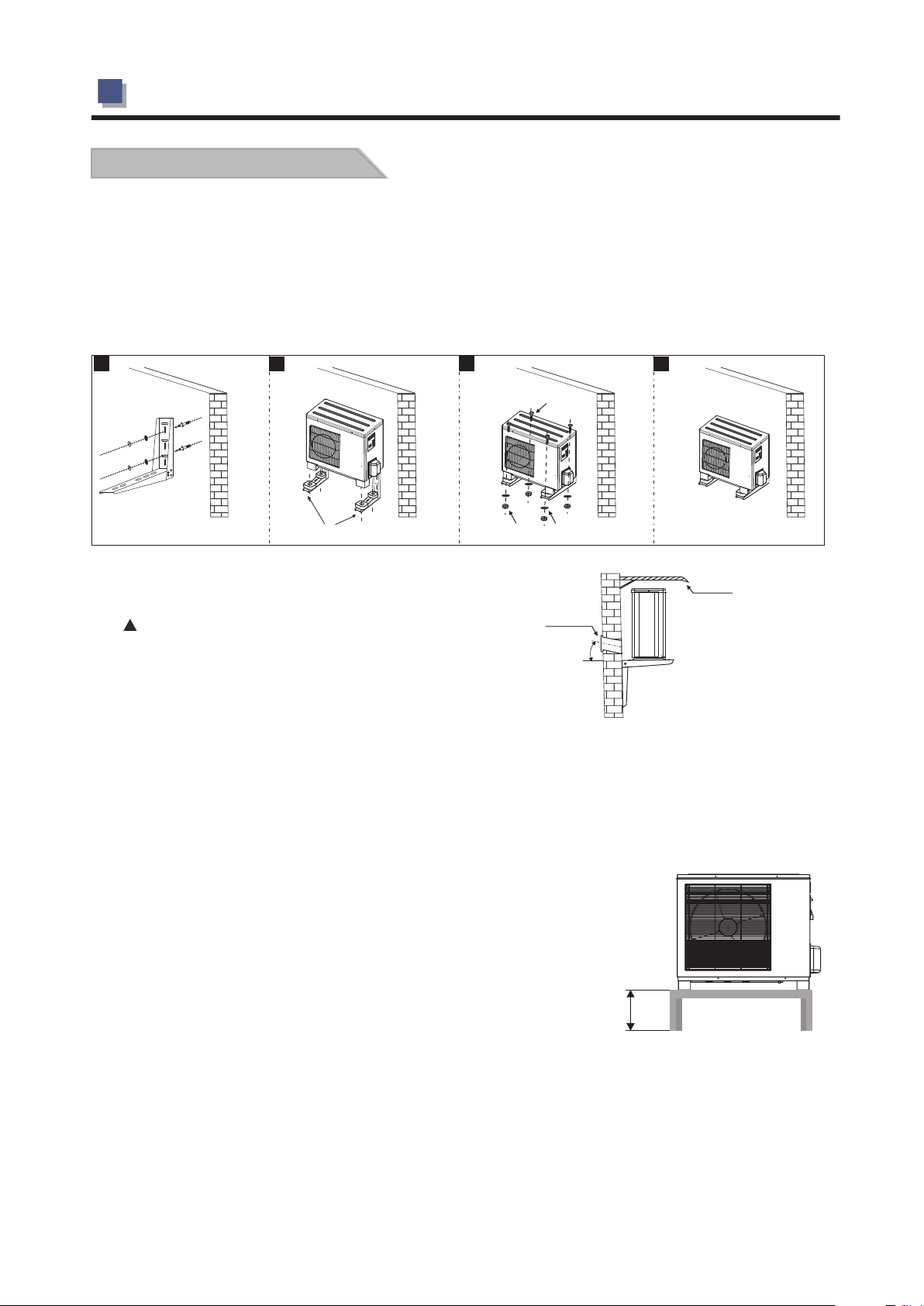

2.4 Outdoor installation

A:If needs to hang the outdoor unit on the wall, please do as followings:

1.Adjust the location of the wall according to the distance between two feet of the unit.

2.Fix the on the wall with expansion bolts.

brackets

3.Place the outdoor unit on the .A

vibration and noise.

4.Fix the unit to the bracket.

brackets

brackets Vibration absorbers are recommended to reduce

1

2

Vibrati on ab sorber

3

Bolt

Nut

Gasket

4

Shield

Sleeve

It is recommended to use a wall sleeve

to guide power cable and piping kits go

≥8°

through the wall.

B:On a concrete stand

User can either use the dedicated mounting bracket from the supplier, or prepare a suitable bracket

for the unit installation. Make sure the installation meets following requirements:

1. The unit must be installed on flat concrete blocks, or a dedicated mounting bracket. The bracket

should be able to support at least 5 times of unit’s weight.

2. All nuts must be tightened after the bracket is fixed; otherwise,

it may cause damage to the equipment;

3.User should double check and make sure the installation

of unit is firm enough.

4. The bracket can be of stainless steel, galvanized steel,

aluminum and other materials as required by the user.

5. Besides the mounting bracket, the user can also install

the outdoor unit on two concrete blocks, or a raised concrete

platform. Please make sure that the unit is securely fastened

after installation.

6.Please refer the dimension of outdoor unit when choose a suitable wall bracket.

For installation on ground where ambient temperature is below 0, use outdoor unit standings

for example the OUS35-55, in order to prevent the unit for freezing up. Concrete standings will

block the drains too much.

50cm

-18-

2.INSTALLATION

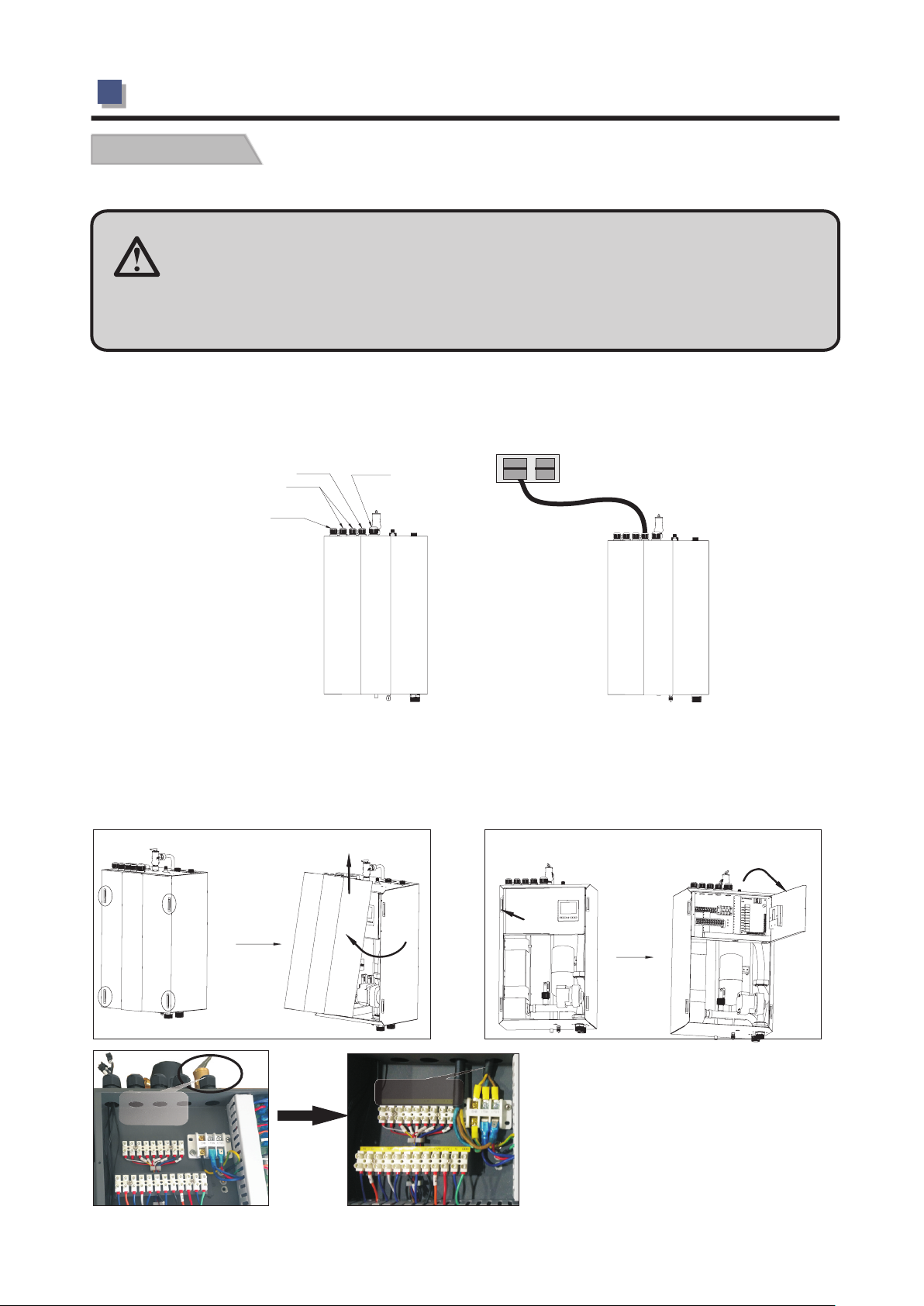

2.5 Wiring

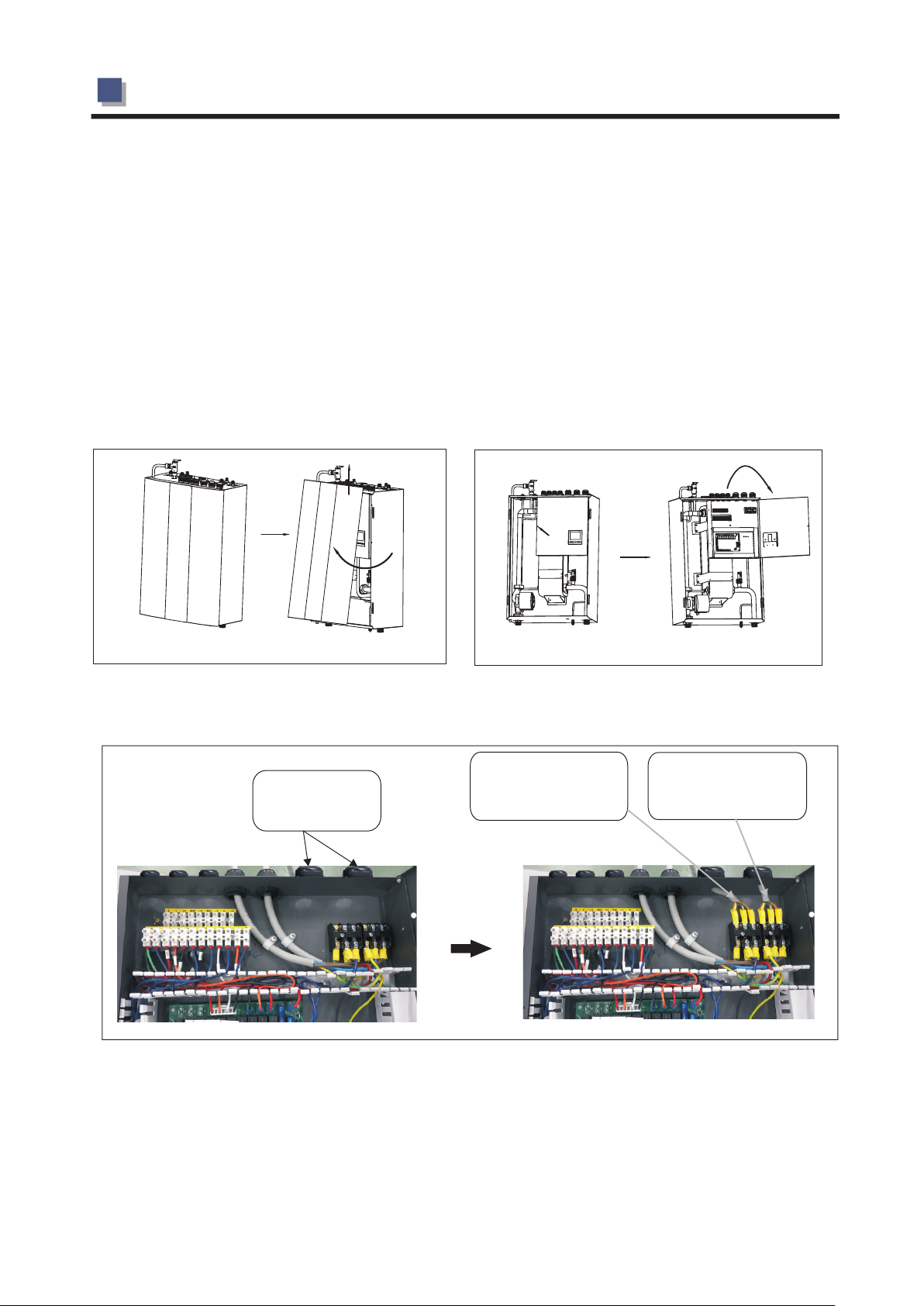

AWH9/11/13-V5+

1.It is recommended to use a suitable breaker for the heat pump and make sure the power

supply to the heater corresponds to the specifications.Otherwise th unit might be

damaged.

2.The power supply to the heat pump unit must be grounded.

3.Cable should be fixed tightly,to ensure it won’t get lossen.

A:Main power cable

1.Main power cable has connected into the terminal block of indoor unit. Please find the cable on

top of indoor unit according to the label, and connect it to main power, as shown in the pictures below.

C

B

A

D

Main pow er in u ser side

A: Sensor cables

B: Signal cables

C: Main power cable

D: Power cable between

indoor and outdoor unit

B:Power cable between indoor and outdoor unit

1. The indoor front panel is fixed by four magnets in two sides of door. Please take off the front panel as fig. 1.

2. Remove one screw in left side of electric box, then open the door of electric box to right side as fig. 2.

3. Prepare a power cable of 3 core 2.5mm2 and four cores with suitable length, insert the cable through

cable gland on top of the indoor unit.

Ins ert the c able

fro m this ca ble

gla nd

Fig. 1

Pow er cabl e

bet ween in door

and o utdoo r unit

Fig. 2

Fig. 3

-19-

2.INSTALLATION

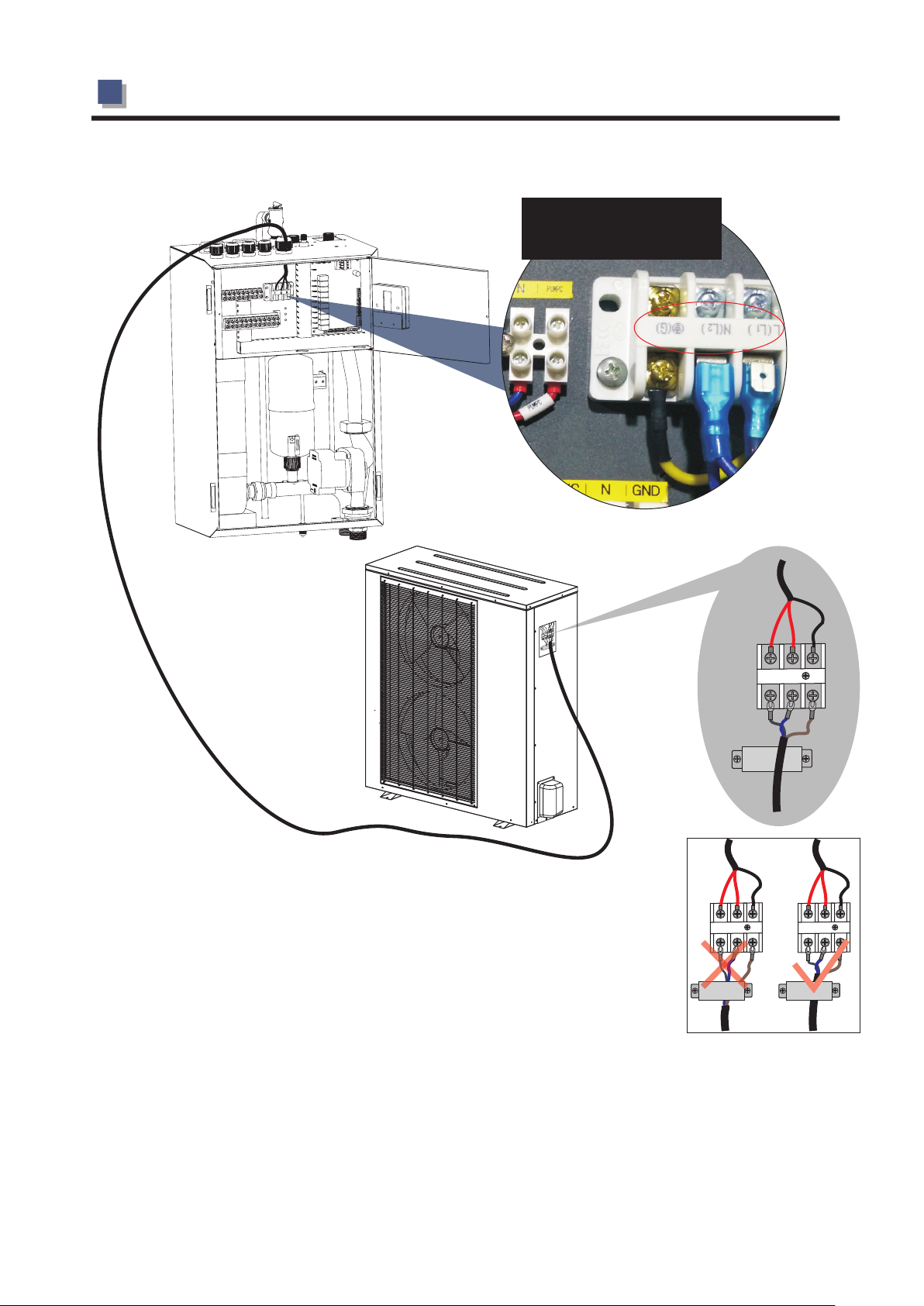

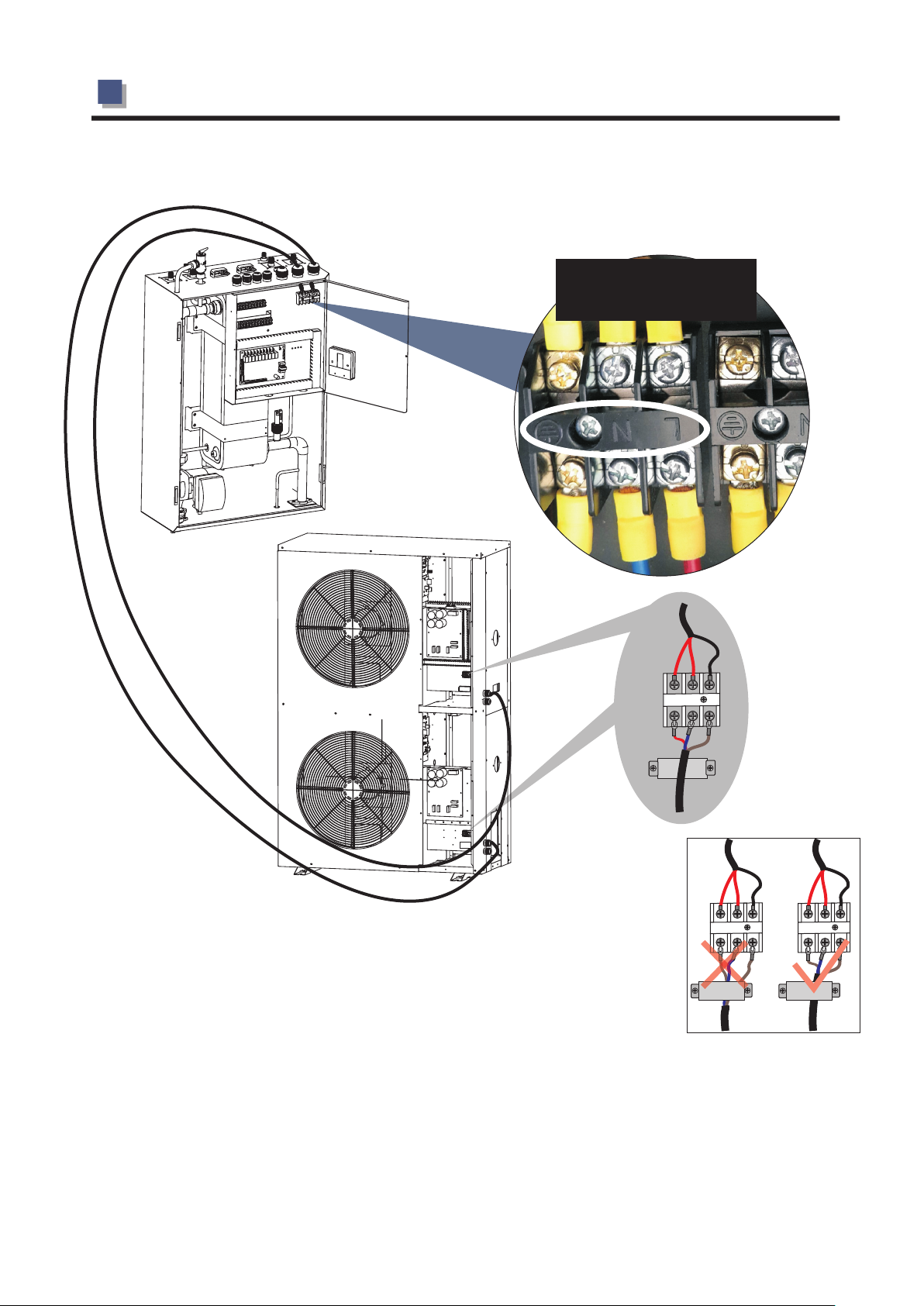

Shown as "L, N, G" on

wiring diagram

G N L

Notice: When fixing the power cable with the wire clip, please be careful to

clamp on the outer layer insulation, don’t clamp on the wires inside,

or it may cause damage on insulation layer of one-core wire.

4. Connect this power cable to "L,N and G" on indoor terminal block according to the wiring diagram of

indoor unit.

5. Fasten the cable gland to ensure the cable won't get loosen.

6. Connect the other side of the power cable to the outdoor unit, according to the wiring diagram. Fix the

cable with cable fixture, to ensure it won’t get loose.

-20-

2.INSTALLATION

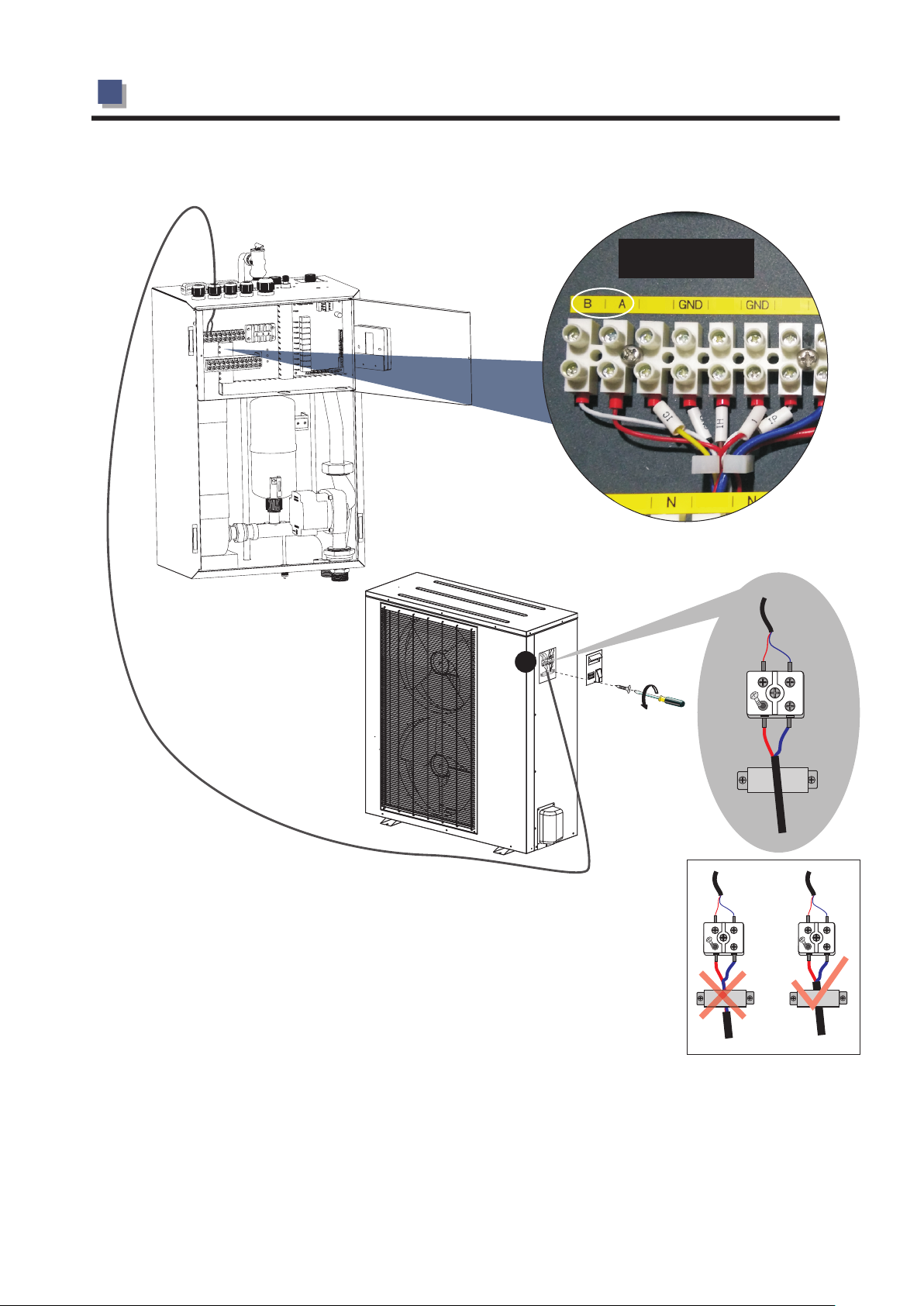

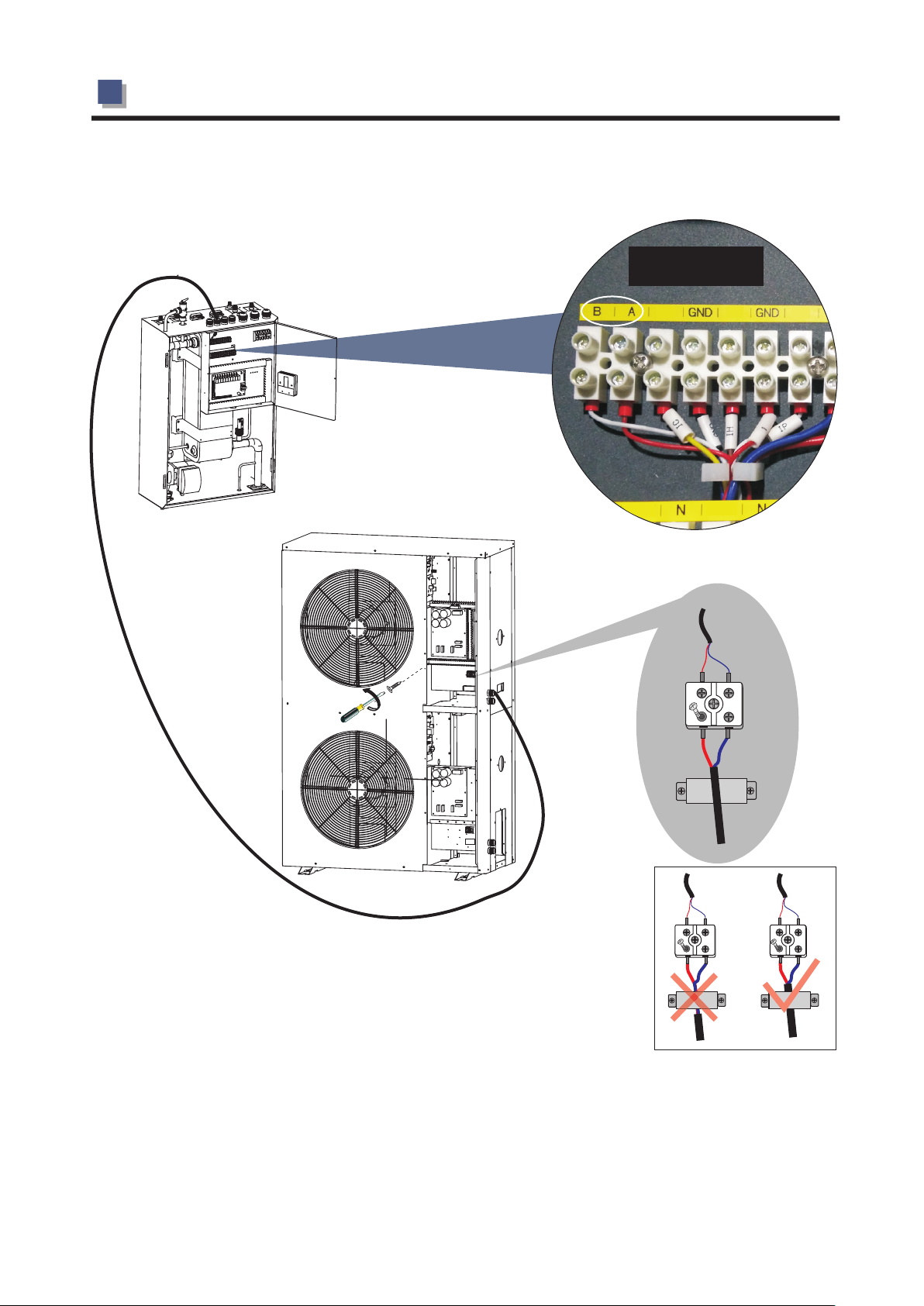

C. Signal cable between indoor and outdoor unit

Take the signal cable out from accessories bag.

corresponding

with each other

CS H S

HW

SH

ES

3

A B

Notice: When fixing the power cable with the wire clip, please be careful to

A B A B

clamp on the outer layer insulation, don’t clamp on the wires inside,

or it may cause damage on insulation layer of one-core wire.

1. Insert one end of this cable through the cable gland on top of the indoor unit, and connect this

cable to A, B on terminal block.

2. Fasten the cable gland to ensure the cable won't get loosen.

.

3 Connect the other end to the terminal block on outdoor unit. A, B on outdoor unit should be

connected with A, B on indoor unit, otherwise unit will show communication failure.

-21-

2.INSTALLATION

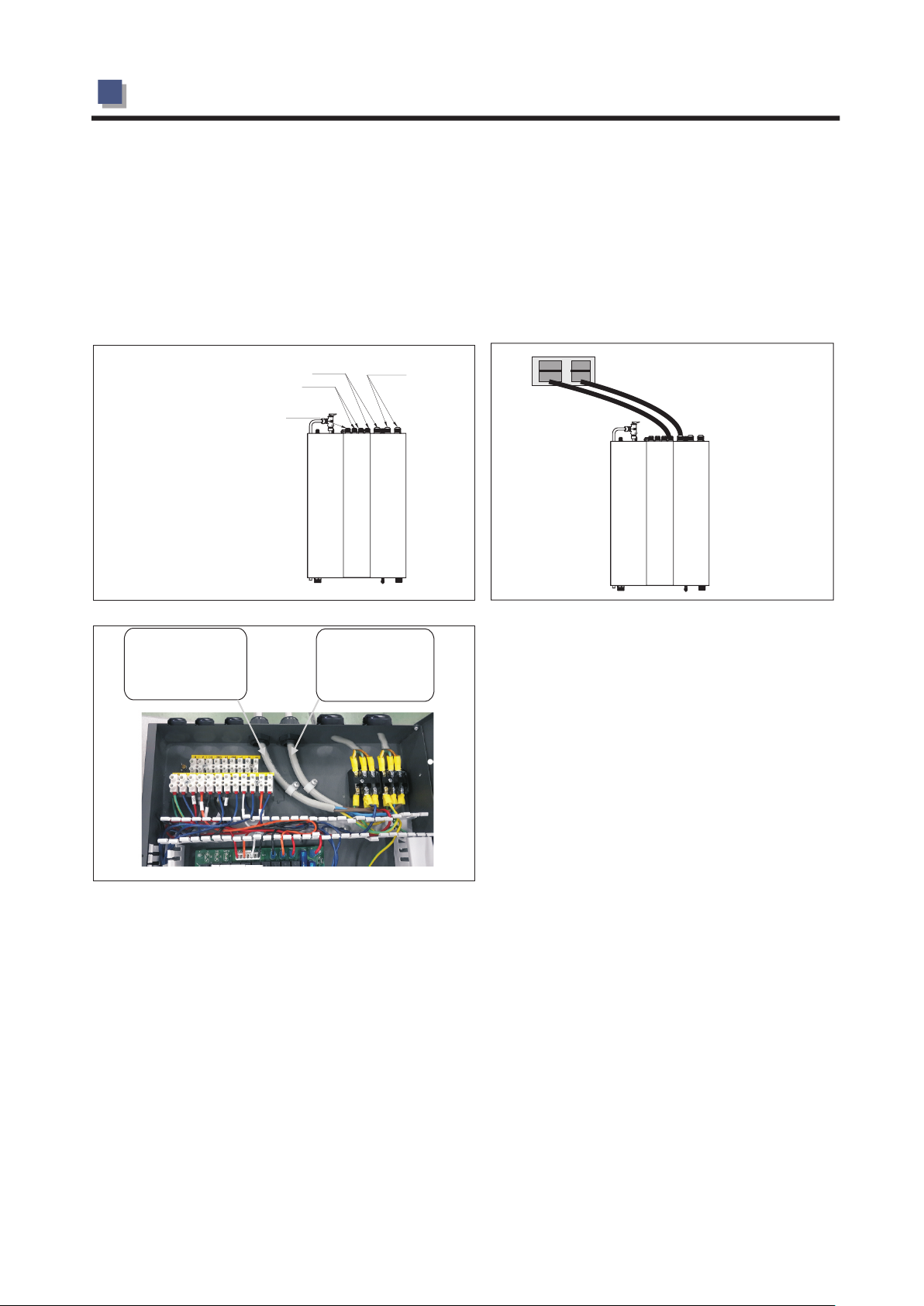

AWH20-V5+

A:Main power cable

1. Main power cable has connected into the terminal block of indoor unit. Please find the cable on

top of indoor unit according to the label, and connect it to main power, as shown in the pictures

below.

A

A: Sensor cables

B: Signal cables

C: Main power cable

D: Power cable between

indoor and outdoor unit

Fig. 1

Power cable

indoor unit

for system 1

C

B

Power cable

indoor unit

for system 2

D

Main pow er in u ser side

Fig.2

Fig. 3

-22-

2.INSTALLATION

B:Power cable between indoor and outdoor unit

1. The indoor front panel is fixed by four magnets in two sides of door. Please take off the front

panel as fig. 1.

2. Remove one screw in left side of electric box, then open the door of electric box to right side

as fig.2.

3. Prepare 2 pos power cable of 3 core 2.5mm2 with suitable length, insert the cable through

cable gland on top of the indoor unit, as fig .3.

Fig. 1

Insert the cable

from this cable

gland

Power cable

betwee n ind oor

and outdoor unit ( stys tem 1)

Fig.3

Fig. 2

Power cable

between indoor

and outdoor unit ( sty ste m 2)

-23-

2.INSTALLATION

Shown as "L, N, G" on

wiring diagram

G

N

L

Notice: When fixing the power cable with the wire clip, please be careful to

clamp on the outer layer insulation, don’t clamp on the wires inside,

or it may cause damage on insulation layer of one-core wire.

2. Connect this power cable to "L,N and G" on indoor terminal block according to the wiring diagram of

indoor unit.

3. Fasten the cable gland to ensure the cable won't get loosen.

4. Connect the other side of the power cable to the outdoor unit, according to the wiring diagram. Fix the

cable with cable fixture, to ensure it won’t get loose.

-24-

2.INSTALLATION

C. Signal cable between indoor and outdoor unit

Take the signal cable out from accessories bag.

corresponding

with each other

CS H S

HW

ES

SH

A B

Notice: When fixing the power cable with the wire clip, please be careful to

A B A B

clamp on the outer layer insulation, don’t clamp on the wires inside,

or it may cause damage on insulation layer of one-core wire.

1. Insert one end of this cable through the cable gland on top of the indoor unit, and connect this

cable to A, B on terminal block.

2. Fasten the cable gland to ensure the cable won't get loosen.

3 Connect the other end to the terminal block on outdoor unit. A, B on outdoor unit should be

.

connected with A, B on indoor unit, otherwise unit will show communication failure.

-25-

2.INSTALLATION

When connecting the power cable between the outdoor unit and indoor unit, cables connected

to the terminal block in indoor unit must match these in outdoor unit.

For example, if the terminals and power cables are connected as →gree/yellow cable,

L→ red cable, N→blue cable, S→black cable in indoor unit, the connections in the outdoor

unit should be in the same way.

Installation sketch

E. Sensor cables

All temperature sensors are preinstalled in the unit, and the unit can be operated without any changes.

Still for different applications it is possible to move the sensors to the place you wish to have the units

temperature readings for the controller. For example if the unit is connected to a buffer tank or

accumulating water tank, it is more efficient to let the heat pump be controlled by the water

temperature in the water tank.

1. Disconnect the sensor with the quick connector inside the indoor unit.

2. Insert the sensor cable from indoor PCB through cable gland on top of indoor unit.

3. Connect the sensor cable which stick out on top of indoor unit with extension cable for sensor.

4. Connect the other side of extension cable with the sensor.

5. Place the sensor in right position, according to your application, as shown in the pictures below.

6.Make sure to let water temperature sensors to have good contact by using cooling past in sensor

pockets, and insulate sensors located directly on water pipes.

Sensor cables

A

Sensor cable connection

Indoor unit

Extension cable for sensor

Sensor

Place all sensors in right positions

-26-

2.INSTALLATION

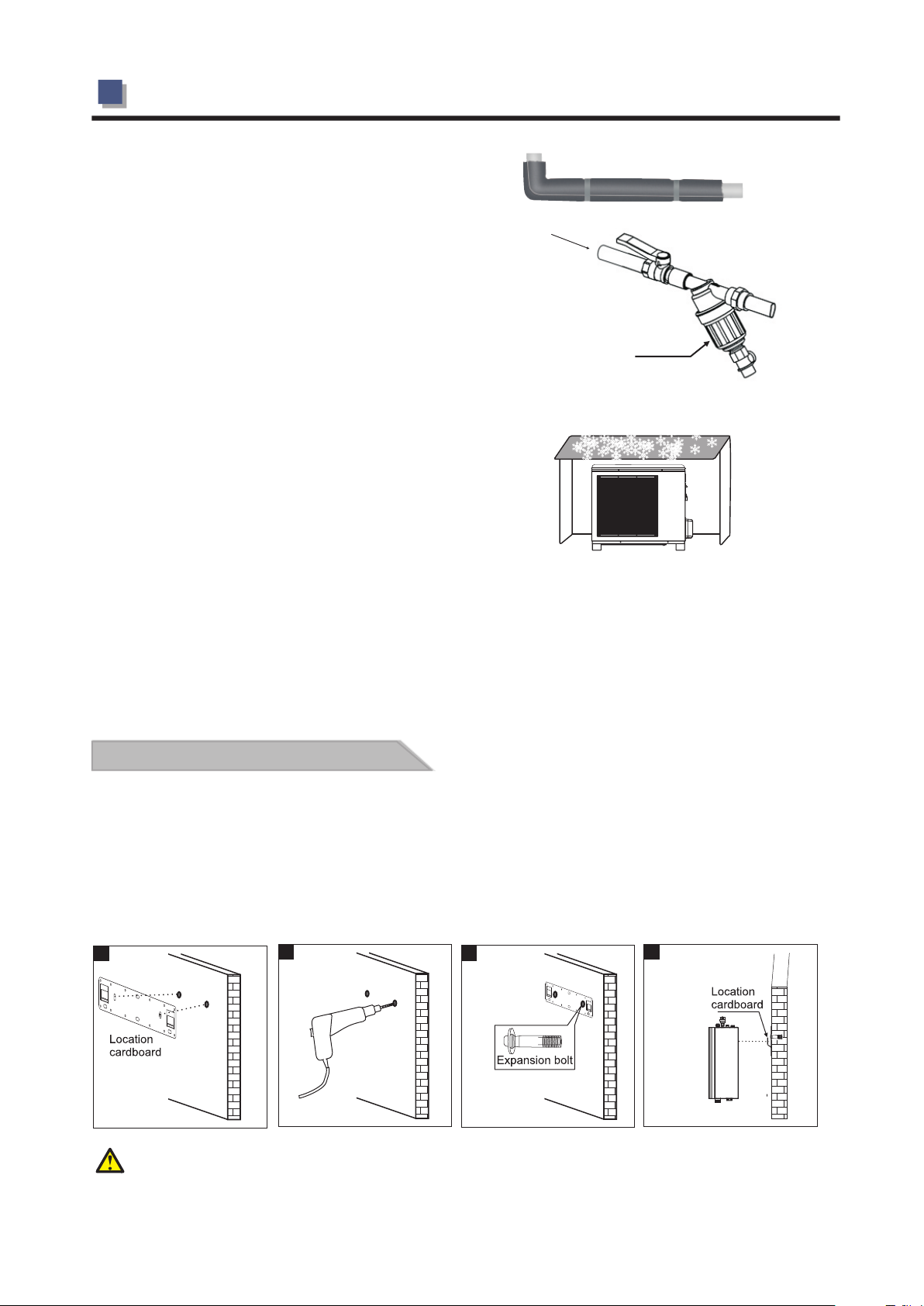

2.6 Connection of refrigerant pipe

AWH9/11/13-V5+

A:For the unit with quick connector

Begin routing from the indoor unit and straighten out the pipes as you go.On the pipe ends in the

installation kit are cap nuts for connection to the cannot be installed incorrectly.Hold the connection

in place with one spanner

and tighten the cap nut

with the other,as

otherwise the connection

can be damaged.

Conect the installation

kit’s pipes to the

connections on the indoor

unit.First screw together

the screw connections by hand and then tighten using the spanners.Tighten the connection fully

without stopping.A hissing noise can be heard.Hold the connection in place with one spanner and

tighten the cap nut with the other.Tighten to at least 18Nm.Use a torque wrench if you are unsure

Never turn the fixed connections.Use the spanner only as a counter hold during connection.If a

counter hold is not used,the connections can turn,which can destroy them.Tighten the connections

24 hours after installation has been completed.

IMPORTANT:

Note that the pipes in the installation kit are filled with gas and must not be cut under any

circumstances.

The plastic plugs on the ends of the pipe must not be removed until the pipes are to be connected.

If the pipes are bent and causing leakage, the couplings must be loosened so that the non-return

valves close.

Route the pipes from the indoor unit and connect them in

the same way to the outdoor unit.

Refrigerant pipes must not be bent to a radius of less than

15cm(check with a cardboard template).Route the electrical

cable along the pipes.Bend the pipes carefully,a little at a

time.Do not bend the pipes too sharply.

-27-

Radius 15 cm

2.INSTALLATION

Connect the installation kit's pipes to the connections on the

outdoor unit.First screw together the screw connections by

hand and then tighten using the spanners.

Tighten the connection fully without stopping.A hissing noise

can be heard.Hold the connection in place with one spanner and

tighten the cap nut with the other.

Never turn the fixed connections.Use the spanner only as a

counter hold is not used,the connections can turn,which can

destroy them.Tigthen the connections 24 hours after

installation has been completed.

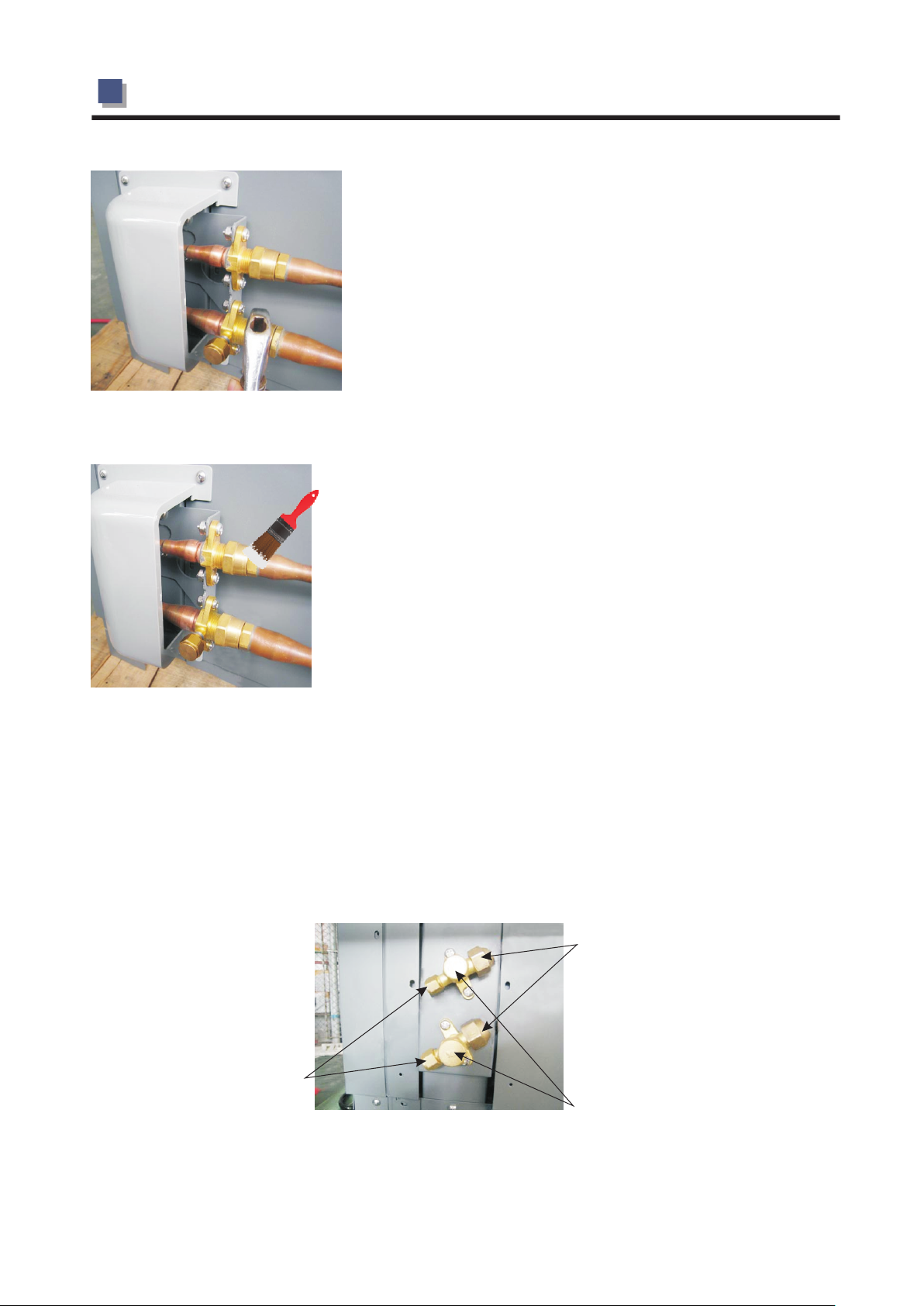

Check the seals and tighten the couplings again 12-24

hours after installation. Check for leaks by wetting with

soapy water. Also check the connections at the indoor unit.

If no bubbles appear, the couplings are properly connected

and tightened!

B:For the unit with flare nut connection

Note:When vacuuming the system,please don’t turn on the high/low pressure valve. Otherwise

refrigerant .leaks

Connector for

refrigerant pipe

Connector of

vacuum pump

High/Low

pressure valve

-28-

2.INSTALLATION

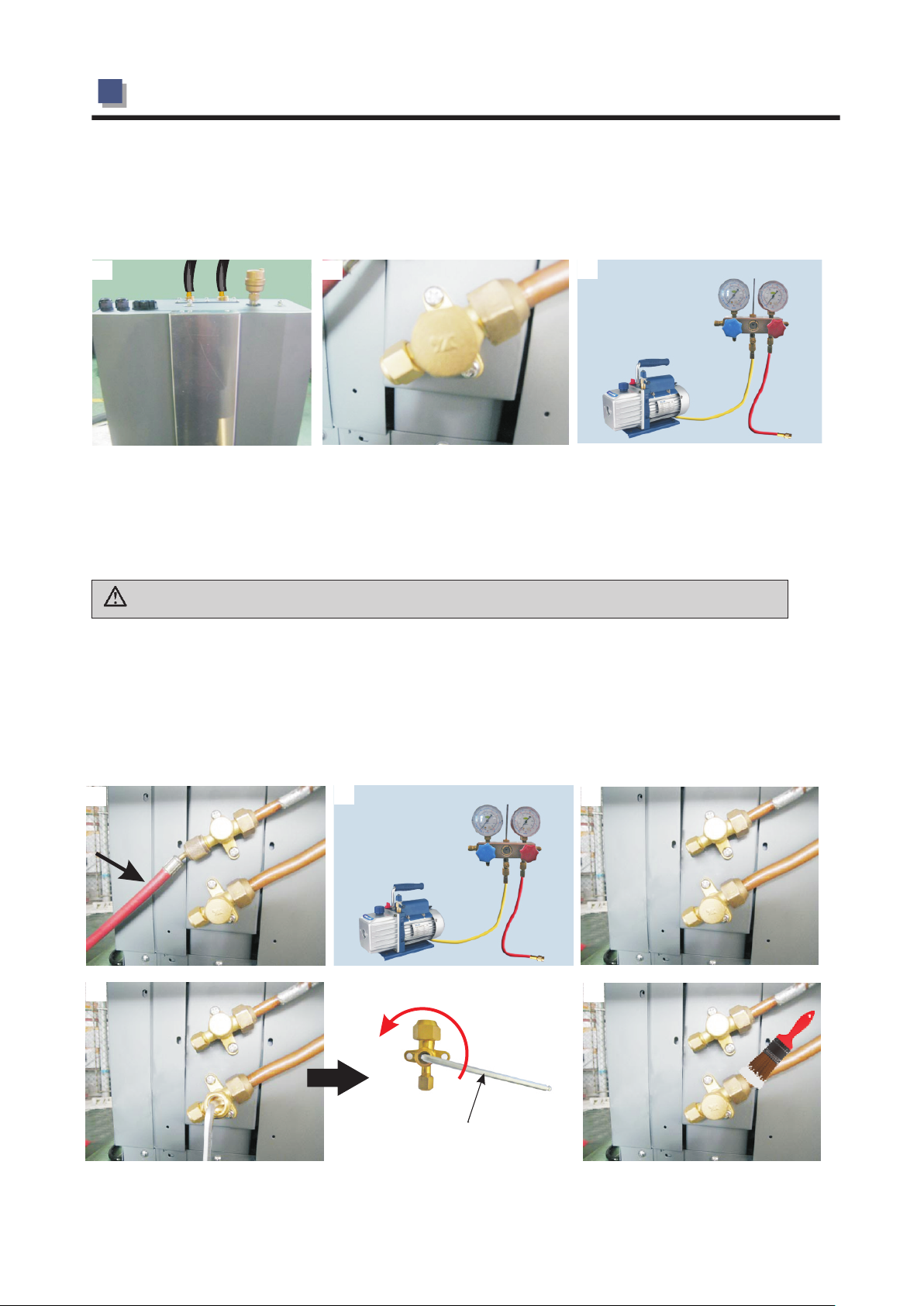

1.Connect the refrigerant piping to the indoor unit(refer fig.1).

2.Connect the other side of the refrigerant pipe to the the outdoor unit(refer fig.2).

3.

Prepare a vacuum pump and a pressure gauge, connect one tube of the pressure gauge to the

vacuum pump.

1

Connect the other tube of the pressure gauge to the outdoor unit.

4. (refer fig.4).

5. Open pressure gauge, and start the vacuum pump to vacuum the unit for around 10 minutes.

When the pressure gauge shows negative pressure, close the pressure gauge and stop vacuuming

(refer fig.5).

Attention:The liquid valve can't be opened until the vacuumizing has been totally finished.

6.Ture off the vacuum pump and install the cooper nut back to the high pressure connector

(refer fig.6).

(refer fig.3).

2

3

7.Use a 5mm hex wrench to open two valves on the unit as shown in the picture(refer fig.7).

8.

Check with leakage detector or soap water if there is any leakage. If not , then put back the copper

nuts onto the valves

4

7

(refer fig.8).

5

Hexagon Spanner M5:

In counter-clockwise

direction

6

8

-29-

Loading...

Loading...