Energy Knight mss-012a Service Manual

Wall Mounted

Mini-Split System

Air Conditioning/Heat Pump

Service Manual

MSS-009B/A

MSS-012B/A, MSH-012B/A

MSS-018B/A, MSH-018B/A

MSS-024B/A, MSH-024B/A

Before servicing the unit, read the

“safety precautions” in this manual.

Only for authorized service personnel.

®

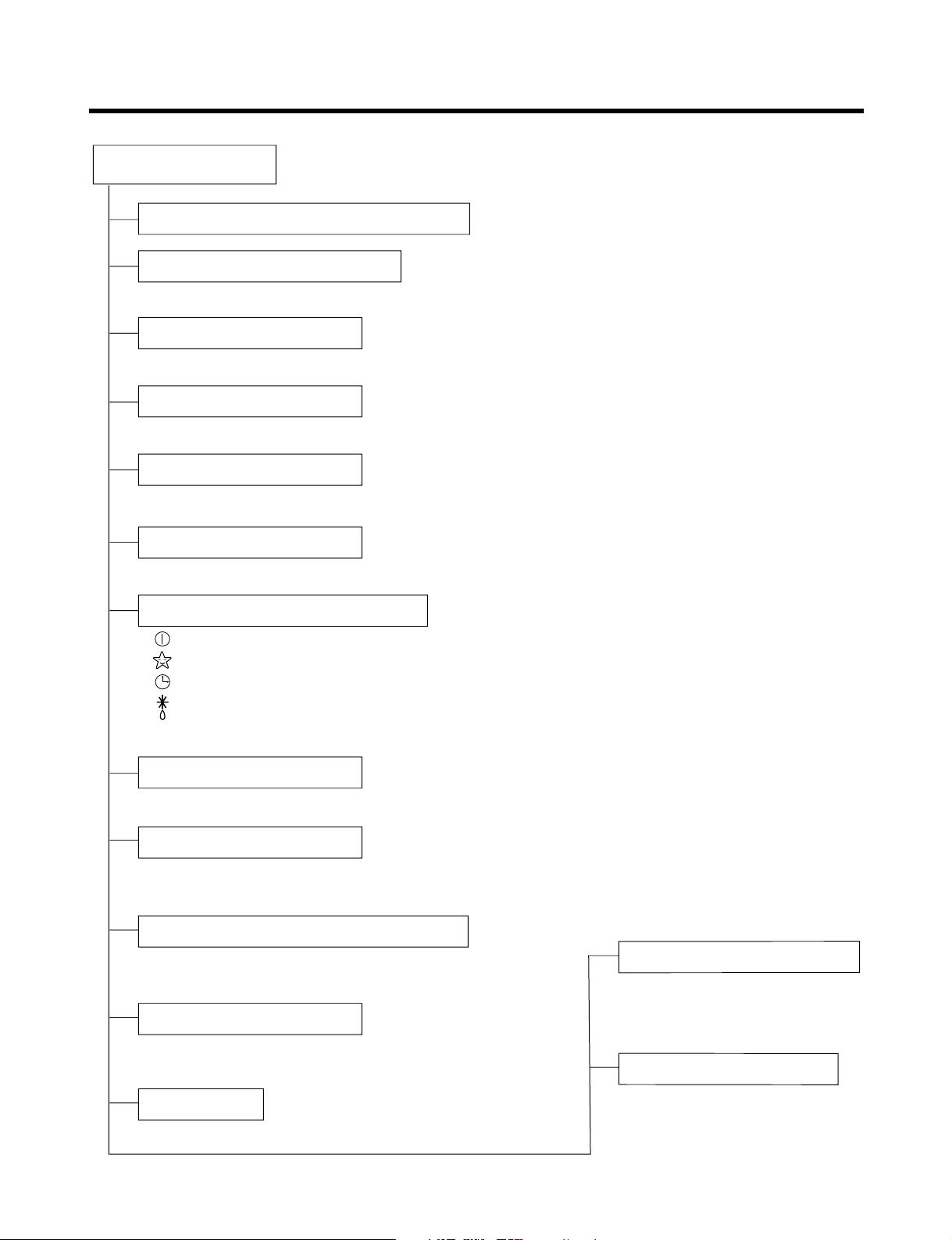

Contents

Functions

Product Specifications

Dimensions

Refrigeration Cycle Diagram

Wiring Diagram

Operation Details

Test Mode

Display Function

Self-diagnosis Function

Installation

Operation

......................................................................................................................................

................................................................................................................

...................................................................................................................................

..........................................................................................................................

.......................................................................................................................

...................................................................................................................................

........................................................................................................................

............................................................................................................

..................................................................................................................................

....................................................................................................................................

3

5

7

.......................................................................................................

9

11

14

22

23

23

24

41

Disassembly of the Parts(Indoor Unit)

Cycle Troubleshooting Guide

Electronic Control Device

Schematic Diagram

Exploded View & Replacement Parts List

....................................................................................................................

...................................................................................................

.........................................................................................................

.....................................................................................

43

49

59

62

...............................................................................

64

- 2 -

Functions

Indoor Unit

Operation ON/OFF by Remote controller

Sensing the Room Temperature

• Room temperature sensor (THERMISTOR)

Room temperature control

• Maintains the room temperature in accordance with the Setting Temp.

Starting Current Control

• Indoor fan is delayed for 5 seconds at the starting.

Time Delay Safety Control

• Restarting is inhibited for approx. 3 minutes.

Indoor Fan Speed Control

• High, Med, Low and Auto

Operation indication Lamps (LED)

--- Lights up in operation

--- Lights up in Sleep Mode

--- Lights up in Timer Mode

--- Lights up in Defrost Mode or Hot Start Mode (only Heating Model)

OUT

--- Lights up during compressor running (only Cooling Model)

DOOR

Soft Dry Operation Mode

• Intermittent operation of fan at low speed

Sleep Mode Auto Control

• The fan is switched to low(Cooling), med(Heating) speed.

• The unit will be stopped after 1, 2, 3, 4, 5, 6, 7 hours.

Auto Air Control by the unit electronic control

• The fan is switched to intermittent or irregular operation.

• The fan speed is automatically switched from high to low speed.

Airflow Direction Control

• The louver can be set at the desired position or swing up

and down automatically.

Defrost control(Heating)

• Both the indoor and outdoor fan stops

during defrosting.

• Hot start will be operated after

defrosting ends.

Hot-start Control (Heating)

AUTO Wind

• The fan speed is automatically switched from high to low speed.

- 3 -

• The indoor fan stops until the

indoor pipe temperature will be

reached at 28°C(82°F).

TEMPERATURETEMPERATURE

LOWLOW

HIGHHIGH

Remote Controller

Operation ON/OFF

Operation Mode Selection

Cooling Operation Mode. ( )

Soft Dry Operation Mode. ( )

(Cooling

model only)

(Heating

model only)

Fan Speed Selection

(Low)

Room Temperature Display

: (High: 98°F LOW : 54°F)

Temperature Setting

Setting the Time or Timer

Timer Selection

: OFF, ON, OFF ON

Timer Setting

(Med)

Cooling

Auto Operation Mode. ( )

Heating Operation Mode. ( )

(High)

Down to 64°F

Heating

Up to 86°F

(AUTO WIND)

Down to 60°F

Up to 86°F

Timer Cancel

: Cancel Sleep Mode, Timer ON or Timer OFF

Sleep Operation

: 1, 2, 3, 4, 5, 6, 7, Off Timer

Airflow Direction Control

Fan Operation Mode

: Fan Operates without cooling or heating.

Reset

- 4 -

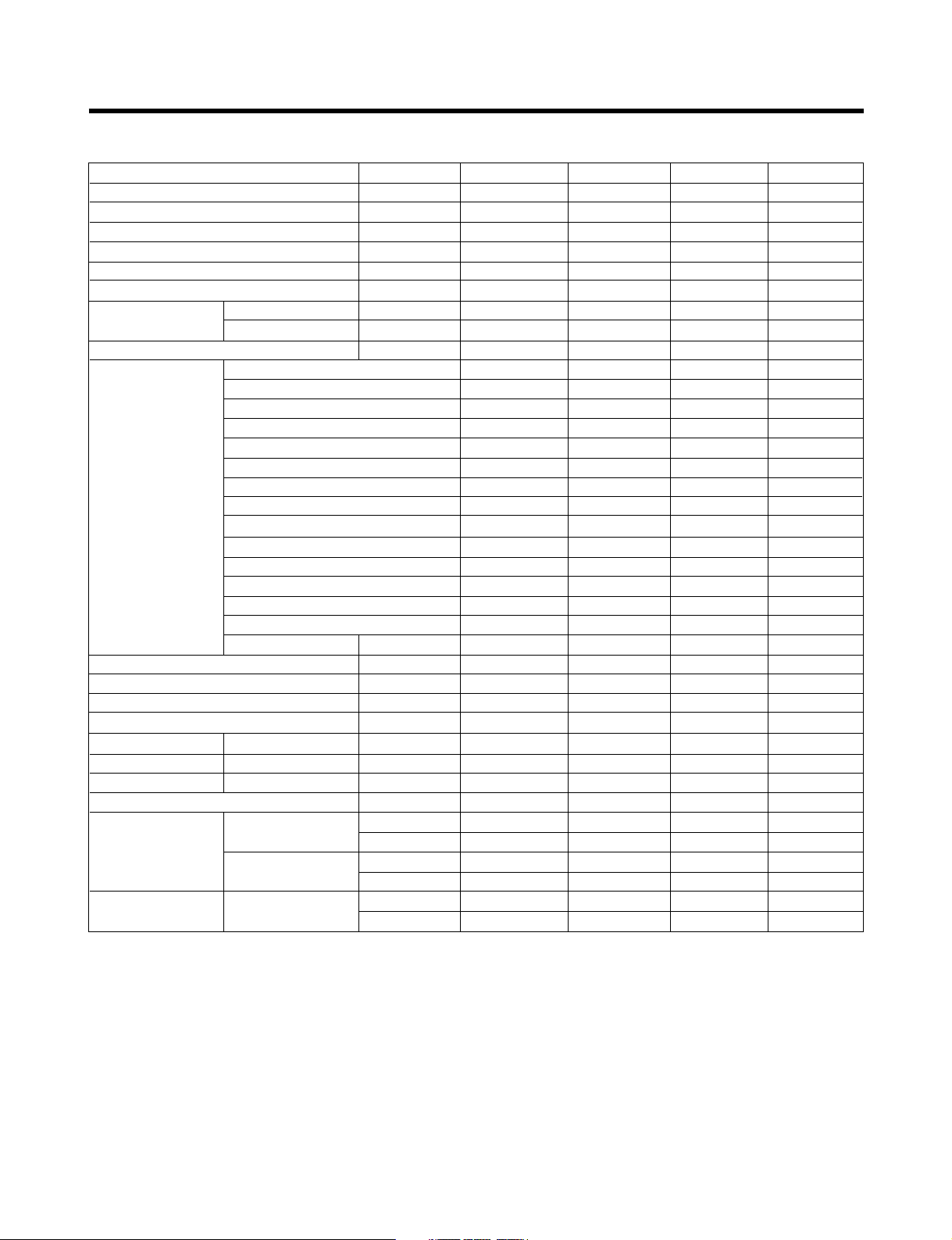

Product Specifications(Cooling Only)

Items Unit MSS-009B/A MSS-012B/A MSS-018B/A MSS-024B/A

Power Supply ø, V, Hz 1,115, 60 1,115, 60 1,230/208,60 1,230/208,60

Cooling Capacity Btu/h 9,000 12,000 18,000/17,800 23,000/22,600

Input W 940 1,290 1,900/1,870 2,550/2,500

Running Current A 8.5 11.7 8.5/9.0 11.5/12.0

COMP. Locked Rotor AMP.

E.E.R Btu/hW 9.6 9.5/9.5 9.5/9.5 9.0/9.0

Air Circulation Indoor(Dry) m3/min(cfm) 8(280) 10(350) 13(460) 15(530)

Outdoor(Dry) m3/min(cfm) 25(882) 25(882) 46(1,610) 46(1,610)

Moisture Removal l/h(pts/hr) 1.5(3.2) 1.7(3.63) 2.5(5.3) 3.1(6.6)

Features Temperature Control Thermistor Thermistor Thermistor Thermistor

AUTO Wind Yes Yes Yes Yes

Air Deflection 4-way 4-way 4-way 4-way

Steps, Fan/Cool 3/3 3/3 3/3 3/3

Airflow Direction Control(up&down) Auto Auto Auto Auto

Airflow Direction Control(left&right) Manual Manual Manual Manual

Remocon Type Wireless LCD Wireless LCD Wireless LCD Wireless LCD

Setting Temperature Range, Cooling Mode

Temperature Increment 2°F2°F2°F2°F

Auto Operation(electronic control) Yes Yes Yes Yes

Self Diagnosis Yes Yes Yes Yes

Timer 24hr, On/Off 24hr, On/Off 24hr, On/Off 24hr, On/Off

Sleep Operation Yes Yes Yes Yes

Soft Dry Operation Yes Yes Yes Yes

Restart Delay minutes 3 3 3 3

Refrigerant(R-22) Charge g(oz) 740(26.1) 1,200(42.3) 1,530(54.0) 1,710(60.3)

Power cord AWG #: P*mm

Fuse or breaker Capacity A 15A 15A 15A 20A

Connecting Cable AWG #: P*mm218:4*0.82 18:4*0.82 18:4*0.82 18:4*0.82

Connecting Tube Liquid Side mm(in) 6.35(1/4) 6.35(1/4) 9.52(3/8) 9.52(3/8)

(ø. Socket Flare) Gas Side mm(in) 12.7(1/2) 12.7(1/2) 15.88(5/8) 15.88(5/8)

Length, std m(ft) 7.62(25) 7.62(25) 7.62(25) 7.62(25)

Additional Drain Hose(Inner Dia.) mm(in) 16(5/8) 16(5/8) 16(5/8) 16(5/8)

Dimensions Indoor mm 900*290*183 900*290*183 1080*290*183 1080*290*183

(WxHxD) in 35.4*11.4*7.2 35.4*11.4*7.2 42.5*11.4*7.2 42.5*11.4*7.2

Outdoor mm 801*555*262 801*555*262 870*655*320 870*655*320

Net Weight Indoor kg(lbs) 9(20) 10(22) 12(26.5) 12(26.5)

Outdoor kg(lbs) 35(77) 34(75) 54(119) 64(141)

A 25 27 49.5 68

64~86°F 64~86°F 64~86°F 64~86°F

2

14:3*2.1 14:3*2.1 14:3*2.1 14:3*2.1

in 31.5*21.8*10.3 31.5*21.8*10.3 34.3*25.8*12.6 34.3*25.8*12.6

* Design and Specifications subject to change without prior notice for product improvement.

- 5 -

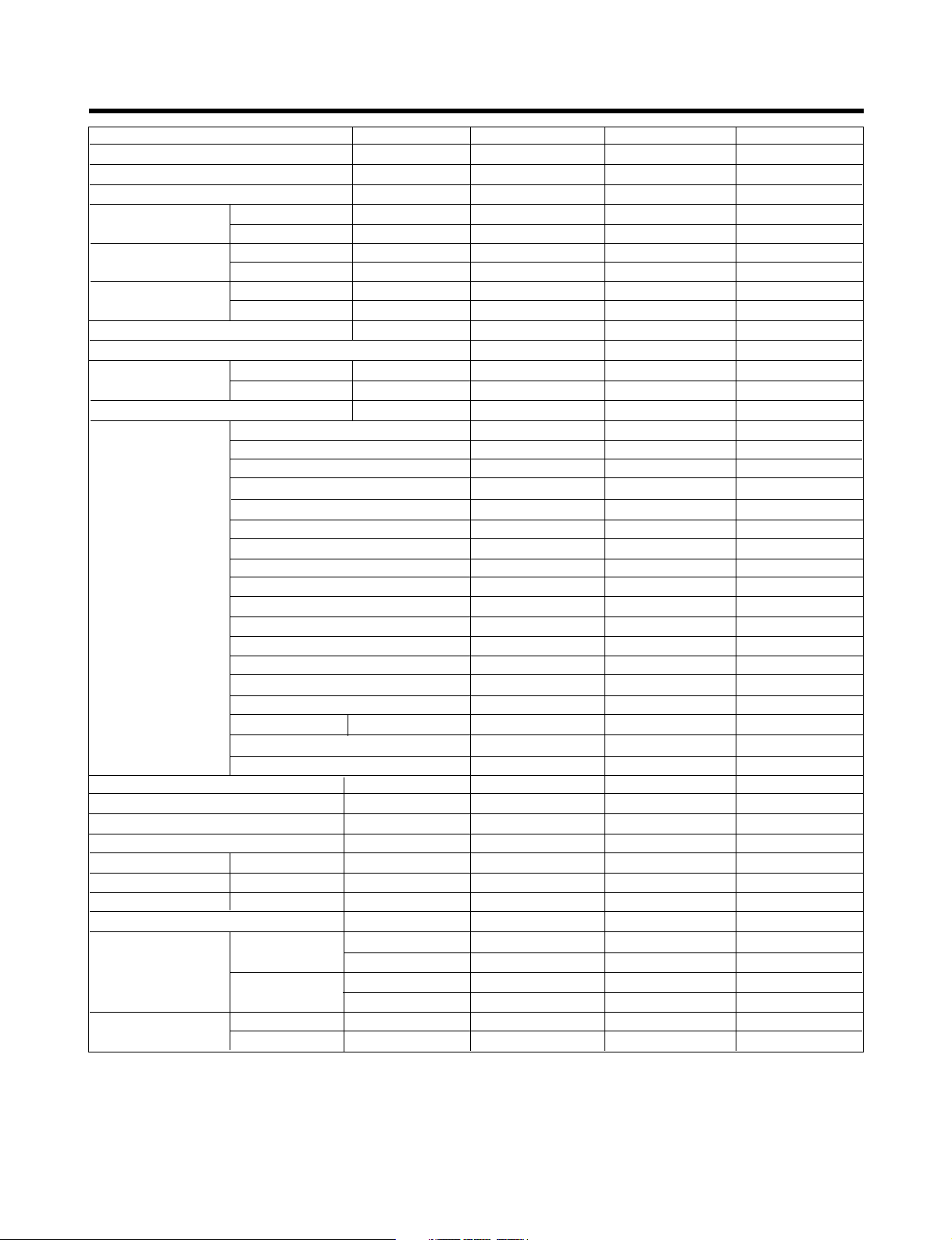

Product Specifications(Cooling & Heating)

Items Unit MSH-012B/A MSH-018B/A MSH-024B/A

Power Supply ø, V, Hz 1,115, 60 1,230/208,60 1,230/208,60

Cooling Capacity Btu/h 12,000 18,000/17,800 23,000/22,600

Heating Capacity Btu/h 12,000 19,000/18,700 23,000/22,600

Input Cooling W 1,290 1,900/1,870 2,550/2,500

Heating W 1,290 1,900/1,870 2,550/2,500

Running Current Cooling A 11.7 8.5/9.0 11.5/12.0

Heating A 11.7 8.5/9.0 11.5/12.0

COMP. Locked Cooling A 27 49.5 68

Rotor AMP. Heating A 27 49.5 68

E.E.R Btu/hW 9.5/9.5 9.5/9.5 9.0/9.0

C.O.P 2.78/2.78 2.9/2.9 2.6/2.6

Air Circulation Indoor(Dry) m3/min(cfm) 10(350) 13(460) 15(530)

Outdoor(Dry) m3/min(cfm) 25(882) 46(1,610) 46(1,610)

Moisture Removal l/h(pts/hr) 1.7(3.63) 2.5(5.3) 3.1(6.6)

Features Temperature Control Thermistor Thermistor Thermistor

AUTO Wind Yes Yes Yes

Air Deflection 4-way 4-way 4-way

Steps, Fan/Cool/Heat 3/3/3 3/3/3 3/3/3

Airflow Direction Control(up&down)

Airflow Direction Control(left&right)

Remocon Type Wireless LCD Wireless LCD Wireless LCD

Setting Temperature Range, Cooling Mode

Heating Mode 60~86°F 60~86°F 60~86°F

Temperature Increment 2°F2°F2°F

Auto Operation(electronic control)

Self Diagnosis Yes Yes Yes

Timer 24hr, On/Off 24hr, On/Off 24hr, On/Off

Sleep Operation Yes Yes Yes

Soft Dry Operation Yes Yes Yes

Restart Delay minutes 3 3 3

Defrost Control Yes Yes Yes

Hot Start Yes Yes Yes

Refrigerant(R-22) Charge g(oz) 1,230(44.1) 1,500(52.9) 1,600(56.4)

Power cord AWG #: P*mm

Fuse or breaker Capacity A 15A 15A 20A

Connecting Cable AWG #: P*mm

Connecting Tube Liquid Side mm(in) 6.35(1/4) 9.52(3/8) 9.52(3/8)

(ø. Socket Flare) Gas Side mm(in) 12.7(1/2) 15.88(5/8) 15.88(5/8)

Length, std m(ft) 7.62(25) 7.62(25) 7.62(25)

Additional Drain Hose(Inner Dia.) mm(in) 16(5/8) 16(5/8) 16(5/8)

Dimensions Indoor mm 900*290*183 1080*290*183 1080*290*183

(WxHxD) in 35.4*11.4*7.2 42.5*11.4*7.2 42.5*11.4*7.2

Outdoor mm 801*555*262 870*655*320 870*655*320

in 31.5*21.8*10.3 34.3*25.8*12.6 34.3*25.8*12.6

Net Weight Indoor kg(lbs) 10(22) 12(26.5) 12(26.5)

Outdoor kg(lbs) 35(77) 55(121) 65(143)

2

2

Auto Auto Auto

Manual Manual Manual

64~86°F 64~86°F 64~86°F

Yes Yes Yes

14:3*2.1 14:3*2.1 14:3*2.1

18:4*0.82 18:4*0.82 18:4*0.82

* Design and Specifications subject to change without prior notice for product improvement.

- 6 -

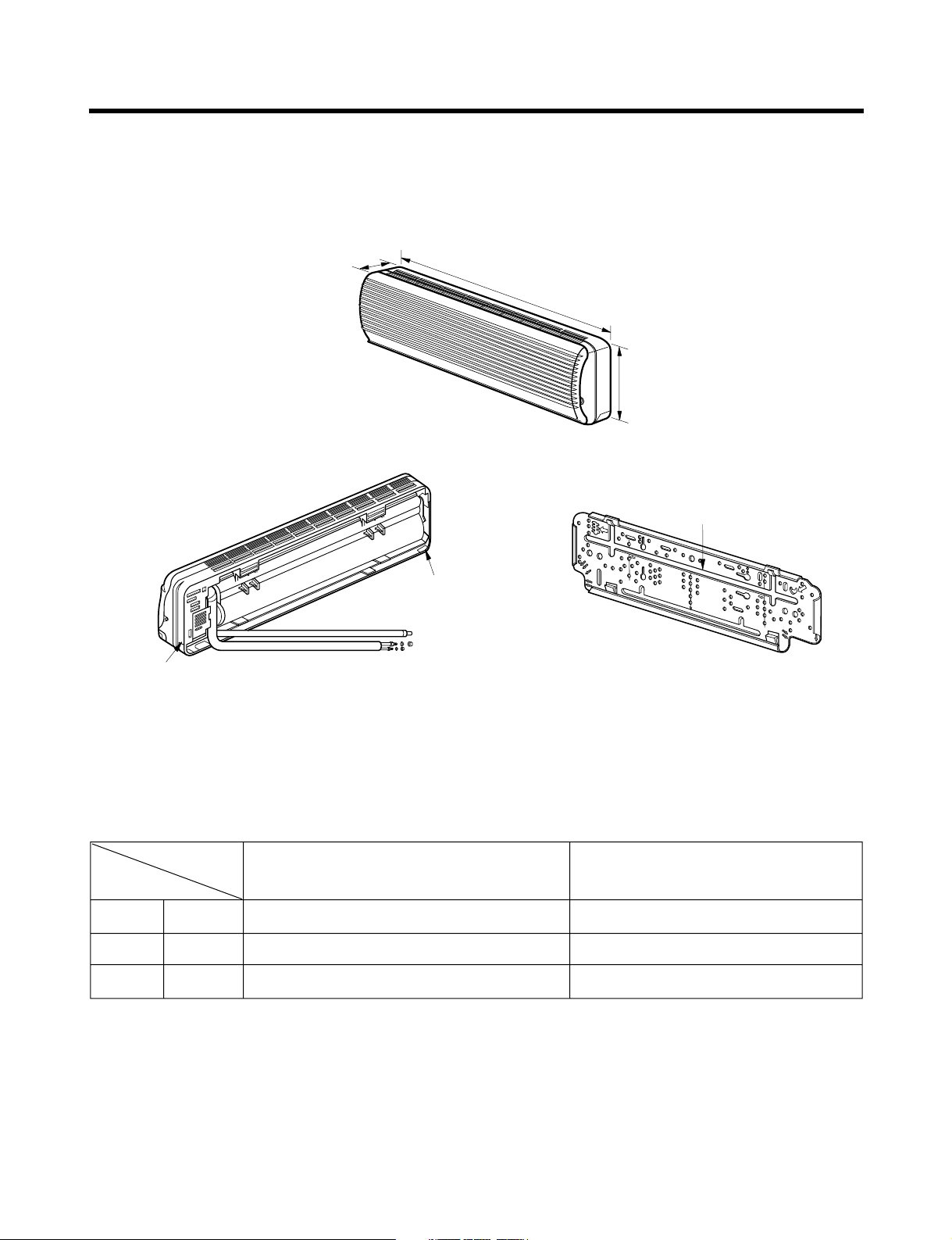

Dimensions

D

W

H

(1) Indoor Unit

Installation plate

Tubing hole cover

Tubing hole cover

MODEL

DIM

W mm(inch) 900(35.4") 1,080(42.5")

H mm(inch) 290(11.4") 290(11.4")

D mm(inch) 183(7.2") 183(7.2")

9k, 12k 18k, 24k

- 7 -

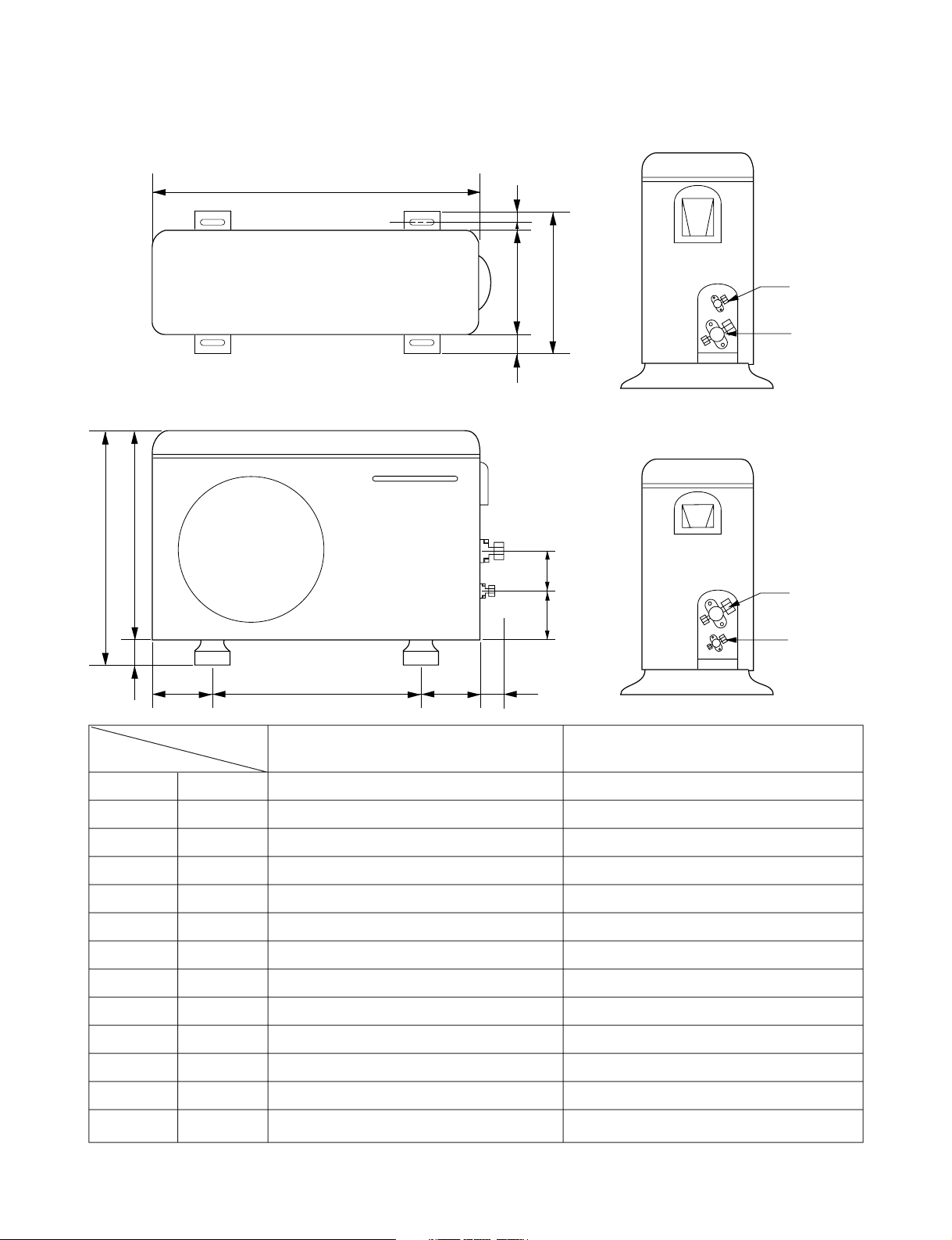

W

L6 L5 L7 L8

D

L1

L2

L9L10

L3L4

H

(2) Outdoor Unit

2-way valve

Gas side

3-way valve

(9k, 12k)

Gas side

3-way valve

3-way valve

MODEL

DIM

W mm(inch) 801(31.5) 870(34.3)

H mm(inch) 555(21.8) 655(25.8)

D mm(inch) 262(10.3) 320(12.6)

L1 mm(inch) 339(13.3) 370(14.6)

L2 mm(inch) 37(1.5) 25(1.0)

L3 mm(inch) 543.6(21.4) 630(24.8)

L4 mm(inch) 11.4(0.45) 25(1.0)

L5 mm(inch) 591(23.3) 546(21.5)

L6 mm(inch) 105(4.13) 162(6.4)

L7 mm(inch) 105(4.13) 162(6.4)

L8 mm(inch) 72.5(2.85) 54(2.1)

L9 mm(inch) 77(3.03) 74.5(2.9)

9k, 12k 18k, 24k

(18k, 24k)

L10 mm(inch) 86.4(3.4) 79(3.1)

- 8 -

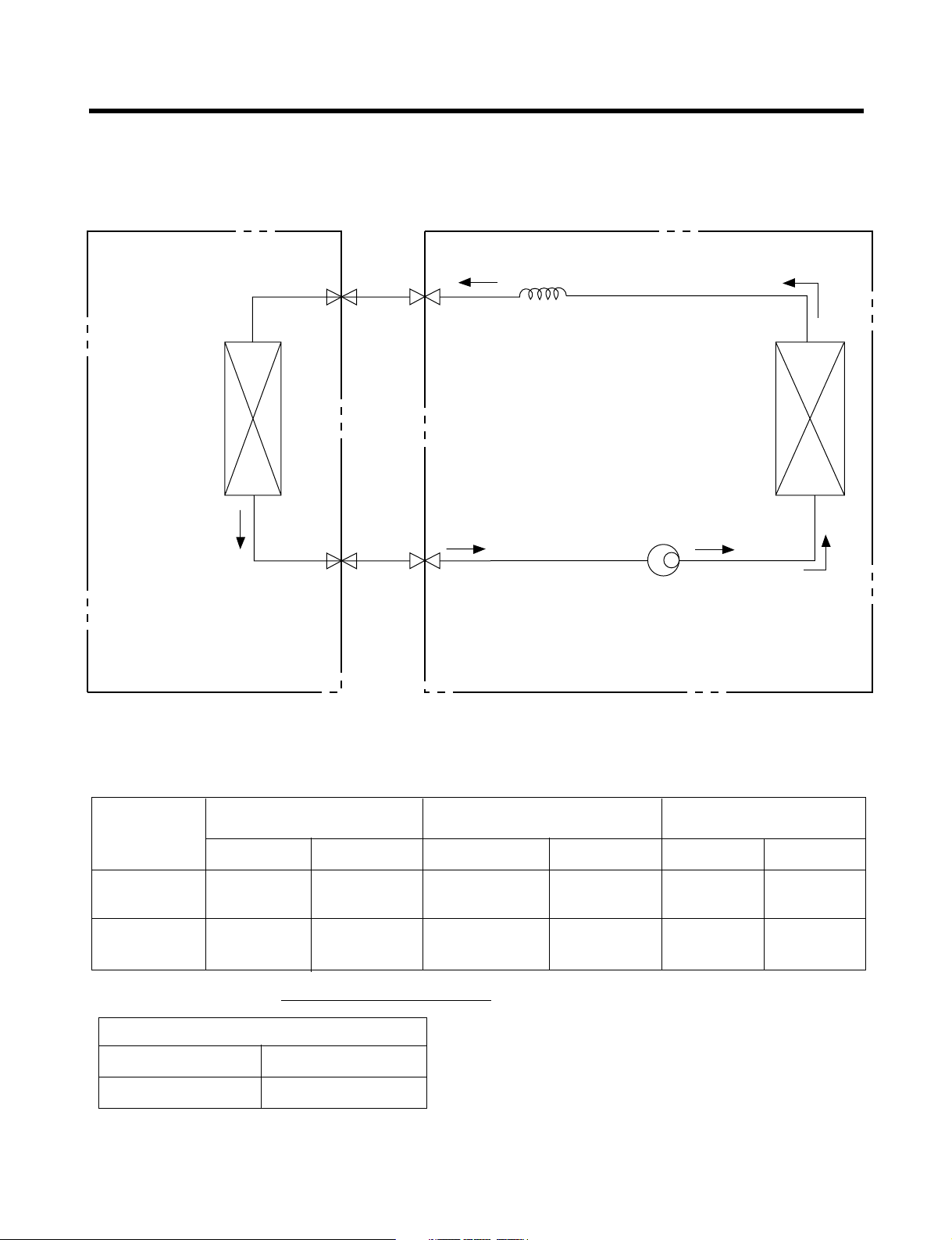

Refrigeration Cycle Diagram

• Cooling Only Models

INDOOR UNIT

HEAT

EXCHANGER

(EVAPORATOR)

GAS SIDE

OUTDOOR UNIT

CAPILLARY TUBE

LIQUID SIDE

HEAT

EXCHANGER

(CONDENSER)

COMPRESSOR

Pipe size(Diameter:ø) Piping length Elevation

MODEL

Gas Liquid Rated Max Rated Max

9k, 12k

(Cooling Only)

18k, 24k

(Cooling Only)

For installation over rated, *a proper quantity of refrigerant should be added for each 5 foot.

a proper quantity of refrigerant

9k, 12k 0.2 Oz

18k, 24k 0.3 Oz

Unit precharged for 25ft. line sets.

1/2" 1/4" 7.62m(25ft) 15m(50ft) 5m(16ft) 8m(26ft)

5/8" 3/8" 7.62m(25ft) 15m(50ft) 5m(16ft) 8m(26ft)

Ex) 18K: When installed at a distance of 30ft, 1.5 Oz of

refrigerant should be added.

(30-25) x 0.302 = 1.5 Oz of refrigerant to add

- 9 -

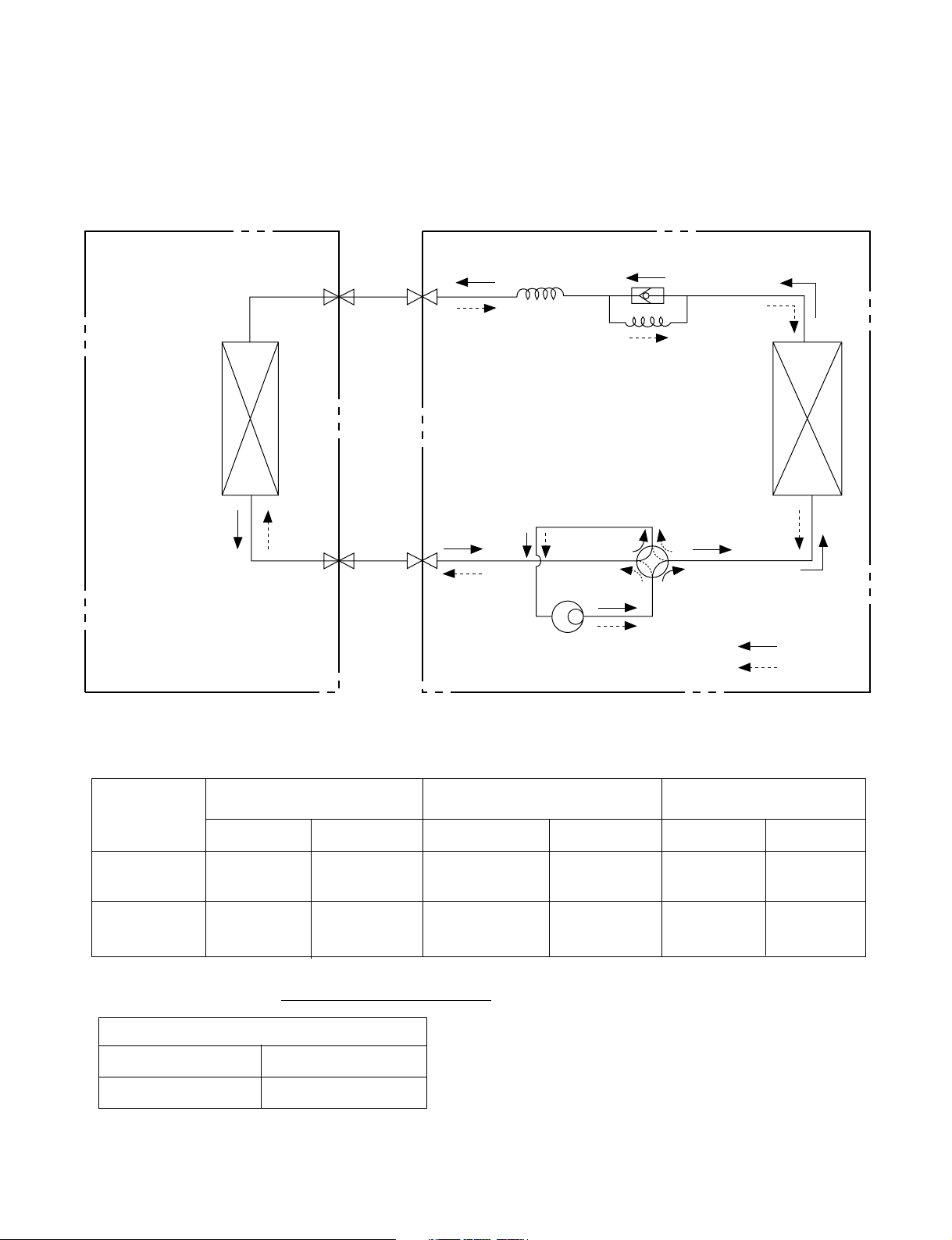

• Cooling & Heating Models

INDOOR UNIT

HEAT

EXCHANGER

(EVAPORATOR)

GAS SIDE

OUTDOOR UNIT

CAPILLARY TUBE

COMPRESSOR

CHECK VALVE

HEAT

EXCHANGER

(CONDENSER)

REVERSING

VALVE

COOLING

HEATING

Pipe size(Diameter:ø) Piping length Elevation

MODEL

9k, 12k

(Cooling & Heating)

18k, 24k

(Cooling & Heating)

For installation over rated, *a proper quantity of refrigerant should be added for each foot.

a proper quantity of refrigerant

9k, 12k 0.2 Oz

18k, 24k 0.3 Oz

Unit precharged for 25ft. line sets.

Gas Liquid Rated Max Rated Max

1/2" 1/4" 7.62m(25ft) 15m(50ft) 5m(16ft) 8m(26ft)

5/8" 3/8" 7.62m(25ft) 15m(50ft) 5m(16ft) 8m(26ft)

Ex) 18K: When installed at a distance of 30ft, 1.5 Oz of

refrigerant should be added.

(30-25) x 0.302 = 1.5 Oz of refrigerant to add

- 10 -

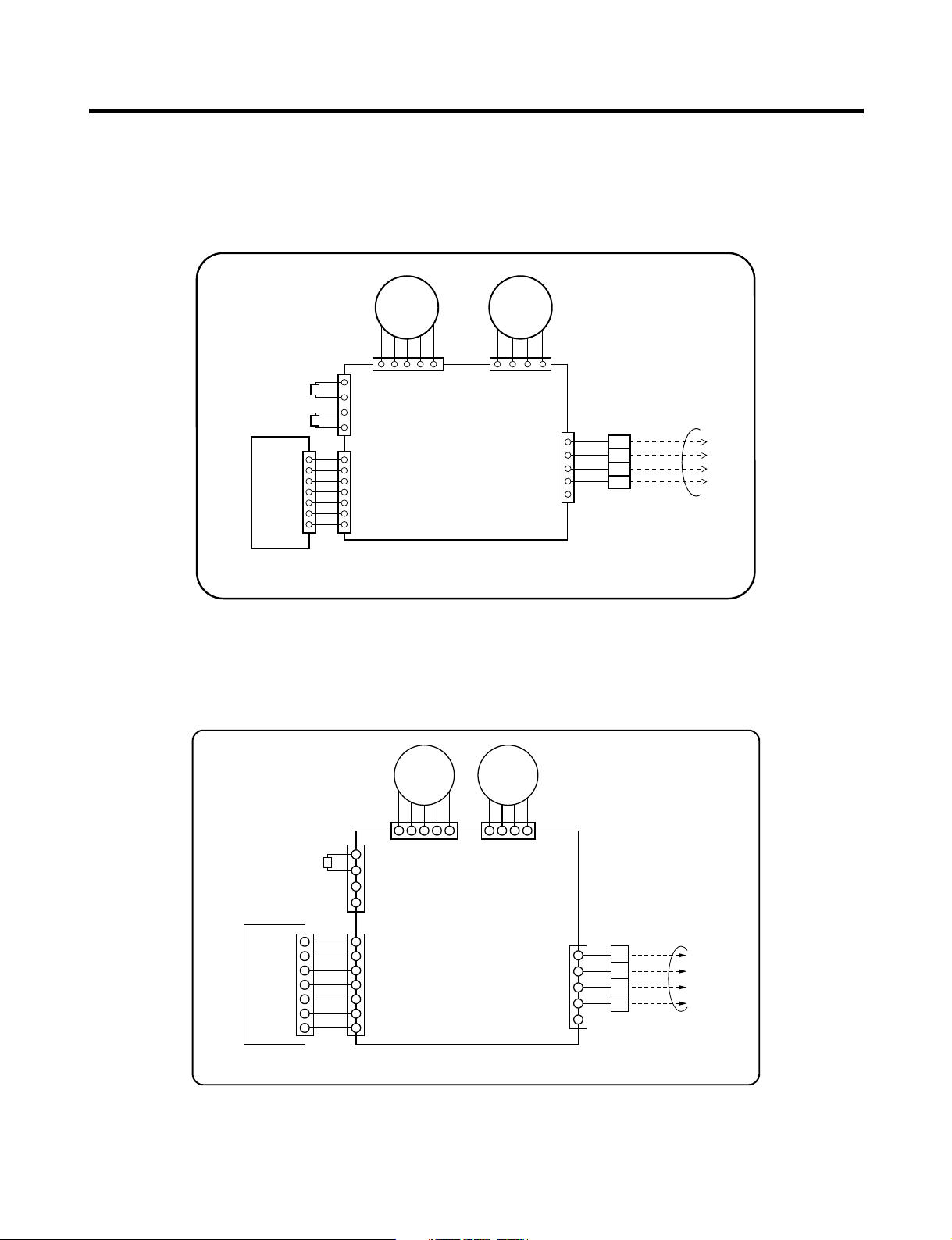

Wiring Diagram

4

3

2

1

BLDC

MOTOR

STEP

MOTOR

MAIN P.C.B

INDOOR WIRING DIAGRAM

TO OUTDOOR UNIT

DISPLAY P.C.B

(ROOM)

(PIPE)

THERMISTOR

CN-UP/DOWN

3854AR7074A

CN-MOTOR

PILLAR

TERMINAL

CN-DC/DC

CN-DISP

CN-TH

BL

BK

BR

RD

4

3

2

1

BL

BK

BR

RD

PILLAR

TERMINAL

ROOM-

THERMISTOR

CN-UP/DOWN CN-MOTOR

STEP

MOTOR

MAIN P.C.B

INDOOR WIRING DIAGRAM

3854AR7209A

BLDC

MOTOR

CN-DC/DC

CN-THCN-DISP

DISPLAY P.C.B

TO OUTDOOR UNIT

(1) Indoor Unit

1. MSS-012, MSS-018, MSH-018, MSS-024, MSH-024

2. MSS-009, MSS-012

- 11 -

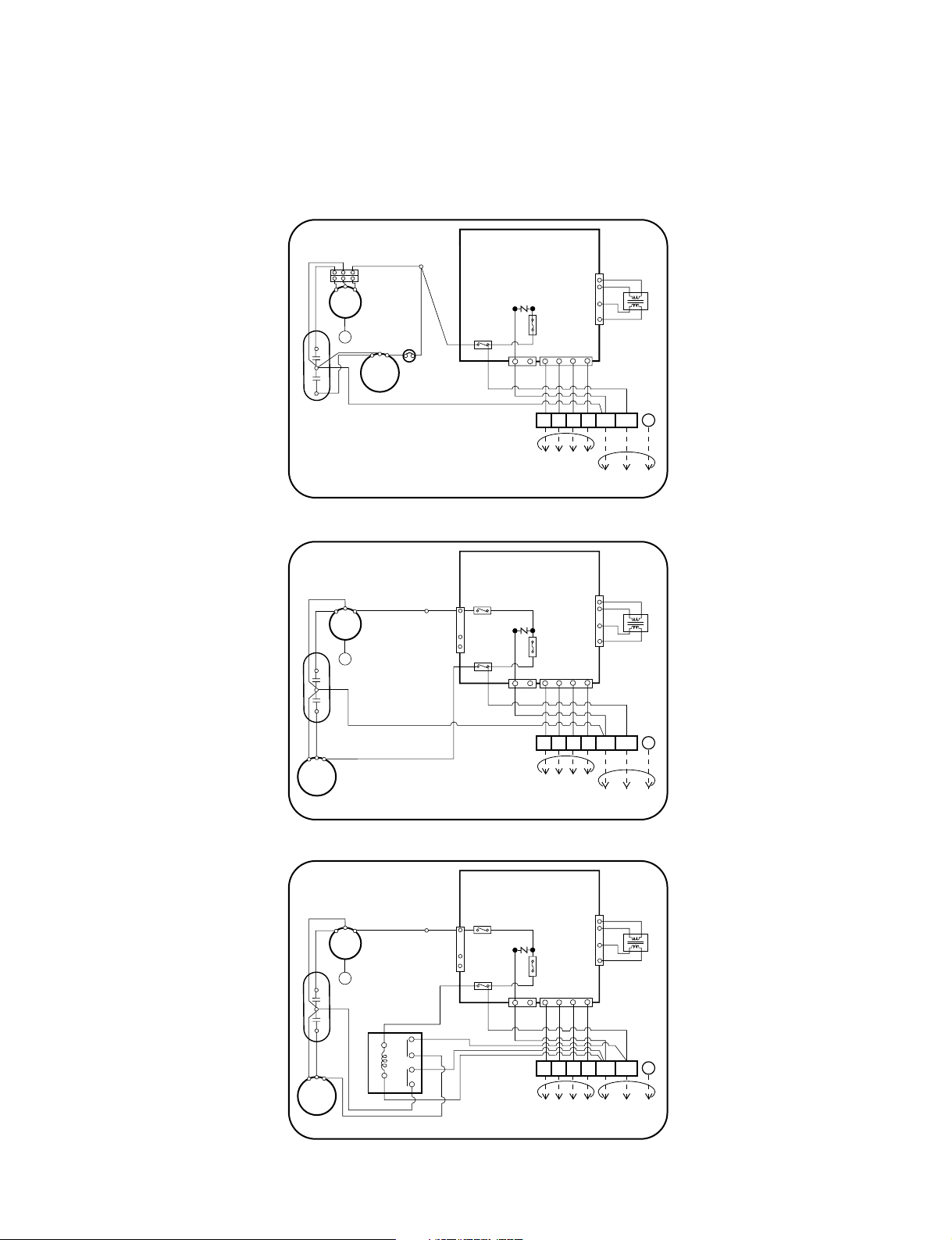

(2) Outdoor Unit

MAIN P.C.B

MOTOR

TERMINAL

BLOCK

POWER

INPUT

TRANSFORMER

CAPACITOR

COMP.

G

OUTDOOR WIRING DIAGRAM

TO INDOOR UNIT

3854AR7077C

OR(BR)

BR YL

4

3

BL

BL

BK

BK

CN-TRANS

CN - FAN

RY-FAN

RY-COMP

CN- POWER

ZNR

CN-DC/DC

FUSE

3.15A

BK

TB/1

BK

YL

GN/YL

BR

RD

BR

BK

BL

BL

BR

S

R

C

H

C

F

G

RD

1

2

3

4

5(L1)

6(L2)

T/B 1

MAIN P.C.B

MOTOR

TERMINAL

BLOCK

POWER

INPUT

TRANSFORMER

CAPACITOR

G

OUTDOOR WIRING DIAGRAM

TO INDOOR UNIT

3854AR2262X

BL

4

3

BL

BL

BK

BK

CN-TRANS

RY-COMP

CN- POWER

ZNR

CN-DC/DC

FUSE

3.15A

YL

YL

RD

GN/YL

BR

BR

BR

BR

RD

RD

BR

BK

BL

BL

BR

S

R

C

H

C

F

G

1

2

3

4

5(L1)

6(L2)

COMP.

O.L.P

MAIN P.C.B

MOTOR

TERMINAL

BLOCK

POWER

INPUT

TRANSFORMER

CAPACITOR

COMP.

G

OUTDOOR WIRING DIAGRAM

TO INDOOR UNIT

3854AR7077D

OR(BR)

BR YL

4

3

BL

BL

BK

BK

CN-TRANS

CN - FAN

RY-FAN

RY-COMP

CN- POWER

ZNR

CN-DC/DC

FUSE

3.15A

BK

TB/1

BK

YL

GN/YL

BR

BR

RD

BR

BK

BL

BL

BR

S

R

C

H

F

G

1

0

2

4

6

8

BR

RD

BR

BL

1

2

3

4

5(L1)

6(L2)

C

• Cooling Only Models

1. 9k, 12k

2. 18k

3. 24k

- 12 -

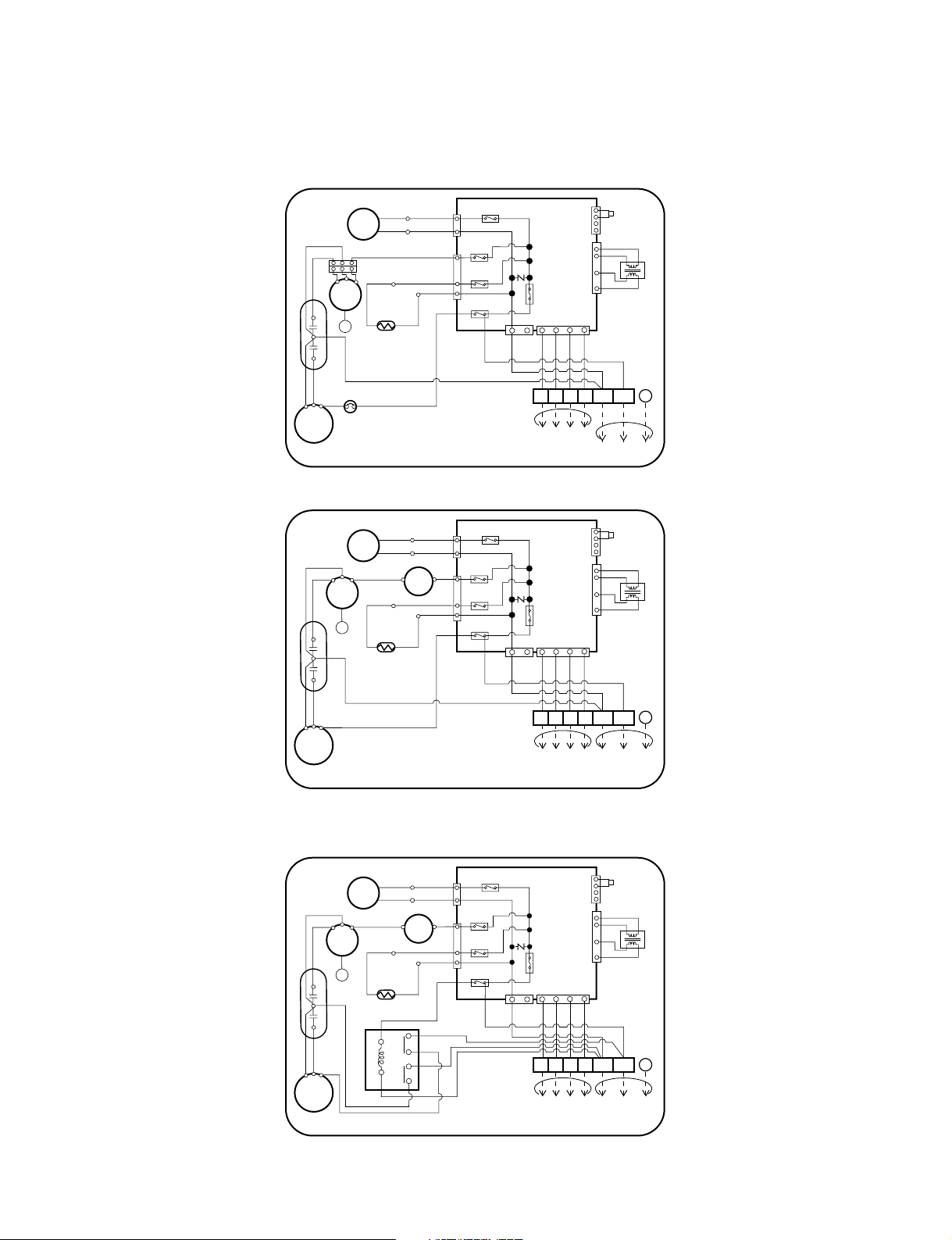

• Cooling & Heating Models

4WAYVALVE

T/B 1

T/B 2

T/B 3

T/B 4

MAIN P.C.B

H.P

SWITCH

MOTOR

CRANK

CASE

HEATER

TERMINAL

BLOCK

POWER

INPUT

TRANSFORMER

THERMISTOR

(COIL)

CAPACITOR

COMP.

G

OUTDOOR WIRING DIAGRAM

TO INDOOR UNIT

3854AR7077A

OR(BR)

BR YL

4

3

BK

BK

BK

BL

BL

BK

BK

RY-4WAY

CN-TH

CN-TRANS

CN - 4WAY

CN - FAN

RY-FAN

RY-HEATER

RY-COMP

CN- POWER

ZNR

CN-DC/DC

FUSE

3.15A

WH

WH

WH

WH

RD

BK

BK

BK

RD

YL

GN/YL

BR

BR

RD

RD

BR

BK

BL

BL

BR

1

2

3

4

5(L1)

6(L2)

S

R

C

H

C

F

G

4WAYVALVE

T/B 1

T/B 2

T/B 4

T/B 3

MAIN P.C.B

MOTOR

CRANK

CASE

HEATER

TERMINAL

BLOCK

POWER

INPUT

TRANSFORMER

THERMISTOR

(COIL)

CAPACITOR

COMP.

G

OUTDOOR WIRING DIAGRAM

TO INDOOR UNIT

3854AR2262Y

BL

BR

BR

YL

4

3

BK

BK

BK

BL

BL

BK

BK

RY-4WAY

CN-TH

CN-TRANS

CN - 4WAY

CN - FAN

RY-FAN

RY-HEATER

RY-COMP

CN- POWER

ZNR

CN-DC/DC

FUSE

3.15A

WH

WH

WH

WH

RD

BK

YL

RD

RD

GN/YL

BR

BR

RD

RD

BR

BK

BL

BL

BR

1

2

3

4

5(L1)

6(L2)

S

R

C

H

C

F

G

O.L.P

4WAYVALVE

T/B 1

T/B 2

T/B 3

T/B 4

MAIN P.C.B

H.P

SWITCH

MOTOR

CRANK CASE

HEATER

TERMINAL

BLOCK

POWER

INPUT

TRANSFORMER

THERMISTOR

(COIL)

CAPACITOR

COMP.

G

OUTDOOR WIRING DIAGRAM

TO INDOOR UNIT

3854AR7077B

OR(BR)

BR YL

4

3

BK

BK

BK

BL

BL

BK

BK

RY-4WAY

CN-TH

CN-TRANS

CN - 4WAY

CN - FAN

RY-FAN

RY-HEATER

RY-COMP

CN- POWER

ZNR

CN-DC/DC

FUSE

3.15A

WH

WH

WH

WH

RD

BK

BK

BK

RD

YL

GN/YL

BR

BR

RD

BR

BK

BL

BL

BR

S

R

C

H

C

F

G

1

0

2

4

6

8

BR

RD

BR

BL

1

2

3

4

5(L1)

6(L2)

1. 12k

2. 18k

3. 24k

- 13 -

Operation Details

0

1

2

3

4

5

115

Cooling

Cooling

Horizontal

Setting point

Heating

Heating

(Close)

6

7

7

9

0

1

2

3

4

5

145

Cooling

Cooling

Horizontal

Setting point

Heating

Heating

(Close)

6

7

8

9

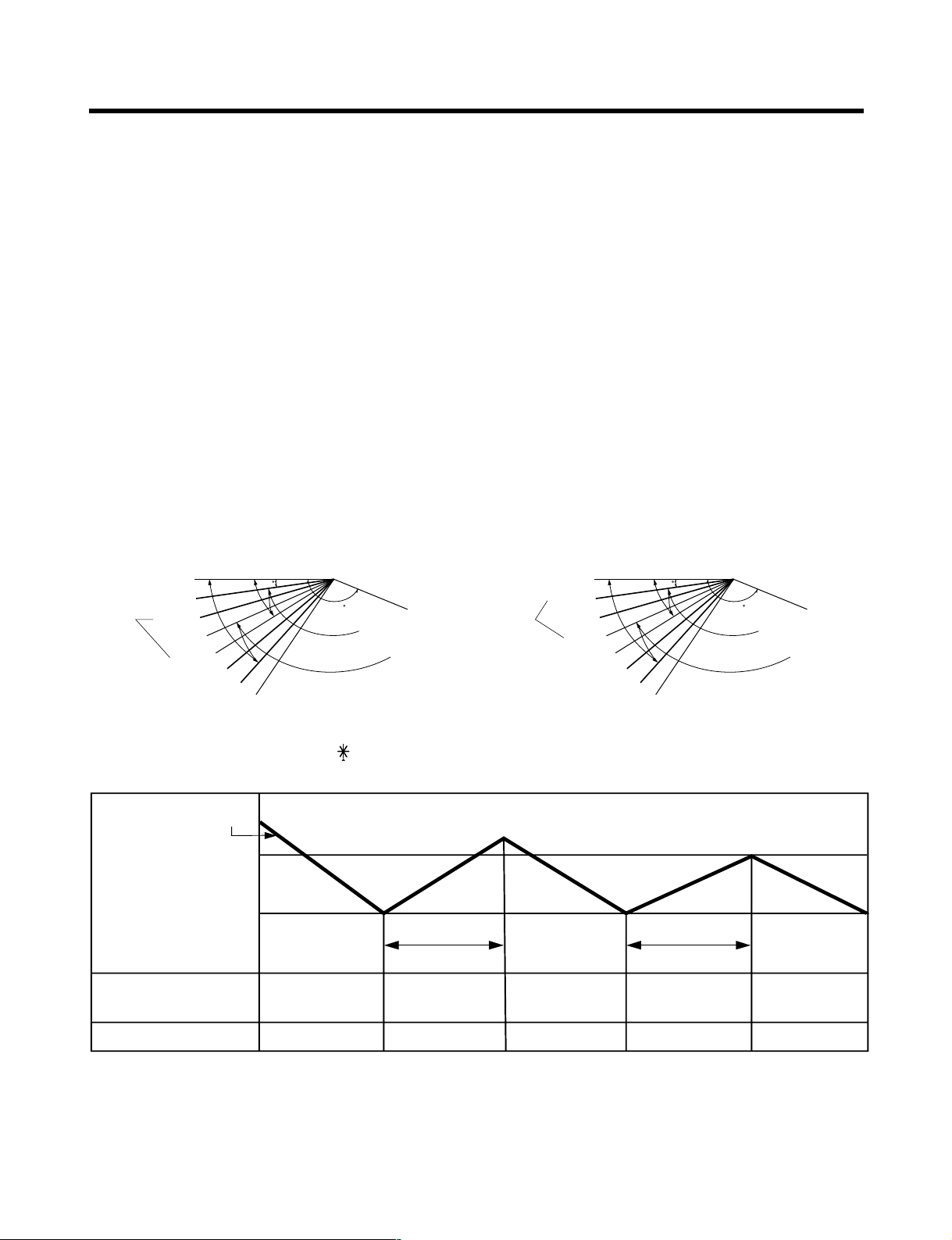

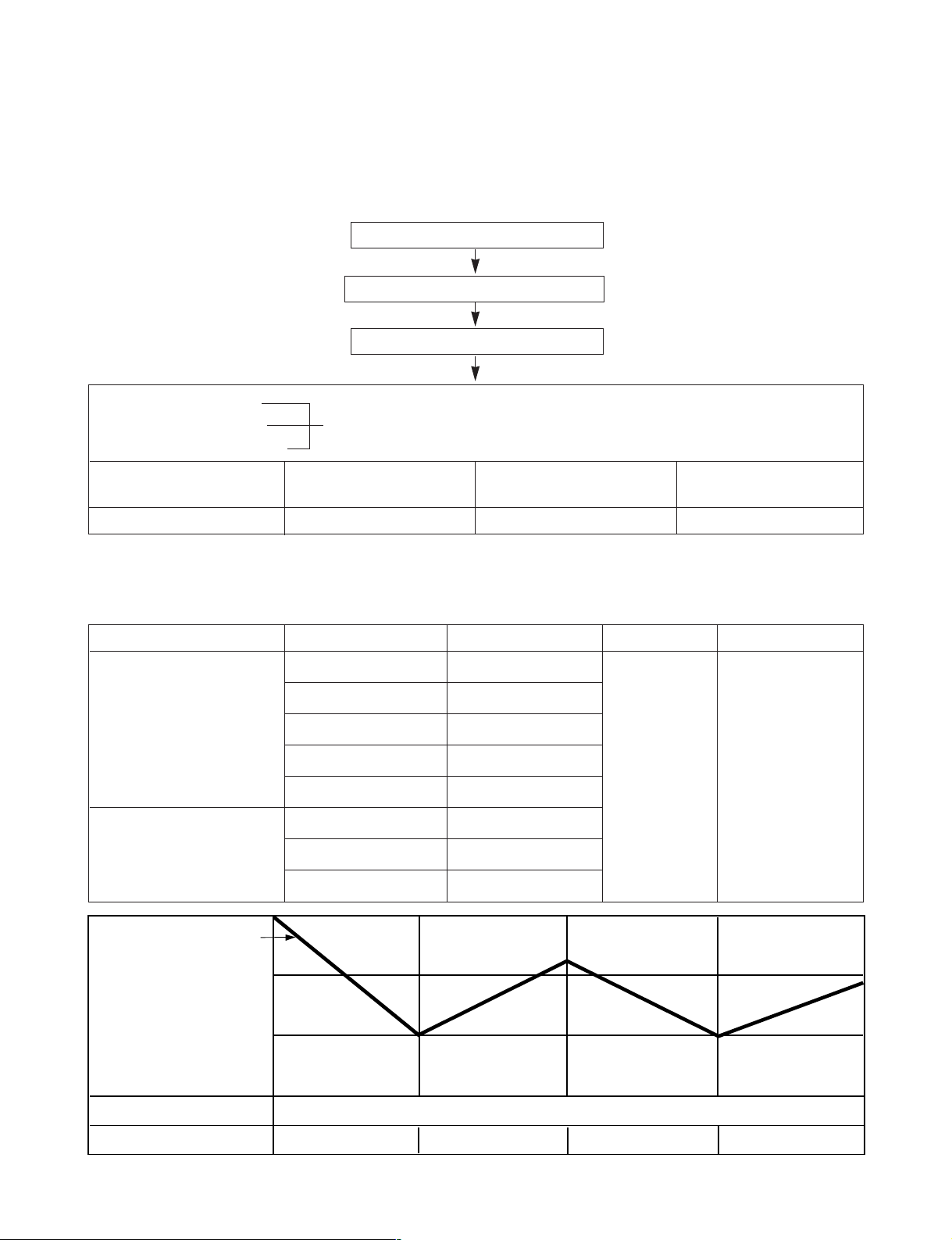

(1) The function of main control

1. Time delay Safety Control

• 3min.; The compressor operation is delayed for 3 minutes to balance the pressure of cycle.

(Protection of compressor)

• 5sec.;

• 2min.; The reversing valve is delayed for 2 minutes to prevent the refrigerant-gas for abnormal noise when

2. Airflow Direction Control

The indoor fan is delayed for 5 seconds, when operating initially, to prevent noises occurred by the vertical

louver and wind.

the heating operation is OFF or switched to the other operation mode while compressor is off.

While compressor is running, it takes 3~5 seconds to switch.

• This function is to swing the vertical louver up and down automatically and to set it at a fixed position.

• The procedure is as the following.

1st ; Press the ON/OFF Button to operate the unit.

2nd ; Press the Airflow Direction Control Button to swing the vertical louver up and down automatically.

3nd ; Repress the Airflow Direction Control Button to set the vertical louver at a fixed position.

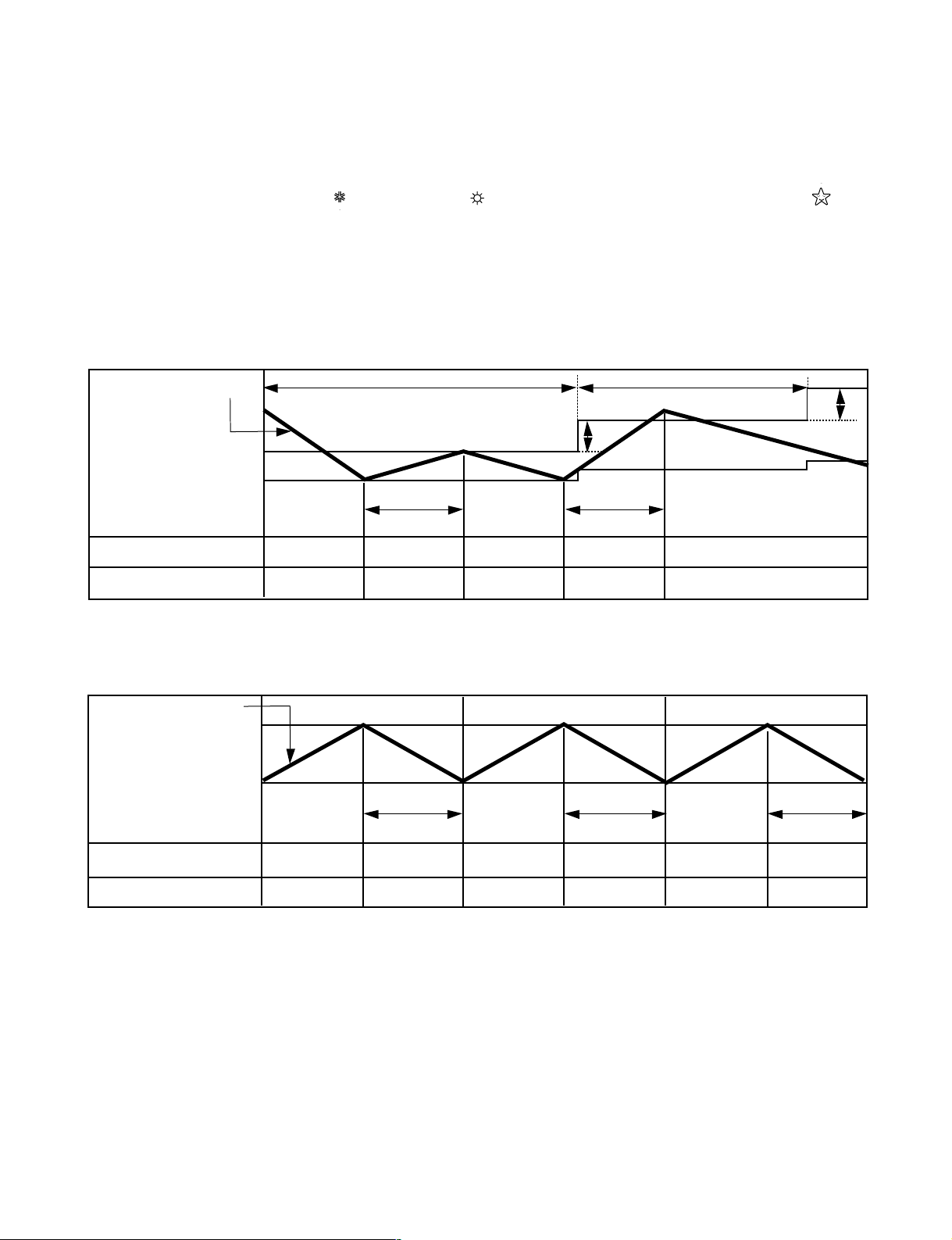

<9k, 12k>

<18k, 24k>

3. Cooling Operation Mode

• When selecting the Cooling( ) Mode Operation, the unit will operate according to the setting by the

remote controller and the operation diagram is shown below.

INTAKE AIR TEMP.

SETTING TEMP. +1°F

(Compressor ON)

SETTING TEMP. -1°F

(Compressor OFF)

INDOOR FAN SPEED Low Low

Selecting

fan speed

COMPRESSOR ON OFF ON OFF ON

■ Protection of the indoor heat exchanger from frosting

• Compressor and outdoor fan stop when indoor pipe temperature is below 32°F and restart at the pipe

temperature is above 45°F.

More than

3 minutes

- 14 -

Selecting

fan speed

More than

3 minutes

Selecting

fan speed

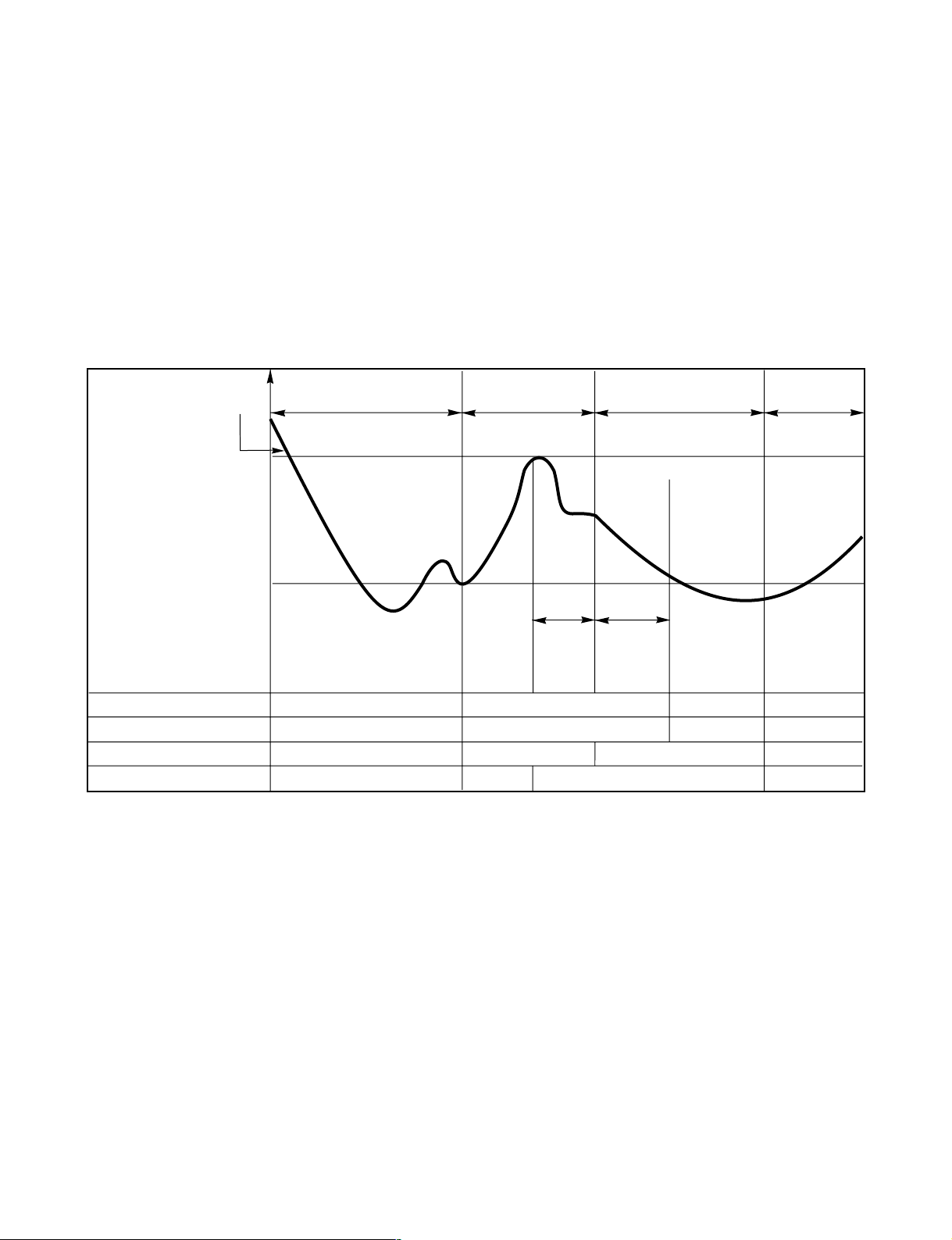

4. Auto Operation (Electronic control mode)

• The operation procedure is shown below. (Cooling & Heating Model)

Press Start/Stop Button

Select Auto Operation Mode

Check the Room temperature

Operation mode

Indoor fan speed are decided automatically by the unit electronic control.

Setting temperature

Intake-air

temperature

Operation Mode

❋ If initial mode is decided, that mode is continued without the room temperature changing.

■ Auto Operation for Cooling

Operation Condition

When Auto Operation

initial start

When pressing room

temperature setting

button during Auto

Operation

Intake-air Temperature Setting Temperature

Over 76°F~below 78°F Intake air -1°C

Over 72°F~below 76°F Intake air -0.5°C

Over 68°F~below 72°F Intake air temperature

Over 64°F~below 86°F Electronic control

below 70°F

Heating

Over 78°F77°F

below 64°F64°F

below 64°F64°F

over 86°F86°F

Over below

70°F76

~

Soft Dry

°

F

Fan Speed Air Direction Control

Controlled by

the electronic

control

Over 76°F

Cooling

In this mode,

when pressing

the vertical air

direction control

button, vertical

louver swings up

and down

automatically.

INTAKE AIR TEMP.

SETTING TEMP. +1°F

(Compressor OFF)

SETTING TEMP. -1°F

(Compressor ON)

INDOOR FAN SPEED The electronic control operation

COMPRESSOR ON OFF ON OFF

- 15 -

■ Auto Operation for Soft Dry(only Heating Model)

• The Setting temperature will be same that of the auto operation for cooling.

- Compressor ON temperature; Setting temperature +2°F

- Compressor OFF temperature; Setting temperture -1°F

Intake-air temp. below 68°F Over 68°F~below 70°F over 86°F

Setting temp. 68°F Intake air temperature +1°F86°F

■ Auto Operation for Heating(only Heating Model)

- Compressor ON temperature; Setting temperature

- Compressor OFF temperature; Setting temperature +6°F

■ Vertical louver auto operation

: In Auto operation mode, when pressing the vertical airflow direction control

button, vertical louver moves as shown below.

MODE0

MODE1

MODE2

MODE3

MODE4

MODE5

End

MODE6

Start

MODE9

(CLOSED)

- 16 -

5. Soft Dry Operation Mode

• During Soft Dry Operation, the compressor ON temperature is the setting temperature plus 2°F, the compres-

sor OFF temperature is the setting temperature minus 1°F.

• When the room temperature rises over the compressor ON temperature, the operation mode is switched to

the Cooling operation.

• When the room temperature falls between the compressor ON temperature and OFF temperature, the opera-

tion mode is switched to the Soft Dry Operation.

• The operation diagram is shown below.

INTAKE AIR TEMP.

Cooling

Operation

Soft Dry Operation

Cooling

Operation

SETTING TEMP. +2°F

(Compressor ON)

SETTING TEMP. -1

(Compressor OFF)

INDOOR FAN SPEED Low Low Low Low Low

°

F

Selecting

fan speed

3 minutes

10 minutes

maximum

7 minutes

3 minutes

maximum

10 minutes

Selecting

fan speed

COMPRESSOR ON OFF ON OFF ON OFF ON

maximum

4 minutes

- 17 -

6. Heating Operation Mode(only Heating Model)

OFF OFFLOW

ON

Selecting

fan speed

The unit will operate according to the setting conditions by the remote controller.

The operation diagram is shown below.

INTAKE AIR TEMP.

°

SETTING TEMP. +6

(Compressor OFF)

F

A

B

SETTING TEMP.

(Compressor ON)

INDOOR FAN SPEED

Selecting

fan speed

minimum

10sec.

Low

OFF

minimum

1 min.

Selecting

Low Low OFF

fan speed

minimum

10sec.

COMPRESSOR ON OFF ON OFF

• A point; While the indoor pipe temperature is higher than 95°F, indoor fan operates at low speed. When the

indoor pipe temperature becomes lower than 95°F, indoor fan stops.

• B point; When the indoor pipe temperature is higher than 82°F, fan operates at selected fan speed.

■ Hot-Start Control

A

• The indoor fan stops until the indoor pipe temperature will be reached at 82°F.

• During heating operation, if indoor pipe temperature falls below 78°F fan stops.

• The operation diagram is shown below.

INDOOR PIPE

1min

TEMP.

82°F

78°F

INDOOR FAN SPEED

COMPRESSOR

- 18 -

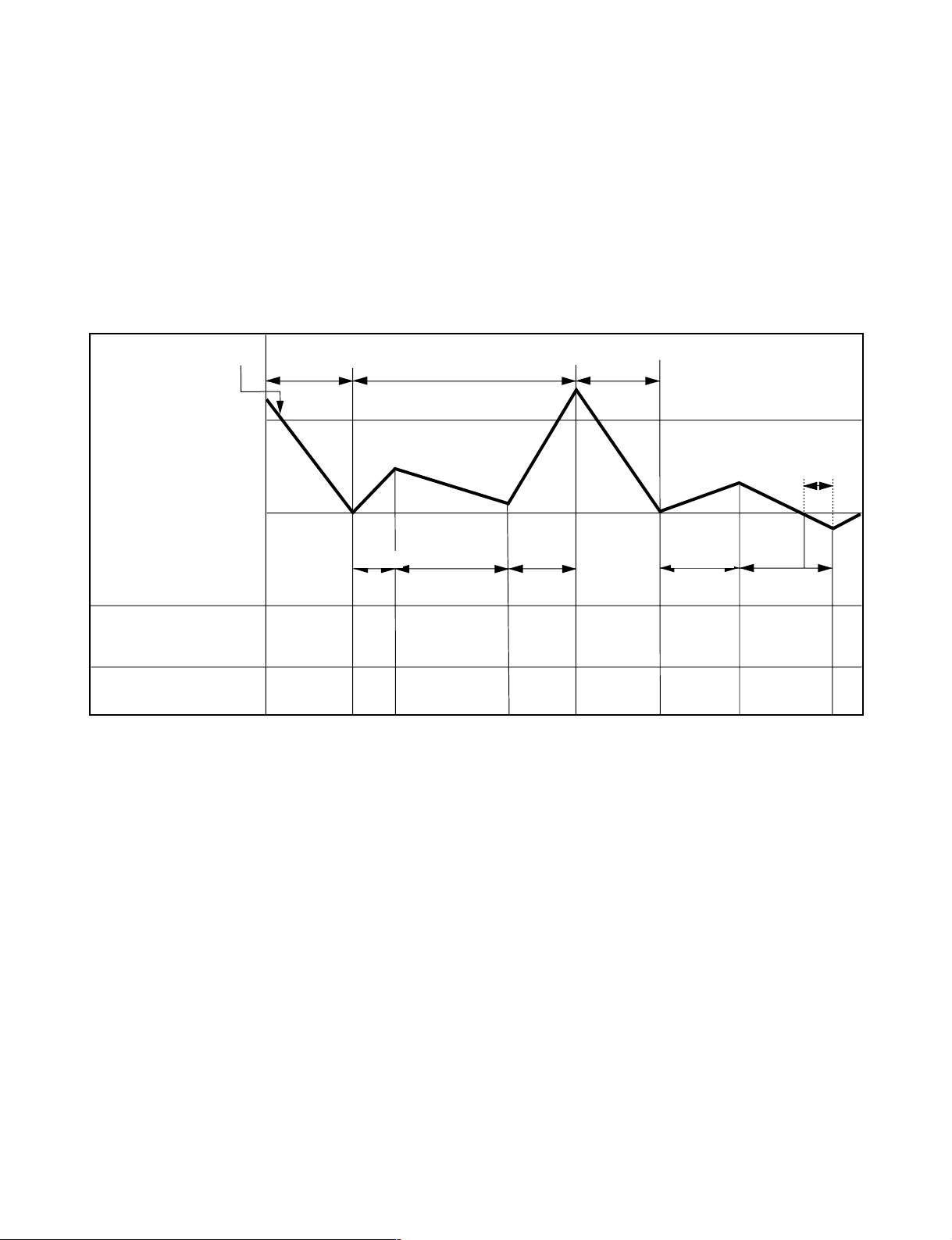

■ Defrost Control

• Defrost operation is controlled by timer and sensing temperature of outdoor pipe.

• The first defrost starts only when the outdoor pipe temperature falls below 21°F after 60 minutes passed from

starting of heating operation and more than 10 minutes operation of compressor.

• Defrost ends after 12 minutes passed from starting of defrost operation or when the outdoor fan operates within 4 minutes after the outdoor pipe temperature rises over 54°F even if before 12 minutes.

• The second defrost starts only when the outdoor pipe temperature falls below 21°F after 60 minutes passed

from ending of the first defrost and more than 10 minutes operation of compressor.

OUTDOOR

PIPE TEMP.

54°F

(DEFROST OFF)

21°F

(DEFROST ON)

INDOOR FAN SPEED ON OFF ON OFF

COMPRESSOR ON ON ON ON

4-WAY VALVE ON OFF ON OFF

OUTDOOR FAN ON OFF ON OFF

More than 60 minutes of

heating operation

More than 10 min.

running of compressor

Within

12minutes

Defrost

Within

4 minutes

More than 60 minutes of

heating operation

More than 10 min.

running of compressor

HOT-

START

Defrost

- 19 -

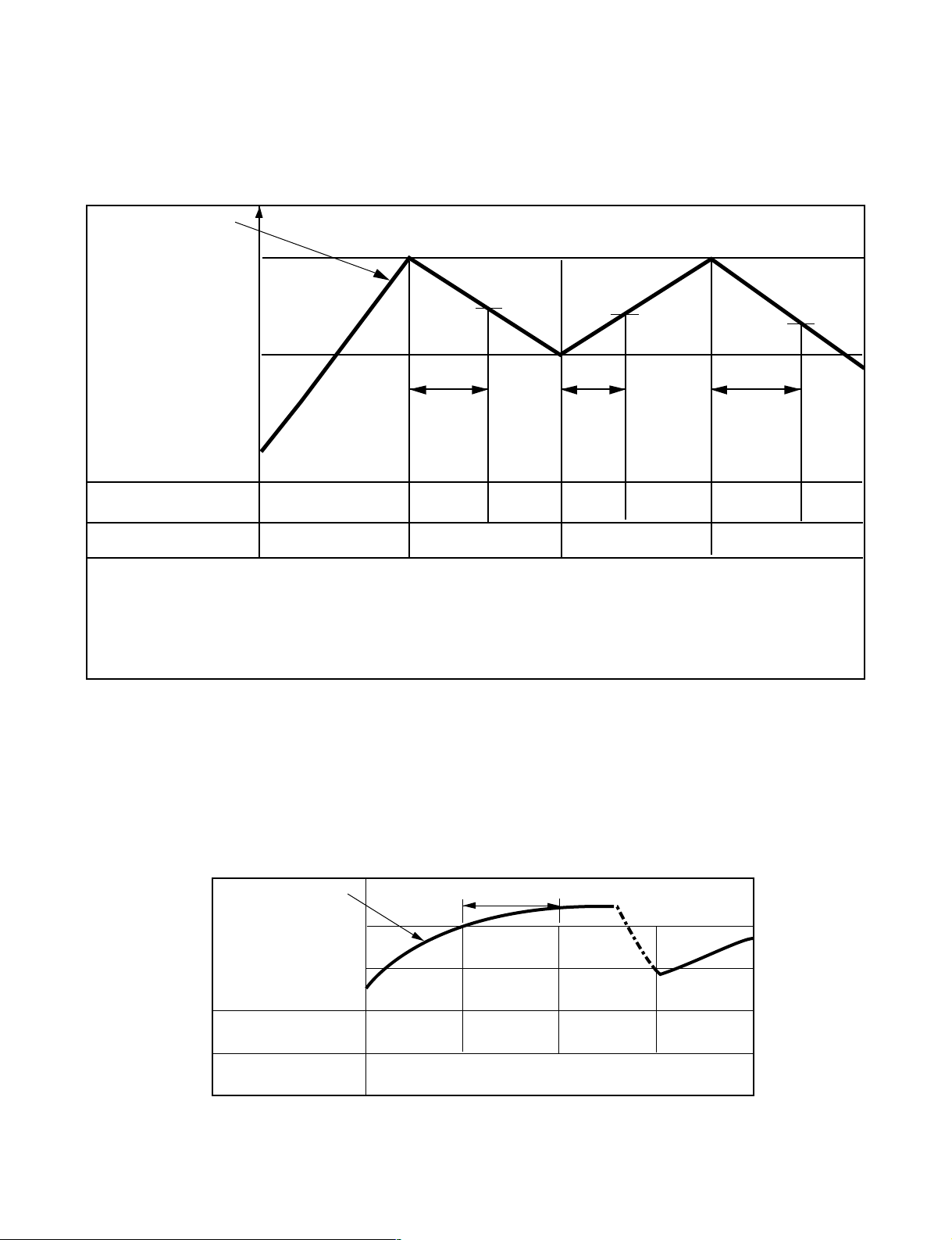

7. Cooling or Heating Mode with Sleep Mode Auto Control

• When selecting the Cooling( ) or the Heating( ) combined with the Sleep Mode Auto Control( ),

the operation diagram is as following.

■ Cooling Mode with the Sleep Mode

• The setting temperature will be automatically raised by 2°F 30 minutes later and by 4

• The operation will be stopped after 1, 2, 3, 4, 5, 6, 7 hours.

INTAKE AIR TEMP.

SETTING TEMP. +1

(Compressor ON)

SETTING TEMP. -1°F

(Compressor OFF)

INDOOR FAN SPEED Low Low Low Low Low

COMPRESSOR ON OFF ON OFF ON

■ Heating Mode with the Sleep Mode(only Heating Model)

INTAKE AIR TEMP.

SETTING TEMP. +6°F

(Compressor OFF)

°

F

30 minutes

More than

3 minutes

2°F

More than

3 minutes

°

F 1 hour later.

30 minutes

2°F

SETTING TEMP.

(Compressor ON)

INDOOR FAN SPEED Med Low or OFF Med Low or OFF Med Low or OFF

COMPRESSOR ON OFF ON OFF ON OFF

More than

3 minutes

More than

3 minutes

More than

3 minutes

- 20 -

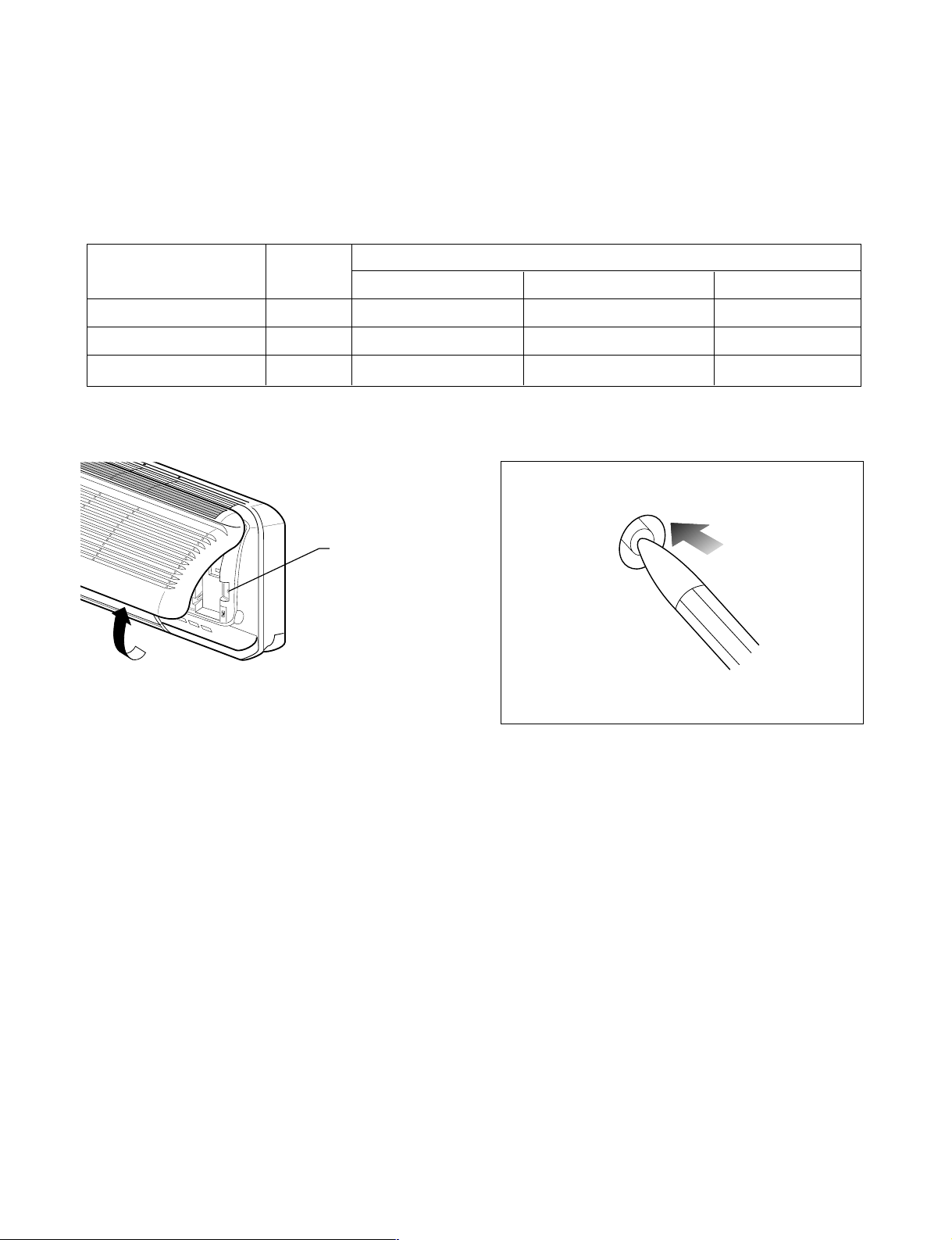

8. Forced Operation

• If you lose wireless remote controller, you can operate the unit with forced operation button.

• The standard conditions are shown below.

Heating Model

Operation Mode

Indoor Fan Speed

Setting Temp.

Cooling

Model

Cooling

High

72°F

Room Temp ≥ 76°F70°F ≤ Room Temp < 76°F Room temp < 70°F

Cooling Soft Dry Heating

High Softe Dry Rule High

72°F74°F76°F

• Unit operates in low fan speed for first 15 seconds, then switched to proper operation mode according to

intake air temperature.

Press the Forced Operation Button.

Forced Operation

Button

Open the front

panel upward

• Press the Forced Operation Button once again

to stop operation.

9. Crank Case Heater Coil Control(only Heating model)

• When the power is applied to the set, the heater operates unconditionally.

• Except for the heating mode operation, the heater is always to be off.

• During the heating mode operation, the heater and compressor are operated by turns.

(Compressor ON → Heater OFF, Compressor OFF → Heater ON)

- 21 -

Test Mode

Test operation will be set by pushing the "Test key" on the main PWB Assy. Each test operation by pushing

count of "Test key" is as well as the following.

(1) Indoor

• Once push : Ignore communication error.

• Twice push : Shorten the proceeding time.(1min → 1sec)

• 3 Times push : Shorten the proceeding time.(1hour → 1sec)

• 4 Times push : All LED ON

• 5 Times push : Up/Down Step Motor ON.

• 6 Times push : Right Step Motor ON. (Not on all Models)

• 7 Times push : Left Step Motor ON.(Not on all Models)

• 8 Times push : Negative lon ON.(Not on all Models)

• 9 Times push : Reset.

Note)

For normal operation after checking by test mode, you should reset main power.

(2) Outdoor

• Once push : Ignore Communication error.

• Twice push : Comp. ON, Outdoor Fan ON

Reversing Valve Coil ON(only Heating Model)

Crank Case heater Coil ON(only Heating Model)

• 3 Times push : Comp. ON, Outdoor Fan ON

Reversing Valve Coil OFF(only Heating Model)

Crank Case Heater Coil OFF(only Heating Model)

• 4 Times push : Same

• 5 Times push : Error LED(Red) ON

• 6 Times push : Comp OFF, Outdoor FAN OFF

• 7 Times push : Reset

Note)

For normal operation after checking by test mode, you should reset main power.

- 22 -

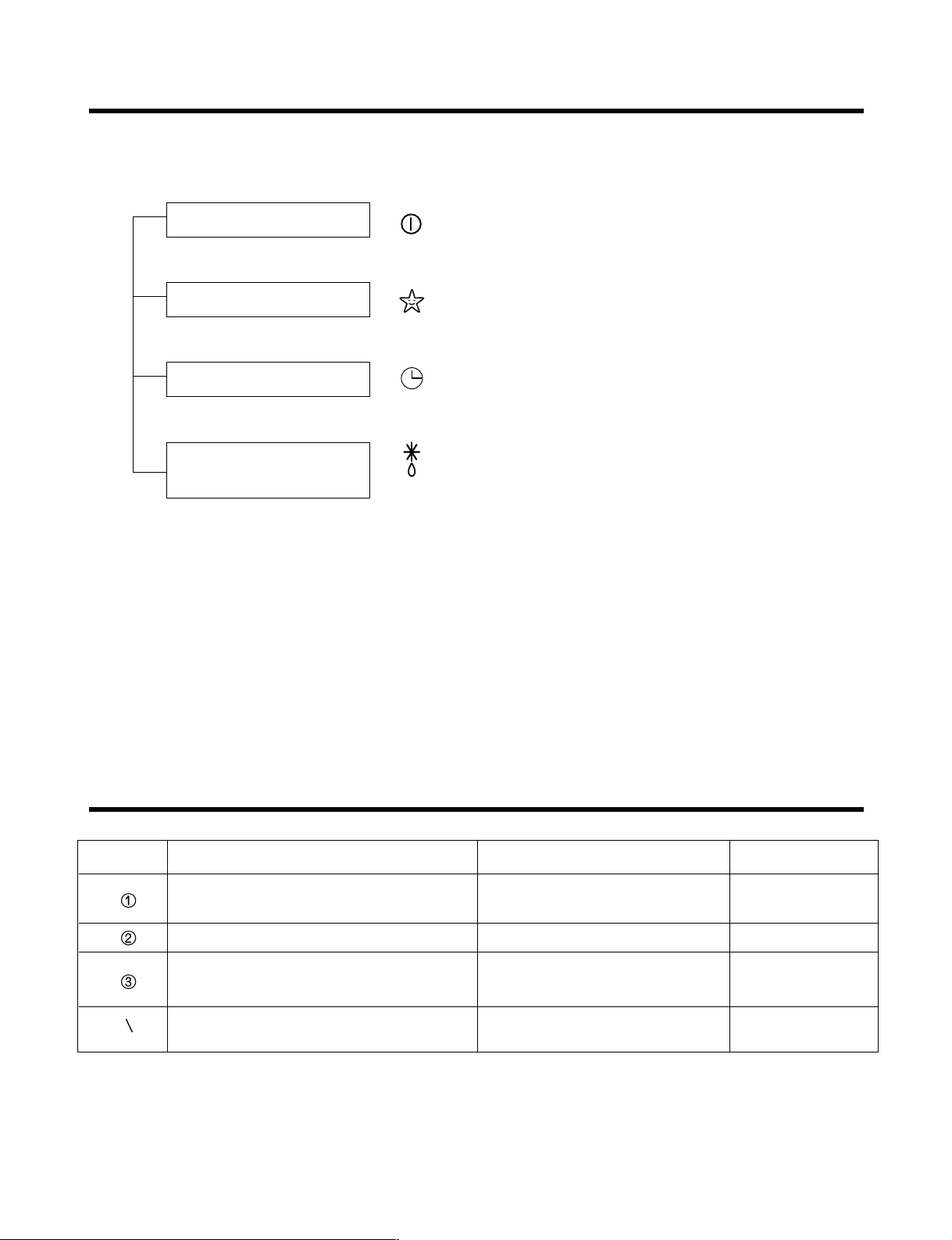

Display Function

Operation Indicator

• Cooling, Soft Dry, Fan, Heating

Sleep timer Indicator

• Sleep Mode

Timer Indicator

• Timer Mode

Defrost Indicator or

Hot start Indicator

OUT

DOOR

• Hot-start, Defrost

• Compressor ON

: Cooling & Heating Model only

: only Cooling Model

• BUZZER SOUND

• Power Input or Reset : One short beep.

• When Operation Stop Button is pressed : One long beep.

• When Remote Controller Buttons except for Operation Stop are pressed : Two short beep.

• When Forced Operation Button is pressed : Two Short beep.

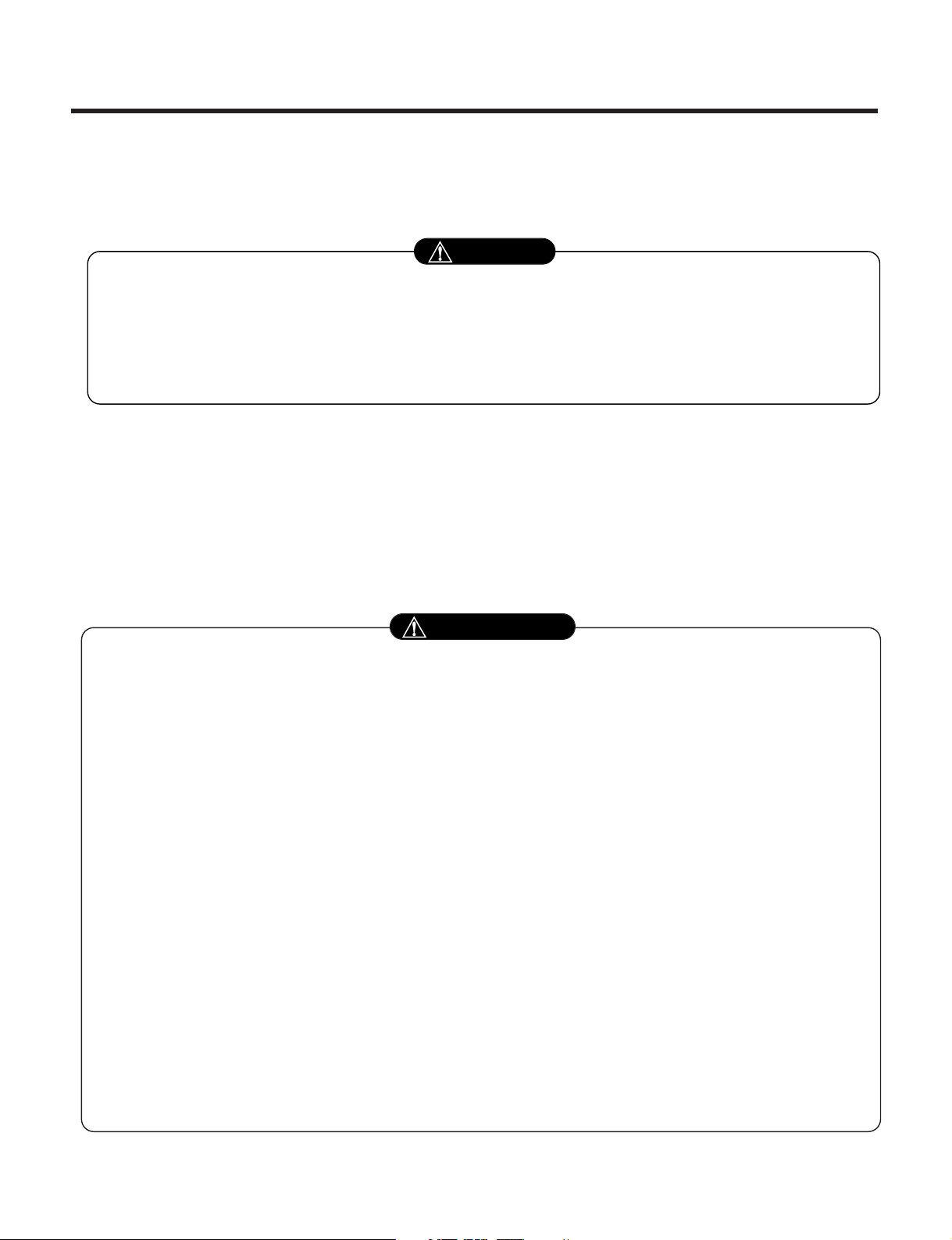

Self-diagnosis Function

CODE NO. DIAGNOSIS Operation Indicator LED Blinks Unit Operation

Indoor room temperature thermistor or

pipe temperature thermistor Short/Open

Once Still Operation

Outdoor pipe thermistor Short/Open Twice Outdoor Unit Off

Communication failure between indoor and

outdoor

Indoor fan locked 8 times Stop

• LED blinks as many times as code No. (0.5 second ON/0.5 second OFF) with 3 seconds interval.

• While the unit is off, no indication displays.

• If more than one code occurs simultaneously, bigger code No. is displayed.

5 times Stop

- 23 -

Installation

IMPORTANT!

Please read this instruction sheet completely before installing the product.

This air conditioning system meets strict safety and operating standards. As the installer or service person, it is an important

part of your job to install or service the system so it operates safely and efficiently.

WARNING

• Installation or repairs made by unqualified persons can result in hazards to you and others.

Installation MUST conform with local building codes or, in the absence of local codes, with the National Electrical Code NFPA 70/ANSI

C1-1993 or current edition and Canadian Electrical Code Part1 CSA C.22.1.

• The information contained in the manual is intended for use by a qualified service technician familiar with safety procedures and

equipped with the proper tools and test instruments.

• Failure to carefully read and follow all instructions in this manual can result in equipment malfunction, property damage, personal injury

and/or death.

CAUTION

: Improper installation, adjustment, alteration, service or maintenance can void the warranty.

The weight of the condensing unit requires caution and proper handling procedures when lifting or moving to avoid

personal injury. Use care to avoid contact with sharp or pointed edges.

Safety Precautions

• Always wear safety eye wear and work gloves when installing equipment.

• Never assume electrical power is disconnected. Check with meter and equipment.

• Keep hands out of fan areas when power is connected to equipment.

• R-22 causes frostbite burns.

• R-22 is toxic when burned.

NOTE TO INSTALLING DEALER

: The Owners Instructions and Warranty are to be given to the owner or

prominently displayed near the indoor Furnace/Air Handler Unit.

Special warnings

When wiring:

Electrical shock can cause severe personal injury or death. Only a qualified, experienced

electrician should attempt to wire this system.

• Do not supply power to the unit until all wiring and tubing are completed or reconnected and checked.

• Highly dangerous electrical voltages are used in this system. Carefully refer to the wiring diagram and these instructions when wiring.

Improper connections and inadequate grounding can cause accidental injury or death.

• Ground the unit following local electrical codes.

• Connect all wiring tightly. Loose wiring may cause overheating at connection points and a possible fire hazard.

When transporting:

Be careful when picking up and moving the indoor and outdoor units. Get a partner to help, and bend your knees when

lifting to reduce strain on your back. Sharp edges or thin aluminum fins on the air conditioner can cut your finger.

When installing...

... in a wall: Make sure the wall is strong enough to hold the unit's weight.

... in a room: Properly insulate any tubing run inside a room to prevent "sweating" that can cause dripping and water

... in moist or uneven locatinons: Use a raised concrete pad or concrete blocks provide a solid, level foundation for the

... in an area with high winds: Securely anchor the outdoor unit down with bolts and a metal frame. Provide a

... in a snowy area(for Heat Pump Model): Install the outdoor unit on a raised platform that is higher than drifting

It may be necessary to construct a strong wood or metal frame to provide added support.

damage to wall and floors.

outdoor unit. This prevents water damage and abnormal vibration.

suitable air baffle.

snow. Provide snow vents.

When connecting refrigerant tubing

• Keep all tubing runs as short as possible.

• Use the flare method for connecting tubing.

• Check carefully for leaks before starting the test run.

When servicing

• Turn the power OFF at the main power box(mains) before opening the unit to check or repair electrical parts and

wiring.

• Keep your fingers and clothing away from any moving parts.

• Clean up the site after you finish, remembering to check that no metal scraps or bits of wiring have been left inside

the unit being serviced.

- 24 -

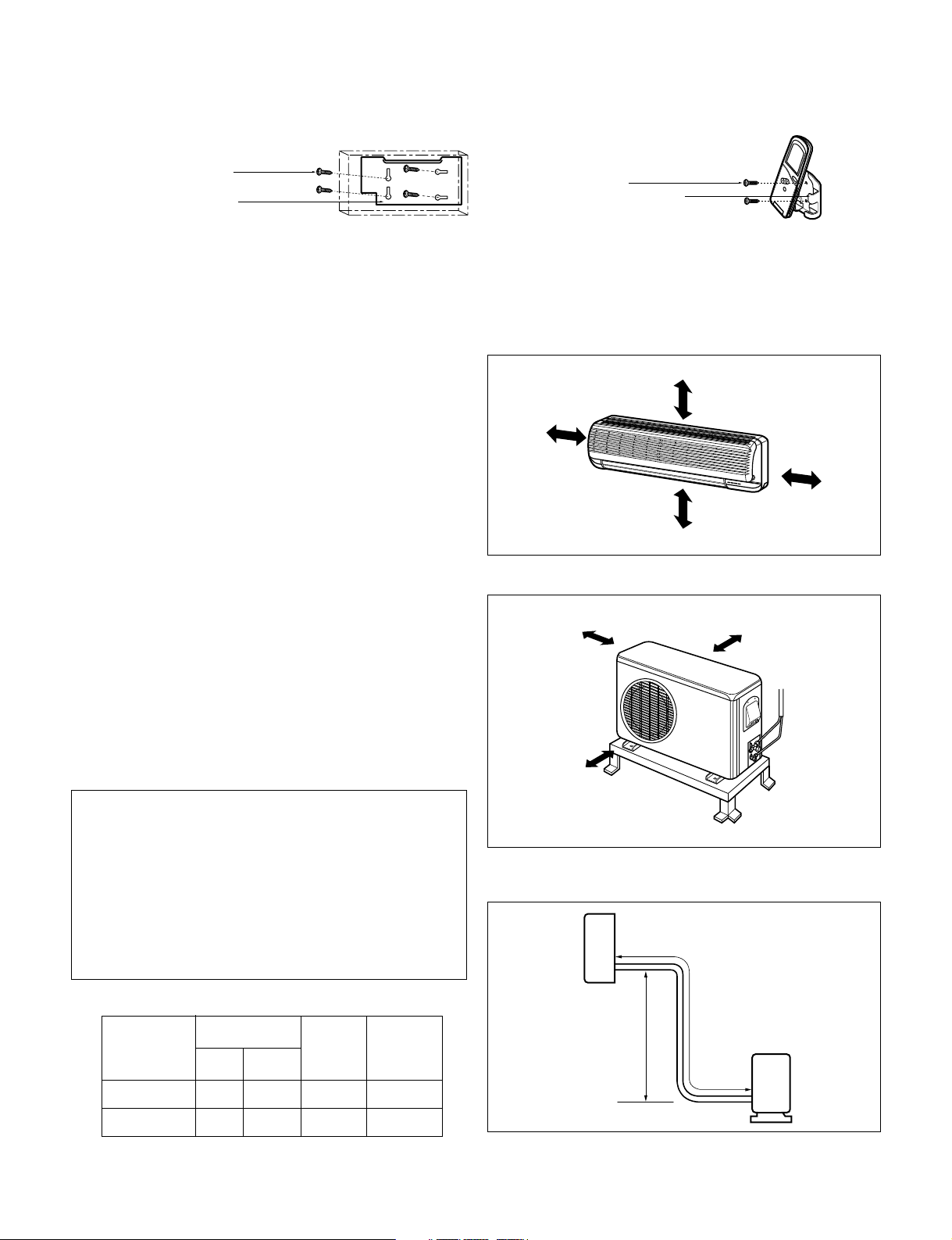

(1) Installation Parts Provided

1. Type "A" screw

2. Installation Plate

(2) Installation of Indoor, Outdoor unit

1) Selection of the best location

1. Indoor unit.

•

There should not be any heat source or steam near

the unit.

• There should not be any obstacles to prevent the air

circulation.

• A place where air circulation in the room will be good.

• A place where drainage can be easily obtained.

• A place where noise prevention is taken into

consideration.

• Do not install the unit near the door way.

• Ensure the spaces indicated by arrows from the wall,

ceiling, fence, or other obstacles.

2. Outdoor unit

• If an awning is built over the unit to prevent direct

sunlight or rain exposure, be careful that heat

radiation from the condenser is not restricted.

• There should not be any animals or plants which could

be affected by hot air discharged.

• Ensure the spaces indicated by arrows from the wall,

ceiling, fence, or other obstacles.

3. Type "B" screw

4. Holder Remote-Controller

More than

5 cm(2")

More than eye level

More than 10 cm(4")

More than 5 cm(2")

More than

5 cm(2")

More than 10 cm(4")

Roof Top Installations

If it is necessary to install units on a roof structure, be

sure to elevate and level the units. Ensure the roof

structure and anchoring method are adequate for unit

location. Consult local codes regarding rooftop mounting.

NOTE: When condensing unit is to be installed on a

bonded guaranted roof, a release must be obtained

from the building owner to free the installer from all

liabilities.

3. Piping length and the elevation

MODEL

(Cooling Capa.)

9k, 12k 1/2" 1/4" 15m(50ft) 8m(26ft)

18k, 24k 5/8" 3/8" 15m(50ft) 8m(26ft)

Pipe Size

GAS LIQUID

Max.

length

A

Max.

Elevation

B

More than 70 cm(28")

Indoor unit

A

B

Outdoor unit

- 25 -

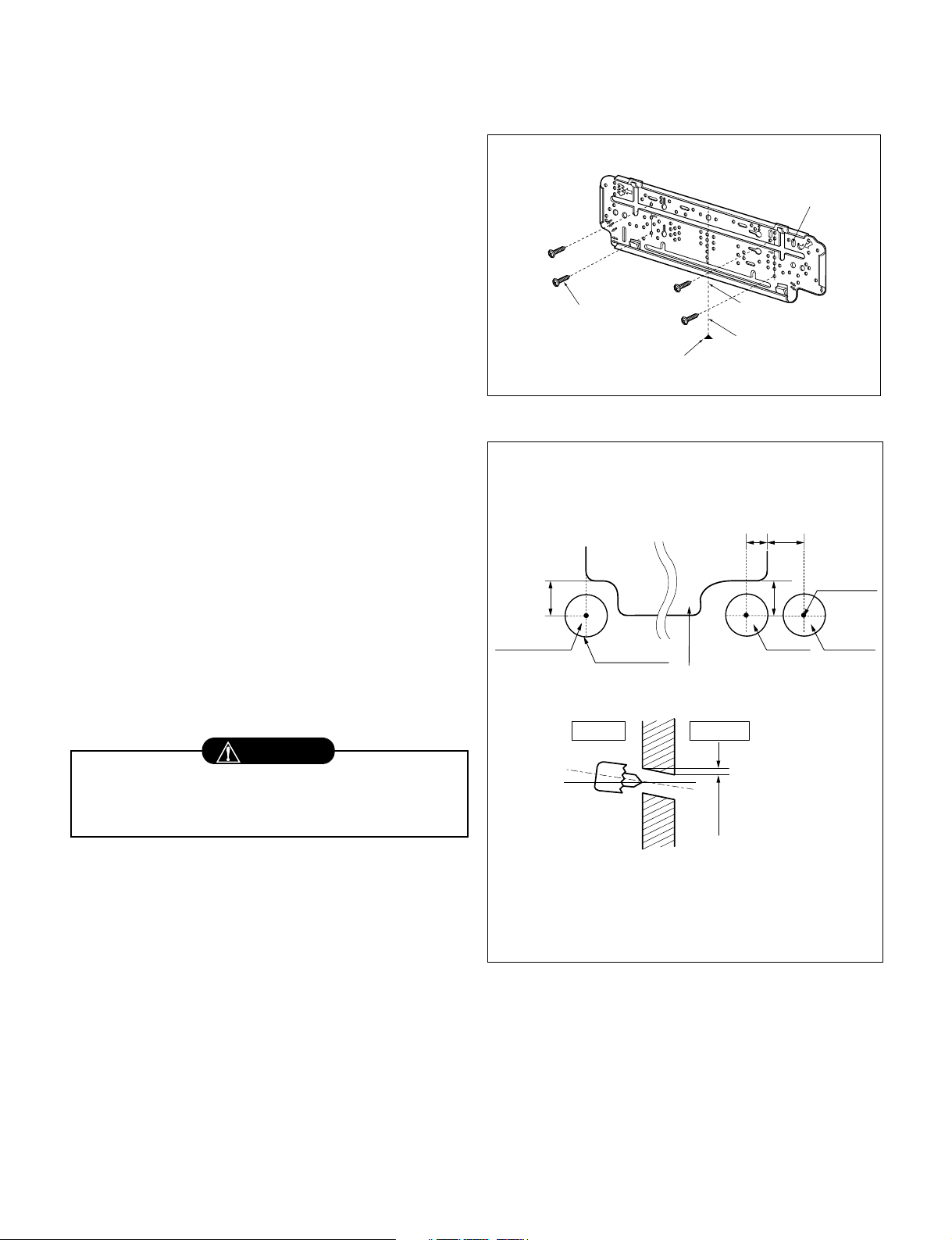

2) Indoor Unit Installation

The mounting wall should be strong and solid enough to

protect it from the vibration.

1.Mount the installation plate on the wall with four

Type "A" screws.

(if mounting the unit on the concrete wall, consider

using anchor bolts.)

• Always mount the Installation Plate horizontally by

aligning the marking-off line by means of the thread

and a level.

2. Drill the piping hole with 70mm(2.75") dia.

holecore drill.

• Drill the Piping hole at either the right or the left and

the hole should be slightly slanted to the outdoor

side.

Installation Plate

Type "A" screw

marking-off line

Thread

Weight

The lower left and right side of Installation Plate

Left rear piping

Right rear piping

1"

(25mm)2"(51mm)

WARNING

Avoid areas where electrical wiring, conduits or

gas lines are located. Accidentally cutting a live

wire or gas line can cause death or injury.

1.8"

(46mm)

9k, 12k, 18k, 24k

2.75"(70mm)

ø

Installation plate

WALL

Indoor Outdoor

5-7mm

9k, 12k

(0.2~0.3")

1.9"

(48mm)

Hole center

18k, 24k

- 26 -

Loading...

Loading...