ENERGY KING 35EKB, 45EKB, A40EKB Installation, Operation & Maintenance Manual

ENERGY KING

Wood/Coal Boilers

Models 35EKB/45EKB &

ASME-Certified Model A40EKB

Installation, Operation & Maintenance Manual

RJM Manufacturing, Inc.

1875 Olson Drive

Chippewa Falls, WI 54729

(715) 720-1794 ♦ Fax (715) 720-1797

www.EnergyKing.com

ENERGY KING Wood/Coal Boilers

Models 35EKB/45EKB & ASME-Certified Model A40EKB

Installation and Operating Instructions

Congratulations on your purchase of an ENERGY KING solid fuel heating appliance!

Your ENERGY KING Wood/Coal Boiler is designed for a lifetime of durable, reliable

performance and easy operation. This manual describes the installation, operation and

maintenance of your ENERGY KING Wood/Coal Boiler.

Before installing your ENERGY KING Wood/Coal Boiler,

please read and be sure you understand this entire owner’s

manual and safety instructions.

ENERGY KING Wood/Coal Boilers have been designed to use independently or as an add-

on to an existing hydronic heating system. The installation of any furnace or boiler is not a

do-it-yourself project. To ensure the ENERGY KING Wood/Coal Boiler will operate safely

and efficiently, the installation must be performed by a qualified installer with specific

knowledge of hydronic heating systems. It is the owner’s responsibility to make certain

that both the appliance and installation are acceptable to their insurance company, as well

as ensuring compliance with all local, state and national codes and regulations.

With proper installation and maintenance, your ENERGY KING Wood/Coal Boiler will give

you years of trouble free service.

Thank you for choosing the ENERGY KING Wood/Coal Boiler.

We are constantly improving and updating our products in order to provide the highest quality and value

possible. RJM Manufacturing, Inc., the manufacturer of this product, reserves the right to alter its products,

their specifications and/or prices without notice.

ENERGY KING is a trademark of RJM Manufacturing, Inc.

Save these instructions.

RJM Manufacturing, Inc

1875 Olson Drive

Chippewa Falls, WI 54729

(715) 720-1794 | Fax (715) 720-1797

www.energyking.com

Email: sales@energyking.com

Safety Instructions

▲ Read this entire manual before installing,

operating or maintaining this product.

Proper installation of this heating

appliance is crucial for safe and efficient

operation. Save these instructions for later

use.

▲ This heating appliance must be

installed in accordance with local,

state, and national codes and

regulations. Contact your local building

or fire officials about installation

restrictions and inspection requirements in

your area.

▲ Do not connect this heating appliance

to a chimney flue serving any other

appliance.

▲ Do not install this heating appliance in

a mobile or manufactured home—this

can be dangerous and will void your

warranty. This heating appliance has not

been tested to meet the strict

requirements necessary for installation

into a mobile or manufactured home.

Failure to follow these safety instructions may result

in property damage, bodily injury or even death.

▲ The fuel loading and ash removal doors

must be closed tightly during operation. All

seals must be maintained in good

condition.

▲ The ENERGY KING Wood/Coal Boiler is

designed to burn air-dried wood, or

anthracite or bituminous coal only.

Burning of any other type of fuel voids

your ENERGY KING warranty.

▲ Do not burn: Treated wood, colored

paper, garbage, cardboard, solvents, or

trash—burning these may result in toxic

fumes, or produce soot and large flakes of

char or fly ash. Burning treated wood,

colored paper, garbage, cardboard,

solvents or trash can be dangerous and

will void your ENERGY KING warranty.

▲ Do not place clothing or other flammable

materials on this heating appliance or

within marked clearances to combustibles.

▲ Do not use, store, or dispose of flammable

liquids near the heating appliance.

▲ Install in an area with adequate air for

combustion and ventilation. The use of

outside air may be required for safe

operation of this heating appliance.

Contact your local building or fire officials

about combustion air requirements in your

area.

▲ All minimum clearances to combustible

materials must be followed.

▲ This Boiler must be installed on a

non-combustible floor or 3/8-inch thick

fireproof millboard or equivalent. See

Installation for further instructions.

▲ Disconnect all power to the ENERGY

KING heating appliance at the breaker

box or service panel before performing

routine maintenance and service. Allow

the heating appliance to cool before

servicing.

▲ Never fire a boiler that is low on water.

Never add water to a hot boiler.

Rev 07/13/09 ENERGY KING™ Wood/Coal Boiler Owner’s Manual U. S. i

▲ DANGER – Risk of Fire or Explosion:

Do not burn garbage, gasoline, naphtha,

drain or engine oil, or other flammable

liquids or inappropriate materials in this

heating appliance.

▲ Do not use chemicals or fluids, such as

gasoline, gasoline-type lantern fuel,

kerosene, charcoal lighter fluid, or similar

liquids to start or freshen up a fire in this

heating appliance.

▲ Establish a routine for the storage of fuel,

care of the heating appliance and firing

techniques.

▲ CAUTION – Hot Surfaces: Keep children

away! Do not touch heating appliance

during operation.

▲ Use caution when opening fuel loading

door. Opening fuel loading door rapidly

can cause smoke or flame to flash out the

door. See Operation for further

instructions.

Safety Instructions

▲ Dispose of ashes with care. Ashes should

be placed in a metal container with a tight

fitting metal lid. The closed container of

ashes should be placed on a

noncombustible floor or on the ground,

well away from all combustible materials,

pending final disposal.

All coal contains small amounts of

dangerous elements. Therefore it is

essential that all coal ash be disposed of

in municipally designated areas.

The National Fire Protection Association has information available on the safe use of solid-fuel

heating appliances. You can contact the NFPA at: National Fire Protection Association, 1

Batterymarch Park, Quincy, MA 02169-7471 or www.nfpa.org.

Failure to follow these safety instructions may result

in property damage, bodily injury or even death.

▲ A working smoke detector must be

installed in the same room as this heating

appliance. For additional safety, RJM

Manufacturing, Inc. also recommends

installing working smoke detectors and a

listed carbon monoxide warning device in

the living areas of the home.

▲ Always keep a working fire extinguisher

on hand in case of fire.

Rev 07/13/09 ENERGY KING™ Wood/Coal Boiler Owner’s Manual U. S. ii

Table of Contents

SAFETY INSTRUCTIONS................................................................................................................................................i

TABLE OF CONTENTS ...................................................................................................................................................1

SPECIFICATIONS............................................................................................................................................................3

COMPONENT DESCRIPTION.......................................................................................................................................4

WHAT IS ASME-CERTIFICATION?.............................................................................................................................6

PREINSTALLATION CONSIDERATIONS ..................................................................................................................7

FUEL REQUIREMENTS ..................................................................................................................................................8

WOOD............................................................................................................................................................................ 8

COAL..............................................................................................................................................................................9

INSTALLATION ..............................................................................................................................................................10

GENERAL REQUIREMENTS ........................................................................................................................................... 10

Zones ........................................................................................................................................................................10

In-floor Heating.......................................................................................................................................................10

Placement.................................................................................................................................................................10

•Floor Protection................................................................................................................................................................... 10

•As Primary Boiler................................................................................................................................................................11

•As Add-On Boiler................................................................................................................................................................ 11

Clearances to Combustibles.................................................................................................................................................11

ASSEMBLING YOUR ENERGY KING WOOD/COAL BOILER..................................................................................... 12

COMBUSTION AIR REQUIREMENTS..............................................................................................................................15

VENTING SYSTEM ......................................................................................................................................................... 16

Masonry Chimney....................................................................................................................................................18

Chimney Connector .................................................................................................................................................18

Barometric Draft Control ........................................................................................................................................19

PLUMBING.....................................................................................................................................................................20

OPERATION ....................................................................................................................................................................22

GENERAL INSTRUCTIONS .............................................................................................................................................22

GATE VALVES ...............................................................................................................................................................22

FIRST FIRE .................................................................................................................................................................... 23

TYPICAL OPERATION CYCLE .......................................................................................................................................23

OVERFIRE...................................................................................................................................................................... 24

POWER FAILURE INSTRUCTIONS..................................................................................................................................24

BURNING WOOD............................................................................................................................................................25

Starting a Wood Fire................................................................................................................................................25

Refueling..................................................................................................................................................................25

BURNING COAL............................................................................................................................................................. 26

Starting a Coal Fire .................................................................................................................................................27

Refueling / Recharging............................................................................................................................................27

MAINTENANCE ..............................................................................................................................................................29

CREOSOTE – FORMATION AND NEED FOR REMOVAL ................................................................................................. 29

DISPOSAL OF ASHES...................................................................................................................................................... 29

GASKET REPLACEMENT ...............................................................................................................................................30

ROUTINE MAINTENANCE..............................................................................................................................................30

TROUBLESHOOTING GUIDE......................................................................................................................................32

APPENDIX A: WIRING DIAGRAM ...........................................................................................................................37

APPENDIX B: EXAMPLE PLUMBING DIAGRAM.................................................................................................39

APPENDIX C: PARTS LIST ........................................................................................................................................41

APPENDIX D: PURCHASE & SERVICE RECORD................................................................................................45

APPENDIX E: WARRANTY CLAIM PROCEDURES .............................................................................................46

LIMITED WARRANTY.................................................................................................................................................49

SUPPLEMENT A: AQUASTAT-IMMERSION CONTROL......................................................................................51

SUPPLEMENT B: 24-V WALL THERMOSTAT.......................................................................................................64

Rev 07/13/09 ENERGY KING™ Wood/Coal Boiler Owner’s Manual U. S. 1

This page is intentionally left blank.

Rev 07/13/09 ENERGY KING™ Wood/Coal Boiler Owner’s Manual U. S. 2

Specifications

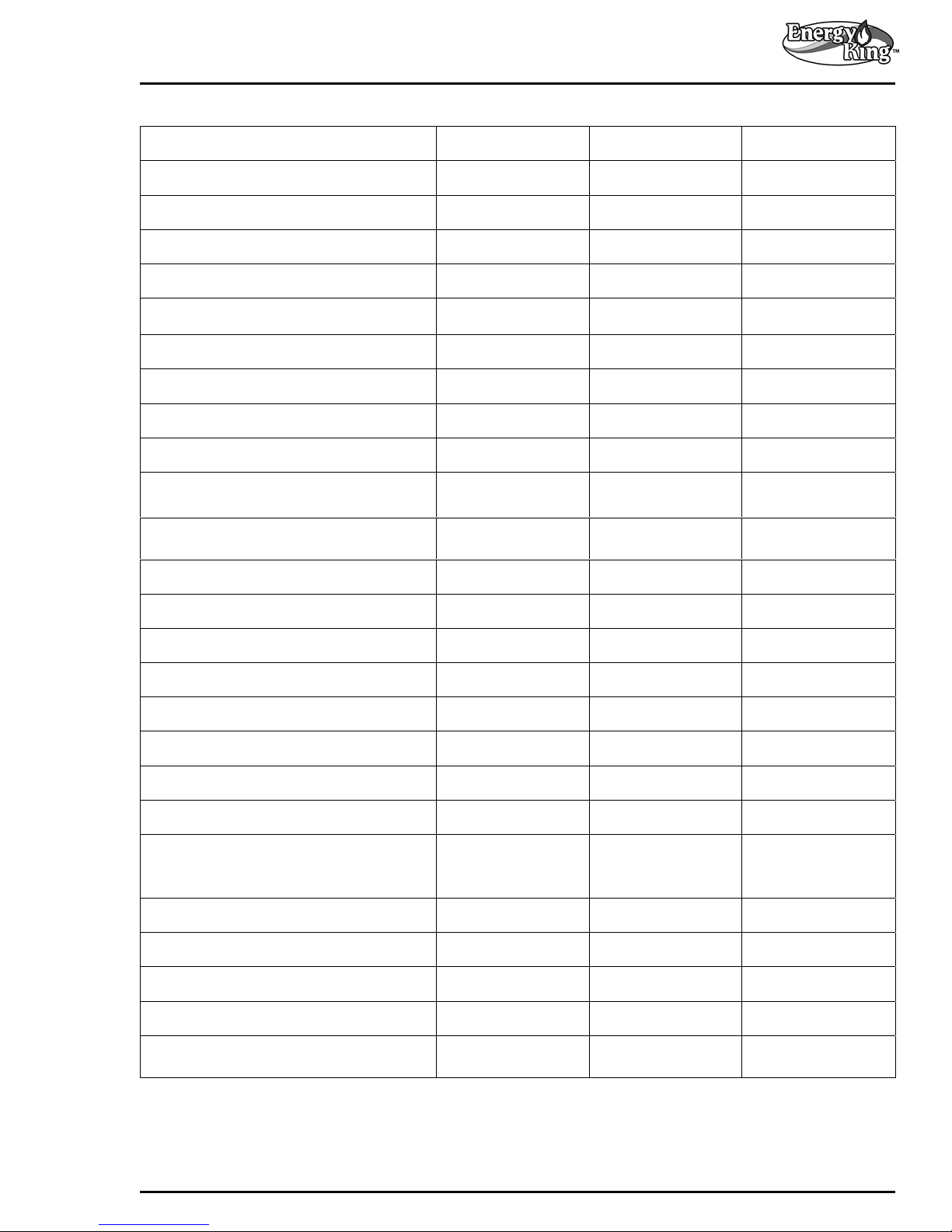

Model Number A40EKB 35EKB 45EKB

Dimensions (H x W x D) 54.5″ x 24″ x 43″ 54.5″ x 24″ x 38″ 54.5″ x 24″ x 43″

Shipping Weight (Approx.) 1,100 lbs. 1,000 lbs. 1,100 lbs.

Heating Capacity* - BTU’s (Approx.) 140,000 BTU 140,000 BTU 160,000 BTU

Heating Area* (Approx.) 1,500–2,500 sq. ft. 1,500–2,500 sq. ft. up to 4,000 sq. ft.

Water Capacity (Approx.) 40 gallons 35 gallons 45 gallons

Water Jacket (Sides, Top, Back)

Burn Chamber Dimensions (H x W x D) 30″ x 17″ x 30″ 30″ x 17″ x 30″ 30″ x 17″ x 35″

Burn Chamber Volume 8.5 cu. ft. 8.5 cu. ft. 10 cu. ft.

Log Length 26″ 26″ 32″

Sliding Smoke Baffle Standard Standard Standard

Cast Iron Fuel Loading Door Size

(H x W)

Cast Iron Ash Removal Door Size

(H x W)

Removable Ash Pan Standard Standard Standard

Flue Size 8″ 8″ 8″

Flue Collar Height 55.5″ 55.5″ 55.5″

Leg Height 4″ 4″ 4″

Insulated Cabinet Standard Standard Standard

Pre-wired Electrical Components Standard Standard Standard

1/4″ SA516-70

Steel Plate

15.5″ x 13.5″ 15.5″ x 13.5″ 15.5″ x 13.5″

7.25″ x 11.5″ 7.25″ x 11.5″ 7.25″ x 11.5″

1/4″ A36 Steel

Plate

1/4″ A36 Steel

Plate

Draft Controls Forced (60CFM) Forced (60CFM) Forced (60CFM)

Wall Thermostat Standard Standard Standard

Electrical Requirements

Cast Iron Stationary (Wood) Grates Standard Standard Standard

Cast Iron Shaker Grates Optional Optional Optional

Cast Iron Hearth Plates (Front & Rear) Standard Standard Standard

Domestic Hot Water Coil, 4″

Complies with Standards

*The heating capacity specifications are provided as guidelines only and in no way guarantee the output or

capacity of the units. The actual BTU output depends on the type of fuel being burned and its condition, the

thermostat setting, the draft adjustments and the chimney into which the unit is installed.

Rev 07/13/09 ENERGY KING™ Wood/Coal Boiler Owner’s Manual U. S. 3

115 Volts, 60HZ,

1 Phase, less than

12 Amp Circuit

N/A

ASME Code,

Section 4

115 Volts, 60HZ,

1 Phase, less than

12 Amp Circuit

Optional Optional

N/A N/A

115 Volts, 60HZ,

1 Phase, less than

12 Amp Circuit

Component Description

1. 8″ Chimney Outlet. Top Vent. Venting must

be provided using a lined masonry chimney

or a listed UL103 type HT chimney. The

chimney exhausts smoke and flue gases that

are a natural result of combustion and

provides “draft” to the Boiler. Draft is the

force that moves air from the burn chamber

up through the chimney. See Venting for

further instructions.

Figure 1: Components (Cutaway View)

2. Sliding Smoke Baffle. When open, the

sliding smoke baffle allows smoke and flue

gases to flow into the chimney connector

without restriction. When closed, smoke and

flue gases are diverted around the sliding

smoke baffle, creating a longer path for the

heated air and allowing your boiler to extract

the maximum amount of heat from the fire.

Rev 07/13/09 ENERGY KING™ Wood/Coal Boiler Owner’s Manual U. S. 4

Component Description

3. 2″ Hot Water Outlet. Your ENERGY

KING Wood/Coal Boiler is equipped with

one hot water outlet, located at the top of

the appliance, which supplies heated

water to your heating system.

Cold Water Inlet (Return). (Not pictured)

Cold water inlets return cooled water back to

your Boiler. The ENERGY KING Model

A40EKB Wood/Coal Boiler is equipped with

one 1-1/2″ cold water inlet, located on the rear

of the appliance. ENERGY KING Models

35EKB/45EKB Wood/Coal Boiler are

equipped with two 1-1/4″ cold water inlets,

located on the rear of the appliance.

4. Cast Iron Doors. Heavy cast iron fuel

loading and ash removal doors are

secured to the ENERGY KING using door

pins (4 included). The door gaskets

provide an airtight seal and should be

inspected regularly to ensure that they are

in good condition at all times. The gasket

must be replaced if it becomes damaged

or worn. Do not operate the ENERGY

KING heating appliance with the fuel

loading or ash removal doors open.

5. Cast Iron Hearth Plates. Cast with the

words “Wood” and “Coal” on opposite

sides, these plates help to ensure the

precise amount of combustion air required

to promote the most efficient combustion

for either fuel. ENERGY KING Wood/Coal

Boilers use two cast iron hearth plates—

one at the front of the burn chamber, and

one at the rear (2 included).

Cast Iron Stationary (Wood) Grates. (Not

pictured) This is where you build your wood

fire. If you selected the Shaker Grate option,

the Wood Grates will have been replaced with

Shaker Grates at the factory.

6. Cast Iron Shaker Grates (Optional).

This is where you build your wood or coal

fire. The handle to control the Shaker

Grates is located at the front of the

ENERGY KING, on the left side of the ash

removal door.

7. Firebrick. (9″ x 4-1/2″ x 1-1/4″) 2000-

degree, heat retentive firebricks protect

the sides of the Boiler’s burn chamber.

ENERGY KING A40EKB Boilers and

35EKB Boilers use 12 firebricks (6 on

each side). The ENERGY KING 45EKB

Boiler uses 14 firebricks (7 on each side).

Rev 07/13/09 ENERGY KING™ Wood/Coal Boiler Owner’s Manual U. S. 5

Ash Removal Pan. (Not Pictured) Designed

for easy cleanup of fine ash accumulation. Do

not operate the ENERGY KING heating

appliance with the ash removal door open;

keep it closed except to remove ashes. The

ash removal door gasket provides an airtight

seal and should be inspected to ensure that it

is in good condition at all times. The gasket

must be replaced if it becomes damaged or

worn.

8. Control Box. Controls the Boiler’s

electrical system. The control box is prewired for forced air draft.

9. Combustion Blower. This blower will

supply air for combustion by forcing air

into the burn chamber when your wall

thermostat calls for heat.

24-V Wall Thermostat. (Not Pictured) Tells

your ENERGY KING heating appliance when

your home has cooled below your preferred

temperature. Your draft system is controlled

primarily by your wall thermostat.

10. Aquastat-Immersion Control. Provides

boiler water regulation by controlling the

high and low water-temperature limits.

See Appendix D for further information.

11. Pressure-Temperature Gauge. Shows

the water pressure and water temperature

within your ENERGY KING Wood/Coal

Boiler.

12. Pressure Relief Valve. A safety feature,

the pressure relief valve will release

excess pressure within your ENERGY

KING Wood/Coal Boiler. See Plumbing for

further instructions.

13. Insulated Cabinet. The colored steel

cabinet panels (sides and top) restrain the

foil-backed insulation, allowing maximum

heat from the Boiler to be circulated

through the home’s hydronic heating

system.

14. Legs. Raise the ENERGY KING heating

appliance off the floor to prevent the

accumulation of moisture between the

floor and the bottom of the appliance.

Domestic Hot Water Coil, 4″ (Optional):

(Not Pictured) For heating domestic hot water.

The domestic hot water coil is not available

on ENERGY KING A40EKB Boilers.

What is ASME-Certification?

ENERGY KING Wood/Coal Boiler model A40EKB is built and tested to the exacting standards of

the American Society of Mechanical Engineers (ASME) Code Section 4, Construction of Heating

Boilers, under the National Board ‘H’ stamp, and is independently inspected by Hartford Steam

Boiler Inspection & Insurance Company.

ENERGY KING Wood/Coal Boiler model A40EKB is constructed of certified, high-grade 1/4”

SA516-70 steel plate and is welded by experienced, ASME-certified welders, to ensure safety and

durability. For additional safety, a 30 PSI pressure relief valve is included with every Energy King

boiler. You can rest easy knowing that ENERGY KING A40EKB boilers conform to an

internationally recognized standard for safety and quality.

The following information was taken from www.ASME.org and is reproduced here for informational

purposes only. Please visit www.ASME.org for more information about the ASME and codes and

standards.

Founded in 1880 as the American Society of Mechanical Engineers, ASME is a not-for-profit

professional organization that promotes the art, science and practice of mechanical and

multidisciplinary engineering and allied sciences throughout the world. The core values of

ASME are rooted in its mission to better enable mechanical engineering practitioners to

contribute to the well-being of humankind.

What is a standard?

A standard can be defined as a set of technical definitions and guidelines, “how to”

instructions for designers, manufacturers and users. Standards promote safety, reliability,

productivity and efficiency in almost every industry that relies on engineering components or

equipment. Standards can run from a few paragraphs to hundreds of pages, and are written

by experts with knowledge and expertise in a particular field who sit on many committees.

Are standards mandatory?

Standards are considered voluntary because they serve as guidelines, but do not of

themselves have the force of law. ASME cannot force any manufacturer, inspector, or

installer to follow ASME standards. Their use is voluntary.

Standards become mandatory when they have been incorporated into a business contract

or incorporated into regulations.

What is a code?

A code is a standard that has been adopted by one or more governmental bodies and has

the force of law.

Why are standards effective?

Standards are a vehicle of communication for producers and users. They serve as a

common language, defining quality and establishing safety criteria. Costs are lower if

procedures are standardized; training is also simplified.

Interchangeability is another reason. It is not uncommon for a consumer to buy a nut in

California for a bolt purchased in New Jersey.

ASME.org

. 2009. American Society of Mechanical Engineers.

19 May 2009 <http://www.asme.org>.

About Codes & Standards

Rev 07/13/09 ENERGY KING™ Wood/Coal Boiler Owner’s Manual U. S. 6

Preinstallation Considerations

The ENERGY KING Wood/Coal Boiler is intended for use in residential buildings. Do not install this

heating appliance in a mobile or manufactured home—this can be dangerous and will void your

warranty. This heating appliance has not been tested to meet the strict requirements necessary for

installation into a mobile or manufactured home.

Always check with local authorities and obtain the necessary permits prior to installing this heating

appliance.

Before the position of the Boiler can be decided, a few questions should be considered.

1. Will this heating appliance be used as a

primary (central) boiler, or will it be installed

as an add-on to your existing hydronic

heating system?

2. Will your preferred heating system require

the use of storage tanks or mixing valves?

Some systems, such as in-floor heating,

cannot withstand the high water

temperatures produced by the ENERGY

KING Wood/Coal Boiler and may require

the heated water to be mixed with cool

water before it can be delivered into the

home.

3. Can the ENERGY KING heating appliance

be vented properly?

a. Is your chimney appropriate for this

application? This heating appliance

requires installation into a lined masonry

chimney or an 8″ UL103 Type HT all-fuel

factory-built chimney. Do not connect

this unit to any chimney flue serving

any other appliance. See Venting for

further instructions.

b. Has your chimney been inspected? For

your safety, it is important your chimney

be clean and free from defect or damage

prior to installing your ENERGY KING

heating appliance.

4. This heating appliance may require an

outside air source for combustion air. Will

this be easily accessed in your desired

location?

Finally, do you have a reliable, consistent source of fuel for your ENERGY KING Wood/Coal Boiler?

Please see Fuel Requirements for further information on fuel supply.

5. Are there any local, state or national codes

or regulations governing the use and

placement of this heating appliance?

6. Can the heating appliance be installed

safely?

a. The heating appliance should not be

installed in a location where it could

come into contact with curtains, drapes,

walls, carpeting, or other combustible

surfaces, and must not be installed in a

sleeping room.

b. Will your desired location require floor

protection?

c. The clearances specified in this manual

are minimum clearances. Any reduction

must be approved by the regulatory

authority and is not recommended by

RJM Manufacturing, Inc.

7. How close is the electrical source? The

power source must conform to the

requirements shown in Specifications.

8. Will the heating appliance be easily

accessible for cleaning, refueling,

maintenance, and repair?

9. Are there any structural reasons why the

heating appliance cannot be placed where

you want?

Rev 07/13/09 ENERGY KING™ Wood/Coal Boiler Owner’s Manual U. S. 7

Fuel Requirements

BURN AIR-DRIED WOOD, OR ANTHRACITE OR BITUMINOUS COAL ONLY

Risk of Fire: Do not store fuel or other combustible

material within the marked installation clearances.

It is important to use fuel that is clean, dry and consistent. Solid-fuel boilers, such as your ENERGY

KING Wood/Coal Boiler, naturally produce ash as a byproduct of the burning process. Even with

the ENERGY KING heating appliance’s highly efficient design, your heating appliance will still

produce some amount of ash which will need to be cleaned periodically. The type and quality of fuel

you burn affects the amount of ash produced and the performance of your heating appliance. To

assist you in determining which fuel to use, here are some guidelines to consider:

Burning wood for heat is as old as civilization itself. More than any other major fuel, wood provides

us with energy independence – an easily available, locally produced and renewable source of heat

on which we can rely.

• The ENERGY KING Wood/Coal Boiler has

been tested for operation with air-dried

wood.

• Wood should be seasoned (dried) for at

least 12 months before burning. Properly

seasoned wood should have about 20% 25% moisture content. To properly season

wood, split the logs as soon as possible

and loosely stack them in a dry spot for at

least 12 months.

You should not burn wet or green wood in

your Boiler. Burning wet or green wood in

your Boiler will not only reduce the

efficiency of your appliance, but also

increases the risk of dangerous creosote

build-up in your appliance and chimney.

• Softwoods, such as pine and fir, are easily

ignited and burn rapidly with hot flames.

With softwoods, you will spend more time

reloading your ENERGY KING Wood/Coal

Boiler, and will have much more difficulty

achieving an overnight burn. For a longer

lasting fire, it is best to use more dense

hardwoods.

• Ideally, you should burn a mixture of

hardwoods and softwoods, using the hotter,

faster burning softwoods to start your fire,

and the denser hardwoods to maintain a

longer-lasting fire.

WOOD

• With this in mind, choosing the kind of

firewood that is best for you depends on

what is available in your area. If hardwoods

are unavailable in your area, you can

control the burn rate by using larger pieces

of wood.

• DO NOT BURN: Treated wood, colored

paper, garbage, cardboard, solvents, or

trash—burning these may result in toxic

fumes, or produce soot and large flakes of

char or fly ash. Burning treated wood,

colored paper, garbage, cardboard,

solvents or trash can be dangerous and will

void your ENERGY KING warranty.

• DANGER – Risk of Fire or Explosion: Do

not burn garbage, gasoline, naphtha, drain

or engine oil, or other flammable liquids or

inappropriate materials in this heating

appliance.

Storage

• Store all fuel in a dry location away from

the elements. Never burn wet or green

wood.

• Do not store fuel within the heating

appliance installation clearances or within

the space required for refueling, ash

removal and other routine maintenance

operations.

Rev 07/13/09 ENERGY KING™ Wood/Coal Boiler Owner’s Manual U. S. 8

Fuel Requirements

BURN AIR-DRIED WOOD, OR ANTHRACITE OR BITUMINOUS COAL ONLY

Risk of Fire: Do not store fuel or other combustible

material within the marked installation clearances.

One of the world’s most widely-used fuel sources, coal can provide the energy independence and

low fuel prices sought by owners of solid-fuel heating appliances.

• The ENERGY KING Wood/Coal Boiler has

been tested for operation with anthracite

(hard) or bituminous (soft) coal.

• Anthracite: Also known as Hard Coal,

anthracite is a hard, lustrous coal with a

high carbon content that burns with a clean

blue, nearly smokeless, flame.

• Bituminous: Also known as Soft Coal,

bituminous coal is a soft type of coal that

has a high sulfur content and burns with a

yellow, smoky flame.

• Bituminous coal tends to contain more

impurities and sulfur than anthracite coal,

which may decrease the expected lifespan

of your ENERGY KING solid-fuel heating

appliance and its components. If you

choose to burn bituminous coal, be sure to

select only high-grade bituminous coal.

• Coal Size: Your ENERGY KING

Wood/Coal Boiler is designed to use coal

that is Nut size or larger.

COAL

• DO NOT BURN: Treated wood, colored

paper, garbage, cardboard, solvents, or

trash—burning these may result in toxic

fumes, or produce soot and large flakes

of char or fly ash. Burning treated wood,

colored paper, garbage, cardboard,

solvents or trash can be dangerous and

will void your ENERGY KING warranty.

• DANGER – Risk of Fire or Explosion:

Do not burn garbage, gasoline, naphtha,

drain or engine oil, or other flammable

liquids or inappropriate materials in this

heating appliance.

Storage

• Store all fuel in a dry location away from

the elements. Never burn wet coal.

• Do not store fuel within the heating

appliance installation clearances or

within the space required for refueling,

ash removal and other routine

maintenance operations.

Rev 07/13/09 ENERGY KING™ Wood/Coal Boiler Owner’s Manual U. S. 9

Installation

Risk of Fire:

• Do not operate with flue draft exceeding .06 in. (14.95 Pa)

water column.

• Do not operate with fuel loading or ash removal doors open.

• Do not store fuel or other combustible material within marked

installation clearances.

• Inspect and clean flues and chimney regularly.

The installation of any solid fuel heating appliance is not a do-it-yourself project. The

ENERGY KING Wood/Coal Boiler should be installed by a qualified installer with specific

knowledge of hydronic heating systems. Check with your fire department and building inspector for

local, state, and federal codes and regulations regarding installation.

Solid-fuel heating appliance related fires are caused almost exclusively by installation, operation, or

maintenance errors. A smoke detector in “working” condition must

KING solid-fuel heating appliance installation—this is the most inexpensive insurance you can buy!

For additional safety, RJM Manufacturing, Inc. recommends installing working smoke detectors and

a listed carbon monoxide warning device in the living areas of the home.

The ENERGY KING Wood/Coal Boiler is designed to be used in conjunction with a listed gas- or

oil-fired boiler, or as a central boiler.

Zones

A “heat dump” zone is required for all

installations. The purpose of this zone is to

circulate heated water away from the boiler

when no other zones are calling for heat. In

this way it will prevent your ENERGY KING

Wood/Coal Boiler from overheating. However,

as a safety feature, if your Boiler should

overheat or build up excess pressure, it will

trigger the pressure relief valve which will

release water, thus relieving pressure. See

Plumbing for further instructions.

In-floor Heating

Many newer homes feature in-floor heating.

The ENERGY KING Wood/Coal Boiler may not

be suitable for such applications as it produces

water temperatures in excess of 185-degrees,

which is much greater than can be withstood by

most standard in-floor heating installations.

To use the ENERGY KING Wood/Coal Boiler

with in-floor heating, a mixing valve may be

required to lower the water temperature before

it is delivered to your in-floor heating system.

Rev 07/13/09 ENERGY KING™ Wood/Coal Boiler Owner’s Manual U. S. 10

Do not connect the ENERGY KING heating appliance

to any chimney flue serving any other appliance.

General Requirements

be a part of every ENERGY

Placement

• Floor Protection

Floor protection must be provided because

of possible spillage of ashes and burning

fuel. The ENERGY KING Wood/Coal Boiler

must be installed on a non-combustible floor

or 3/8-inch thick fireproof millboard or

equivalent.

The non-combustible material must be

placed underneath the heating appliance,

and must extend at least 18 inches on all

sides of the heating appliance.

Additionally, the non-combustible material

must extend at least 18 inches on either side

of the chimney connector.

Consult your local ENERGY KING dealer for

possible sources of non-combustible floor

protection material acceptable for use with

your ENERGY KING Wood/Coal Boiler.

Installation

• As Primary Boiler

Locate the ENERGY KING Wood/Coal

Boiler as close to the new or existing

chimney as possible. The ENERGY KING

heating appliance should be placed so that

you can easily complete operation and

maintenance procedures.

Locate the 24-V Wall Thermostat provided

with your ENERGY KING heating appliance

in the living area of the home. Your draft

system is controlled primarily by the wall

thermostat, so proper placement and

installation of the wall thermostat is crucial.

Strictly adhere to all requirements

pertaining to clearances to combustibles,

combustion air, venting system, draft

control, and thermostat installation.

• As Add-On Boiler

The ENERGY KING Wood/Coal Boiler is

designed to be used in conjunction with a

listed gas- or oil-fired boiler, but not all

boilers will accept an add-on application.

Some small boilers may not be used in an

add-on installation.

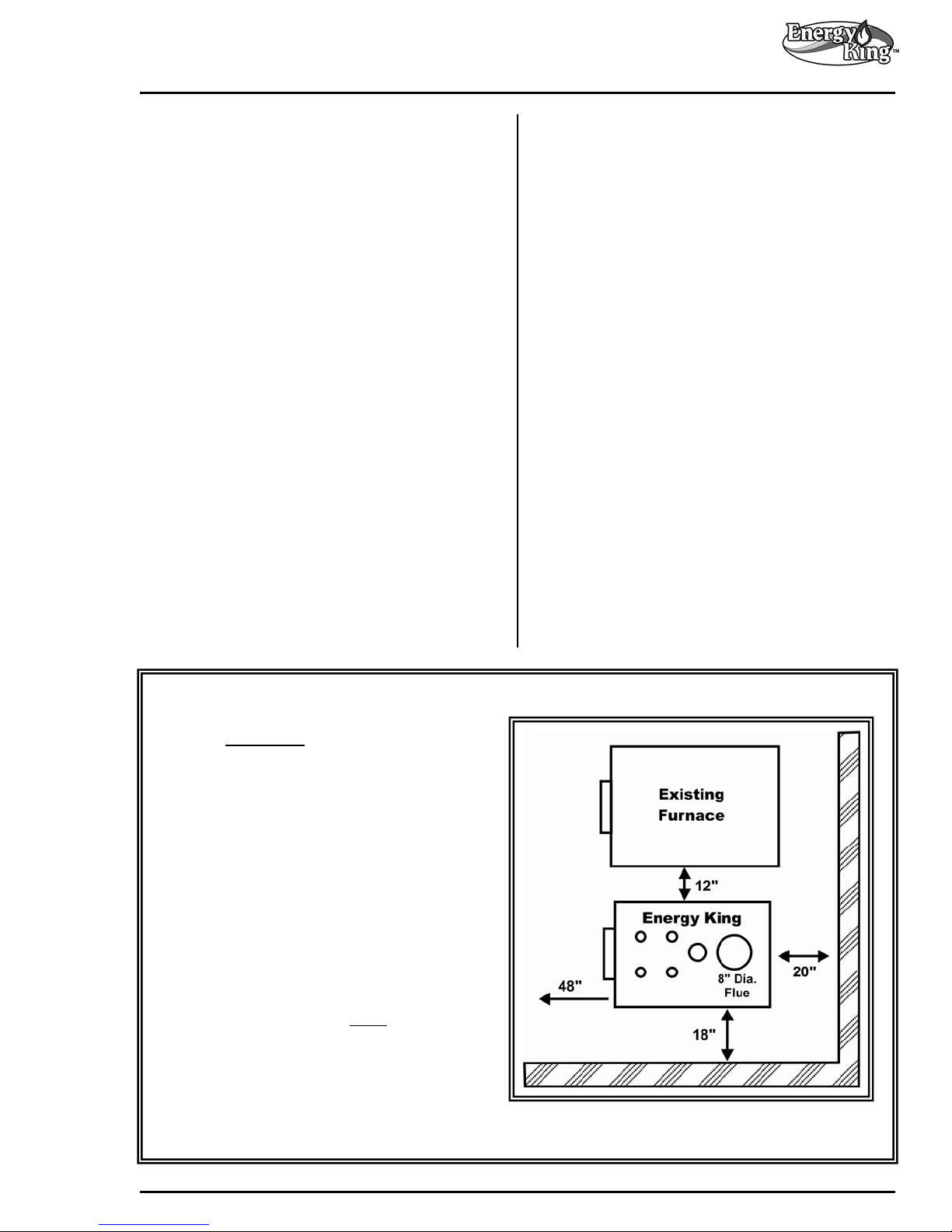

Clearances to Combustibles

• Sides: The ENERGY KING Wood/Coal

Boiler must have

from the sidewall of the ENERGY KING

Wood/Coal Boiler to combustibles.

• Front: Leave a minimum clearance of 48

inches in front of your ENERGY KING

heating appliance. This is for safe, easy

loading and cleaning of your ENERGY

KING heating appliance.

• Rear: The minimum clearance from the

rear of the ENERGY KING Wood/Coal

Boiler to combustibles is 20 inches.

• Top: The minimum clearance from the

top of the ENERGY KING Wood/Coal

Boiler to combustibles is 18 inches.

• Stovepipe: Stovepipe must

minimum of 18 inches to combustibles.

• Additionally, when using your ENERGY

KING Wood/Coal Boiler as an add-on, a

12-inch minimum clearance is required

between the ENERGY KING Wood/Coal

Boiler and your existing boiler.

clearances of 18 inches

have a

Before installing your ENERGY KING

Wood/Coal Boiler, consult your heating

contractor and local, state and national

building codes and regulations to determine

if your existing hydronic heating system is

compatible with the ENERGY KING

Wood/Coal Boiler.

When using your ENERGY KING

Wood/Coal Boiler in an add-on application,

locate the ENERGY KING Wood/Coal

Boiler as close to the new or existing

chimney as possible, and as close to your

existing boiler as practical. However a

minimum clearance of 12-inches is required

between your existing boiler and your

ENERGY KING Wood/Coal Boiler.

Locate the 24-V Wall Thermostat provided

with your ENERGY KING heating appliance

in the living area of the home, near your

existing thermostat. Your draft system is

controlled primarily by the wall thermostat,

so proper placement and installation of the

wall thermostat is crucial.

Figure 2: Clearances to Combustibles

Rev 07/13/09 ENERGY KING™ Wood/Coal Boiler Owner’s Manual U. S. 11

Installation

Assembling Your ENERGY KING Wood/Coal Boiler

The entire installation should be planned before putting the Boiler in place to ensure compliance

with all the requirements outlined in the owner’s manual.

Your new ENERGY KING Wood/Coal Boiler will have been shipped on a pallet with several boxed

components that will need to be assembled prior to installation. Please see “Components” for a list

of everything that was shipped along with your ENERGY KING Wood/Coal Boiler.

Once your Boiler is placed in your desired location:

1. Remove the protective plastic coating from

the outer cabinet of the heating appliance

before assembling.

2. Cast Iron Hearth Plates. Position front and

rear cast iron hearth plates in burn chamber.

Your primary type of fuel (wood or coal) will

determine how to position the hearth plates.

The purpose of proper location is to

introduce the precise amount of combustion

air into the burn chamber to promote the

most efficient combustion for either fuel.

The words “Wood” and “Coal” are cast into

the hearth plates on opposite sides.

a. If you are going to burn wood, position

the hearth plates with the word “Wood”

facing out, not into the burn chamber.

b. If you plan to primarily burn coal,

position the hearth plates with the word

“Coal” facing out.

3. Firebrick. The firebrick in your ENERGY

KING heating appliance will have been

installed at the factory; however they may

have shifted during shipment. If adjustments

are needed, position the firebrick by standing

up on end on the left and right sides of the

burn chamber.

ENERGY KING A40EKB and 35EKB Boilers

use 12 firebricks (6 on each side). ENERGY

KING 45EKB Boilers use 14 firebricks (7 on

each side).

4. Cast Iron Doors. Mount the fuel loading

door and ash removal door on the front of

the heating appliance and secure with the

enclosed door pins (4 included).

5. Control Box.

a. Remove the control box cover. See

Figure 3: Control Box for Forced Air Draft.

b. Mount the control box on the lower left

side of the heating appliance using the

screws provided.

Do not connect power to your ENERGY

KING Wood/Coal Boiler until the

installation is complete.

Rev 07/13/09 ENERGY KING™ Wood/Coal Boiler Owner’s Manual U. S. 12

Installation

6. Draft System.

a. Insert the conduit leading from your draft system

into the control box and tighten screw to secure.

b. Mount the pre-wired forced air draft blower to the

draft opening located next to the ash removal door

on the lower left front of the Boiler and secure

using the bolts found on the draft opening.

7. Pressure-Temperature Gauge. Insert the PressureTemperature Gauge into the right-front receptacle

located on top of the Boiler.

8. Pressure Relief Valve. Insert the Pressure Relief

Valve into either the left-middle or right-middle

receptacle located on the top of the boiler. The

Pressure Relief Valve must be plumbed with a

discharge tube that empties into a floor drain. See

Plumbing for further instructions.

Figure 3: Control Box for Forced Air Draft

Figure 4: Forced Air Draft Blower

Rev 07/13/09 ENERGY KING™ Wood/Coal Boiler Owner’s Manual U. S. 13

Installation

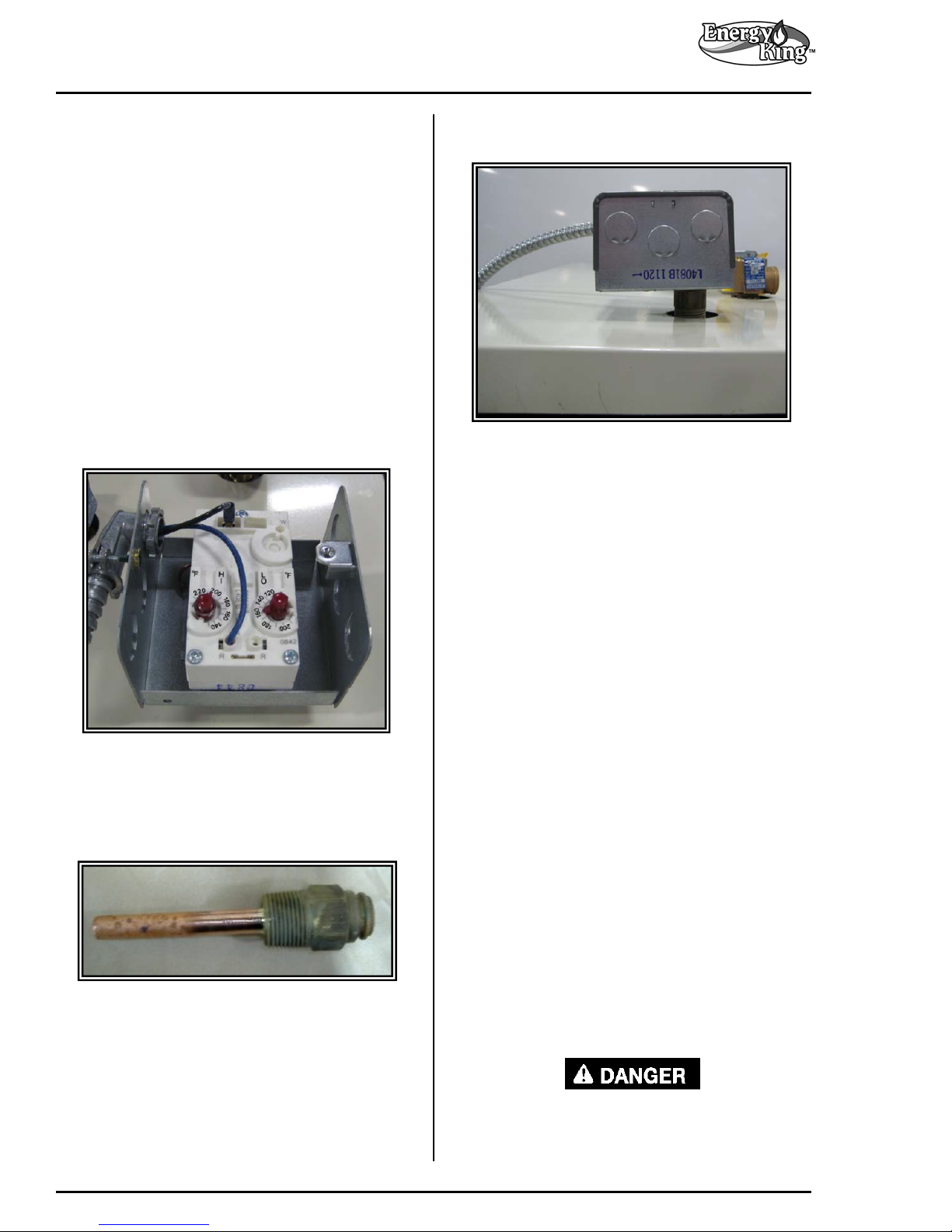

9. Aquastat-Immersion Control.

a. Remove the cover of the prewired

Aquastat-Immersion Control to adjust the

High and Low temperature limits.

i. High Limit. Set the High Limit pointer to

the temperature at which contacts are

to open to prevent the boiler from

overheating. Normal setting for the High

Limit is 185º. Always set the high limit

20º or more above the low limit.

ii. Low Limit. Set the Low Limit pointer to

the lowest water temperature you would

like the boiler to maintain. Normal

setting is 160º. Always set the high limit

20º or more above the low limit.

Figure 5: Aquastat-Immersion Control

Blue

Black

b. Insert the probe well into the left-front

receptacle located on the top of the Boiler

and tighten to secure.

Figure 6: Probe Well

c. Squeeze the entire tube of heat-

conductive grease (included) into the

probe well, and then insert the AquastatImmersion Control probe into the probe

well, and secure.

Figure 7: Aquastat-Immersion Control,

10. 4″ Domestic Hot Water Coil (Optional).

a. Unscrew & remove the 4″ plug located at

the upper left on the back of the ENERGY

KING Wood/Coal Boiler model 35EKB or

45EKB.

b. Apply pipe joint compound (not included) to

the threads of the 4″ domestic hot water

coil.

c. Insert the 4″ domestic hot water coil into

the opening at the upper left on the back of

the ENERGY KING Wood/Coal Boiler and

turn clockwise until tightened.

d. Connect your domestic water supply

according to the coil manufacturer’s

instructions.

11. 24-V Wall Thermostat. Locate the 24-V Wall

Thermostat provided with your ENERGY

KING heating appliance in the living area of

the home and install according to the

thermostat manufacturer’s installation

instructions (Supplement B).

12. Wiring. Do not connect power to your

ENERGY KING Wood/Coal Boiler until the

installation is complete. Once you’ve

completed the installation of your ENERGY

KING Wood/Coal Boiler, you may connect

your 110V power supply in to the left side of

the control box. Please see Appendix A:

Wiring Diagram.

panel or breaker box before servicing

ENERGY KING Wood/Coal Boiler.

Risk of electric shock.

Disconnect power at the service

Mounted

Rev 07/13/09 ENERGY KING™ Wood/Coal Boiler Owner’s Manual U. S. 14

Installation

Combustion Air Requirements

The ENERGY KING Wood/Coal Boiler must have a minimum supply

All fuel-burning appliances must have air (oxygen) for proper combustion. The incomplete

combustion that takes place when a solid-fuel appliance is “air-starved” causes carbon monoxide

(CO) production in quantities that can be dangerous inside a building. Combustion air from outside

may need to be brought in to prevent “air starvation”. Although an outside air source is strongly

recommended for all installations, it may be necessary if:

• The heating appliance does not draw steadily, smells, experiences smoke rollout, burns poorly, or backdrafts, whether or not there is combustion present.

Failure to provide adequate combustion air can

lead to increased carbon monoxide production

and increased emissions of combustion gases

into the building, which may cause death or

serious injury.

of 70 cubic feet of air per minute.

• Any of the above symptoms are alleviated by opening a window slightly on a

calm day.

• The house is equipped with a well-sealed vapor barrier and tight fitting windows

and/or has any powered devices which exhaust house air, such as clothes

dryers.

• A ventilation system is installed in the house.

Consult a qualified boiler installer to analyze whether the air supply in your installation environment

is adequate.

Rev 07/13/09 ENERGY KING™ Wood/Coal Boiler Owner’s Manual U. S. 15

Installation

Venting System

• Failure to provide correct chimney venting can lead to increased

carbon monoxide production and increased emissions of

combustion gases into the building, which may cause death or

serious injury.

• Do not connect the ENERGY KING heating appliance to any

chimney flue serving any other appliance.

• Risk of Fire: Inspect and clean flues and chimney regularly.

• Risk of Fire: Do not operate with the flue draft exceeding .06″

(14.95 Pa) water column.

Consult a qualified boiler installer, your local building inspector and your fire

officials to make sure the chimney and all connections conform to all local, state and

national codes and regulations.

Your venting system is an extremely important

part of any solid-fuel heating appliance

installation and has two key functions:

1. To exhaust smoke and flue gases which

are the natural result of combustion.

2. To provide “draft.” The draft, along with

your combustion blower, provides a

continuous supply of fresh air for proper

combustion.

A chimney connector and chimney make up the

venting system and must be properly installed

and maintained to protect against a fire.

Consult a chimney and venting specialist.

The ENERGY KING Wood/Coal Boiler requires

installation into a lined masonry chimney or an

8-inch listed UL103 type HT all-fuel factory-built

chimney. Minimum 24 gauge black steel

chimney connector is required. An existing

chimney must be cleaned and inspected to be

sure it is clean and free from defect or damage.

All connections must comply with NFPA

Standard 211 and all applicable building codes

and regulations.

When installing a factory-built chimney, follow

all installation instructions provided by the

chimney manufacturer.

For best performance, RJM Manufacturing, Inc.

recommends using insulated chimney rather

than triple wall or air cooled chimney.

Important venting installation clearances and

points for proper operation and safety:

• The connection from the ENERGY KING

Wood/Coal Boiler to the chimney must be

made using 8″ black steel material with a

minimum 24 gauge. Do not use galvanized

steel. See Chimney Connector.

• A minimum distance of 18 inches must be

maintained between the chimney connector

and combustible ceiling surfaces.

• A minimum of 18 inches must be maintained

between the chimney connector and the

backwall, and 20 inches between the

connector and sidewalls.

• Secure all connector pipe joints with at least

three sheet metal screws.

• Avoid using more than two elbows in

connecting the heating appliance to the

chimney.

• Any horizontal runs of connector pipe should

have a minimum rise of 1/2-inch per linear

foot. Use extra support hangers or brackets

every three feet if it is absolutely necessary

to have a run of more than six feet, which is

not recommended.

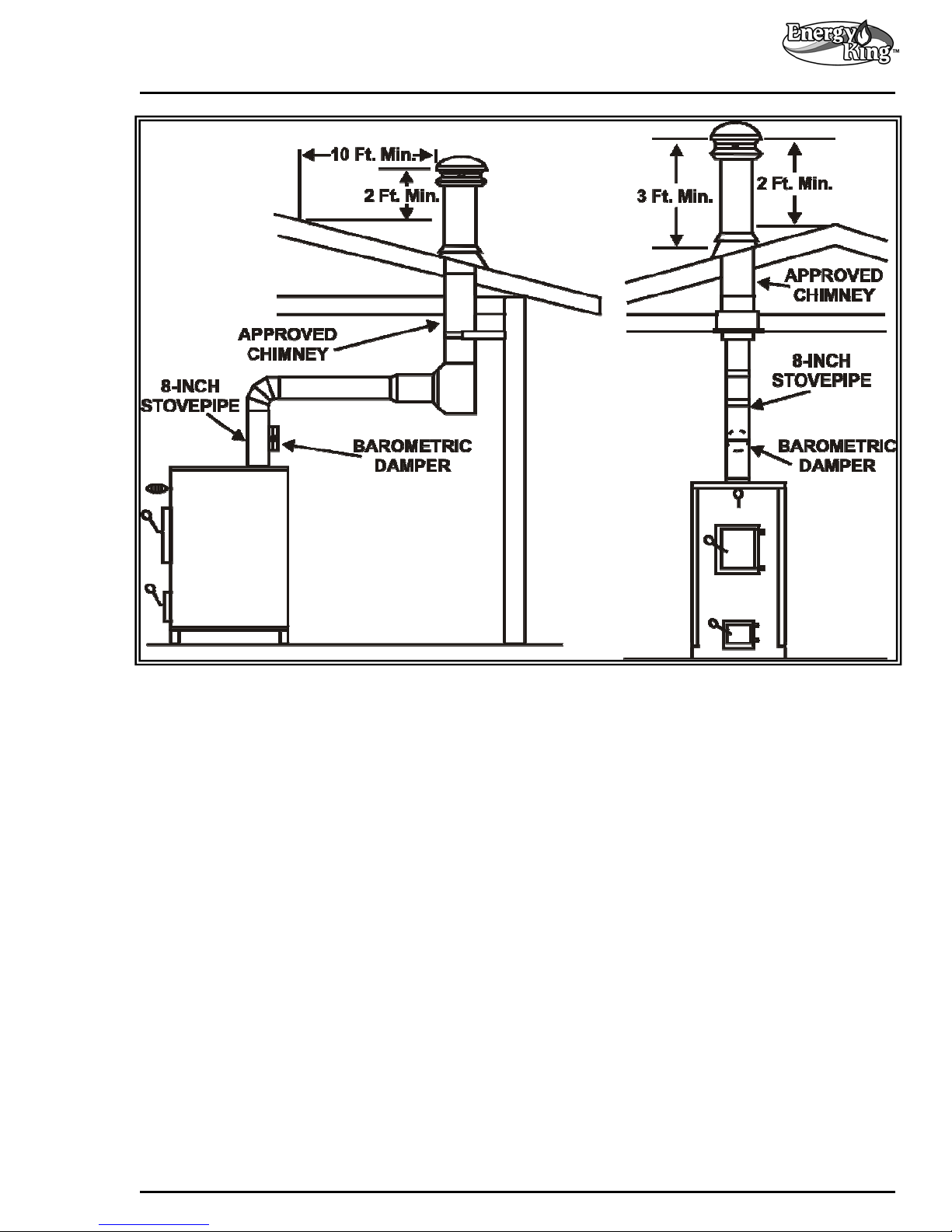

• The chimney must be at least 3 feet higher

than the highest point where it passes

through the roof, and at least 2 feet higher

than the highest part of the roof or structure

that is within 10 feet of the chimney,

measured horizontally. Please refer to Figure

8: Venting Requirements.

Rev 07/13/09 ENERGY KING™ Wood/Coal Boiler Owner’s Manual U. S. 16

Installation

The Chimney must be at least 3 feet higher than the highest point where it passes through the roof,

and at least 2 feet higher than the highest part of the roof or structure that is within 10 feet of the

chimney, measured horizontally.

.

Figure 8: Venting Requirements

Rev 07/13/09 ENERGY KING™ Wood/Coal Boiler Owner’s Manual U. S. 17

Loading...

Loading...