Energx Dyna TF6000E, Dyna TF4500E Owner's Manual

OWNERS MANUAL

60707-023

EA8EL)fiw

- - -

-

-

-

-

-

-

-----

--

---

-

--

-

--

---

-

---

-

CORPORATION

READ AND UNDERSTAND ALL INSTRUCTIONS IN

THE MANUAL BEFORE STARTING AND OPERATING

THE GENERATOR SET.

USING THIS MANUAL

Congratulations on your choice of an ENERGX generator set. You have selected

a

high-quality, precisionengineered generator set designed and tested to give

you years of satisfactory portable service.

To get the best performance from your new engine

generator set, it is important that you carefully read and

follow the operating instruction in this manual.

Should you experience a problem please follow the

"Things To Check" near the end of this manual. The

warranty in the back of this manual describes what you

can expect from ENERGX should you need service

assistance in the future.

PROPER USE AND INSTALLATION

You must be sure your new engine generator set is:

*

Properly serviced before starting

Operated in a well ventilated area

*

Exhaust gases are dispersed safely

Wired by a qualified electrician

Operated only for its designed purposes

*

Used only by operators who understand its

operation

Properly maintained

TABLE

OF CONTENTS

PAGE

INTRO

......................................

I

GUIDE TO PRODUCT SAFETY

................

A1

BASIC INFORMATION

.......................

B1

Specifications..

.........................

B1

Intended Uses

...........................

B1

Restricted Uses

.........................

B1

Unit Capabilities.

........................

B1

Where is Everything Located

..............

82

PREPARING THE UNIT

......................

C1

Unpacking the unit

......................

C1

Oil Requirements

........................

C2

Fuel Requirements.

......................

C2

Battery Installation.

......................

C3

BASIC OPERATION

.........................

Dl

Operating Procedure

.....................

Dl

Connecting the Loads..

..................

D3

Conserver operation

.....................

D3

Low Oil Shutdown Operation

..............

D3

INSTALLATION

.............................

El

Wiring

.................................

El

OPERATOR MAINTENANCE

..................

F1

Engine Care

............................

F1

Generator Care

..........................

F1

Unit Cleaning

...........................

F1

Things to Check before you call for Service . F2

.......................

ENERGX WARRANTY

COPY YOUR MODEL AND SERIAL

NUMBER HERE

No other ENERGX generator has the same serial number as yours. It is important that you record the number

and other vital information here, if you should ever need

to contact us on this unit it will help us to respond to

your needs faster.

MODEL

................

SERIAL NUMBER..

......

DATE PURCHASED

......

DEALER.

...............

GUIDE

TO

PRODUCT SAFETY

This engine generator set has been designed and

manufactured to insure your personal safety. Improper

use can result in potential deadly hazards; from electrical shock, exhaust gas asphyxiation, or fire. Please

read all safety instructions carefully before installation

or use. Keep these instructions handy for future reference. Take special note and follow all warnings on the

unit and in the manuals.

CAUTION:

Possible Damage to Equip-

ment. CAUTION notes indicate any con-

[-]

dition or practice, which if not strictly

observed or remedied, could result in

damage or destruction of the equipment.

WARNING:

Personal Danger. WARNING notes indicate any condition or

practice, which

if

not strictly observed,

could result in personal injury or possible loss of life.

a

ELECTRIC SHOCK

-

The output voltage present in this equipment can cause a fatal electric

shock. This equipment must be operated by a

responsible person.

A. Do not allow anyone to operate the genera-

tor without proper instruction.

B. Guard against electric shock.

C. Avoid contact with live terminals or receptacles.

D. Use extreme care

if

operating this unit in rain or

snow.

E.

Use only three-prong grounded receptacles and

extension cords.

F. Be sure the unit is properly grounded to an ex-

ternal ground rod driven into the earth.

2.

FIRE HAZARD

-

Gasoline and other fuels always pre-

sent a hazard of possible explosion

andlor fire.

A. Do not refuel when the engine is running or hot.

Allow the engine to cool at least two minutes

before refueling.

B. Keep fuel containers out of reach of children.

C. Do not smoke or use open flame near the

generator set or fuel tank.

D. Keep a fire extinguisher nearby and know its pro-

per use. Fire extinguishers rated ABC by NFPA

are appropriate.

E. Store fuel only in an approved container, and on-

ly in a well-ventilated area.

3.

DEADLY EXHAUST GAS

-

Exhaust fumes from any

gasoline engine contain carbon monoxide, an odorless and deadly gas that must be mixed with fresh

air.

A. Operate only in well ventilated areas.

B

.

Never operate indoors.

C. Never operate the unit in such a way as to allow

exhaust gases to seep back into closed rooms (i.e.

through windows, walls or floors).

4.

NOISE HAZARD

-

Excessive noiseis not only tiring, but continual exposure can lead to loss of

hearing.

.

A .Use hearing protection equipment when working

around this equipment for long periods of time.

B. Keep your neighbors in mind when permanently

installing this equipment.

5.

CLEANLINESS

-

Keep the generator and surrounding

area clean.

A. Remove all grease,

ice,s.now or materials that

create slippery conditions around the unit.

B.Remove any rags or other material that could

create potential fire hazards.

C.Carefully wipe up any gas or oil spills before start-

ing the unit.

D .Never allow leaves or other flammable material to

build up around the engine exhaust area.

6.

SERVICING EQUIPMENT

-

All service, including the

installation or replacement of service parts, should

be performed only by a qualified technician.

A .Use only factory approved repair parts.

B.Do not work on this equipment when fatigued.

C.Never remove the protective guards, cover or

receptacle panels while the engine is running.

D.Use extreme caution when working on electrical

components. High output voltages from this equip-

ment can cause serious injury or death.

E. When servicing this unit always avoid hot mufflers,

exhaust manifolds, and engine parts. They all can

cause severe burns instantly.

F. Installing and wiring a home-standby generator is

not a "do it yourself" project. Consult a qualified,

licensed electrician or contractor. The installation

must comply with all national, state, and local

codes.

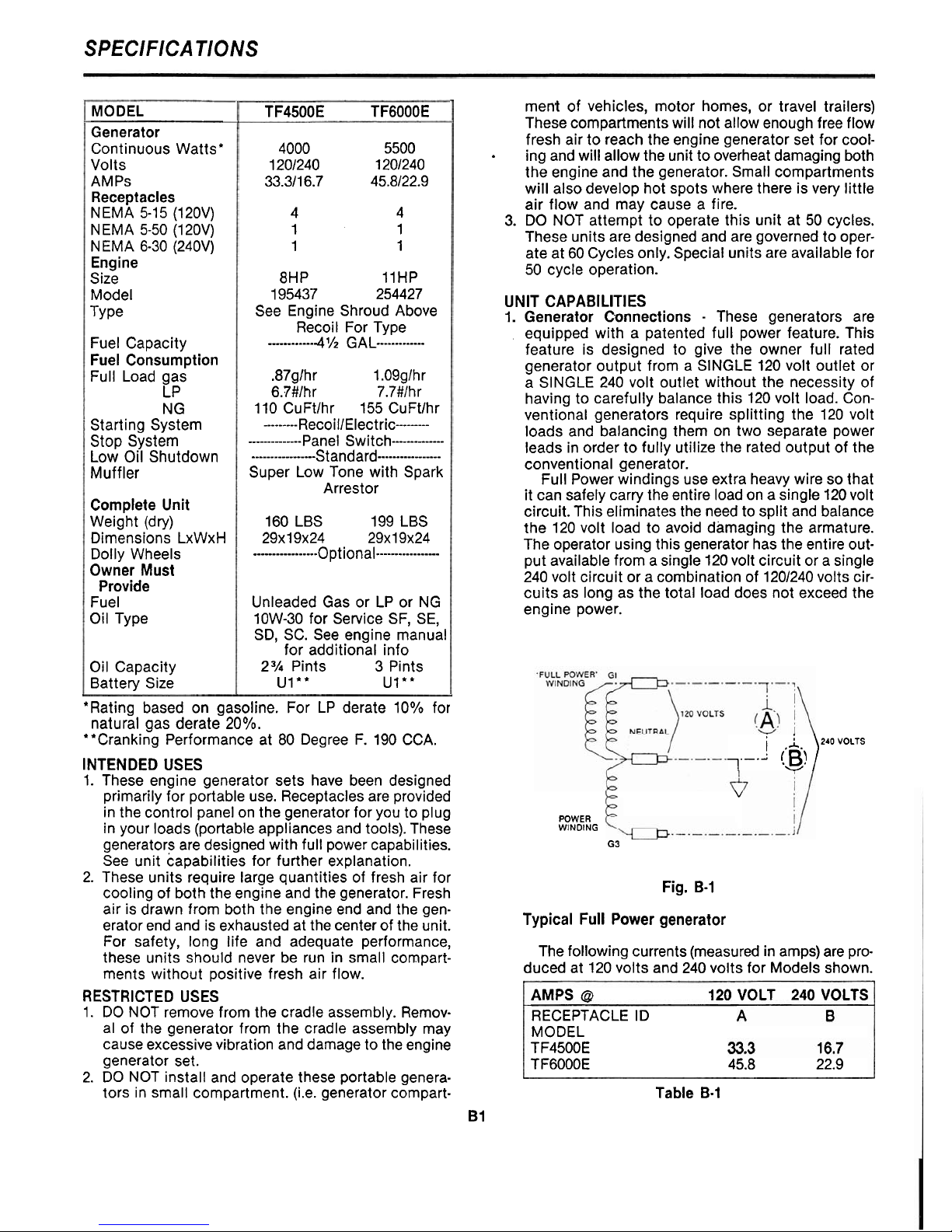

SPEClFlCA TIONS

*Rating based on gasoline. For LP derate 1O0/0 for

natural gas derate 20%.

**Cranking Performance at 80 Degree F. 190 CCA.

MODEL

Generator

Continuous Watts'

Volts

AM Ps

Receptacles

NEMA 5-15 (120V)

N EMA 5-50 (1 20V)

N

EMA 6-30 (240V)

Engine

Size

Model

TY pe

Fuel Capacity

Fuel Consumption

Full Load gas

LP

NG

Starting System

Stop System

Low Oil Shutdown

Muffler

Complete Unit

Weight (dry)

Dimensions

LxWxH

Dolly Wheels

Owner Must

Provide

Fuel

Oil Type

Oil Capacity

Battery Size

INTENDED USES

1.

These engine generator sets have been designed

primarily for portable use. Receptacles are provided

in the control panel on the generator for you to plug

in your loads (portable appliances and tools). These

generators are designed with full power capabilities.

See unit capabilities for further explanation.

2. These units require large quantities of fresh air for

cooling of both the engine and the generator. Fresh

air is drawn from both the engine end and the generator end and is exhausted at the center of the unit.

For safety, long life and adequate performance,

these units should never be run in small compartments without positive fresh air flow.

TF4500E TF6000E

4000 5500

1201240 1201240

33.311 6.7 45.8122.9

4

4

1 1

1 1

8HP 11HP

195437 254427

See Engine Shroud Above

Recoil For Type

----.--em--m-

41/* GAL

------------.

.87glhr 1.09glhr

6.'/#lhr 7.7#lhr

110CuFtlhr 155CuFtlhr

---------

RecoillElect ric---------

--------------

Panel Switch

--------------

-----------------

Standard

-----------------

Super Low Tone with Spark

Arrestor

160 LBS 199 LBS

29x19~24 29x1 9x24

.----------.----.

Optional

-----------------

Unleaded Gas or LP or NG

10W-30 for Service SF, SE,

SD, SC. See engine manual

for additional info

23/4 Pints

3

Pints

Ul*' Ul*'

RESTRICTED USES

1.

DO NOT remove from the cradle assembly. Removal of the generator from the cradle assembly may

cause excessive vibration and damage to the engine

generator set.

2. DO NOT install and operate these portable generators in small compartment.

(i.e. generator compart-

ment of vehicles, motor homes, or travel trailers)

These compartments will not allow enough free flow

fresh air to reach the engine generator set for cool-

-

ing and will allow the unit to overheat damaging both

the engine and the generator. Small compartments

will also develop hot spots where there is very little

air flow and may cause a fire.

3.

DO

NOT attempt to operate this unit at 50 cycles.

These units are designed and are governed to operate at 60 Cycles only. Special units are available for

50 cycle operation.

UNIT CAPABILITIES

1. Generator Connections - These generators are

equipped with a patented full power feature. This

feature is designed to give the owner full rated

generator output from a SINGLE 120 volt outlet or

a SINGLE 240 volt outlet without the necessity of

having to carefully balance this 120 volt load. Conventional generators require splitting the 120 volt

loads and balancing them on two separate power

leads in order to fully utilize the rated output of the

conventional generator.

Full Power windings use extra heavy wire so that

it can safely carry the entire load on a single 120 volt

circuit. This eliminates the need to split and balance

the 120 volt load to avoid damaging the armature.

The operator using this generator has the entire output available from a single 120 volt circuit or a single

240 volt circuit or a combination of 1201240 volts circuits as long as the total load does not exceed the

engine power.

j

,j.

240

VOLTS

!

B!

)

1-

v

v

POWER

WINDING

G3

Fig. B-1

Typical Full Power generator

The following currents (measured in amps) are pro-

duced at 120 volts and 240 volts for Models shown.

AMPS

@

120 VOLT 240 VOLTS

RECEPTACLE

ID

MODEL

TF4500E

TF6000E 45.8 22.9

Table B-1

B 1

SPECIFICATIONS

(continued)

2.

Starting Electric Motors - Electric motors require

much more current (amps) to start them than to run

them. Some

moJors, particularly low cost split-phase

motors are very-hard to start and require 5 to 7 times

as much current to start them as to run them. Capacitor motors are easier to start and usually require

2 to 4 times as much current to start them as to run

them. Repulsion Induction motors are the easiest to

start and usually require

1% to 2% times as much

to start them as to run them.

Most fractional horsepower motors take about the

same amount of current to run them whether they

are of Repulsion-Induction (RI), Capacitor (Cap), or

Split-Phase (SP) type. The chart below shows the approximate current required to start and run various

types of sizes of 120 volt 60 cycle electric motors

under average load conditions.

RUNNING

Sf

ARTlNG AMPS

HP AMPS SP CAP

R

I

116 3.2

16 TO 22 6 TO 13

5 TO 8

114 4.5

22TO32

9TO18 7TO12

113 5.2

26TO35 10TO21

8TO17

112 7.2

NOT MADE 14 TO 29

11 TO 18

1 13.0

NOT MADE 26 TO 52

20 TO 33

and no harm is done. Under these conditions the

motor may revolve a few times when it is first turned

on, and then stop.

On the other hand, suppose an electric motor that

requires just a little more output than the generator

can produce is connected to it. It will run but will not

reach a high enough speed for the centrifugal switch

to disconnect the starting winding. The generator

output voltage, instead of being 120, may drop to 70

or 80 volts. RUNNING THE GENERATOR UNDER

THESE CONDITIONS MAY RESULT IN BURNING

OUT THE GENERATOR ARMATURE AS WELL AS

THE MOTOR WINDINGS.

Because the heavy surge of current required for

starting motors is required for only an instant, the

generator will not be damaged

if

it can bring the

motor up to speed in a few seconds of time. If difficulty is experienced in starting motors, turn all

other electrical loads off and if possible reduce the

load on the electric motor.

3.

Motor Starting Capacity - listed below you will find

the motor starting capability of your engine generator set.

The figures given above are for average load such

as a blower or fan. If the electric motor is connected

to a hard starting load such as an air compressor,

it will require more starting current. If it is connected

Trying to start a larger motor or a higher code (ie

to a light load, or no load such as a power saw, it

J

or

K)

motor may result in damage to both the gen-

will require less starting current. The exact require-

erator and the electric motor, especially 120 volt

ment will also vary with the brand or design of the motors.

motor.

For 240 volt motor, the "running" current is half

WHERE IS EVERYTHING LOCATED

as much as shown for the 120 volt motors of the

same size. Some dual voltage 1201240 volt motors

are difficult to start on 240 volts when driven by

enginelgenerators and can be started more easily when

connected to operate on 120 volts. This is particularly

true of "capacitor start-induction run" motors.

Sometimes a 240 volt motor which cannot be started

on the 240 volt circuit of a 1201240 volt generator can

be started on a 120 volt circuit and then quickly

switched to the 240 volt circuit after it is started. This

can be done in applications where the motor is manually controlled and is started under "no load" conditions.

A self-excited generator responds differently to

severe overloading than a transformer connected to

a power line. To illustrate, suppose that a 240 volt

5

H.P.

"capacitor start-Induction Run" motor is connected to a small transformer that would not be able

to supply enough power to bring the motor up to operating speed. It would be very severely overloaded

and probably would burn out in a short time. The

motor might also be damaged. When this motor is

connected to a self-excited 4000 watt generator, its

output voltage drops to practically zero. Thus, there

is virtually no load on the generator or the engine,

1. Starter

2. Battery Positive Connection

3. Battery Negative Connection

4. Fuel Mixture Valve

5.

Vapor Fuel Connection Point

6. Demand Regulator

7. Start Switch

Loading...

Loading...