Page 1

P/N 1706-3421

REV 03 Printed 0900-2000

Specifications Subject to Change

1001 Oakdale Road, Oakdale, PA 15071-1500

(412) 788-4353 • Toll Free 1-800-DETECTS

FAX 412-788-8353 • Service Dept. 1-888-788-4353

Multi-Gas Monitor

ATX612

Instruction

Manual

GUARANTEED.

FOR LIFE.

INDUSTRIAL SCIENTIFIC

CORPORATION

Page 2

OUR MISSION

Design - Manufacture - Sell:

Highest quality products

for the preservation of

life and property.

Provide:

Best customer service

available.

Page 3

Dear Valued Customer,

Thank you for buying and using Industrial Scientific’s

Model ATX612 Multi-Gas Monitor.

Your ATX612 can be relied upon for dependable service,

day after day. It has been designed, manufactured, tested

and proven under the most scrutinizing conditions

possible. With the minimal care and maintenance

described in this Instruction Manual, it will provide you

with years of reliable monitoring.

I am most concerned that you be pleased with the

performance of your ATX612 in the months and years

ahead. I urge you to call us with any questions or

comments you may have. Often times a phone call and a

question can save you hours of frustration. Please never

hesitate to contact me at 1-800-DETECTS (338-3287).

All of us at Industrial Scientific appreciate the opportunity

to serve you.

Sincerely,

Kent D. McElhattan

President & CEO

Industrial Scientific Corporation

1

Page 4

Multi-Gas

Monitor

ATX 612

1. W

ARNINGS ANDCAUTIONARYSTATEMENTS

3

2. U

NPACKINGTHEINSTRUMENT

4

3. ATX612 F

EATURES

4

4. I

NSTRUMENTOPERATION

5

4

.1 Charging the Battery

5

4.1.1 Alkaline Battery Option 8

4.2Turning the ATX612 On and Off 8

4.3 Display Backlight 8

4.4 Internal Sampling Pump 8

4.5 Operating Modes 9

4.5.1 Reading 9

4.5.2 Sensor Configuration 9

4.5.3 PPM Hydrocarbon 9

4.5.4 Zero 9

4.5.5 Peak 9

4.5.6 Peak Clear 10

4.5.7 Date 10

4.5.8 Cal Date 10

4.5.9 Log Time 10

4.5.10 TWA 10

4.5.11 STEL 10

4.5.12 Hygiene Reset 10

4.6 Alarm Indicators 10

4.6.1 Low Alarm 10

4.6.2 High Alarm 11

4.6.3 Over-Range Indication 11

4.6.4 Combustible Gas Over-Range 11

4.6.5 Low Battery Warning 11

4.6.6 Battery Failure 12

4.6.7 Fault Indication 12

5. C

ALIBRATING THE

ATX612 12

6. C

HANGINGINSTRUMENTSETTINGS

15

6

.1 Setspan

15

6.2

Alarms

16

6.3 Code 17

7. H

YGIENE/DATALOGGINGFUNCTIONS

17

7.

1 Definition of Terms 17

7.1.1 Data Log 17

7.1.2 Period 18

7.1.3 Logging Session 18

7.1.4 Real Time Clock 18

7.1.5 Log Time Clock 18

7.1.6 Calendar 18

7.1.7 TWA 18

7.1.8 STEL 18

7.2 Principles of Operation 18

7.3 Resetting the Hygiene Functions 19

7.4 Downloading the ATX612 19

8. MAINTENANCE 20

8.1 Cleaning 20

8.2 Changing the Battery 20

8.2.1 Replacing the Nicad Battery Module 20

8.2.2 Replacing Alkaline Battery Cells 21

8.3 Opening the Instrument for Service 21

8.4 Installing or Changing Sensors 21

8.4.1 Toxic/Oxygen Sensor Removal/Replacement 22

8.4.2 Combustible Sensor Removal/Replacement 22

8.5 Changing the Internal Filter 22

9. R

EPLACEMENTPARTS

23

10. S

PECIFICATIONS

26

11. D

EFAULTALARMSETTINGS

27

12. ATX612 O

PTIONS

& O

RDERINGINFORMATION

27

13. W

ARRANTY

28

TABLE OF CONTENTS

2 3

1.

W

ARNINGS ANDCAUTIONARYSTATEMENTS

Failure to perform certain procedures or note certain

conditions may impair the performance of the

instrument. For maximum safety and performance,

please read and follow the procedures and conditions

outlined below.

Oxygen deficient atmospheres may cause combustible

gas readings to be lower than actual concentrations.

Oxygen enriched atmospheres may cause combustible

gas readings to be higher than actual concentrations.

Calibrate the combustible gas sensor after each

incident where the combustible gas content causes the

instrument to latch in the OVER-RANGE alarm condition.

Silicone compound vapors may affect the combustible

gas sensor and cause readings of combustible gas to be

lower than actual gas concentrations. If the instrument has

been used in an area where silicone vapors were present,

always calibrate the instrument before next use to ensure

accurate measurements.

Sensor openings and water barriers must be kept clean.

Obstruction of the sensor openings and/or contamination

of the water barriers may cause readings to be lower than

actual gas concentrations.

Sudden changes in atmospheric pressure may cause

temporary fluctuations in the oxygen reading.

Recharge battery only in a non-hazardous location.

Use the RS-232 port only in a non-hazardous location.

Instrument is tested for intrinsic safety in explosive

gas/air (21% oxygen) mixtures only.

CAUTION: High Over-Range (+OR) combustible

gas readings may indicate an

explosive concentration of

combustible gas.

!

!!!!!!!!!

Page 5

4 5

2.

U

NPACKING THEINSTRUMENT

The shipping box should contain the following items.

Account for each item before discarding the box.

QUANTITY PART NUMBER DESCRIPTION

1 1810-2707 ATX612 Multi-Gas Monitor

1 1706-3421 ATX612 Instruction Manual

1 1706-3256 Maintenance Tool

1 1810-0628 Shoulder Strap

1 1810-3077 Charging Adapter

(with Nicad Battery Only)

1 1705-1710 Power Cord

After unpacking, if any listed item is missing, contact

either your local distributor of Industrial Scientific products,

or call Industrial Scientific Corporation at 1-800-DETECTS

(338-3287) in the United States and Canada, or

412-788-4353.

3.

ATX612 F

EATURES

The Industrial Scientific ATX612 Multi-Gas Monitor may

be configured to continuously monitor one, two, three or

four gases in any combination of the following:

• Oxygen

• Combustible gases (%LEL) or methane (% by volume

CH

4

). User selects %LEL or %CH4prior to calibration.

• Any two of the following toxic gases:

Carbon Monoxide

Hydrogen Sulfide

Sulfur Dioxide

Chlorine

Nitrogen Dioxide

Chlorine Dioxide

• The ATX612 automatically recognizes and displays the

installed sensors when switched on.

• One-Button calibration (microprocessor controlled).

• Built-in pump for remote gas sampling.

• Backlit display for viewing in low light conditions.

• Round-the-clock monitoring capability using the

interchangeable rechargeable nickel-cadmium (Nicad) or

replaceable alkaline battery packs.

• Plug-in sensors that can be changed or replaced without

special tools or soldering equipment.

• 90 dB audible and ultra-bright visual alarm indicators.

• Optional external audible or vibrating alarms.

• High and low alarms for combustible and toxic gases;

enrichment and depletion alarms for oxygen.

• User selectable latching alarms.

• User selectable access code for security of calibration

and alarm settings.

• Combustible gas OVER-RANGE protection.

• PEAK reading mode.

• Press and hold power switch to prevent accidental turn

ON or turn OFF.

• Hygiene/Datalogging option that can be installed by the

factory or the customer, to provide short term exposure

limit (STEL) and time-weighted average (TWA)

readings with 110 hours datalogging capacity.

• The ATX612 is classified as intrinsically safe by the

following agencies:

- Underwriters Laboratories (UL).

- Canadian Standards Association (CSA). Canadian

Standards Association has assessed only the

combustible gas portion of this instrument for

performance.

- Mine Safety and Health Administration (MSHA).

- Workcover Authority, NSW , Australia.

- Department of Mineral Resource, NSW, Australia.

- CENELEC (DEMKO)

4.

I

NSTRUMENTOPERATION

4.1 CHARGING THE BATTERY

(NICAD BATTERY OPTION)

If the ATX612 is equipped with a Nicad battery pack, fully

charge the battery pack before use. A universal charging adapter

is included with the unit for charging the ATX612 battery pack.

The battery pack may be charged while attached to the

instrument or when removed to allow round-the-clock operation

of the ATX612 using a spare battery.

The ATX612 is equipped with a nickel-cadmium battery pack

with a built-in “smart” charging system. When plugged into the

charging adapter, the battery will recharge at a high rate until

fully charged and then will reduce to a maintenance trickle

charge rate. The battery will not be damaged if it is left

connected to the charger for extended periods.

Page 6

INDUSTRIAL

SCIENTIFIC

ATX612

OXYGEN

LEL

E

BATT

PPM

%

ON/OFF MODE

6 7

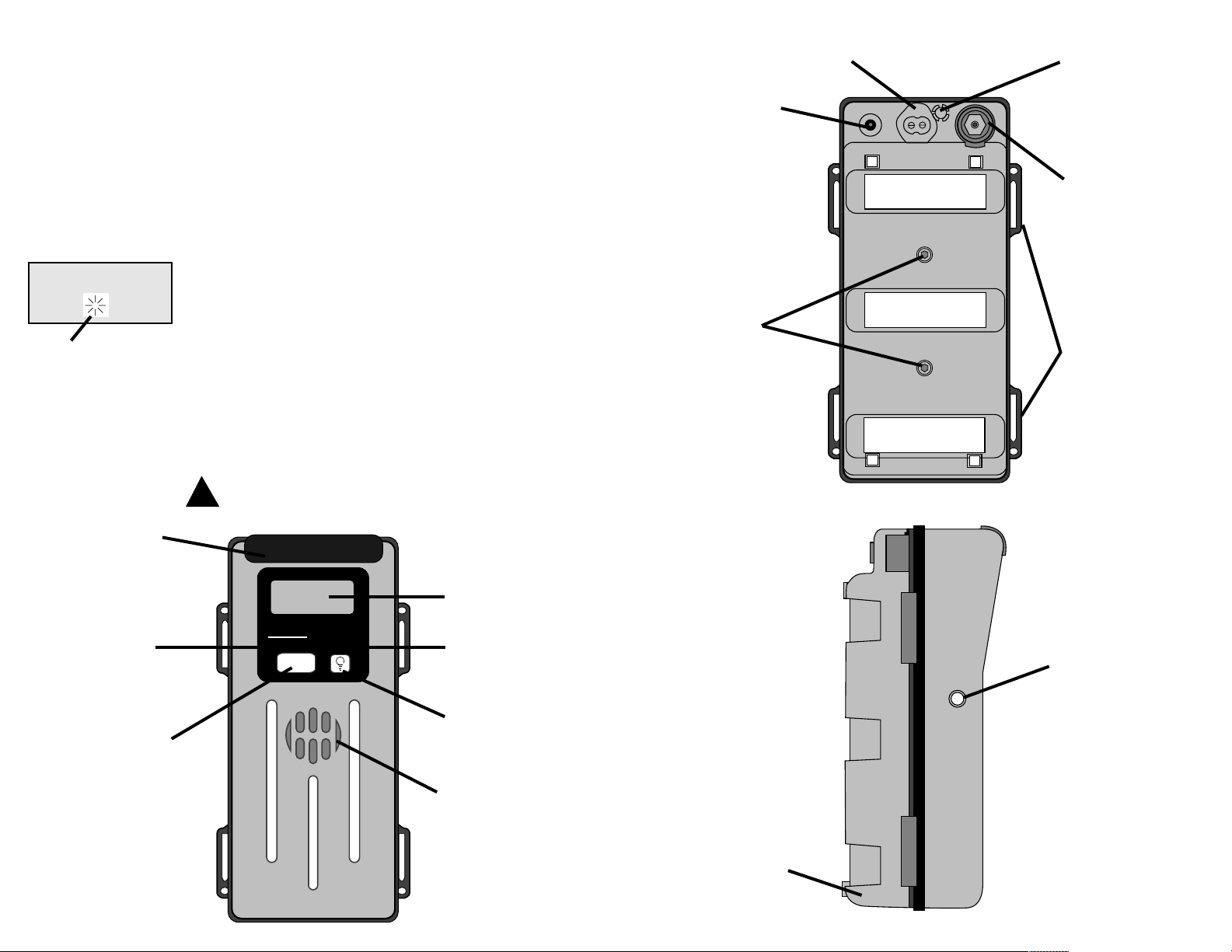

Hidden (+) Key

Alarm Speaker

On/Off/Mode Key

Ultra-bright Visual

Alarm Light Bar

Battery Status

Indicator

Hidden (-) Key

Display

Enter/Backlight Key

Charging Socket

(Nicad Versions)

Infrared Data Interface

Gas Sample Inlet

Fitting

Pump Exhaust Port

Shoulder Strap/

Optional Handle

Attachment

Battery Pack

Hex Screws

External Alarm Jack

Interchangeable Nicad

or Alkaline Battery

Pack

A dead battery will be fully recharged in 4.5 hours. The

Nicad battery pack has a LED charge status indicator to

show the current status when connected to the charger.

The LED indicator has five states as follows:

• Solid Amber: Fast charge in progress

• Solid Green: Fully charged, in trickle

charge mode

• Flashing Green: Battery too hot/cold to be

fast charged, in trickle

charge mode

• Flashing Amber: Instrument running, fast

charge mode

• Alternating Green/Amber: Trouble, electrical problem

in battery pack

A fully charged Nicad battery pack will typically operate a

four-gas configured ATX612 for up to 16 hours. When the

instrument is in the normal viewing mode, an eightsegment battery status indicator continuously displays the

battery condition. Each segment represents approximately

2 hours of operating time. When the battery is fully

discharged, the display will read BATTERY FAIL and the

instrument will emit a short beep once a second (See

Section 4.6.6). Turn off the instrument and recharge the

battery pack when BATTERY FAIL appears.

WARNING: Recharge Nicad battery pack only in a

non-hazardous location.

00

21.0 0

Figure 1

Figure 2

Figure 3

!

Page 7

8 9

CO H2S

02 LEL

ATX612

VER 1.0

5

O 0

21.0 0

The remote sample tube should be connected to the barbed

inlet fitting on the bottom of the ATX612 (See Figure 3).

NOTE: When drawing a remote sample, allow 2 seconds

per foot (0.3 meter) of tubing length in addition to

the normal sensor response time before observing

the instrument readings.

The instrument is protected from drawing liquid and dust

into the pump and sensors by an internal 1.2 micron dust

filter/water stop.

4.5 OPERATING MODES

The ATX612 offers different operating modes to access

various instrument features. To scroll through the

operating modes, press and release the MODE switch. The

operating modes will appear in the following order:

4.5.1 READING

This is the normal operating mode. The current reading of

all sensors is displayed along with the graphical battery

charge indicator.

4.5.2 SENSOR CONFIGURATION

This mode will display the type of sensor in the position in

which it is installed in the instrument.

4.5.3 PPM HYDROCARBON

This mode displays the level of total hydrocarbons with 50

PPM resolution. The PPM reading may be rezeroed at

anytime by pressing the enter (E) key. The display will

return to the normal operating mode if the gas

concentration exceeds the LEL alarm level set in the

instrument.

4.5.4 ZERO

This mode allows the user to zero the instrument and

calibrate all installed sensors. Refer to Section 5,

Calibrating the ATX612, for instruction on the use of the

automatic zero and calibration functions.

4.5.5 PEAK

This mode will display the highest level of toxic and

combustible gas and the lowest level of oxygen measured

since the peak readings were last cleared.

HOLD

RELEASE

4.1.1 ALKALINE BATTERY OPTION

The ATX612 is available with an optional alkaline battery

pack which will typically operate continuously for up to

20 hours using 6 C-cell batteries.

WARNING:

Replace alkaline battery cells only in a

non-hazardous location. Use only Duracell, Energizer,

Procell, Panasonic, Varta or Kodak C-cell alkaline batteries. Use

of another battery type may present a risk of fire or explosion

and will violate the intrinsic safety certification of the ATX612.

4.2 TURNING THE ATX612 ON AND OFF

• Press and hold the ON/OFF/MODE switch. The display

will read HOLD and the instrument sounds a short beep

once a second.

• Continue holding the MODE switch for 5 beeps until the

RELEASE screen appears. (Stop here if turning the

instrument off.)

• After the instrument is turned ON, the following startup

screens will be displayed:

SOFTWARE VERSION: The version of the operating

software installed in the instrument is displayed.

SENSOR CONFIGURATION. The type of sensors

installed in the instrument will be displayed.

WARM-UPTIMER. The display will indicate the

number of seconds remaining until the instrument begins

normal operation.

After the warm-up sequence has been completed, the

ATX612 will enter the normal operating mode and will

be continuously monitoring all calibrated sensors.

4.3 DISPLAY BACKLIGHT

The display backlight is automatically switched on when

the ATX612 is in an alarm condition. To manually activate

the backlight, press and release the (E) key. The backlight

will remain on for approximately 15 seconds.

4.4 INTERNAL SAMPLING PUMP

The ATX612 is equipped with a built-in pump for remote

gas sampling. The sampling pump will draw a constant flow

sample from up to 100 feet (30 meters) using 1/8 inch (3

mm) diameter tubing.

CO H2S

02 LEL

PPM EXP

0

ZERO

PRESS

65P 8

19.3K 12

!

Page 8

10

11

4.6.2 HIGH ALARM

When a monitored gas concentration reaches the high

alarm level setpoint, the instrument emits a continuous dual

tone alarm. As with the low alarm condition, the red alarm

light bar and backlight will flash simultaneously with the

displayed gas value. If the hygiene/datalogging option is

installed, the STEL alarm will mimic the high alarm

indicator and the STEL display value in alarm will flash.

NOTE: The ATX612 uses the continuous high alarm tone

for both low (depletion) and high (enrichment)

oxygen alarm conditions.

4.6.3 OVER-RANGE INDICATION

An over-range condition occurs when a sensor reading

exceeds the upper limit of the instrument display range.

Over-Range is indicated by +OR in the appropriate sensor

display location. With the exception of combustible gas

over-range, all over-range conditions will clear

automatically when the gas concentrations have decreased

to levels within the display range of the instrument.

4.6.4 COMBUSTIBLE GAS OVER-RANGE

When the ATX612 detects combustible gases in excess of

100% of LEL (5% CH4 by volume), a high alarm

condition is latched (locked on) and +OR is displayed in

place of the combustible gas reading. Power is removed

from the combustible gas sensor to prevent damage due to

the high level of combustible gas.

To clear the combustible gas over-range alarm:

• Exit the hazardous area immediately.

• Press (E) key in clean air.

NOTE: When the instrument is turned on, the combustible

gas level must be less than 100% of LEL (5%

CH

4

) to clear the combustible gas over-range

condition.

4.6.5 LOW BATTERYWARNING

With 15-60 minutes of run time remaining, the ATX612

will emit a short beep once every 60 seconds and the

battery status indicator will be replaced with a flashing

“B” to indicate the low battery condition.

NOTE: The length of warning time will increase when

there is no combustible gas sensor installed in the

instrument.

4.5.6 PEAK CLEAR

This mode will clear all stored peak readings from the

instrument. Press enter (E) to clear the peak readings. The

display will return to the PEAK mode and indicate that the

peak readings have been reset.

If the hygiene/datalogging option is installed, the following

operating modes may also be accessed. See Section 7,

Hygiene/Datalogging Functions, for further instructions.

4.5.7 DATE

This screen allows the user to see the current date

(month/day).

4.5.8 CALDATE

This mode allows the user to see the date the instrument

was last calibrated.

4.5.9 LOG TIME

This mode allows the user to view the current real time

(RT) and the length of time that data has been recorded in

the current session (LT).

4.5.10 TWA (Time-Weighted Average)*

This mode displays the current time-weighted average

exposure values of the toxic sensors.

4.5.11 STEL (Short Term Exposure Limit)*

This mode displays the short term average exposure values

of the toxic sensors installed in the instrument.

4.5.12 HYGIENE RESET

This mode allows the user to reset the hygiene session and

the STEL and TWA exposure values.

4.6 ALARM INDICATORS

4.6.1 LOW ALARM

When a monitored gas concentration reaches the low level

alarm setpoint, the instrument emits a short beep

approximately every 1.2 seconds. The red alarm light bar

and backlight will flash simultaneously along with the

displayed gas value. If the hygiene/datalogging option is

installed, the TWA alarm will mimic the low alarm

indicator and the TWA display value in alarm will flash.

CALDATE

5/13

RT06:45

LT01:15

0 0

TWA

0 0

STEL

+OR 0

21.0 0

HYGIENE

PRESS

DATE

5/21

O 0

21.0 +OR

O0

21.0 0

B

*

TWA and STEL

readings do not

apply to oxygen

and combustible

gas exposure.

PK CLR

PRESS

Page 9

12

13

ZERO

PRESS

ZEROING

21.0

02 CAL

4.6.6 BATTERY FAILURE

When the battery has insufficient charge to operate the

instrument, “BATTERY FAIL” is displayed. The visual

alarm will be activated and the instrument will emit a

short beep once every second for approximately 30

seconds after which the instrument will turn itself off.

Recharge or replace the battery (See Section 8.2).

4.6.7 FAULT INDICATION

The ATX612 will emit a short beep once a second if a

newly installed sensor does not agree with the previous

sensor type for that position. The corresponding display

position will be blank. This fault indication also occurs

when a sensor becomes disconnected or a combustible

sensor fault is detected during normal operation. Installed

sensor types are accepted and displayed only after a

successful calibration has been completed.

The sampling pump system is equipped with a low flow

detection alarm. Alow flow alarm condition will occur if

the dust filter/water stop becomes clogged or the sample

line becomes blocked in any way. The instrument will

sound a continuous tone, the red alarm light bar will flash

and the display will read PUMP FAULT. If this should

occur, replace the dust filter/water stop immediately (See

Section 9). The unit will not operate and a low flow alarm

condition will remain if the dust filter/water stop is

removed from the instrument. The PUMP FAULT alarm

will be reset once the obstruction has been cleared from

the sample line.

5.

C

ALIBRATING THE

ATX612

BATTERY

FAIL

PUMP

FAULT

If an instrument fails to operate properly following any

functional “bump” test, a full instrument calibration

should be performed prior to use.

Calibration is most accurate when the instrument has been

in a stable temperature environment for at least one hour

prior to calibrating.

NOTE: Instrument zero and oxygen span calibration

should be performed in clean air containing

20.95% (21%) oxygen. If you are measuring a

known combustible gas, use a known

concentration of that gas for calibration. For

general combustible gas measurement, Industrial

Scientific Corporation recommends calibrating to

pentane in the 15-50% LEL range. The measured

LEL concentration of gases other than the

calibration gas may not correspond on a one-toone basis with the monitor reading. Always use

teflon or teflon-lined tubing when calibrating.

The ATX612 utilizes a one-button calibration system.

When using multi-gas cylinders, a full instrument

calibration can be performed in a single step. Multi-gas

cylinders are available for the most common instrument

configurations.

To calibrate the ATX612:

• From the normal READING mode, press the MODE

switch twice to access the ZERO operating mode.

• Press the (E) key to start the instrument zeroing process.

The instrument display will indicate ZEROING.

• When zeroing is complete the instrument display will

indicate O2 CAL and will show the current full span

value of the oxygen sensor. The oxygen sensor will be

calibrated to 21.0 in approximately 30 seconds.

Instrument zeroing and oxygen calibration may be aborted

at any time by pressing the MODE switch.

NOTE: Zeroing the instrument in clean air is preferred,

provided that there is no trace of toxic or

combustible gas. If the air purity is uncertain, use

a cylinder of zero grade air to zero the instrument

and span the oxygen sensor.

• At the completion of the oxygen sensor calibration, the

instrument will emit a short beep and the display will

indicate GO CAL. The message PRESS (E) to CAL will

scroll across the bottom of the display. Press (E) to

continue calibrating the remaining sensors. If you ignore

this message the instrument will return to the normal

operating mode in approximately eight seconds.

The ATX612 is a potential life saving device. Recognizing

this fact, Industrial Scientific Corporation recommends

that a functional (“bump”) test be performed on every

instrument prior to each use. Afunctional test is defined as

a brief exposure of the monitor to a known concentration

of gas(es) for the purpose of verifying sensor and alarm

operation. It is not intended to be a measure of the

accuracy of the instrument.

Industrial Scientific also recommends that a full

instrument calibration be performed using a certified

concentration(s) of calibration gas(es) monthly to ensure

maximum accuracy.

Page 10

14

15

CODE 0

PRESS

• To continue full calibration, press (E) and the instrument

will display the first sensor to be calibrated along with

the calibration gas setting. The message APPLY CAL

GAS will scroll across the bottom of the display.

NOTE: If the gas concentration does not match the

setting, press the MODE switch to abort

calibration. See Section 6.1, SETSPAN to change

the calibration gas settings.

NOTE: APPLY CAL GAS means connect the sample

tubing to the appropriate calibration gas cylinder

with either a ILPM or preferrably a demand flow

regulator. Connect the tubing to the gas sample

inlet of the ATX612. Turn on gas supply.

• Apply the calibration gas. The instrument will wait for

five minutes to sense that calibration gas has been

applied before aborting and failing calibration. When the

sensor detects a gas concentration greater than 50% of

the calibration gas value, the display will indicate the

current full span value for that sensor. The message CAL

IN PROGRESS will scroll across the bottom of the

display.

• When calibration of the sensor has been successfully

completed, the instrument will automatically step to the

next sensor to be calibrated and the preceding step will

be repeated.

• When all sensors have been calibrated successfully the

instrument will emit a short beep and the sensor

configuration will be shown on the display.

• If calibration results in marginal sensor span values,

sensor identifiers will flash on the display. Marginal

calibration will occur if the sensor full span value is less

than 70% of the applied gas concentration. Amarginal

sensor calibration may be an early warning sign that the

sensor will soon need to be replaced.

NOTE: If the sensor full span value is less than 50% of

the calibration gas value, calibration will fail and

the instrument will immediately return to the real

time READING mode. When failed calibration or

low sensitivity is indicated, verify that the

calibration cylinder has not emptied or that the

cylinder expiration date has not passed.

• After displaying the sensor configuration, the

instrument will automatically return to the real time

READING mode.

6.

C

HANGINGINSTRUMENTSETTINGS

Instrument settings, including alarm values, calibration gas

concentrations and security code, may only be accessed

and changed during the instrument startup sequence.

The (+) and (-) hidden keys are used to set instrument

alarm and calibration values. Refer to page 6, Figure 1 for

the location of the hidden keys.

To access the instrument menus:

• Turn the ATX612 off and back on again.

• When the display shows the warm up timer, press the

plus (+) and minus (-) keys simultaneously.

If the instrument security code has been set to a value

other than “0”, the CODE screen will be displayed along

with the scrolling prompt PRESS (+) OR (-) TO SET (E)

TO ENTER. Use the (+) and (-) keys to input the correct

security code value and press (E). When the correct code

has been entered successfully, the instrument will

immediately enter the settings mode.

The settings mode consists of three functions:

SETSPAN

ALARMS

CODE

The scrolling prompt, PRESS (+) FOR NEXT (E) TO

SELECT appears on each screen. Press the (+) to step

through the list and (E) to select any of the functions.

Pressing the MODE switch at any one of the functions

will cause the instrument to return to the normal

operating mode.

6.1 SETSPAN

The SETSPAN function allows the user to set the

combustible sensor monitoring range to either LEL or CH

4

and to set the calibration gas values for the combustible

and toxic sensors.

GO CAL

PRESS

25 LEL

APPLY

SETSPAN

PRESS

Page 11

16

17

CODE

PRESS

CODE 123

PRESS

• Press (+) to step to the INSTANT function and set

instantaneous alarm values. The display will indicate

INSTANT along with the scrolling prompt PRESS (+)

FOR NEXT (E) TO SELECT.

• Press (E) to enter the instantaneous alarms function. The

display will show the first alarm to be set along with the

scrolling prompt PRESS (+) FOR NEXT (E) TO

SELECT. The alarm type will be indicated on the display

as either high (H) or low (L).

• Press (E) to select the desired alarm to be changed. The

display will flash the current alarm value along with the

prompt PRESS (+) OR (-) TO SET (E) TO SELECT.

• Press the (+) and (-) keys to set the desired alarm value

and (E) to enter the value into memory.

• Press MODE to return to the INSTANT function.

• Press (+) to step to the TWA and STEL alarm functions.

The TWA and STEL alarm values are set as

previously described.

6.3 CODE

The CODE function allows the user to select a security

code to protect calibration and all instrument alarm

settings. When the code is set to any value other than “0”,

the user will be prompted to enter the proper code prior to

entering the settings or calibration modes.

• Press (+) to step from the ALARMS function to the

CODE function.

• Press (E) to enter the code function. The display will

show the current code setting along with the scrolling

prompt PRESS (+) OR (-) TO SET (E) TO ENTER.

• Press the (+) and (-) keys to set the code to any value

between 0 and 999, and (E) to enter the value

into memory.

• Press MODE to return to the CODE function.

7.

H

YGIENE/DATALOGGINGFUNCTIONS

7.1 DEFINITION OF TERMS

7.1.1 DATA LOG

The record of measured gas concentrations, including time

and date, stored in the instrument’s electronic memory.

LEL

PRESS

25 LEL

PRESS

ALARMS

PRESS

LATCH

INSTANT

PRESS

10L LEL

PRESS

LATCH

PRESS

OFF

PRESS

• Press (E) to enter the SETSPAN function. The display

will show LEL along with the prompt PRESS (+) TO

CHANGE.

• Press (+) to toggle between LEL and CH

4

combustible

sensor span ranges.

• Press MODE to enter the calibration gas values for all

sensors. The display will show the first span value, eg.

25 LEL, along with the prompt PRESS (+) FOR NEXT

(E) TO SELECT.

• Press (E) to select the value you wish to change. The

display will flash the current gas value and will scroll the

prompt PRESS (+) or (-) TO SET (E) TO ENTER.

• Press the (+) and (-) minus keys to set the desired

calibration gas value and (E) to enter the value into

memory. Once the value has been entered into memory,

it will become the standard gas value used during

instrument calibration.

• Press the MODE switch to return to the SETSPAN

function.

6.2 ALARMS

The ALARMS function allows you to set the values for

the HI and LOW alarms for each installed sensor. Default

alarm settings for each gas are listed in Section 11. If the

hygiene/datalogging option is installed, you will also be

able to set the STEL and TWA alarm values.

• Press (+) to step from the SETSPAN function to the

ALARMS function.

• Press (E) to enter the ALARMS function. The LATCH

function will lock the alarm indicators on when a

monitored gas concentration reaches the high alarm

setpoint. The alarm will reset after the gas concentration

has fallen below the alarm setpoint and the user has

pressed the (E) key. The display will indicate LATCH

along with the scrolling prompt PRESS (+) FOR NEXT

(E) to SELECT.

• Press (E) to select the LATCH function. The display will

indicate LATCH along with the prompt PRESS (+) FOR

NEXT (E) TO SELECT.

• Press (E) to set the ATX612 high alarm latch as ON or

OFF. Press MODE to return to the LATCH screen.

Page 12

18 19

The datalogging section of the instrument is always

powered and a battery backup circuit protects it from loss

of data for up to 40 minutes during battery changes.

NOTE: The instrument must be stored on a battery

charger when not in use to prevent loss of data

due to battery discharge.

7.3 RESETTING THE HYGIENE FUNCTIONS

NOTE: If you are using the datalogging feature, be sure

the correct date and time are programmed by

checking/setting the Real Time Clock and

Calendar using the optional ATX

Hygiene/Datalogging Software.

• Press MODE repeatedly to step to the HYGIENE screen.

• Press (E) to reset the hygiene function and begin a new

datalogging session.

The instrument display will return to the LOG TIME

mode and the display will indicate that the log time (LT)

will be reset to 00:00. The TWA and STEL values for all

toxic sensors will also be reset to zero.

If there is insufficient memory to log approximately 12

hours of data when the hygiene function is reset, the real

time clock value will be displayed as RTOR:OR.

When the memory is full, both the real time and log time

will be displayed as OR:OR. At this time, the data may be

cleared by performing a hygiene reset as described above.

All currently stored data will be overwritten. The stored

data may be down-loaded using the ATX

hygiene/datalogging software.

7.4 DOWNLOADING THE ATX612

To connect the ATX612 for downloading data to the PC:

• Start the datalog software on the PC.

• Connect the interface cable to the infrared data port on

the bottom of the ATX612.

• Select CONNECT from the menu on the datalog

software.

• Turn on the instrument when prompted.

• The ATX612 will show CONNECT and the instrument

will begin communicating with the PC.

RT06:45

LT00:00

RTOR:OR

LT00:00

RTOR:OR

LT0R:0R

7.1.2 PERIOD

The logging time that begins when the instrument is

turned on and initiates normal operation and lasts until the

instrument is turned off.

7.1.3 LOGGING SESSION

One or more periods of normal instrument operation

between hygiene function resets.

7.1.4 REALTIME CLOCK

The internal clock that maintains the current time.

7.1.5 LOG TIME CLOCK

The running clock that monitors the length of time logged

during a session.

7.1.6 CALENDAR

A part of the real time clock that maintains the

current date.

7.1.7 TWA (TIME-WEIGHTED AVERAGE)

The accumulated gas exposure averaged over a

predetermined time, typically eight hours.

7.1.8 STEL(SHORT TERM EXPOSURE LIMIT)

The accumulated gas exposure value averaged for the

proceeding fifteen minutes.

7.2 PRINCIPLES OF OPERATION

If the ATX612 is equipped with the hygiene/datalogging

option, all sensor readings are sent to the hygiene module.

Once every minute the readings are averaged, saved to the

memory and the TWA and STEL values are calculated for

the toxic sensors. The TWA and STEL values are then

tested for possible alarm conditions.

The default time base for calculating TWA values is eight

hours. However, the time base may be changed to any

value in the range from one to 40 hours using the

optional ATX Hygiene/Datalogging Software and a

personal computer.

The instrument memory provides storage capacity for

approximately 110 hours of logged data in an instrument

with four sensors installed.

Page 13

20 21

• Remove the battery pack from the instrument as

described in Section 8.2.

• Remove the two screws which hold the battery module

in place as shown in Figure 4.

• Lift the Nicad battery module from the battery pack.

• Place the new Nicad module in the battery pack.

• Replace the two screws which hold the Nicad module

in place.

8.2.2 REPLACING ALKALINE BA TTERYCELLS

The alkaline battery pack holds 6 C-cell batteries. To

replace the alkaline battery cells:

• Remove the battery pack from the instrument as

described in Section 8.2.

• Remove the alkaline cells from the battery pack.

• Insert the new cells making sure to observe proper

polarity.

NOTE: Proper polarity of the alkaline battery cells is

identified by the molded “+” and “-” symbols in

the bottom of the battery pack. In addition the

positive (+) battery contact is identified by the red

polarizing tab.

8.3 OPENING THE INSTRUMENT FOR SER VICE

To open the instrument for service:

• Remove the battery pack as described in Section 8.2.

• Remove the four screws from the bottom of the

instrument chassis.

• Gently lift the case top from the chassis.

8.4 INSTALLING OR CHANGING SENSORS

To change sensors in the ATX612:

• Open the instrument as described in Section 8.3.

• Remove the three screws which hold the sensor manifold

in place.

• Gently lift the sensor manifold away from the chassis as

shown in Figure 5.

NOTE: It is not necessary to disconnect the sample tubing

from the manifold to replace the sensors.

8.1 CLEANING

Wipe the outside of the instrument with a soft, clean cloth.

Never use solvents or cleaning solutions of any type.

8.2 CHANGING THE BATTERY PACK

To change the ATX612 battery pack:

• Hold the instrument with battery pack facing up.

• Using the maintenance tool provided with the

instrument, turn counter-clockwise and loosen the two

hex screws in the battery pack.

• Remove the battery pack. (See Section 8.2.1 for

instructions of replacing the Nicad battery module)

• Place the battery pack on the instrument.

• Turn the hex screws clockwise until the screws are tight

and reach the stops. DO NOT OVER TIGHTEN.

8.2.1 REPLACING THE NICAD BA TTER YMODULE

The Nicad cells within the battery pack may be replaced

when necessary by installing a new Nicad battery module.

To replace the Nicad battery module:

Figure 5

Figure 4

Battery Pack

Hex Screws

Nicad Battery

Module

Battery Pack

8.

M

AINTENANCE

Page 14

22

23

ITEM PART NUMBER DESCRIPTION (QTY)

1 1705-8868 Main PC Board (1)

2 1705-6755 Display PC Board (1)

3 1705-9247 Interface PC Board (1)

4 1705-9031 Chassis (1)

5 1706-3447 Pump Assembly (1)

6 1705-9494 Nicad Battery Pack

or 1705-9312 Alkaline Battery Pack

7 1706-0716 Case Gasket (1)

8 1706-2498 Filter Housing (1)

9 1705-8157 Dust Filter/Water Stop (1.2 Micron) (1)

10 1705-7118 Speaker (1)

11 1705-8660 Speaker Gasket (1)

12 1705-8140 Speaker Water Barrier (1)

13 1706-0674 Sensor Manifold (1)

14 1702-8374 External Alarm Jack (1)

15 1705-0295 RFI Screen (1)

16 1706-1284 Case Top (1)

17 1705-8306 Key Pad (1)

18 1706-0500 Alarm Lens (1)

19 1705-8652 Alarm Lens Gasket (1)

The following items numbers refer to the exploded view

drawing on pages 24 and 25.

9.

R

EPLACEMENTPARTS

WARNING: When removing a sensor from

service, the appropriate sensor plug

must be installed to ensure proper

instrument operation. Toxic/O

2

Sensor Plug P/N 1704-6947

Combustible Sensor Plug

P/N 1706-2647

8.4.1 TOXIC/OXYGEN SENSOR REMOVAL/

REPLACEMENT

• To remove a toxic or oxygen sensor, grasp the sensor

and lift it straight up. Use care to avoid bending the

sensor pins.

WARNING: When removing a toxic sensor for

storage, connect a shorting wire to

the two pins as shown.

• New toxic sensors are shipped with a shorting wire

attached. Remove the shorting wire from the new

sensor.

• Immediately install the sensor in the instrument. Never

apply pressure to the area inside of the black O-Ring seal

at the top of the sensor.

8.4.2 COMBUSTIBLE SENSOR REMOVAL/

REPLACEMENT

• To remove the combustible sensor, grasp the sensor and

lift it straight up.

• Press the new sensor firmly into the sockets on the

PC board.

8.5 CHANGING THE INTERNAL FILTER

If the internal dust filter/water stop becomes blocked, a

PUMP FAULT alarm will result. The filter must be

replaced immediately before continuing operation. To

remove and replace the internal dust filter/water stop from

the instrument:

• Unscrew and remove the knurled sample inlet fitting from

the instrument as shown in Figure 6.

• Grasp the dust filter/water stop from the instrument and

pull straight out to remove.

• Replace the dust filter/water stop making sure that the

larger diameter opening of the filter is facing inward.

• Replace the knurled sample inlet fitting.

NOTE: The ATX612 will remain in a PUMP FAULT

condition if operation is attempted with the dust

filter/water stop removed.

!

!

Shorting Wire

Figure 6

Page 15

24

25

Page 16

2726

11.

D

EFAULTALARMSETTINGS

GAS LOW ALARM HIGH ALARM

O

2

19.5% 23.5%

LEL 10% 20%

CH

4

1.0% 1.5%

CO 35 PPM 70 PPM

H2S 10 PPM 20 PPM

SO

2

2.0 PM 4.0 PPM

NO

2

3.0 PPM 6.0 PPM

Cl

2

0.5 PPM 1.0 PPM

ClO

2

0.3 PPM 1.0 PPM

NOTE: Factory alarm settings may not coincide with

local regulations. Consult all appropriate local

regulations for appropriate alarm settings in

your region.

10.

S

PECIFICATIONS

CASE: Type 304 Stainless Steel

DIMENSIONS: 8.2

”L x 3.7”W x 3.2”H

(208 X 94 X 81 mm)

W

EIGHT

: 3.4 lbs (1.5 kg)

S

ENSORS

: Combustible Gases and Methane-

Catalytic

Oxygen and Toxic GasesElectrochemical

M

EASURINGRANGE

:

LEL (Combustible Gases)

0 to 100% LEL in 1% increments

CH4(Methane)

0 to 5% of volume in 0.1% increments

O2(Oxygen)

0 to 30% of volume in 0.1% increments

CO (Carbon Monoxide)

0 to 999 PPM (parts per million) in 1 PPM increments

H2S (Hydrogen Sulfide)

0 to 999 PPM (parts per million) in 1 PPM increments

SO2(Sulfur Dioxide)

0 to 99.9 PPM (parts per million) in 0.1 PPM increments

NO2(Nitrogen Dioxide)

0 to 99.9 PPM (parts per million) in 0.1 PPM increments

C12(Chlorine)

0 to 99.9 PPM (parts per million) in 0.1 PPM increments

C1O2(Chlorine Dioxide)

0 to 99.9 PPM (parts per million) in 0.1 PPM increments

P

OWERSOURCE

: Rechargeable, replaceable nickel-cadmium battery

pack, or replaceable cell alkaline battery pack

B

ATTERYLIFE

: With Nicad Battery Pack - 16 hours typical

With Alkaline Battery Pack - 20 hours typical

R

EADOUT

: Alpha-Numeric Liquid Crystal Display

TEMPERATURE RANGE: -

20ºC to 50ºC (-4

ºF to 122ºF

)

With H2S Sensor -40ºC to 50ºC (-40ºF to 122ºF)

HUMIDITY RANGE: 0% to 99% RH (Non-condensing)

STORAGE TEMPERATURE: 0ºC to 20ºC (32ºF to 68ºF)

PART NUMBER DESCRIPTION (QTY)

1705-0788-PPM Combustible Sensor

1705-0129 Oxygen Sensor

1704-1898 Hydrogen Sulfide Sensor

1704-1880 Carbon Monoxide Sensor

1704-1914 Chlorine sensor

1704-4204 CLO

2

sensor

1704-1922 Nitrogen Dioxide Sensor

1704-1906 Sulfur Dioxide Sensor

1810-1386 Stainless Steel Extendible Probe - 6ft.

1810-1428 Polycarbonate Probe

1705-9494 Rechargeable Nicad Battery Pack

1705-9312 Replaceable Alkaline Battery Pack (6 C-cell)

1810-3259 Leather Carrying Case for ATX612

1810-0628 Shoulder Strap

1810-2921 Carrying Handle for ATX612

1810-1154 External Audible/V isual Alarm

1810-2146 External Vibrating Alarm

1810-2187 Cylinder Cal. Gas, H

2

S, CO, Pentane and Oxygen

1810-1576 Cylinder, Cal. Gas, Carbon Monoxide, Pentane and Oxygen

1810-2165 Cylinder, Cal. Gas, Carbon Monoxide, Methane and Oxygen

1810-1584 Cylinder, Cal. Gas, Zero Air

1810-2222 Cylinder, Cal. Gas, 5 PPM Sulfur Dioxide

1810-1758 Cylinder, Cal. Gas, 10 PPM Chlorine

1810-2219 Cylinder, Cal. Gas, 5 PPM Nitrogen Dioxide

1810-2509 Demand Flow Regulator with Pressure Gauge

12.

ATX612 O

PTIONS

& O

RDERINGINFORMATION

Page 17

28 29

Industrial Scientific portable gas monitoring instruments

are warranted to be free from defects in material and

workmanship for as long as the instrument is in service.

The above warranty does not include sensors, battery

packs, internal pumps or filters, all of which are warranted

to be free from defects in material and workmanship for

eighteen months from the date of shipment, or one year

from the date of first use, whichever occurs first, except

where otherwise stated in writing in Industrial Scientific

literature accompanying the product.

All other Industrial Scientific products are warranted to be

free from defects in material and workmanship for a

period of eighteen (18) months from the date of shipment,

or one (1) year from the date of first use, whichever

occurs first, except where otherwise stated in writing in

Industrial Scientific literature accompanying the product.

LIMITATION OF LIABILITY

INDUSTRIAL SCIENTIFIC MAKES NO OTHER

WARRANTIES, EITHER EXPRESSED OR IMPLIED,

INCLUDING BUT NOT LIMITED TO THE

WARRANTIES OF MERCHANTABILITY OR FITNESS

FOR PARTICULAR PURPOSE.

SHOULD THE PRODUCT FAILTO CONFORM TO

THE ABOVE WARRANTY, BUYER’S ONLY REMEDY

AND INDUSTRIAL SCIENTIFIC’S ONLY

OBLIGATION SHALL BE, AT INDUSTRIAL

SCIENTIFIC’S SOLE OPTION, REPLACEMENT OR

REPAIR OF SUCH NON-CONFORMING GOODS OR

REFUND OF THE ORIGINAL PURCHASE PRICE OF

THE NON-CONFORMING GOODS. IN NO EVENT

WILL INDUSTRIAL SCIENTIFIC BE LIABLE FOR

ANY OTHER SPECIAL, INCIDENTAL OR

CONSEQUENTIAL DAMAGES, INCLUDING LOSS

OF PROFIT OR LOSS OF USE, ARISING OUT OF THE

SALE, MANUFACTURE OR USE OF ANYPRODUCTS

SOLD HEREUNDER WHETHER SUCH CLAIM IS

PLEADED IN CONTRACT OR IN TORT, INCLUDING

STRICT LIABILITY IN TORT.

13.

W

ARRANTY

It shall be an express condition to Industrial Scientific’s

warranty that all products be carefully inspected for

damage by Buyer upon receipt, be properly calibrated for

Buyer’s particular use, and be used, repaired, and

maintained in strict accordance with the instructions set

forth in Industrial Scientific’s product literature. Repair or

maintenance by non-qualified personnel will invalidate the

warranty, as will the use of non-approved consumables or

spare parts. As with any other sophisticated product, it is

essential and a condition of Industrial Scientific’s warranty

that all personnel using the products be fully acquainted

with their use, capabilities and limitations as set forth in

the applicable product literature.

Buyer acknowledges that it alone has determined the

intended purpose and suitability of the goods purchased. It

is expressly agreed by the parties that any technical or

other advice given by Industrial Scientific with respect to

the use of the goods or services is given without charge

and at Buyer’s risk; therefore, Industrial Scientific

assumes no obligations or liability for the advice given or

results obtained.

Loading...

Loading...