Energie ECO 250esm, ECO 300i, ECO 300esms, ECO 250i, ECO 250is Technical Manual

...

Eco

Technical Manual

1

Review: 8

Version: 1

Date: 22/09/2015

Directives European Certification

EN 60335-1

EN 60335-2-21

EN 60335-2-40

2006/95/CE

Technical Manual

ENG

ECO

200esm | 250esm | 300esm

300esms

250i | 300i |250is | 300is |450is

250ix | 300ix

250isx | 300isx | 450isx

Eco

2

Technical Manual

Esteemed Client,

We would like to thank you for your choice when you acquired an equipment for

sanitary water heating.

The thermodynamic solar system Eco will surely meet all your expectations and

provide many years of comfort with maximum power saving.

Our organization dedicates much time, energy and economic resources in order

to develop innovations that will promote power saving in our products.

Your choice has demonstrated your good sense and concern with power

consumption, a matter that affects the environment.

We have taken on a permanent commitment to conceive innovative and efficient

products so that this rational use of energy can actively contribute to the

preservation of the environment and natural resources of the planet.

Keep this manual whose objective is to inform, alert and advise about the use

and maintenance of this equipment.

Our services are always at your disposal. Feel free to call upon us!

Eco

Technical Manual

3

INDEX

1. IMPORTANT ........................................................................................................................................... 5

1.1. Symbols .......................................................................................................................................... 5

1.2 Pre-installation Information ........................................................................................................... 5

1.3 Safety information ......................................................................................................................... 5

2. PACKAGE ............................................................................................................................................... 6

2.1. Contents ......................................................................................................................................... 6

2.2. Transport........................................................................................................................................ 7

3. SPECIFICATIONS ..................................................................................................................................... 8

3.1. Running principle ........................................................................................................................... 8

3.2. Technical features .......................................................................................................................... 9

3.3. Technical features ........................................................................................................................ 10

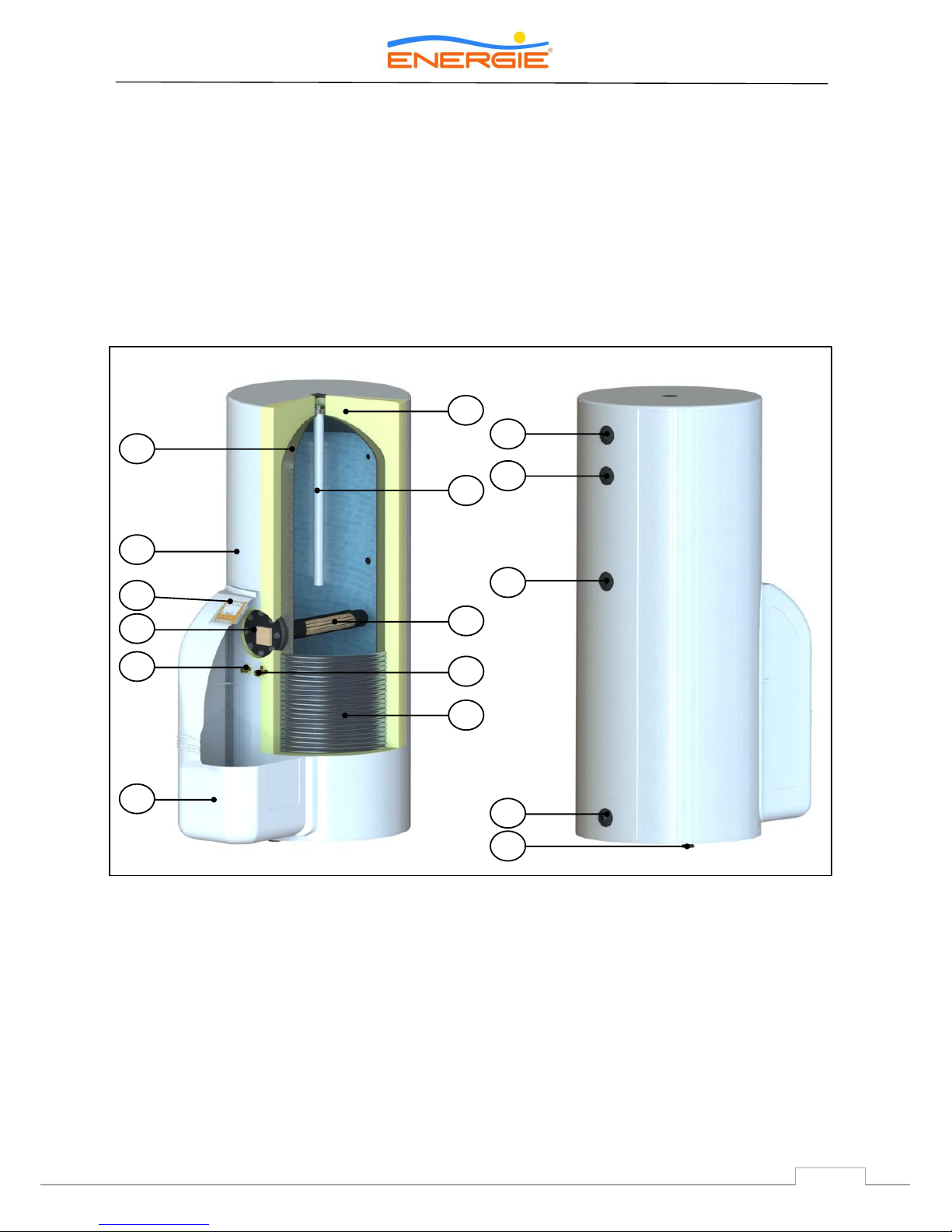

3.4. Main Components ........................................................................................................................ 11

3.4.1. General diagram of assembly ............................................................................................... 11

3.4.2. Thermodynamic Solar Panel ................................................................................................ 12

3.4.3. Storage Water Heater .......................................................................................................... 13

3.4.4. Thermodynamic Block .......................................................................................................... 16

3.4.5. Cooling Fluid ........................................................................................................................ 17

3.5. Safety and Control Devices ........................................................................................................... 17

3.5.1. Pressure gauge of high/low pressure ................................................................................... 17

3.5.2. Safety Thermostat ................................................................................................................ 17

3.5.3. Temperature Sensor............................................................................................................. 17

3.5.4. Protection against corrosion ................................................................................................ 17

3.5.5. Bipolar Socket ...................................................................................................................... 17

3.5.6. Expansion Vessel .................................................................................................................. 18

3.5.7. Safety Device ....................................................................................................................... 18

3.5.8. Pressure Reducing Valve ...................................................................................................... 19

4. INSTALATION ....................................................................................................................................... 19

4.1. Attachment of Panel ..................................................................................................................... 19

4.2. Set-up of the Storage Water Heater ............................................................................................. 21

4.3. Installation of Thermodynamic Block ........................................................................................... 21

4.4. Refrigerant Connections ............................................................................................................... 22

4.4.1. Connection to the Panel (x1)................................................................................................. 22

4.4.2. Connection to the Panels (x2) ............................................................................................... 23

Eco

4

Technical Manual

4.4.3. Connection of Thermodynamic Block and Storage Water Heater ......................................... 24

4.4.4. Connection of Thermodynamic Block and Thermodynamic Panel ........................................ 25

4.4.5. Load of Nitrogen ................................................................................................................... 26

4.4.6. Create Vacuum ..................................................................................................................... 26

4.4.7. Load of Complementary Cooling Fluid .................................................................................. 27

4.4.8. Checking good running condition.......................................................................................... 27

4.5. Hydraulic Couplings ...................................................................................................................... 27

4.6. Electric Connections...................................................................................................................... 28

5. FIRST USE ............................................................................................................................................. 31

5.1. Filling the tank .............................................................................................................................. 31

5.2. Start-up of the System .................................................................................................................. 31

6. SYSTEM OPERATION ............................................................................................................................ 32

6.1. Control Panel ................................................................................................................................ 32

6.2. Keys (Functions) ............................................................................................................................ 32

6.3. Description ................................................................................................................................... 33

6.4. Symbols ........................................................................................................................................ 33

6.5. Operating Modes ......................................................................................................................... 34

6.5.1. ECO Operating Mode ........................................................................................................... 34

6.5.2. AUTO Operating Mode ......................................................................................................... 34

6.5.3. BOOST Operating Mode ....................................................................................................... 34

6.6. Extra Functions ............................................................................................................................. 35

6.6.1. DISINFECT Function .............................................................................................................. 35

6.6.2. HOLIDAYS Function .............................................................................................................. 35

6.6.3. PV Function .......................................................................................................................... 35

7. SYSTEM MENU ..................................................................................................................................... 36

8. PARAMETERS DESCRIPTION ................................................................................................................ 37

9. TABLE OF ERRORS ................................................................................................................................ 38

10. GRAPHIC OF PROBES ........................................................................................................................... 38

11. RESOLUTION OF PROBLEMS ................................................................................................................ 39

12. SYSTEM MAINTENANCE ....................................................................................................................... 41

12.1. General Inspection....................................................................................................................... 41

12.2. Magnesium Anode....................................................................................................................... 41

12.3. Cleaning Filter of Throttle Valve .................................................................................................. 41

12.4. Safety Thermostat ....................................................................................................................... 41

12.5. Empty the Storage Water Heater ................................................................................................. 42

Eco

Technical Manual

5

1. IMPORTANT

1.1. Symbols

All the information that the

supplier believes to be an asset

for better performance and

preservation of the equipment,

will be signalled together with the

information sign.

1.2 . Pre-installation Information

WARNING / DANGER

The electrical installation of the equipment must

comply with the national regulations for

electrical installations in effect.

Eco will only operate after receiving its load of

coolant.

The maximum water pressure into the hydraulic

circuit inlet is 0.3 Mpa and the minimum

pressure is 0.1 MPa.

The power supply is 230 V, 50 Hz, and the power

supply cable is plugged into a socket with earth

wiring.

If the power supply cable is damaged, it must be

replaced by the manufacturer, by its customer

service, or by staff with similar training in order

to avoid any danger.

Eco will only operate if the storage water heater

is filled with water.

DANGER

This device can be used by 8 year

old children and older, or people

with physical, sensorial or mental

handicaps, or lacking experience /

knowledge, if they received

training regarding the running of

the device in a safe way and are

aware of the dangers involved.

Children must not play with the

appliance.

1.3 . Safety information

When installing:

The installation of a thermodynamic

equipment for heating sanitary water

must be carried out by staff with suitable

training and qualified for this purpose;

The device should not be installed in

places that present a risk of impact, shock

or explosion;

Keep the equipment packed until you

reach the place and moment of

installation;

Make sure all hydraulic couplings are

watertight before connecting the

equipment to the power supply.

Maintenance of the equipment:

Equipment maintenance should be

carried out by customer service, except

operations of general and continuous

cleaning which could/should be carried

out by the user;

Every process that the supplier

believes to be conducive to

harmful danger and/or material

damage, will be signalled with a

danger sign.

For a better characterization of

the danger, the symbol will be

followed by one of these words:

DANGER: when there is

the possibility of harm to

the operator and/or

people in the vicinity of

the equipment.

WARNING: when there is

the possibility of material

damage to the

equipment and/or

attached materials.

Eco

6

Technical Manual

Power supply to the equipment must be

disconnected when doing maintenance

operations;

The supplier recommends at least one

annual inspection to the equipment, by a

qualified technician;

Cleaning and maintenance must not be

carried out by children unless they are

under supervision.

High pressure and temperature:

The principle for running this equipment

is directly linked to high temperature and

pressure; thus, the processes that imply

contact with the equipment must be

thought out with caution to prevent the

risk of burns and projection of material;

Cooling Fluid

The cooling fluid employed in the whole

process is R134a, CFC-free, noninflammable and without harmful effects

for the ozone layer;

However, according to the law, the fluid in

this equipment cannot be released into

the environment;

Handling of the fluid in the equipment

must be carried out by a qualified

technician.

Information for the Client

The Installer must inform the client about

the running of the equipment, its dangers,

rights and duties of the client;

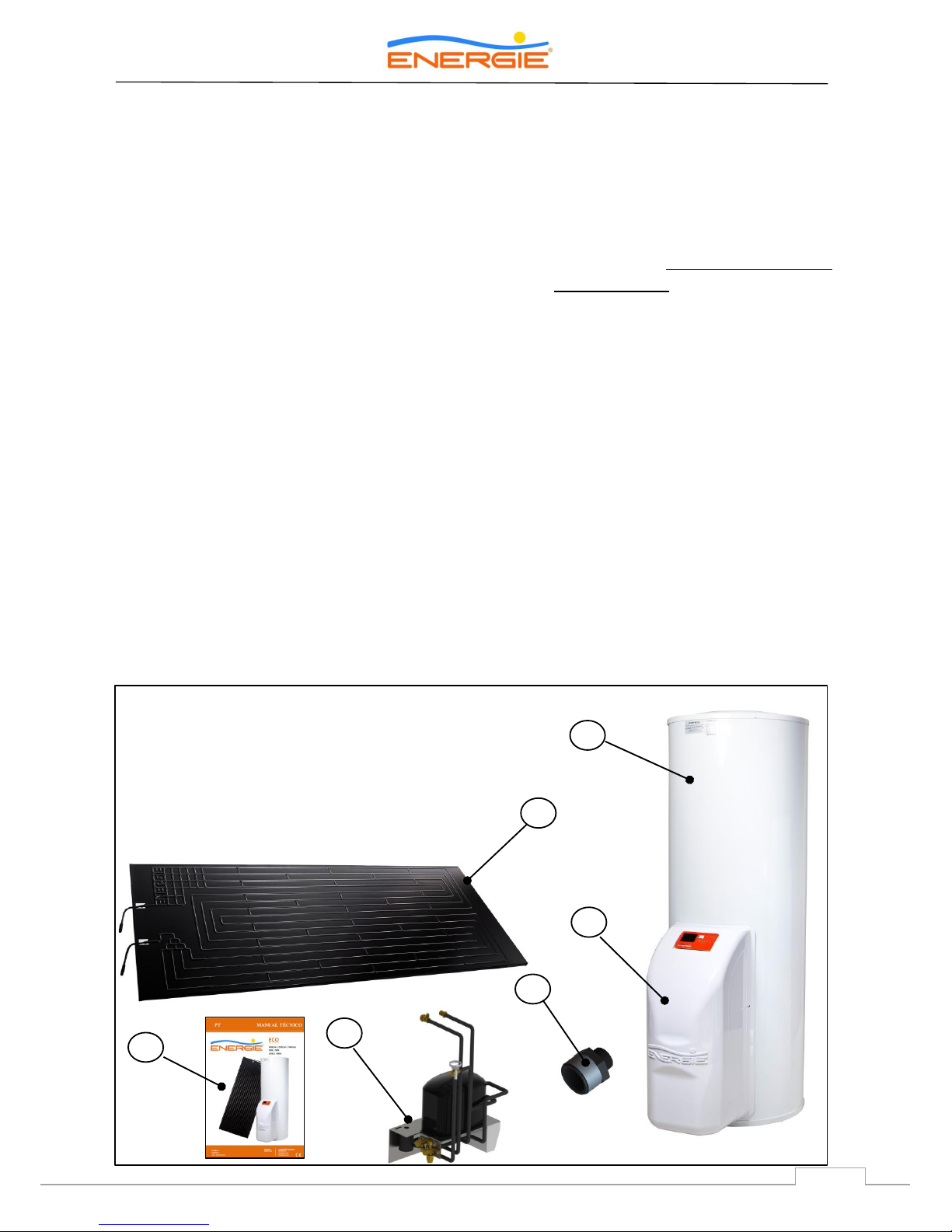

2. PACKAGE

2.1. Contents

The equipment is supplied in three packages, one for the thermodynamic panel and its attachment

elements, one for the storage water heater and another for the thermodynamic block together with the

hood and elements to attach to the storage water heater.

The packages contain:

I. Thermodynamic panel + its attachment elements

II. Storage Water Heater

III. Thermodynamic block + attachment elements

IV. Hood + Electronic panel

V. Installation manual and Warranty

VI. Dielectric joints (except stainless steel tank)

II

I

V

III

IV

VI

Eco

7

Technical Manual

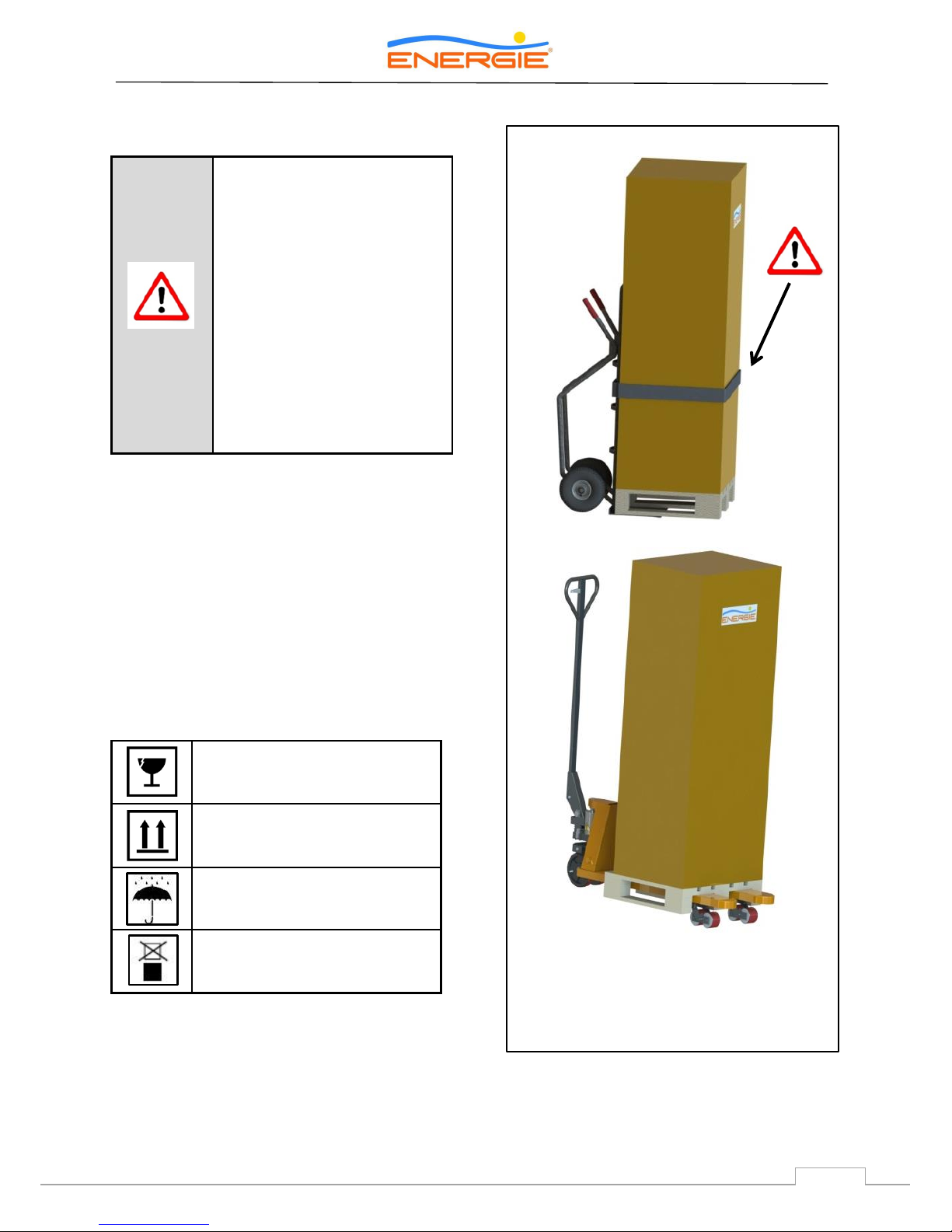

2.2. Transport

The equipment must be transported in its original

package to the place of installation. Check, before

beginning transport of the external unit, if the

path you will travel is unobstructed, in order to

prevent collisions that could cause damage to the

device.

The packages contain the following information

symbols:

WARNING

Transporting the equipment

must be carried out with an

inclination below 45º;

The equipment must be raised

and lowered with extreme

care to avoid impact that

could damage the material;

Make sure the belts and/or

transportation straps do not

damage the material;

Always use means of

transportation suitable for the

equipment (pallet lift, forklift,

etc…);

Fragile, handle with extreme

caution

Make sure the arrows are always

up

Keep the package dry

Do not stack packages

Eco

8

Technical Manual

3. SPECIFICATIONS

3.1. Running principle

The thermodynamic solar system Eco, is an

equipment based upon the principle of cooling by

compression – Principle of Carnot – which we

designate Thermodynamic Solar Systems: solar

panel and heat-pump. The solar panel, the main

component, placed outside, is in charge of

collecting the energy from:

Diffuse and direct solar radiation.

External air, by natural convection.

The wind effect (almost invariably

available).

Rainwater.

The temperature gradient caused by the external

agents mentioned, ensures the klea (ecological

cooling fluid) will evaporate inside the solar panel.

The absence of glass in the panel allows for an

increased thermal exchange by convection.

After circulation in the panel, the klea is aspirated

by the system’s mechanical component, the

compressor, which will increase its temperature

and pressure; it is then transferred to the water

circuit through a heat exchanger.

Before the Klea returns to the solar panel it is

necessary that there should be a narrowing, that

is, reduce the pressure and ensure that it is again

in a liquid state, thus completing the cycle.

The easy way we combine technology with a law

of Nature (change of state of a fluid),

demonstrates the true potential of the

Thermodynamic Solar System - Eco.

Eco

9

Technical Manual

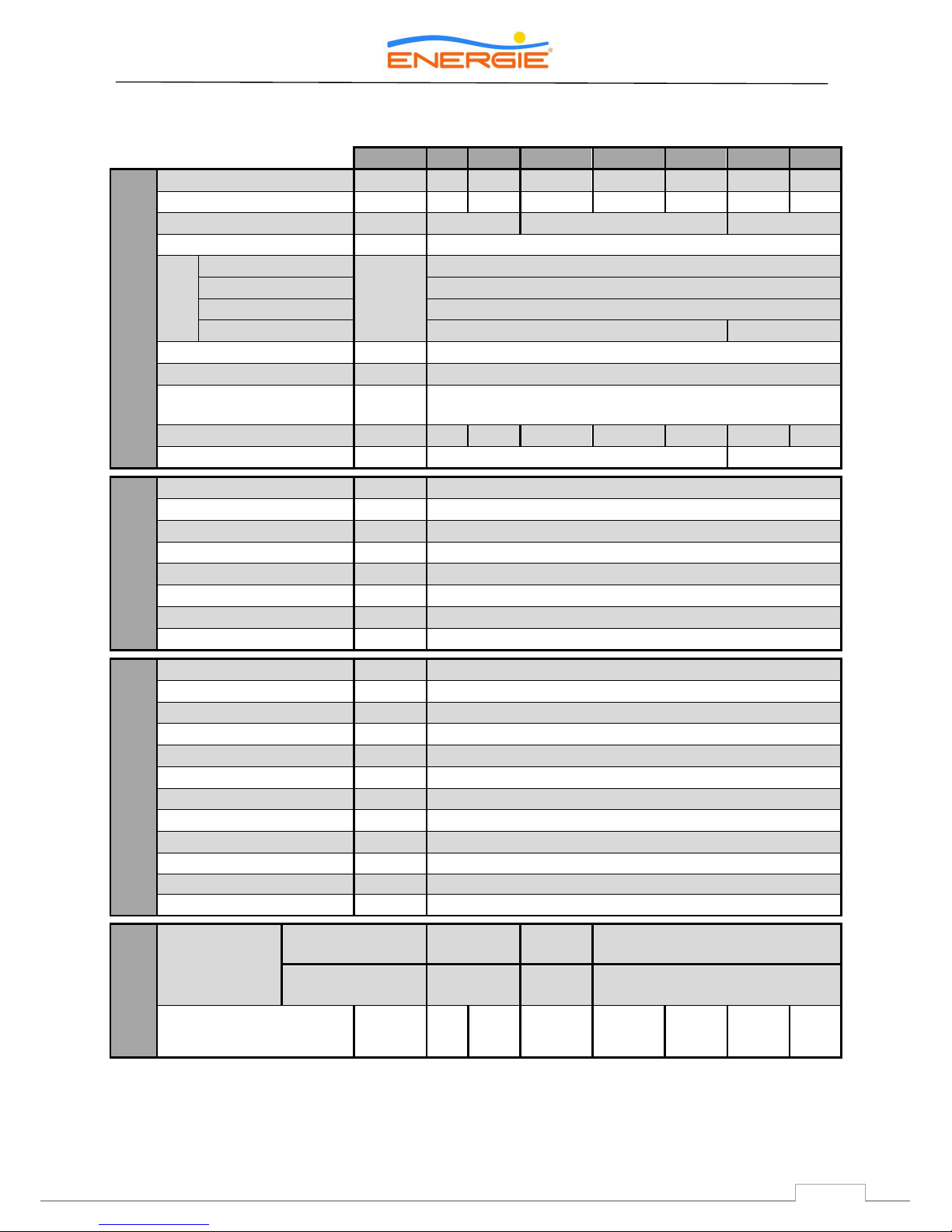

3.2. Technical features (x1 panel)

Unid

250i

300i

200esm

250esm

300esm

250ix

300ix

HOT WATER CYLINDER

Dry Weight

Kg

62

74

73

83

95

69

81

Capacity

lts

250

300

200

250

300

250

300

Internal Protection

-

Stain. Steel

Enamelled

Stain. Steel

Cathodic Protection

-

Magnesium Anode (1”1/4 Female)

Hydraulic

Joints

Water – Inlet and Outlet

inch

3/4” Male

TP Valve

1/2” Female

Recirculation

3/4” Male

Coil – Inlet and Outlet

Not Applicable

1” Male

Maximum Pressure

bar

7

Test Pressure

bar

10

Maximum Water

Temperature

°C

80

Heat Loss (EN 12897)

kWh/24h

1,01

1,17

1,04

1,2

1,39

1,01

1,17

Exchanger Output Power

1

kW

Not Applicable

a)30,0; b)18,0

THERMODYNAMIC

SOLAR PANEL

Material

-

Solokote Anodized Aluminium

Dimensions (L x W x H)

mm

2000 x 800 x 20

Weigh

kg

8

Max Working Pressure

bar

12

Test Pressure

bar

15

Max Exposure Pressure

°C

120

Min Running Temperature

°C

- 5

Min Exposure Temperature

°C

- 40

THERMODYNAMIC BLOCK

Width / Height / Depth

mm

320 / 710 / 280

Weight

kg

17,5

Absorved Power (Med/Max)

W

390 - 550

Thermal Power (Med/Max)

W

1690 / 2900

Electrical Backup Power

W

1500

Compressor Type

-

Hermetic

Compressor Noise Level

dB

39

Refrigerant / Qt.2

- / g

R134a / 11002

Piping Material - Copper (DHP ISO1337)

Line (Liq. | Asp.)

inch

1/4” | 3/8”

Power Supply

V / Hz

230 monophase / 50

Fuse (Main | Elect. Heater) A 10 | 10

Performance

Performance

Coeficient

(COP)

3

EN 255 – 3

(air 7 ºC / air 20 ºC)

3,4 / 4,6

3,3 / 4,5

3,4 / 4,6

EN 16147

(air 7 ºC)

2,9

2,8

2,9

Amount of Useful Water at

40 ºC

lts

317

369

242

321

374

308

360

1) a) Primary (Tin=90 ºC; Tout=80 ºC); Production DHW (Tin=10 ºC; Tout=60 ºC)

b) Primary (Tin=70 ºC; Tout=60 ºC); Production DHW (Tin=10 ºC; Tout=60 ºC)

2) The amount of fluid must be checked by the installer. In some cases it is necessary to add or remove fluid in order to ensure the

correct running of the system.

3) Water temperature from 10 ºC to 54 ºC

Eco

10

Technical Manual

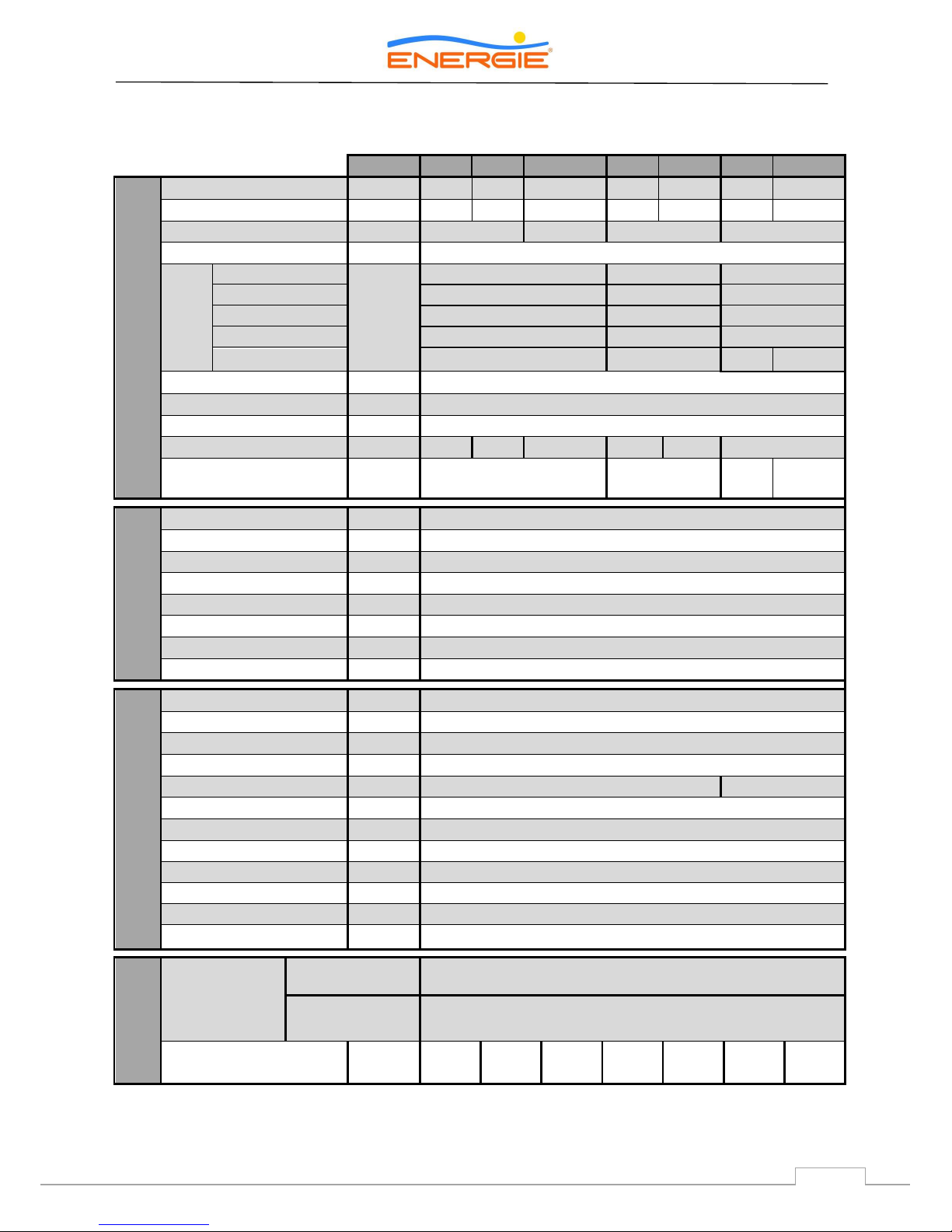

3.3. Technical features (2x panels)

Unid

250is

300is

300esms

250isx

300isx

450is

450isx

HOT WATER CYLINDER

Dry Weight

Kg

62

74

95

69

81

110

121

Capacity

lts

250

300

300

250

300

445

445

Internal Protection

-

Stain. Steel

Enamelled

Stain. Steel

Stain. Steel

Cathodic Protection

-

Magnesium Anode (1”1/4 Female)

Hydraulic

Joints

Inlet

inch

3/4” Male

3/4” Male

1” Male

Outlet

3/4” Male

3/4” Male

1” Male

TP Valve

1/2” Female

1/2” Female

1/2” Female

Recirculation

3/4” Male

3/4” Male

3/4” Male

Coil – Inlet and Outlet

Not Applicable

1” Male

N/A

1” Male

Maximum Pressure

bar

7

Test Pressure

bar

10

Maximum Temperature

°C

80

Heat Loss

(EN 12897)

kWh/24h

1,01

1,17

1,39

1,01

1,17

1,81

Exchanger Output Power1

kW

Not Applicable

a)30,0; b)18,0

N/A

a)54,2;

b)32,5

THERMODINAMIC

SOLAR PANEL

Material

-

Solokote Anodized Aluminium

Dimensions (L x W x H)

mm

2000 x 800 x 20

Weight

kg

8

Max. working pressure

bar

12

Test pressure

bar

15

Max. exposure temp.

°C

120

Min. running temperature

°C

- 5

Min. exposure temp.

°C

- 40

THERMODYNAMIC

BLOCK

Width / Height / Depth

mm

320 / 710 / 280

Weight

kg

20,5

Absorbed power (Med/Max)

W

595 / 890

Thermal power (Med/Max)

W

2800 / 4550

Electrical Backup Power

W

1500

2200

Compressor Type

-

Hermetic

Compressor Noise Level

dB

39

Refrigerant / Qt.2

- / g

R134a / 1300

2

Piping Material - Copper (DHP ISO1337)

Line (Liq. | Asp.)

inch

3/8” | 1/2”

Power Supply

V / Hz

230 Monophase / 50

Fuse (Main | Elect. Heater) A 10 | 10

Performance

Performance

Coeficient

(COP) 3

EN 255 – 3

(air 7 ºC / air 20 ºC)

3,5 / 4,7

EN 16147

(air 7 ºC)

3,0

Amount of Useful Water

at 40 ºC

lts

317

369

374

308

360

530

517

1) a) Primary (Tin=90 ºC; Tout=80 ºC); Production DHW (Tin=10 ºC; Tout=60 ºC)

b) Primary (Tin=70 ºC; Tout=60 ºC); Production DHW (Tin=10 ºC; Tout=60 ºC)

2) The amount of fluid must be checked by the installer. In some cases it is necessary to add or remove fluid in order to ensure the

correct running of the system.

3) Water temperature from 10 ºC to 54 ºC

Eco

11

Technical Manual

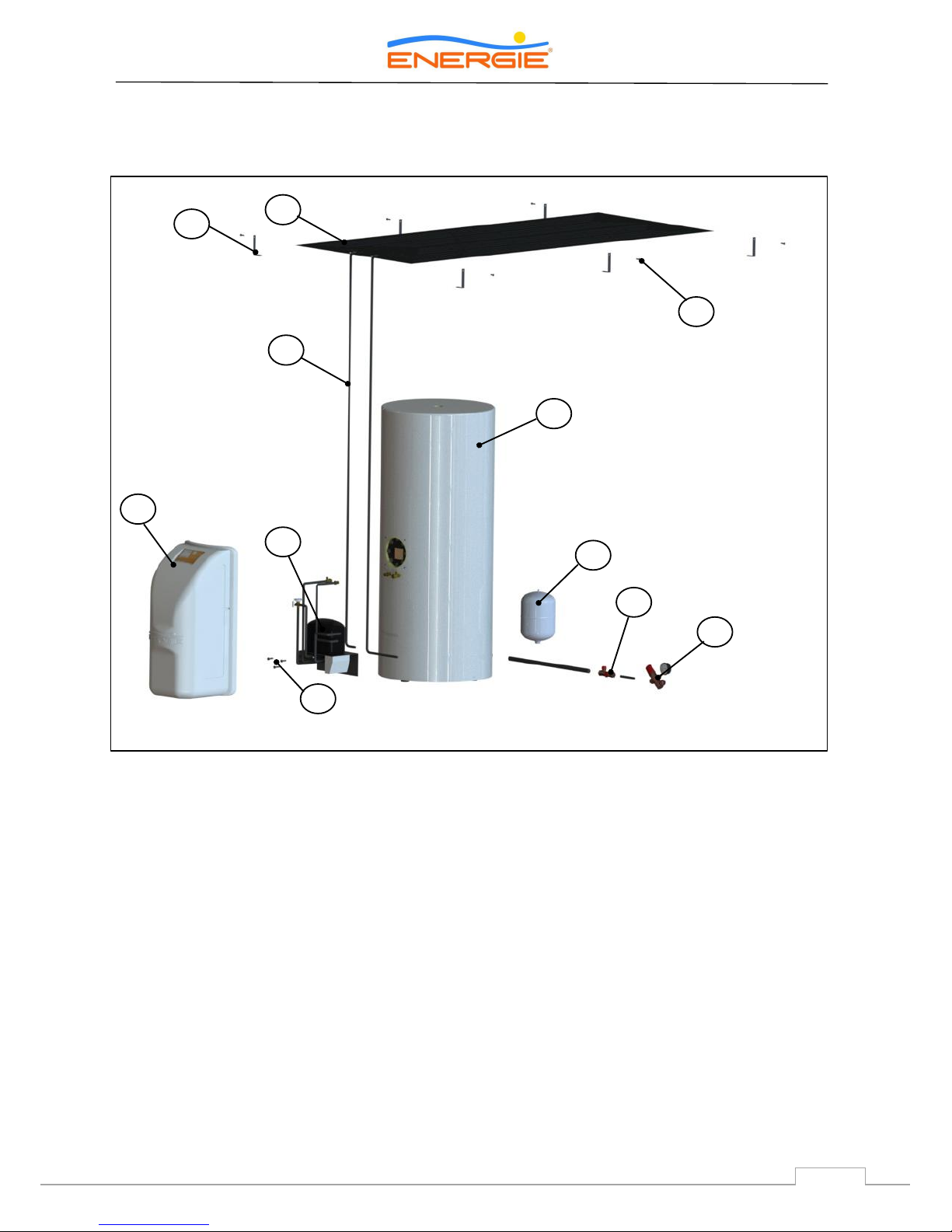

3.4. Main Components

3.4.1. General diagram of assembly

[1]

Thermodynamic Solar Panel

[2]

L-shaped fastenings for attachment of Aluminium Panel

[3]

Set of bolt, female, washer and bushing (6x or 8x)

[4]

Copper pipes

[5]

Water storage heater

[6]

Thermodynamic block

[7]

Hood + Display

[8]

Bolts CHC M8

[9]

Expansion tank

[10]

Safety device

[11]

Pressure reduction valve

3 1 2

5 4 9

10

8

11

7

6

Eco

12

Technical Manual

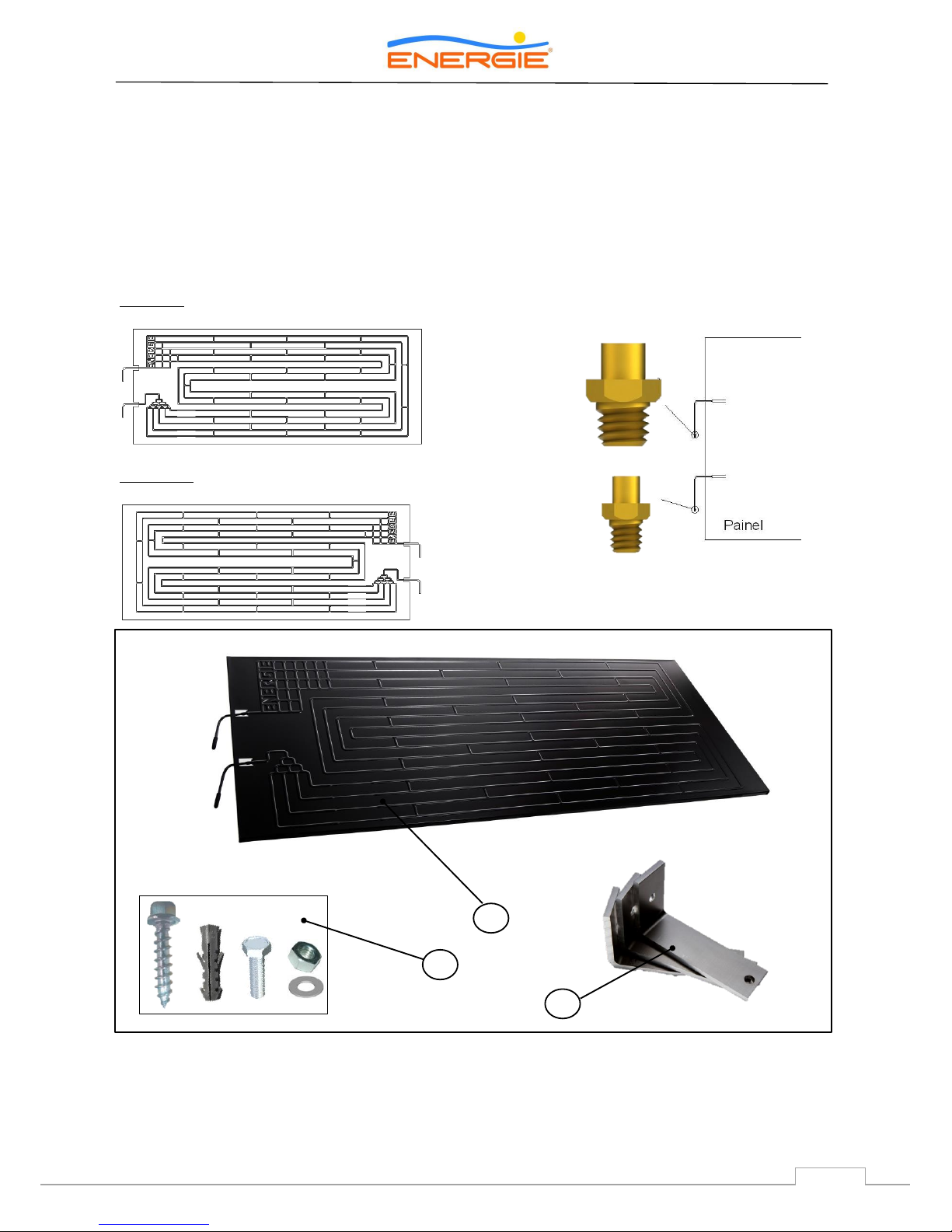

3.4.2. Thermodynamic Solar Panel

The solar panel is a roll-bond type plate

manufactured in double channel pressed

aluminium, with a post-press anodizationoxidation that creates a dark tone aspect. There

are two types of panels available: left and right

(designated according to side of connections).

Left Panel

Right Panel

The panel has a standard dimension of 2000 mm x

800 mm x 20 mm.

The panel connections are Flare SAE (threaded)

type. These connections are used only in the

equipments with one panel.

3/8’’ Aspiration (upper part)

1/4’’ Liquid (lower part)

[12]

Thermodynamic Solar Panel

[13]

Aluminium L-shaped fastenings for attachment of Thermodynamic Panel (6x or 12x)

[14]

Elements for attachment of Thermodynamic Panel

12

13

ODS (welded to panel)

3/8” flare Male SAE

ODS (welded to panel)

1/4” flare Male SAE

14

Eco

13

Technical Manual

3.4.3. Storage Water Heater

The hot storage water heater is vertical and rests

on the floor. The tank is made of carbon steel with

enamel coating or in stainless steel. The thermal

insulation is of expanded polyurethane with a

thickness of 40 mm.

The storage water heater has a cold water inlet,

hot water outlet, AQS return and an outlet for the

expansion valve. It also comes equipped with a

magnesium anode in the upper section.

There is, in the central part of the storage water

heater, a flanged opening for placing the support

resistance, as well as safety thermostat and

temperature probe.

[14]

Hood of Eco

[25]

Adjustable support foot

[15]

Condenser / Coil

[26]

Cold water inlet

[16]

“One-Shot” Female Valve

[27]

Recirculation

[17]

“One-Shot” Male Valve

[28]

TPR Valve

[18]

Temperature Probe + Safety Thermostat

[29]

Hot water outlet

[19]

Resistance

[20]

Display

[21]

External Sheet

[22]

Magnesium Anode

[23]

Tank

[24]

Polyurethane Insulation

23

22

24

20

21

18

17

19

16

15

14

29

27

25

26

28

Eco

14

Technical Manual

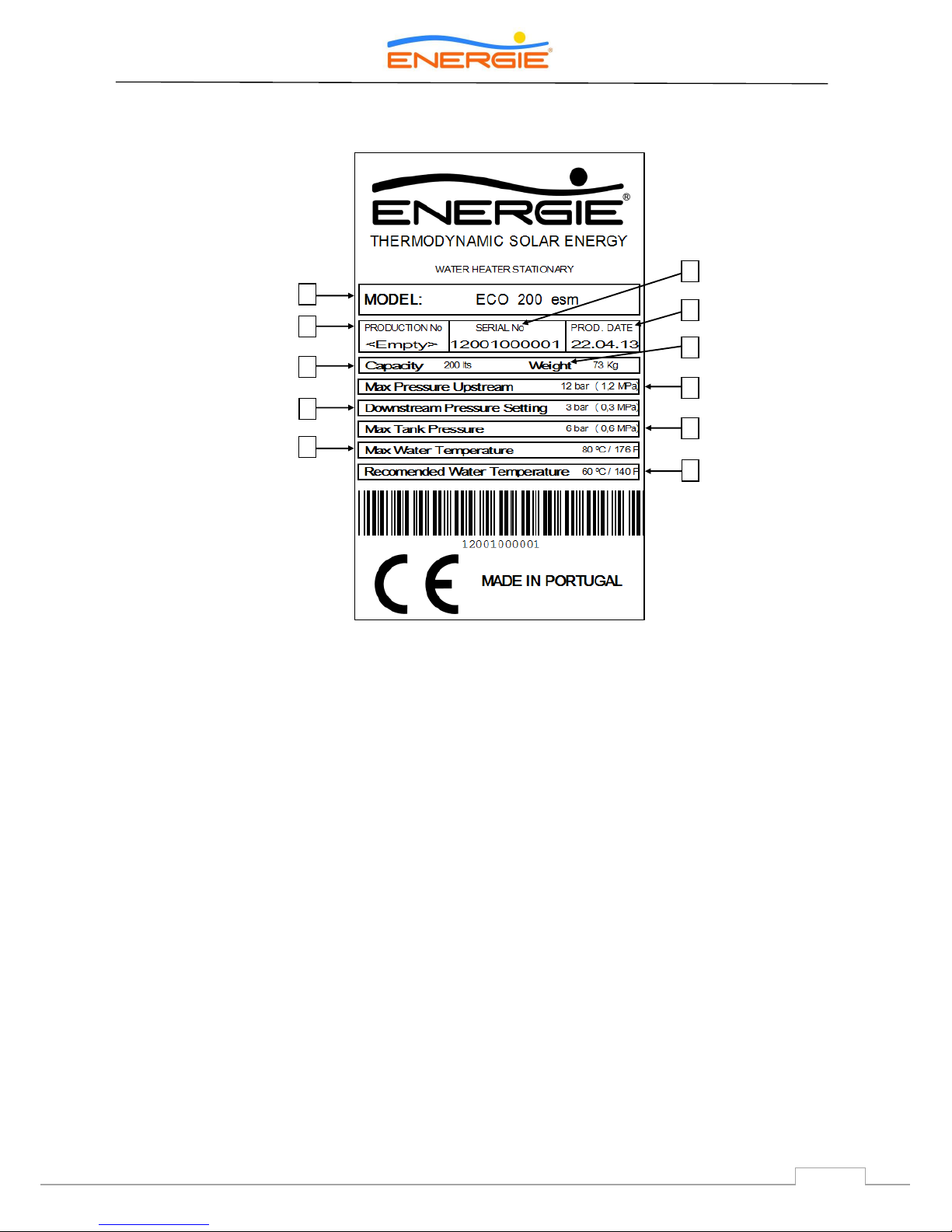

Seal with features

[A]

Model

[B]

Production number

[C]

Serial number

[D]

Production date

[E]

Volume

[F]

Weight

[G]

Downstream pressure of pressure throttle valve

[H]

Upstream Maximum Pressure of pressure throttle valve

[I]

Maximum pressure in Storage Water Heater

[J]

Maximum Temperature in Storage Water Heater

[L]

Recommended Temperature in Storage Water Heater

A

B E G

J

C

D

F H I

L

Loading...

Loading...