Energie AquaPura Split 200esm, AquaPura Split 250esm, AquaPura Split 300i, AquaPura Split 250ix, AquaPura Split 300ix Technical Manual

...

TECHNICAL MANUAL

EN

Review: 3

Date: 26/Sep/2014

Directives European Certification

EN 60335-1

EN 60335-2-21

EN 60335-2-40

2006/95/CE

AQUAPURA SPLIT

200esm | 250esm

250i | 300i

250ix | 300ix

Version: 0

AquaPura Split

2

Technical Manual

Esteemed Client,

We would like to thank you for your choice when you acquired an equipment for

sanitary water heating.

The heat-pump AquaPura Split will surely meet all your expectations and

provide many years of comfort with a maximum power saving.

Our organization dedicates much time, energy and economic resources in order

to develop innovations that will promote power saving in our products.

Your choice has demonstrated your good sense and concern with power

consumption, a matter that affects the environment.

We have taken on a permanent commitment to conceive innovative and efficient

products so that this rational use of energy can actively contribute to the

preservation of the environment and natural resources of the planet.

Keep this manual whose objective is to inform, alert and advise about the use

and maintenance of this equipment.

Our services are always at your disposal. Feel free to call upon us!

AquaPura Split

3

Technical Manual

INDEX

1. Important .............................................................................................................................................. 5

1.1. Symbols .......................................................................................................................................... 5

1.2. Pre-installation Information ........................................................................................................... 5

1.3. Safety Information ......................................................................................................................... 5

2. Package ................................................................................................................................................. 7

2.1. Contents ......................................................................................................................................... 7

2.2. Transport........................................................................................................................................ 8

3. Specifications......................................................................................................................................... 9

3.1. Running Principle ........................................................................................................................... 9

3.2. Technical Features........................................................................................................................ 10

3.3. Main Components ........................................................................................................................ 11

3.3.1. Internal Unit – Storage Water Heater.................................................................................. 11

3.3.2. External Unit ........................................................................................................................ 12

3.4. Dimensions .................................................................................................................................... 13

3.5. Safety and Control Devices ............................................................................................................ 14

3.5.1. Pressure gauge of high/low pressure ................................................................................... 14

3.5.2. Safety Thermostat ................................................................................................................ 14

3.5.3. Temperature Sensor............................................................................................................. 14

3.5.4. Protection against corrosion ................................................................................................ 14

3.5.5. TP Safety Valve .................................................................................................................... 14

3.5.6. Bipolar Socket ...................................................................................................................... 15

3.5.7. Expansion tank ..................................................................................................................... 16

3.5.8. Safety Device ....................................................................................................................... 16

3.5.9. Pressure Throttle Valve ....................................................................................................... 16

4. Installation .......................................................................................................................................... 16

4.1. Set-Up ........................................................................................................................................... 16

4.2. Coolant Couplings .......................................................................................................................... 18

4.2.1. Coolant Couplings ................................................................................................................. 18

4.2.2. Load of Nitrogen ................................................................................................................... 20

4.2.3. Create Vacuum ..................................................................................................................... 20

4.2.4. Load of Complementary Cooling Fluid .................................................................................. 21

AquaPura Split

4

Technical Manual

4.2.5. Checking good running condition.......................................................................................... 22

4.3. Hydraulic Couplings ....................................................................................................................... 22

4.4. Electric Connections ...................................................................................................................... 22

5. First Use ............................................................................................................................................... 25

5.1. Filling the tank ............................................................................................................................... 25

5.2. Start-up of the System ................................................................................................................... 25

5.3. Complementary Gas Load .............................................................................................................. 26

6. System Operation ................................................................................................................................ 27

6.1. Control Panel ................................................................................................................................. 27

6.2. Keys (Functions) ............................................................................................................................ 27

6.3. Description .................................................................................................................................... 28

6.4. Symbols ......................................................................................................................................... 28

6.5. Operating Modes ........................................................................................................................... 29

6.5.1. ECO operating mode ............................................................................................................ 29

6.5.2. AUTO Operating Mode ......................................................................................................... 29

6.5.3. BOOST Operating Mode ....................................................................................................... 29

6.6. Extra Functions ............................................................................................................................. 30

6.6.1. DISINFECT Function .............................................................................................................. 30

6.6.2. HOLIDAYS Function .............................................................................................................. 30

6.7. End of Useful Life of the System ................................................................................................... 30

7. System Menu ....................................................................................................................................... 31

8. Parameters Description ....................................................................................................................... 31

9. Table of Errors ..................................................................................................................................... 32

10. Graphic of Probes ................................................................................................................................ 32

11. Troubleshooting .................................................................................................................................. 33

12. System Maintenance ........................................................................................................................... 34

12.1. General Inspection ...................................................................................................................... 34

12.2. Magnesium Anode ...................................................................................................................... 34

12.3. TP Safety Valve ............................................................................................................................ 35

12.4. Safety Thermostat ........................................................................................................................ 35

12.5. Empty the Storage Water Heater ................................................................................................. 36

AquaPura Split

5

Technical Manual

All the information that the

supplier believes to be an asset

for better performance and

preservation of the equipment,

will be signalled together with the

information sign.

WARNING

The electrical installation of the equipment must

comply with the national regulations for

electrical installations in effect.

AquaPura Split will only operate after receiving

its load of coolant.

Power supply is 230 V, 50 Hz.

If the power supply cable is damaged, it must be

replaced by the manufacturer, by its customer

service, or by staff with similar training in order

to avoid any danger.

AquaPura Split will only operate if the storage

water heater is filled with water.

These assembly instructions must be read

before running the equipment!

Every process that the supplier

believes to be conducive to

harmful danger and/or material

damage, will be signalled with a

danger sign.

For a better characterization of

the danger, the symbol will be

followed by one of these words:

DANGER: when there is

the possibility of harm to

the operator and/or

people in the vicinity of

the equipment.

WARNING: when there is

the possibility of material

damage to the

equipment and/or

attached materials.

WARNING

This device should not be used by

people with physical, sensorial or

mental handicaps (including

children), or lacking experience /

knowledge, unless they are

supervised by someone responsible

for their safety, or received training

regarding the running of the

device.

1. Important

1.1. Symbols

The heater-pump AquaPura Split is only for

heating drinking water within the temperature

limits indicated!

Heating other liquids such as industrial waste

water is not allowed.

You must take into account the technical rules for

installing drinking/potable water (DIN 1988).

When working on AquaPura Split, it should

always be unplugged.

1.2. Pre-installation Information

1.3. Safety Information

When installing:

The installation of a thermodynamic

equipment for heating sanitary water

must be carried out by staff with suitable

training and qualified for this purpose;

The device should not be installed in

places that present a risk of impact, shock

or explosion;

Keep the equipment packed until you

reach the place and moment of

installation;

AquaPura Split

6

Technical Manual

Make sure all hydraulic couplings are

watertight before connecting the

equipment to the power supply.

Maintenance of the equipment:

Equipment maintenance should be

carried out by customer service, except

operations of general and continuous

cleaning which could/should be carried

out by the user;

Power supply to the equipment must be

disconnected when doing maintenance

operations;

The supplier recommends at least one

annual inspection to the equipment, by a

qualified technician;

High pressure and temperature:

The principle for running this equipment

is directly linked to high temperature and

pressure; The processes that imply

contact with the equipment must be

thought out with caution to prevent the

risk of burns and projection of material;

Refrigeration Gases

The cooling fluid employed in the whole

process is R134a, CFC-free, noninflammable and without harmful effects

for the ozone layer;

However, according to the law, the fluid in

this equipment cannot be released into

the environment;

Handling of the fluid in the equipment

must be carried out by a qualified

technician.

Information for the Client

The Installer must inform the client about

the running of the equipment, its dangers,

rights and duties of the client;

AquaPura Split

7

Technical Manual

XI

VIII

I

IX

II

V

X

VI

VII

III

IV

2. Package

2.1. Contents

The equipment is delivered in two packages, each over a wooden pallet, with protection units and wrapped

in cardboard.

The package contains:

I. An external unit (Heater-Pump) and its components:

II. Paste for sealing the space between the piping sleeve and the wall

III. Bush for draining the condensate.

IV. Insulation tape roll for the tubes

V. Tube for draining condensate

VI. Piping sleeve

VII. Washer for piping shaft

VIII. An internal unit (Storage Water Heater + Hood)

IX. Two dielectric joint 3/4” (connection with storage water heater)

X. TP valve

XI. Installation Manual

AquaPura Split

8

Technical Manual

WARNING

Transporting the equipment

must be carried out with an

inclination below 45º;

The equipment must be raised

and lowered to avoid impact

that could damage the

material;

Make sure the belts and/or

transportation straps do not

damage the material;

Always use means of

transportation suitable for the

equipment (pallet lift, forklift,

etc…)

Fragile, handle with extreme

caution

Make sure the arrows are always

up

Keep the package dry

Do not stack packages

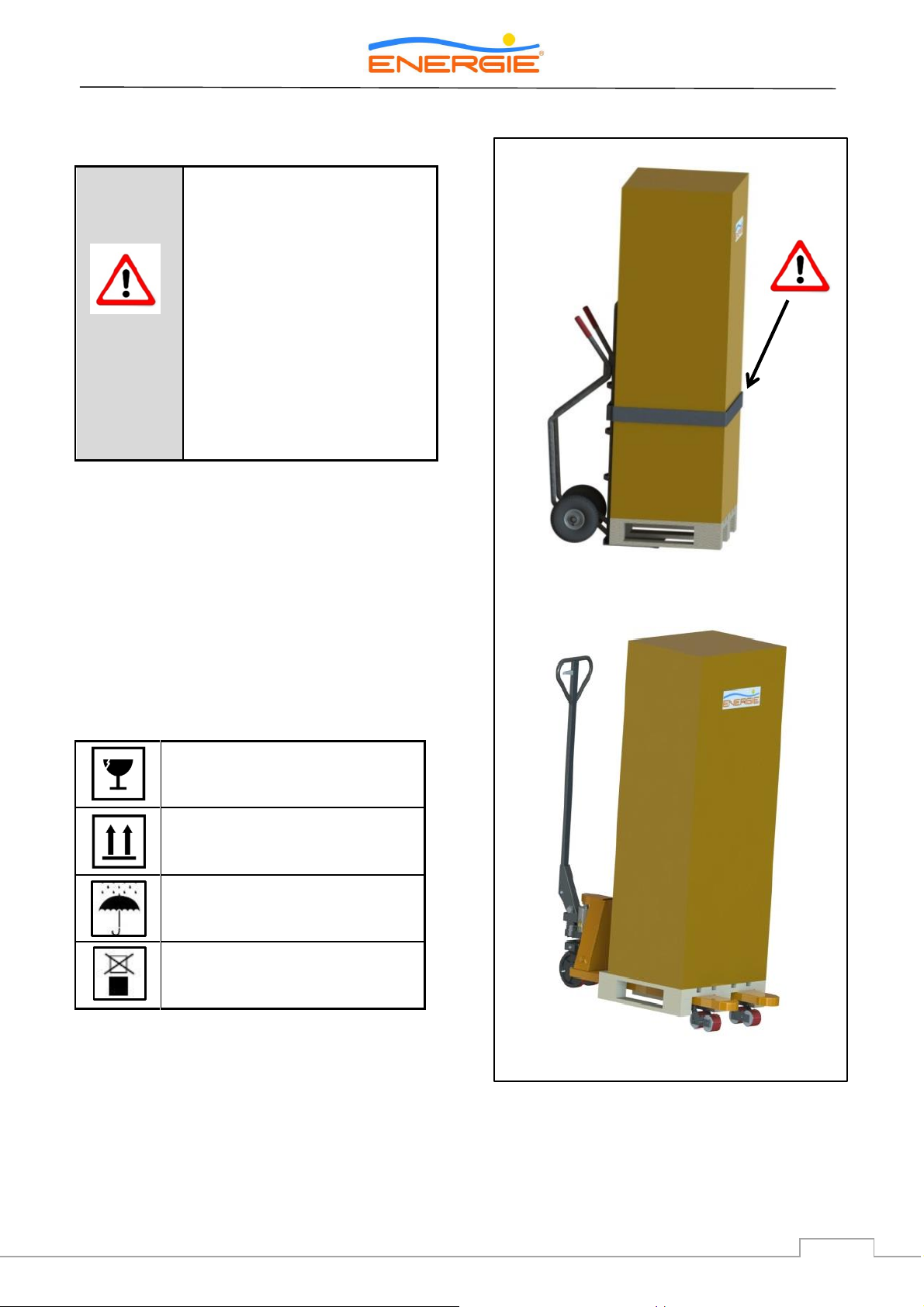

2.2. Transport

The equipment must be transported in its original

package to the place of installation. Check, before

beginning transport of the external unit, if the

path you will travel is unobstructed, in order to

prevent collisions that could cause damage to the

device.

The packages contain the following information

symbols:

AquaPura Split

9

Technical Manual

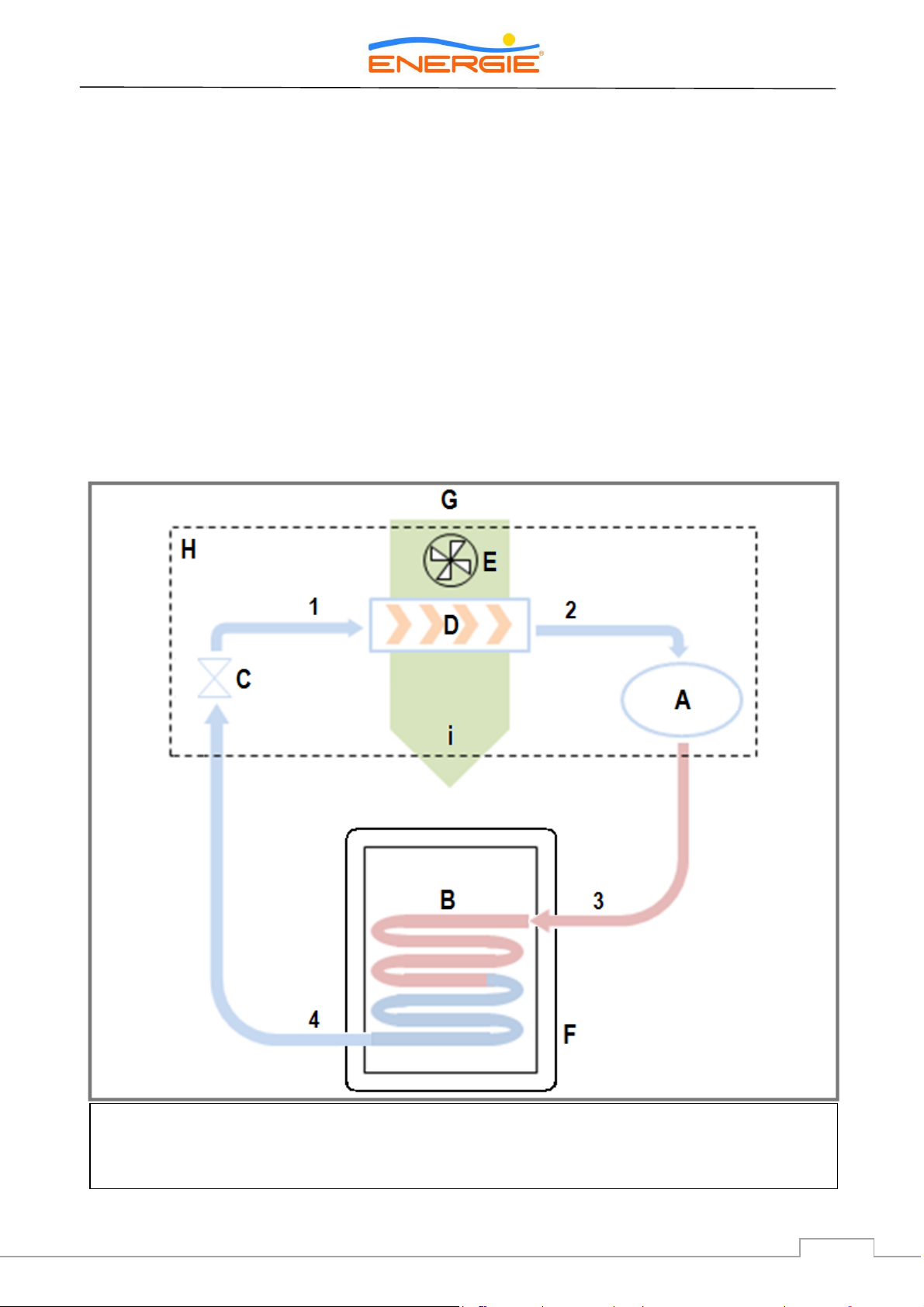

A → Compressor B → Condenser C → Expansion Valve D → Evaporator

E → Fan F → Storage water heater G → Environment H → External Unit

3. Specifications

3.1. Running Principle

The heater-pump AquaPura Split employs

environmental air to heat sanitary water.

The cooling fluid in the heater-pump runs a

thermodynamic cycle that enables the

transference of energy from the environmental air

to the water contained in the storage water

heater.

G-i The air from the environment is forced

through the external unit of the device by a fan.

1-2 When it crosses the evaporator, the cooling

fluid collects the heat from the environmental

heat.

2-3 The compressor aspirates and compresses the

cooling fluid and raises the temperature to a quite

high degree.

3-4 The heat produced by the compressor is

transferred to the condenser that remains in

contact with the sanitary water in the storage

water heater.

4-1 The cooling fluid expands when going through

the expansion valve, and is now ready to collect

the energy present in the environmental air in the

evaporator.

AquaPura Split

10

Technical Manual

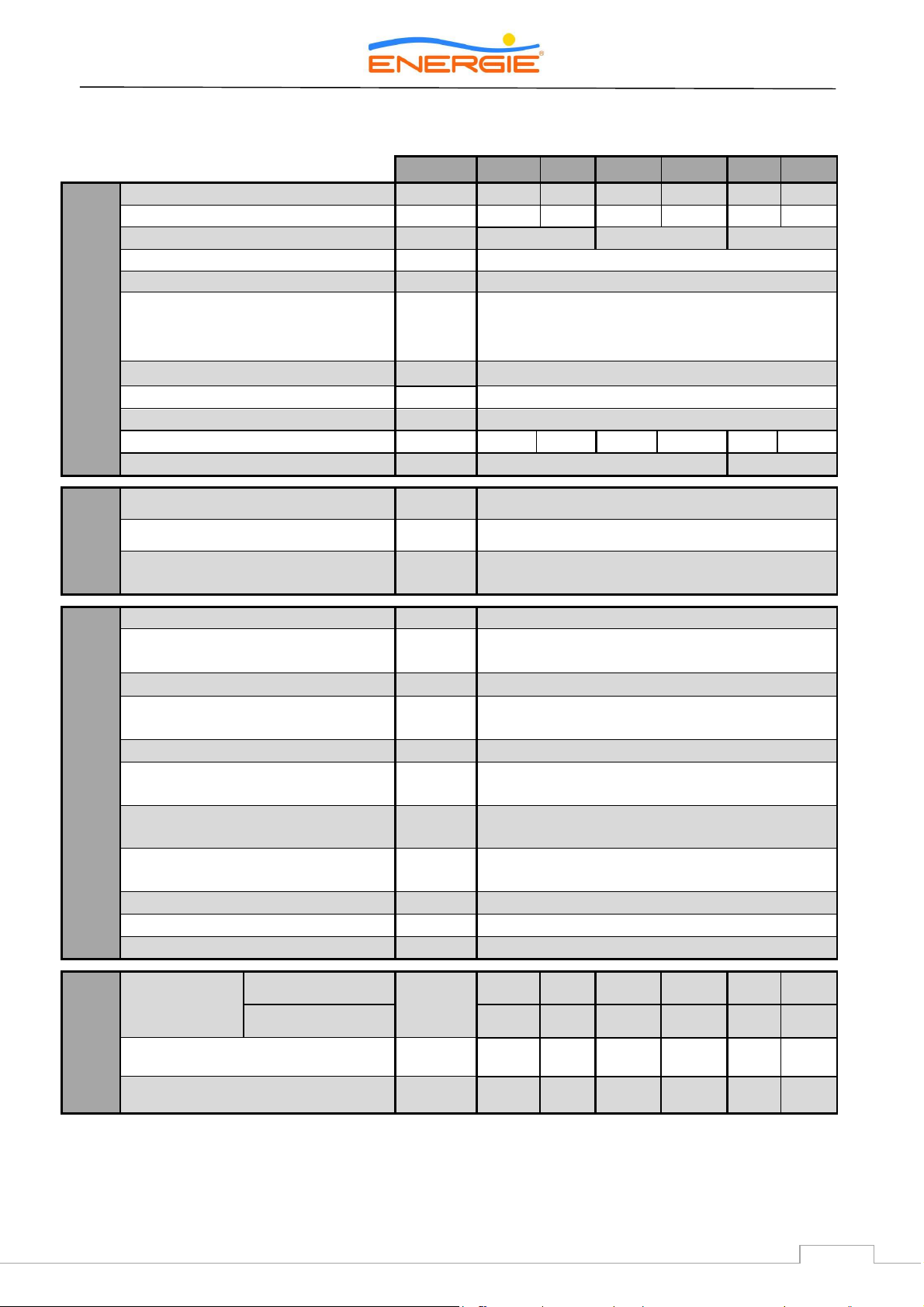

Unit

250 i

300i

200esm

250esm

250ix

300ix

STORAGE HEATER

Dry weight

Kg

62

74

73

83

69

81

Volume

lts

250

300

200

250

250

300

Type of Internal Protection

Stainless steel

Enamel

Stainless steel

Cathodic Protection

Magnesium Anode

Insulation

Polyurethane

Hydraulic Connections

(Cold water | Hot water | PT Valve |

Recirculation | Coil inlet* | Coil outlet*)

Pol.

3/4" Male | 3/4" Male |1/2" Female | 3/4" Male |

1” Male* | 1" Male*

*only on 250ix and 300ix versions

Refrigeration Connections

Pol.

1/4" & 3/8", flare type

Maximum Pressure

bar

7

Maximum Temperature

°C

80

Heat Loss1

kWh/24h

1,01

1,17

1,04

1,2

1,01

1,17

Exchanger Output Power2

kW

#######################

a)30,0; b)18,0

EXTERAL

UNIT

Weight

Kg

28

Refrigeration onnections

Pol.

1/4” & 3/8”, flare type

Level of Sound Pressure at Distance

of 5m

dB(A)

33

CHARACTERISTICS

OF EQUIPMENT

Voltage/ Frequency

(V / Hz)

230 Monophase / 50

General fuse (resistance and

electronic circuit-breaker)

A

7

Compressor fuse

A

7

Average Power absorbed by Heat

Pump

W

600

Max power absorbed by Heat Pump

W

1000

Power absorbed by Electrical

Resistance (Support)

W

1500

Max Distance between Refrigeration

Couplings

m

5

Max Gradient between Refrigeration

Couplings

m

3

Min Temperature of External Air

°C

-5

Max Temperature of External Air

°C

42

Cooling Fluid / Amount

3

- / Kg

R 134a / 1,1

PERFORMANCES

Performance

Coefficient

(COP)

According EN255-3

3,5

3,5

3,4

3,5

3,5

3,5

According EN16147

2,9

2,9

2,8

2,9

2,9

2,9

Heating Time

4

(hh:mm)

05:36

06:51

04:31

05:29

05:31

06:45

Amount of Useful Water at 40 °C

5

l

300

356

236

308

291

351

1) According EN12897:2006

2) a) Primary (Tin=90 ºC; Tout=80 ºC); Production DHW (Tin=10 ºC; Tout=60 ºC)

b) Primary (Tin=70 ºC; Tout=60 ºC); Production DHW (Tin=10 ºC; Tout=60 ºC)

3) The amount of fluid must be checked by the installer. In some cases it is necessary to add or remove fluid in order to ensure the

correct running of the system.

4) Temperature of aspirated air: 7 °C; Relative humidity: 89%; Inlet water temperature: 10 °C; (according to EN16147)

5) Water heating from 10 °C to 54 °C; Air temperature: 7 °C; Relative humidity: 89%; (according to EN16147)

3.2. Technical Features

AquaPura Split

11

Technical Manual

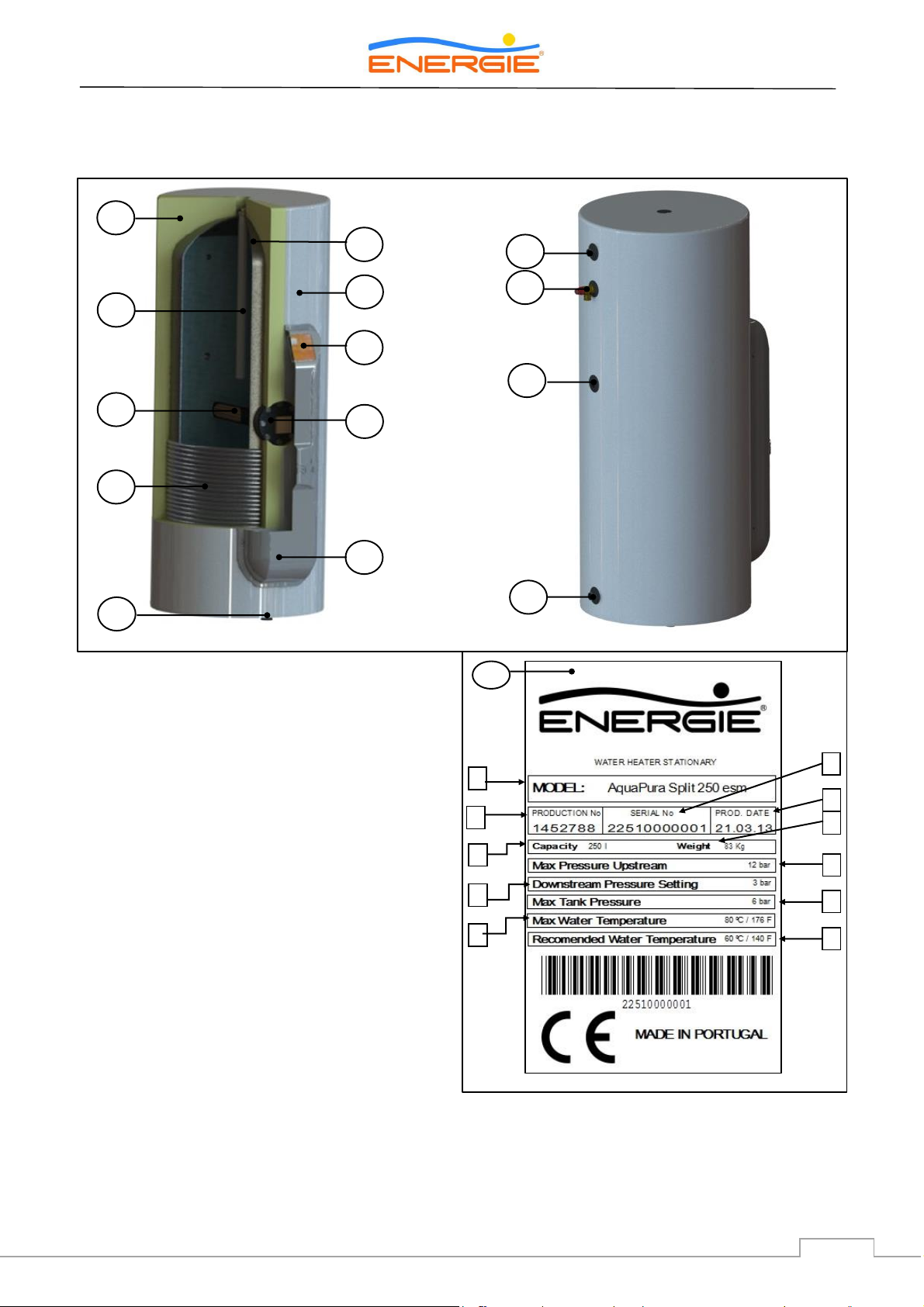

[1]

Adjustable foot

[2]

“Split” hood Top Lid

[3]

Condenser / Serpentine

[4]

Thermostat

[5]

Resistance

[6]

Display

[7]

Magnesium Anode

[8]

External Plate

[9]

Tub

[10]

Polyurethane Insulation

[11]

Cold water inlet + Bipolar Socket

[12]

Recirculation

[13]

TPR Valve

[14]

Hot water outlet + bipolar Socket

[15]

Seal with features (Storage heater)

[A]

Model

[B]

Production Nº

[C]

Series Nº

[D]

Production Date

[E]

Capacity

[F]

Weight

[G]

Downstream pressure of pressure reducing valve

[H]

Upstream Maximum Pressure of pressure reducing valve

[I]

Maximum Pressure in Storage Water Heater

[J]

Maximum Temperature in Storage Water Heater

[L]

Recommended Temperature in Storage Water Heater

1

3

5

7

10

2

4

6

8

9

11

12

13

14

15

C B F H G I J L D A E

15

3.3. Main Components

3.3.1. Internal Unit – Storage Water Heater

AquaPura Split

12

Technical Manual

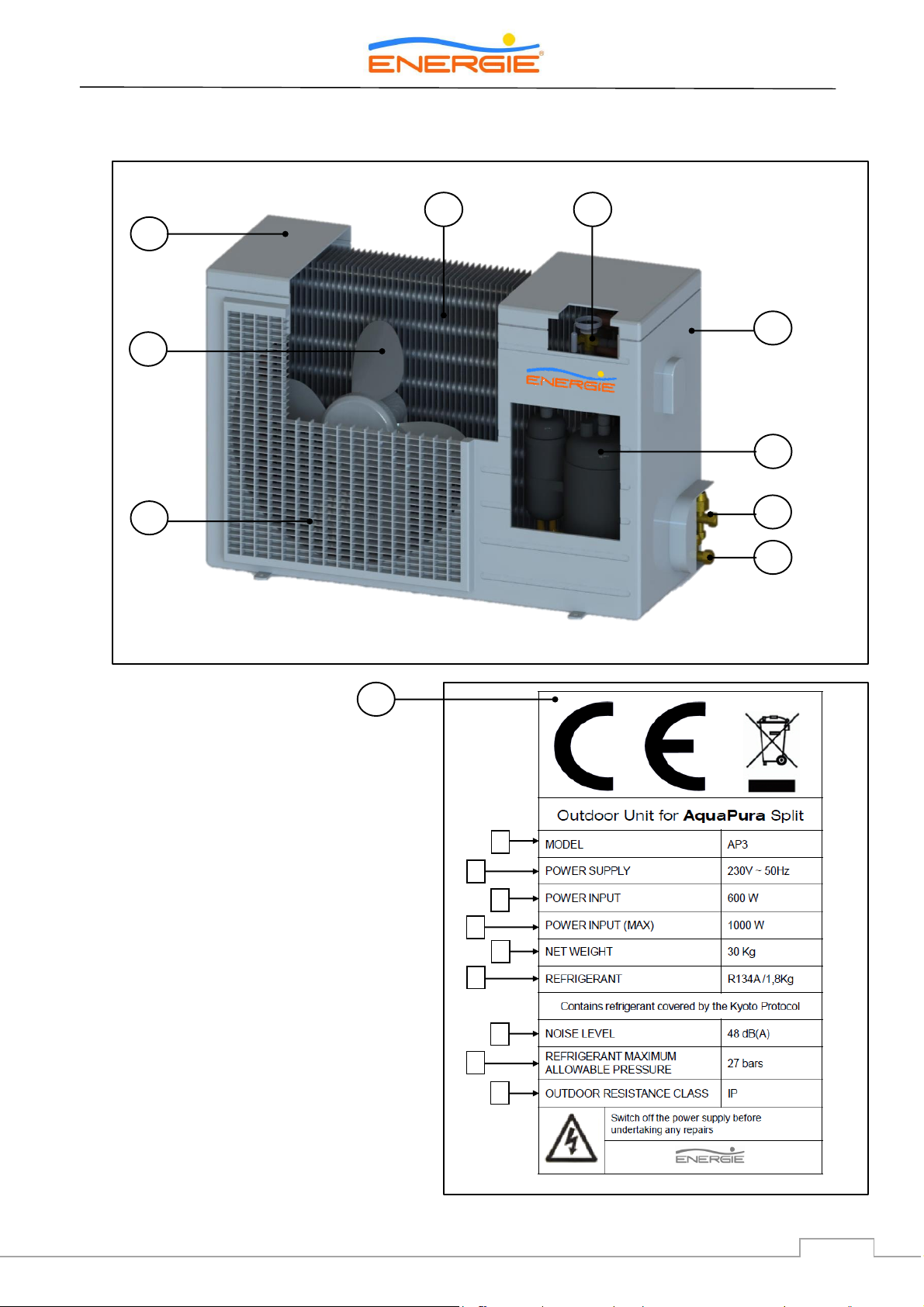

[16]

Top lid

[17]

Fan

[18]

Grill

[19]

Evaporator

[20]

Expanding Valve

[21]

Unit box

[22]

Compressor

[23]

3 way valve (Aspiration)

[24]

2 way valve (Liquid)

[25]

Seal with features (split)

[M]

Model

[N]

Power supply

[O]

Average power consumption

[P]

Maximum power consumption

[Q]

Weight

[R]

Fluid

[S]

Noise level

[T]

Admissible maximum pressure of fluid

[U]

Level of protection

16

17

19

18

20

21

22

23

24

M

N O P Q R

S T U

25

3.3.2. External Unit

Loading...

Loading...