350W Drill Press

ENB540DBT

Barcode:5052931253630

Warning! Read the instructions before using the product!

Original Instructions_MNL_ENB540DBT_V02_111222

ENB540DBT by ENERGER

GB

IE

Let's

get started...

These instructions are for your safety. Please read through them

thoroughly before use and retain them for future reference.

Getting

Your product

Technical and legal information

Before you start

In

more

Product functions

Care and maintenance

Trouble shooting

Recycling and disposal

Guarantee

EC declaration of conformity

started

detail

03

04

05

12

18

19

24

28

30

31

32

03

ENB540DBT by ENERGER

GB

IE

Your product

Getting started...

12

10

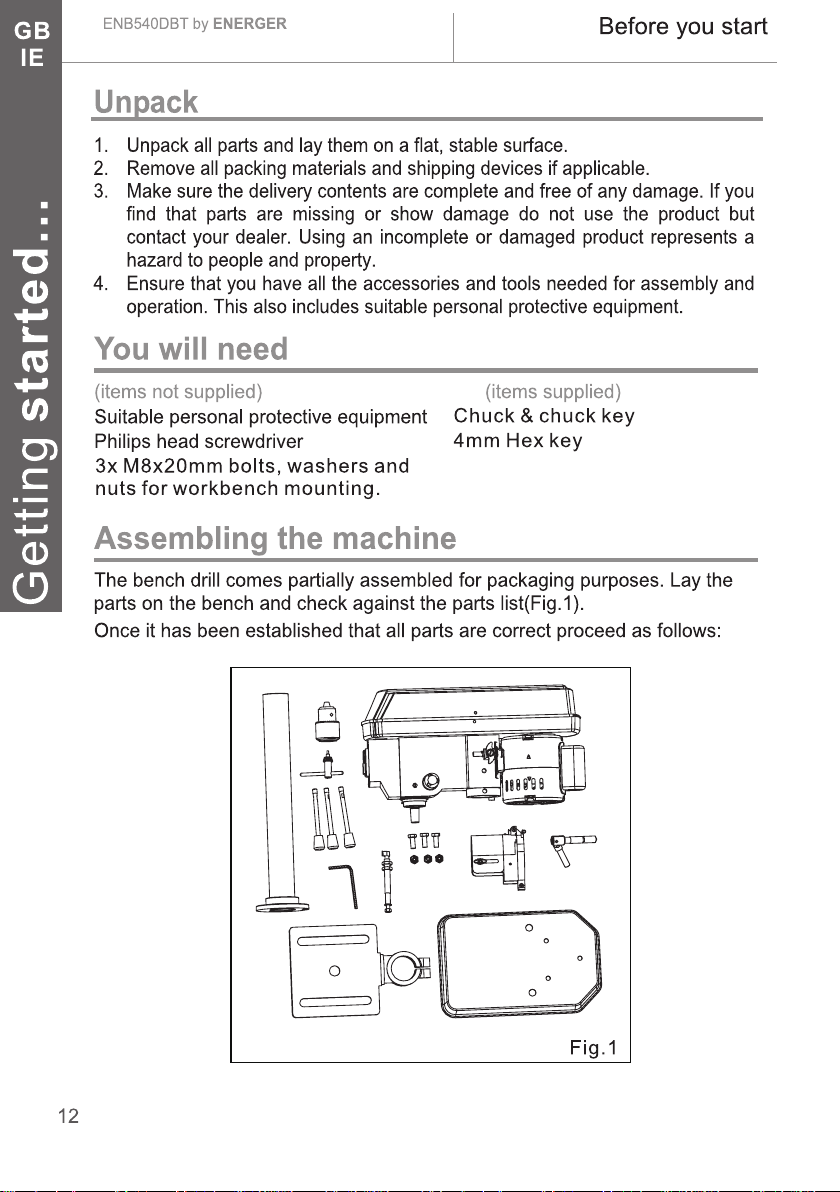

Your product

13

14

15

04

1. Pulley guard

2. Motor

3. Feed handles

4. Chuck guard

5. Column

6. Support lock

7. Base

8. Table

9. Chuck

10. Machine casing

11. On/off switch

12. Drill depth gauge

13. Grub screw

14. Pulley guard cross screw

15. Belt tension lock knob

ENB540DBT by ENERGER

Safety warnings

WARNING! When using electric tools basic safety precautions should

always be ic shock and personal followed to reduce the risk of fire, electr

!

injury including the following.

Read all these instructions before attempting to operate this product

and save these instructions.

Technical and legal information

GB

IE

Safe operation

1. Keep work area clear

- Cluttered areas and benches invite injuries.

2. Consider work area environment

- Do not expose tools to rain.

- Do not use tools in damp or wet locations.

- Keep work area well lit.

- Do not use tools in the presence of flammable liquids or gases.

3. Guard against electric shock

- Avoid body contact with earthed or grounded surfaces (e.g. pipes, radiators,

ranges, refrigerators).

4. Keep other persons away

- Do not let persons, especially children, not involved in the work touch the tool

or the extension cord and keep them away from the work area.

5. Store idle tools

- When not in use, tools should be stor ed in a dry locked-up place, out of reach

of children.

6. Do not force the tool

- It will do the job better and safer at the rate for which it was intended.

In more detail...

7. Use the right tool

- Do not force small tools to do the job of a heavy duty tool.

- Do not use tools for purposes not intended; for example do not use circular

saws to cut tree limbs or logs.

8. Dress properly

- Do not wear loose clothing or jewellery, they can be caught in moving parts.

- Non-skid footwear is recommended when working outdoors.

07

GB

IE

ENB540DBT by ENERGER

- Wear protective hair covering to contain long hair.

9. Use protective equipment

- Use safety glasses.

- Use face or dust mask if working operations create dust.

10.Connect dust extraction equipment

- If the tool is provided for the connection of dust extraction and collecting

equipment, ensure these are connected and properly used.

11. Do not abuse the cord

- Never yank the cord to disconnect it from the socket. Keep the cord away from

heat, oil and sharp edges.

12. Secure work

- Where possible use clamps or a vice to hold the work. It is safer than using

your hand.

13. Do not overreach

- Keep proper footing and balance at all times.

14. Maintain tools with care

- Keep cutting tools sharp and clean for better and safer performance.

In more detail...

- Follow instruction for lubricating and changing accessories.

- Inspect tool cords periodically and if damaged have them repaired by an

authorized service facility.

- Inspect extension cords periodically and replace if damaged.

- Keep handles dry, clean and free from oil and grease.

Technical and legal information

15. Disconnect tools

- When not in use, before servicing and when changing accessories such as

blades, bits and cutters, disconnect tools from the power supply.

16. Remove adjusting keys and wrenches

- Form the habit of checking to see that keys and adjusting wrenches are

removed from the tool before turning it on.

17. Avoid unintentional starting

- Ensure switch is in "off" position when plugging in.

18. Use outdoor extension leads

- When the tool is used outdoors, use only extension cords intended for outdoor

use and so marked.

08

ENB540DBT by ENERGER

19. Stay alert

- Watch what you are doing, use common sense and do not operate the tool

when you are tired.

20. Check damaged parts

- Before further use of tool, it shoul d be carefully checked to determine that it

will operate properly and perform its intended function.

- Check for alignment of moving parts, binding of moving parts, breakage of

parts, mounting and any other conditions that may affect its operation.

- A guard or other part that is damaged should be properly repaired or replaced

by an authorized service centre unless otherwise indicated in this instruction

manual.

- Have defective switches replaced by an authorized service centre.

- Do not use the tool if the switch does not turn it on and off.

21. Warning

- The use of any accessory or attachment other than one recommended in this

instruction manual may present a risk of personal injury.

22. Have your tool repaired by a qualified person

- This electric tool complies with t he relevant safety rules. Repairs should only

be carried out by qualified persons using original spare parts, otherwise this may

result in considerable danger to the user.

Technical and legal information

GB

IE

In more detail...

ADDITIONAL SAFETY RULES FOR BENCH DRILL PRESS

Warning!

!

- This machine must be firmly secured to a suitable workbench or other stable

work surface. When selecting a suitable location for mounting this machine

consideration must be given to the maximum length of the material to be drilled or

machined and the position of the operator.

- Before starting the machine ensure that drills and other recommended cutting

tools are fitted correctly and that all the securing bolts are tight. Check all

guards are fitted and operating correctly and that the chuck key and any other

adjustment tools have been removed.

- Keep hands well away from rotating drills and other cutting tools at all times.

- When drilling use the correct cutting lubricant /coolant for the material being

drilled. Use only sufficient to prevent the drill from overheating and make sure that

Ensure that power tools are disconnected from the mains supply when

not in use, making adjustments and before servicing, lubricating or

when changing accessories such as blades, bits and cutters.

09

GB

IE

ENB540DBT by ENERGER

it is kept well away from electrical components. Never use water as a coolant.

Keep drills and other cutters sharp and in good condition. This will improve cutting

and reduce the load on the machine ensuring a longer life of the cutting tools

and the machine.

- Use only drill bits, cutters and other accessories recommended by the

manufacturer. Select the correct spindle speed for the size of drill being used.

See the instruction manual. Do not attempt to modify the machine or its

accessories in any way.

- Do not force the machine, let the machine do the work. This will reduce the

wear on the machine and cutter and increase its efficiency and operating life.

- Use approved safety glasses or goggles at all times, and a face mask and ear

defenders when using for prolonged periods.

- When drilling long lengths of material ensure that there is adequate support at

both ends of the material.

Never use the machine without the safety guards in position and operating

correctly.

- When drilling wood and wood type materials, ensure that the work piece is free

from any nails or other foreign objects that could damage the drills and other

cutting tools.

In more detail...

- Always secure the workpiece in a suitable drill vice.

- Never try and secure the workpiece with your hands.

- Be aware that swarf can be very sharp and hot and can fly off the rotating drill.

When handling swarf always wear suitable gloves. Swarf should not be

disposed of with domestic waste, it should be disposed of at a recycling centre.

- Never leave the machine running while unattended. If you are interrupted when

operating the drill, complete the process and switch off before looking up.

- Always allow the machine to come to a complete stop and disconnect from the

power supply before leaving the unit unattended.

- Never use your hands to remove dust, chips or waste close by the drill bit.

Even when the tool is used as prescribed it is not possible to eliminate all residual

risk factors. The following hazards may arise in connection with the tool抯

construction and design:

- Contact with the drill bit.

- Kickback of work piece and parts of workpiece.

- Bit fracture.

Technical and legal information

10

ENB540DBT by ENERGER

- Catapulting of bit pieces.

- Damage to hearing if effective ear defenders are not worn.

- Damage to lungs if effective breathing protection is not worn in operations in

which dust is produced.

- Damage to sight if effective eye protection is not worn.

Technical and legal information

GB

IE

Wear goggles

Wear ear defenders

Wear a breathing mask

In more detail...

11

ENB540DBT by ENERGER

Before you start

GB

IE

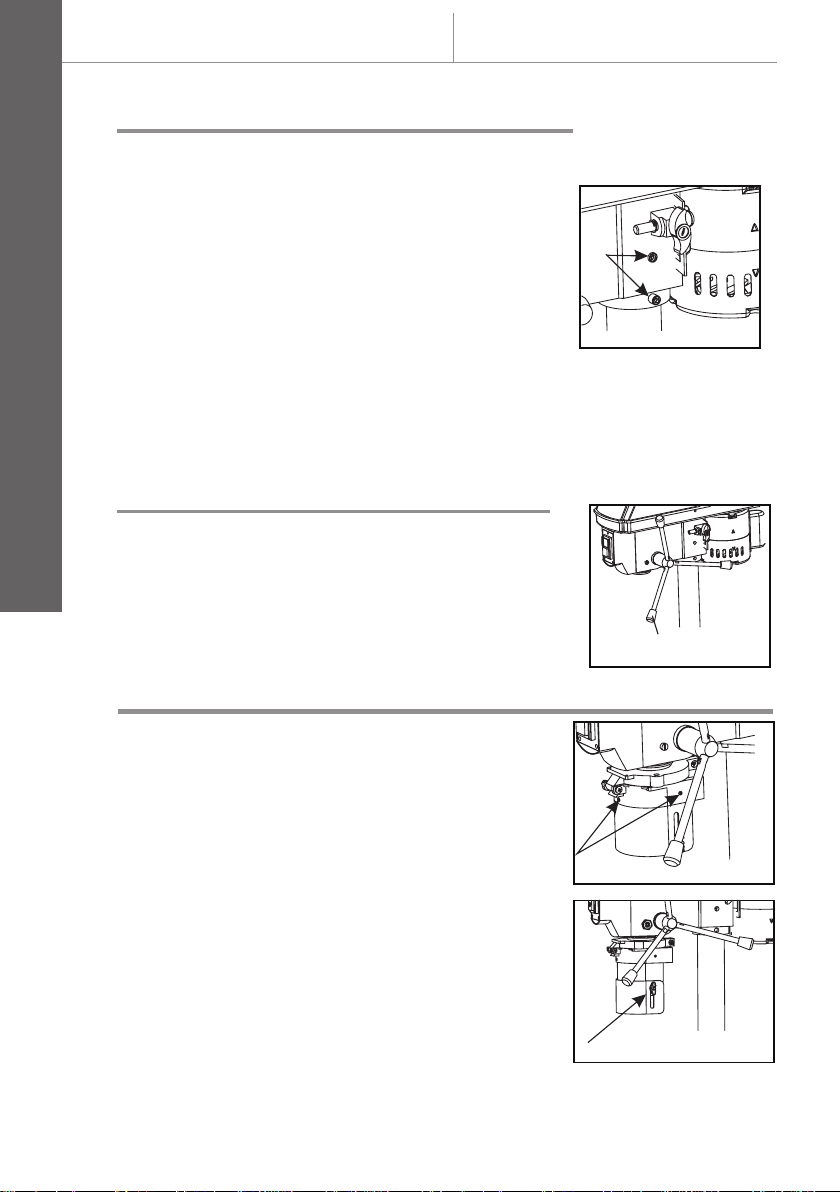

Mounting the base plate

Select a suitable location for the drill on a

workbench. Be aware of table legs and

anything which might reduce access to

the underneath of the workbench. A suitable

mains supply socket must also be accessible

for the plug. Locate the base plate(7) in the

selected position. Select two suitable length

bolts, washers and nuts (not supplied).

Using the base plate as a template drill (7)

two holes through the workbench.Bolt

the base plate to the bench. Do not over (7)

tighten as this could crack the cast base plate . (Fig.2)

7

Fig.2

Fitting the column

Align the three threaded holes on the

base plate(7) with the column(5) support holes.

Secure with the three bolts.

Do not over tighten as this could crack the cast

base plate(7) and column(5)

support(Fig.3).

5

Getting started...

Fig.3

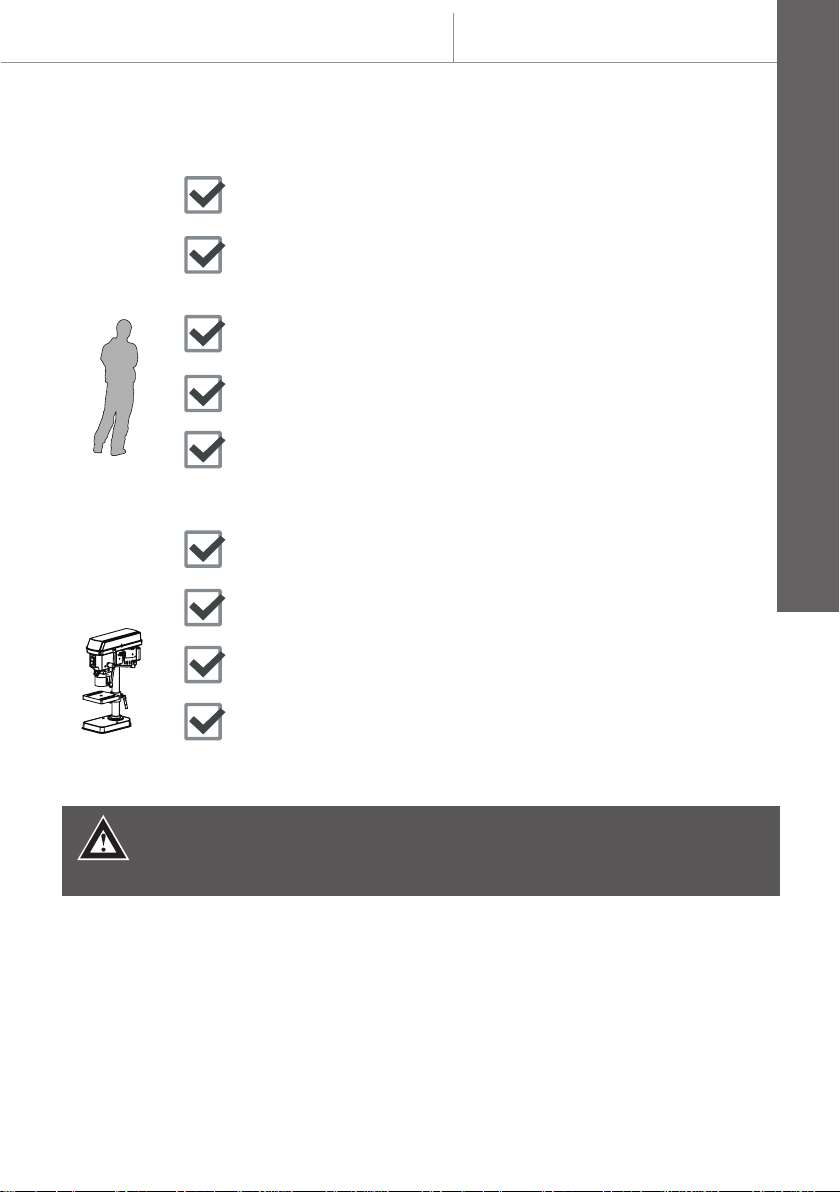

Fitting the table

Lower the table assembly onto the column(5). The

assembly will slide easily into position so do not use

force. Make sure the table assembly will rotate 360

Tighten the support lock to secure the table assembly

into position . (Fig.4)

O

8

6

5

Fig.4

13

GB

IE

ENB540DBT by ENERGER

Before you start

Fitting the head stock and motor

Locate the two grub screws in the side of the

head stock and motor assembly. Using a

hexagonal key slacken the two grub screws.

Lift the head stock and motor assembly and

lower it onto the column(. Make sure that it

slides down and locates fully on the column.

Position the head stock and motor assembly

ensuring it is aligned with the base plate(7).

Tighten the two grub screws to secure the

head stock and motor assembly into place(Fig.5).

Retain the hexagonal keys for future adjustments.

13

Fig.5

Fitting the hand feed handles

Locate and install the three hand feed handles(3).

Simply screw the handles into the three (3)

Getting started...

threaded holes located in the feed shaft boss.

Make sure that all three handles are tight . (3) (Fig.6)

3

Fig.6

Fitting the chuck guard

Warning:never attempt to use the machine

without the chuck guard(4) fitted.

The telescopic chuck guard is partially (4)

assembled onto the machine.

Remove three cross head screws just

below the hinge on the red collar.

Position the transparence plastic shield into the

red collar and secure in place with the three

small cross head screws . The chuck (Fig.7-1)

guard(4) is spring loaded and on a hinge which

allows the guard to be moved upwards to (4)

expose the chuck for drill installation and (9)

Fig.7-1

Fig.7-2

14

ENB540DBT by ENERGER

removal. Always return the guard(4) to cover rotating parts. Simply unscrew the

wing nuts and the two piece guard will extend vertically up or down. Chuck

guard(4) is adjustable to varying depths to give more protection(Fig.7-2).

Before you start

Fitting the drill depth gauge

Remove the red pointer and uscrew M6

Nut from the bar. Insert the bar into the

hole and the hole guard(4), located in chuck

then screw the nut, assemble the red

pointer in the spindle(Fig.8).

Fig.8

Fitting the 3 jaw chuck

This machine is supplied with a Morse taper

stub shaft fitted into the spindle. To fit the

chuck(9), clean the protective film from the

chuck internal taper and the stub shaft (9)

external taper with white spirit. Place the

chuck onto the exposed stub shaft. Place (9)

a piece of wood onto the drill table. Using the

feed handles(3) lower the chuck onto the (9)

wood.Gently apply pressure to engage the

taper and then let the spindle raise to its

upper position . (Fig.9)

9

Fig.9

GB

IE

Getting started...

The drill is now fully assembled and secured

in position. The following adjustments and

setting up instruction must be carried out

before connecting the machine to the mains

supply.

Fig.10

15

ENB540DBT by ENERGER

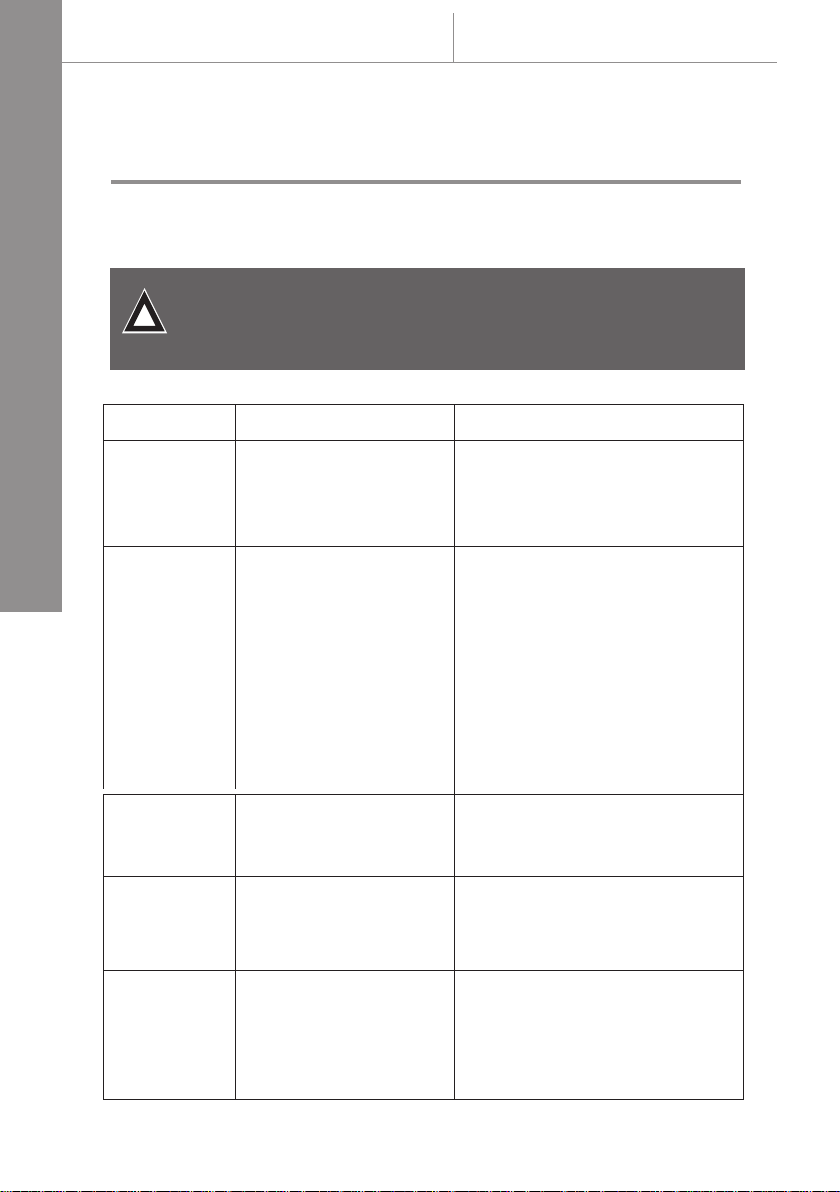

Check that you have noted all the following instructions:

Before starting you must have fully read and understood

the entire instruction manual.

Working with this product is demanding; therefore ensure

you are physically and mentally fit to complete the job

safely.

Ensure that you have all the accessories and tools needed

for assembly and operation.

Make sure that you wear suitable personal protective

equipment.

Ensure that no unauthorised people, especially children,

and pets are nearby or could enter the working area.

Ensure that the product is free from damage and that it is

not worn.

Safety

GB

IE

Make sure that safety devices and accessories are

correctly fixed.

Double check that all assembly tools have been removed

from the product before use.

Undertake periodic structural checks of this product; do not

WARNING! For your own and the safety of other people you must

read and follow the safety instructions in section “In more detail Technical and legal information - Safety warnings”.

use it if you have any doubts about its suitability for its

intended purpose.

17

Getting started...

ENB540DBT by ENERGER

GB

IE

In more detail

In more detail...

18

Product functions

Care and maintenance

Trouble shooting

Recycling and disposal

Guarantee

EC declaration of conformity

19

24

28

30

31

32

ENB540DBT by ENERGER

Intended use

Product functions

GB

IE

This drill press

product is used to drill holes in metal and wood.

The product should not be used on masonry and materials that are harmful to

health.

This product is intended for private domestic use only, not for any commercial

trade use. It must not be used for any purposes other than those described.

ENB540DBT

is designated with a rated input of 350 Watts. This

Adjusting the table height

To adjust the table height, slacken the (8)

support lock(6) at the rear of the table

support assembly.Raise table(8) up or down to

desired height. When the desired height has

been achieved, do not forget to re-secure the

support lock(Fig.11).

Work table swing 360

The table may also be swung through 180 either way to allow larger workpieces (8)

to be accommodated on the base plate. Simply unclamp the table and manoeuvre

either clockwise or anti-clockwise to the rear of the machine.

o

o

8

6

Fig.11

Tilting the table ± 45°

In more detail...

Locate the securing bolt underneath the

table(8). With a suitable socket loosen the bolt.

On the table support assembly casting there

is a graduated 0 - 45 scale. Set the table to (8)

the required angle and retighten the bolt.

Note: The graduated scale is for guidance

only we recommend the use of an engineers

protractor when setting any angles.

o

Fig.12

19

GB

IE

ENB540DBT by ENERGER

Product functions

Using a machine vice(vice not supplied)

WARNING: The drill should never be used

without the work piece being securely held in

a machine vice or clamped directly to the drill

table . The drill table is designed to accept a (8) (8)

variety of machine vice which can be fastened

directly to the drill table . Always secure the (8)

vice to the table with bolts, washers and nuts. (8)

If the drill jams into the work piece an

unsecured machine vice will spin out of

control causing the drill to snap and possibly

injure the operator . (Fig.13)

Fig.13

Using the 3 jaw chuck

Select the drill bit required. Open the jaws and

insert the drill shank centrally into the chuck(9).

Rotate the chuck by hand until the jaws (9) grip

the drill bit. The chuck has three holes (9)

around the chuck body. Locate the chuck key

In more detail...

and using an even torque move from each

hole location until all three holes have been

covered. Continue with the steady torque

until tight. Do not over tighten otherwise you

will have difficulty removing the drill bit . (Fig.14)

Fig.14

Note: remove the chuck key before use.

Different drill bits and chisels can be used with this product depending

on the workpiece material and application required.

WARNING! Always use drill bits according to the intended use!

For example, never use a drill bit intended for working on wood for

working on stone or vice versa!

Observe the technical requirements of this product (see section

“Technical specifications") when purchasing and using drill bits!

Some drill bits are very sharp and become hot during use!

Handle them carefully! Wear safety gloves when handling drill bits in

order to avoid injuries like burns and cuts!

20

GB

IE

ENB540DBT by ENERGER

Drill speed chart

Belt setting Spindle speed (min-1)

1 500

2 890

3 1400

4 1900

5 2500

Slacken the belt tension locking knob. This will

allow the tension on the drive belt to be

released. The motor assembly is hinged to

allow tensioning of the drive belt. To move the

drive belt to the desired pulley arrangement

push the belt on the largest drive spindle pulley

towards the next smallest pulley and at the

same time rotate the drive spindle, by hand

until the drive belt locates onto the next

smallest pulley. Repeat this procedure on the

motor pulley until the desired pulley

In more detail...

arrangement has been achieved( . Fig.18)

NOTE: Do not cross the belt to give

intermediate speeds this will cause damage to

the machine.

Product functions

15

Fig.18

Belt tension

When the desired pulley arrangement has

been achieved tension the drive belt. To check

that the correct tension has been achieved,

press your finger onto the centre of the drive

belt. The drive belt should move approximately

13mm.

Re-tighten the belt tension locking knob( . Fig.19)

Fig.19

General guidelines for drilling

Always centre punch the position for drilling. A centre punch is a pointed tool that

marks the material to be drilled with a small indent. It stops the drill bit moving

from the desired position.

Always start by drilling a small pilot hole and gradually progress in drill diameter.

When drilling metal, lubricate the drill tip with oil.

22

ENB540DBT by ENERGER

NEVER cool with water or water based lubricant otherwise an electric shock

could or brass. Care should be occur. DO NOT use oil when drilling copper

taken when drilling copper and brass as the drill bit will be prone to jamming.

Small diameter drills require a higher speed and as the drill diameter increases

the slower the speed required.

The following drilling speed chart is a guide only and only covers the more

common materials, drill diameters and speeds.

Product functions

Drill speed chart

GB

IE

Duty cycle(S2)

This product has a rated duty cycle of S2. This product must only be run

continuously for a maximum of 15 minutes. It must be then switched off and

allowed to cool down to room temperature before being run again for 15 minutes.

Drilling speed chart (guide only )

Material to be drilled

Drill dia

mm

3 2500

4 2500

5 1900

6 1900

7 1400

8 1400

9 890

10

11

12

13

Steel Cast iron Gun metal Aluminium Plastics Wood

890

500

500

500

2500

2500 2500 2500 2500 2500

2500 2500 2500 2500 2500

2500 2500 2500 2500 2500

1900 2500 2500 2500 2500

1900 2500 2500 2500 2500

1400 1900 2500 2500 2500

1400 1900 1900 2500 2500

890 1400 1900 1900 2500

890 1400 1400 1900 1900

500 890 1400 1400 1900

Drill speed (min-1)

2500

2500

2500

2500

In more detail...

23

GB

IE

ENB540DBT by ENERGER

The golden rules for care

In more detail...

WARNING! Always switch the product off, disconnect it from power

supply and let the product cool down before performing inspection,

maintenance and cleaning work!

WARNING! Only perform repairs and maintenance work according to

these instructions! All further works must be performed by a qualified

specialist!

NOTE: Do not use chemical, alkaline, abrasive or other aggressive

i

detergents or disinfectants to clean this product as they might be

harmful to its surfaces.

Always wear sturdy gloves when handling or changing bits and cutters as they can

be very sharp.

Keep the tools air vents unclogged and clean at all times.

Regually check to see if any dust or foreign matter has entered the grills near the

motor and around the switch. Use a soft brush to remove any accumulated dust.

Wear safety glasses to protect your eyes whilst cleaning.

Re-lubricate all moving parts at regular intervals.

Clean the product with a dry cloth. Use a brush for areas that are hard to reach.

The drill requires very little maintenance apart from keeping all unpainted

surfaces coated in light oil. Keep the machine clear of swarf which should be

disposed of in a proper manner and not put into household refuse bins.

Always inspect and check the set up and adjustments before using the machine.

Care and maintenance

CAUTION:Water must never come into contact with the tool.

Quill spring adjustment

WARNING: The quill spring is under extreme

tension.The quill spring is located in a metal

housing on the opposite side of the feed shaft

boss and returns the spindle to its upper most

position( . Fig.20)

Fig.20

Adjustment is normally only required after many hours of use when it fails to

return the spindle to its uppermost position. With the spindle in its uppermost

position. It can be seen that the metal cover has a total of three notches cut into

24

ENB540DBT by ENERGER

the edge that align with the cast body of the head stock. One of these notches is

located on to a cast peg that is part of the main casting.

WARNING: Before slackening the lock nuts ensure that the metal housing

is held ip or wrench. If not held securely the quill securely with a suitable gr

!

spring will fully uncoil.

Eye protection must be worn.Carefully slacken the lock nuts only enough to allow

the chrome housing to be pulled out far enough to just clear the cast peg while

holding the metal cover with suitable grips. The spring is still under tension and

will try to uncoil as soon as it is released so be sure to resist the torque. As soon

as the chrome housing is able to clear the cast peg, turn the chrome housing in

an anti-clockwise direction until the next notch locates onto the peg. While holding

the metal housing in this position tighten the lock nuts. Do not over tighten

otherwise you will damage the metal cover.

Care and maintenance

Spindle play

Locate the spindle play adjustment set

screw. Loosen the lock nut and finger tighten

the grub screw. Hold the grub screw into

position with a hex key and tighten the lock

nut( . Fig.21)

GB

IE

In more detail...

General inspection

Regularly check that all the fixing screws are

tight. They may vibrate loose over time.

If the supply cord requires replacing, the task

must be carried out by the manufacturer, the

manufacturers agent, or an authorised service

centre to avoid a safety hazard( .Fig.22)

Fig.21

Fig.22

Power cord

If the power cord is damaged, it must be replaced by the manufacturer, its service

agent or similarly qualified persons in order to avoid a safety hazard.

WARNING! Check the voltage! The voltage must comply with the

!

information on the rating label!

25

GB

IE

ENB540DBT by ENERGER

In more detail...

Care and maintenance

26

13

Blue

ENB540DBT by ENERGER

Repair

This product does not contain any parts that can be repaired by the consumer.

Contact a qualified specialist to have it checked and repaired.

Care and maintenance

Storage

1. Clean the product as described above.

GB

IE

2. Store the product and its access

3. Always store the product in a place that is inaccessible to children. The ideal

storage temperature is between 10 and 30 C.

4. We recommend using the original package for storage or covering the

product with a suitable cloth to protect it against dust.

o ries in a dry, frost-free place.

o

C

o

Transportation

1. Switch the product off and disconnect it from power supply before

transporting it anywhere.

2. Attach transportation guards, if applicable.

3. The product is heavy. Always carry supporting the motor, column and base plate.

4. Protect the product from any heavy impact or strong vibrations which may

occur during transportation in vehicles.

5. Secure the product t o prevent it from slipping or falling over.

In more detail...

27

GB

IE

ENB540DBT by ENERGER

Trouble shooting

Trouble shooting

Suspected malfunctions are often due to causes that the users can fix themselves.

Therefore check the product using this section. In most cases the problem can be

solved quickly.

WARNING! Only perform the steps described within these

instructions! All further inspection, maintenance and repair work

!

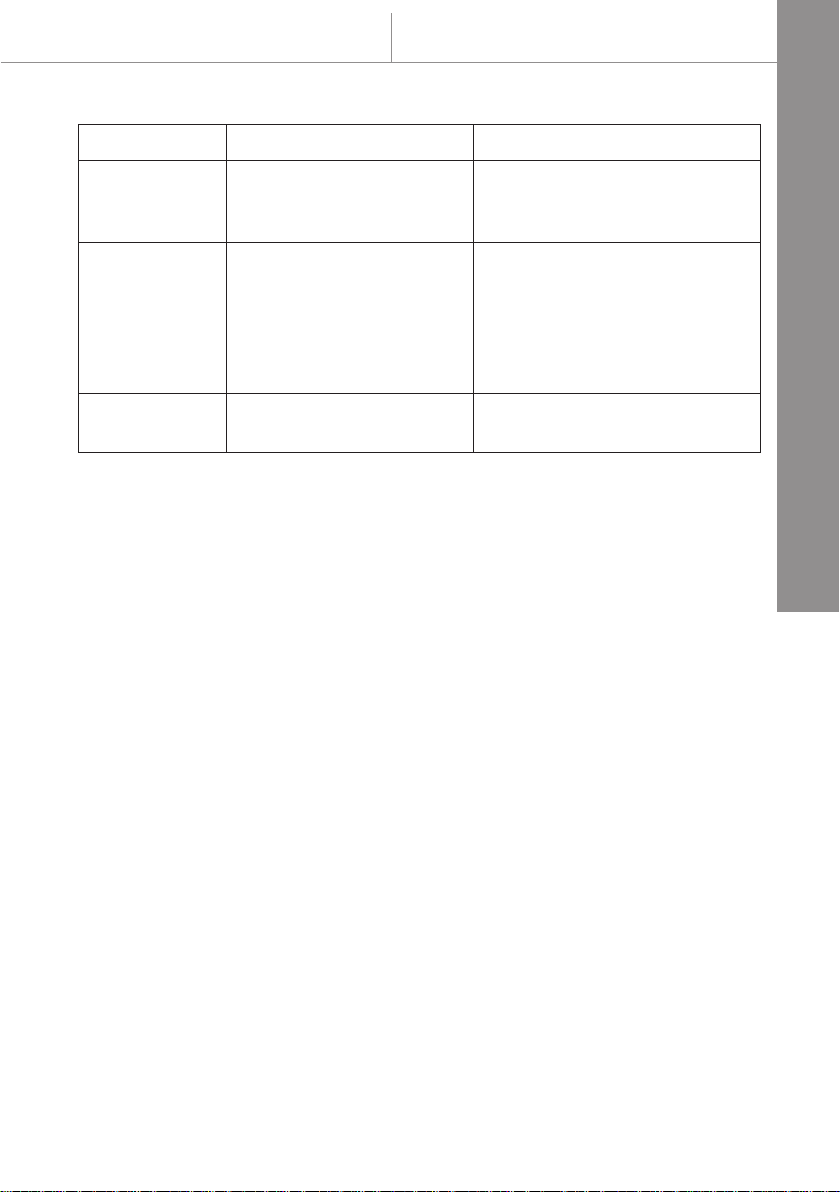

Problem Possible cause Solution

must be performed by an authorised service centre or a similarly

qualified specialist if you cannot solve the problem yourself!

1.Noisy

operation

In more detail...

2.Drill bit gets

excessively

hot

3.Wood

splinters on

underside

4. Drill bit

binds

5. Excessive

drill bit runout

or wobble

28

1.1 Incorrect belt tension

1.2 loose spindle pulley

1.3 loose motor pulley

2.1 Incorrect speed

2.2 Chips not coming out

of hole

2.3 Dull drill bit

2.4 Feeding too slow

2.5 Drill bit not being allowed

to cool down or not lubricated

in use

3. No back-up material

under workpiece

4.1 Not supported or

clamped properly

4.2 Improper belt tension

5.1 Bent drill bit

5.2 Worn spindle bearing

5.3 Chuck not properly

installed

1.1 Adjust tension

1.2 Tighten the pulley insert nut

1.3 Tighten the screws

2.1 Adjust the speed

2.2 Retract drill bit frequently to

clear chips

2.3 Resharpen drill bit

2.4 Feed fast enough, allow drill bit

to cut

2.5 Lubricate drill bit when cutting.

Follow S2 duty cycle time.

3. Use back-up material

4.1 Support workpiece or clamp

workpiece

4.2 Adjust tension

5.1 Change drill bit

5.2 Change bearing

5.3 Install chuck properly

ENB540DBT by ENERGER

Problem Possible cause Solution

Trouble shooting

GB

IE

6. Quill returns

too s ow or l

too fast

7.Chuck falls

when attached

to spindle, falls

off when trying

to install it

8.Pulley

sliding

off

6.Spring has improper

tension

7. Dirty, grease, or oil on

the tapered inside surface

of chuck or on the

spindles tapered surface.

8. Belt is not tight 8. Tighten the belt

6. Adjust spring tension

7. Clean it

In more detail...

29

GB

IE

ENB540DBT by ENERGER

Recycling and disposal

Waste electrical products should not be disposed of with household waste.

Please recycle where facilities exist. Check with your local authority or local

store for recycling advice.

Recycling and disposal

In more detail...

30

ENB540DBT by ENERGER

Guarantee

GB

IE

In more detail...

31

ENB540DBT by ENERGER

EC declaration of conformity

32

GB

Powersmith (UK) LTD.

Trade House Mead Avenue, BA22 8RT

Loading...

Loading...