Residential Heat Pump

USER GUIDE

Please read this guide before

operating the heat pump

GENERATION 5

FOR INFORMATION ONLY

Configuration Management

M-Tech Industrial (Pty) Ltd

2

Table of contents

MTRHP-AH1-0009-Rev2

Table of contents 2

1. SAFETY CAUTIONS AND WARNINGS 3

2. HEAT PUMP CONTROLLER FUNCTIONS 4

2.1 Controller and Button Functions 4

2.2 Heat Pump Modes 4

2.3 Setting the Time & Day 6

2.4 Timer Function 6

3. ELEMENT BACK-UP 8

4. LEGIONELLA DISINFECTION CYCLE 9

5. MICRO CIRCULATION FUNCTION 10

6. HEAT PUMP OPERATING PARAMETERS 11

6.1 Changing Parameters 13

7. MAINTENANCE AND SERVICING 15

7.1 Self-maintenance by the user 15

7.1.1 Cleaning the strainer 15

7.1.2 Other general maintenance considerations 16

7.2 Annual service performed by the installer 16

7.3 Heat pump self-protection codes 17

8. OPTIMISE ENERGY SAVINGS 20

8.1 How it works 20

8.2 How to optimise energy efficiency 21

8.3 Suggested timer settings 22

RESIDENTIAL HEAT PUMP WARRANTY 23

Warranty Conditions 23

INSTALLATION HANDOVER CERTIFICATE 25

PERFORMANCE SPECIFICATIONS 27

FOR INFORMATION ONLY

Configuration Management

M-Tech Industrial (Pty) Ltd

3

SAFETY CAUTIONS AND WARNINGS

!

WARNING

It is the responsibility of the user to operate and use the heat pump

according to the instructions detailed in this guide. The user shall ensure that the

health and safety of any other person in the area or site near where the heat pump is

installed is not endangered by his conduct or activities when operating the heat pump.

The user is responsible to prevent any tampering with the heat pump.

!

WARNING

This appliance is not intended for use by persons (including children)

with reduced physical, sensory or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision or instruction concerning use of

the appliance by a person responsible for their safety. Incorrect handling can cause a

serious hazard depending on the situation.

!

WARNING

Ensure that the electricity installation complies with local standards

and regulations. This appliance must be installed in accordance with the national

wiring regulations as contained in SANS 10142.

!

WARNING

Do not turn off main power supply to the heat pump during a vacation

or if not in use. The heat pump must have electricity in order to protect itself during

cold climate conditions. It is recommended that the target temperature be set to 25

°C in order to save electricity during prolonged periods of non-use.

!

CAUTION

Installation and maintenance must only be performed by qualified

personnel who are familiar with local codes and regulations.

!

CAUTION

Note that the unit contains a rotating fan that may cause injury if the

protective grid is removed. Ensure not to touch or work on the unit while in operation.

!

WARNING

Children should be supervised to ensure that they do not play with the appliance.

!

WARNING

Ensure that the electricity/power supply is switched off before any

installation work begins. Note that electric shock is dangerous and can cause death.

!

WARNING

Do not turn the unit off and immediately on again. Allow 30 seconds

for the refrigerant pressure to equalize. Do not disconnect/connect power while heat

pump is in operation.

!

CAUTION

There are some sharp edges within the unit that may cause injury.

1

FOR INFORMATION ONLY

Configuration Management

M-Tech Industrial (Pty) Ltd

4

HEAT PUMP CONTROLLER FUNCTIONS

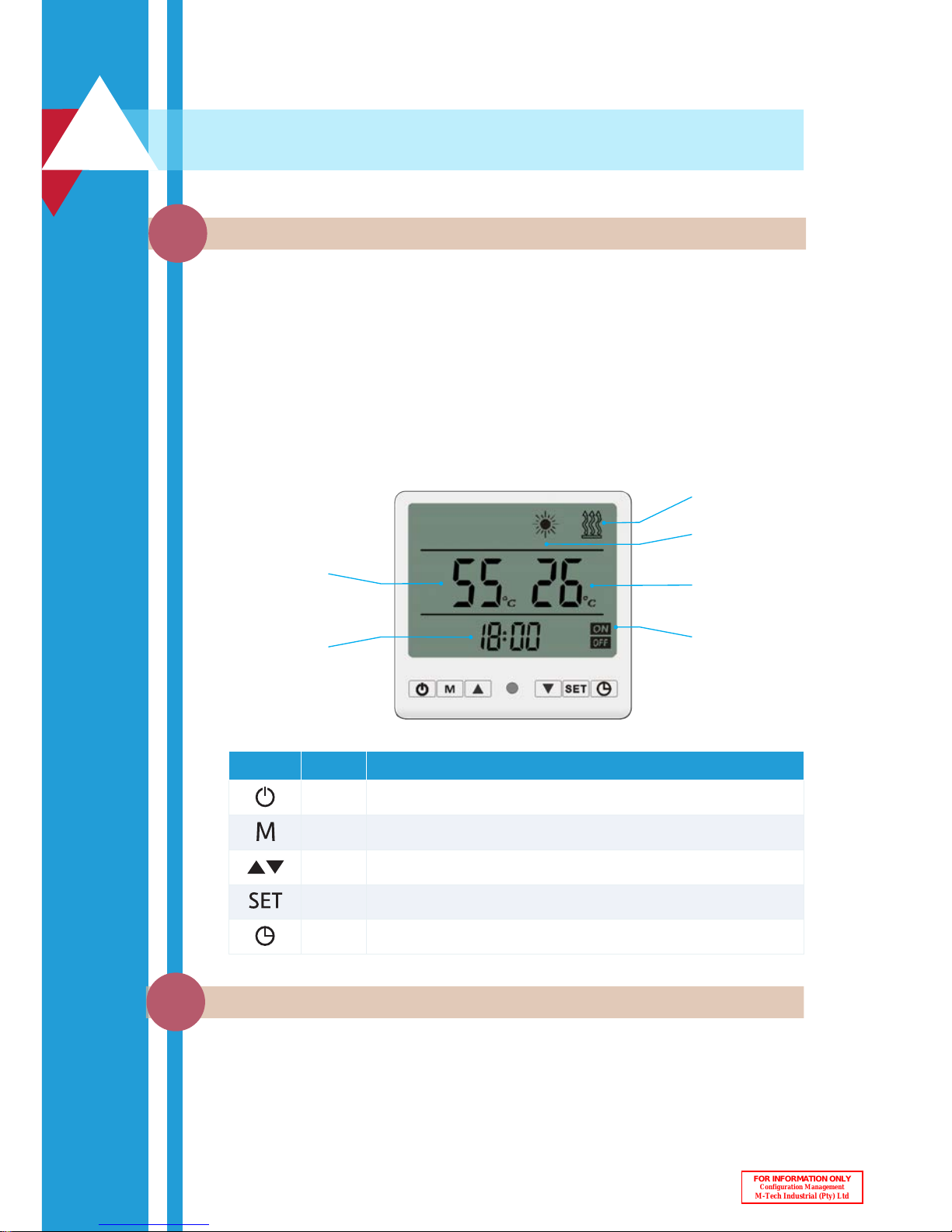

Your Enerflow heat pump makes use of an intelligent LCD controller. This controller

can be used to inform the user of certain parameters and change settings on the heat

pump unit. The changes that can be made with this controller include the following:

• Changing the desired water temperature;

• Setting up the timers and

• Activating the electrical element for fast heating mode.

Below is a depiction of the controller interface and buttons:

Controller and Button Functions

2.1

Once the system is switched on at the main power distribution board (DB), the

intelligent controller will start up and display the initialization phase for a few seconds

after which the time will be displayed as 00:00. The unit is now in standby mode and

ready for operation.

Desired water

temperature

Time

Heating with

electric element

Heating with

heat pump

Timer active

Current water

temperature

2

Display Name Function

Power Switches the heat pump between heating mode and standby mode.

Mode Activates the fast heating mode by also engaging the geyser element.

Arrows Used for changing the current setting up or down.

Settings Used to change the time, day or parameter settings of the unit.

Clock Used for activating and setting up timers.

Heat Pump Modes

2.2

FOR INFORMATION ONLY

Configuration Management

M-Tech Industrial (Pty) Ltd

5

Heating

Mode

Fast

Heating

Mode

The user can select between standby mode and heating mode by pressing the

Obutton.

The user can also activate a fast heating mode by pressing the M button.

This will activate both the backup element inside the geyser and the heat pump to

work simultaneously to heat the water.

NOTE:

Fast heating mode activates the electrical element which will lead to more

energy consumption and should only be used in the exemption when reheating time

needs to be reduced due to a temporary higher demand of hot water.

!

WARNING

Do not turn off main power supply to the heat pump during a vacation or

if not in use. The heat pump must have electricity in order to protect itself during cold

climate conditions. It is recommended that the heat pump is placed in standby mode

with all timers removed and the target temperature set at 25°C to keep the heat pump

from heating the water.

Initialization phase Ready for Operation

FOR INFORMATION ONLY

Configuration Management

M-Tech Industrial (Pty) Ltd

6

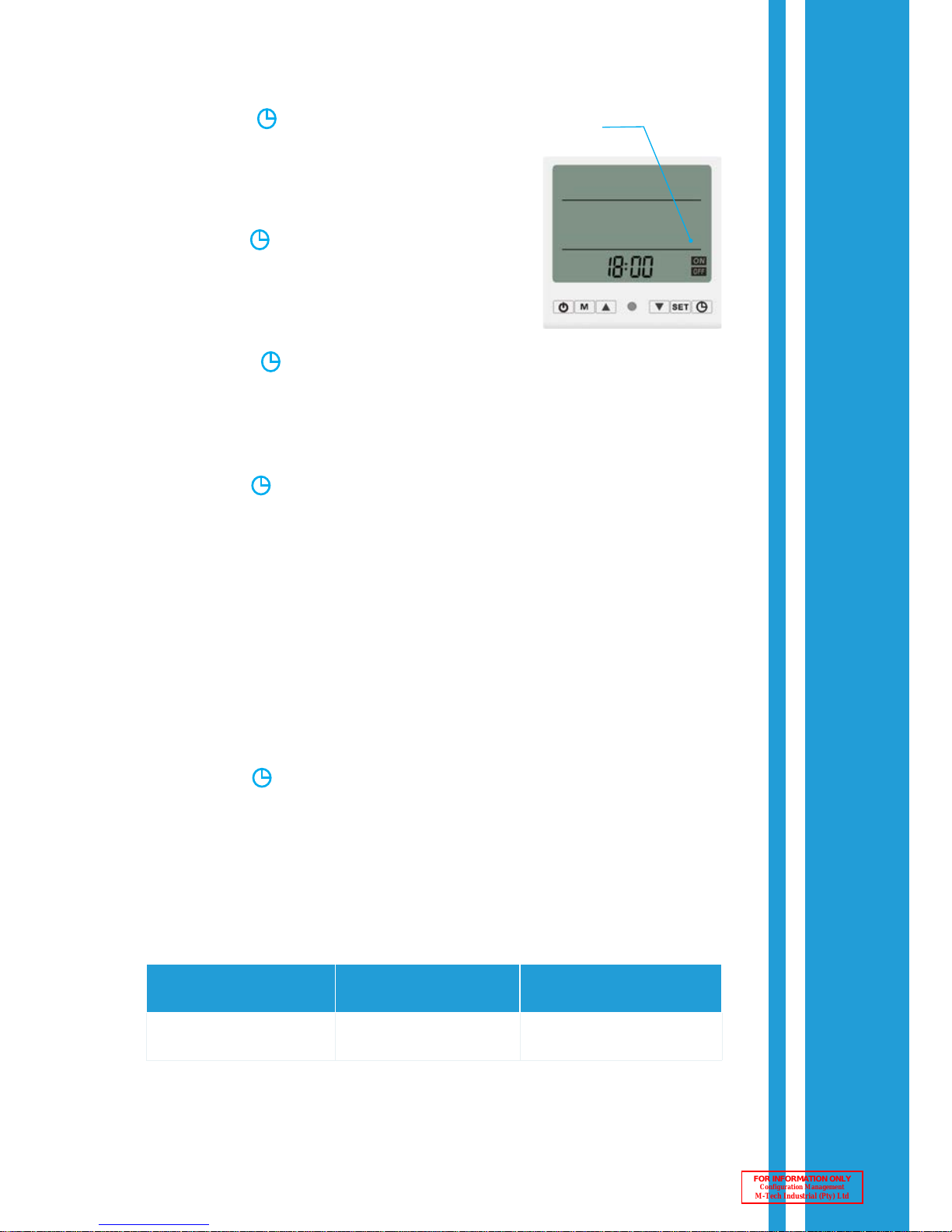

Timer Function

2.4

The Enerflow heat pump has intelligent control that can be optimised to run more

efficiently and also be adjusted to suit the user’s daily routing. As part of this control,

the time zones that the heat pump may operate in needs to be set up. The following

steps will help you to set the Day and Time settings required for the timer.

1. Press the SET button once.

(The Day will now be flashing.)

2. Make use of the buttons to change the Day.

(0=Sunday, 1 = Monday…6=Saturday)

3. Press the SET button again to acknowledge the Day

setting and continue to the Hours setting.

(The Hour position will now be flashing.)

4. Make use of the buttons to change the Hour.

(Change to the current Hour)

Press the SET button again to acknowledge the

Hours setting and continue to the Minutes setting.

(The Minutes position will now be flashing.)

5. Make use of the buttons to change the Minutes.

(Change to the current Minutes.)

6. Press SET to acknowledge the Minutes setting.

Time Setting

NOTE:

To lock or unlock the intelligent controller, press and hold the button and

the SET button simultaneously for a few seconds.

The Enerflow heat pump can be set to only run during specific periods of the day. This

function allows the heat pump to adjust to the user’s daily routine and ensures that

hot water is available when it should be. This function also ensures that the heat pump

can be set to operate mainly during the hottest part of the day when it is most efficient

and thus saving as much energy as possible.

Follow the steps below to set the Timer Function:

1. Press the button once to enter Timer 1 ON slot.

(The Hours and the “1 ON” sign will flash.)

2. Make use of the buttons to set the Hour.

(Set to the first start-up Hour)

Setting the Time & Day

2.3

FOR INFORMATION ONLY

Configuration Management

M-Tech Industrial (Pty) Ltd

7

COLUMN 1

Time Zone 1

COLUMN 2

Time Zone 2

COLUMN 3

Active Time Zone

O

N at 08h00

OFF at 23h00

ON at 04h00

OFF at 09h00

ON at 04h00

OFF at 09h00

Follow the steps below to cancel the Timer Function (thus allowing the heat pump to

reheat the water as and when required during a 24 hour day):

1. Press the button.

2. Press the SET button.

3. Repeat steps 1 and 2 four times to cancel all 4 time settings (1 ON, 1 OFF, 2 ON

and 2 OFF.

NOTE:

•

It is possible to decrease your saving by setting your timers incorrectly (such as

letting the heat pump operatre during the coldest part of the day).

•

The heat pump will operate even without any timers being engaged.

•

For energy efficient timer settings please see Section 9: How to optimise energy savings.

The heat pump will therefore only run between 4 AM and 9 AM irrespective of the first

time Zone allowing it to run till 11 PM

NOTE:

Time zones in the Timer Function are NOT allowed to overlap.

The table illustrates an incorrect timer setting where time zone 1 and time zone 2

overlaps with a resulting allowed operational time in column 3

3. Press the button to acknowledge the Hour

setting and continue to the Minutes setting.

(The Minutes and the “1 ON” sign will flash.)

4. Make use of the buttons to set the Minutes

parameter. (Set to the first start-up Minutes)

5. Press the button to acknowledge the Minutes

setting and continue to the “1 OFF” Hour setting.

(The Hours and the “1 OFF” sign will flash.)

6. Make use of the buttons to set the Hour.

(Set to the first shutdown Hour)

7. Press the button to acknowledge the Hour setting and continue to the

Minutes setting.

(The Minutes and the “1 OFF” sign will flash.)

8. Make use of the buttons to set the Minutes.

(Set to the first shutdown Minutes)

9. Press the button to acknowledge the Minutes setting and continue to the

“2 ON” Hour setting.

(The Hours and the “2 ON” sign will flash.)

10. To set up the second time zone, repeat steps 2 to 7 above for “2 ON” and “2 OFF”.

Timer

Active

FOR INFORMATION ONLY

Configuration Management

M-Tech Industrial (Pty) Ltd

8

The Enerflow heat pump is equipped with the intelligent function to use the electrical

element located in the geyser as a backup system. This is to ensure that the user will

have hot water even in the adverse event where the heat pump has entered into selfprotection caused by an external event (such as too low or too high electrical supply

voltage). During such an event the Enerflow heat pump will display the corresponding

Error Code (see Trouble Shooting section of this guide) and an audible “Beep” will be

heard to ensure the user takes note of the fault. The backup element will automatically

be actived during such an event.

In the unlikely event where the heat pump is struck by lightning for instance, the

intelligent controller may not function properly anymore. In such an event, the

Enerflow heat pump is also equipped with an electrical cross-over switch (located

on the side panel of the heat pump) which can be used to bypass the heat pump

completely. By turning the switch from the default Auto position to the ON position

redirects the electrical power away from the intelligent controller directly to the

electric element (Auto = Heat pump operation, On = Backup element only). Once the

power is switched over to the electric element, it will be controlled by the element

thermostat to heat the water inside the geyser to the thermostat set-temperature.

ELEMENT BACK-UP

3

Electric

Element

only

Heat

Pump

Mode

!

WARNING

Always ensure that an appropriate and approved geyser thermostat is

installed. When the cross-over switch is engaged, electrical power to the control of

the heat pump is removed. The heat pump will not be able to protect itself during

extremely cold weather conditions (<3°C) and it is therefore recommended that an

authorised installer is contacted as soon as possible to determine the fault and switch

the heat pump back to Auto after the fault has been rectified.

!

WARNING

Take note that if the thermostat temperature may be set higher than the

heat pump set temperature. The resulting water then be hotter and could cause scalding.

NOTE:

The cross-over switch can be used to remove the “Beeping” sound without

disengaging the element. Please write down the self-protection error code before

switching the cross-over switch so that the installer may be informed of what

caused the error.

FOR INFORMATION ONLY

Configuration Management

M-Tech Industrial (Pty) Ltd

9

The Enerflow heat pump has the ability to disinfect your geyser once a week (Monday

mornings at 02h00) from bacteria such as Legionella*. During this process the

heat pump will automatically be started to heat the water to 55°C where after the

electric element will be activated until the target temperature (set in parameter

6** - recommended 60°C) is reached (geyser thermostat set to 60°C as default

during installation). This temperature will be maintained for the time period as set in

parameter 7 (10 to 30 min).

NOTE:

During the Disinfection Cycle the sign will flash on the LCD controller:

* The pathogenic Gram-negative bacterium that grows in central heating and air conditioning

systems at a certain temperature that can cause Legionnaires’ disease.

** Standard geyser maximum temperature is 75°C controlled by the thermostat.

For more information please visit

www.health24.com/Medical/infectious-diseases/Bacterial-infections/Legionnaires-disease-20120721-2

!

WARNING

When this function is set to activate, the water may be hotter than 55°C

and may result in scalding. Adequate care should be taken to prevent scalding in small

children or individuals with mental impairment.

Legionella Disinfection Cycle

4

FOR INFORMATION ONLY

Configuration Management

M-Tech Industrial (Pty) Ltd

10

!

WARNING

All plumbing installations must comply with local standards, regulations

and bylaws. Refer to the latest versions of SANS 1352, SANS 10252, SANS 10254

NOTE:

•

Ring-main systems are less energy efficient due to higher thermal losses in the circulation pipes.

•

To minimise thermal losses it is very important that the circulating piping in the ring-main

system be insulated properly with at least R-1 rated lagging. In the case of a 20mm (3/4

inch) pipe, R-1 rated lagging has a thickness of about 25mm.

5

MICRO CIRCULATION FUNCTION

Your Enerflow heat pump has the functionality of heating a central, ring-main water distribution

pipeline. This function is used to ensure that hot water is supplied throughout the residence as

an instant hot-water-on-tap solution. The installer will ensure that the commissioning valve on

the return line is set to an approximate 10% bypass (i.e. closed 90%). Activate the micro circulation function by changing Parameter 8 to the value of 1 (see section on Heat Pump Operating

Parameters) on the intelligent controller. With this function enabled, the water pump will run for

40 seconds during the period set in Parameter 9 (adjustable between 2 and 60 minutes). Thus, if

Parameter 9 is set to 10, the heat pump will start the water circulation pump every 10 minutes for

the predefined 40 seconds. Depending on the volume of water in the ring-main, the Parameter

9 interval should be adjusted accordingly (more volume = smaller intervals to ensure that the

water is kept at the desired temperature).

Micro Circulation Function

(See Section 3.8)

0 = function off;

1 = function on.

FOR INFORMATION ONLY

Configuration Management

M-Tech Industrial (Pty) Ltd

11

Heat Pump Operating Parameters

The heat pump operation is governed by 22 input parameters. Some of the operating parameters

may be adjusted by the user if required. The remainder of the parameters are set by the qualified

installer and should not be changed. The function and range of all the parameters are explained

in the following table:

Parameter

Description Range Default Remark

0 Target water temperature* 25 ~ 75°C 55°C Adjustable

1

Set temperature difference

- Difference between actual

measured water temperature at

the position of the heat pump

temperature probe and set/

required water temperature. (The

smaller the difference, the more

frequently the heat pump restarts)

2 ~ 5°C 5°C Adjustable

2 Defrosting interval 30 ~ 90 min 40 min Do not change

3

Temperature at which defrosting

operation starts

-30 ~ 0°C -7°C Do not change

4

Temperature at which defrosting

operation stops

2 ~ 30°C 13°C Do not change

5 Duration of defrosting operation 2 ~ 12 min 8 min Do not change

6

Target water temperature for

disinfecting cycle

60 ~ 90°C 60°C Adjustable

7 Duration of disinfecting cycle 10 ~ 120 min 30 min Do not change

8

Micro circulation function

(Off = 0; On = 1)

0 / 1 0 Adjustable

9 Micro circulation cycle interval 2 ~ 60 min 2 min Adjustable

10 Installer function 1 ~ 10 min 3 min Do not change

11 Installer function 70 ~ 100°C 90°C Do not change

12 Installer function 5 ~ 30°C 20 °C Do not change

13

Compressor discharge protection

temperature

90 ~ 125°C 115°C/b5 Do not change

14

Temperature for exiting the

compressor discharge protection

5 ~ 30°C 30°C Do not change

6

FOR INFORMATION ONLY

Configuration Management

M-Tech Industrial (Pty) Ltd

12

*A maximum water temperature of 55°C can be reached by the heat pump without using auxiliary

heaters. However, if the target temperature is set between 55°C and 75°C the electric heater will

be activated above 55°C to reach this temperature.

Parameter

Description Range Default Remark

15

Heat pump auto restart mode

(Off = 0; On = 1)

0 / 1 1 Adjustable

16

Starting temperature for defrosting

evaporator

-9 ~ 10 °C 4°C Do not change

17 Beeper (Off = 0; On = 1) 0 / 1 1 Adjustable

18 Disinfecting cycle (Off = 0; On = 1) 0 / 1 1 Do not change

19

Geyser temperature measurement

probe offset

-10 ~ 10°C 3°C Do not change

20

Automatic geyser temperature

measurement probe offset

0 (fixed) / 1

(calculated)

0 Do not change

21 EEV setting 0 - 5 0 - 5

See remarks at

the end of the

table

22

HP temperature measurement

probe offset

-5 ~ 5 °C 3 °C Do not change

A Water temperature -9 ~ 90°C Reading

Temperature

output

B Evaporator coil temperature -9 ~ 90°C Reading

Temperature

output

C Compressor discharge temperature 0 ~ 127°C Reading

Temperature

output

D Ambient temperature -9 ~ 90°C Reading

Temperature

output

E

Heat pump return water

temperature

-9 ~ 90°C Reading

Temperature

output

F

Electronic expansion valve

operating parameter

0 ~ 50 Reading

Valve open

output

FOR INFORMATION ONLY

Configuration Management

M-Tech Industrial (Pty) Ltd

13

Remarks

• Parameter 0 – It is advised to set the target temperature at 55°C.

• Parameter 1 – Temperature difference between target and measured

temperature before heat pump starts. Recommended to set this at 5°C.

• Para meter 1 3 – It is advised to set the temperature at 115°C which is indicated as b5.

• Parameter 14 – It is advised to set the temperature at 30°C

• Parameter 21 – Parameter 21 should be set to a specific number with regards

to the unit you have:

• Parameter 21 should be set as “1” for ERHP-SU08E-MS;

• Parameter 21 should be set as “2” for ERHP-SU14E-MS & ERHP-SU14E-PL;

• Parameter 21 should be set as “3” for ERHP-SU08E- PL;

• Parameter 21 should be set as “4” for ERHP-SU20E-MS & ERHP-SU20E-PL;

• Parameter 21 should be set as “5” for ERHP-SU26E-MS.

To adjust or change the parameter settings, follow the steps below:

If the target temperature needs to be changed, parameter 0 can be modified as

explained in the steps or alternatively the user can simply press the buttons.

1. Press the Power Obutton to engage standby mode.

(The picture of the sun will no longer be on the display)

2. Press and hold the SET button for 3 seconds.

(Display will “Beep” and parameter number “00” and the current setting “55°C”

will flash)

Current water

temperature

Target water

temperature

Changing Parameters

6.1

Parameter 1: Temperature difference

before heat pump starts:

2°C = Heat Pump Starts More Frequently

5°C = Heat Pump Starts Less Frequently

FOR INFORMATION ONLY

Configuration Management

M-Tech Industrial (Pty) Ltd

14

1. Make use of the buttons to select between the different operating parameters.

2. To change an operating value, press the SET button once. (Quickly)

(The parameter number “At the bottom” will not be flashing anymore, but the

current setting “Indicated between the lines” will continue to flash)

Note: If both continue to flash, please ensure the heat pump is in Standby mode.

3. Make use of the buttons to change the value to the desired or default value.

4. Press the SET button to confirm the setting and return to selecting an operating parameter.

(To change the values of these parameters, repeat steps 3 to 6.)

5. To exit this mode automatically, wait for 5 seconds without pressing any buttons

or press the Obutton to exit manually.

FOR INFORMATION ONLY

Configuration Management

M-Tech Industrial (Pty) Ltd

15

The following maintenance should be done by the user at least quarterly. In areas

where excessive debris is present in the water (i.e. at construction sites or where repairs

were done on municipal water lines) more frequent maintenance may be required.

Before undertaking any maintenance on the heat pump, engage the Standby Mode as

indicated in section 3.2 Heat pump modes.

The strainer can be cleaned by using the diagram above and following the steps listed below:

1. Close the outlet and inlet ball valves at the heat pump.

2. Remove the Bonnet of the strainer by using the correct size spanner.

3. Remove the strainer element or Sieve.

4. Rinse and clean the strainer element under running water by slightly opening the

inlet ball valve.

5. Reinsert the strainer and close the Bonnet hand tight only.

6. Open the outlet ball valve slightly to allow any air that may have entered into the

heat pump to be released through the strainer.

7. Close the bonnet completely now by using the correct size spanner again.

8. Open the ball valves to the full open position.

7

Maintenance and Servicing

Self-maintenance by the user

7.1

Cleaning the strainer

7.1.1

Outlet ball valve

Strainer element

Bonnet

Strainer

Inlet ball valve

FOR INFORMATION ONLY

Configuration Management

M-Tech Industrial (Pty) Ltd

16

Other general maintenance considerations

Annual service performed by the installer

7.1.2

7.2

• Clear away any objects or trim vegetation that is within 500mm from the heat

pump unit and that could restrict air flow into the heat pump.

• The airway of the fan and the evaporator needs to be cleaned at least annually to

ensure effective airflow and heat transfer. If any obstruction such as cobwebs,

leaves and the like on the outside of the heat pump is observed, clear this out

immediately. Do not use a high pressure water hose to spray down the unit; the

heat exchanger fins may be damaged.

• Ensure that all the parameters are set correctly.

Although your Enerflow heat pump is a self-contained and reliable means of providing

eco-friendly hot water, an annual service is required to ensure efficient performance

and that warranty conditions are met. The following items must be checked:

• Ensure that the water supply pressure and flow rate is sufficient at all times.

• Ensure that the geyser tank probe is still correctly inserted and fastened into the

geyser probe pocket or onto the geyser flange.

• Open and service the water circulation pump.

• Ensure that water drainage holes in the heat pump base plate are not blocked.

Water build up in the base of the heat pump unit could lead to premature rust

and damage internal components.

• Service the heat pump Diverter Valve.

• Test the Back-up element to ensure that it is still in a good working condition.

• Descale the heat pump unit using a non-industrial descaling fluid such as Brown

Vinegar or Kettle Cleaner.

• Ensure the refrigerant charge (i.e. amount of gas inside the heat pump) is still sufficient.

• No maintenance needs to be performed on the internal refrigerant components

of your Enerflow heat pump.

• The unit is designed with a close loop refrigerant cycle that does not need short

term maintenance or service under normal operation.

• Ensure that the system is drained completely of water if it is not going to be used

in the winter in order to avoid a pipe from bursting due to freezing.

FOR INFORMATION ONLY

Configuration Management

M-Tech Industrial (Pty) Ltd

17

NOTE:

The service operations as described in the section above shall only be carried

out by qualified installer/personnel who are well trained within their respective fields.

In areas where hard water conditions are present, this service may need to be performed more frequently (such as every 4-6 months).

Fault/Error Possible Cause

Recommended

Action/Remark

Heat pump

does not start.

• Geyser temperature is

(<55°C).

• Circuit breaker off.

• Heat pump protection Error.

• Loose electrical connections.

• Unit failure.

• Check water temperature.

• Check Circuit Breaker.

• Identify the Error and attempt to correct.

• Contact an Electrician.

• Contact the Installer.

Fan does not

work

• High air temperature (> 35°C).

• Physical obstruction.

• Fan failure.

• Check the air temperature

• Check if the fan rotates freely and that no

restrictions are present.

• Contact the Installer.

Heat pump

works with

insufficient

heating.

• Very cold air temperature

(<2°C).

• Finned coil is dirty.

• Obstacle blocks air inlet/

outlet.

• Fan not running.

• Check the air temperature.

• Clean the finned coil as per maintenance

section.

• Remove the obstacle.

• Contact the installer.

P01

Water inlet temperature sensor

failure.

In case of any of these failures the

Installer must be contacted to check

the connections and replace sensor if

required.

P02

Evaporator coil temperature

failure.

P03

Compressor discharge

temperature sensor failure.

P04

Ambient temperature sensor

failure.

P05 HP Switch failure.

P06 LP Switch failure.

P07

Too high compressor discharge

temperature.

• Switch off main power supply to the

heat pump, wait 30 seconds and switch

on again.

• Clean strainer and open a hot water tap to

flush/prime the water lines.

• Check municipal water supply pressure.

• Contact the installer to open and clean

water circulation pump.

Heat pump self-protection codes

7.3

NOTE:

Please make use of the following table to do troubleshooting if an error or fault

occurs. If the problem persists shut down the system and switch off the main power

supply or activate the crossover switch as described in this guide. Hereafter, contact

your installer for assistance.

FOR INFORMATION ONLY

Configuration Management

M-Tech Industrial (Pty) Ltd

18

Fault/Error Possible Cause

Recommended

Action/Remark

P08

First class anti-freeze

protection.

Error will automatically disappear after

ambient temperatures rises.

P09

Second class anti-freeze

protection.

Error will automatically disappear after

ambient temperatures rises.

P10 Water level sensor failure. Contact the installer.

P11 Overload protection. Contact the installer.

P12

Heat pump return water temp.

failure.

In case of any of these failures the

Installer must be contacted to check the

connections and replace sensor if required.

E01 Phase protection sensor failure. Contact the installer.

E04 Phase rotation detected. Contact the installer.

E05 HP switch protection.

• Electric element will be activated

automatically.

• Switch off main power supply to the

heat pump, wait 30 seconds and switch

on again.

• Clean inline water strainer.

• Check municipal water supply pressure.

• Contact the installer to open and clean

water circulation pump.

E06 LP switch failure. Contact the installer.

E07

Too high compressor discharge

temperature.

• Switch off main power supply to the

heat pump, wait 30 seconds and switch

on again.

• Clean strainer and open a hot water tap

to flush/prime the water lines.

• Ensure that the fan is not restricted by

dirt or leafs.

• Check municipal water supply pressure.

• Contact the installer to open and clean

water circulation pump.

E08 Communication failure.

• Reconnect LCD display unit extension

cable.

• Ensure the plugs has a proper connection.

• Contact the installer.

Defrosting sign

indicating

Defrosting mode activated.

Heat pump will continue with normal

operation after defrosting is completed.

NOTE:

If any of the errors above appear frequently, contact your installer.

FOR INFORMATION ONLY

Configuration Management

M-Tech Industrial (Pty) Ltd

19

PLEASE NOTE THE FOLLOWING:

1.

Outdoor temperature, water inlet temperature and parameter settings may

affect the performance and power consumption of the heat pump unit.

2.

Ensure that the heat pump air flow is not blocked.

3.

If the ambient temperature is too high, the fan may stop working temporarily in

order to protect the system. The heat pump will however still provide hot water

to the geyser. If the temperature decreases the fan will resume operation again.

4.

If the unit enter the defrosting mode the fan may stop working temporarily.

Once the evaporator coil temperature has reached an acceptable level, the fan

will resume operation.

5.

Ensure that the unit is well ventilated and that no cold air is redirected back into

the evaporator (i.e. do not install the heat pump in small enclosed rooms).

6.

Ensure that all the isolation valves are open before the heat pump is turned on.

FOR INFORMATION ONLY

Configuration Management

M-Tech Industrial (Pty) Ltd

20

optimise energy savings

8

In this section the basic functioning of a heat pump is explained to enable the user to

optimise the energy savings of the heat pump.

The Enerflow heat pump uses an air-source-vapour-compression-cycle to transfer

heat from ambient temperatures in the atmosphere to the water in a geyser. A

refrigeration/gas cycle is normally made up of four components (Evaporator,

Compressor, Condenser, and Expansion Valve) each with a very specific function.

Below is a depiction of such a gas

cycle that interacts with a water

circulation cycle similar to what

can be found in the Enerflow heat

pumps. The picture below (for

illustration purposes only) shows

the major components and is used

to briefly explain how they interact

to deliver energy efficient hot

water. The evaporator is used as

a heat exchanger that enables heat

transfer from the warmer ambient

air to the colder gas inside the

evaporator tubes. An electric fan is

used to ensure the air is drawn over

the evaporator fins and enhance

heat transfer. This absorbed heat/

energy is then further intensified

(i.e. more energy added) by passing

the gas through the compressor which increases the pressure and temperature of the

gas cycle. This high-pressure-high-temperature gas is then able to transfer the energy

to the water through a second heat exchanger, the condenser. The water from the

geyser is pumped through the condenser where it collects the energy in the condenser

tube, transfers it to the water and thereby heating it. Finally the cooler-high-pressure

gas is passed through an intelligently controlled expansion valve that rapidly lowers

the gas pressure and temperature. This low-pressure-low-temperature gas is then

passed to the evaporator where energy can once again be harvested from the warmer

atmospheric air. This closed loop cycle operation will continue until the water in the

geyser is at the heat pump set temperature. At this stage the intelligent controller

will turn off the components in a specific protective sequence and put the heat pump

in standby.

(Picture reference http://aboutyourrefrigeration.blogspot.com)

How it works

8.1

FOR INFORMATION ONLY

Configuration Management

M-Tech Industrial (Pty) Ltd

21

From the basic explanation of how a heat pump works, it should be clear that the

refrigeration gas cycle will absorb more energy when the outside ambient temperature

is hotter (i.e. when there is more energy available). This section will advise the user of the

heat pump how to optimise the energy savings by setting up the heat pump timers properly.

The graph below depicts a typical Enerflow heat pump’s saving at certain atmospheric

air- and inlet water temperatures. In this picture it can be clearly seen that the heat

pump will save more energy (i.e. money) at higher outside air temperatures.

The picture below depicts the typical average daily ambient temperature on an hourly

basis for South Africa

(reference: www.worldclim.org).

In the picture it can be seen that the temperatures is at its lowest during the late

evenings and early mornings. Therefore, it is recommended that the heat pump be

operated as little as possible during these colder periods of the day (i.e. between 11PM

at night to 8AM in the morning).

How to optimise energy efficiency

8.2

FOR INFORMATION ONLY

Configuration Management

M-Tech Industrial (Pty) Ltd

22

Every household’s daily hot water consumption profile is different and therefore not

all timer settings could be the same. However, this section may be used as a guideline

that can be followed to enhance energy saving. The assumption made herein is that

no large quantity of hot water will be consumed before 13h00-14h00 and that the

majority of hot water is consumed between 19h00-21h30.

ON 1: This is used to turn the heat pump

on, and should be set to as late as

possible in the early afternoon i.e. 14h00.

OFF 1: This is used to turn the heat pump

off and should be set to 1 hour after the

family has gone to bed e.g. 23h00, thus

leaving geyser with hot water ready to be

used for the morning showers etc.

ON 2: This is used to activate the second

timeslot at which the heat pump should

turn on, and should be set to 1-2 hours

before hot water is to be consumed in

the morning. The heat pump will further

heat the water that may not have been

heated by ON1 and also recover the heat

loss of the geyser during the night.

OFF 2: This is used to deactivate the

second timeslot and should be set to

heat just enough water for morning

consumption (i.e. two showers). It is best

to let the heat pump deactivate before

consumption starts.

Below are some examples of timer settings to guide the user.

NOTE:

•

The LCD controller will turn off the internal components of the heat pump and

enter into standby mode when the desired set water temperature is reached.

During this time, the water temperature will be monitored and if the temperature

falls below the set temperature (see allowed temperature deviation as set in

Parameter 1) the heat pump will start heating the water again. Thus, it is important

to note that the timer settings allows the heat pump to operate during that

specified interval only.

•

The Enerflow heat pump may heat the geyser faster than an electrical element

in outside air temperatures higher than 18°C, but may take longer when outside

air temperatures are below 18°C. Therefore the timers should allow the heat

pump to reheat the water as long as the conditions outside is favourable.

Suggested timer settings

8.3

ON 1: 08:00

OFF 1: 23:00

ON 2: 04:00

OFF 2: 05:00

ON 1: 11:00

OFF 1: 23:00

ON 2: 04:00

OFF 2: 05:00

Example 1: For a family with someone at

home during the morning.

Example 2: For a family not home during

the morning.

FOR INFORMATION ONLY

Configuration Management

M-Tech Industrial (Pty) Ltd

23

The Enerflow residential heat pump unit is covered by a carry-in warranty. The

manufacturer will therefore be liable for all costs with regards to repairing the heat

pump at any of their appointed service centres during the warranty period. The heat

pump removal, delivery and re-installation cost is not covered by the manufacturer’s

warranty and the manufacturer will not be responsible for these costs.

The client can alternatively request an authorised field service agent to repair the

heat pump onsite. The callout fee and travel to the site will be for the clients account.

The replacement/repair of parts still covered by the manufacturer’s warranty and the

associated labour cost to perform this replacement/repair of the parts will be for the

manufacturer’s account.

1. M-Tech Industrial (the manufacturer) warrants the product to be free from

defects in material and workmanship for a period of twenty four (24) months. An

additional twelve (12) months warranty (thus thirty six (36) months in total) will

be granted on the water circulation pump and an additional 36 months (thus a

total of sixty (60) months) will be granted on the compressor unit of the product.

2. The warranty will only be valid provided that proof of the correct installation,

commissioning and operating procedures - as set out during training and

certification - were followed.

3. The date of commencement of the warranty period stipulated in clause 1.1 will

be the date of first installation of the products – with accompanying proof of

installation - or three (3) months after the date of sale or delivery of the products

to the distributor, whichever is the shortest.

4. Any product or part of the product proving defective within the warranty period

will be repaired or replaced at M-Tech Industrial’s opinion when returned to

M-Tech Industrial’s domicilium (or written communicated alternative address),

transportation charges pre-paid. M-Tech Industrial will not be responsible for

any installation or removal costs.

5. Any product or part of the product that was repaired under the conditions of

clause 1.4 and that was still within the warranty period shall be subject to the

original warranty period as set out in 1.3 or an additional six (6) months warranty,

whichever is the greater.

6. Any product or part that was repaired not under the conditions of clause 1.4 shall

be warranted for 6 months.

RESIDENTIAL HEAT PUMP WARRANTY

Warranty Conditions

FOR INFORMATION ONLY

Configuration Management

M-Tech Industrial (Pty) Ltd

24

1. Damage caused to components due to rust is not covered under these warranty

conditions.

2. Wetted component warranties will only be valid where products are installed to

handle water that complies with SANS241 Class 1.

3. Under no circumstances shall M-Tech Industrial be responsible for loss of

Distributor’s profit or for any consequential or indirect or any other damages of

any nature whatsoever and from whatever cause arising. Nor shall any state of

damage or non-functionality be warranted as a result of acts of God (including

damage due to extreme cold and frost) or Force Majeure.

4. Notwithstanding the provisions where goods are to be manufactured to the

instructions, drawings or specifications of Distributor, M-Tech Industrial shall

not be liable in any way for any loss, injury or damage whatsoever sustained by

Distributor or any other person.

5. M-Tech Industrial reserves the right to do quality checks, in addition to that

already performed at the manufacturing plant, on a batch sample. M-Tech

Industrial will be responsible for the cost of transport (including return fees) for

these batch sample products.

FOR INFORMATION ONLY

Configuration Management

M-Tech Industrial (Pty) Ltd

25

This certificate should be kept in a safe place. The client may be required to present it

in the event of a warranty claim.

• Once the installation is complete and the system tested, the installer shall

ensure that the client understands the operational and safety requirements of

the heat pump.

• All repair- and service work must only be performed by a person authorised by

the manufacturer. Failure to comply with this will void the warranty.

• Ensure that the details of the certificate below are comprehensively completed by

both the client and the installer to ensure the warranty on the heat pump is instated.

Heat Pump Serial Number:

Installation date:

INSTALLER DETAILS

Company Name: Reference Number:

Surname: Name:

Signature:

Tel:

CLIENT DETAILS

Surname: Name:

Address:

Suburb:

City:

Tel:

I (the undersigned) acknowledge that the installation was completed and tested as fully

functioning. I confirm that the installer has shown me the workings and operation of my Enerflow

heat pump. I also understand the operation and safety requirements for this heat pump unit.

Signature:

Installation Handover Certificate

Residential Heat Pumps

FOR INFORMATION ONLY

Configuration Management

M-Tech Industrial (Pty) Ltd

26

FOR INFORMATION ONLY

Configuration Management

M-Tech Industrial (Pty) Ltd

27

Please visit www.enerflow.co.za for the performance specifications of your specific heat

pump model.

Performance Specifications

FOR INFORMATION ONLY

Configuration Management

M-Tech Industrial (Pty) Ltd

www.enerflow.co.za

M-Tech Industrial

24 Totius street, Totius Park,

Potchefstroom, South Africa

+27 (0)18 297 0326/7

+27 (0)18 297 0318

rhp@enerflow.co.za

Tel:

Fax:

Email:

SWIMMING POOL

HEAT PUMPS

Harvests free thermal energy

from the atmosphere and

transfers it to your pool.

FOR INFORMATION ONLY

Configuration Management

M-Tech Industrial (Pty) Ltd

Loading...

Loading...