Page 1

TM

TM

Voltage:

110

Phase:

1

Cycles:

50/60

Variable Speed

to 3800RP M

SM600-1

TM

Voltage:

220

Phase:

1

Cycles:

50/60

Variable Speed

to 3800RP M

SM600-2

SM600-1 & SM600-2

NON-POSITIONER SERVO MOTOR USER INSTRUCTIONS & PARTS LISTING

INSTRUCTION ET LISTE DES PIÈCES DE L’UTILISATERU DU MOTERU SERVO

DE NON-POSITIONNEUR

INSTRUCCIÓN DE USO DE NO POSICIONADOR SERVO MOTOR & LISTA DE

PARTES

SM600-1 ENDURO™ PRO SM600-2 ENDURO™ PRO

INSTRUCTIONS DU FRANCAIS - PAGE 7 >

LISTE DES PIECES DU FRANCAIS - PAGE 11 >

INSTRUCCIÓN EN ESPAÑOL - PÁGINA 12 >

LISTA DE PARTES EN ESPAÑOL - PÁGINA 16 >

Copyright © 2011 Enduro™ Servo Motor

To us Droits Réservé © 201

Derecho de autor© 2011 Enduro™ Servo Motor

1 Moteur Servo Enduro™

www.endurosaves.com

ENGLISH INSTRUCTIONS - PAGE 2 >

ENGLISH PARTS LISTING - PAGE 6 >

Page 2

2 - ENGLISH

SM600-1 & SM600-2 ENDURO™ PRO NON-POSITIONER

SER

VO MOTOR USER INSTRUCTIONS

Congratulations!

You have purchased the Enduro™ Pro SM600 motor that pays for itself with a remarkable 60% to 80%

energy savings compared to clutch motors. With the high and rising cost of electricity, you just can’t

afford to run a clutch motor any longer. The power and dependability of the brushless Enduro™ Pro

SM600 is adequate for light duty sewing.

Please read these instructions carefully before installation, operation or maintenance.

General Introduction

The Enduro™ Pro SM600 Servo Motor is designed to meet almost all basic light duty requirements of

various commercial sewing machines. It utilizes extremely powerful rare-earth Neodymium permanent

magnets. The motor produces almost no noise, saves energy and is brushless, speed adjustable and

durable. It provides a high starting torque even at low speed or from a complete stop.

By using a modern technologically advanced microprocessor, Hall sensor and Pulse-Width Modulation

technology, the Enduro™ Pro SM600 can be set to rotate at different maximum speeds, in either normal

or reverse directions, and can start with different accelerating speeds. It will stop automatically with any

interruption such as in-line voltage, electrical surge, radio frequency interference or overloading. It is

fully protected by the software and will give error messages indicating which problem is encountered. It

even works well in environments with an unstable electrical power supply.

CAUTION

1. Remove your foot from the pedal when turning the power ON.

2. Turn the power switch OFF before replacing or threading the needle.

3. Turn the power OFF when leaving the machine.

4. When performing maintenance on the sewing machine, turn the motor power switch to

the OFF position. Remove the power cord from the back of the motor to completely

disable all power to the sewing machine.

5. Always ground the grounding wire.

6. Always turn off the power switch before connecting or disconnecting each connector.

7. To

Warranty

This product is covered with a 1 year limited warranty. If the motor fails to perform its designed function

due to manufacturer’s defects, contact the place you purchased it from for repair or replacement.

This warranty does not cover defects due to dropping, power surge, spikes or misuse.

Installation

Put the mounting bracket of the motor upwards to the bottom of the tabletop and fi x the motor to the

tabletop with the bolts provided. Connect the treadle rod with the connecting rod joint. Install the female

plug of the cable from the switch box into the power inlet socket in the back of the motor box.

avoid an accident, do not alter this motor and control box.

www

.endurosaves.com

Page 3

Wiring

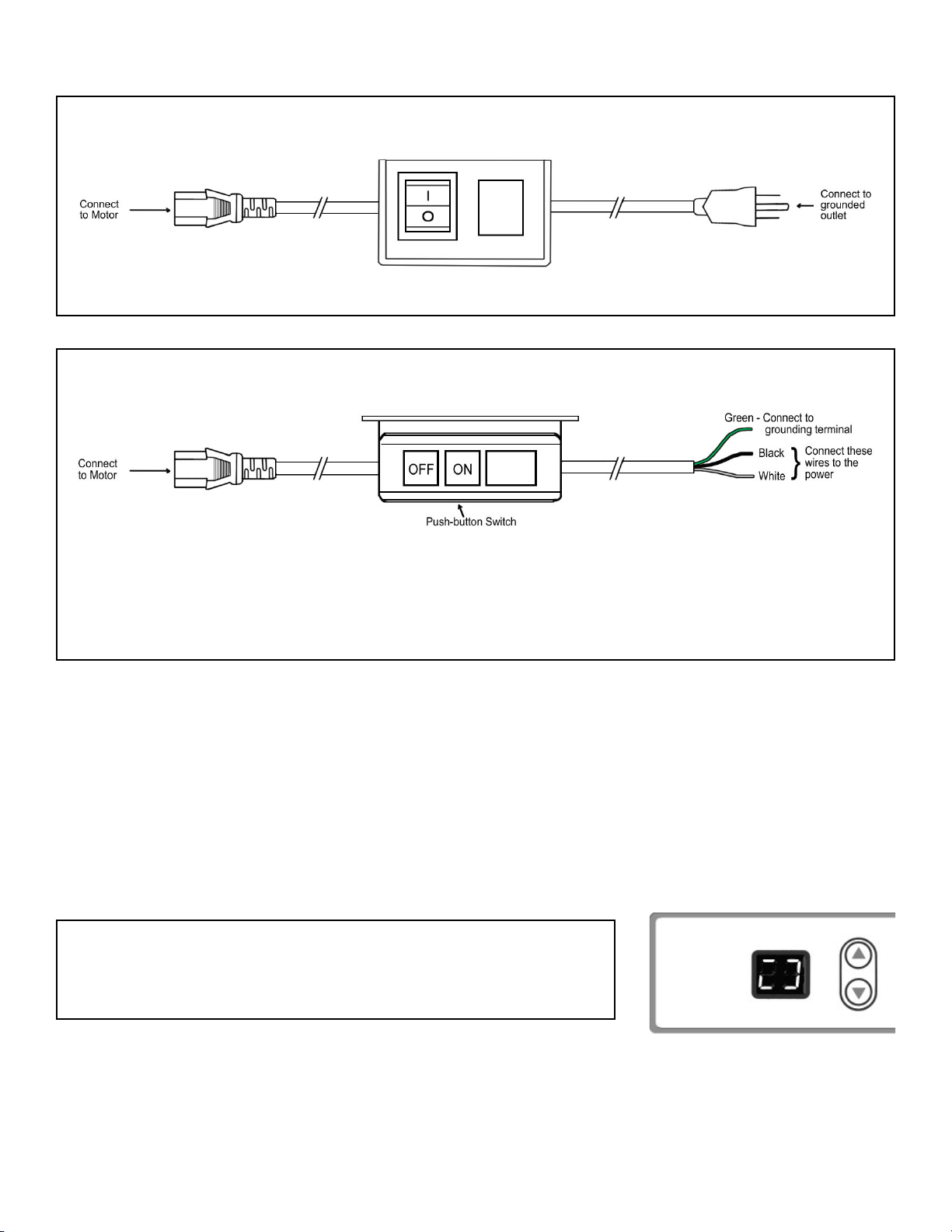

For 110 volt single phase motor follow the diagram below:

For 220 volt single phase motor follow the diagram below:

ENGLISH - 3

Note: When wiring the motor to the power source, connect both the black and white wires to

achieve 220 Volts (green to ground). If you are in an area (China / Europe) that supplies 220 Volts

from a single lead, then connect the power source to the black wire. The white wire will then be the

neutral and the green wire will be the ground.

Error Message and Trouble Shooting

E2: Motor Phase signal error.

E3: Motor protected against over-current.

E4: Circuit board error.

E5: Display module and control module communication error.

E6: Pedal position sensor error.

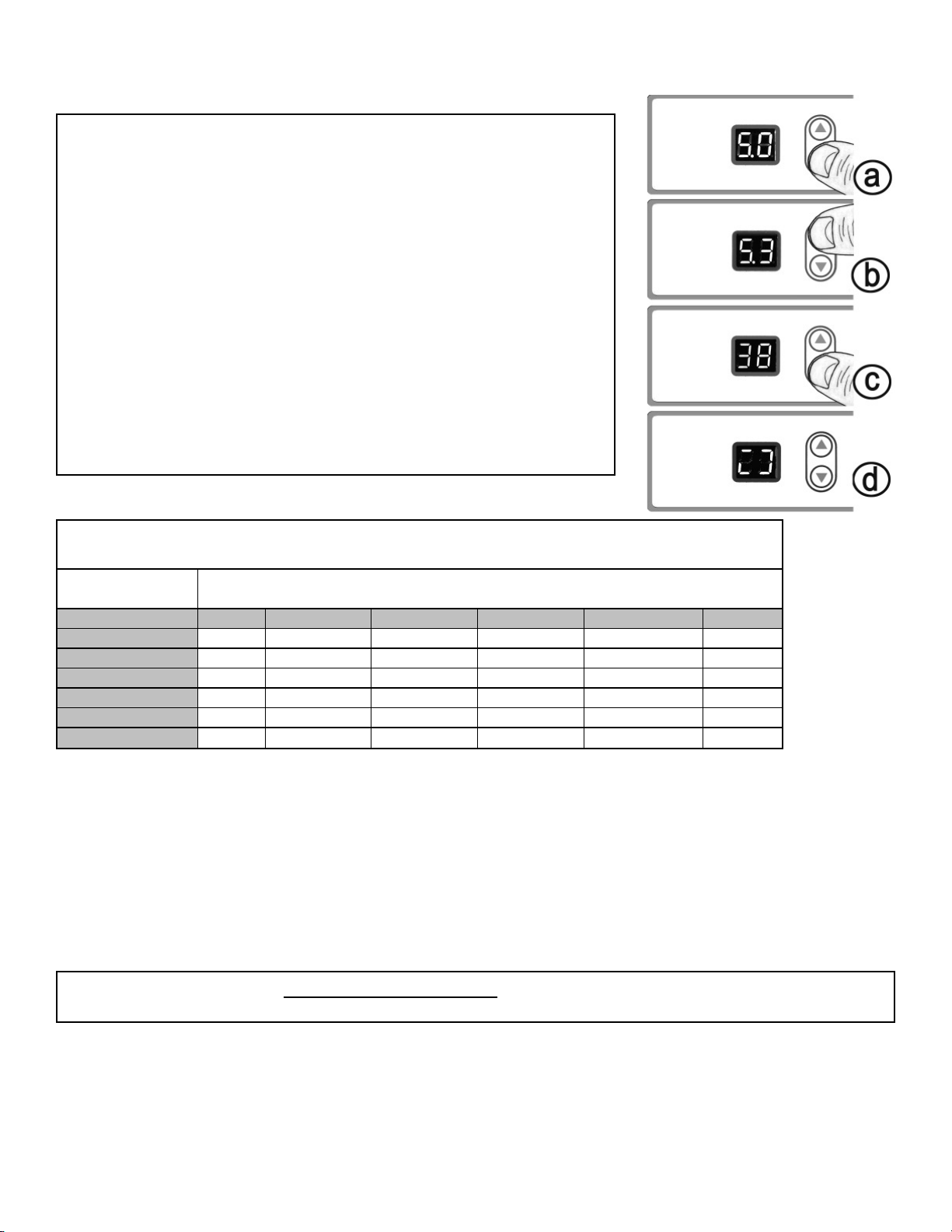

Setting Up

Turn on the switch located on the switchbox. The display will

show roughly a circle with a running blinking bar, this means the

motor is in "ready" status, ready to work or be set.

www.endurosaves.com

"ready" status

Page 4

4 - ENGLISH

Motor Rotating Direction Setting

Setting up Number 2

a. Keep "▼" button pressed for several seconds, until LED

display indicates "S.0".

b. Press "▲" button 2 times to indicate "S.2", which means

"Setting up No. 2".

c. Press "▼" button and LED will indicate "r.E" or "r.P"

Press "▼/▲" to switch between E and P, to meet the

requirement of sewing machine.

"E" means the motor will run in reversed direction.

"P" means the motor will run in normal direction.

d. Setting will be automatically saved 5 seconds after no buttons

are pressed. The motor returns to "ready" status.

"ready" status

Slow Starting Speed

Setting up Number 1

1. The "slow period time" = 128 milliseconds * X, (slow starting setting), X = 0~9 (as setting up in

the motor).

2. Example: The treadle is depressed approximately half way down producing a motor speed

of about 2,000 RPM and if the Slow Starting is set at 9, then the time from 0 to 2000RPM is

theoretically 128 milliseconds X 9 = 1152 milliseconds, plus the electrical-mechanical delay

which is about 0.8 seconds.

3. If the Slow Starting is set at 0, the "real starting time" and time from 0-2000RPM is about 0.8

seconds, which is due to the unavoidable electrical-mechanical delay only.

a. Keep "▼" button pressed for several seconds, until LED

display indicates "S.0".

b. Press "▲" button 1 time to indicate "S.1", which means

"Setting up No. 1".

c. Press "▼" button and LED indicates "L.X" (X is 0-9),

Press "▼/▲" to adjust from 0 to 9 according to your own

application. 0 means the quickest. 9 means the slowest. The

manufacturer’s default setting is 0.

d. Setting will be automatically saved 5 seconds after no buttons

are pressed. The motor returns to "ready" status.

www.endurosaves.com

"ready" status

Page 5

Maximum Speed Setting

Setting up Number 3

a. Keep "▼" button pressed for several seconds, until LED

indicates show "S.0".

b. Press "▲" button 3 times to indicate "S.3", which means

"Setting up No. 3".

c. Then press "▼" button and LED indicates "XX"(XX is 1-38),

which means the highest motor speed in RPM. ("38" means

3800rpm, and "10" means 1000 rpm)

Press "▼/ ▲" to adjust the Maximum Speed from 100rpm to

3800rpm. The manufacturer’s default setting is 3800rpm.

d. Setting will be automatically saved 5 seconds after no buttons

are pressed. The motor returns to "ready" status.

ENGLISH - 5

"ready" status

STITCHES PER MINUTE AT 3800 RPM MOTOR SPEED

MOTOR PULLEY

DIAMETER

MM / INCHES

50 = 2 3800 3200 2800 2200 1700 1300

60 = 2-3/8 4500 3800 3300 2700 2000 1500

75 = 3 5700 4800 4200 3400 2500 1900

80 = 3-1/4 6200 5200 4500 3700 2700 2100

90 = 3-5/8 7000 5800 5000 4100 3000 2300

100 = 4 7600 6400 5500 4500 3300 2500

50 = 2 60 = 2-3/8 70 = 2-3/4 85 = 3-3/8 115 = 4-5/8 150 = 6

SEWING MACHINE HANDWHEEL PULLEY SIZE

Changing the Pulley

Remove pulley cover and pulley.

Securely tighten the new chosen pulley

.

Caution – Incomplete tightening may cause malfunctions. Also, be sure the pulley cover is correctly

positioned to avoid rubbing against the pulley or the V-belt.

Motor pulley outer

diameter (mm)

=

Normal sewing machine speed

(*) Motor Speed

X

www.endurosaves.com

Sewing machine pulley

diameter

+ 5 mm

Page 6

6 - ENGLISH

SM600-1 & SM600-2 PARTS LISTING

No. Fig. Description

SM68 A Sensor only with screws (single channel for non-positioner motor)

SM603 B Tr

SM618 C Complete wire harness for 110 volt models, fused (877C)

SM619 D Fuse only for 110 volt wire harness

SM620 E Fuse cap for 110 volt wire harness

SM621 F On/Off toggle replacement switch only

SM78 G Complete horizontal wire harness for 220 volt models (431C)

SM622 H SM600-1 label

SM623 H SM600-2 label

SM625 I SM600 Pro control box cover with 4 screws (431C Matte)

SM627 J 2 Digit LED display with screws

SM628 K SM600-1 Circuit board with 6 screws

SM629 K SM600-2 Circuit board with 6 screws

SM631 L Motor mounting bracket complete with 4 screws (431C)

SM50 M 50mm pulley with mounting hardware

SM60 M 60mm pulley with mounting hardware

SM75 M 75mm pulley with mounting hardware

SM80 M 80mm pulley with mounting hardware

SM90 M 90mm pulley with mounting hardware

SM100 M 100mm pulley with mounting hardware

SM79 N Pulley cover bracket with screws and washers

SM86 O Pulley cover with screw and washer (431C Matte)

SM632 P Rear motor cover panel SM600-1 and SM600-2 with 6 screws (431C)

SM81 R Power inlet receptacle with wires, terminals and screws complete

eadle Sensor Plate Assembly complete with 4 screws (single channel for non-positioner motor) (431C)

www.endurosaves.com

SM600-1&2 2011-2

Page 7

FRANCAIS - 7

NON-POSITIONNEUR SM600-1 & SM600-2 ENDURO™ PRO

INSTRUCTION DE L

’UTILISATEUR DU MOTERU SERVO

Félicitations!

Vous avez acheté le moteur d’Enduro™ Pro SM600 qui est payée remarquablement pour sa capacité

de l’économie d’énergie de 60% à 80% comparé auxquels d’embrayage. Avec l’augmentation du prix

d’électricité, vous ne peut plus acheter des moteurs d’embrayage. La puissance et capacité de dépense

de SM600 de non-brosse Enduro™ Pro est suffi sante pour le travail de textile léger.

Avant l’installation, l’opération et le maintien, lisez cette instruction.

Instruction générale

Le moteur Servo de SM600 Enduro™ Pro est désigné spécialement pour le travail léger fondamental

et demandes continues d’utilisation de différents genres de machine industrielle textile. Il utilise l’aimant

permanent de Neodymium de rare-sol avec l’énergie extrême. Le moteur ne produit presque pas de

bruit, économise l’énergie. Il est non- brosse, ajustable et durable en vitesse. Il offre une torque haute

de commence même si la vitesse est basse ou il y a une arrête complète.

Avec le micro-processeur avancé de technologie moderne, le capteur de grande salle et la technologie

de Modulation Pulse- Ampleur, de SM600 Enduro™ Pro peut s’ajuster à rotation de vitesses de maximum

différentes dans la direction normale et inverse. Il peut aussi mettre en fonction à vitesses accélérées

différentes. Il peut s’arrêter automatiquement avec toute interruption, par exemple, voltage de ligne,

condensateur électrique, interférence ou surcharge de la fréquence de radio. Il est entièrement protégé

par logiciel. Quand il rencontre des problèmes, il émettra les messages d’indication. Il travail aussi bien

dans l’environnement de fourniture branlante de force électrique.

CAUTION

1. En allumant le moteur, enlevez vos pieds.

2. Si vous voulez remplacer ou connecter le fi

3. Eteindrez le moteur en quittant.

4. Eteindrez le moteur s’il y a une maintenance de la machine textile Enlevez le cordage

d’électricité derrière le moteur pour cesser complètement l’électricité de la machine

textile.

5. Toujours connecter la mise à la terre.

6. Toujours éteindrez le moteur avant de connecter ou déconnecter chaque connecteur.

7. Pour éviter des accidents, n’ajustez pas le moteur ou la boîte de contrôle.

Garantie

Ce produit est fourni avec une garantie de 1 an Si le moteur ne travail pas comme les fonctions

désignés car des fautes de manufacture, contactez le vendeur pour réparation ou remplacement.

Cette garantie n’inclut pas les situations comme tombe, élévation brutale de force, spike ou abus.

Installation

Mettez le support d’installation du moteur en haut sur le fond de table et le fi xez dans la tableau avec

les culasses of

prise femelle du câble de la boîte de transforme à la prise d’entrée d’électricité derrière le moteur.

fertes. Connectez la perche de pédale avec le poteau joint de connection. Installez la

lament, éteindrez le moteur.

www.endurosaves.com

Page 8

8 - FRANCAIS

Circuit

Pour le moteur monophase de 110 V, opérez selon le tableau suivant:

Connectez

au moteur

Connectez

la prise de

terrain

Pour le moteur monophase de 220 V, opérez selon le tableau suivant:

Vert- connectez au

terminal de terre

Connectez

au moteur

Noir

Blanc

Change du bouton poussé (Éteint / Allumé)

Connectez les

fi l s à l’électricité

Note: En connectant le moteur à la source d’électricité, connectez le fi l blanc et noir pour acquérir

220 V (vert au terre). Si vous êtes dans les régions (Chine/Europe) ou l’électricité est 220 V du

cliché en plomb monophase et puis connectez la source d’électricité au lil noir. Le fi l blanc sera

neutre et lequel vert au terre.

Message de faute et envoyeur de peine

E2: Peine de signal du moteur de phase.

E3: Moteur protégé contre sur-courant.

E4: Peine du circuit de planche.

E5: Peine de module d’affi chage et de la communication du module de contrôle .

E6: Peine du capteur de la position de pédale.

Établissement

Allumez le bouton d’ajustement dans la boîte d’ajustement.

L’affi c h age présentera un cercle avec un tableau brillant qui signifi e

que le moteur est préparé à travailler.

Statut « préparé »

www.endurosaves.com

Page 9

Disposition de la direction de rotation du moteur

Établissement numéro 2

a. Pressez le bouton « ▼ » pour quelques minutes jusqu’à ce

que le LED montre

« S.0 ».

b. Pressez le bouton « ▲ » pour 2 fois pour faire montrer « S.2 »

qui signifi

e « disposition numéro 2 ».

c. Pressez le bouton « ▼ » et le LED montre « r.E » ou « r.P ».

Pressez le bouton « ▼/▲ » pour ajuster de E à P pour atteindre les

demandes machine textile.

« E

« P » signifi e que le moteur travaillera dans la direction normale.

» signifi e que le moteur travaillera dans la direction inverse.

d. Disposition se souviendra automatiquement 5 secondes

après la condition si aucun bouton n’est pressé Le moteur

montre « préparé ».

FRANCAIS - 9

Statut « préparé »

Vitesse lente de commencement

Établissement numéro 1

1. Le période lent de temps = 128 milliseconds * X, (disposition du commencement lent), X = 0~9

(fi xé dans le moteur).

2. Exemple : La perche est approximativement pressée en demi route produisant la vitesse de

moteur à presque 2,000 RPM et si le commencement lent est 9, le temps de 0 à 2,000 RPM

sera théorétiquement 128 milliseconds X 9 = 1152 milliseconds. En plus, le retard électoralemécanique sera environ 0.8 secondes.

3. Si le commencement lent est 0, le temps du commencement réel de 0 à 2,000 RPM sera

environ 0.8 secondes, qui est du au retard électorale-mécanique inévitable.

a. Pressez le bouton « ▼ » pour quelques minutes jusqu’à ce

que le LED montre « S.0 ».

b. Pressez le bouton « ▲ » pour une fois pour faire montrer S.1

qui signifi e « disposition numéro 1 ».

c. Pressez le bouton « ▼ » et LED montre « L.X » (X est 0-9),

pressez le bouton « ▼/▲ » pour ajuster de 0 à 9 d’après

votre même application. 0 signifi e le plus rapide. 9 signifi e le

plus lent. La disposition originale de manufacture est 0.

d. Disposition se souviendra automatiquement 5 secondes

après la condition si aucun bouton n’est pressé. Le moteur

montre « préparé ».

www.endurosaves.com

Statut « préparé »

Page 10

10 - FRANCAIS

Disposition de vitesse maximum

Établissement numéro 3

a. Pressez le bouton « ▼ » pour quelques minutes jusqu’à ce

que le LED montre « S.0 ».

b. Pressez le bouton « ▲ » pour une fois pour faire montrer S.3

qui signifi e « disposition numéro 3 ».

c. Pressez le bouton « ▼ » et LED montre « XX » (X est 1-38) qui

signifi e le moteur plus haut dans RPM. ("38" signifi e 3800rpm,

et "10"signifi e 1000 rpm)

Pressez le bouton « ▼/▲ » pour ajuster la vitesse maximum

de 100rpm à 3800rpm. La disposition originale de manufacture

est 3800rpm.

d. Disposition se souviendra automatiquement 5 secondes après

la condition si aucun bouton n’est pressé Le moteur montre

« préparé ».

Statut « préparé »

AIGUILLLE CHAQUE MINUTE À LA VITESSE DU MOTEUR 3800 RPM

LE DIAMÈTRE

DE POULIE DU

MOTERUR

MM / pied

50 = 2 3800 3200 2800 2200 1700 1300

60 = 2-3/8 4500 3800 3300 2700 2000 1500

75 = 3 5700 4800 4200 3400 2500 1900

80 = 3-1/4 6200 5200 4500 3700 2700 2100

90 = 3-5/8 7000 5800 5000 4100 3000 2300

100 = 4 7600 6400 5500 4500 3300 2500

50 = 2 60 = 2-3/8

DIMENSION DE POULIE DU VOLANT DE LA MACHINE TEXTILE

70 = 2-3/4 85 = 3-3/8 115 = 4-5/8 150 = 6

En changeant la poulie

Enlevez la couverture de poulie et la poulie.

Resserrez fortement la nouvelle poulie choisie.

Caution – le resserrement incomplet peut-être causera des malfonctions Assurez que la couverture de

poulie est correctement mise pour éviter le rodage contre la poulie ou V

-belt.

Diamètre de la poulie

extérieure du moteur

(mm)

=

Vitesse normale de machine textile

(*) vitesse de moteur

X

www.endurosaves.com

Diamètre de la poulie de machine

textile

+ 5 mm

Page 11

FRANCAIS - 11

Liste de pièce de SM600-1 et de SM600-2

Connectez

au moteur

Change du bouton poussé

(Éteint / Allumé)

Vert - connectez au

terminal de terre

Noir

Connectez les

fi l s à l’électricité

Blanc

Numéro Fig. Description

SM68 A Capteur avec vis seulement (canal singulier pour moteur de non-positionneur)

SM603 B L’assemblage complet du palier de perche avec 4 vis (canal singulier pour le moteur

avec positionneur) (431 C)

SM618 C Le semple complet de fi l pour modèle de 110 V (877C)

SM619 D Le fusible seulement pour le semple complet de110 V

SM620 E Le chapeau du fusible seulement pour le semple complet de110 V

SM621 F L’ajustement du replacement de culasse On/Off

SM78 G Le semple complet de fi l horizontal pour modèle de 220 V (431C)

SM622 H label SM600-1

SM623 H label SM600-2

SM625 I La couverture de la boîte de contrôle SM1000 Elite avec 4 vis (431C Matte)

SM627 J 2 LED digital montrent avec vis

SM628 K Le circuit de planche SM600-1 avec 6 vis

SM629 K Le circuit de planche SM600-2 avec 6 vis

SM631 L Le support d’installation complet du moteur avec 4 vis (431C)

SM50 M Poulie de 50mm avec matériel d’élevé

SM60 M Poulie de 60mm avec matériel d’élevé

SM75 M Poulie de 75mm avec matériel d’élevé

SM80 M Poulie de 80mm avec matériel d’élevé

SM90 M Poulie de 90mm avec matériel d’élevé

SM100 M Poulie de 100mm avec matériel d’élevé

SM79 N Le support de la couverture de poulie avec vis et rondelle

SM86 O La couverture de poulie avec vis et rondelle (431C Matte)

SM632 P Planche de la couverture de poulie du moteur derrière SM600-1 et SM600-2 avec 6 vis (431C)

SM81 R La douille d’entrée d’électricité avec fi ls, terminaux et vis complets

www.endurosaves.com

SM600-1&2 2011-2

Page 12

12 - ESPAÑOL

SM600-1 & SM600-2 ENDURO™ PRO NO POSICIONADOR

INSTRUCCIÓN DE USO DE SER

VO MOTOR

Felicidades!

Usted ha comprado el Enduro™ Pro SM600 motor que se paga por sí con un notable ahorro de energía del

60% al 80% en comparación con motores de embrague. Con el costo de electricidad alto y en aumento, no

puedes soportar utilizar un motor de embrague más. El poder y la confi abilidad de Enduro SM600 ™ Pro sin

escobilla es adecuada para la costura ligera.

Por favor, léa esta instrucción con cuidado antes de la instalación, la operación y el mantenimiento

Introducción general

El Enduro™ Pro SM600 Servo Motor se diseña para satisfacer casi todos los requisito de la costura ligera básco

de varias máquinas de costura comercial. Se utiliza magnetos permanentes con neodimio de las tierras raras

muy potentes. El motor apenas produce ruido. Ahorra la energía y es sin escobilla. La velocidad es variable y

durable. Proporciona una alta fuerza de torsión, incluso a velocidad baja o desde una parada completa.

Mediante el uso de un microprocesador moderno tecnológicamente avanzados, el censor Hall y la tecnología

de modulación "Pulse - Width", el Enduro SM600™ Pro se puede confi gurar para girar a velocidades máximas

diferentes, en ambos sentidos normal o invertida, y puede comenzar con diferentes velocidades de aceleración.

Se detendrá automáticamente con cualquier interrupción como en el voltaje de línea, subida de tensión,

interferencias de radiofrecuencia o sobrecargas. Se protege totalmente por el software y da mensajes de error

que indica cuál es el problema que se encuentre. También funciona bien en ambientes con un suministro de

energía eléctrica inestable.

ATENCIÓN

1. Quite el pie del pedal cuando se enciende.

2. Apague el interruptor de alimentación antes de sustituir o enhebrar la aguja.

3. Apague la alimentación al dejar la máquina.

4. Al realizar el mantenimiento en la máquina de coser, ajuste el interruptor de

la posición OFF. Retire el cable de alimentación de la parte posterior del motor para impedir por

completo toda la energía a la máquina de coser.

5. Siempre dejan la cable a tierra en el suelo.

6. Siempre apague el interruptor de alimentación antes de conectar o desconectar todos los

conectores.

7. Para evitar un accidente, no altere este motor y la caja de control.

Garantía

Este producto tiene una garantía limitada de 1 año. Si el motor no cumple con su función diseñada por defectos

de fabricación, contacte con el lugar donde lo compró para la reparación o el reemplazo.

Esta garantía no cubre los defectos causados por caídas, subidas de tensión, púas o mal uso.

Instalación

Coloque el soporte de montaje del motor hacia arriba hasta la parte inferior de la mesa y fi j

mesa con los tornillos suministrados. Conecte la varilla de pedal con la articulación de biela. Instale el enchufe

hembra del cable de la caja del interruptor en enchufe de acceso de corriente en la parte posterior de la caja

del motor.

potencia del motor a

a el motor a la

www.endurosaves.com

Page 13

Cableado

Para motor monofásico de 110 voltios siga el diagrama siguiente:

ESPAÑOL - 13

Conecte al

motor

Conectar a

la salida de

tierra

Para motor monofásico de 220 voltios siga el diagrama siguiente:

Verde - Conectar a la

terminal de tierra

Conecte al

motor

Negro

Blanco

Interruptor de botón

Conecte estos

cables a la

potencia

Nota: Al conectar el motor a la fuente de alimentación, conecte ambos los cables negros y blancos

para obtener 220 voltios (verde al suelo). Si usted está en una área (China / Europa) que suministra

220 voltios desde un cable simple, a continuación, conecte la fuente de alimentación al cable

negro. El cable blanco será el neutro y el cable verde será el cable a tierra.

Mensaje de error y Solución de Problemas

E2: Error de señal de fase del motor.

E3: Motor protegido contra sobrecargas de corriente.

E4: Error de tablero de circuito.

E5: Visualizar módulo y control el error de la comunicación de .

E6: Error del sensor de la posición del pedal .

guración

Confi

Encienda el interruptor en la caja de distribución. La pantalla

mostrará un círculo con una activada barra intermitente brillante,

que signifi c a que el motor se encuentra ahora en el estado

"preparado", listo para trabajar o confi gurar.

Estado ¨preparado¨

www.endurosaves.com

Page 14

14 - ESPAÑOL

Confi guración de la dirección de rotación del motor

Confi guración Número 2

a. Mantenga "▼" apretado el botón por unos segundos, hasta

que la pantalla LED indique "S.0"..

b. Apriete el botón "▲" 2 veces para indicar "S.2", que signifi ca

"Confi guración Nº 2".

c. Apriete el botón "▼" y el LED indicará "r.E" o "r.P". Apriete

el botón "▼ / ▲" para alterar entre E y P, para cumplir con el

requisito de la máquina de coser.

"P" signifi

"E" signifi ca que el motor funcionará en la dirección inversa.

ca que el motor funciona enla dirección normal.

d. La confi guración se guardarán automáticamente en 5

segundos sin pulsar ningún botón. El motor vuelve al estado

"preparado".

Estado ¨preparado¨

Velocidad de inicio baja

Confi guración Número 1

1. El "tiempo de período lento" = 128millisegundos * X, (confi guración de inicio lento), X = 0 ~ 9

(como la confi guración en el motor).

2. Ejemplo: El pedal se presiona alrededor la mitad hacia abajo produciendo una velocidad del

motor de 2.000 RPM y si el inicio lento se confi gura en 9, entonces el tiempo de 0 a 2000RPM

es teóricamente 128 milisegundos x 9 = 1.152 milésimas de segundo, más el retardo eléctricomecánico que es sobre 0.8 segundos.

3. Si el inicio lento se fi ja en 0, el "tiempo real de inicio" y el tiempo de 0-2000RPM es sobre 0.8

segundos, que se debe solamente a la demora inevitable eléctrico-mecánico.

a. Mantenga "▼" apretado el botón por unos segundos, hasta

que la pantalla LED indique "S.0".

b. Apriete el botón "▲" una vez para indicar "S.1", que signifi ca

"Confi guración de la Nº 1".

c. Apriete el botón "▼" y el LED indica "LX" (X es 0-9),

apriete "▼/▲" para ajustar el 0-9 de acuerdo con su propia

aplicación. 0 signifi ca el más rápido. 9 signifi ca el más lento.

La confi guración predeterminada del fabricante es 0.

d. La confi guración se guardarán automáticamente en 5

segundos sin pulsar ningún botón. El motor vuelve al estado

"preparado".

www.endurosaves.com

Estado ¨preparado¨

Page 15

Confi guración de la velocidad máxima

Confi guración Número 3

a. Mantenga el botón "▼" apretado durante unos segundos, hasta

que el LED indica "S.0".

b. Apriete el botón "▲" tres veces para indicar "S. 3", que signifi ca

"Confi guración Nº 3".

c. A continuación, apriete el botón "▼" y el LED indica "XX" (XX es

1-38), lo que signifi ca la velocidad máxima del motor en RPM.

("38" signifi ca 3800rpm, y "10" signifi ca 1000 rpm)

Apriete el botón "▼/▲" para ajustar la velocidad máxima de 100

rpm a 3800rpm. La confi guración predeterminada del fabricante

es 3800rpm.

d. La confi guración se guardarán automáticamente en 5 segundos sin

pulsar ningún botón. El motor vuelve al estado "preparado".

ESPAÑOL - 15

PUNTOS POR MINUTO EN VELOCIDAD DEL MOTOR 3800 RPM

DIÁMETRO DE

LA POLEA DE

MOTOR

MM/PULGADAS

50 = 2 3800 3200 2800 2200 1700 1300

60 = 2-3/8 4500 3800 3300 2700 2000 1500

75 = 3 5700 4800 4200 3400 2500 1900

80 = 3-1/4 6200 5200 4500 3700 2700 2100

90 = 3-5/8 7000 5800 5000 4100 3000 2300

100 = 4 7600 6400 5500 4500 3300 2500

50 = 2 60 = 2-3/8 70 = 2-3/4 85 = 3-3/8 115 = 4-5/8 150 = 6

TAMAÑO DE POLEA DE VOLANTE DE MÁQUINA DE COSER

Cambiar la polea

Quite la tapa del polea y polea.

Apriete bien la polea recién elegido.

Estado ¨preparado¨

Atención – El aprieto incompleto puede causar un mal funcionamiento. Ta

cubierta de la polea está en la posición correcta para evitar el roce contra la polea o el cinto-V

Diámetro externo de la

polea del motor (mm)

=

Velocidad normal de la máquina de coser

(*) velocidad de motor

X

www.endurosaves.com

mbién, asegúre que la

Diámetro de la polea de máquina de

coser

.

+ 5 mm

Page 16

16 - ESPAÑOL

SM600-1 y SM600-2 Lista De Partes

Conecte al

motor

Interruptor de botón

Verde - Conectar a la

terminal de tierra

Conecte estos

Negro

cables a la

Blanco

potencia

No. Fig. Descripción

SM68 A Sensor con los tornillos (de un solo canal para el motor no posicionador)

SM603 B La asamblea de la placa de sensor de pedal completa con 4 tornillos (de un solo canal para

el motor no posicionador) (431C)

SM618 C instrumento de cables completo para modelos de 110 voltios (877C)

SM619 D Fusible sólo para cables de 110 voltios

SM620 E Tapon de fusible para cables de 110 voltios

SM621 F On / Off reemplazo interruptor de palanca única

SM78 G Instrumento horizontal de cables completo para modelos de 220 voltios

SM622 H SM600-1 label

SM623 H SM600-2 label

SM625 I Cubierta de caja de control de SM600 Pro con 4 tornillos (431C Mate)

SM627 J 2 LED digitales con tornillos

SM628 K SM600-1 Circuit board with 6 screws

SM629 K SM600-2 Circuit board with 6 screws

SM631 L Soporte de montaje del motor con 4 tornillos (431C)

SM50 M polea de 50mm con el hardware de montaje

SM60 M polea de 60mm con el hardware de montaje

SM75 M polea de 75mm con el hardware de montaje

SM80 M polea de 80mm con el hardware de montaje

SM90 M polea de 90mm con el hardware de montaje

SM100 M polea de 100mm con el hardware de montaje

SM79 N soporte de la cubierta de la polea con tornillos y arandelas

SM86 O Cubierta de la polea con el tornillo y la arandela (431C mate)

SM632 P Panel cubierto de motor trasero de SM600-1 y SM600-2 con 6 tornillos (431C)

SM81 R Receptáculo de acceso de corriente con cables, terminales y tornillos completos

www.endurosaves.com

SM600-1&2 2011-2

Loading...

Loading...