Page 1

TI00250T/09/EN/14.16

71343992

Products Solutions Services

Technical Information

Thermowell TA535

For general industrial applications and processes

generating medium to high stress

Thermowell for temperature inserts

Welded version with hexagonal extension and

threaded process connection

Application

The thermowell with a hexagonal extension is employed in industrial applications

which generate medium to high stress. For pipes or tanks that have threaded process

connections. It can accommodate sensors with a diameter of 6 mm (0.24 in) and can

also be used in combination with thermometers without a thermowell. It is available

with NPT, gas and M20 connections (on thermometer and process sides).

Your benefits

• Several types of process connection can be selected as standard

• Also large choice of outer diameters as standard

• Thermometer connection: ½" NPT, G ½" or M20x1.5 thread

• Thermowell made of SS 316L / 1.4404

• The immersion length can be selected to suit the process requirements, maximum

standard length 10 m (32.8 ft).

Page 2

Function and system design

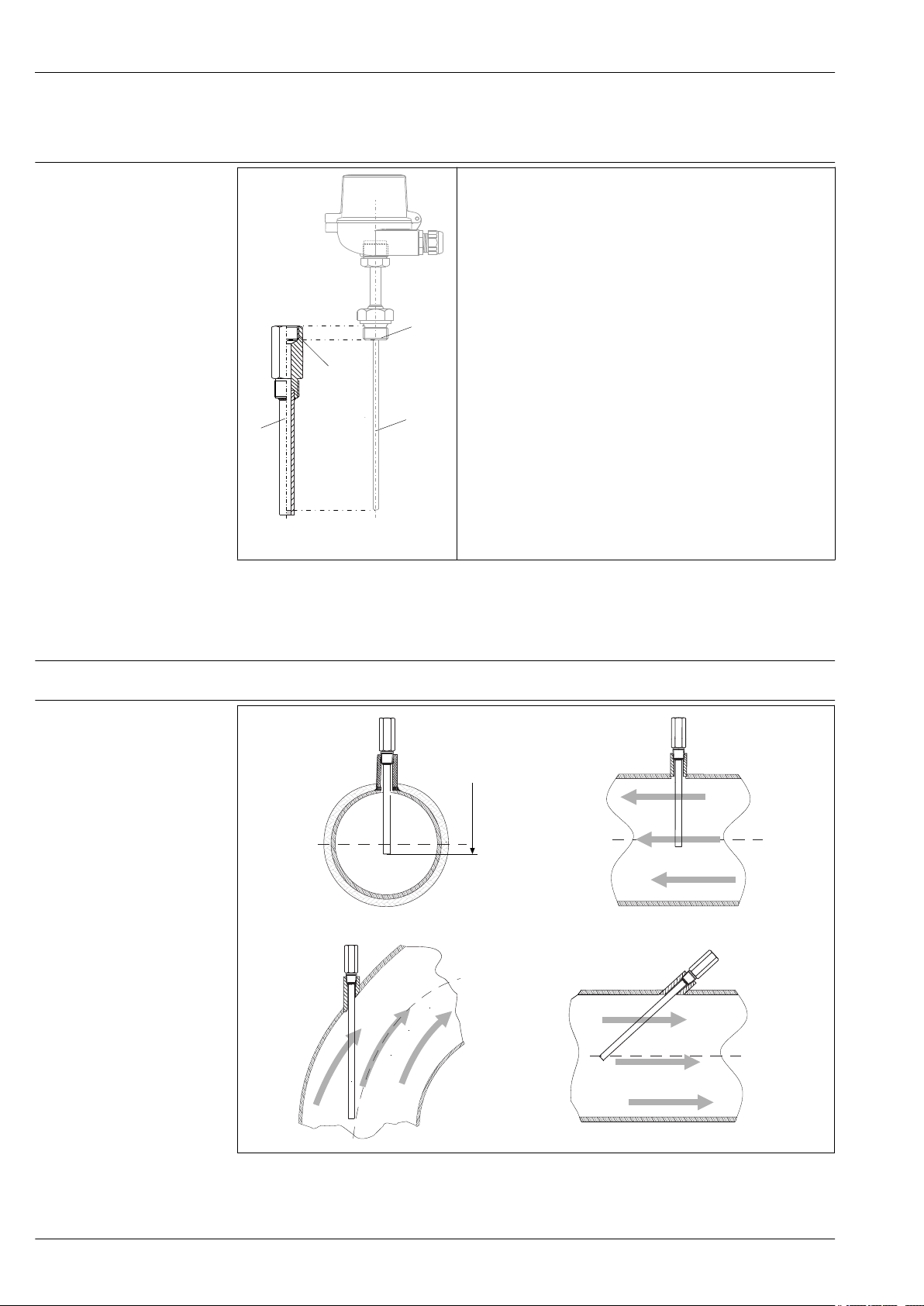

1

2

3

4

L

1

2

3

4

Thermowell TA535

Equipment architecture

The TA535 is a straight thermowell (1) made from a welded tube. It

is perfect to accommodate temperature inserts (2) with a customary

diameter of 6 mm (0.25 in). The hexagonal extension is available in

several lengths and ends with a female thread (3), enabling the

thermowell to be connected to temperature inserts with an adjustable

compression fitting, for example, or thermometers with a matching

extension neck male thread (4).

A0032225

1 Thermowell design

Orientation

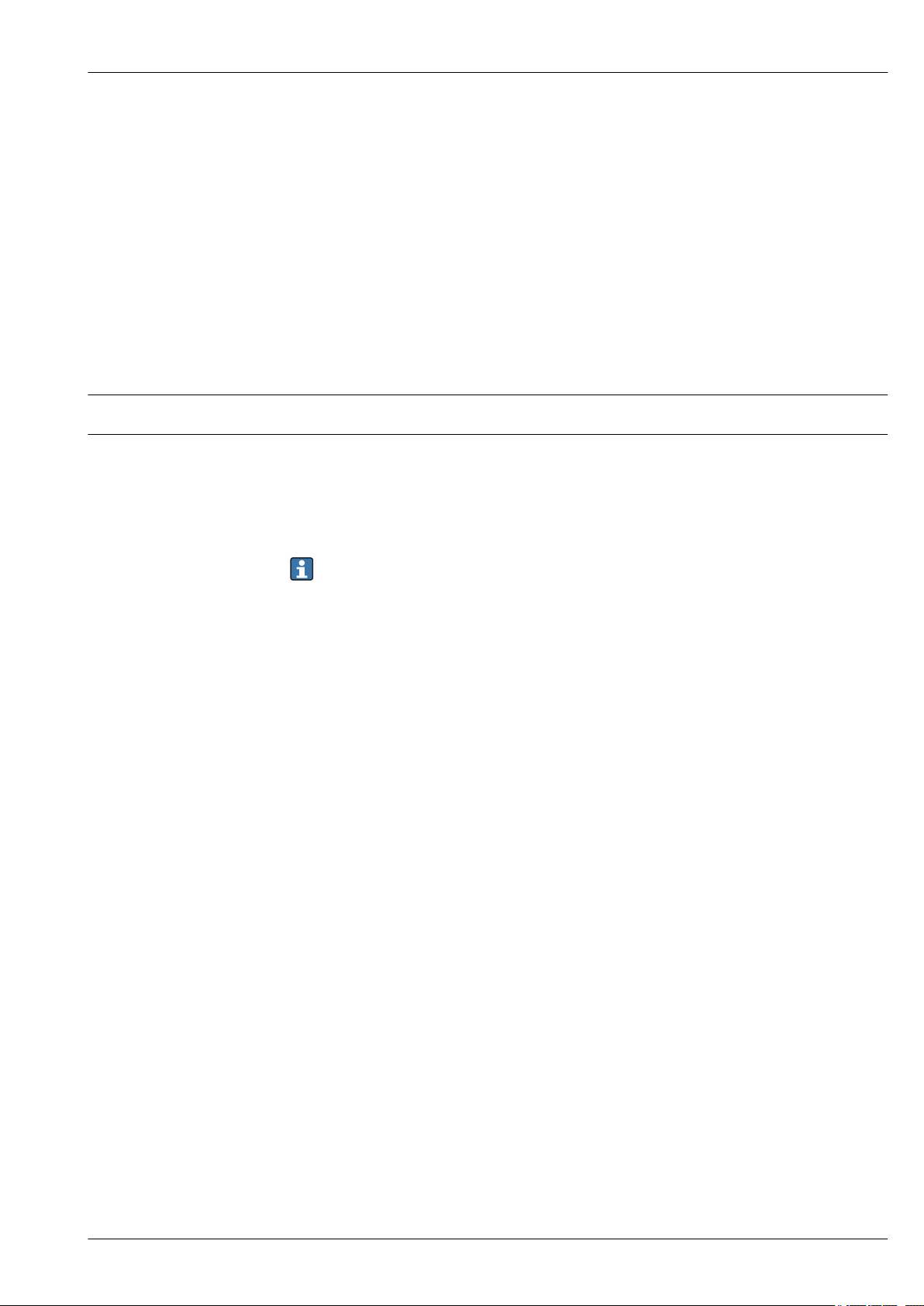

Installation instructions

Installation

No restrictions.

2 Mounting examples

2 Endress+Hauser

A0032231

Page 3

Thermowell TA535

The immersion length of the thermometer influences the accuracy. If the immersion length is too

small, errors in the measurement are caused by heat conduction via the process connection and the

container wall. For installation in a pipe, therefore, the recommended installation depth ideally

corresponds to half of the pipe diameter (see 1 and 2). Installation at an angle (see 3 and 4) could be

another solution. When determining the immersion length or installation depth all the parameters

of the thermometer and of the process to be measured must be taken into account (e.g. flow velocity,

process pressure).

• Installation possibilities: Pipes, tanks or other plant components

• Recommended minimum immersion depth = 80 to 100 mm (3.15 to 3.94 in)

The immersion depth should be at least 8 times the diameter of the thermowell.

Process

Process temperature range

Process pressure (static)

–200 to +650 °C (–328 to +1 202 °F)

Max. 100 bar (1 450 psi)

Permitted flow velocity depending on the immersion length

The maximum flow velocity tolerated by the thermowell diminishes with increasing thermowell

immersion length exposed to the stream of the fluid. In addition, it depends on the shape and size of

the thermowell, the medium type, process temperature and process pressure.

Thermowell sizing tool

It is possible to check the mechanical loading capacity as a function of the installation and

process conditions online in the TW Sizing Module for protection tubes in the Endress+Hauser

Applicator software. See https://wapps.endress.com/applicator

Endress+Hauser 3

Page 4

Mechanical construction

T

L

ML

3 (0.12)

T

L

ML

!

!

TL

A

A

3 (0.12)

1 2

Thermowell TA535

Design, dimensions

All dimensions in mm (in). Surface roughness Ra ≤ 1.6 µm (63 µin)

A0019038

1 Version with NPT connection thread

2 Version with G or M20 connection thread

A Thermometer connection

L Immersion length

ML Insertion length of insert

T Extension

TL Screw-in length 8 mm (0.32 in)

⌀ Thermowell outer diameter

Thermometer connectionAExtension T Immersion length L Thermowell outer diameter ⌀

Thread M20X1.5

Thread NPT ½"

Thread G ½"

Weight

Material

50 mm (1.97 in)

70 mm (2.76 in)

90 mm (3.54 in)

110 mm (4.33 in)

Other values up to a

maximum of

500 mm (19.7 in) can be

specified separately.

For correct temperature measurement, ensure that the tip of the insert touches the bottom of

the thermowell. To accurately determine the insertion length of the insert (ML), factor in the

type of connection on the thermometer used.

When using Endress+Hauser thermometers, the following lengths apply:

• Omnigrad S TMT162R, TMT162C, TR62, TC62: ML = (L+T) - 8 mm (0.32 in)

• Omnigrad S TR88, TC88: ML = (L+T)

Typical values, around 0.2 to 1 kg (0.44 to 2.2 lb) depending on the version and standard length.

The temperatures for continuous operation specified in the following table are only intended as

reference values for use of the various materials in air and without any significant compressive load.

50 to 5 000 mm (1.97 to 197 in)

10 to 10 000 mm (0.39 to 393.7 in) • 9 mm (0.35 in)

Internal diameter: 6.5 mm (0.26 in)

• 10 mm (0.39 in)

Internal diameter: 7 mm (0.28 in)

• 12 mm (0.47 in)

Internal diameter: 8 mm (0.32 in)

4 Endress+Hauser

Page 5

Thermowell TA535

SW/

AF

T

L

T

L

TL

SW/

AF

TL

The maximum operating temperatures are reduced considerably in some cases where abnormal

conditions such as high mechanical load occur or in aggressive media.

Process connection

Description Short form Recommended max.

temperature for

continuous use in air

AISI 316L/

1.4404

Threaded connection Version Screw-in length TL in

Parallel (version M, G) Conical (version NPT) M M20x1.5 20 (0.79) 27

X2CrNiMo17-12-2 650 °C (1 202 °F) • Austenitic, stainless steel

G G ½"

NPT NPT ½" 8 (0.32) 27

Properties

• High corrosion resistance in general

• Particularly high corrosion-resistance in

chlorine-based and acidic, non-oxidizing

atmospheres through the addition of

molybdenum (e.g. phosphoric and sulfuric

acids, acetic and tartaric acids with a low

concentration)

• Increased resistance to intergranular corrosion

and pitting

Width across

mm (in)

G ¾" 30

NPT ¾" 8.5 (0.33)

flats (SW/AF)

A0032278

Seal

A process connection seal must be used for parallel threads (M20x1.5, G ½", G ¾").

Possible seal sizes:

• M20x1.5: seal 24x20.3x1.5 (copper)

• G ½": seal 26x21.3x1.5 (copper)

• G ¾": seal 32x27.3x2 (copper)

The material of the seal must be resistant to the process medium. The seal is not included in the

scope of supply.

Certificates and approvals

Material certification

The material certificate 3.1 (according to standard EN 10204) can be selected directly in the order

code. Other material-specific certificates can be requested separately. The "short form" certificate

includes a simplified declaration and has no enclosures of documents related to the materials used,

but guarantees the traceability of the materials through the identification number of the thermowell.

The data related to the origin of the materials can subsequently be requested by the client if

necessary.

Endress+Hauser 5

Page 6

Thermowell TA535

Ordering information

Detailed ordering information is available from the following sources:

• In the Product Configurator on the Endress+Hauser website: www.endress.com -> Click "Corporate"

-> Select your country -> Click "Products" -> Select the product using the filters and search field ->

Open product page -> The "Configure" button to the right of the product image opens the Product

Configurator.

• From your Endress+Hauser Sales Center: www.addresses.endress.com

Product Configurator - the tool for individual product configuration

• Up-to-the-minute configuration data

• Depending on the device: Direct input of measuring point-specific information such as

measuring range or operating language

• Automatic verification of exclusion criteria

• Automatic creation of the order code and its breakdown in PDF or Excel output format

• Ability to order directly in the Endress+Hauser Online Shop

Accessories

Service-specific accessories

Accessories Description

Applicator Software for selecting and sizing Endress+Hauser measuring devices:

• Calculation of all the necessary data for identifying the optimum measuring

device: e.g. pressure loss, accuracy or process connections.

• Graphic illustration of the calculation results

Administration, documentation and access to all project-related data and

parameters over the entire life cycle of a project.

Applicator is available:

• Via the Internet: https://wapps.endress.com/applicator

• On CD-ROM for local PC installation.

Konfigurator

W@M Life cycle management for your plant

+temperature

Software for selecting and configuring the product depending on the measuring

task, supported by graphics. Includes a comprehensive knowledge database and

calculation tools:

• For temperature competence

• Quick and easy design and sizing of temperature measuring points

• Ideal measuring point design and sizing to suit the processes and needs of a wide

range of industries

The Konfigurator is available:

On request from your Endress+Hauser sales office on a CD-ROM for local PC

installation.

W@M supports you with a wide range of software applications over the entire

process: from planning and procurement, to the installation, commissioning and

operation of the measuring devices. All the relevant device information, such as

the device status, spare parts and device-specific documentation, is available for

every device over the entire life cycle.

The application already contains the data of your Endress+Hauser device. Endress

+Hauser also takes care of maintaining and updating the data records.

W@M is available:

• Via the Internet: www.endress.com/lifecyclemanagement

• On CD-ROM for local PC installation.

FieldCare FDT-based plant asset management tool from Endress+Hauser.

It can configure all smart field units in your system and helps you manage them. By

using the status information, it is also a simple but effective way of checking their

status and condition.

For details, see Operating Instructions BA00027S and BA00059S

6 Endress+Hauser

Page 7

Thermowell TA535

Supplementary documentation

Technical Information:

• RTD thermometer, Omnigrad S field transmitter TMT162R (TI00266T/02)

• TC thermometer, Omnigrad S field transmitter TMT162C (TI00267T/02)

• Omnigrad S: TR62 modular thermometer with resistance insert (RTD), TC62 modular

thermometer with thermocouple insert (TC) (TI01024T/09)

• Omnigrad S: TR88 with resistance insert (RTD), TC88 with thermocouple insert (TC) - Extension

neck and threaded connection for installation in an existing thermowell (TI01098T/09)

Endress+Hauser 7

Page 8

www.addresses.endress.com

Loading...

Loading...