Endress+Hauser Liquipoint T Series, Liquipoint T FTW 32, Liquipoint FTW 31 Technical Information

Technical Information

TI 375F/00/en

Level Limit Detection in Liquids

liquipoint T FTW 31, FTW 32

Level limit switch for multiple point detection

in conductive liquids

Applications

Liquipoint T sensors are used in

conductive liquids (as of 10 µS/cm) for

determining level limits.

Depending on the number of measuring

points (up to 5 rods or ropes), measuring

tasks such as overspill protection, dry

running protection, two-point control of

pumps or multiple point detection can be

implemented for an existing process

connection.

Your benefits

•

Detect up to five level limits with one

probe

•

Two-point control and additional

maximum and minimum detection

•

Option between rod or rope version for

optimum adaptation to the application

•

Flexible instrumentation:

– with built-in electronic insert, either

transistor or relay output for 2 or

3 rod/rope probes

– for connection to a separate

transmitter power supply unit

•

No calibration required;

standard setting for the most common

conductive liquids

•

No moving parts in the tank:

– long service life

– reliable operation with no wear or

blockages

•

WHG approval

•

Four measuring ranges can be set

100 Ω, 1 kΩ, 10 kΩ, 100 kΩ

•

Cost-effective probe for conductive

liquids

•

Electronic inserts for:

– NAMUR output

– Relais output

– Transistor output

Table of contents

Liquipoint T FTW 31, FTW 32

Function and system design . . . . . . . . . . . . . . . . . . 3

Measuring principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Measuring system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Measured variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Measuring range (application) . . . . . . . . . . . . . . . . . . . . . . 5

Input signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Electronic insert FEW 52 (DC-PNP) . . . . . . . . . . . . . . . . . . 5

Electronic insert FEW 54 (relay) . . . . . . . . . . . . . . . . . . . . . 6

Electronic insert FEW 58 (NAMUR) . . . . . . . . . . . . . . . . . . . 8

Cable monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Power supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Electrical connection (wiring diagrams) . . . . . . . . . . . . . . . 9

Cable entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Cable specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Accuracy with built-in electronic insert . . . . . . . . 14

Reference operating conditions . . . . . . . . . . . . . . . . . . . . 14

Measuring error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Repeatability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Hysteresis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Switch-on delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Influence of ambient temperature . . . . . . . . . . . . . . . . . . . 14

Certificates and approvals . . . . . . . . . . . . . . . . . . . 23

CE mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Overspill protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Other standards and guidelines . . . . . . . . . . . . . . . . . . . . 23

Ex-approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Type of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Ordering information . . . . . . . . . . . . . . . . . . . . . . . 24

Liquipoint FTW 31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Liquipoint FTW 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Liquipoint T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Supplementary Documentation . . . . . . . . . . . . . . . 26

Operating Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Certificates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Installation conditions . . . . . . . . . . . . . . . . . . . . . . 14

Installation instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Ambient temperature range . . . . . . . . . . . . . . . . . . . . . . . 17

Storage temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Climate class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Degree of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Shock resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Vibration resistance (at min. rod length) . . . . . . . . . . . . . . 17

Electromagnetic compatibility . . . . . . . . . . . . . . . . . . . . . . 17

Process conditions. . . . . . . . . . . . . . . . . . . . . . . . . 17

Medium temperature limits . . . . . . . . . . . . . . . . . . . . . . . . 17

Conductivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Limiting medium pressure range . . . . . . . . . . . . . . . . . . . 17

Mechanical construction . . . . . . . . . . . . . . . . . . . . 18

Design, dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Fitted electrodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Human interface . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Operating elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Display elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2

Endress + Hauser

Liquipoint T FTW 31, FTW 32

Function and system design

Measuring principle An alternating voltage exists between the rod probes in an empty tank.

As soon as the conductive liquid in the tank creates a connection between the ground probe rod

and, for example, the maximum probe rod, a measurable current flows and the Liquipoint T

switches. With level limit detection, the Liquipoint T switches back as soon as the liquid clears the

maximum probe. With two-point control, the Liquipoint T does not switch back until the MAX and

MIN probe is cleared.

Using alternating voltage prevents corrosion of the probe rods and electrolytic destruction of the

product. The material used for the tank walls is not important for measurement because the

system is designed as a closed potential-free circuit between the probe rods and the electronics.

There is absolutely no danger if the probe rods are touched during operation.

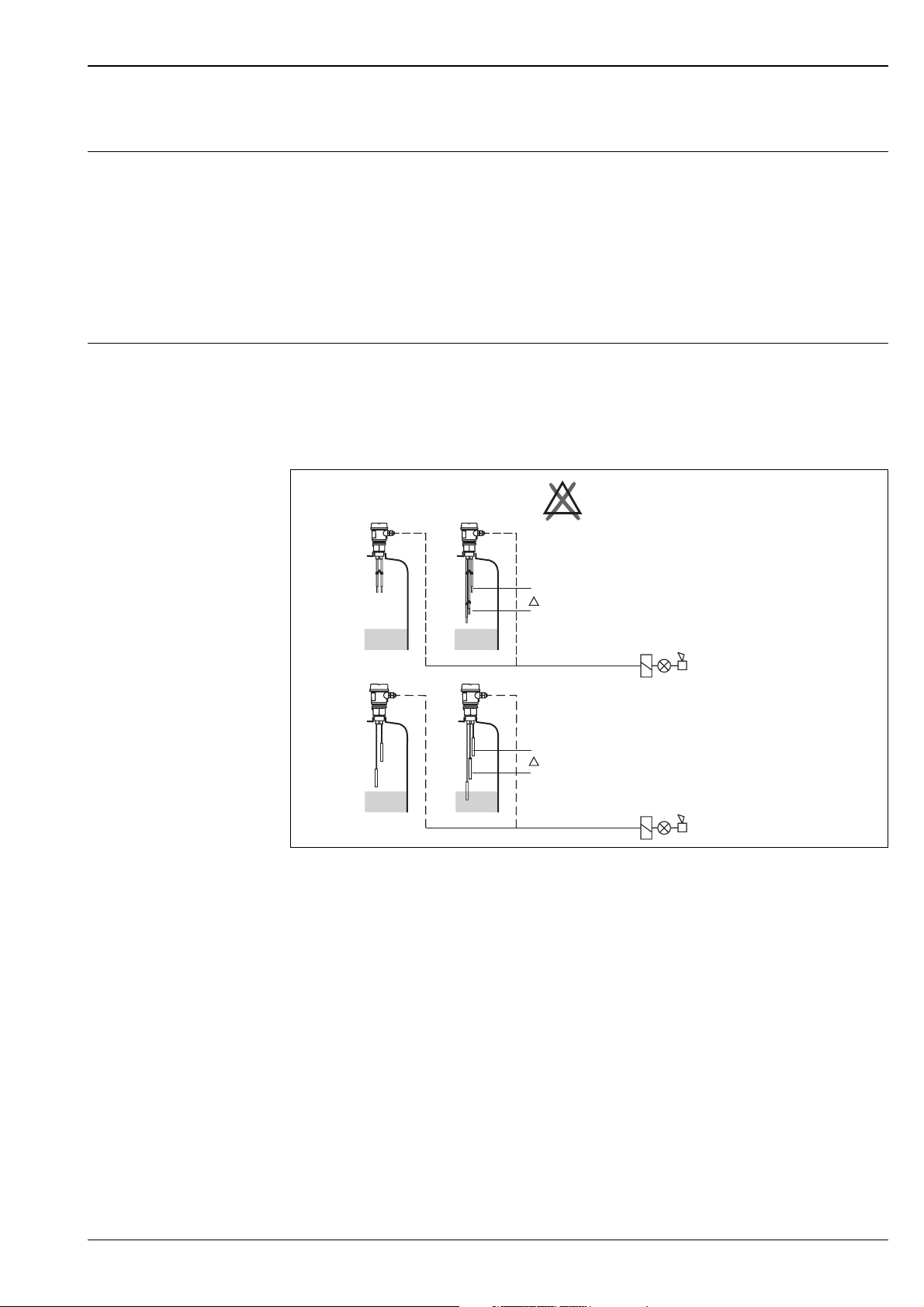

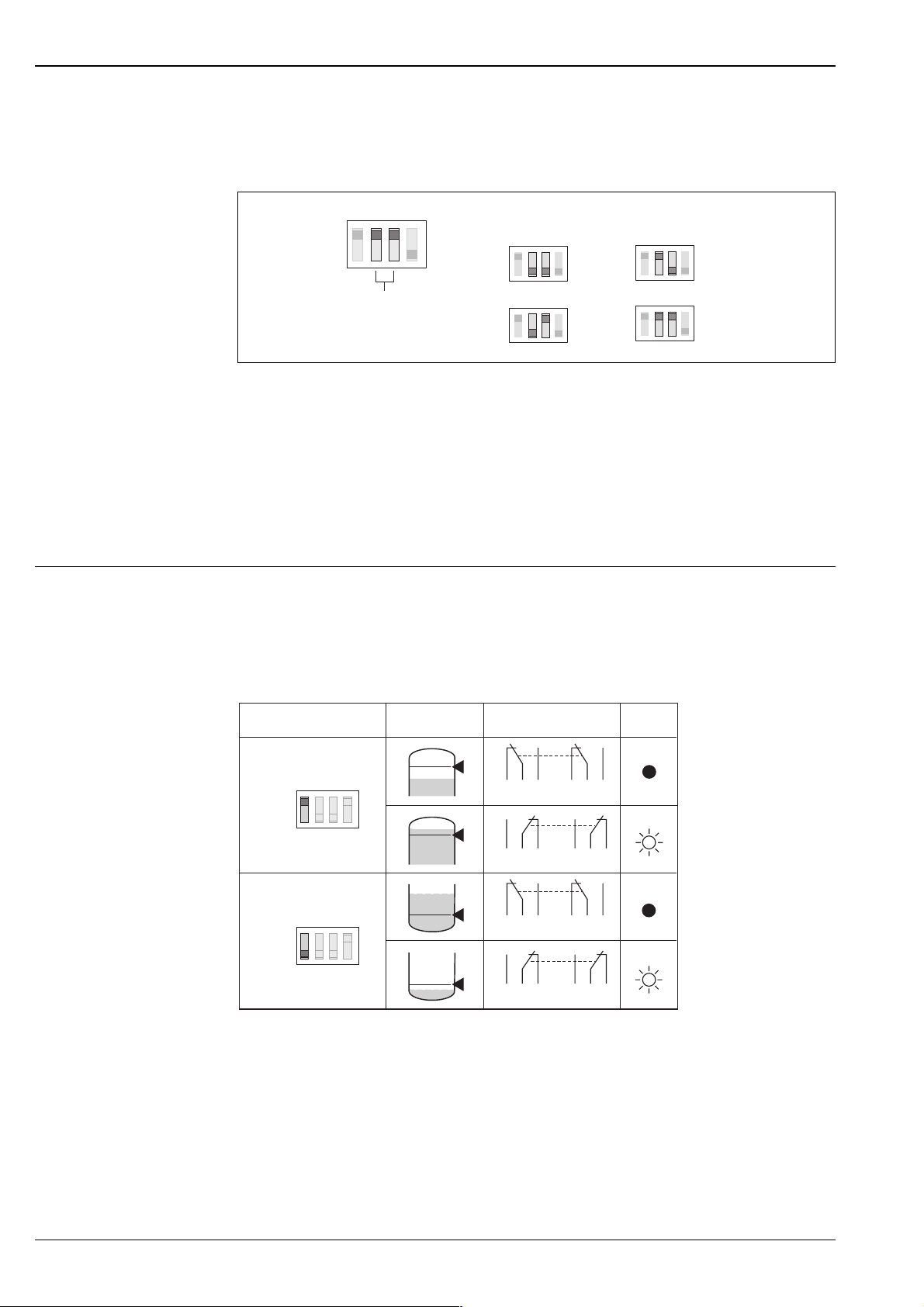

Measuring system Probes with integrated electronic insert (compact-instrument version)

The measuring system consists of:

•

FTW 31, FTW 32 with two/three rods or ropes and an electronic insert

•

Control units, switches or signal transmitters, e.g. process control systems PLC, relays, etc.

!

X

E

FTW 31

1 - 2 points

2 - 3 rods

s

FTW 32

1 - 2 points

2 - 3 ropes

s

L00-FTW3xxxx -14-05-xx-en-001

Independent of the tank material

Note!

The compact-instrument version with three probes or rods is always used in ∆s mode.

Endress + Hauser 3

Liquipoint T FTW 31, FTW 32

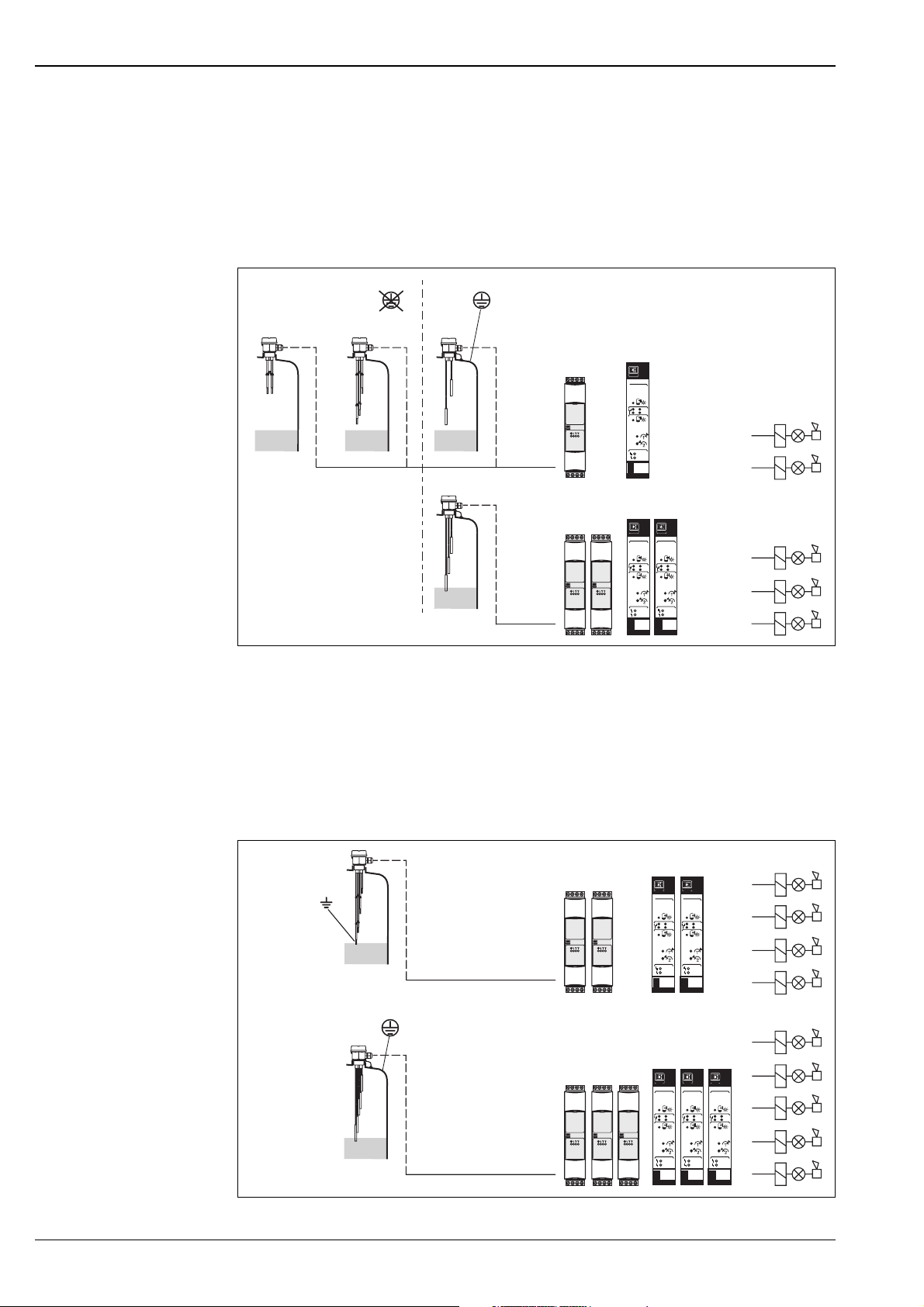

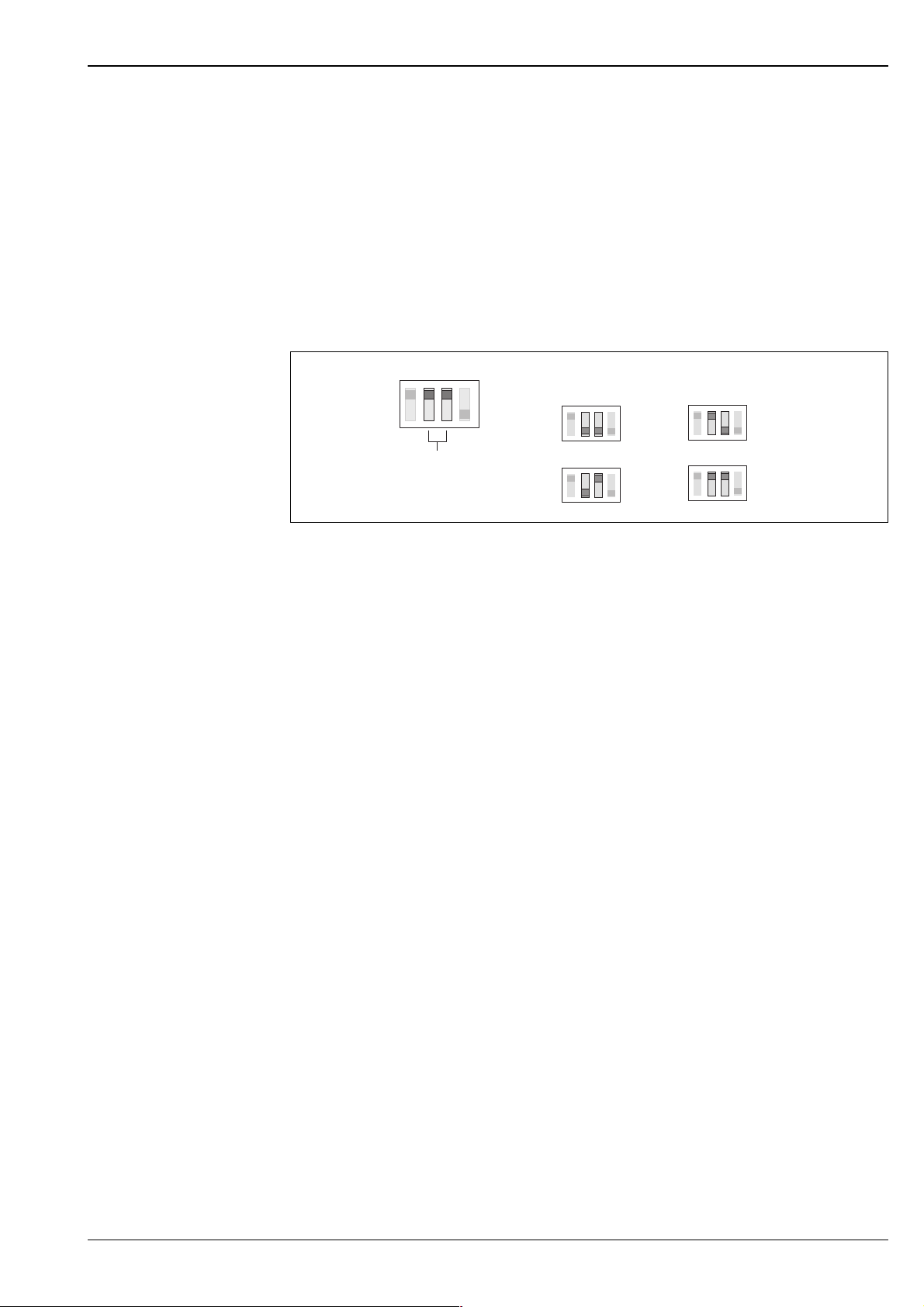

Probes without integrated electronic insert (separate-instrument version) for one or two

point detection respectively

The measuring system consists of:

•

FTW 31, FTW 32 with two/three rods or ropes

•

Nivotester FTW 325 or FTW 470 Z

•

Control units, switches or signal transmitters, e.g. process control systems PLC, relays, etc.

FTW 31/32

1 - 2 points

2 - 3 rods/ropes

FTW 325 or FTW 470 Z

FTW470Z

1

2

FTW 325

1

2

FTW 31/32

FTW 325 or FTW 470 Z

3 points

3 rods/ropes

FTW 325

FTW470Z

FTW470Z

1

1

2

2

FTW 325

1

1

2

2

L00-FTW3xxx x-14-05-xx-en-002

Switch points dependent on the tank material

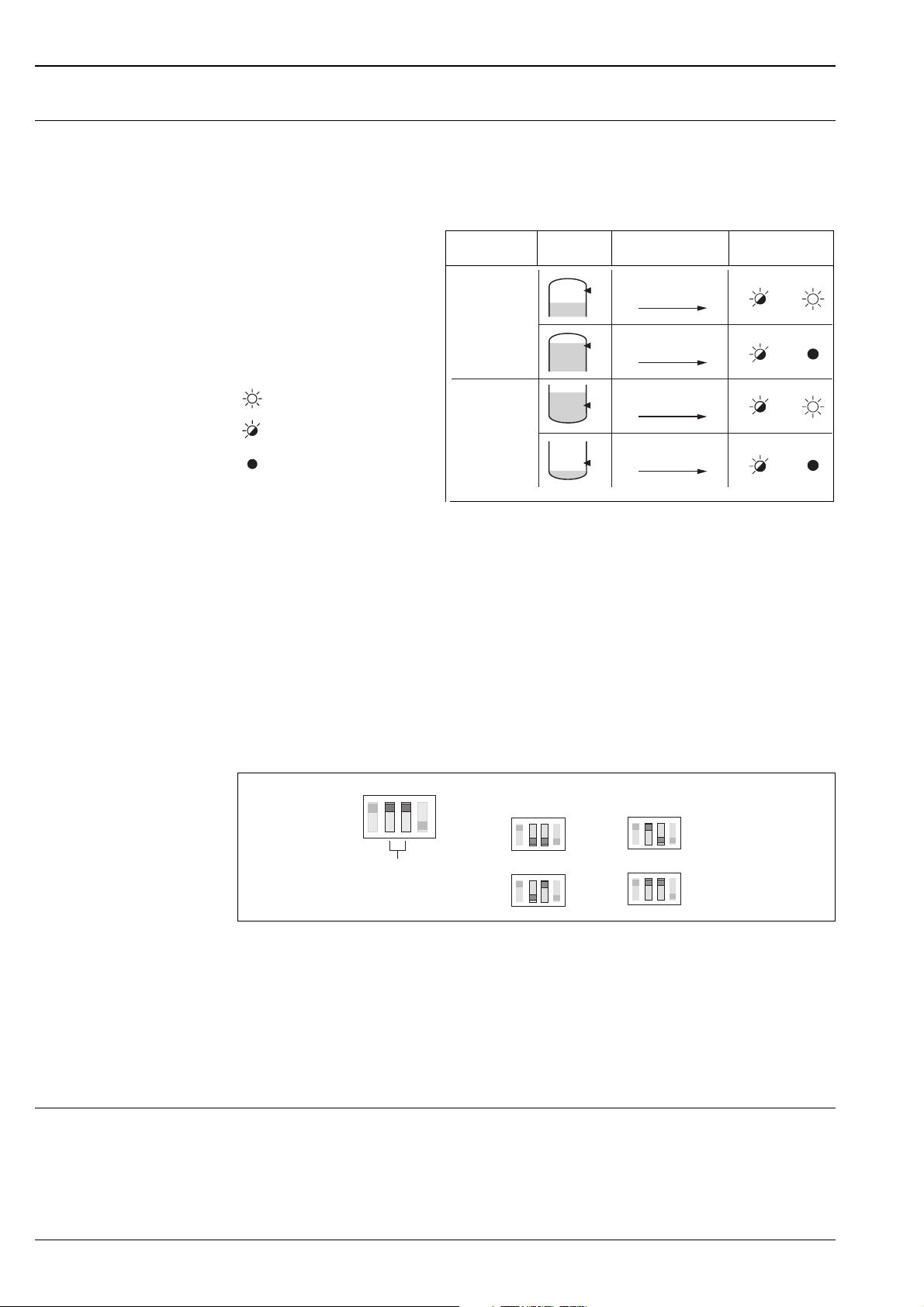

Probes without integrated electronic insert for multiple point detection

The measuring system consists of:

•

FTW 31, FTW 32 with five rods or ropes

•

Two Nivotester FTW 325 or FTW 470 Z

•

Control units, switches or signal transmitters, e.g. process control systems PLC, relays, etc.

FTW 31/32

4 points

5 rods/ropes

FTW 325 or FTW 470 Z

FTW470Z

FTW 325FTW 325

FTW470Z

1

1

2

2

1

1

2

2

FTW 31/32

5 points

5 rods/ropes

FTW 325 or FTW 470 Z

FTW470Z

FTW 325FTW 325

FTW 325

FTW470Z

FTW470Z

1

1

2

1

2

1

2

2

1

1

2

2

L00-FTW3xxx x-14-05-xx-en-003

Switch points dependent on the tank material

4 Endress + Hauser

Liquipoint T FTW 31, FTW 32

Input

Measured variable Resistance change between two conductors caused by the presence or absence of a conductive

product.

Measuring range (application)

The measuring range is dependent on the mounting location of the probes.

Rod probes can have a max. length of 4000 mm and rope probes up to 15 000 mm.

Input signal Probes covered => a measurable current is flowing between the probes.

Probes uncovered => there is no measurable current flowing between the probes.

Output

Electronic insert FEW 52 (DC-PNP)

Output signal

Three-wire direct current version

Preferred in conjunction with programmable logic controllers (PLC).

Positive signal at the switch output of the electronics (PNP).

The output is blocked after the level limit is reached.

Fail-safe mode Switch point Output signal

MAX

Max.

L+

1 3

1 3

1

*

I

L

2

*

< 100 µA

rd

3

*

4

*

L+

I

L

Min.

MIN

*1 = load current (connected); *2 residual current (disconnected); *3 LED not lit; *4 LED lit

See also Electrical connection on page 8.

1 3

+

< 100 µA

1 3

L00-FTW3xxxx -15-05-xx-en-001

If the probe is covered and the red LED flashes continuously, the next more sensitive measuring

range has to be set. This ensures a safe switch point even if the conductivity of the medium varies

slightly.

Fail-safe mode

Selecting the correct fail-safe mode ensures that the output always runs in quiescent current

fail-safe.

•

Maximum fail-safe: the output voltage is 0 V if the switch point is exceeded

(probe covered), a fault occurs or the power supply fails.

•

Minimum fail-safe: the output voltage is 0 V if the switch point is undershot

(probe uncovered), a fault occurs or the power supply fails.

Switching delay

A switching delay of 2.0 s can be activated or deactivated via a DIL switch.

If the switching delay is set to 0 s, the device switches after approx. 0.3 s.

Endress + Hauser 5

Liquipoint T FTW 31, FTW 32

Measuring ranges

A total of four measuring ranges (100 Ω; 1 kΩ; 10 kΩ; 100 kΩ) can be set via two DIL switches

(SENS). The setting on delivery is 100 kΩ.

Electronic insert FEW 54 (relay)

MAX

MIN

2 s

0 s

SENS = 100 - 100kΩΩ

100 Ω

1 kΩ

10 kΩ

100 kΩ

L00-FTW3xxx x-15-05-xx-xx-001

Signal on alarm

In the event of a power failure or a damaged probe: < 100 µΑ

Load

The load is switched via a transistor (PNP).

Cycled overload and short-circuit protection,

continuous ≤ 200 mA (short-circuit proof).

Residual voltage at transistor at I

max

< 2.9 V

Output signal

AC/DC connection with relay output

When connecting a device with high inductance, a spark barrier must be fitted to protect the relay

contact. A fine-wire fuse (load-dependent) protects the relay contact in the event of a short-circuit.

Both relay contacts switch simultaneously.

Fail-safe mode Switch point Output signal

MAX

Max.

Min.

MIN

354

354

354

354

1

*

687

2

*

687

687

687

rd

3

*

4

*

L00-FTW3xxx x-15-05-xx-en-002

*1 = relay energised; *2 relay de-energised; *3 LED not lit; *4 LED lit

See also Electrical connection on page 9.

If the probe is covered and the red LED flashes continuously, the next more sensitive measuring

range has to be set. This ensures a safe switch point even if the conductivity of the medium varies

slightly.

6 Endress + Hauser

Liquipoint T FTW 31, FTW 32

Fail-safe mode

Selecting the correct fail-safe mode ensures that the relay always runs in quiescent current

fail-safe.

•

•

Measuring ranges

A total of four measuring ranges (100 Ω; 1 kΩ; 10 kΩ; 100 kΩ) can be set via two DIL switches

(SENS). The setting on delivery is 100 kΩ.

Maximum fail-safe: the relay de-energises when the switch point is exceeded

(probe covered), a fault occurs or the power supply fails.

Minimum fail-safe: the relay de-energises when the switch point is undershot

(probe uncovered), a fault occurs or the power supply fails.

MAX

MIN

2 s

0 s

SENS = 100 - 100kΩΩ

100 Ω

1 kΩ

10 kΩ

100 kΩ

L00-FTW3xxxx-15-05-xx-xx-001

Switching delay

A switching delay of 2.0 s can be activated or deactivated via a DIL switch.

If the switching delay is set to 0 s, the device switches after approx. 0.3 s.

Signal on alarm

Output signal in the event of a power failure or a damaged probe: relay de-energised.

Load

Loads are switched via 2 potential-free change-over contacts.

I~ max. 4 A, U~ max. 253 V;

P~ max. 1000 VA, cos ϕ = 1, P~ max. 700 VA, cos ϕ > 0.7;

I– max. 4 A to 30 V, I– max. 0.2 A to 150 V.

When connecting a functional extra-low voltage circuit with double insulation in accordance with

IEC 1010: the sum of the relay output and power supply voltages is max. 300 V.

Galvanic isolation

All input channels, output channels and relay contacts are galvanically isolated from each other.

Endress + Hauser 7

Liquipoint T FTW 31, FTW 32

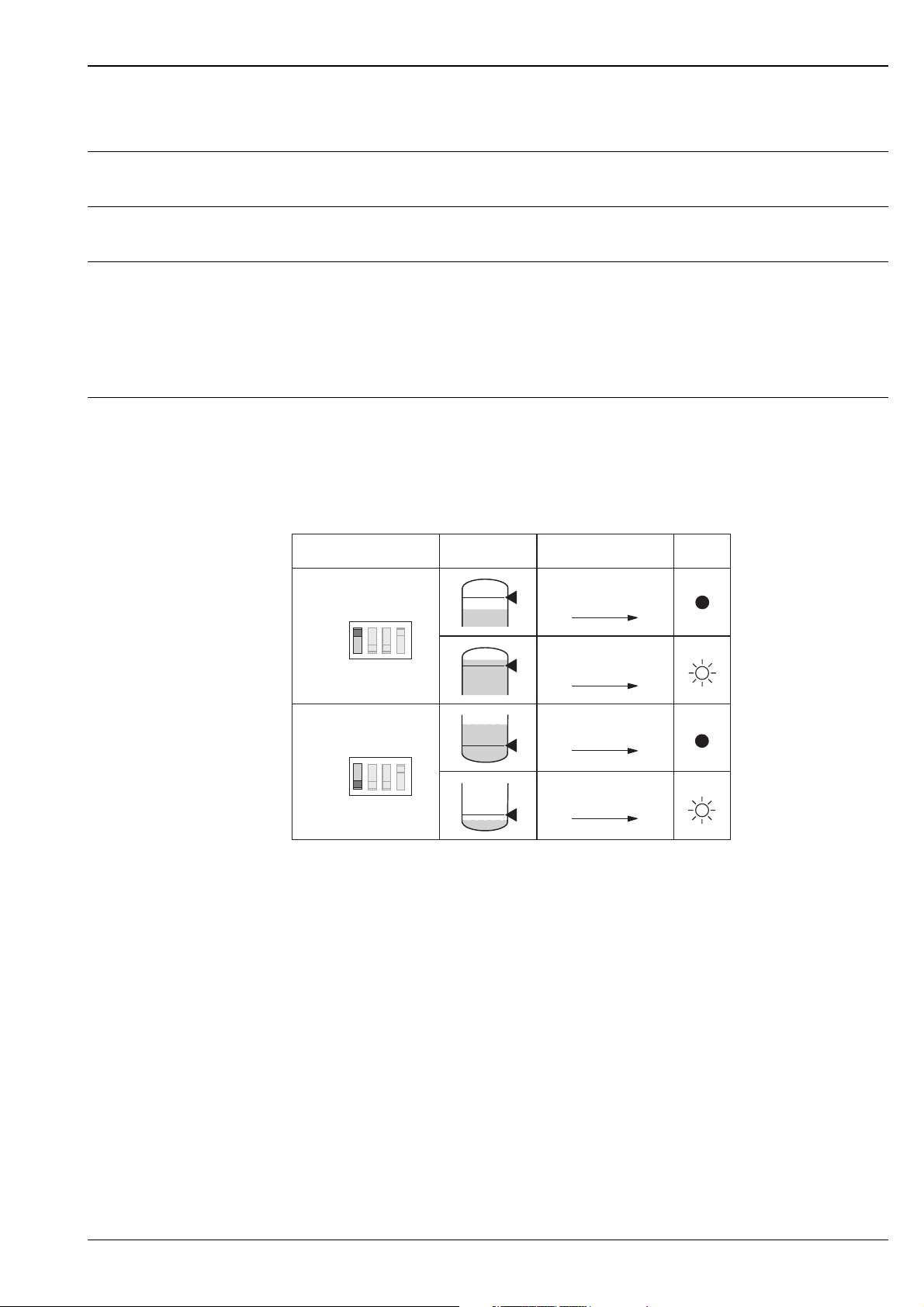

Electronic insert FEW 58 (NAMUR)

Output signal

For connecting to isolating amplifiers acc. to NAMUR (IEC 60947-5-6)

Output signal jump from high to low current on limit (H-L-edge).

L00-FTL5xxx x-07-05-

xx-xx-002

= lit

= flashes

= unlit

Fail-safe

circuit

Max.

Min.

Level Output signal LEDs

gn ye

2.2 …

+

6.5 mA

2 1

0.4 …

+

1.0 mA

2 1

2.2 …

+

6.5 mA

2 1

0.4 …

+

1.0 mA

2 1

L00-FTW3xxxx-04-05-xx-xx-006

Fail-safe mode

Selecting the correct fail-safe mode ensures that the relay always runs in quiescent current

fail-safe.

•

Maximum fail-safe: the output signal is < 1.0 mA when the switch point is exceeded

(probe covered), a fault occurs or the power supply fails.

•

Minimum fail-safe: the output signal is < 1.0 mA when the switch point is undershot

(probe uncovered), a fault occurs or the power supply fails.

Measuring ranges

A total of four measuring ranges (100 Ω; 1 kΩ; 10 kΩ; 100 kΩ) can be set via two DIL switches

(SENS). The setting on delivery is 100 kΩ.

MAX

MIN

2 s

0 s

SENS = 100 - 100kΩΩ

100 Ω

1 kΩ

10 kΩ

100 kΩ

L00-FTW3xxx x-15-05-xx-xx-001

Switching delay

A switching delay of 2.0 s can be activated or deactivated via a DIL switch.

If the switching delay is set to 0 s, the device switches after approx. 0.3 s.

Load

Refere to "Technical Data" date sheet of the connected isolating amplifier acc. to

NAMUR (IEC 60947-5-6)

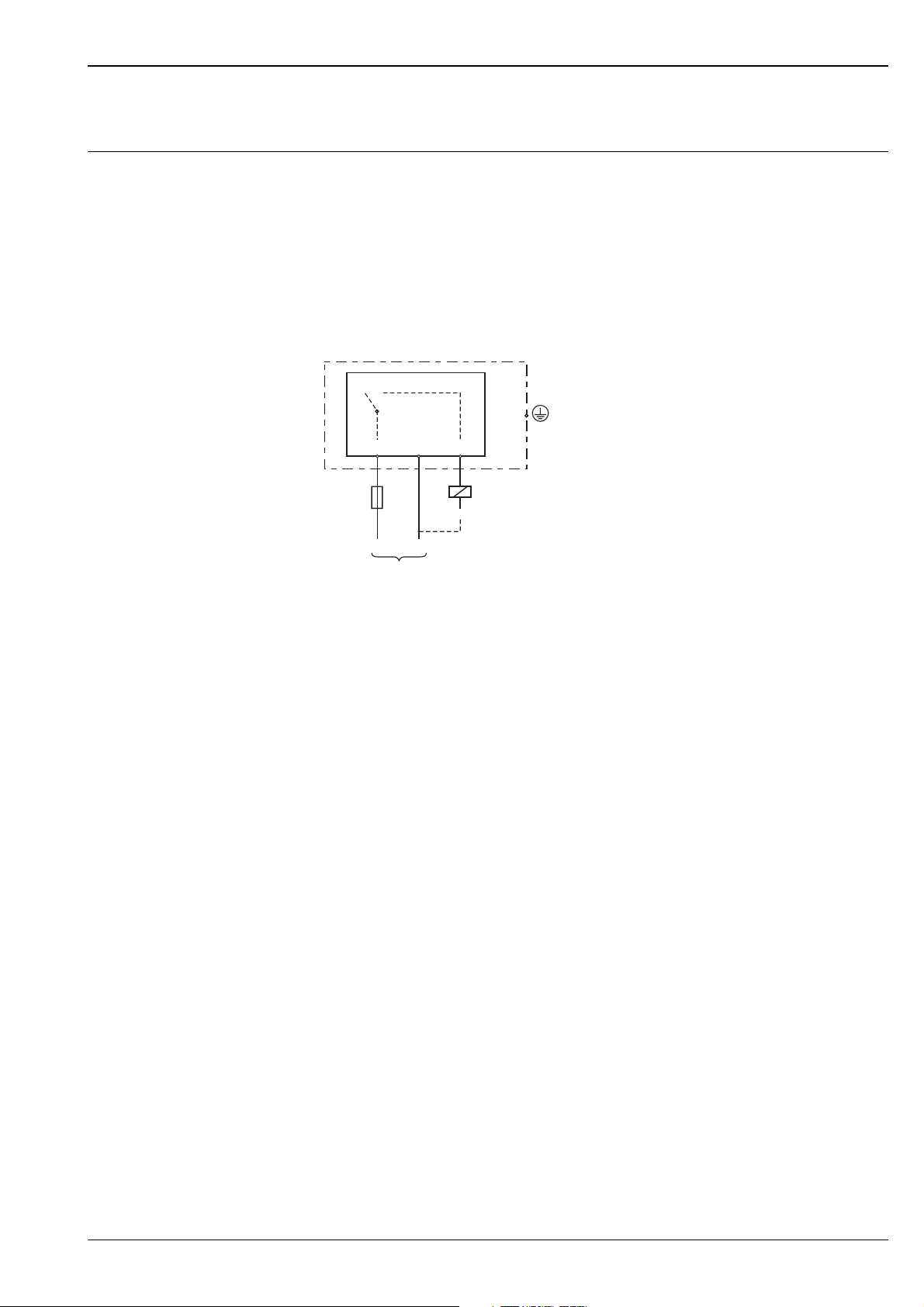

Cable monitoring For probes without an electronic insert, an additional printed circuit board must be installed in the

housing, which enables cable monitoring. It is always switched or connected between rod/rope

1 and 2.

!

Note!

When using switching units (transmitters) that do not support cable monitoring, these must be

removed.

8 Endress + Hauser

Liquipoint T FTW 31, FTW 32

Power supply

Electrical connection (wiring diagrams)

Compact instrumentation with FEW 52

Transistor circuit for load

The load connected to terminal 3 is switched by a transistor, contactless and therefore without

bouncing. In normal switching status, terminal 3 has a positive signal.

The transistor is blocked in the event of a level alarm or a power failure.

Protection against voltage peaks

When connecting a device with high inductance, always connect a voltage limiter.

FEW 52

M

123

F

L+ L–

Mains

Connecting the FEW 52 electronic insert.

(+)

R

–

L00-FTW3xxxx -04-05-xx-en-001

– F: Fine-wire fuse 500 mA, semi-time lag

– M: Ground connection to protective earth

Power supply (FEW 52)

•

Supply voltage: U= 10.8 V...45 V

•

Load connection: open collector; PNP

•

Switching voltage: max. 45 V

•

Connected load, continuous: max. 200 mA

•

Protected against reverse polarity

Power consumption

•

P < 1.1 W

Current consumption

•

I < 25 mA (without load)

Endress + Hauser 9

Loading...

Loading...