Endress+Hauser Liquiline CM442, Liquiline CM444, Liquiline CM448 Operating Instructions Manual

Products Solutions Services

Operating Instructions

Liquiline CM442/CM444/CM448

Universal four-wire multichannel controller

Field device

BA00444C/07/EN/19.16

71309796

Valid as of version

01.06.00

Table of contents

Endress+Hauser 3

Table of contents

1 Document information .............. 5

1.1 Warnings ............................ 5

1.2 Symbols .............................. 5

1.3 Symbols at the device .................... 5

1.4 Documentation ........................ 6

2 Basic safety instructions ............ 7

2.1 Requirements for the personnel ............ 7

2.2 Designated use ........................ 7

2.3 Occupational safety ..................... 7

2.4 Operational safety ...................... 8

2.5 Product safety ......................... 8

3 Device description .................. 9

3.1 Housing closed ........................ 9

3.2 Housing open ......................... 9

3.3 Slot and port assignment ................ 10

3.4 Terminal diagram ..................... 11

4 Incoming acceptance and product

identification ..................... 12

4.1 Incoming acceptance ................... 12

4.2 Product identification ................... 12

4.3 Scope of delivery ...................... 13

4.4 Certificates and approvals ............... 13

5 Installation ....................... 14

5.1 Installation conditions .................. 14

5.2 Mounting measuring device .............. 15

5.3 Post-installation check .................. 18

6 Electrical connection .............. 19

6.1 Connection conditions .................. 19

6.2 Connecting the measuring device .......... 20

6.3 Connecting the sensors ................. 26

6.4 Connecting additional inputs, outputs or

relays .............................. 28

6.5 Connecting digital communication ......... 32

6.6 Hardware settings ..................... 35

6.7 Ensuring the degree of protection .......... 36

6.8 Post-connection check .................. 37

7 System integration ................ 38

7.1 Web server .......................... 38

7.2 Service interface ...................... 39

7.3 Fieldbuses ........................... 40

8 Operation options ................. 42

8.1 Overview ............................ 42

8.2 Access to the operating menu via the local

display ............................. 43

8.3 Configuration options .................. 44

9 Commissioning .................... 47

9.1 Function check ....................... 47

9.2 Power up ............................ 47

9.3 Basic setup .......................... 49

10 Operation ......................... 50

10.1 Display ............................. 50

10.2 General settings ....................... 52

10.3 Current inputs ........................ 64

10.4 Outputs ............................. 65

10.5 Binary inputs and outputs ............... 72

10.6 Additional functions ................... 78

11 Calibration ...................... 103

12 Diagnostics and troubleshooting .. 104

12.1 General troubleshooting ................ 104

12.2 Diagnostic information on the local display .. 105

12.3 Diagnostic information via web browser .... 105

12.4 Diagnostic information via fieldbus ........ 105

12.5 Adapting the diagnostic information ...... 105

12.6 Overview of diagnostic information ....... 107

12.7 Pending diagnostic messages ............ 110

12.8 Diagnostics list ...................... 110

12.9 Event logbook ....................... 111

12.10 Simulation ......................... 113

12.11 Device test .......................... 115

12.12 Resetting the measuring device .......... 115

12.13 Device information ................... 115

12.14 Firmware history ..................... 117

13 Maintenance .................... 120

13.1 Cleaning ........................... 120

14 Repairs .......................... 122

14.1 Spare parts ......................... 122

14.2 Return ............................. 125

14.3 Disposal ........................... 125

15 Accessories ...................... 126

15.1 Protective cover ...................... 126

15.2 Post mounting kit .................... 126

15.3 Measuring cable ..................... 126

15.4 Sensors ............................ 126

15.5 Additional functionality ................ 131

15.6 Software ........................... 133

15.7 Other accessories ..................... 133

Table of contents

4 Endress+Hauser

16 Technical data ................... 136

17 Installation and operation in

hazardous environment Class I Div.

2 (only CM442)(only CM444R and

CM448R) ........................ 148

Index ................................. 149

Liquiline CM442/CM444/CM448 Document information

Endress+Hauser 5

1 Document information

1.1 Warnings

Structure of information Meaning

L

DANGER

Causes (/consequences)

Consequences of non-compliance

(if applicable)

‣

Corrective action

This symbol alerts you to a dangerous situation.

Failure to avoid the dangerous situation will result in a fatal or serious

injury.

L

WARNING

Causes (/consequences)

Consequences of non-compliance

(if applicable)

‣

Corrective action

This symbol alerts you to a dangerous situation.

Failure to avoid the dangerous situation can result in a fatal or serious

injury.

L

CAUTION

Causes (/consequences)

Consequences of non-compliance

(if applicable)

‣

Corrective action

This symbol alerts you to a dangerous situation.

Failure to avoid this situation can result in minor or more serious injuries.

NOTICE

Cause/situation

Consequences of non-compliance

(if applicable)

‣

Action/note

This symbol alerts you to situations which may result in damage to

property.

1.2 Symbols

Symbol Meaning

Additional information, tips

Permitted or recommended

Not permitted or not recommended

Reference to device documentation

Reference to page

Reference to graphic

Result of a step

1.3 Symbols at the device

Symbol Meaning

Reference to device documentation

Document information Liquiline CM442/CM444/CM448

6 Endress+Hauser

1.4 Documentation

The following instructions complement these Operating Instructions and are available on

the product pages on the internet:

• Brief Operating Instructions for Liquiline CM44x, KA01159C

• Operating Instructions for Memosens, BA01245C

– Software description for Memosens inputs

– Calibration of Memosens sensors

– Sensor-specific diagnostics and troubleshooting

• Operating Instructions for HART communication, BA00486C

– Onsite settings and installation instructions for HART

– Description of HART driver

• Guidelines for communication via fieldbus and web server

– HART, SD01187C

– PROFIBUS, SD01188C

– Modbus, SD01189C

– Web server, SD01190C

– EtherNet/IP, SD01293C

Liquiline CM442/CM444/CM448 Basic safety instructions

Endress+Hauser 7

2 Basic safety instructions

2.1 Requirements for the personnel

• Installation, commissioning, operation and maintenance of the measuring system may

be carried out only by specially trained technical personnel.

• The technical personnel must be authorized by the plant operator to carry out the

specified activities.

• The electrical connection may be performed only by an electrical technician.

• The technical personnel must have read and understood these Operating Instructions

and must follow the instructions contained therein.

• Measuring point faults may be repaired only by authorized and specially trained

personnel.

Repairs not described in the Operating Instructions provided may only be carried out

directly by the manufacturer or by the service organization.

2.2 Designated use

2.2.1 Non-hazardous atmosphere

Liquiline CM44x is a multichannel controller for connecting digital sensors with

Memosens technology in non-hazardous locations.

The device is designed for use in the following applications:

• Water and wastewater

• Power stations

• Chemical industry

• Other industrial applications

2.2.2 Hazardous location as per FM/CSA Class I Div. 2 (CM442 only)

‣

Pay attention to the control drawing and the specified operating conditions in the

appendix to this manual and follow the instructions.

2.2.3 Non-designated use

Use of the device for any purpose other than that described, poses a threat to the safety of

people and of the entire measuring system and is therefore not permitted.

The manufacturer is not liable for damage caused by improper or non-designated use.

2.3 Occupational safety

As the user, you are responsible for complying with the following safety conditions:

• Installation guidelines

• Local standards and regulations

• Regulations for explosion protection

Electromagnetic compatibility

• The product has been tested for electromagnetic compatibility in accordance with the

applicable European standards for industrial applications.

• The electromagnetic compatibility indicated applies only to a product that has been

connected in accordance with these Operating Instructions.

Basic safety instructions Liquiline CM442/CM444/CM448

8 Endress+Hauser

2.4 Operational safety

1. Before commissioning the entire measuring point, verify that all connections are

correct. Ensure that electrical cables and hose connections are undamaged.

2. Do not operate damaged products, and safeguard them to ensure that they are not

operated inadvertently. Label the damaged product as defective.

3. If faults cannot be rectified:

Take the products out of operation and safeguard them to ensure that they are not

operated inadvertently.

L

CAUTION

Cleaning not switched off during calibration or maintenance activities

Risk of injury due to medium or cleaning agent

‣

If a cleaning system is connected, switch if off before removing a sensor from the

medium.

‣

If you wish to check the cleaning function and have therefore not switched off the

cleaning system, please wear protective clothing, goggles and gloves or take other

appropriate measures.

2.5 Product safety

2.5.1 State of the art

The product is designed to meet state-of-the-art safety requirements, has been tested, and

left the factory in a condition in which it is safe to operate. The relevant regulations and

European standards have been observed.

2.5.2 IT security

We only provide a warranty if the device is installed and used as described in the

Operating Instructions. The device is equipped with security mechanisms to protect it

against any inadvertent changes to the device settings.

IT security measures in line with operators' security standards and designed to provide

additional protection for the device and device data transfer must be implemented by the

operators themselves.

Liquiline CM442/CM444/CM448 Device description

Endress+Hauser 9

3 Device description

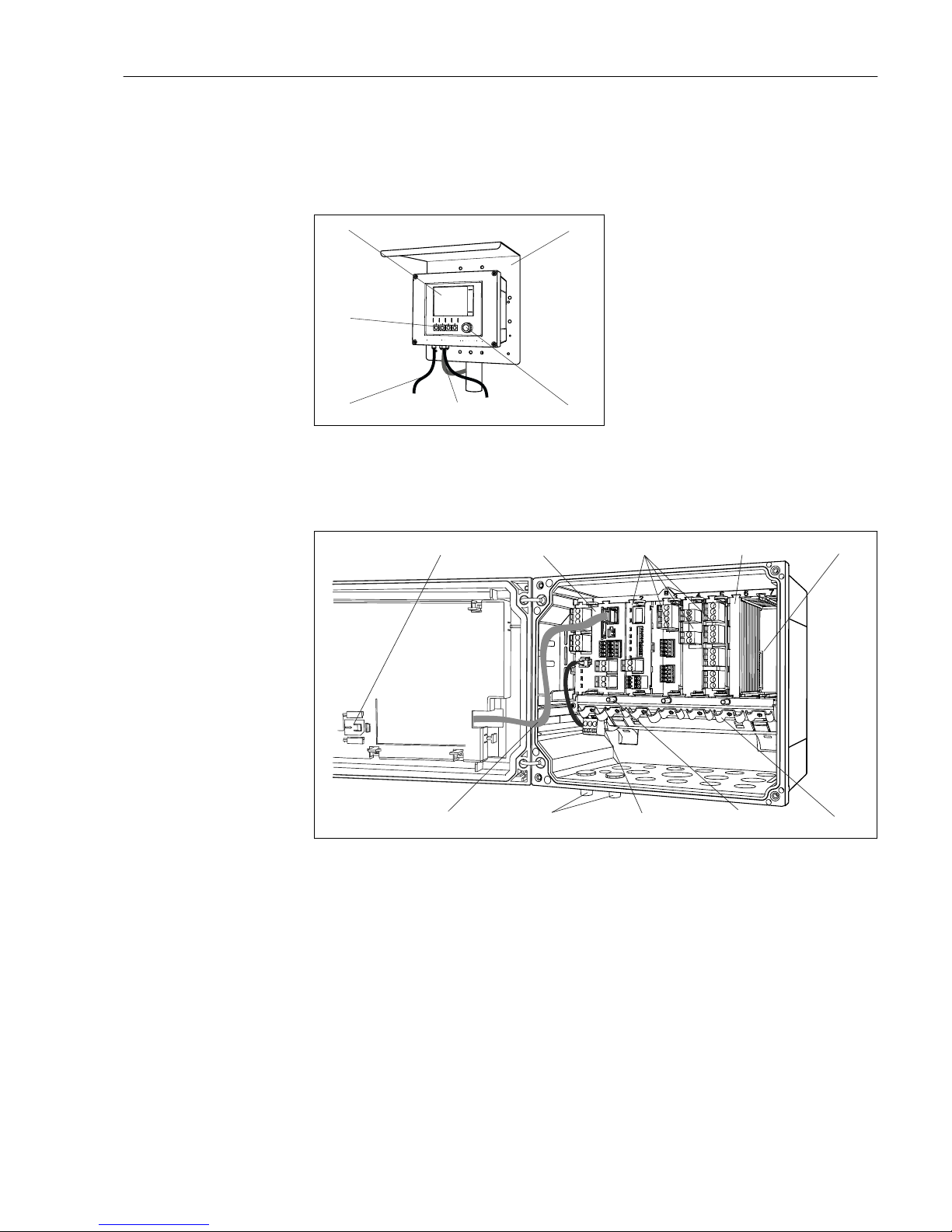

3.1 Housing closed

1 2

3

4

5

6

A0025813

1 Mounted on a post

1 Display

2 Weather protection cover (optional)

3 Navigator

4 Sensor cable or current output cable

5 Power supply cable

6 Soft keys, assignment depends on menu

3.2 Housing open

1

2

3

4 5

6

789

10

A0025814

2 Example of a four-channel device with an open display cover (without wiring)

1 Storage slot for SD card 6 Cable mounting rail

2 Basic module 7 Threaded bolt for protective ground connection

3 Extension modules (optional) 8 Extension power unit with internal cable

4 Shock protection, dummy cover and end cover 9 M12 connectors for sensor connection

(optional)

5 Extension backplane 10 Display cable

Device description Liquiline CM442/CM444/CM448

10 Endress+Hauser

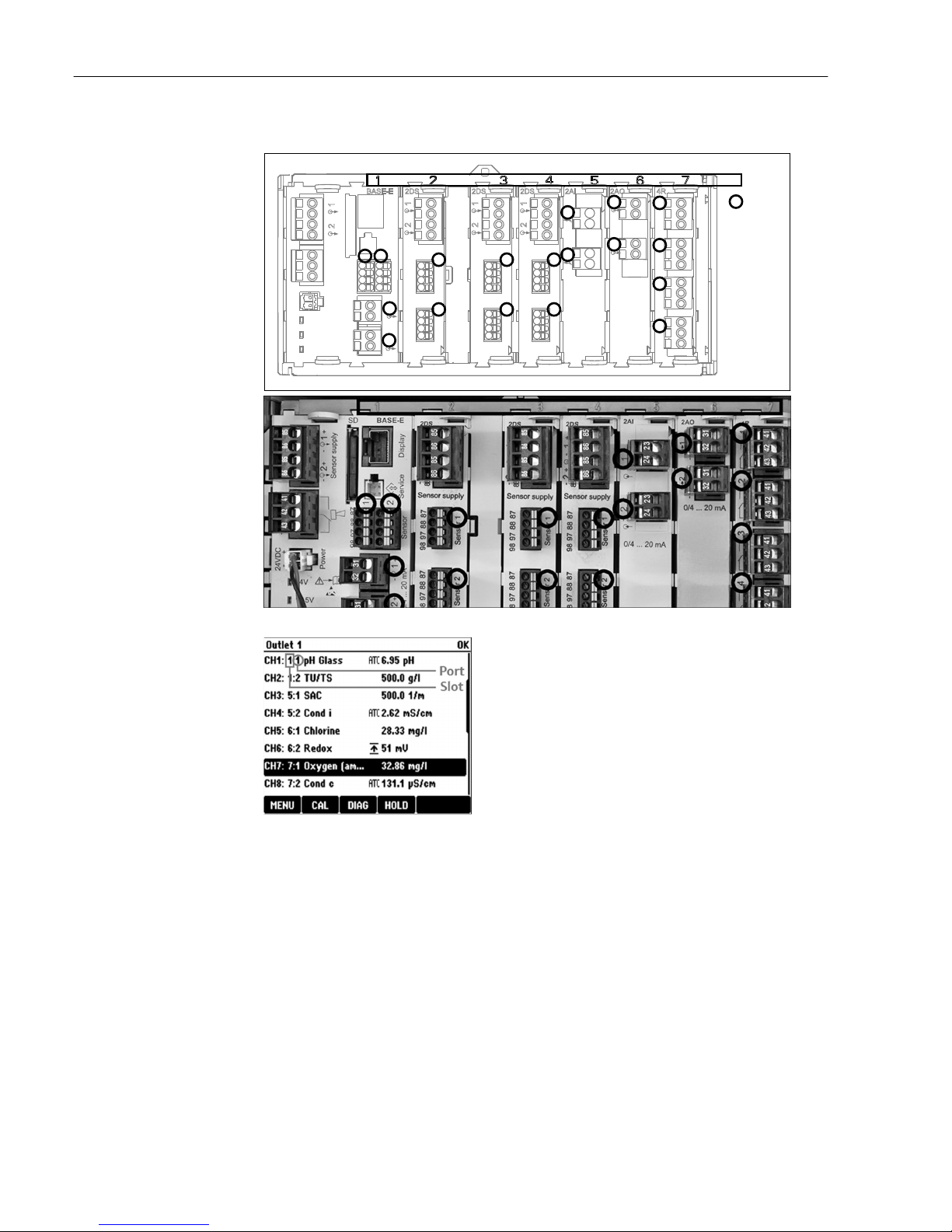

3.3 Slot and port assignment

Slots

1

2

1

2

1

2

1

2

Ports

BASE-E

2DS 2DS 2DS 2AI 2AO 4R

1

2

Sensor 1

Sensor 1

Sensor 1

Sensor 2

Sensor 2

Sensor 2

1

2

1

2

1

2

1

2

3

4

3 Slot and port assignment of the hardware modules

4 Slot and port assignment on the

display

• Inputs are assigned to measuring channels in the

ascending order of the slots and ports.

Adjacent example:

"CH1: 1:1 pH glass" means:

Channel 1 (CH1) is slot 1 (basic module) : Port 1 (input

1), pH glass sensor

• Outputs and relays are named according to their

function, e.g. "current output", and are displayed with the

slot and port numbers in ascending order

Liquiline CM442/CM444/CM448 Device description

Endress+Hauser 11

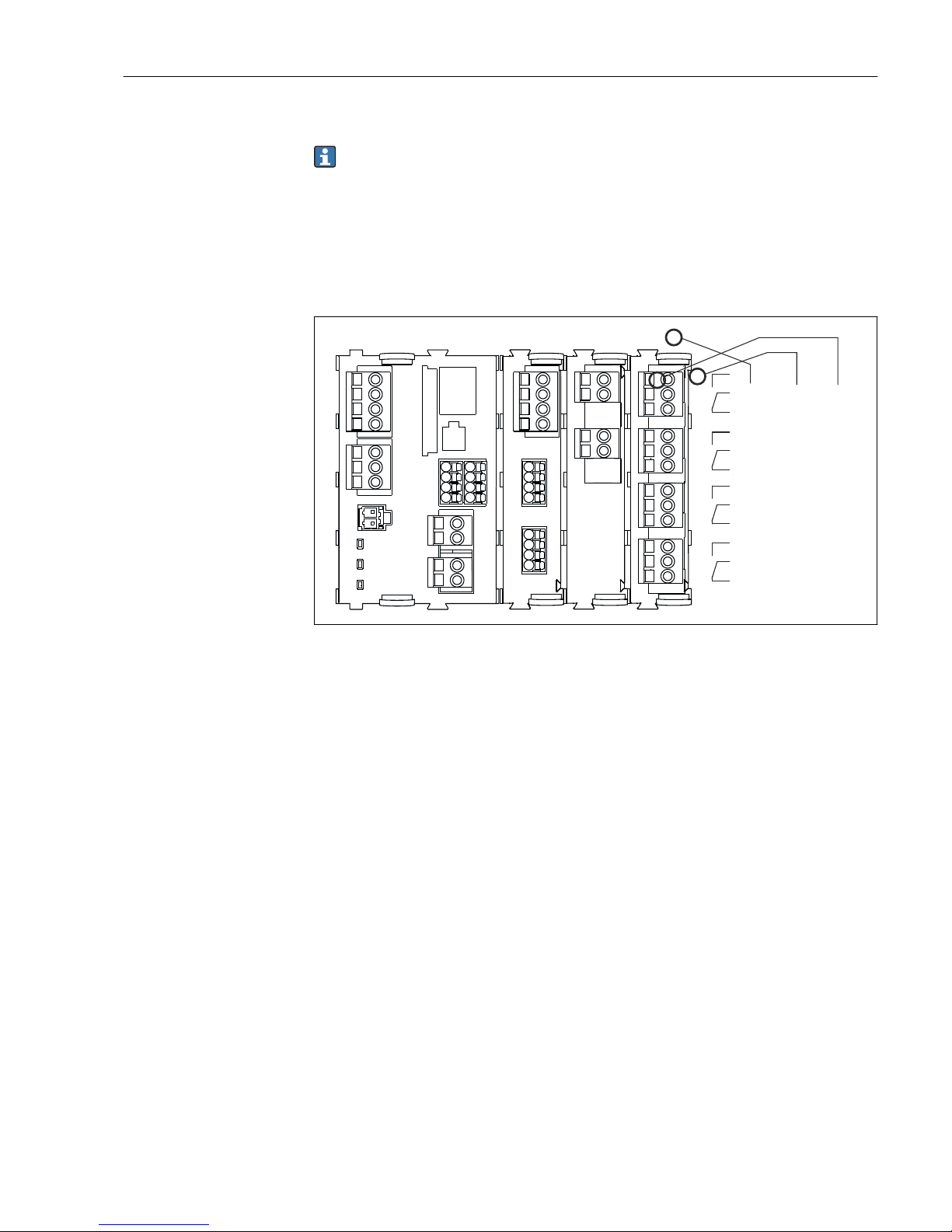

3.4 Terminal diagram

The unique terminal name is derived from:

Slot no. : Port no. : Terminal

Example, NO contact of a relay

Device with 4 inputs for digital sensors, 4 current outputs and 4 relays

• Base module BASE-E (contains 2 sensor inputs, 2 current outputs)

• Module 2DS (2 sensor inputs)

• Module 2AO (2 current outputs)

• Module 4R (4 relays)

1 2

3

4

43

42 41

43

42 41

43

42 41

43

42 41

Relay 1

Relay 2

Relay 3

Relay 4

Slot

Slot 4

Port 1

Pin 41

A0025105

5 Creating a terminal diagram using the example of the NO contact (terminal 41) of a relay

Incoming acceptance and product identification Liquiline CM442/CM444/CM448

12 Endress+Hauser

4 Incoming acceptance and product

identification

4.1 Incoming acceptance

1. Verify that the packaging is undamaged.

Notify your supplier of any damage to the packaging.

Keep the damaged packaging until the matter has been settled.

2. Verify that the contents are undamaged.

Notify your supplier of any damage to the delivery contents.

Keep the damaged products until the matter has been settled.

3. Check the delivery for completeness.

Check it against the delivery papers and your order.

4. Pack the product for storage and transportation in such a way that it is protected

against impact and moisture.

The original packaging offers the best protection.

The permitted ambient conditions must be observed (see "Technical data").

If you have any questions, please contact your supplier or your local sales center.

4.2 Product identification

4.2.1 Nameplate

The nameplate provides you with the following information on your device:

• Manufacturer identification

• Order code

• Extended order code

• Serial number

• Firmware version

• Ambient and process conditions

• Input and output values

• Activation codes

• Safety information and warnings

‣

Compare the data on the nameplate with your order.

4.2.2 Product identification

Product page

www.endress.com/cm442

www.endress.com/cm444

www.endress.com/cm448

Interpreting the order code

The order code and serial number of your product can be found in the following locations:

• On the nameplate

• In the delivery papers

Obtaining information on the product

1. Go to the product page for your product on the Internet.

Liquiline CM442/CM444/CM448 Incoming acceptance and product identification

Endress+Hauser 13

2. At the bottom of the page, select the "Online Tools" link followed by "Check your

device features".

An additional window opens.

3. Enter the order code from the nameplate into the search field, and then select "Show

details".

You will receive information on each feature (selected option) of the order code.

4.3 Scope of delivery

The scope of delivery comprises:

• 1 multichannel controller in the version ordered

• 1 mounting plate

• 1 wiring label (attached at the factory to the inside of the display cover)

• 1 printed copy of the Brief Operating Instructions in the language ordered

If you have any questions, please contact your supplier or your local sales center.

4.4 Certificates and approvals

4.4.1

mark

The product meets the requirements of the harmonized European standards. As such, it

complies with the legal specifications of the EC directives. The manufacturer confirms

successful testing of the product by affixing to it the mark.

4.4.2 EAC

The product has been certified according to guidelines TP TC 004/2011 and TP TC

020/2011 which apply in the European Economic Area (EEA). The EAC conformity mark

is affixed to the product.

4.4.3 cCSAus

The product complies with "CLASS 2252 05 - Process Control Equipment" and "CLASS 2252

85 - Process Control Equipment - Certified to US Standards" requirements.

4.4.4 FM/CSA

CM442 only

The device has been developed and tested according to the following standards:

• FM3600 (2011)

• FM3611 (2010)

• FM3810 (2005)

• ANSI/ISA NEMA250 (1991)

• ANSI/IEC 60529 (2001)

4.4.5 MCERTS

CM442 only

The device has been assessed by Sira Certification Service and complies with "MCERTS

Performance Standards for Continuous Water Monitoring Equipment, Part 2: online

analysers, Version 3.1, dated August 2010"; Certificate No.: Sira MC140246/01.

Installation Liquiline CM442/CM444/CM448

14 Endress+Hauser

5 Installation

5.1 Installation conditions

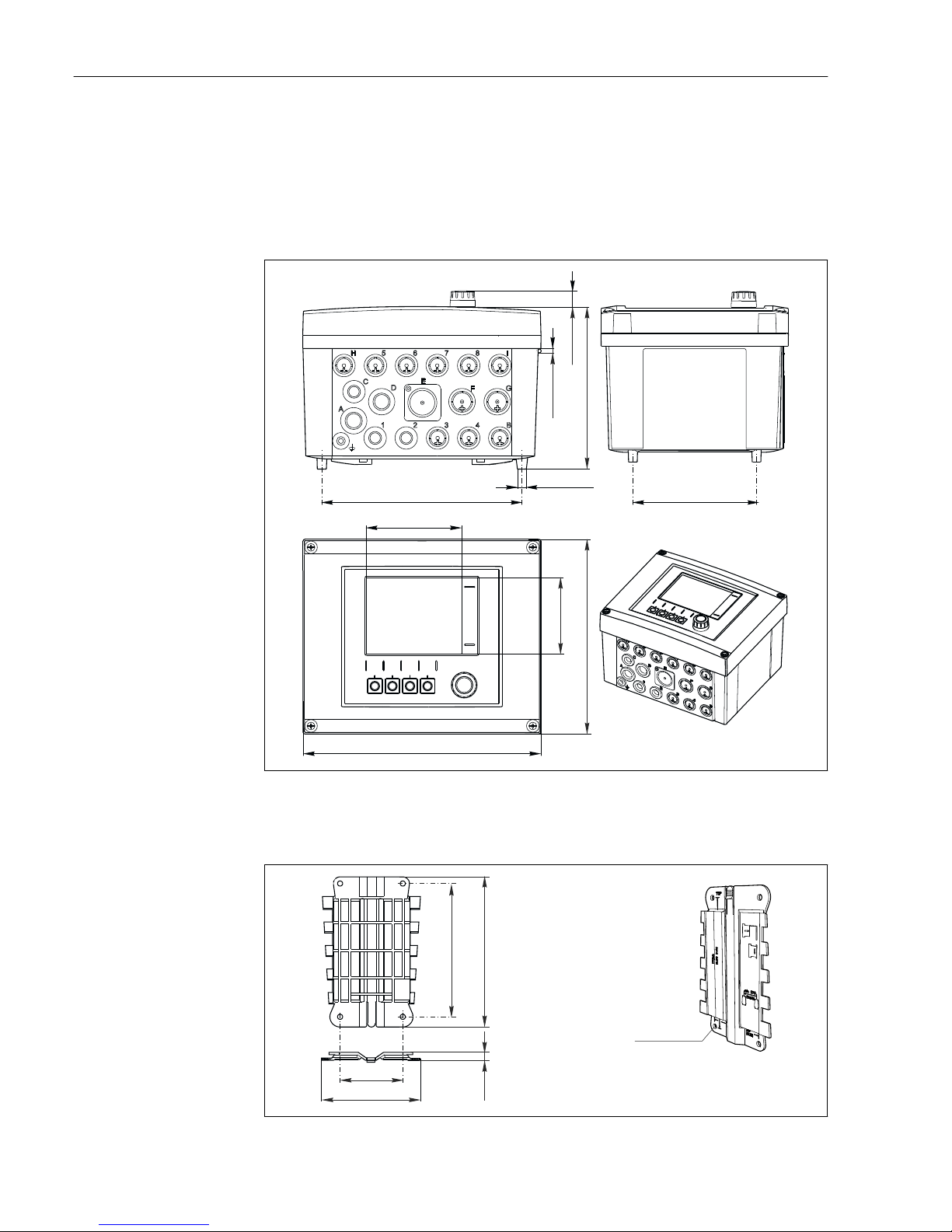

5.1.1 Dimensions

H 5 6 7 8 I

GF

E

D

C

A

1 2 3 4 B

162 (6.38)

14 (0.55)

Ø4 (0.16)

Ø9 (0.35)

199 (7.38) 128 (5.04)

237 (9.33)

194 (7.64)

76 (2.99)

95 (3.74)

A0012396

6 Dimensions of field housing in mm (inch)

5.1.2 Mounting plate

80 (3.15)

190 (7.48)

3 (0.12)

4 x 6.5 (0.26)

170 (6.69)

125 (4.92)

A0012426

7 Mounting plate in mm (inch)

Liquiline CM442/CM444/CM448 Installation

Endress+Hauser 15

5.1.3 Protective cover

NOTICE

Effect of climatic conditions (rain, snow, direct sunlight etc.)

Impaired operation to complete transmitter failure

‣

When installing outside, always use the weather protection cover (accessory).

320 (12.6)

270 (10.6)

300 (11.8)

80 (3.15)

170 (6.69)

170 (6.69)

80 (3.15)

8 x Ø 7 (0.28)

A0012428

8 Weather protection cover in mm (inch)

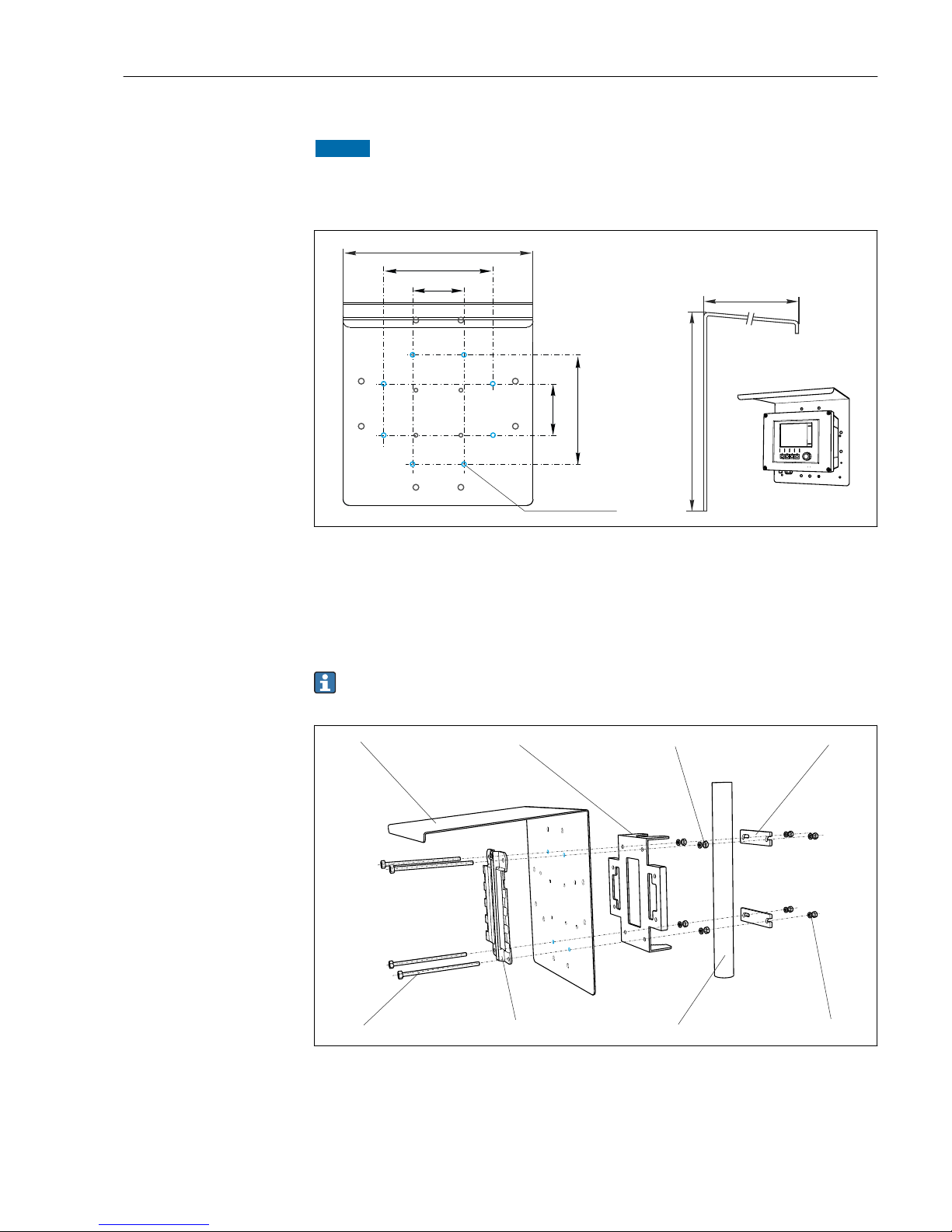

5.2 Mounting measuring device

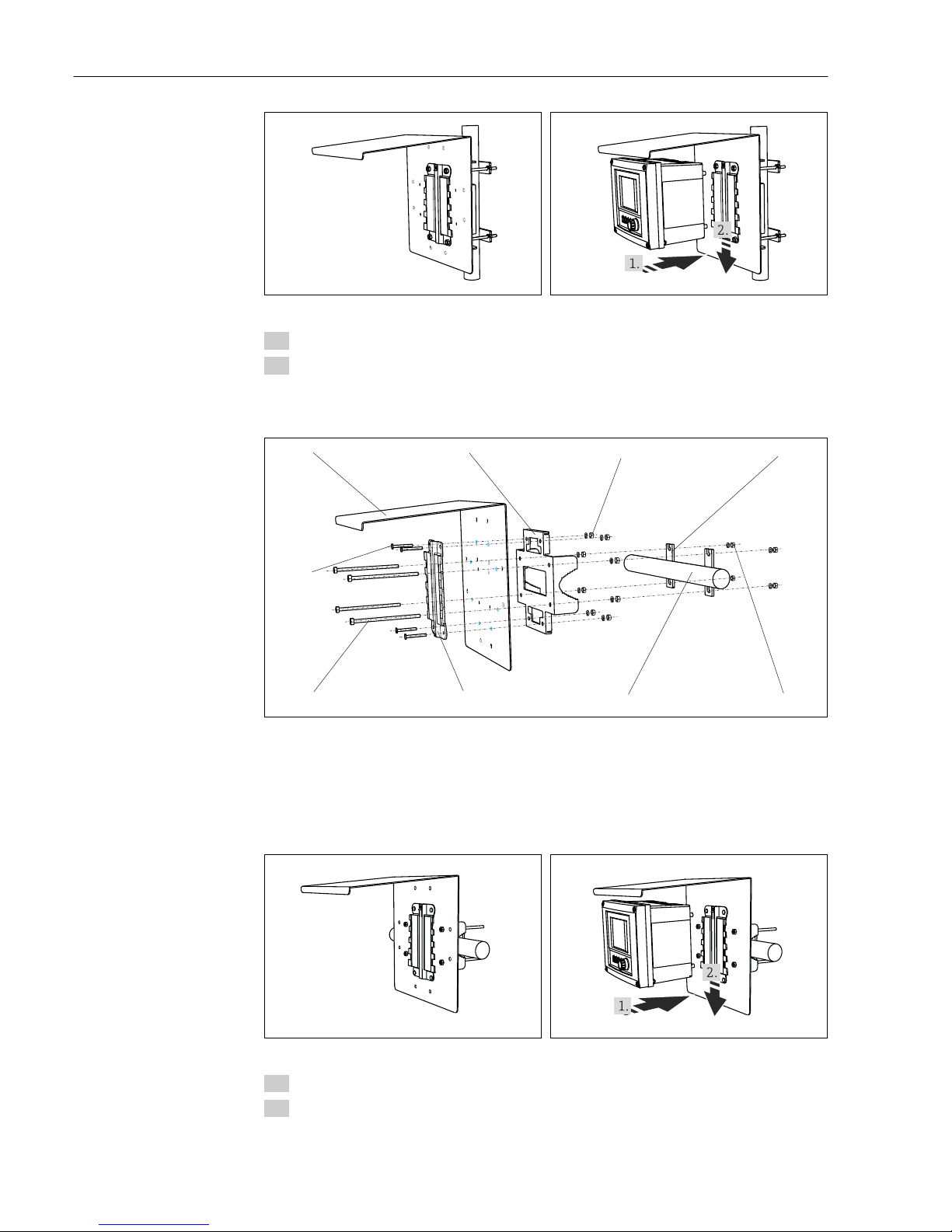

5.2.1 Post mounting

You require the post mounting kit (optional) to mount the unit on a pipe, post or

railing (square or circular, span range 20 to 61 mm (0.79 to 2.40")).

1 2

3

4

56

7

8

A0012665

9 Post mounting

1 Weather protection cover (optional) 5 Spring washers, nuts (post mounting kit)

2 Post mounting plate (post mounting kit) 6 Pipe or railing (circular/square)

3 Spring washers, nuts (post mounting kit) 7 Mounting plate

4 Pipe clamps (post mounting kit) 8 Threaded rods (post mounting kit)

Installation Liquiline CM442/CM444/CM448

16 Endress+Hauser

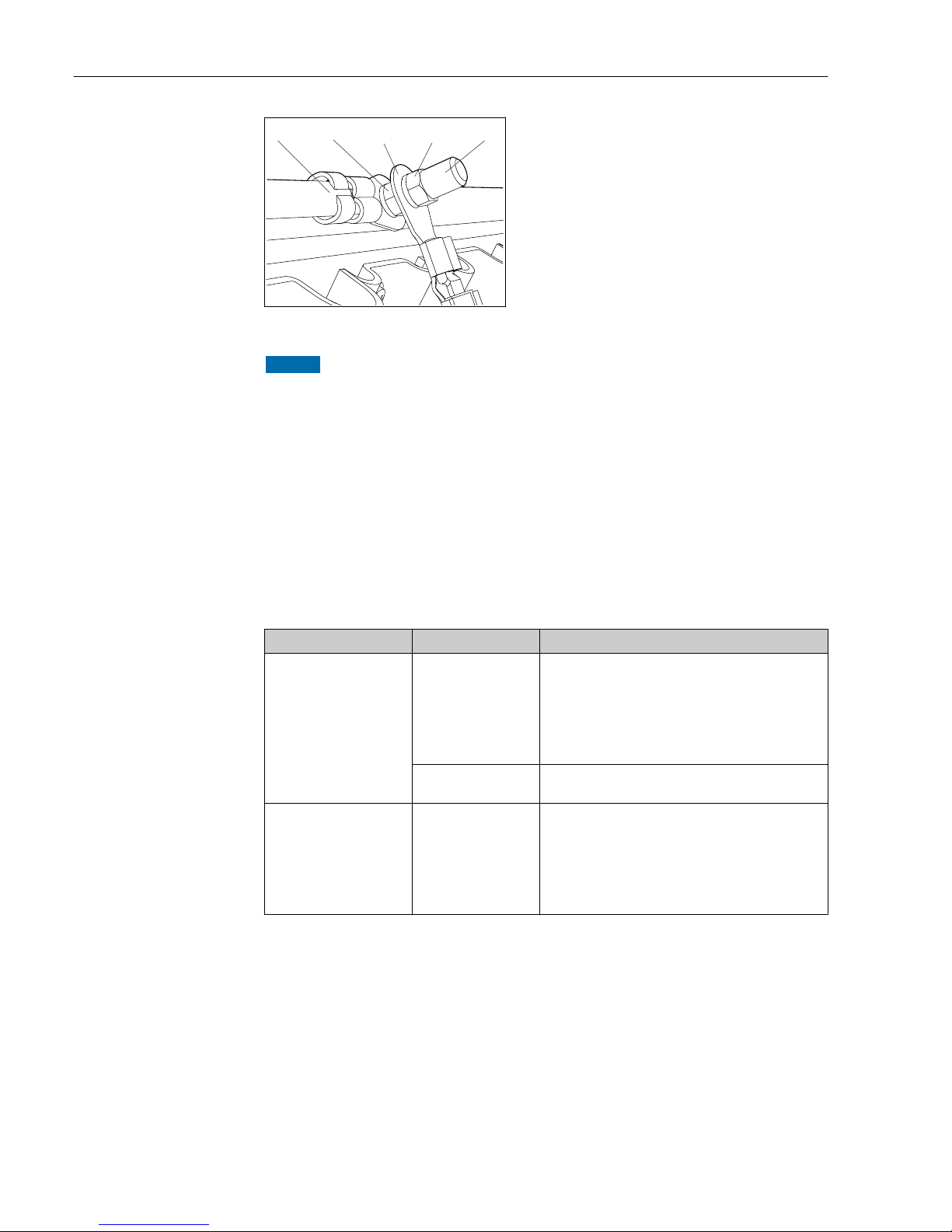

A0025884

10 Post mounting

A0025885

11 Attach the device and click it into place

1. Bring the device to the mounting plate.

2. Slide the device downwards in the guide on the mounting rail until it clicks into place.

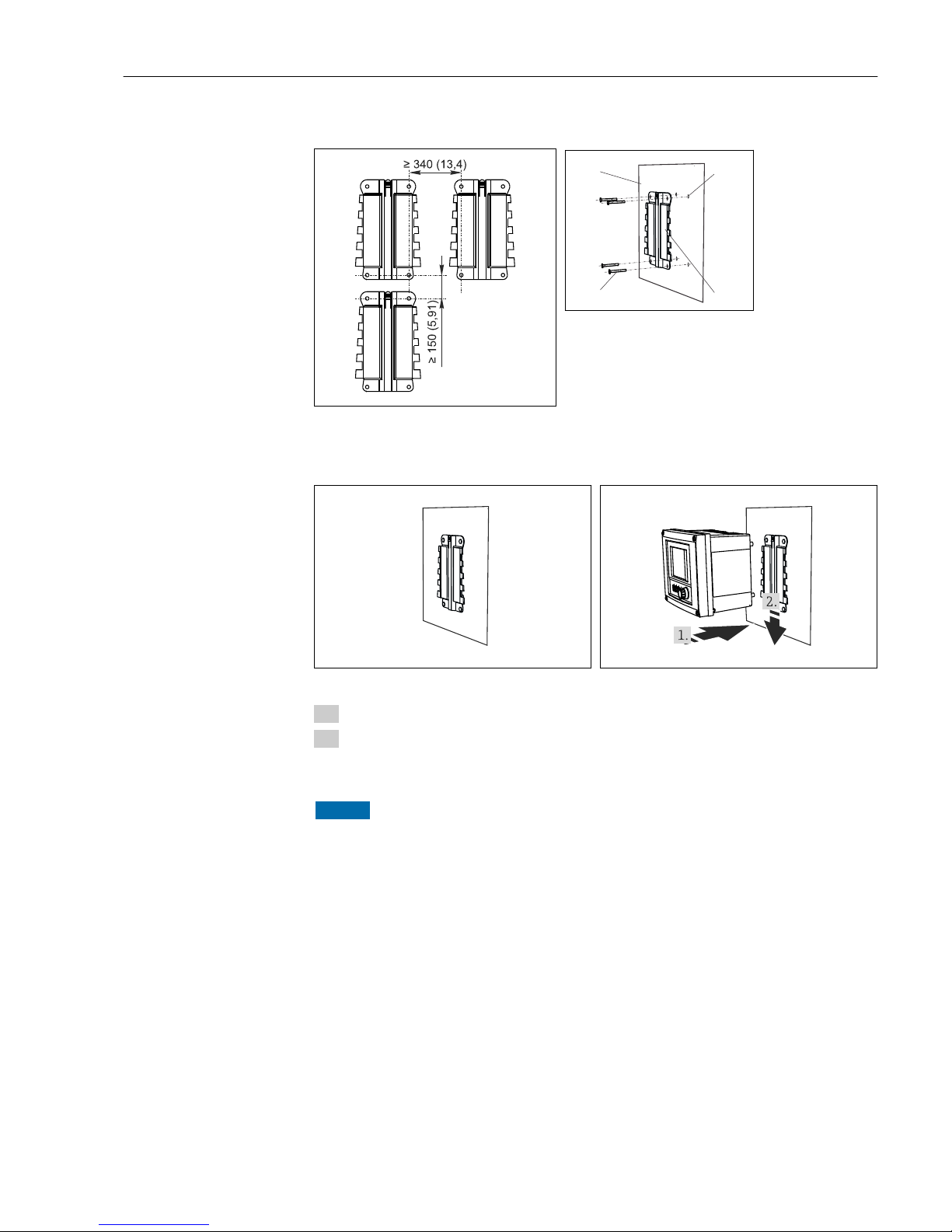

5.2.2 Rail mounting

1 2

3

4

56

7

8

9

A0012668

12 Rail mounting

1 Weather protection cover (optional) 6 Pipe or railing (circular/square)

2 Post mounting plate (post mounting kit) 7 Mounting plate

3 Spring washers, nuts (post mounting kit) 8 Threaded rods (post mounting kit)

4 Pipe clamps (post mounting kit) 9 Screws (post mounting kit)

5 Spring washers, nuts (post mounting kit)

A0025886

13 Rail mounting

A0027803

14 Attach the device and click it into place

1. Bring the device to the mounting plate.

2. Slide the device downwards in the guide on the mounting rail until it clicks into place.

Liquiline CM442/CM444/CM448 Installation

Endress+Hauser 17

5.2.3 Wall mounting

A0012686

15 Mounting distance in mm (inch)

1

3

4

2

16 Wall mounting

1 Wall

2

4 drill holes

1)

3 Mounting plate

4 Screws Ø 6 mm (not part of scope of supply)

1)

The size of the drill holes depends on the wall plugs used. The wall plugs and screws must be provided by the

customer.

A0027799

17 Wall mounting

A0027797

18 Attach the device and click it into place

1. Bring the device to the mounting plate.

2. Slide the device downwards in the guide on the mounting rail until it clicks into place.

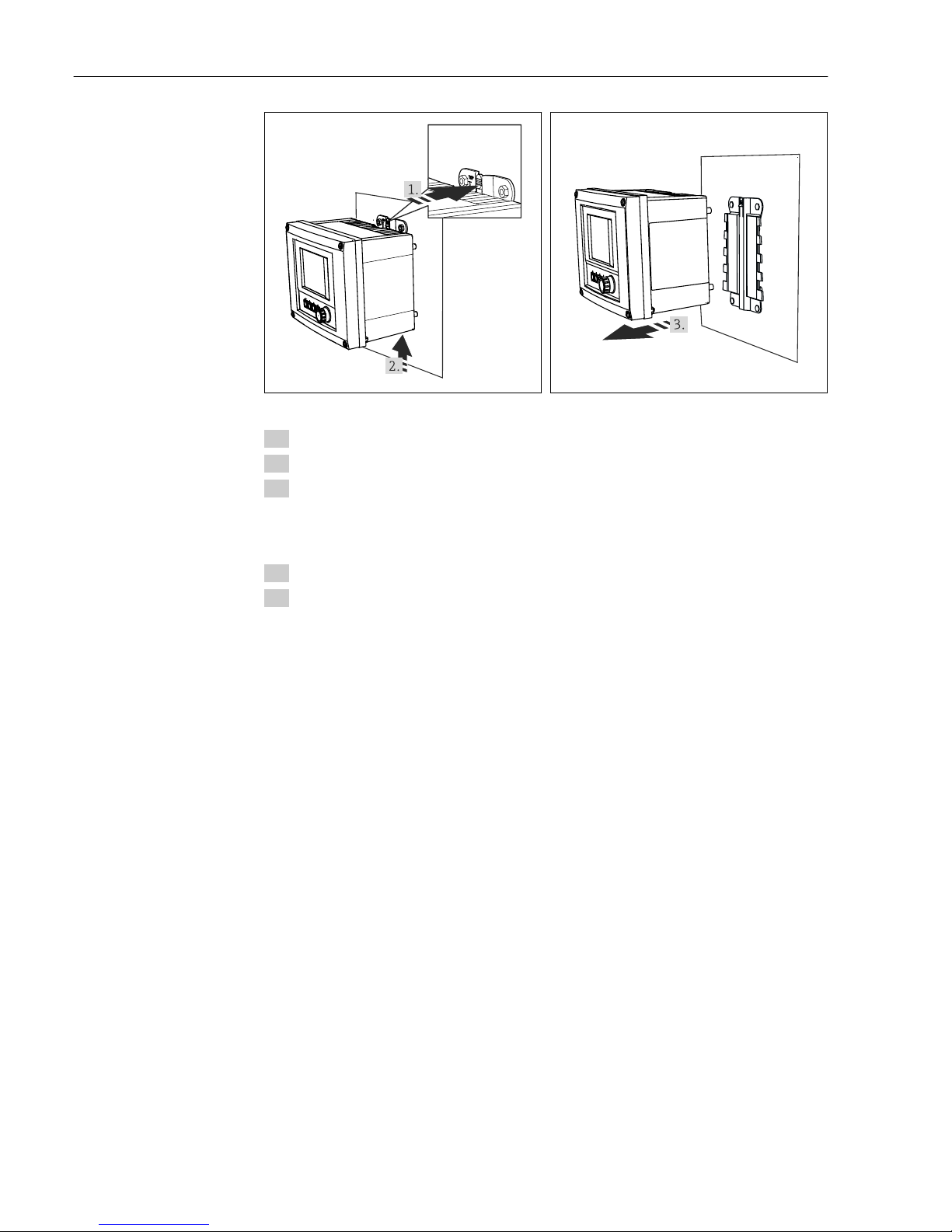

5.2.4 Disassembly (for conversion, cleaning etc.)

NOTICE

The device can be damaged if dropped

‣

When pushing the housing out of the holder, secure the housing in such a way that you

do not drop it. If possible, ask a second person to help you.

Installation Liquiline CM442/CM444/CM448

18 Endress+Hauser

A0025890

19 Disassembling

A0025891

20 Disassembling

1. Hold down the catch.

2. Push up the device to remove it from the holder.

3. Remove the device towards the front.

5.3 Post-installation check

1. After installation, check the transmitter for damage.

2. Check whether the transmitter is protected against moisture and direct sunlight (e.g.

by the weather protection cover).

Liquiline CM442/CM444/CM448 Electrical connection

Endress+Hauser 19

6 Electrical connection

6.1 Connection conditions

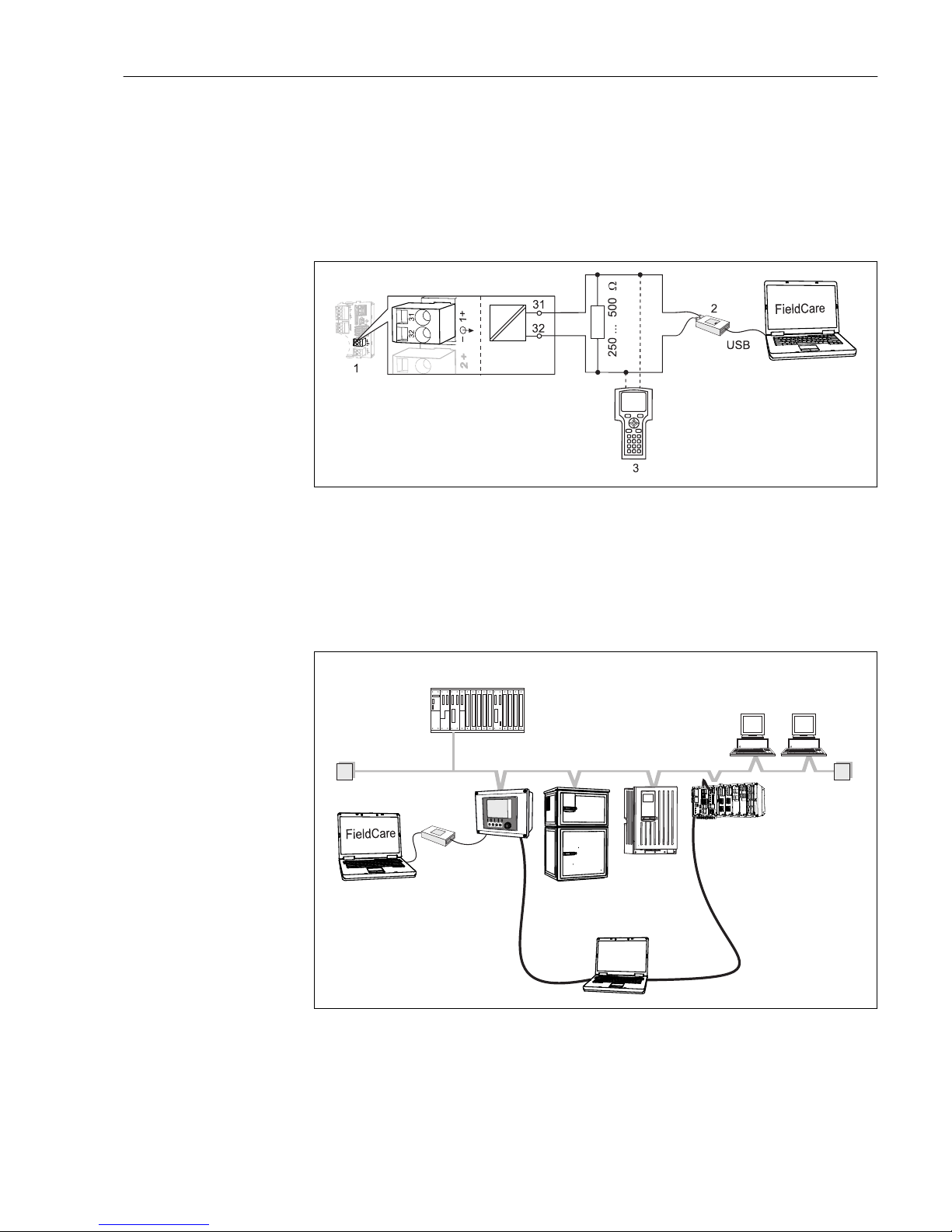

6.1.1 Via HART (e.g. using HART modem and FieldCare)

A0028995

21 HART using modem

1 Device module Base L, H or E: current output 1 with HART

2

HART modem for connection to PC, e.g. Commubox FXA191 (RS232) or FXA195 1) (USB)

3 HART handheld terminal

1)

Switch position "on" (substitutes the resistor)

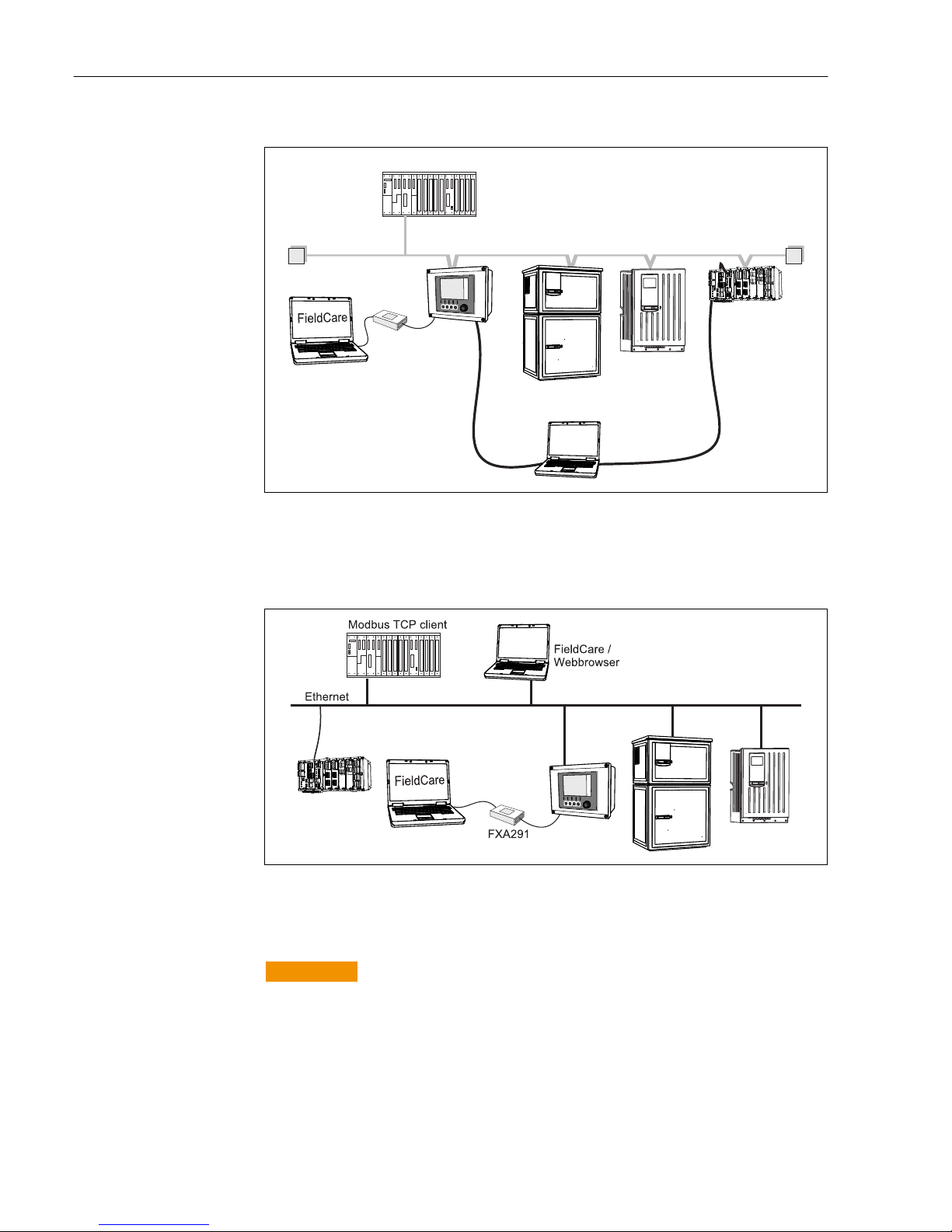

6.1.2 Via PROFIBUS DP

FXA291

Master class 1

(PLC, DCS)

T T

Ethernet

PROFIBUS DP

(RS485)

Master class 2 (FieldCare, PDM)

FieldCare /

Webbrowser

A0028991

22 PROFIBUS DP

T Terminating resistor

Electrical connection Liquiline CM442/CM444/CM448

20 Endress+Hauser

6.1.3 Via Modbus RS485

FXA291

Modbus Master / Gateway

T T

Ethernet

Modbus RS485

(RTU, ASCII)

FieldCare /

Webbrowser

A0028993

23 Modbus RS485

T Terminating resistor

6.1.4 Via Ethernet/Web server/Modbus TCP/EtherNet/IP

A0028994

24 Modbus TCP and/or EtherNet/IP

6.2 Connecting the measuring device

L

WARNING

Device is live

Incorrect connection may result in injury or death

‣

The electrical connection may be performed only by an electrical technician.

‣

The electrical technician must have read and understood these Operating Instructions

and must follow the instructions contained therein.

‣

Prior to commencing connection work, ensure that no voltage is present on any cable.

Liquiline CM442/CM444/CM448 Electrical connection

Endress+Hauser 21

NOTICE

The device does not have a power switch

‣

The customer must provide a protected circuit breaker in the vicinity of the device.

‣

The circuit breaker must be a switch or power switch, and you must label it as the

circuit breaker for the device.

‣

At the supply point, the power supply must be isolated from dangerous live cables by

double or reinforced insulation in the case of devices with a 24 V supply voltage.

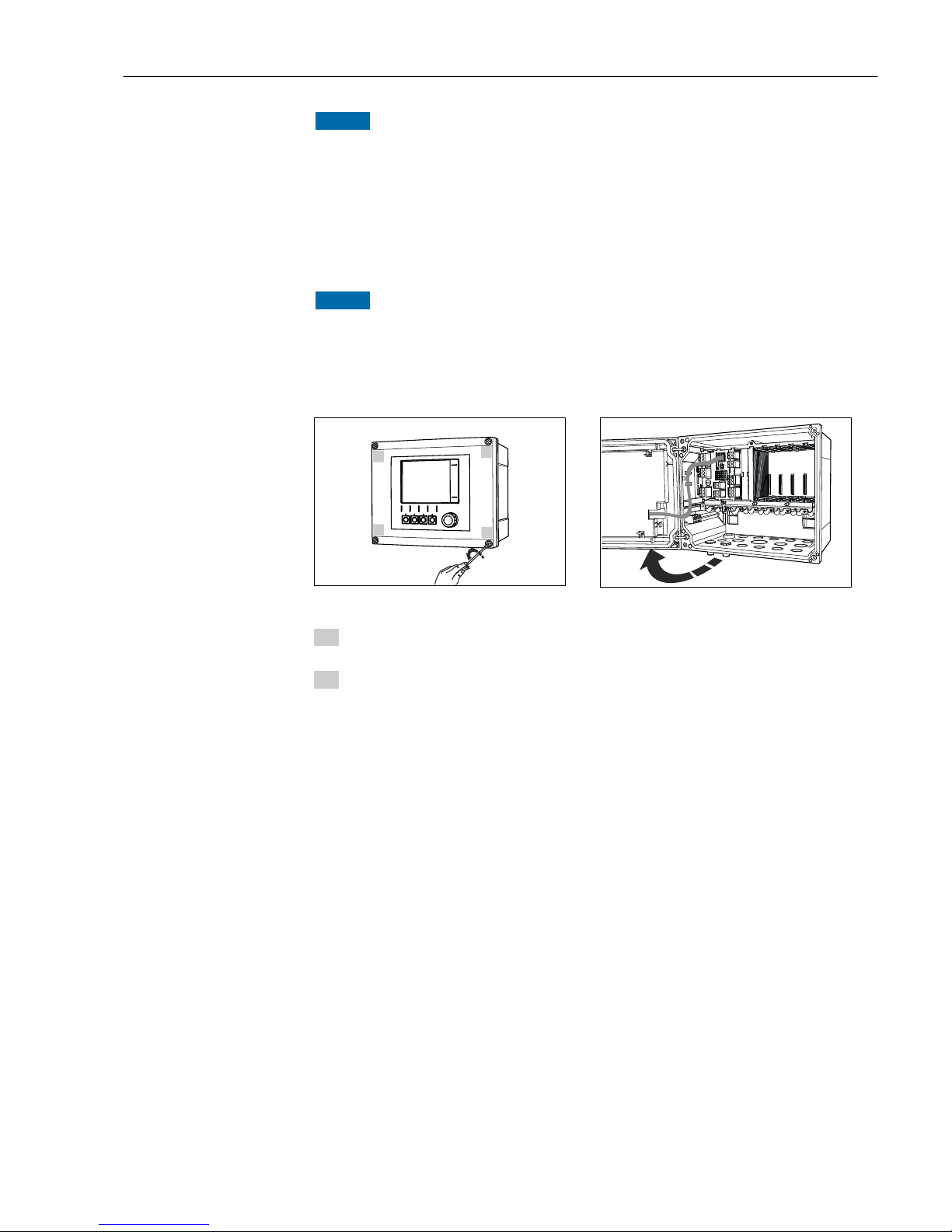

6.2.1 Open the housing

NOTICE

Pointed or sharp tools

If unsuitable tools are used, they can scratch the housing or damage the seal, and thus

have a negative impact on the leak-tightness of the housing.

‣

Do not use any sharp or pointed objects, such as a knife, to open the housing.

‣

Only use a suitable Phillips screwdriver.

1.

2.

3.

4.

25 Releasing housing screws in a diagonally

opposite sequence with Phillips screwdriver

£180°

26 Opening display cover, max. opening angle

180˚ (depends on installation position)

1. Release the housing screws step by step. Start with any screw and then release the

screw diagonally opposite etc.

2. When closing the housing, also tighten the screws step-by-step in a diagonally

opposite sequence.

Electrical connection Liquiline CM442/CM444/CM448

22 Endress+Hauser

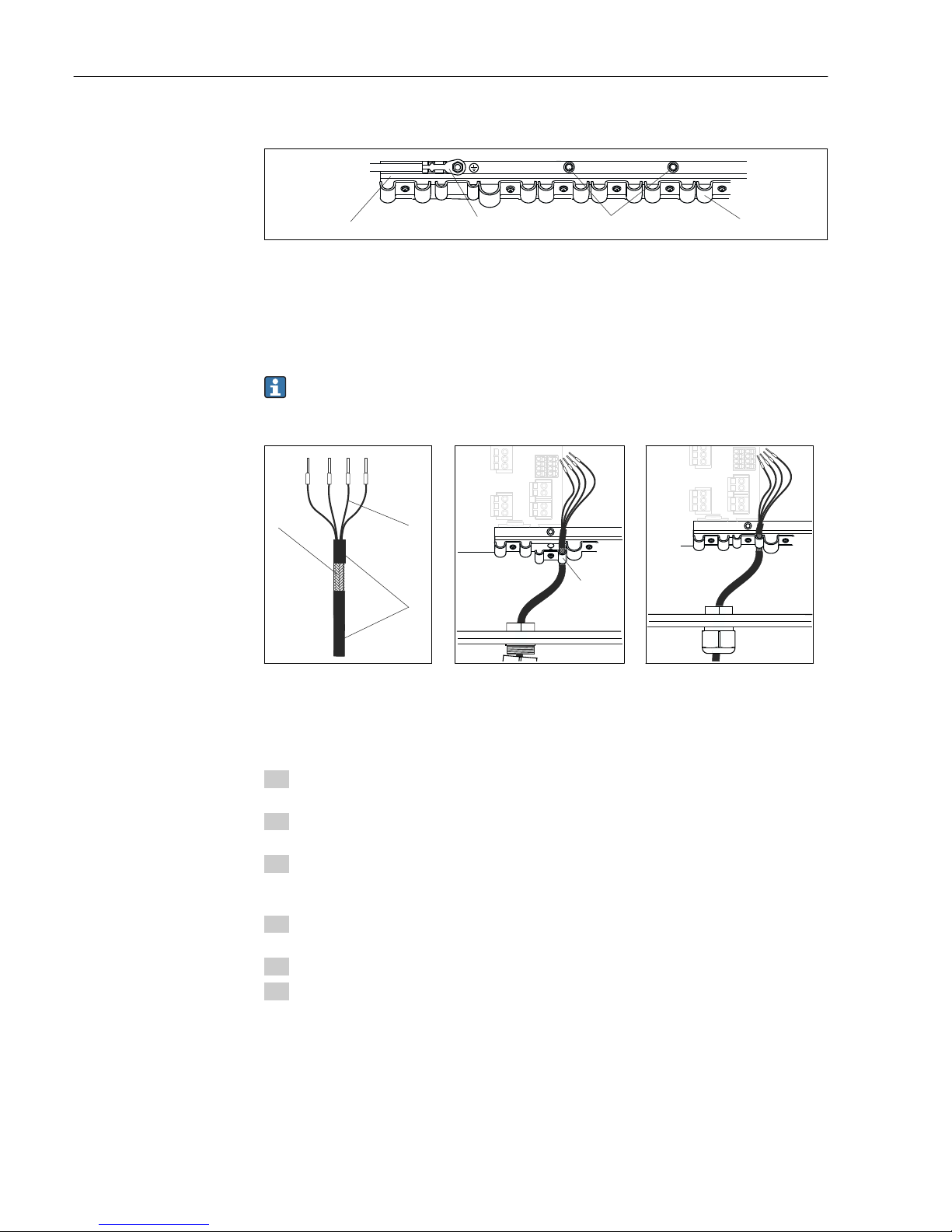

6.2.2 Cable mounting rail

1 32 4

A0025171

27 Cable mounting rail and associated function

1 Cable mounting rail 3 Additional threaded bolts for ground connections

2 Threaded bolt (protective ground connection,

central grounding point)

4 Cable clamps (fixing and grounding the sensor

cables)

6.2.3 Connecting the cable shield

If possible, only use terminated genuine cables. The sensor, fieldbus and ethernet

cables must be shielded.

Cable sample (does not necessarily correspond to the genuine cable supplied)

1

2

3

28 Terminated cable

1 Outer shield (exposed)

2 Cable cores with ferrules

3 Cable sheath (insulation)

4

29 Inserting the cable

4 Grounding clip

30 Tighten screw (2 Nm)

Cable shield is grounded using the

grounding clamp

1)

1) Please note the instructions in the "Guaranteeing the degree of protection" section (→ 36)

1. Release a suitable cable gland on the underside of the housing and remove the

dummy plug from the entry.

2. Making sure the gland is facing the right direction, thread the gland onto the cable

end and pull the cable through the entry and into the housing.

3. Route the cable in the housing in such a way that the exposed cable shield fits into

one of the cable clamps and the cable cores can be easily routed as far as the

connection plug on the electronics module.

4. Screw on the cable clamp and clamp the cable in place. Then tighten the screw of the

cable clamp.

5. Connect the cable cores as per the wiring diagram.

6. Lastly, tighten the cable gland from the outside.

Liquiline CM442/CM444/CM448 Electrical connection

Endress+Hauser 23

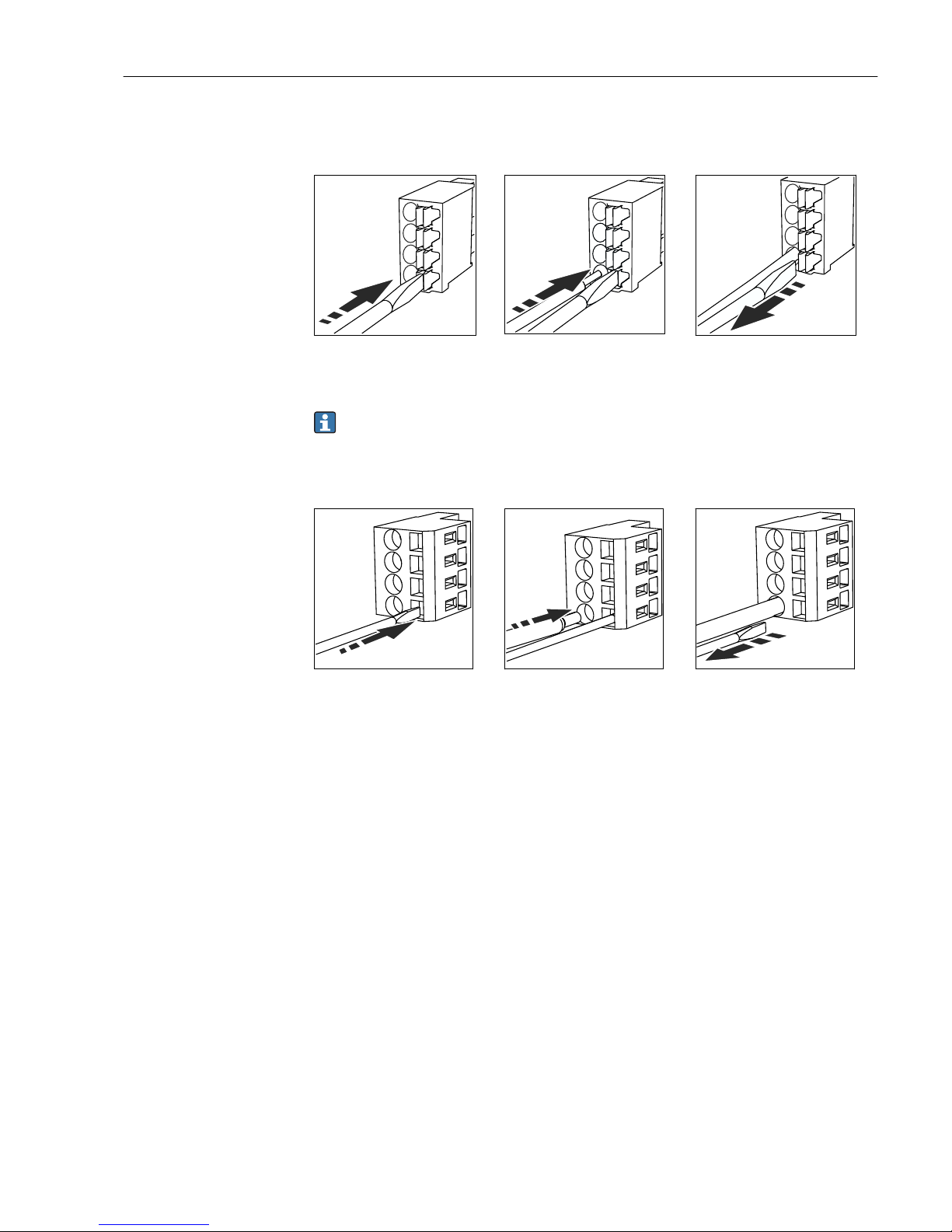

6.2.4 Cable terminals

Plug-in terminals for Memosens and PROFIBUS/RS485 connections

Press the screwdriver against the clip

(opens the terminal)

Insert the cable until the limit stop

Remove the screwdriver (closes the

terminal)

After connection, make sure that every cable end is securely in place. Terminated

cable ends, in particular, tend to come loose easily if they have not been correctly

inserted as far as the limit stop.

All other plug-in terminals

Press the screwdriver against the clip

(opens the terminal)

Insert the cable until the limit stop Remove the screwdriver (closes the

terminal)

Electrical connection Liquiline CM442/CM444/CM448

24 Endress+Hauser

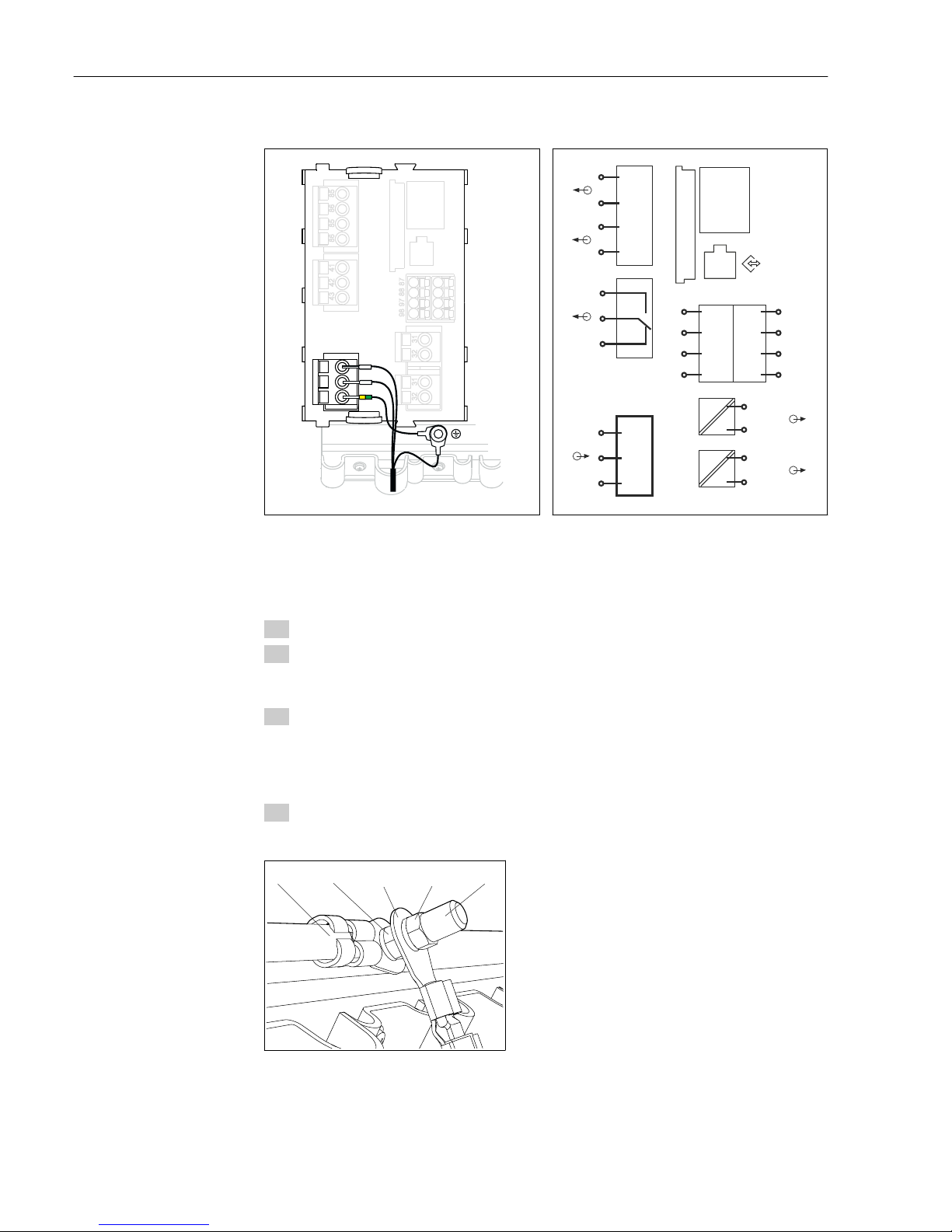

6.2.5 Connecting the supply voltage for the CM442

N/- L/+

43

42

41

86

85

86

85

98

97

88

87

32

31

32

31

PE

A0015825

31 Connecting power supply on the BASE-H or -L

H Power unit 100 to 230 VAC

L Power unit 24 VAC or 24 VDC

85

85

86

86

SD

Display

Sensor supply

+

+

–

Service

PK

GY

PK

GYGY

1

2

–

L

N

*

Power

L / +

N / –

PE

87

88

97

98

1

2

Sensor

BN

WH

GN

YE

BN

WH

GN

YE

87

88

97

98

+

–

A

B

+

–

A

B

41

43

42

Alarm

31

31

32

32

0/4 ... 20 mA

+

+

–

1

2

–

HART

A0012404

32 Overall wiring diagram for BASE-H or -L

Connecting the supply voltage

1. Route the power supply cable into the housing through the suitable cable entry.

2. Step 2 applies only to the 100 to 230 V AC power unit.

Connect the protective ground of the power unit to the threaded bolt specially

provided on the cable mounting rail.

3. Protective ground or grounding provided by the customer (absolutely essential for

24 V power unit, additionally recommended for 100 to 230 V AC power unit):

You must provide a ground cable (min. 0.75 mm2 (corresponding to 18 AWG)). Guide

the ground cable also through the cable entry and connect it to the threaded bolt on

the cable mounting rail.

4. Connect the cable cores L and N (100 to 230 V AC) or + and ‐ (24 V DC) to the plugin terminals on the power unit in accordance with the wiring diagram.

1 2

3

4

5

33 Protective ground or grounding

connection

1 Protective ground of power unit

2 Serrated washer and nut

3 Protective ground / ground cable, provided by the

customer (min. 0.75 mm2 ( 18 AWG))

4 Serrated washer and nut

5 Mounting bolts

Liquiline CM442/CM444/CM448 Electrical connection

Endress+Hauser 25

NOTICE

Protective ground/ground cable with end sleeve or open cable lug

The cable can become loose. Loss of the protective function.

‣

To connect the protective ground or ground cable to the threaded bolt, only use a cable

with a closed cable lug as per DIN 46211, 46225, form A.

‣

Never connect the protective ground or ground cable to the threaded bolt with an end

sleeve or an open cable lug!

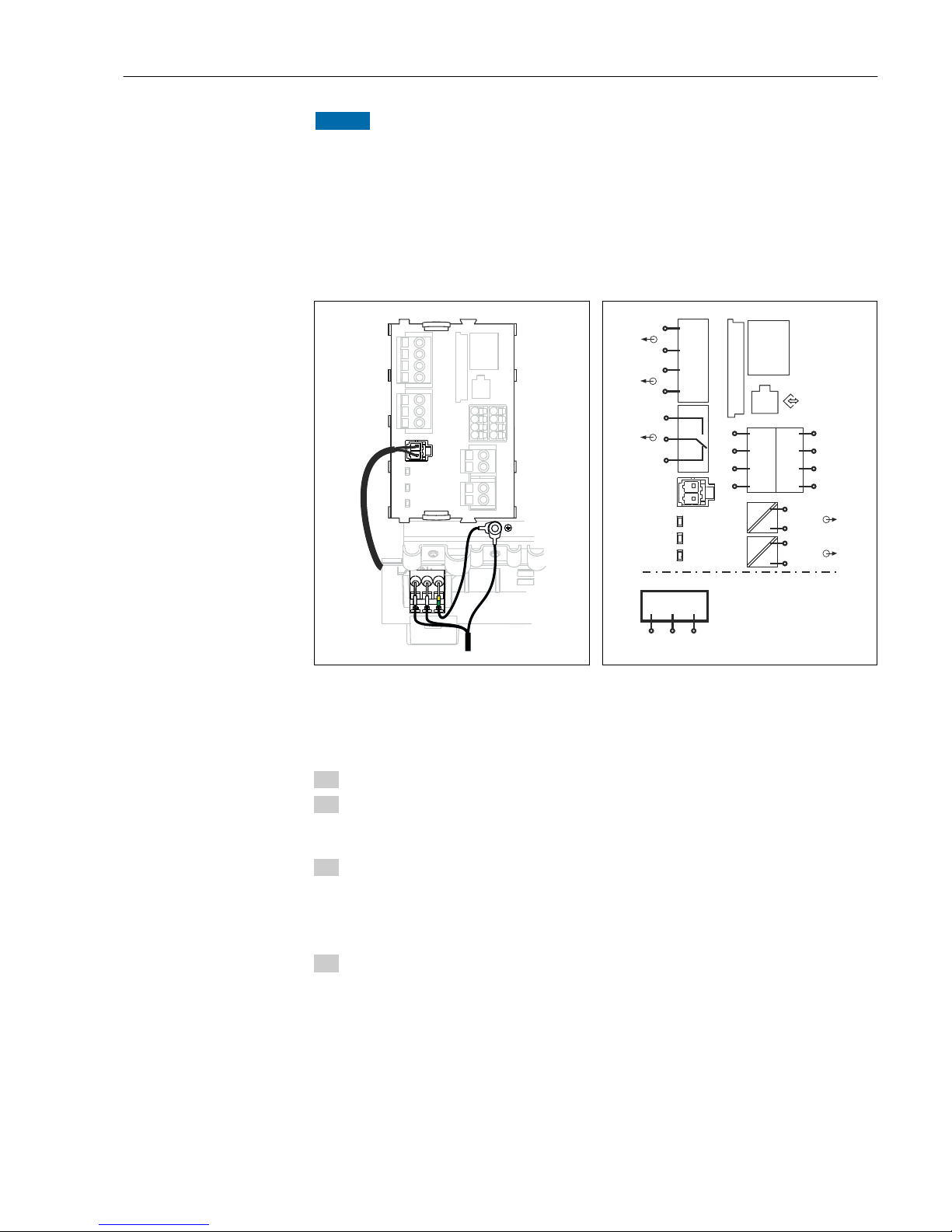

6.2.6 Connecting the supply voltage for the CM444 and the CM448

L+ N- PE

A

43 42 41

86 85 86 85

98 97 88 87

32 31

32 31

B

A0015872

34 Power supply connection on the BASE-E

A Internal power supply cable

B Extension power unit

85

85

86

86

41

43

42

L/+

N/–

*

Power

87

88

97

98

31

31

32

32

SD

Display

1

2

Sensor

0/4 ... 20 mA

Sensor supply

+

+

–

+

+

–

1

2

Service

PK

GY

PK

GY

1

2

–

L/+

N/–

PE

BN

WH

GN

YE

BN

WH

GN

YE

87

88

97

98

+

–

A

B

+

–

A

B

–

Alarm

HART

Power

(internal)

B

A0015873

35 Overall wiring diagram BASE-E and

extension power unit (B)

Connecting the supply voltage

1. Route the power supply cable into the housing through the suitable cable entry.

2. Step 2 applies only to the 100 to 230 V AC power unit.

Connect the protective ground of the power unit to the threaded bolt specially

provided on the cable mounting rail.

3. Protective ground or grounding provided by the customer (absolutely essential for

24 V power unit, additionally recommended for 100 to 230 V AC power unit):

You must provide a ground cable (min. 0.75 mm2 (corresponding to 18 AWG)). Guide

the ground cable also through the cable entry and connect it to the threaded bolt on

the cable mounting rail.

4. Connect the cable cores L and N (100 to 230 V AC) or + and ‐ (24 V DC) to the plugin terminals on the power unit in accordance with the wiring diagram.

Electrical connection Liquiline CM442/CM444/CM448

26 Endress+Hauser

1 2

3

4

5

36 Protective ground or grounding

connection

1 Protective ground of power unit

2 Serrated washer and nut

3 Protective ground / ground cable, provided by the

customer (min. 0.75 mm2 ( 18 AWG))

4 Serrated washer and nut

5 Mounting bolts

NOTICE

Protective ground/ground cable with end sleeve or open cable lug

The cable can become loose. Loss of the protective function.

‣

To connect the protective ground or ground cable to the threaded bolt, only use a cable

with a closed cable lug as per DIN 46211, 46225, form A.

‣

Never connect the protective ground or ground cable to the threaded bolt with an end

sleeve or an open cable lug!

6.3 Connecting the sensors

6.3.1 Sensor types with Memosens protocol

Sensors with Memosens protocol

Sensor types Sensor cable Sensors

Digital sensors without

additional internal power

supply

With plug-in

connection and

inductive signal

transmission

• pH sensors

• ORP sensors

• Combined sensors

• Oxygen sensors (amperometric and optical)

• Conductivity sensors with conductive measurement of

conductivity

• Chlorine sensors

Fixed cable Conductivity sensors with inductive measurement of

conductivity

Digital sensors with

additional internal power

supply

Fixed cable • Turbidity sensors

• Sensors for interface measurement

• Sensors for measuring the spectral absorption

coefficient (SAC)

• Nitrate sensors

• Optical oxygen sensors

• Ion-sensitive sensors

The following rule applies if connecting CUS71D sensors:

• CM442

– Only one CUS71D is possible; an additional sensor is not permitted.

– The second sensor input may also not be used for another type of sensor.

• CM444

No restrictions. All the sensor inputs can be used as required.

• CM448

– If a CUS71D is connected, the number of sensor inputs that can be used is limited to a

maximum of 4.

– Of these, all 4 inputs can be used for CUS71D sensors.

– Every combination of CUS71D and other sensors is possible, provided that the total

number of connected sensors does not exceed 4.

Liquiline CM442/CM444/CM448 Electrical connection

Endress+Hauser 27

6.3.2 Connecting the sensors

Types of connection

• Direct connection of sensor cable to terminal connector of sensor module 2DS or of base

module L, H or E (→ 37 ff.)

• Optional: Sensor cable plug connected to the M12 sensor socket on the underside of the

device

With this type of connection, the device is already wired at the factory (→ 40).

1. Sensor cable connected directly

Connect the sensor cable to the Memosensterminal connector of the sensor module

2DS or of base module L, H or E.

2. When connecting via M12 connector

Connect the sensor connector to an M12 sensor socket which has been previously

installed or is supplied on delivery.

Sensor cable connected directly

43 42 41

86 85 86 85

98 97 88 87

32 31

32 31

BN

WH

GN

YE

Sensor

A0023038

37 sensors without additional supply voltage

43 42 41

86 85 86 85

98 97 88 87

32 31

32 31

PK

GY

GN

YE

Sensor

A0023039

38 sensors with additional supply voltage

85 86

85

2DS

1

2

86

97 88 8798

97 88 8798

Sensor 1

Sensor 2

PK

GY

GN

YE

BN

WH

GN

YE

Sensor

Sensor

A0016197

39 sensors with and without additional supply

voltage on 2DS sensor module

Electrical connection Liquiline CM442/CM444/CM448

28 Endress+Hauser

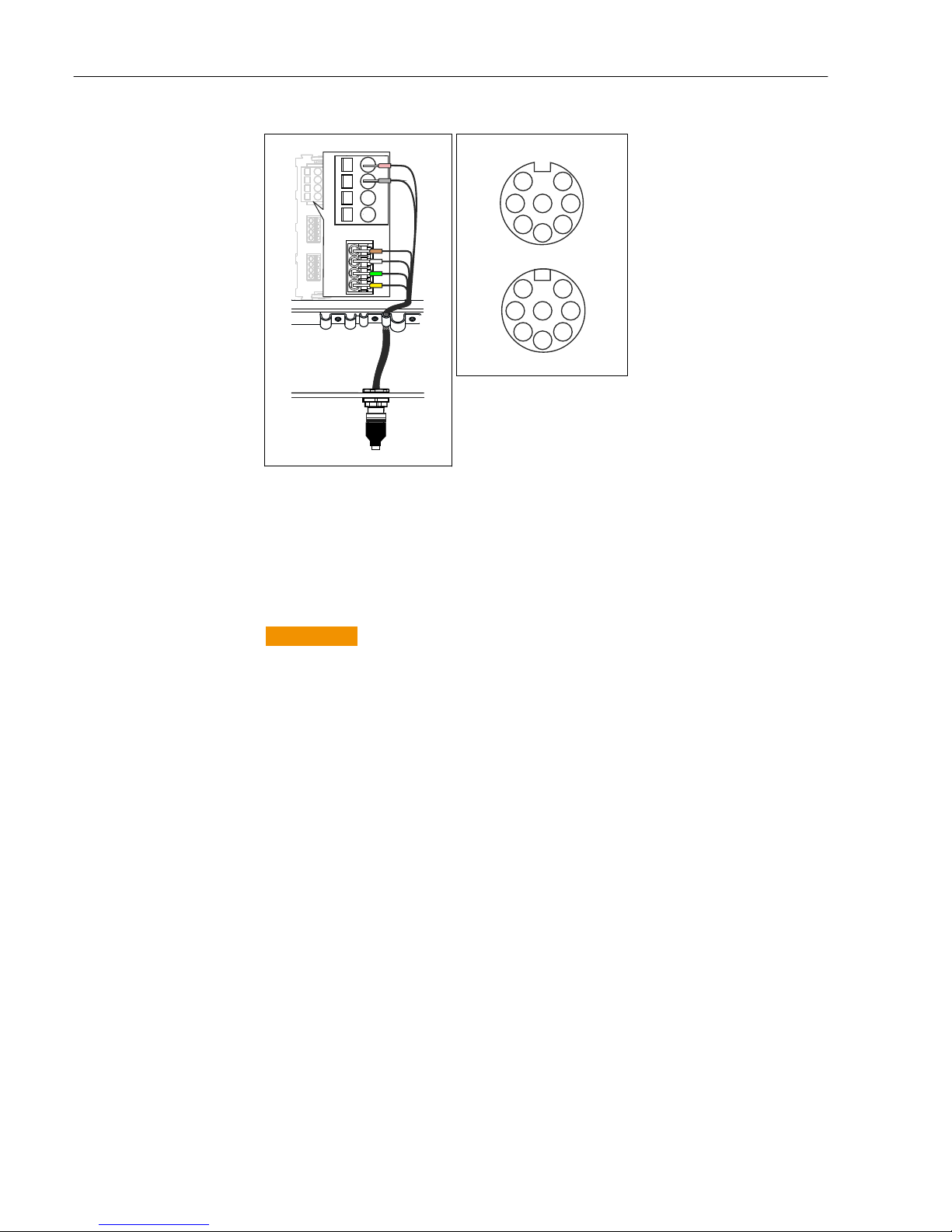

connection via M12 connection

85 86

85

1

2

86

97 88 8798

Sensor 1

PK

GY

GN

YE

BN

WH

1

A0018019

40 M12 plug-in connection (e.g.

at sensor module)

1 Sensor cable with M12

connector

6

4

1

NC

2

3

5

7

4

6

2

NC

1

7

5

3

A0018021

41 M12 assignment Top:

socket Bottom: connector

(top view in each case)

1 PK (24 V)

2 GY (Ground 24 V)

3 BN (3 V)

4 WH (Ground 3 V)

5 GN (Memosens)

6 YE (Memosens)

7,NCNot connected

Device versions with a pre-installed

M12 socket are ready-wired upon

delivery. Install an M12 socket, which

is available as an accessory, in a

suitable cable gland opening in the

base of the housing, and connect the

cables to the Memosens terminals of

the sensor or base module as per the

wiring diagram.

Connecting the sensor

‣ Plug the connector of the sensor

cable (item 1) directly into the M12

socket.

Please note the following for these

device versions:

• The internal device wiring is always

the same regardless of what kind of

sensor you connect to the M12

socket (plug&play).

• The signal and power supply cables

are assigned in the sensor plug-in

head in such a way that the PK and

GY power supply cables are either

used (e.g. optical sensors) or not

(e.g. pH or ORP sensors).

6.4 Connecting additional inputs, outputs or relays

L

WARNING

Module not covered

No shock protection. Danger of electric shock!

‣

If you are modifying or extending your hardware, always fill the slots from left to right.

Do not leave any gaps.

‣

If not all slots are occupied, always insert a dummy or end cover into the slot to the

right of the last module. (→ 2, 9)This ensures the that unit is shock-protected.

‣

If not all slots are occupied, always insert a dummy or end cover into the slot to the

right of the last module. This ensures the that unit is shock-protected.

‣

Always ensure shock protection is guaranteed particularly in the case of relay modules

(2R, 4R, AOR).

Liquiline CM442/CM444/CM448 Electrical connection

Endress+Hauser 29

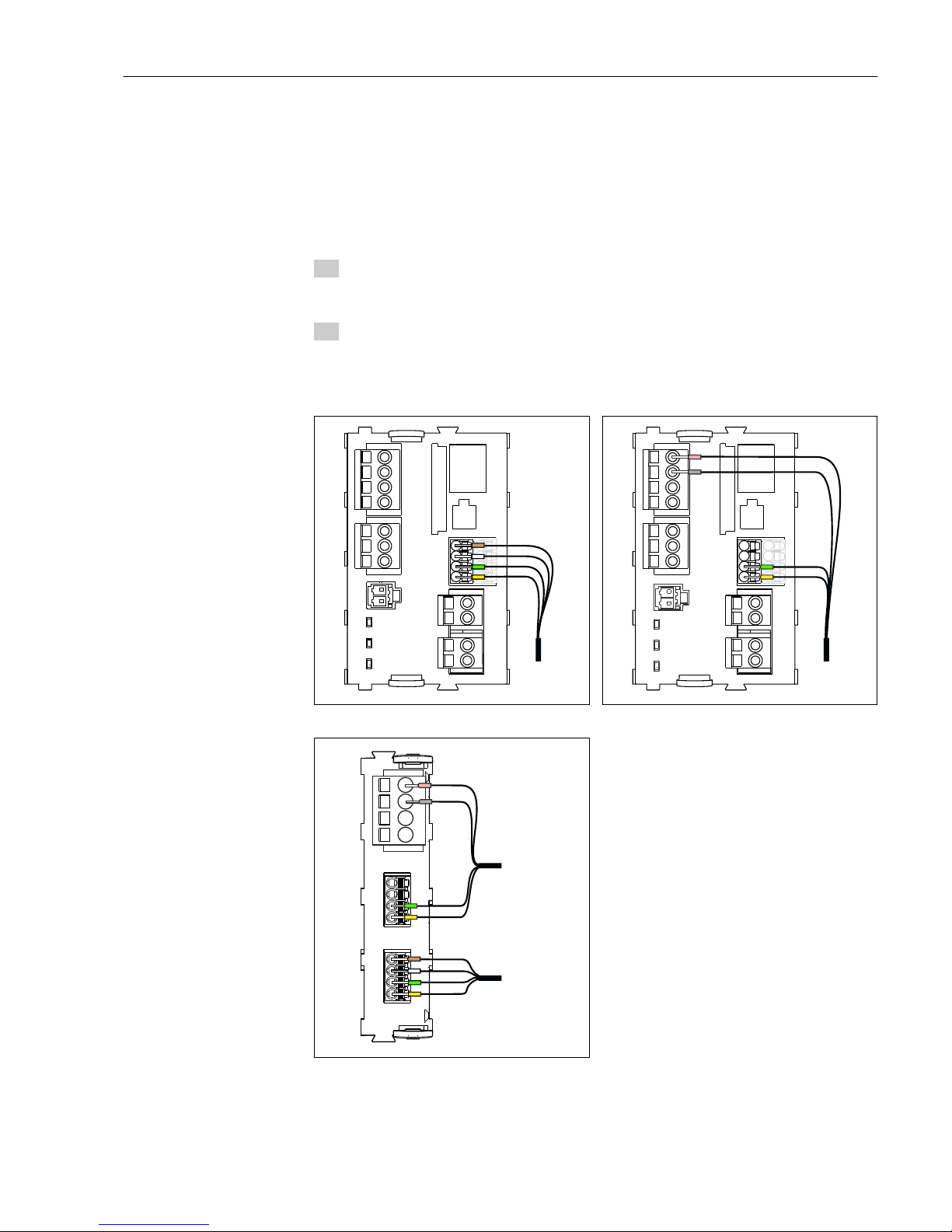

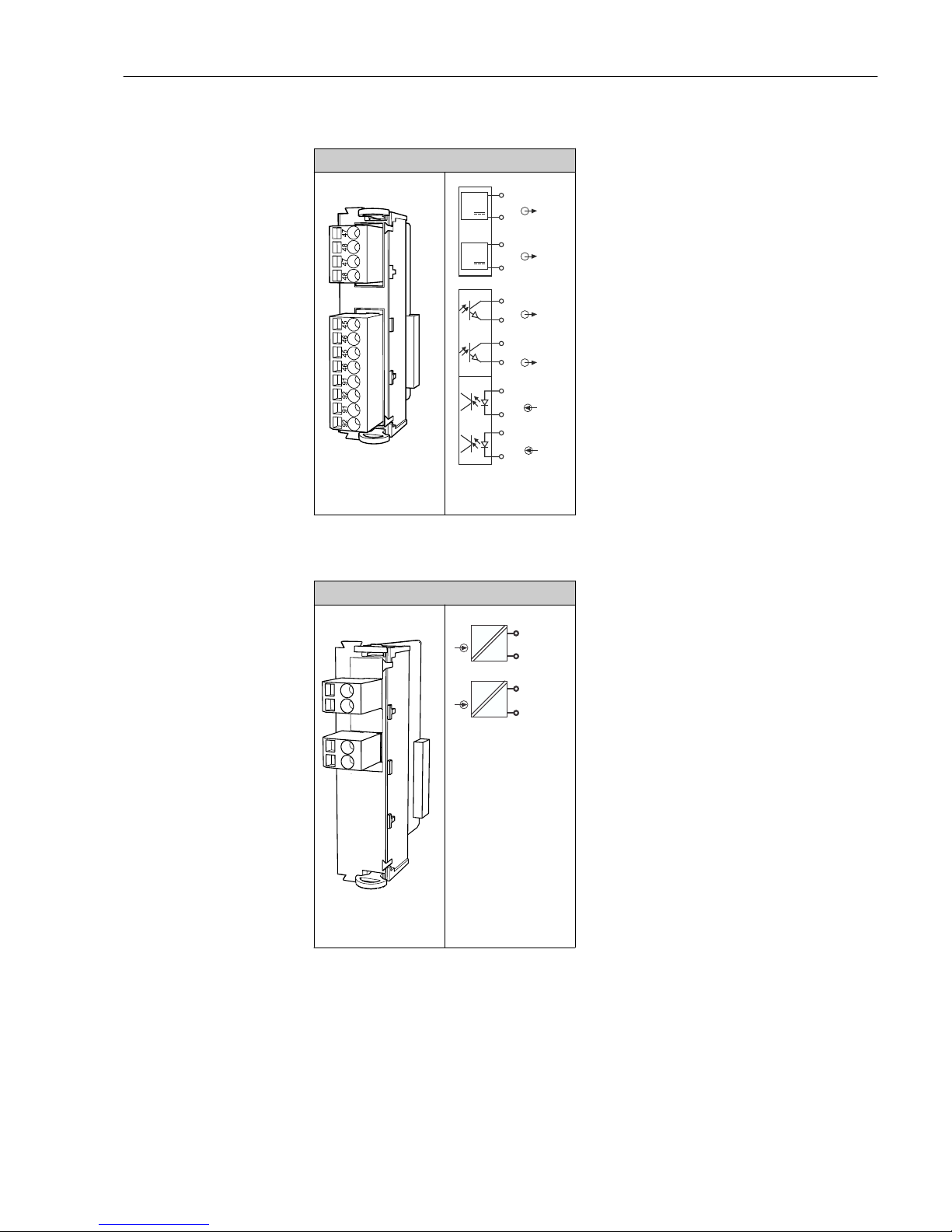

6.4.1 Digital inputs and outputs

DIO module

42 Module

47

47

48

48

+

+

–

1

2

–

1

2

1

2

+

–

–

+

+

–

+

–

45

46

45

46

91

92

91

92

43 Wiring

diagram

6.4.2 Current inputs

Module 2AI

2324

2324

44 Module

23

23

24

24

0/4 ... 20 mA

+

+

–

1

2

–

45 Wiring

diagram

Electrical connection Liquiline CM442/CM444/CM448

30 Endress+Hauser

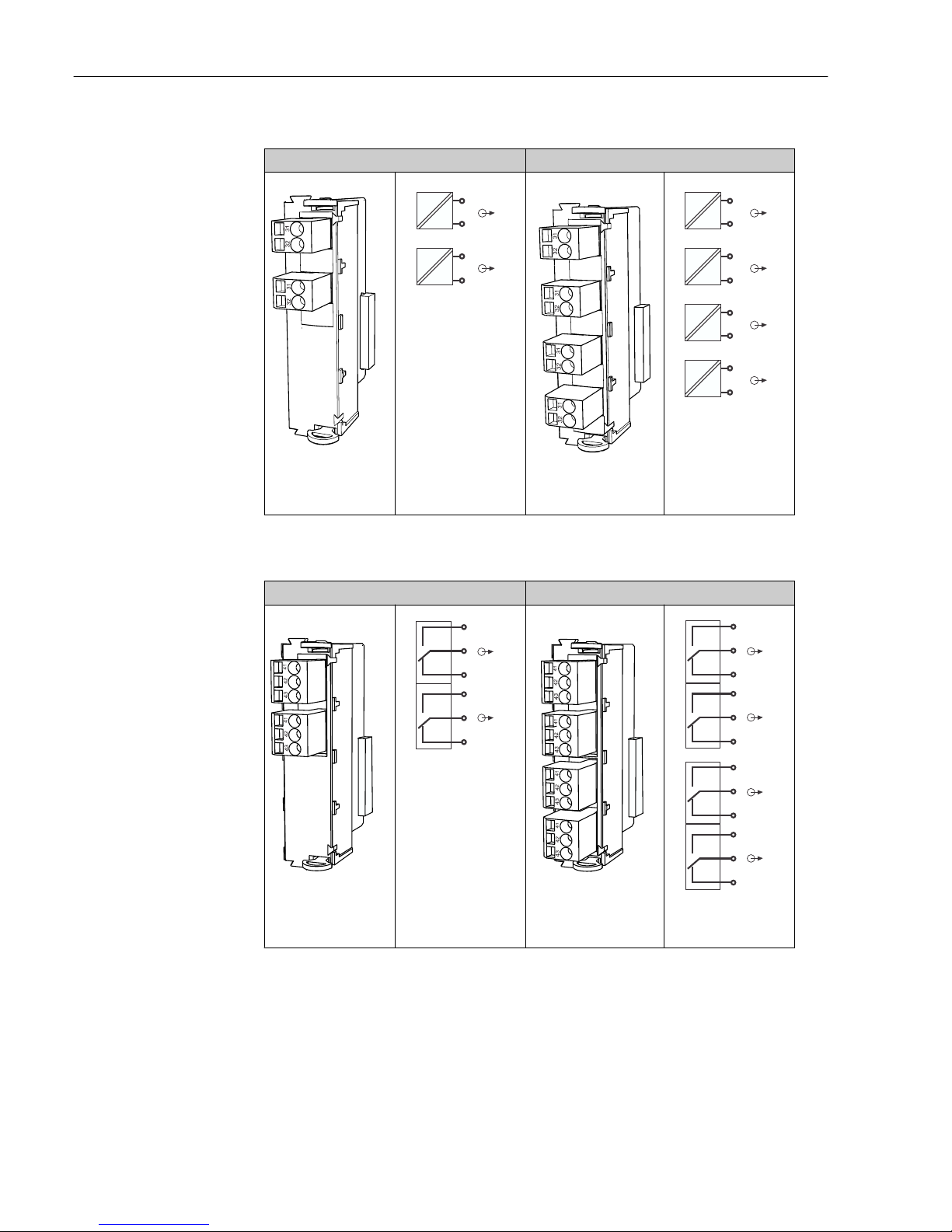

6.4.3 Current outputs

2AO 4AO

46 Module

31

31

32

32

0/4 ... 20 mA

+

+

–

1

2

–

47 Wiring

diagram

48 Module

31

31

32

32

0/4 ... 20 mA

+

+

–

1

2

–

31

31

32

32

0/4 ... 20 mA

+

+

–

3

4

–

49 Wiring

diagram

6.4.4 Relay

Module 2R Module 4R

50 Module

41

43

42

Relay 1

41

43

42

Relay 2

51 Wiring

diagram

52 Module

41

43

42

Relay 3

41

43

42

Relay 4

41

43

42

Relay 1

41

43

42

Relay 2

53 Wiring

diagram

Loading...

Loading...