Endress+Hauser Liquicap T FMI21 Technical Information

TI393F/00/en

Technical Information

Liquicap T FMI21

Capacitive level measurement

Two-rod probe for continuous measurement in liquids

Application

The Liquicap T sensor is used in conductive liquids

(as of 30 µS/cm) for continuous level measurement and

is preconfigured from factory 0 %...100 % to probe length

ordered.

As of a conductivity of 30 µS/cm, the measurement is

independent of the dc-value (dielectric constant) of the

liquid. It can also be deployed in Ex area, Zone 2.

The Liquicap T is particularly suited to the following

applications:

• Small measuring ranges (as of 150 mm)

• Cistern measurements

• Aggressive liquids such as acids and alkalis

• Independent of the tank material (plastic, stainless

steel or concrete) or the tank shape

Used in conjunction with the Fieldgate FXA320 (remote

measured value interrogation using Internet technology),

Liquicap T is an ideal solution for inventorying material

and optimising logistics (inventory control).

Your benefits

• Safe function regardless of tank geometry thanks to

probe design

• No calibration necessary (preconfigured from factory

0 %...100 % to probe length ordered)

• High quality, non-corrosive materials (carbon fibre,

stainless steel) for use in aggressive liquids and liquids

which present a hazard to water (WHG-approved

(German Water Resources Law))

• No moving parts in tank - long operating life dependable function without wear

• Cost-effective solution for continuous measurement of

levels in conductive liquids

• Optimised storage by simply shortening the probe rods

on site (probe shortening set)

Liquicap T FMI21

2

Endress+Hauser

Table of contents

Function and system design. . . . . . . . . . . . . . . . . . . . . 3

Measuring principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Measuring system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operating medium . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Measured variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Measuring range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Input signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Electronic insert FEI20 (4...20 mA) . . . . . . . . . . . . . . . . . . . . . . . . 5

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Electrical connection (wiring diagram) . . . . . . . . . . . . . . . . . . . . . 6

Transmitter power supply units from Endress+Hauser . . . . . . . . . . 6

Supply voltage (FEI20) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Current consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Cable entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Cable specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Performance characteristics

with installed electronic insert . . . . . . . . . . . . . . . . . . 7

Reference operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Maximum measured error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Repeatability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Start-up settling time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Influence of ambient temperature . . . . . . . . . . . . . . . . . . . . . . . . . 7

Integration time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Factory calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installation instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Ambient temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Ambient temperature limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Storage temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Climate class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Degree of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Shock resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Vibration resistance (with min. rod length 150 mm) . . . . . . . . . . . 8

Electromagnetic compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Conductivity of medium . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Process pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Mechanical construction . . . . . . . . . . . . . . . . . . . . . . 10

Design, dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Probe shortening set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Fitted electrodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Human interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Operating elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Display elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Certificates and approvals . . . . . . . . . . . . . . . . . . . . . 13

CE mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Overfill protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Other standards and guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Ex approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Type of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Ordering information. . . . . . . . . . . . . . . . . . . . . . . . . 14

Liquicap T FMI21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Liquicap T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Technical Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Operating Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Certificates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Liquicap T FMI21

Endress+Hauser 3

Function and system design

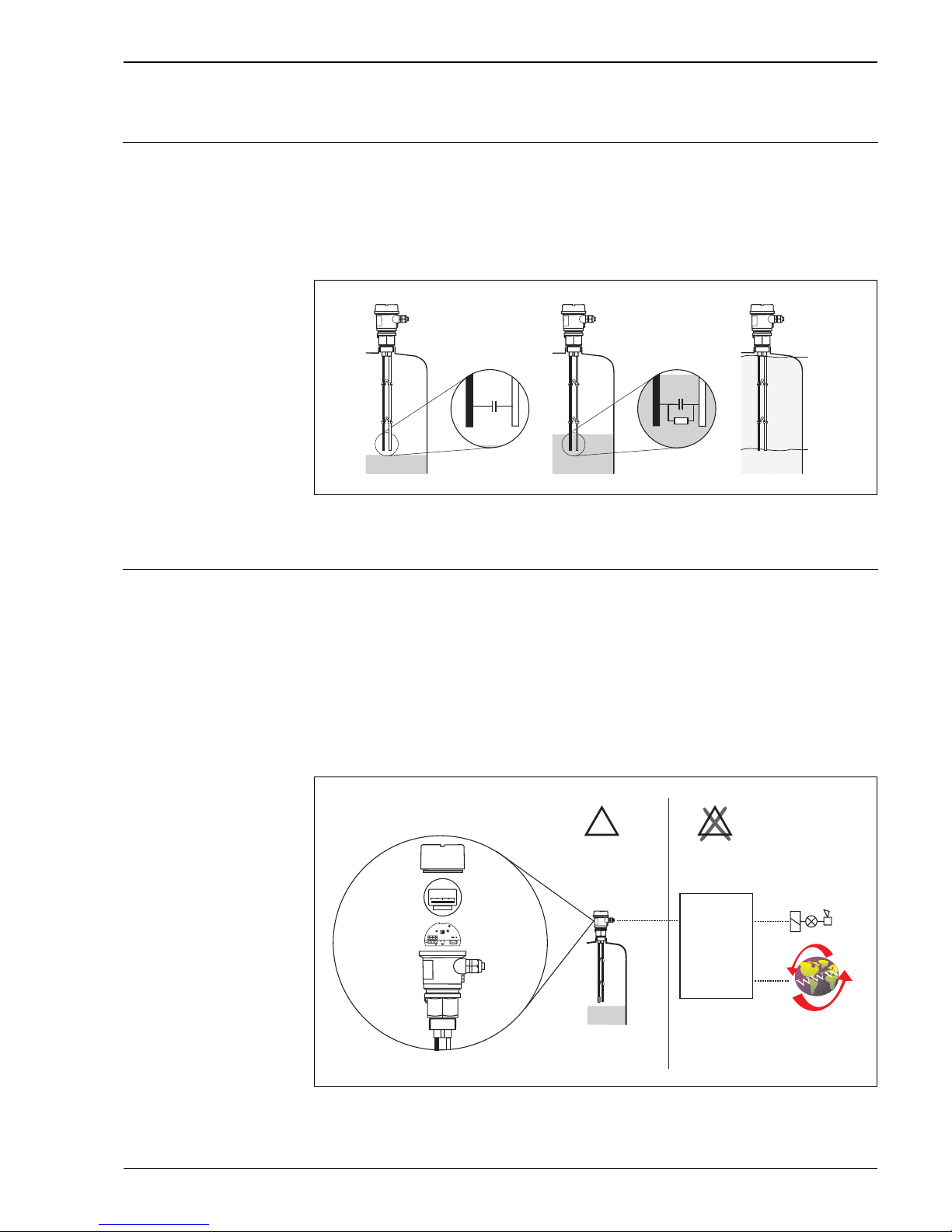

Measuring principle The probe, medium and ground rod (counter electrode) form an electric capacitor.

If the probe is in the air ➀, a certain low initial capacitance is measured.

When the tank is filled, the capacitance of the capacitor increases the more the probe is covered ➁ ➂.

As of a conductivity of 30 µs/cm, the measurement does not depend on the dc-value of the liquid.

The electronic insert of the probe converts the capacitance measured to a current, in proportion to the level,

in the range of 4...20 mA, thus making it possible to interpret the level.

All input and output channels are safely galvanically isolated from one another.

L00-FMI21xxx-15-05-xx-xx-001

CA : Initial capacitance (probe exposed)

C

E

: Final capacitance (probe covered)

Measuring system Probe with integrated electronic insert

The measuring system consists of:

• The components of a capacitive probe Liquicap T FMI21:

➀ Housing with two probe rods

(one probe rod fully insulated and the second uninsulated (ground potential))

➁ Electronic insert FEI20

➂ Display (optional)

➃ Housing cover (optional: cover with sight glass in conjunction with display)

• A transmitter power supply unit

L00-FMI21xxx-14-05-xx-en-000

mn o

C

A

R

C

C

C

E

A

E

X

E

X

–+

– +

FEI20

1 2

+ –

–

+

m

n

o

p

ATEX II 3G

RN221N

RNS221

RMA421

RMA422

FXA320

FMI21

0…100%

100,0

Remote

interrogation

Liquicap T FMI21

4 Endress+Hauser

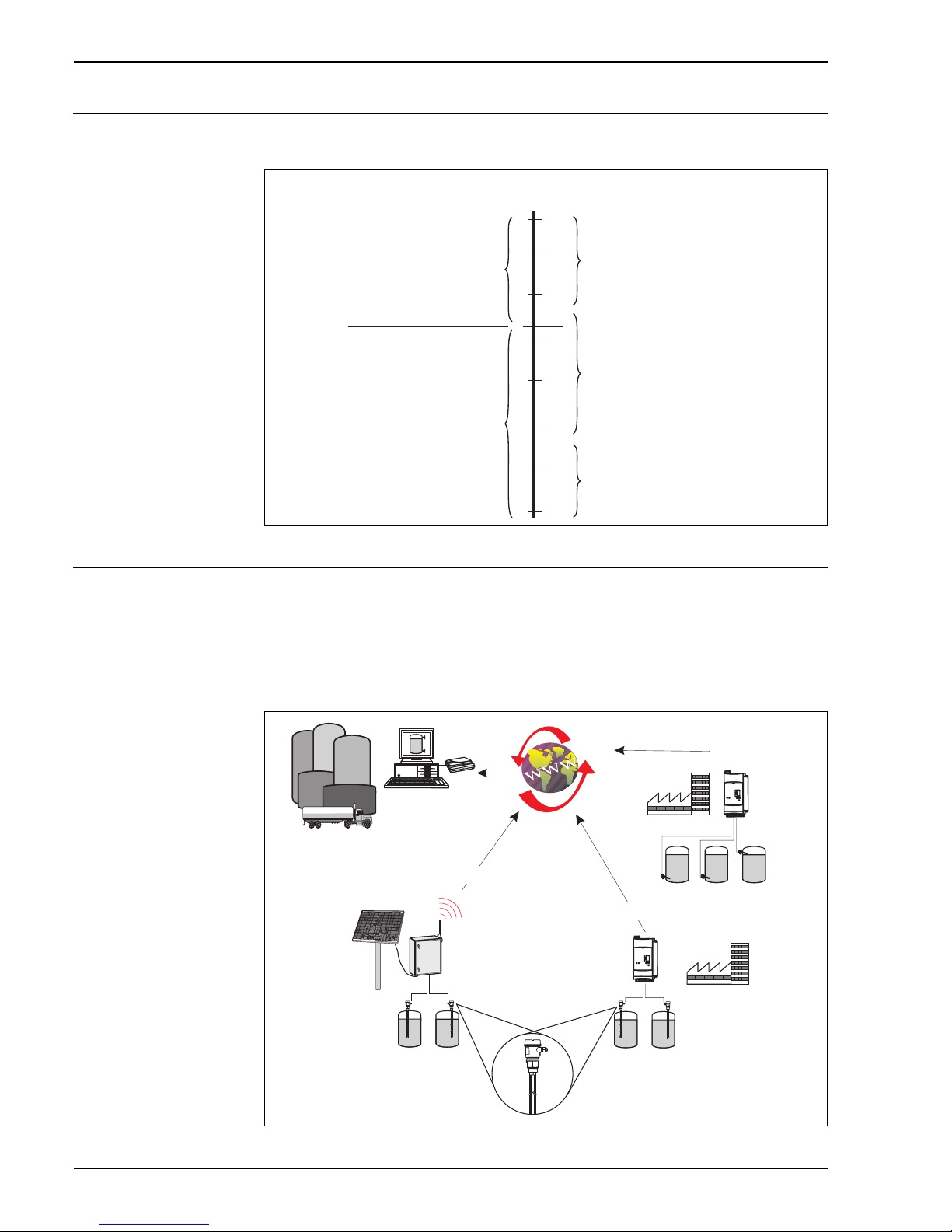

Operating medium Due to the probe design, the Liquicap T FMI21 can be used as of a conductivity of 30 µs/cm. The measurement

is independent of the dc-value and the conductivity of the liquid.

L00-FMI21xxx-05-06-xx-en-000

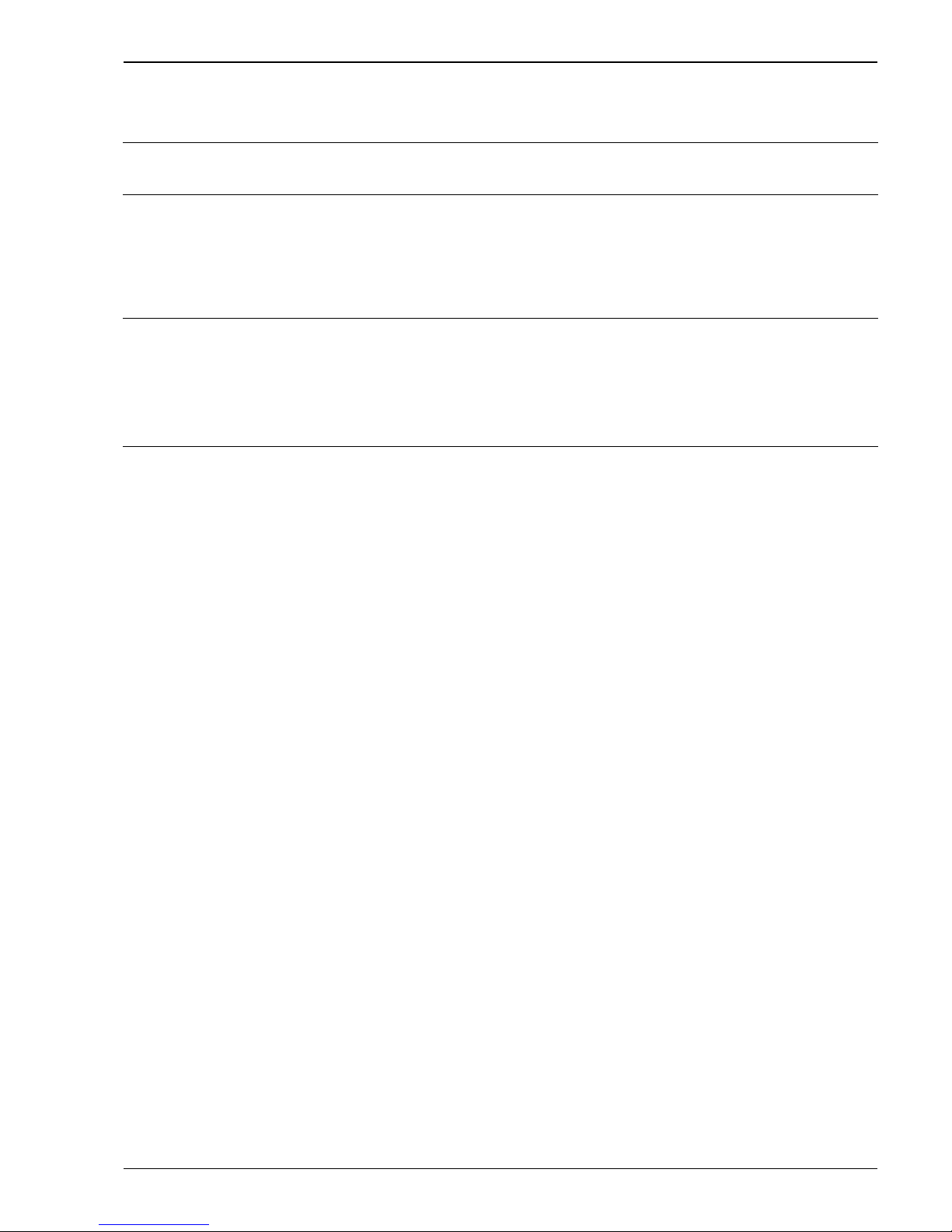

Applications Vendor Managed Inventory

The remote interrogation of tank or silo levels via Fieldgate enables suppliers of raw materials to gather

information about the current inventories of their regular customers at any time and, for example, take this into

account in their own production planning. The Fieldgate monitor the configured level limits and automatically

trigger the next delivery as required. Here, the spectrum of possibilities ranges from a simple purchasing

requisition by e-mail through to fully automatic order processing by incorporating XML data into the planning

systems on both sides.

L00-FMI21xxx-02-00-06-en-001

10

–3

10

–2

10

–1

1

10

10

2

10

3

10

4

30

Conductivity [µS/cm]

Liquicap T operating range

independent of the conductivity

and DK value (dielectric constant)

e.g. Hydrocarbons with

water contents below 0.1%,

petrols, oils, solvents

e.g. Hydrocarbons with

higher water contents,

demineralised water

e.g. Water-based liquids,

aqueous solutions of salts,

acids and alkalis,

aqueous dispersions and emulsions,

wastewater, electrolytes, beverages

Recommendation:

e.g. Multicap or Liquicap M

Levelflex M

Prosonic T/M

Micropilot M

Not suitable for Liquicap T

Fieldgate

FXA320

FMI21

Fieldgate

FXA320

Solar box with

FXA320

Solar panel

GSM

Vendor

Client A

Analog

4...20 mA

Analog

4...20 mA

Ethernet

Client B

Limit

switch

Telephone

Liquicap T FMI21

Endress+Hauser 5

Input

Measured variable Continuous measurement of the change in capacitance between two probe rods depending on the level of a

conductive liquid. Maximum viscosity = 2000 cst

Measuring range The measuring range is between 150...2500 mm, depending on the probe length ordered.

• Probe length: 150...2500 mm

• Adjustable initial capacitance: C

A

= 0...2000 pF

• Permitted span: ∆C = 25...2000 pF

• End capacitance: C

E

= max. 2100 pF

• Measuring frequency: 250 kHz

Input signal Probes covered => high capacitance

Probes exposed => low capacitance

Output

Electronic insert FEI20

(4...20 mA)

Output signal

3.8...20.5 mA

Switch-on current

Max. 20 mA (< 500 ms)

Signal on alarm

> 21 mA

Loading...

Loading...