Endress and Hauser and Co FMR6XEL User Manual

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT DRAFTDRAFT DRAFT DRAFT

TI01304F/00/EN/04.18

71394735

Products

Solutions Services

Technical Information

Micropilot FMR67

Freistrahlendes Radar

Füllstandmessung in Schüttgütern

Application

• Continuous, non-contact level measurement of bulk solids

ranging from powdery to lumpy

• PTFE drip-off antenna or PTFE-plated, flush-mounted antenna

• Maximum measuring range: 125 m (410 ft)

• Temperature: –40 to +200 °C (–40 to +392 °F)

• Pressure: –1 to +16 bar (–14.5 to +232 psi)

• Accuracy: ± 3 mm (0.12 in)

• Linearity protocol (3-point, 5-point)

Your benefits

• Innovative drip-off antenna made of PTFE

• Reliable measurement thanks to improved focusing and small beam angle,

particularly in silos with many internal fittings

• Safety by design - ensures highest safety

• Easy, guided commissioning with intuitive user interface

• Bluetooth® wireless technology for commissioning, operation and maintenance via

free iOS / Android app SmartBlue

• Maximum reliability thanks to multi-echo tracking

• HistoROM configuration memory makes for easier commissioning,

maintenance and diagnostics

• Purge air connection for cleaning in extreme conditions

• Alignment device for easy adaptation of sensor

• SIL2 as per IEC 61508, SIL3 for homogeneous or diverse redundancy

• Easy proof testing for SIL

• RFID TAG - easy identification of measuring points for improved data access

• Heartbeat Technology

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT DRAFTDRAFT DRAFT DRAFT

Table of contents

Micropilot FMR67

Important document information ............... 4

Safety symbols ............................... 4

Electrical symbols ............................. 4

Symbols for certain types of information .............. 4

Symbols in graphics ............................ 4

Symbols at the device ........................... 5

Terms and abbreviations ..................... 6

Registered trademarks ....................... 7

Function and system design ................... 8

Measuring principle ............................ 8

Input ..................................... 9

Measured variable ............................. 9

Measuring range .............................. 9

Operating frequency ........................... 9

Transmission power ............................ 9

Output .................................. 10

Output signal ............................... 10

Signal on alarm .............................. 11

Linearization ............................... 11

Galvanic isolation ............................ 11

Protocol-specific data .......................... 11

Power supply ............................. 13

Terminal assignment .......................... 13

Device plug connectors ......................... 17

Supply voltage .............................. 18

Power consumption ........................... 19

Current consumption .......................... 19

Power supply failure .......................... 19

Potential equalization ......................... 19

Cable entries ............................... 20

Cable specification ............................ 20

Overvoltage protection ......................... 20

Performance characteristics .................. 21

Reference operating conditions ................... 21

Reference accuracy ........................... 21

Measured value resolution ...................... 21

Response time .............................. 22

Influence of ambient temperature ................. 22

Installation ............................... 23

Installation conditions ......................... 23

Installation: Drip-off antenna PTFE 50 mm / 2" ......... 28

Installation: flush mount antenna .................. 29

Purge air connection for FMR67 ................... 30

Container with heat insulation .................... 31

Environment .............................. 32

Ambient temperature range ..................... 32

Ambient temperature limits ..................... 32

Storage temperature .......................... 33

Climate class ............................... 33

Altitude according to IEC61010-1 Ed.3 .............. 34

Degree of protection .......................... 34

Vibration resistance ........................... 34

Electromagnetic compatibility (EMC) ............... 34

Process .................................. 35

Process temperature, process pressure ............... 35

Dielectric constant ............................ 37

Mechanical construction .................... 38

Dimensions ................................ 38

Weight ................................... 49

Materials: GT18 housing (stainless steel, corrosion-

resistant) .................................. 50

Materials: GT19 housing (plastic) .................. 51

Materials: GT20 housing (die-cast aluminum, powder-

coated) ................................... 52

Materials: antenna and process connection ........... 53

Materials: Weather protection cover ................ 55

Operability ............................... 56

Operating concept ............................ 56

Local operation .............................. 57

Operation with remote display and operating module

FHX50 ................................... 57

Operation via Bluetooth® wireless technology .......... 58

Remote operation ............................ 58

SupplyCare inventory management software .......... 60

Certificates and approvals ................... 63

CE mark ................................... 63

RoHS ..................................... 63

RCM-Tick marking ............................ 63

Ex approval ................................ 63

Dual seal according to ANSI/ISA 12.27.01 ............ 63

Functional safety ............................. 63

WHG ..................................... 63

Pressure equipment with allowable pressure

≤ 200 bar (2 900 psi) .......................... 63

Marine approval ............................. 64

Radio standard EN 302729-1/2 ................... 64

Radio standard EN 302372-1/2 ................... 65

FCC ...................................... 65

Industry Canada ............................. 65

CRN approval ............................... 65

Test, certificate .............................. 67

Hard-copy product documentation ................. 67

Other standards and guidelines ................... 68

Ordering information ....................... 69

Ordering information .......................... 69

3-point linearity protocol ....................... 70

5-point linearity protocol ....................... 71

Customer-specific configuration ................... 72

Tagging (TAG) .............................. 72

Services ................................... 72

2 V. 4, Rev. 1, 19-03-2018 Endress+Hauser

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT DRAFTDRAFT DRAFT DRAFT

Micropilot FMR67

Application Packages ....................... 73

Heartbeat Diagnostics ......................... 73

Heartbeat Verification ......................... 74

Heartbeat Monitoring ......................... 75

Accessories ............................... 76

Device-specific accessories ...................... 76

Communication-specific accessories ................ 82

Service-specific accessories ...................... 83

System components ........................... 83

Supplementary documentation ............... 84

Standard documentation ........................ 84

Safety Instructions (XA) ........................ 84

Endress+Hauser V. 4, Rev. 1, 19-03-2018 3

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT DRAFTDRAFT DRAFT DRAFT

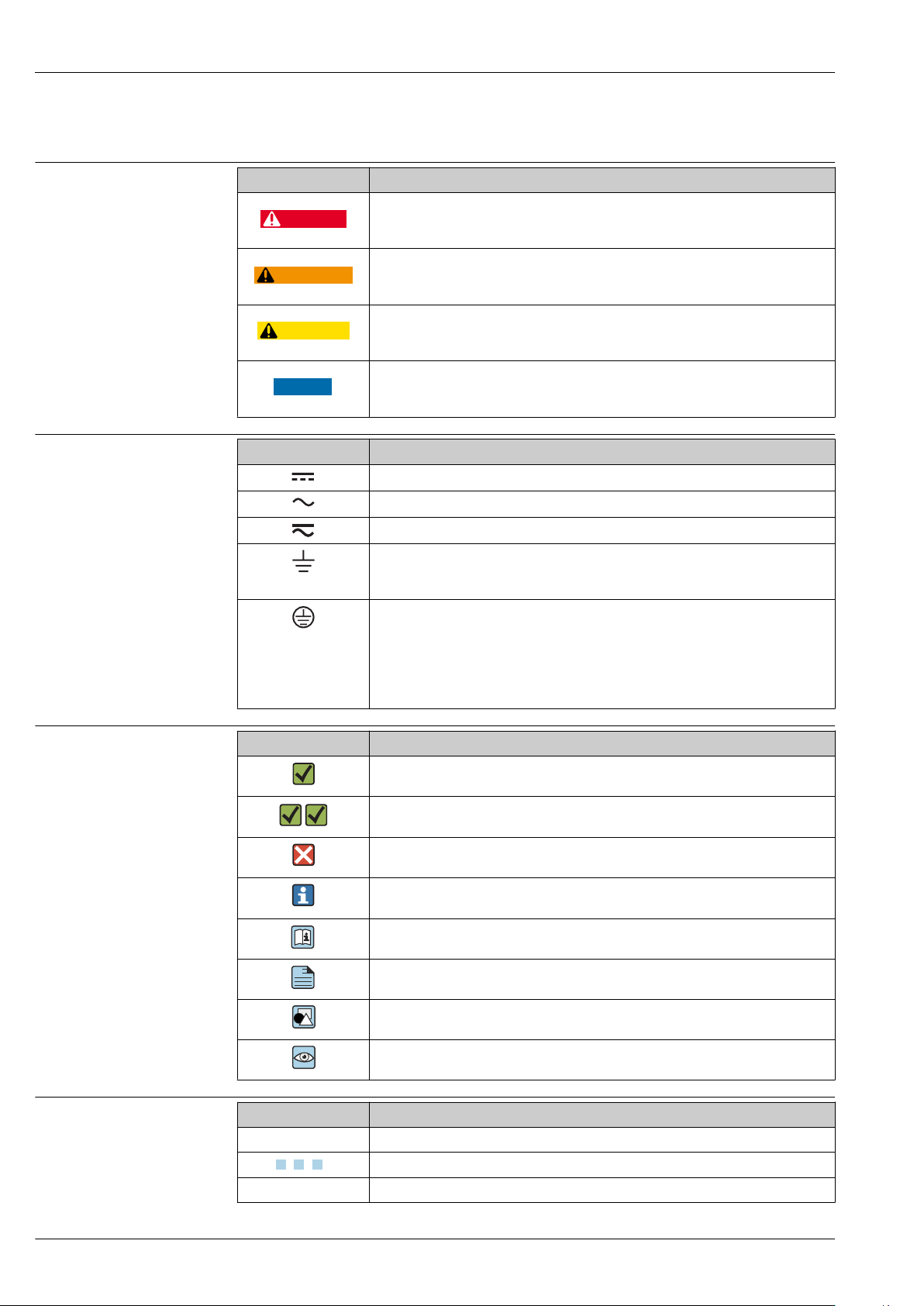

Important document information

DANGER

WARNING

CAUTION

NOTICE

A

1.

Micropilot FMR67

Safety symbols

Electrical symbols

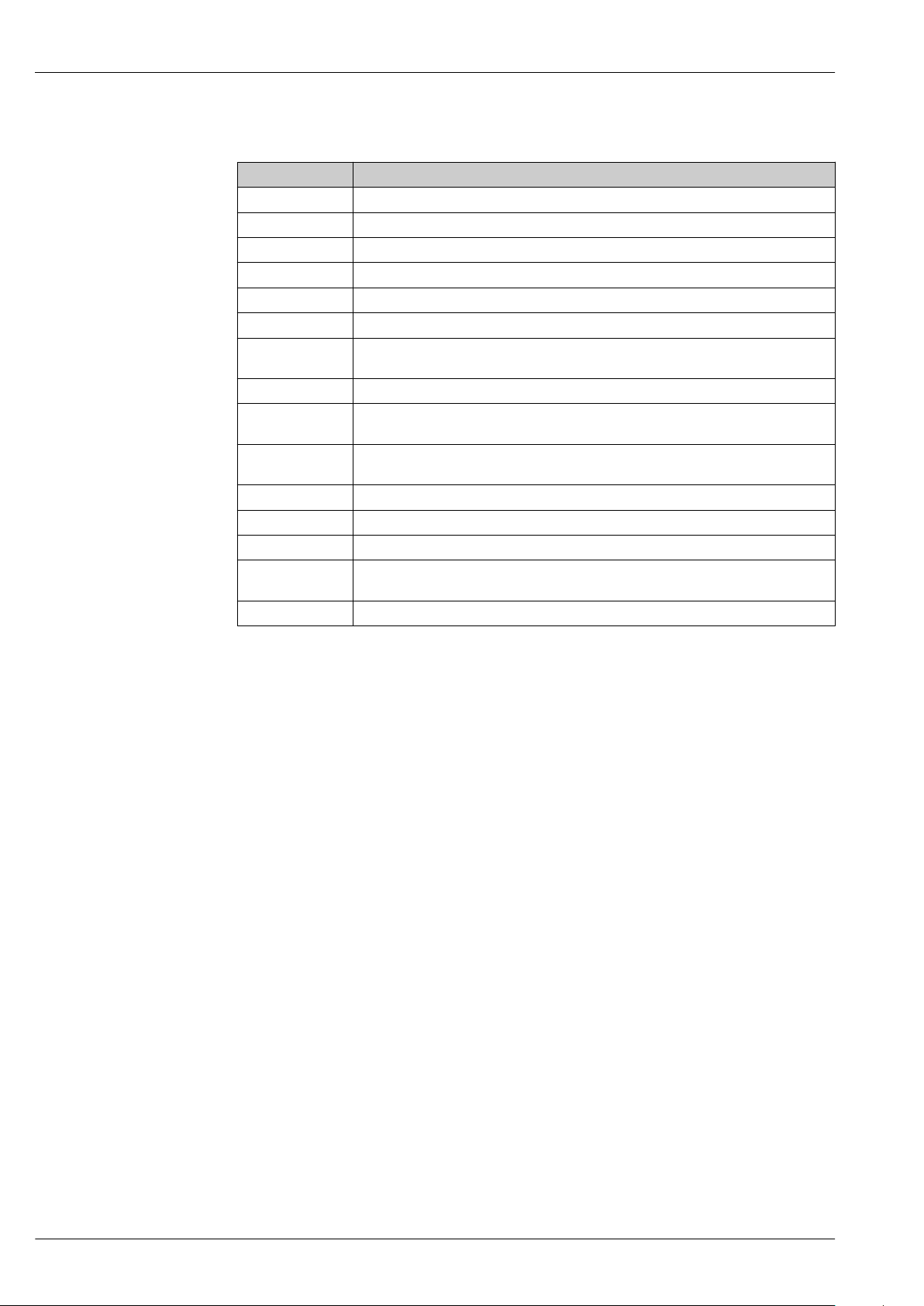

Symbol Meaning

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will

result in serious or fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in minor or medium injury.

NOTE!

This symbol contains information on procedures and other facts which do not result in

personal injury.

Symbol Meaning

Direct current

Alternating current

Direct current and alternating current

Ground connection

A grounded terminal which, as far as the operator is concerned, is grounded via a

grounding system.

Protective Earth (PE)

A terminal which must be connected to ground prior to establishing any other

connections.

The ground terminals are situated inside and outside the device:

• Inner ground terminal: Connects the protectiv earth to the mains supply.

• Outer ground terminal: Connects the device to the plant grounding system.

Symbols for certain types of information

Symbols in graphics

Symbol Meaning

Permitted

Procedures, processes or actions that are permitted.

Preferred

Procedures, processes or actions that are preferred.

Forbidden

Procedures, processes or actions that are forbidden.

Tip

Indicates additional information.

Reference to documentation.

Reference to page.

Reference to graphic.

Visual inspection.

Symbol Meaning

1, 2, 3 ... Item numbers

, 2., 3.… Series of steps

A, B, C, ... Views

4 V. 4, Rev. 1, 19-03-2018 Endress+Hauser

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT DRAFTDRAFT DRAFT DRAFT

Micropilot FMR67

-

.

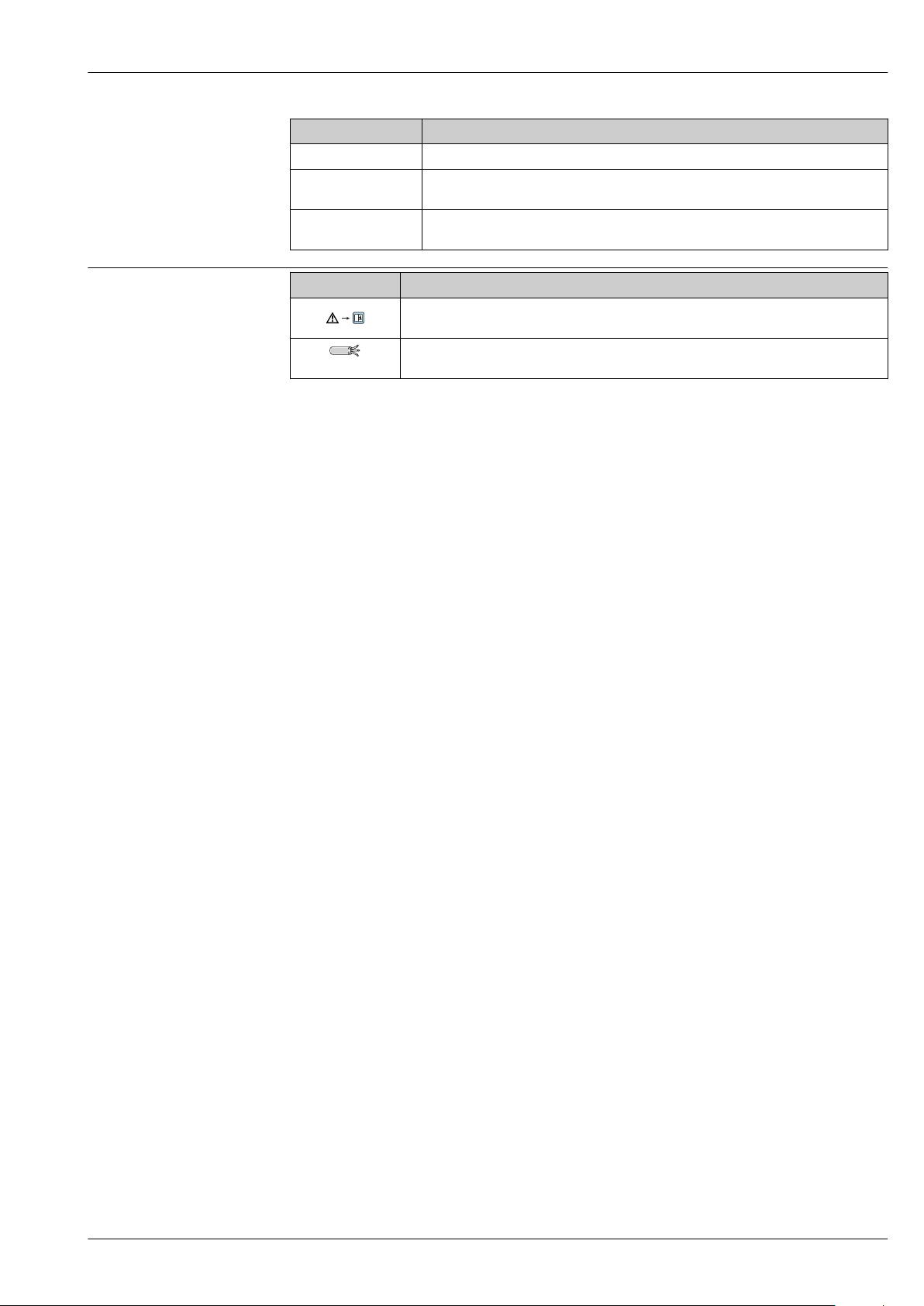

Symbol Meaning

A-A, B-B, C-C, ... Sections

Hazardous area

Indicates a hazardous area.

Safe area (non-hazardous area)

Indicates the non-hazardous area.

Symbols at the device

Symbol Meaning

Safety instructions

Observe the safety instructions contained in the associated Operating Instructions.

Temperature resistance of the connection cables

Specifies the minimum value of the temperature resistance of the connection cables.

Endress+Hauser V. 4, Rev. 1, 19-03-2018 5

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT DRAFTDRAFT DRAFT DRAFT

Micropilot FMR67

Terms and abbreviations

Term/abbreviation Explanation

BA Document type "Operating Instructions"

KA Document type "Brief Operating Instructions"

TI Document type "Technical Information"

SD Document type "Special Documentation"

XA Document type "Safety Instructions"

PN Nominal pressure

MWP Maximum Working Pressure

The MWP can also be found on the nameplate.

ToF Time of Flight

FieldCare Scalable software tool for device configuration and integrated plant asset management

solutions

DeviceCare Universal configuration software for Endress+Hauser HART, PROFIBUS,

FOUNDATION Fieldbus and Ethernet field devices

DTM Device Type Manager

DD Device Description for HART communication protocol

DC Relative dielectric constant ε

Operating tool The term "operating tool" is used in place of the following operating software:

FieldCare / DeviceCare, for operation via HART communication and PC

BD Blocking Distance; no signals are analyzed within the BD.

r

6 V. 4, Rev. 1, 19-03-2018 Endress+Hauser

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT DRAFTDRAFT DRAFT DRAFT

Micropilot FMR67

Registered trademarks

HART®

Registered trademark of the HART Communication Foundation, Austin, USA

Bluetooth®

The Bluetooth® word mark and logos are registered trademarks owned by the Bluetooth SIG, Inc. and

any use of such marks by Endress+Hauser is under license. Other trademarks and trade names are

those of their respective owners.

Apple®

Apple, the Apple logo, iPhone, and iPod touch are trademarks of Apple Inc., registered in the U.S.and

other countries. App Store is a service mark of Apple Inc.

Android®

Android, Google Play and the Google Play logo are trademarks of Google Inc.

KALREZ®, VITON®

Registered trademark of DuPont Performance Elastomers L.L.C., Wilmington, USA

TEFLON®

Registered trademark of E.I. DuPont de Nemours & Co., Wilmington, USA

Endress+Hauser V. 4, Rev. 1, 19-03-2018 7

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT DRAFTDRAFT DRAFT DRAFT

Function and system design

D

R

f

t

1

2

f

2

f

1

∆t

∆f

Micropilot FMR67

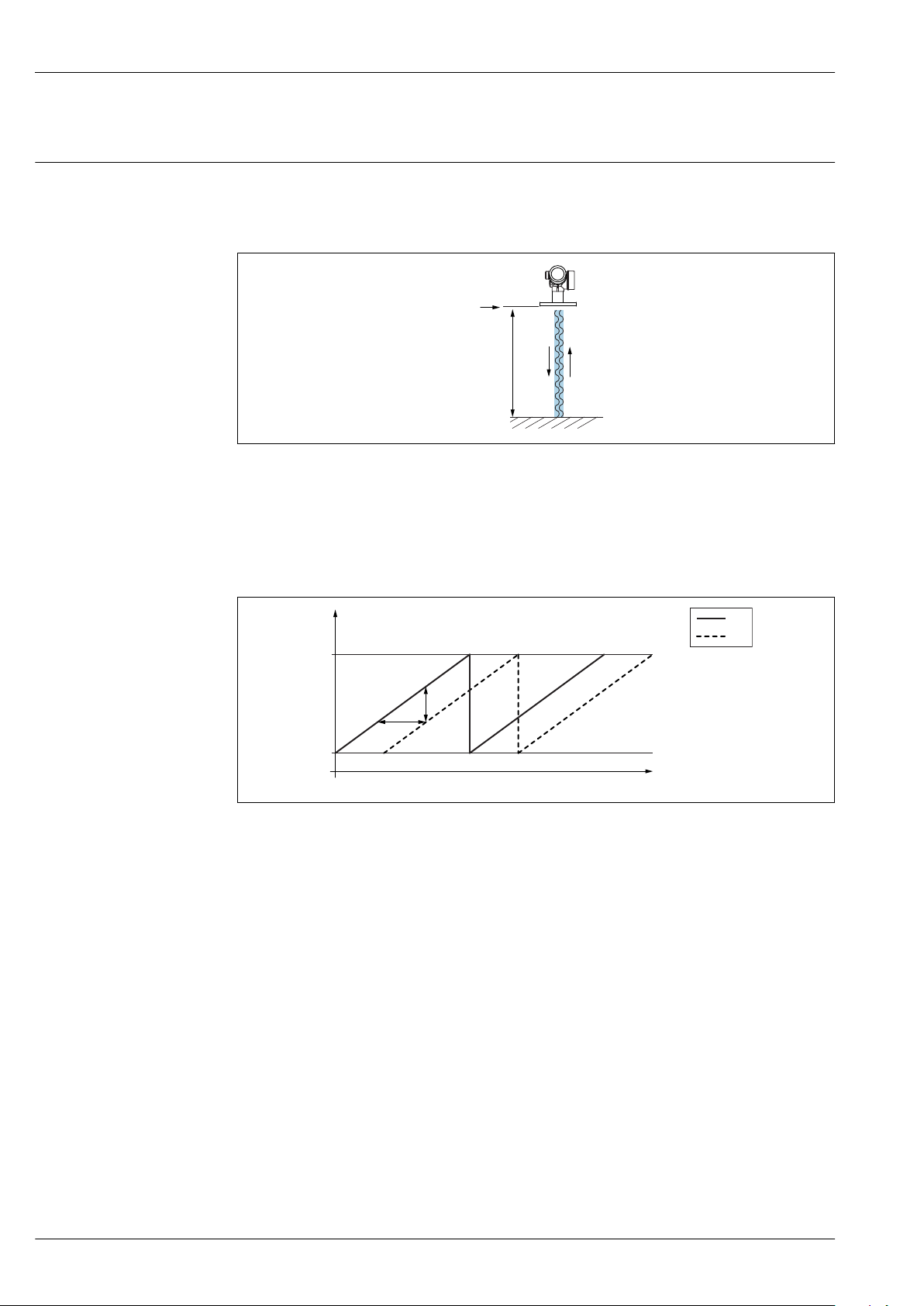

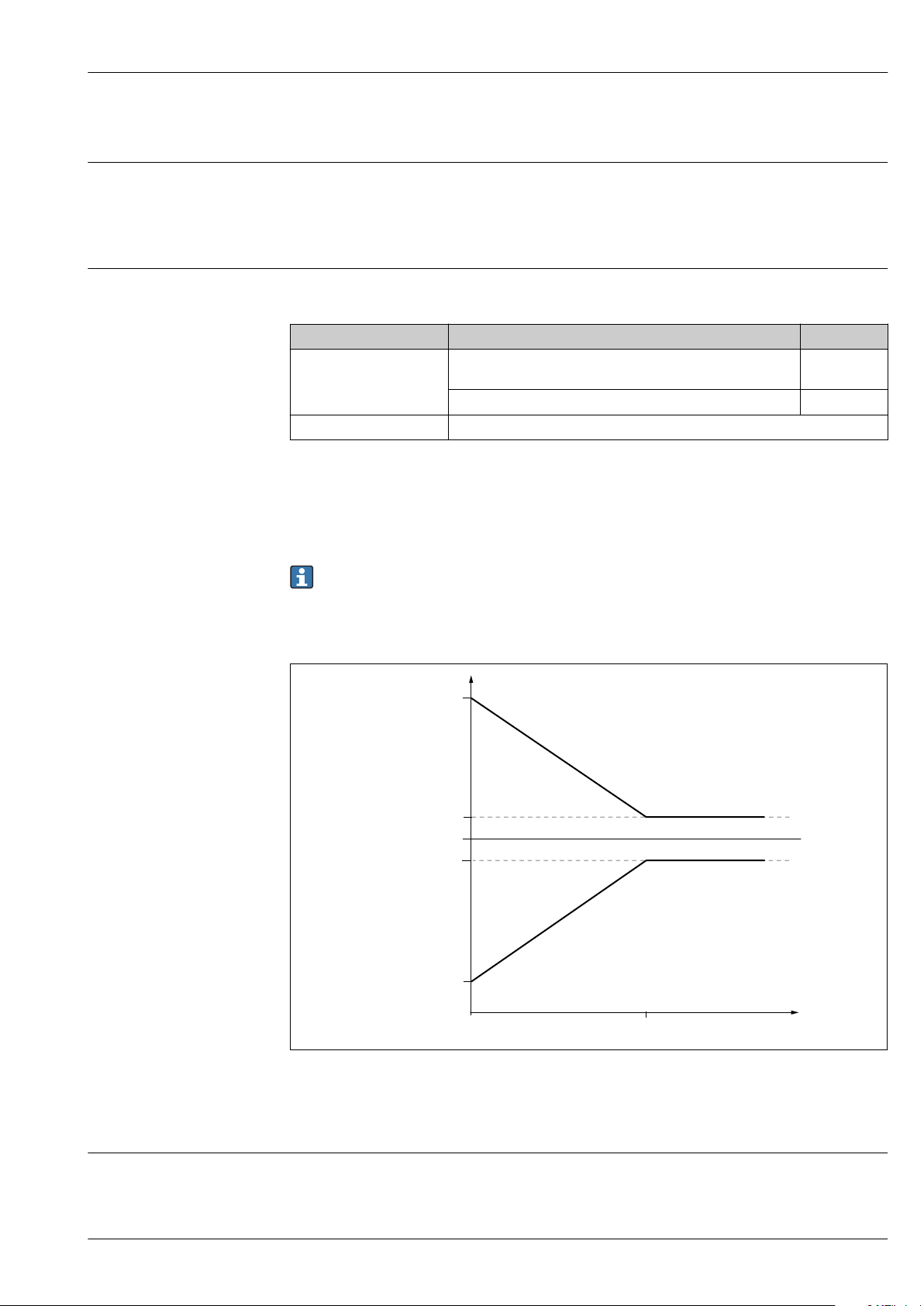

Measuring principle

The Micropilot is a "downward-looking" measuring system, operating based on the frequency

modulated continuous wave method (FMCW). The antenna emits an electromagnetic wave at a

continuously varying frequency. This wave is reflected by the product and received again by the

antenna.

A0032017

1 FMCW principle: transmission and reflection of the continuous wave

R Reference point of measurement

D Distance between reference point and product surface

The frequency of this wave is modulated in the form of a sawtooth signal between two limit

frequencies f1 and f2:

2 FMCW principle: result of frequency modulation

1 Transmitted signal

2 Received signal

This results in the following difference frequency at any time between the transmitted signal and the

received signal:

Δf = k Δt

where Δt is the run time and k is the specified increase in frequency modulation.

Δt is given by the distance D between the reference point R and the product surface:

D = (c Δt) / 2

where c is the speed of propagation of the wave.

In summary, D can be calculated from the measured difference frequency Δf. D is then used to

determine the content of the tank or silo.

8 V. 4, Rev. 1, 19-03-2018 Endress+Hauser

A0023771

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT DRAFTDRAFT DRAFT DRAFT

Micropilot FMR67

Input

Measured variable

Measuring range Maximum measuring range

Operating frequency

Transmission power

The measured variable is the distance between the reference point and the product surface. The level

is calculated based on "E", the empty distance entered. Optionally, the level can be converted to other

variables (volume, mass) by linearization (32 value pairs).

Device Antenna

FMR67 GA:

Drip-off, PTFE 50 mm / 2"

GP:

PTFE flush mount 80 mm / 3"

1) Feature 070 in the product structure

Usable measuring range

The usable measuring range depends on the antenna size, the medium's reflective properties, the

installation position and any possible interference reflections.

Approx. 80 GHz

Up to 8 devices can be installed in the same tank without interfering with each other.

• Peak power: 6.3 mW

• Average output power: 63 µW

1)

Maximum measuring range

50 m (164 ft)

125 m (410 ft)

Endress+Hauser V. 4, Rev. 1, 19-03-2018 9

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT DRAFTDRAFT DRAFT DRAFT

Output

Output signal HART

Signal coding FSK ±0.5 mA over current signal

Data transmission rate 1 200 Bit/s

Galvanic isolation Yes

Bluetooth® wireless technology

Device version Ordering feature 610 "Accessory mounted", option NF "Bluetooth"

Operation / configuration By the SmartBlue app.

Range under reference conditions > 10 m (33 ft)

Encryption Encrypted communication and password encryption prevent incorrect

Switch output

Micropilot FMR67

operation by unauthorized persons.

For HART devices, the switch output is available as an option. See product structure, feature 20:

"Power Supply, Output", option B: "2-wire; 4-20mA HART, switch output"

Switch output

Function Open collector switching output

Switching behavior Binary (conductive or non-conductive), switches when the programmable switch

point is reached

Failure mode non-conductive

Electrical connection values U = 16 to 35 VDC, I = 0 to 40 mA

Internal resistance RI < 880 Ω

The voltage drop at this internal resistance has to be taken into account on

planning the configuration. For example, the resulting voltage at a connected

relay must be sufficient to switch the relay.

Insulation voltage floating, Insulation voltage 1 350 VDC to power supply aund 500 VAC to ground

Switch point freely programmable, separately for switch-on and switch-off point

Switching delay freely programmable from 0 to 100 s, separately for switch-on and switch-off

point

Number of switching cycles corresponds to the measuring cycle

Signal source

device variables

Number of switching cycles unlimited

• Level linearized

• Distance

• Terminal voltage

• Electronic temperature

• Relative echo amplitude

• Diagnostic values, Advanced diagnostics

10 V. 4, Rev. 1, 19-03-2018 Endress+Hauser

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT DRAFTDRAFT DRAFT DRAFT

Micropilot FMR67

Signal on alarm

Depending on the interface, failure information is displayed as follows:

• Current output (for HART devices)

– Failsafe mode selectable (in accordance with NAMUR Recommendation NE 43):

– Failsafe mode with user-selectable value: 3.59 to 22.5 mA

• Local display

– Status signal (in accordance with NAMUR Recommendation NE 107)

– Plain text display

• Operating tool via HART communication or service interface (CDI)

– Status signal (in accordance with NAMUR Recommendation NE 107)

– Plain text display

Linearization

The linearization function of the device allows the conversion of the measured value into any unit of

length or volume. Linearization tables for calculating the volume in cylindrical tanks are preprogrammed. Other linearization tables of up to 32 value pairs can be entered manually or semiautomatically.

Galvanic isolation

All circuits for the outputs are galvanically isolated from each other.

Protocol-specific data HART

Manufacturer ID 17 (0x11)

Device type ID 0x112B

HART specification 7.0

Device description files (DTM, DD) Information and files under:

HART load min. 250 Ω

HART device variables The measured values can be freely assigned to the device variables.

Supported functions • Burst mode

Minimum alarm: 3.6 mA

Maximum alarm (= factory setting): 22 mA

• www.endress.com

• www.fieldcommgroup.org

Measured values for PV (primary variable)

• Level linearized

• Distance

• Electronic temperature

• Relative echo amplitude

• Area of incoupling

• Analog output adv. diagnostics 1

• Analog output adv. diagnostics 2

Measured values for SV, TV, FV (second, third and fourth variable)

• Level linearized

• Distance

• Electronic temperature

• Terminal voltage

• Relative echo amplitude

• Absolute echo amplitude

• Area of incoupling

• Analog output adv. diagnostics 1

• Analog output adv. diagnostics 2

• Additional transmitter status

Wireless HART data

Minimum start-up voltage 16 V

Start-up current 3.6 mA

Start-up time 65 s

Minimum operating voltage 14.0 V

Endress+Hauser V. 4, Rev. 1, 19-03-2018 11

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT DRAFTDRAFT DRAFT DRAFT

Micropilot FMR67

Multidrop current 4.0 mA

Set-up time 15 s

12 V. 4, Rev. 1, 19-03-2018 Endress+Hauser

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT DRAFTDRAFT DRAFT DRAFT

Micropilot FMR67

1

+

2

4-20mA

1-channel overvoltage protection

-

[16]

A

7

4...20 mA

5

4

1

2

3

+

–

+

–

"

1

+

2

4...20mA

HART

10 mm

Spare part

71108xxx

2- wire level

4-20 mA 4-20 mA

HART

[21]

open

-

8

9

#

B

+

–

4...20 mA

5

4

1

2

3

+

–

6

"

Power supply

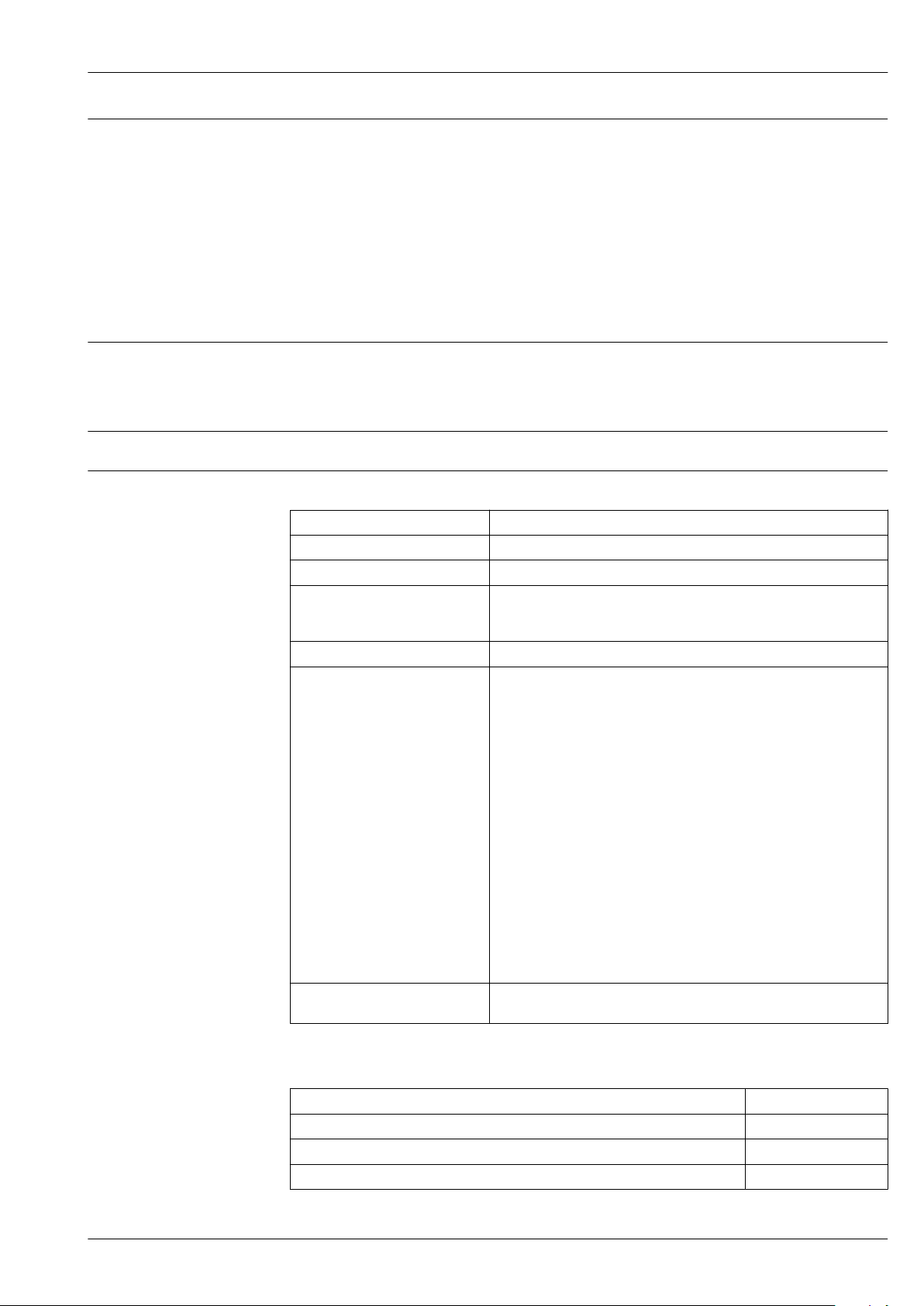

Terminal assignment 2-wire: 4-20mA HART

A0011294

3 Terminal assignment 2-wire; 4-20mA HART

A Without integrated overvoltage protection

B With integrated overvoltage protection

1 Active barrier with power supply (e.g. RN221N): Observe terminal voltage

2 HART communication resistor (≥ 250 Ω): Observe maximum load

3 Connection for Commubox FXA195 or FieldXpert SFX350/SFX370 (via VIATOR Bluetooth modem)

4 Analog display device: Observe maximum load

5 Cable screen; observe cable specification

6 4-20mA HART (passive): Terminals 1 and 2

7 Overvoltage protection module

8 Terminal for potential equalization line

9 Cable entry

Endress+Hauser V. 4, Rev. 1, 19-03-2018 13

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT DRAFTDRAFT DRAFT DRAFT

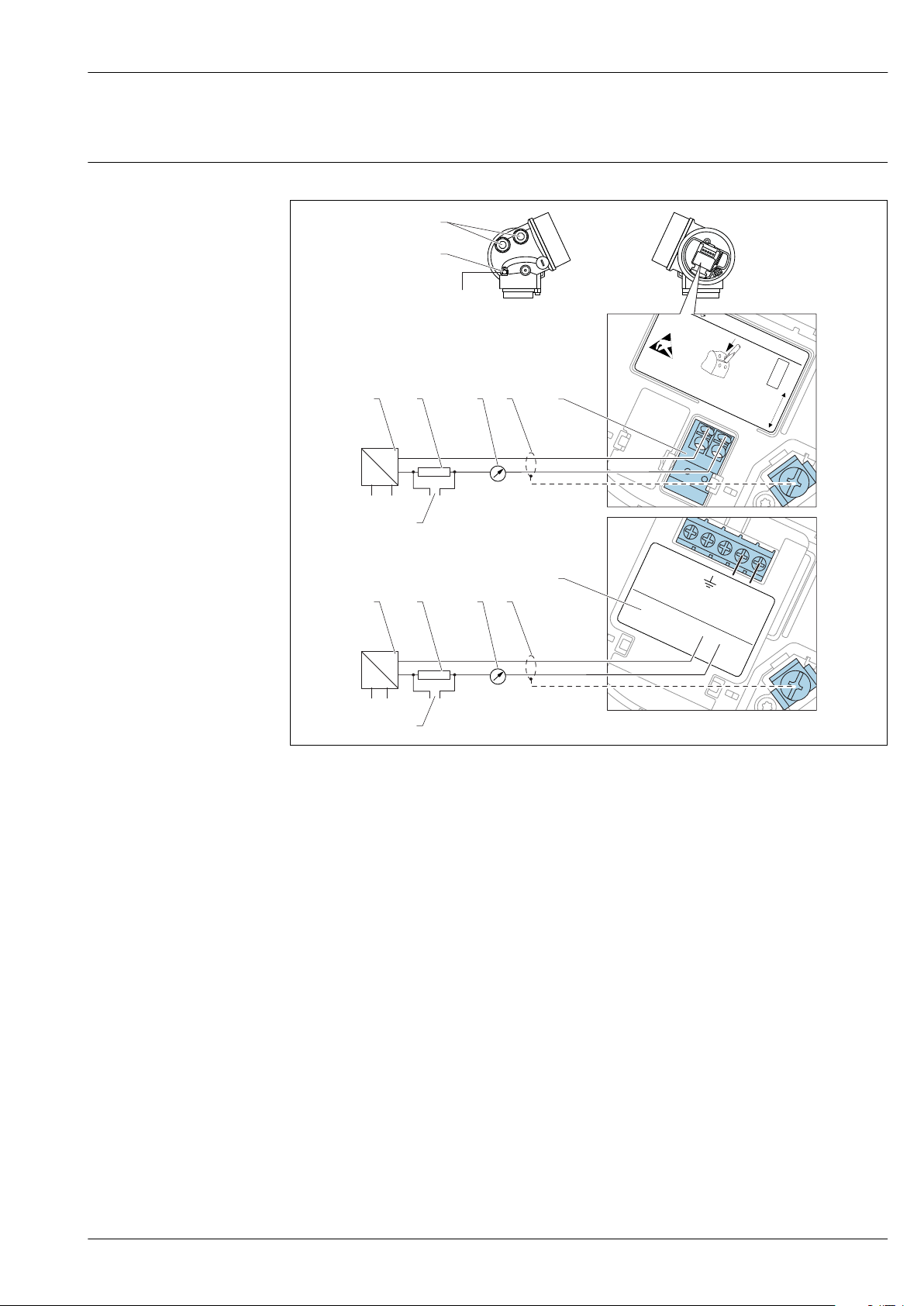

2-wire: 4-20mA HART, switch output

1

3

+

+

2

4

4-20mA/

FIELDBUS

4-20mA/

2-channel overvoltage protection

-

-

[17]

B

10

9

8

6

!

A

1

+

2

4...20 mA

HART

10 mm

Spare part

71108xxx

2- wire

4-20 mA PFS

HART

[02/03]

open

-

1

+

2

-

3

+

4

-

7

11

+

+

-

-

2

3

3

4

4

5

5

1

4...20 mA

≥250 Ω

3+

3+

4-

4-

+

–

%

4...20 mA

≥250 Ω

2

1

+

–

%

Micropilot FMR67

4 Terminal assignment 2-wire; 4-20mA HART, switch output

A Without integrated overvoltage protection

B With integrated overvoltage protection

1 Active barrier with power supply (e.g. RN221N): Observe terminal voltage

2 HART communication resistor (≥ 250 Ω): Observe maximum load

3 Connection for Commubox FXA195 or FieldXpert SFX350/SFX370 (via VIATOR Bluetooth modem)

4 Analog display device: Observe maximum load

5 Cable screen; observe cable specification

6 4-20mA HART (passive): Terminals 1 and 2

7 Switch output (open collector): Terminals 3 and 4

8 Terminal for potential equalization line

9 Cable entry for 4-20mA HART line

10 Cable entry for switch output line

11 Overvoltage protection module

14 V. 4, Rev. 1, 19-03-2018 Endress+Hauser

A0013759

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT DRAFTDRAFT DRAFT DRAFT

Micropilot FMR67

A

1

3

+

+

2

4

4-20mA/

FIELDBUS

4-20mA/

2-channel overvoltage protection

-

-

[17]

14

13

12

!

1

3

+

+

2

4

4...20mA

HART

4...20mA

10 mm

Spare part

71108xxx

2- wire level

4-20 mA 4-20 mA

HART

[04/05]

open

-

-

11

+

+

+

+

-

-

-

-

3

3

9

9

5

5

8

8

6

6

7

7

4

4

4

4

+

–

+

–

4...20 mA

4...20 mA

10

B

4...20 mA

4...20 mA

#

#

#

#

+

–

+

–

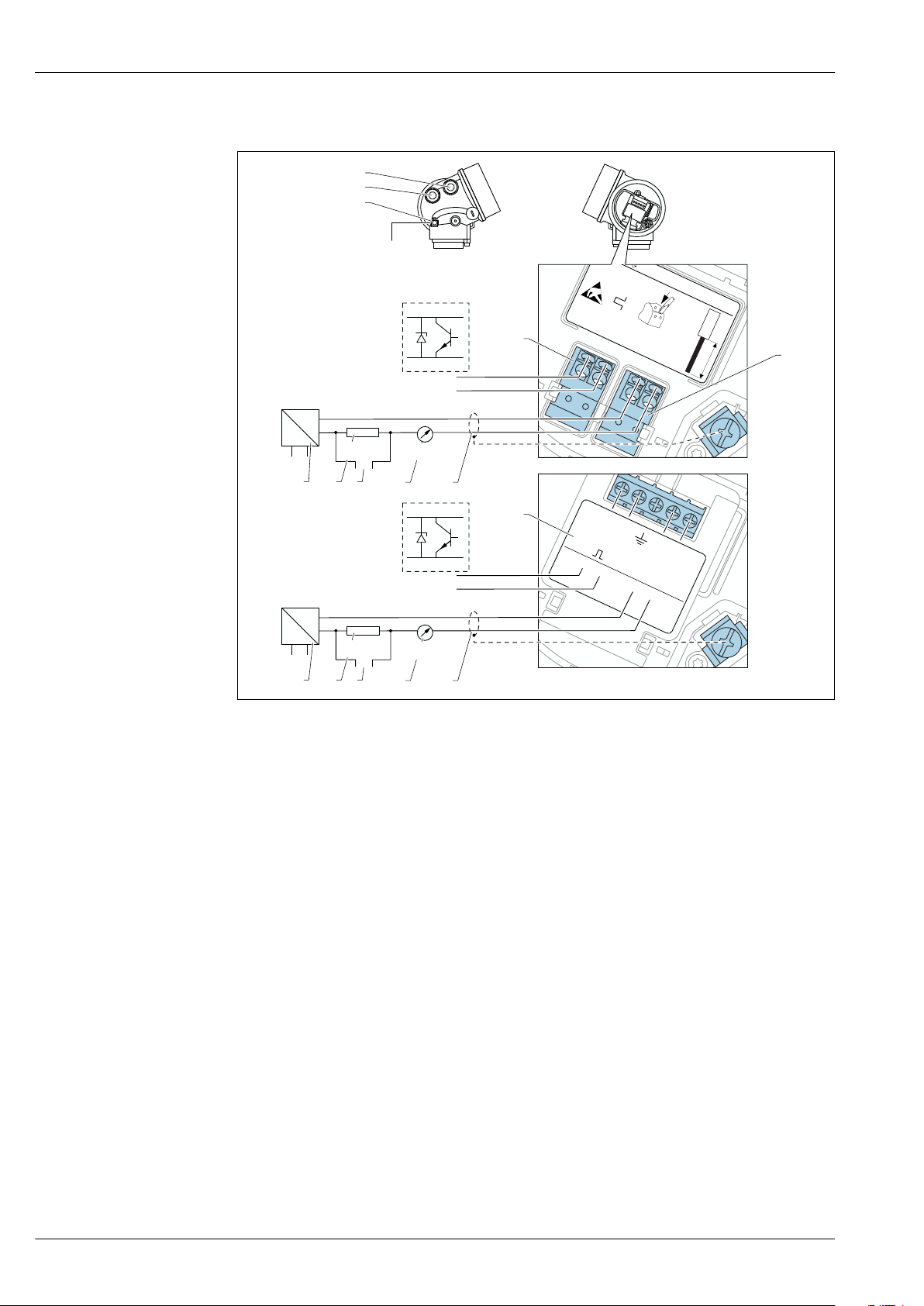

2-wire: 4-20mA HART, 4-20mA

5 Terminal assignment 2-wire, 4-20 mA HART, 4...20mA

A Without integrated overvoltage protection

B With integrated overvoltage protection

1 Connection current output 2

2 Connection current output 1

3 Supply voltage for current output 1 (e.g. RN221N); Observe terminal voltage

4 Cable screen; observe cable specification

5 HART communication resistor (≥ 250 Ω): Observe maximum load

6 Connection for Commubox FXA195 or FieldXpert SFX350/SFX370 (via VIATOR Bluetooth modem)

7 Analog display device ; observe maximum load

8 Analog display device ; observe maximum load

9 Supply voltage for current output 2 (e.g. RN221N); Obeserve terminal voltage

10 Overvoltage protection module

11 Current output 2: Terminals 3 and 4

12 Terminal for the potential equalization line

13 Cable entry for current output 1

14 Cable entry for current output 2

This version is also suited for single-channel operation. In this case, current output 1 (terminals

1 and 2) must be used.

Endress+Hauser V. 4, Rev. 1, 19-03-2018 15

A0013923

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT DRAFTDRAFT DRAFT DRAFT

Micropilot FMR67

3+

+

-

4-

R

i

3+

2

1

+

4-

R

i

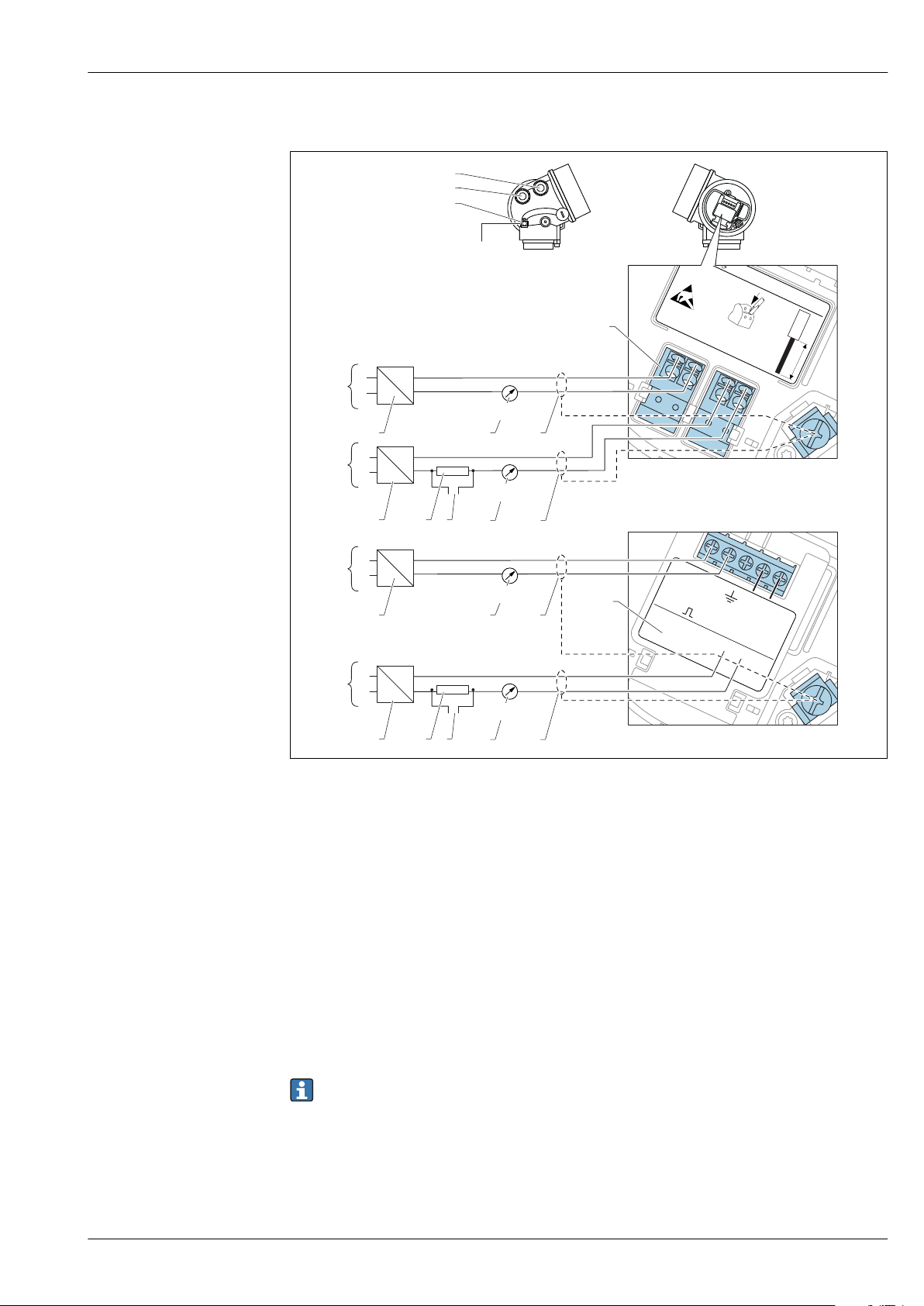

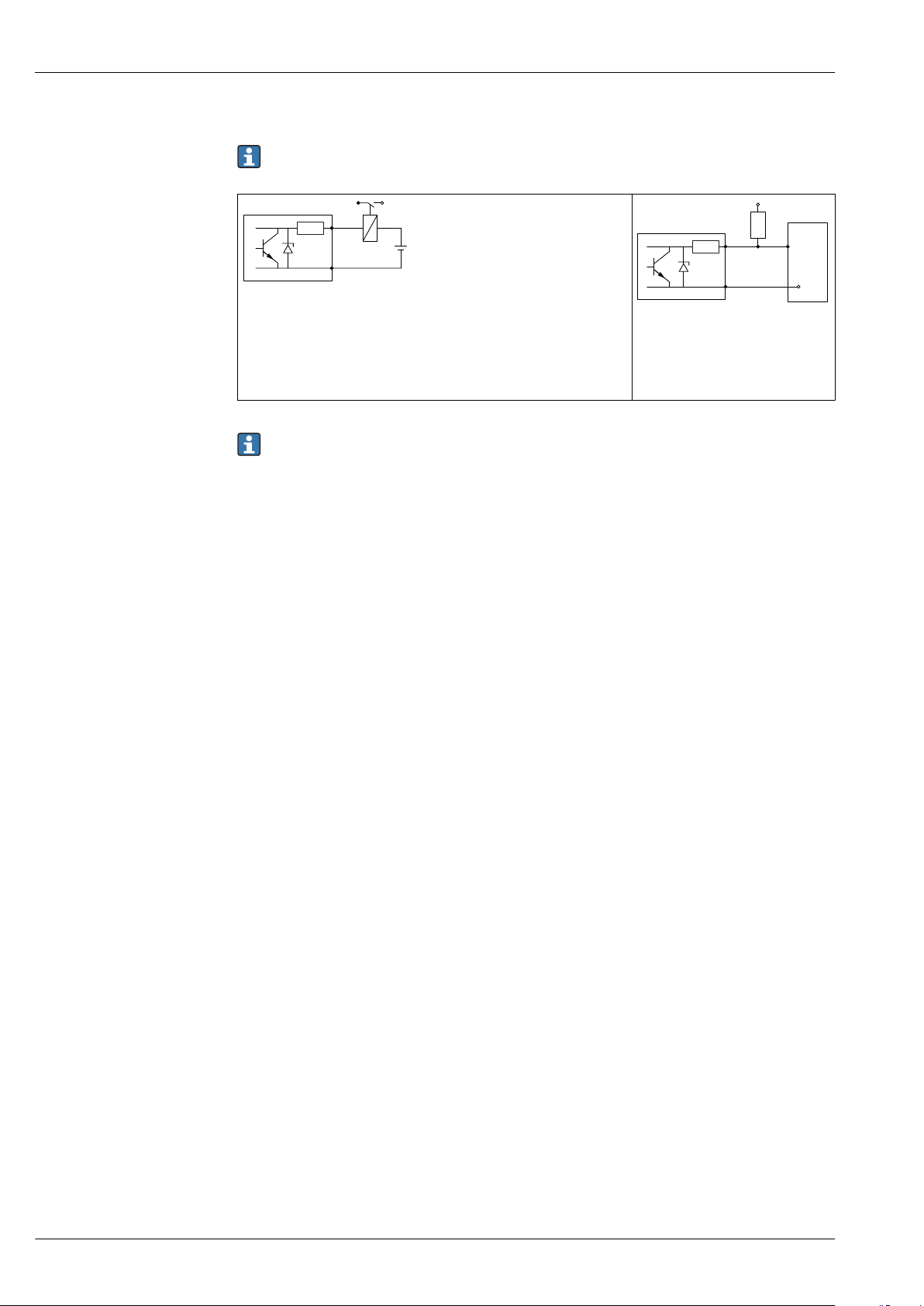

Connection examples for the switch output

For HART devices, the switch output is available as an option. See product structure, feature 20:

"Power Supply, Output", option B: "2-wire; 4-20mA HART, switch output"

A0015909

6 Connection of a relay

Suitable relays (examples):

• Solid-state relay: Phoenix Contact OV-24DC/480AC/5 with mounting

rail connector UMK-1 OM-R/AMS

• Electromechanical relay: Phoenix Contact PLC-RSC-12DC/21

For optimum interference immunity we recommend to connect an external resistor (internal

resistance of the relay or Pull-up resistor) of < 1 000 Ω.

7 Connection of a digital input

1 Pull-up resistor

2 Digital input

A0015910

16 V. 4, Rev. 1, 19-03-2018 Endress+Hauser

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT DRAFTDRAFT DRAFT DRAFT

Micropilot FMR67

2

1

3

4

4

2

3

1

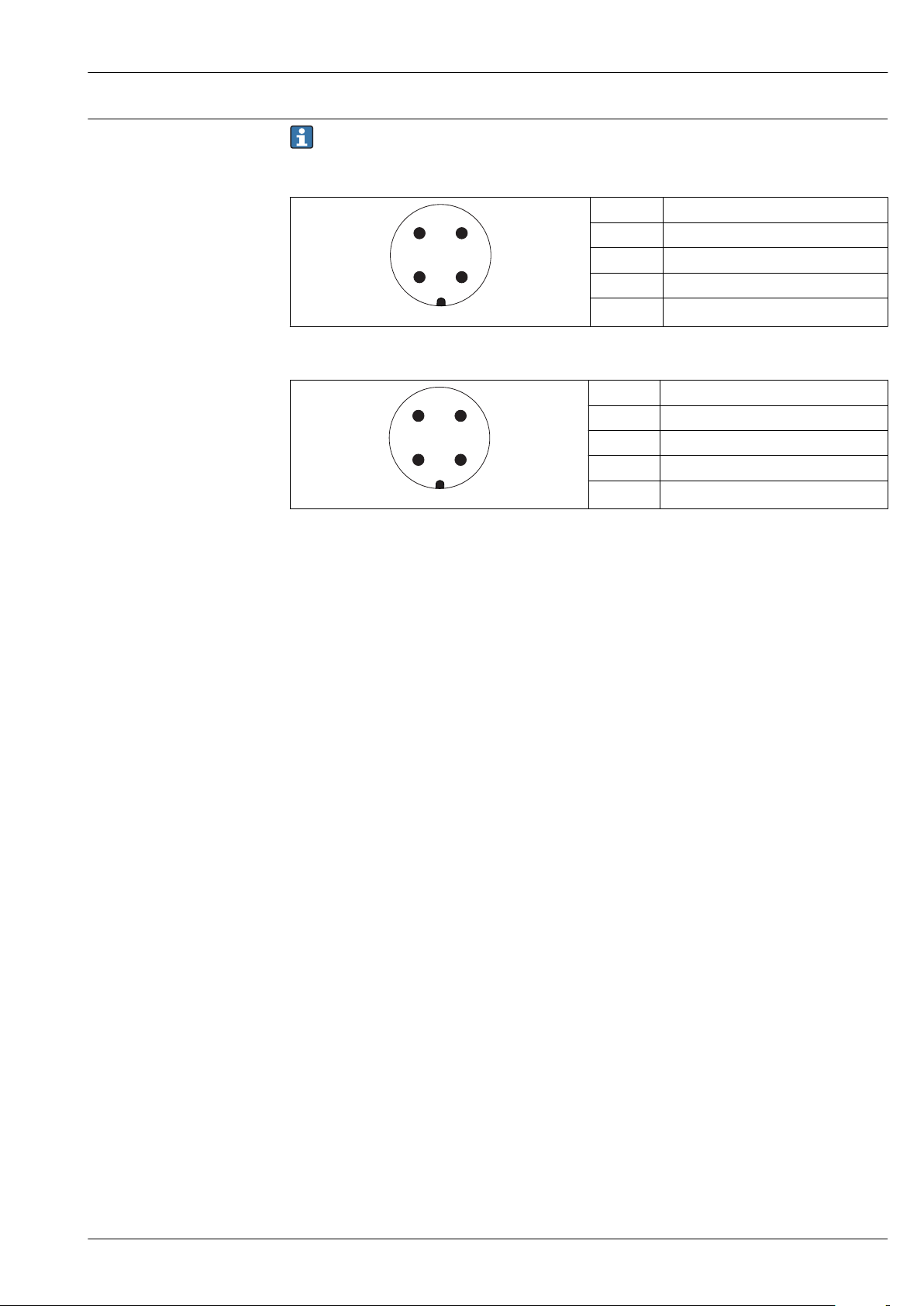

Device plug connectors

For the versions with fieldbus plug connector (M12 or 7/8"), the signal line can be connected

without opening the housing.

Pin assignment of the M12 plug connector

Pin Meaning

1 Signal +

2 not connected

3 Signal -

4 Ground

A0011175

Pin assignment of the 7/8" plug connector

Pin Meaning

1 Signal -

2 Signal +

3 Not connected

4 Screen

A0011176

Endress+Hauser V. 4, Rev. 1, 19-03-2018 17

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT DRAFTDRAFT DRAFT DRAFT

Micropilot FMR67

R [ ]W

U0[V]

10

14

25

20 30 35

0

500

R [ ]W

U0[V]

10

16

27

20 30 35

0

500

Supply voltage

An external power supply is necessary.

Various power supply units can be ordered as an accessory from Endress+Hauser.

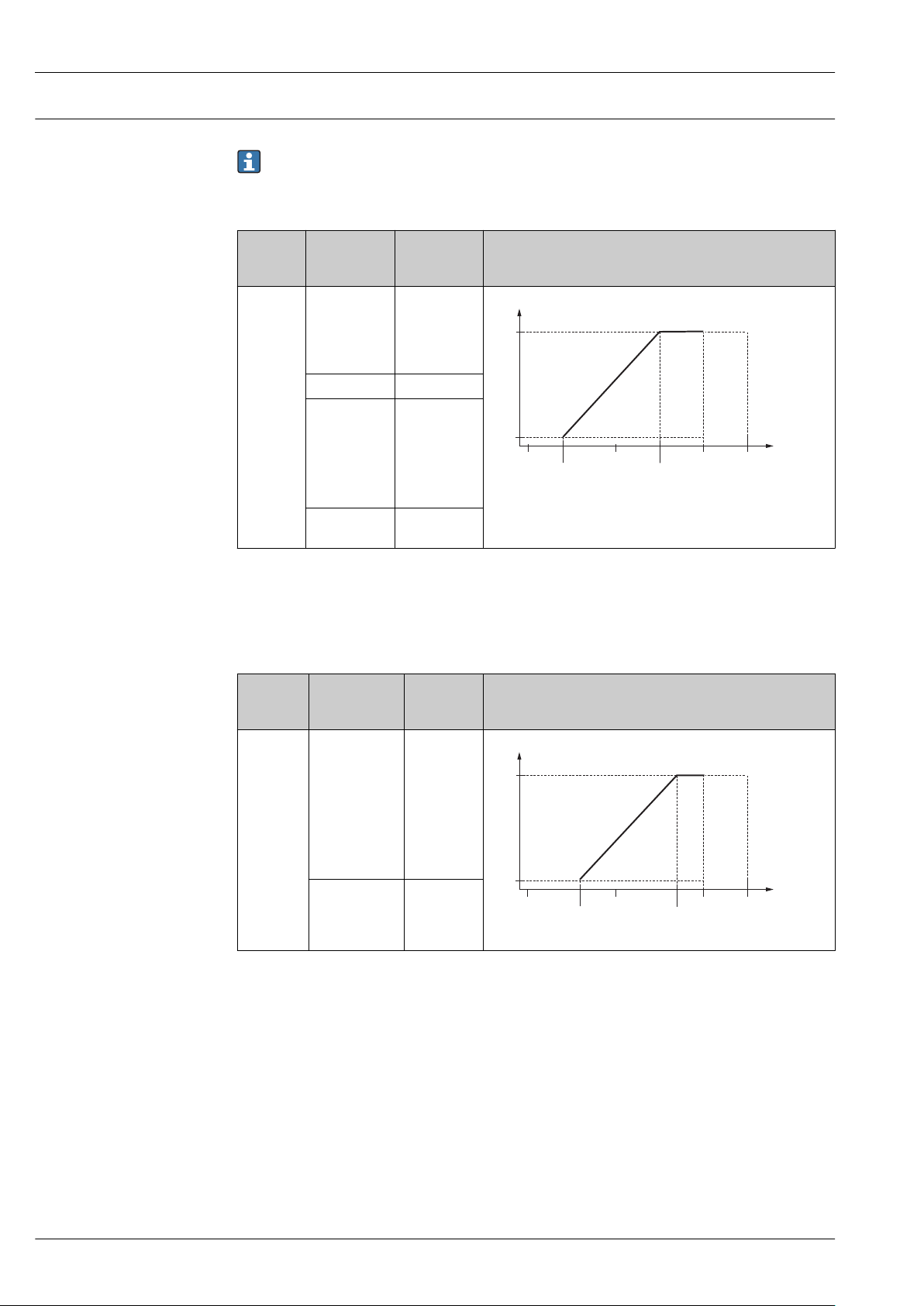

2-wire, 4-20mA HART, passive

"Power

supply,

output"

A:

2-wire;

4-20mA

HART

1) Feature 020 in the product structure

2) Feature 010 in the product structure

3) If the Bluetooth modem is used, the minimum supply voltage increases by 2 V.

4) At ambient temperatures TTa ≤ –20 °C, a terminal voltage U ≥ 16 V is required to start the device with the

"Approval"

1)

• Nonhazardous

• Ex nA

• Ex ic

• CSA GP

Ex ia / IS 14 to 30 V

• Ex d(ia) /

XP

• Ex ic(ia)

• Ex nA(ia)

• Ex ta / DIP

Ex ia + Ex

d(ia) / IS + XP

min. error current (3.6 mA).

2)

Terminal

voltage U at

device

14 to 35 V

14 to 35 V

14 to 30 V

Maximum load R,

depending on the supply voltage

U0 of the power supply unit

3)

3)

3) 4)

A0031745

3)

"Power

supply,

output"

B:

2-wire;

4-20 mA

HART,

switch

outpu

1) Feature 020 in the product structure

2) Feature 010 in the product structure

3) If the Bluetooth modem is used, the minimum supply voltage increases by 2 V.

"Approval"

1)

• Nonhazardous

• Ex nA

• Ex nA(ia)

• Ex ic

• Ex ic(ia)

• Ex d(ia) / XP

• Ex ta / DIP

• CSA GP

• Ex ia / IS

• Ex ia + Ex

d(ia) / IS +

XP

2)

Terminal

voltage U at

device

16 to 35 V

16 to 30 V

Maximum load R,

depending on the supply voltage

U0 of the power supply unit

3)

3)

A0031746

18 V. 4, Rev. 1, 19-03-2018 Endress+Hauser

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT DRAFTDRAFT DRAFT DRAFT

Micropilot FMR67

R [ ]W

U0[V]

10

16

27

20 30 35

0

500

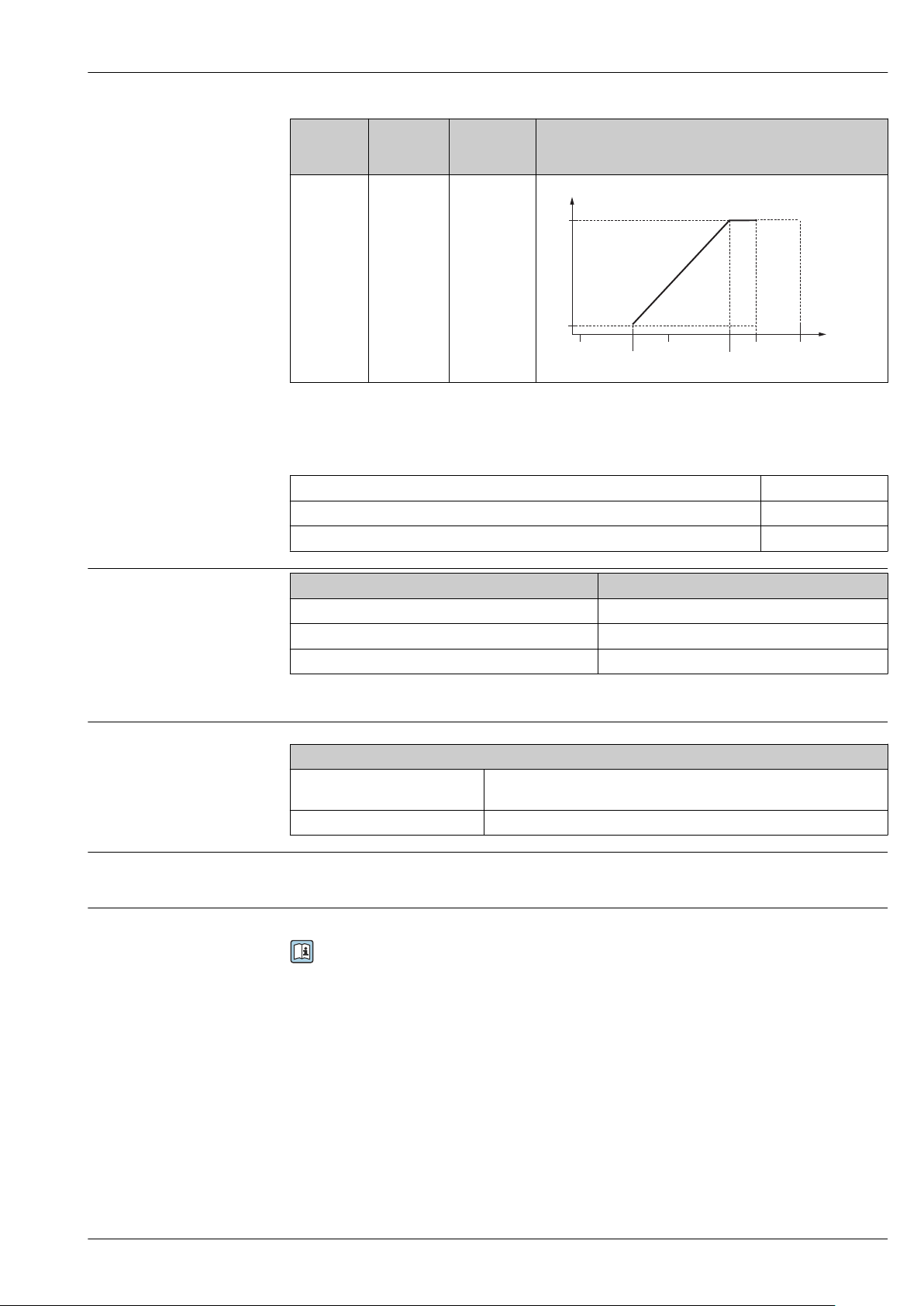

"Power

supply,

output"

C:

2-wire;

4-20mA

HART,

4-20mA

1) Feature 020 in the product structure

2) Feature 010 in the product structure

3) If the Bluetooth modem is used, the minimum supply voltage increases by 2 V.

Integrated polarity reversal protection Yes

Permitted residual ripple with f = 0 to 100 Hz USS < 1 V

Permitted residual ripple with f = 100 to 10 000 Hz USS < 10 mV

"Approval"

1)

All 16 to 30 V

2)

Terminal

voltage U at

device

Maximum load R,

depending on the supply voltage

U0 of the power supply unit

3)

A0031746

Power consumption

Current consumption

Power supply failure

Potential equalization

"Power supply; Output"

A: 2-wire; 4-20mA HART < 0.9 W

B: 2-wire; 4-20mA HART, switch output < 0.9 W

C: 2-wire; 4-20mA HART, 4-20mA < 2 x 0.7 W

1) Feature 020 of the product structure

HART

Nominal current 3.6 to 22 mA the start-up current for multidrop mode can be parametrized

Breakdown signal (NAMUR NE43) adjustable: 3.59 to 22.5 mA

1)

(is set to 3.6 mA on delivery)

Power consumption

• Configuration is retained in the HistoROM (EEPROM).

• Error messages (incl. value of operated hours counter) are stored.

No special measures for potential equalization are required.

If the device is designed for hazardous areas, observe the information in the documentation

"Safety Instructions" (XA).

Endress+Hauser V. 4, Rev. 1, 19-03-2018 19

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT DRAFTDRAFT DRAFT DRAFT

Cable entries Connection of power supply and signal line

To be selected in feature 050 "Electrical connection"

• Gland M20; Material dependent on the approval:

– For Non-Ex, ATEX, IECEx, NEPSI Ex ia/ic:

Plastics M20x1.5 for cable ⌀5 to 10 mm (0.2 to 0.39 in)

– For Dust-Ex, FM IS, CSA IS, CSA GP, Ex nA:

Metal M20x1.5 for cable ⌀7 to 10 mm (0.28 to 0.39 in)

– For Ex d:

No gland available

• Thread

– ½" NPT

– G ½"

– M20 × 1.5

• Plug M12 / Plug 7/8"

Only available for Non-Ex, Ex ic, Ex ia

Connection of remote display FHX50

Dependent on feature 030: "Display, Operation":

• "Prepared for display FHX50 + M12 connection":

M12 socket

• "Prepared for display FHX50 + custom connection":

M16 cable gland

Micropilot FMR67

1)

Cable specification

Overvoltage protection

• Devices without integrated overvoltage protection

Pluggable spring-force terminals for wire cross-sections 0.5 to 2.5 mm2 (20 to 14 AWG)

• Devices with integrated overvoltage protection

Screw terminals for wire cross-sections 0.2 to 2.5 mm2 (24 to 14 AWG)

• For ambient temperature TU≥60 °C (140 °F): use cable for temperature TU +20 K.

HART

• A normal device cable suffices if only the analog signal is used.

• A shielded cable is recommended if using the HART protocol. Observe grounding concept of the

plant.

If the measuring device is used for level measurement in flammable liquids which requires the use of

overvoltage protection according to DIN EN 60079-14, standard for

test procedures 60060-1 (10 kA, pulse 8/20 μs), an overvoltage protection module has to be

installed.

Integrated overvoltage protection module

An integrated overvoltage protection module is available for 2-wire HART devices.

Product structure: Feature 610 "Accessory mounted", option NA "Overvoltage protection".

Technical data

Resistance per channel 2 × 0.5 Ω max.

Threshold DC voltage 400 to 700 V

Threshold impulse voltage < 800 V

Capacitance at 1 MHz < 1.5 pF

Nominal arrest impulse voltage (8/20 μs) 10 kA

External overvoltage protection module

HAW562 or HAW569 from Endress+Hauser are suited as external overvoltage protection.

1) The material of the gland is dependent on the housing type; GT18 (stainless steel housing): 316L (1.4404); GT19 (plastic housing) and GT20

(aluminum housing): nickel-coated brass (CuZn).

20 V. 4, Rev. 1, 19-03-2018 Endress+Hauser

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT DRAFTDRAFT DRAFT DRAFT

Micropilot FMR67

1.5 (4.92)

20 (0.79)

3 (0.12)

-3 (-0.12)

-20 (-0.79)

D [m (!)]

∆

[mm (in)]

R

0

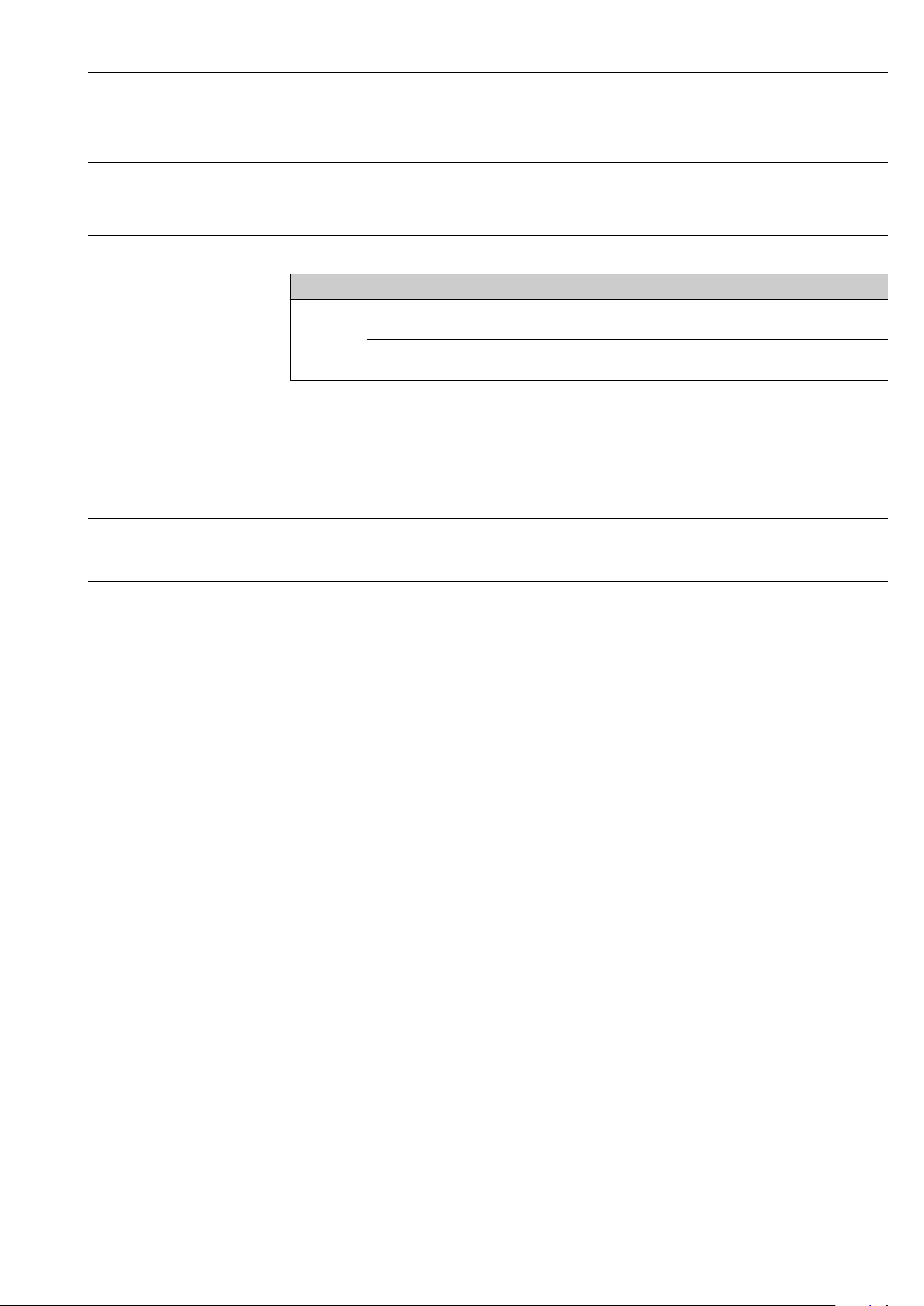

Performance characteristics

Reference operating conditions

Reference accuracy

• Temperature = +24 °C (+75 °F) ±5 °C (±9 °F)

• Pressure = 960 mbar abs. (14 psia) ±100 mbar (±1.45 psi)

• Humidity = 60 % ±15 %

• Reflector: metal plate with diameter ≥ 1 m (40 in)

• No major interference reflections inside the signal beam

Typical data under reference operating conditions: DIN EN IEC 61298-2 / DIN EN IEC 60770-1;

percentage values in relation to the span.

Output: digital analog

Accuracy (Sum of nonlinearity, nonrepeatability

and hysteresis)

Non-repeatability

1) Add error of the analogous value to the digital value.

2) If the reference conditions are not met, the offset/zero point arising from the mounting conditions may be

up to ±4 mm (0.16 in). This additional offset/zero point can be compensated for by entering a correction

(parameter "level correction") during commissioning.

3) The non-repeatability is already considered in the accuracy.

2)

3)

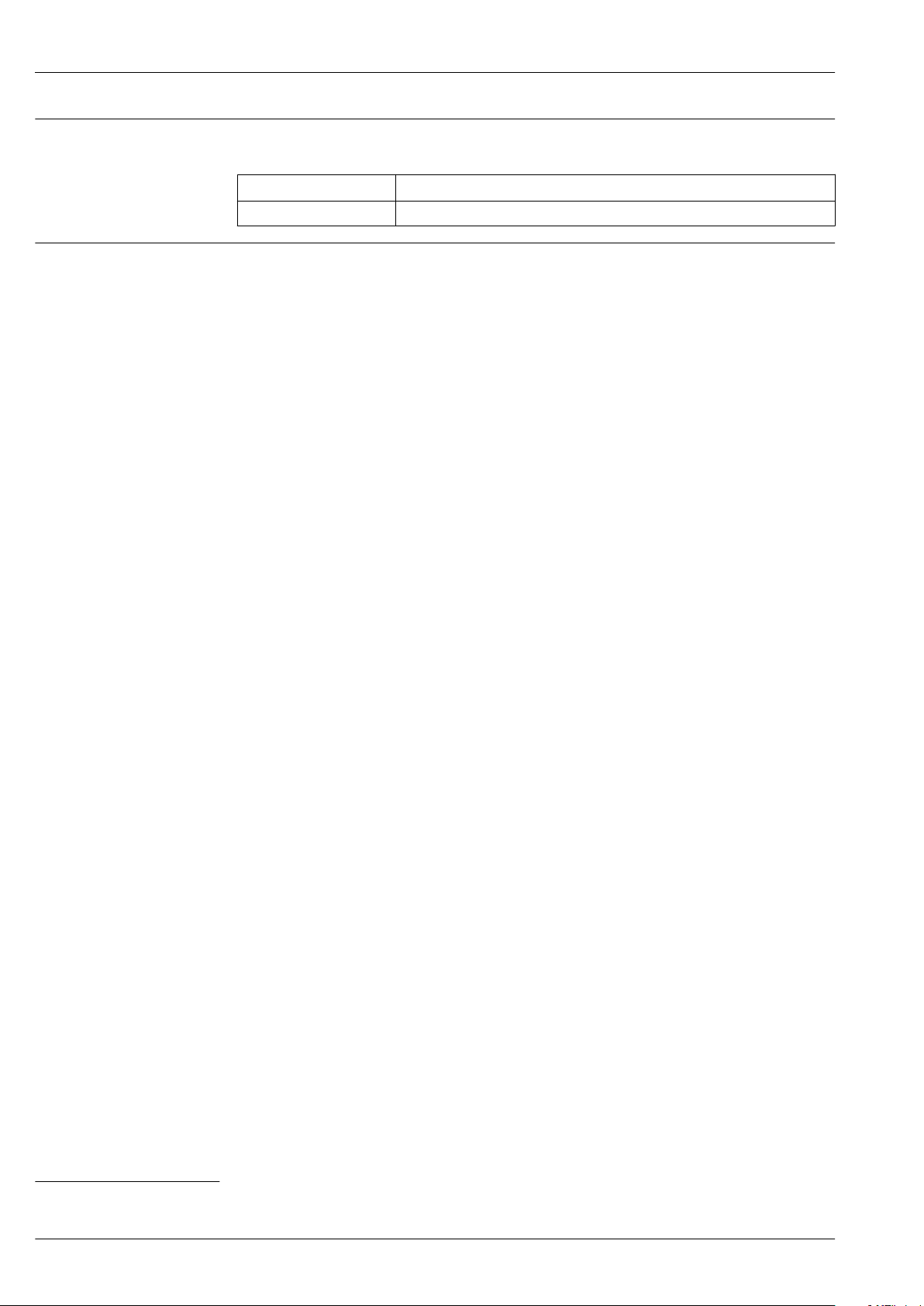

Measuring distance up to 1.5 m (4.92 ft): max.

±20 mm (±0.79 in)

Measuring distance > 1.5 m (4.92 ft): ±3 mm (±0.12 in) ±0.02 %

≤ 1 mm (0.04 in)

1)

±0.02 %

The devices are optimized for bulk solid applications on delivery. An additional reference

condition for the accuracy specifications of bulk solid applications is Bin type = Workbench

test

Differing values in near-range applications

A0032637

8 Maximum measured error in near-range applications

Δ Maximum measured error

R Reference point of the distance measurement

D Distance from reference point of antenna

Measured value resolution

Dead band according to DIN EN IEC 61298-2 / DIN EN IEC 60770-1:

• Digital: 1 mm

• Analog: 1 µA

Endress+Hauser V. 4, Rev. 1, 19-03-2018 21

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT DRAFTDRAFT DRAFT DRAFT

Micropilot FMR67

Response time

Influence of ambient temperature

The response time can be configured. The following step response times (in accordance with

DIN EN IEC 61298-2 / DIN EN IEC 60770-1)

Sampling rate

Response time < 3.6 s

The measurements are performed according to DIN EN IEC 61298-3 / DIN EN IEC 60770-1

• Digital (HART): average TK = 3 mm/10 K

• Analog (current output):

– Zero point (4 mA): average TK = 0.02 %/10 K

– Span (20 mA): average TK = 0.05 %/10 K

≥1.3 s–1 at U ≥ 24 V

2)

are when damping is switched off:

2) According to DIN EN IEC 61298-2 / DIN EN IEC 60770-1, the step response time is the time that elapses after an abrupt change in the input

signal until the change in the output signal has adopted 90% of the steady-state value for the first time.

22 V. 4, Rev. 1, 19-03-2018 Endress+Hauser

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT DRAFTDRAFT DRAFT DRAFT

Micropilot FMR67

A

1 2 3

Installation

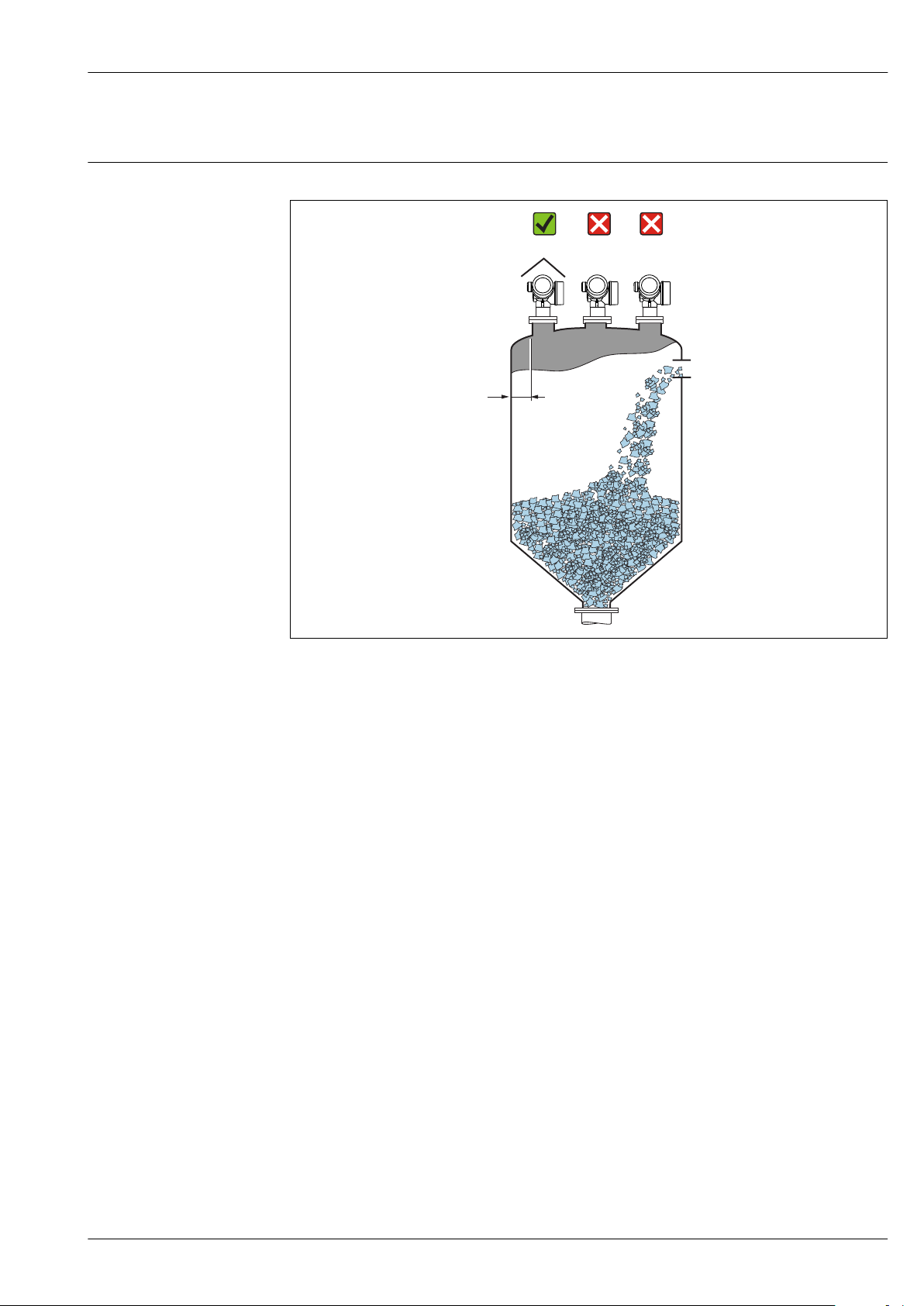

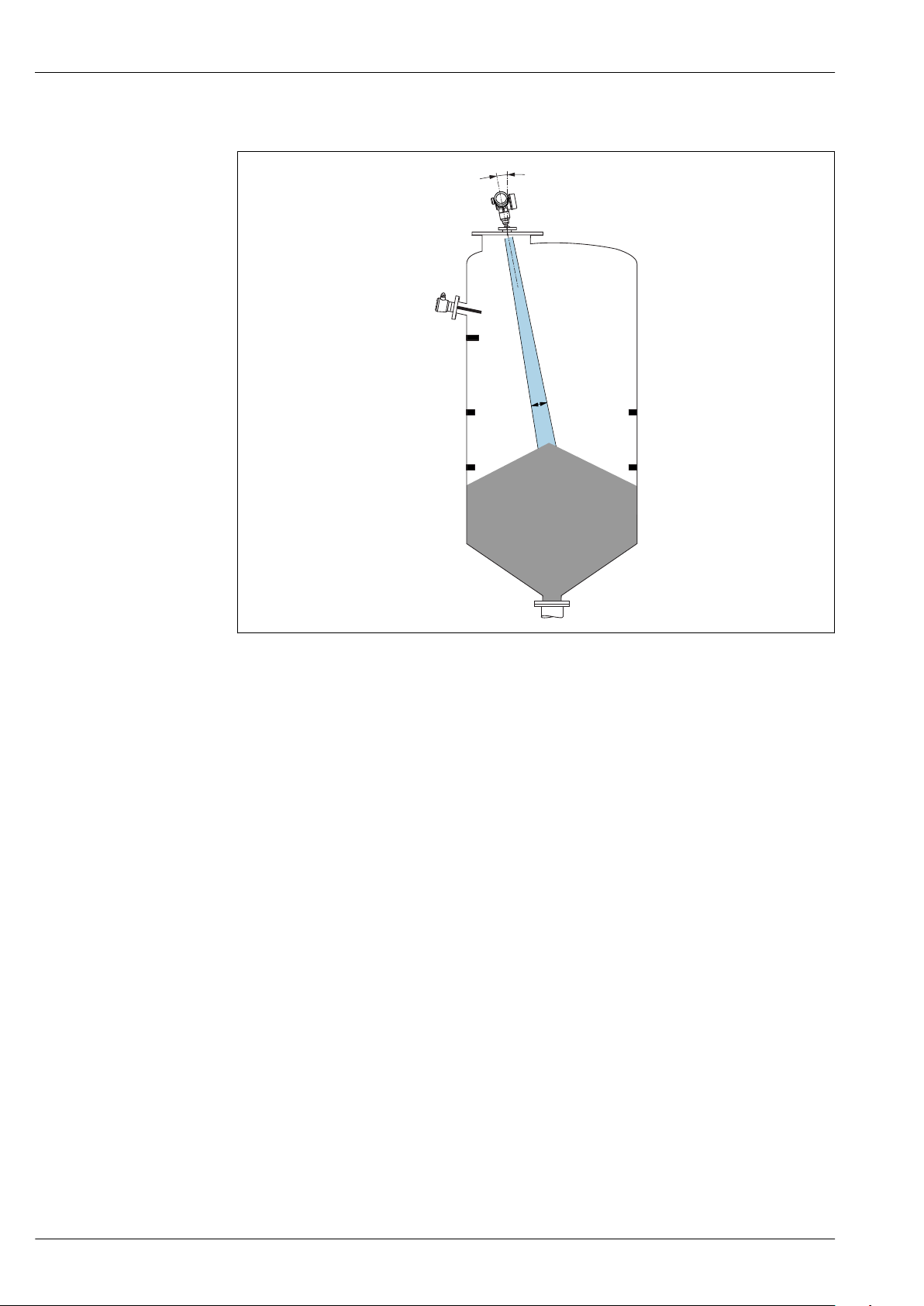

Installation conditions Mounting position

A0016883

• Recommended distance A wall - nozzle outer edge: ~ 1/6 of the container diameter. However, the

device must not under any circumstances be mounted closer than 20 cm (7.87 in) to the container

wall.

If the container wall is not smooth (corrugated iron, welding seams, joints, etc.) it is recommended

to maintain the largest possible distance from the wall. Where necessary use an alignment unit to

avoid interference reflections from the container wall.→ 28

• Not in the center (2) as interference can cause signal loss.

• Not above the filling curtain (3).

• The use of a weather protection cover (1) is recommended to protect the transmitter from direct

sunlight or rain.

• In applications with strong dust emissions, the integrated purge air connection can prevent the

antenna from becoming clogged → 30.

Endress+Hauser V. 4, Rev. 1, 19-03-2018 23

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT DRAFTDRAFT DRAFT DRAFT

Internal container fittings

α

β

Micropilot FMR67

A0031814

Avoid the location of internal fittings (limit switches, temperature sensors, struts etc.) inside the

signal beam. Pay attention to the beam angle → 26.

24 V. 4, Rev. 1, 19-03-2018 Endress+Hauser

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT DRAFTDRAFT DRAFT DRAFT

Micropilot FMR67

β

α

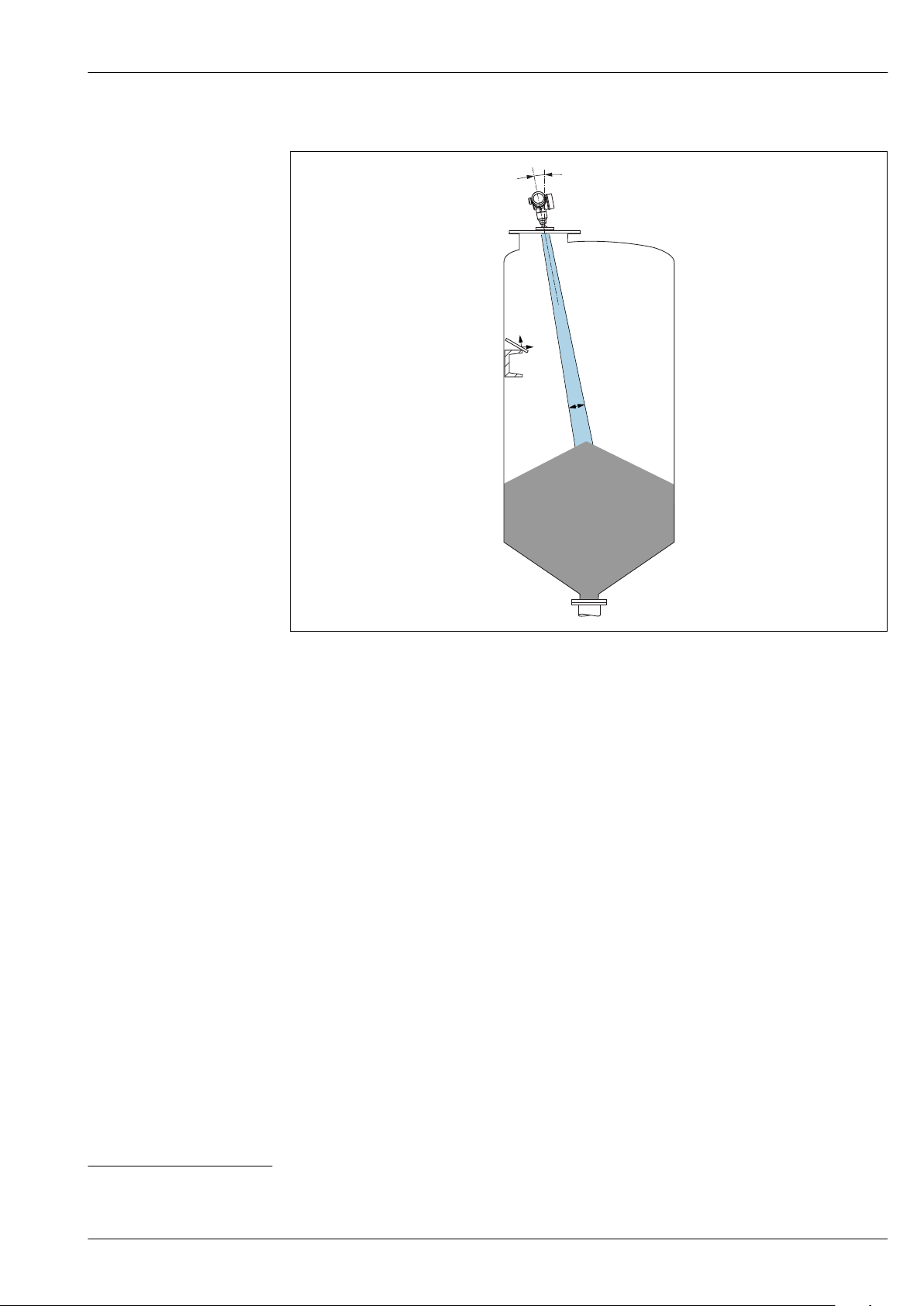

Avoiding interference echoes

A0031817

Metal deflection plates installed at an angle to scatter the radar signals help prevent interference

echoes.

Optimization options

• Antenna size

The larger the antenna the smaller the beam angle α,resulting in fewer interference echoes

→ 26.

• Mapping

Measurement can be optimized by electronically suppressing interference echoes.

• Adjustable flange seal for FMR67

Adjustable flange seals of sizes DN80 to DN150 (3" to 6") are available for the FMR67 with Dripoff antenna

3)

. They can be used to align the device to the product surface. Maximum angle of

alignment: 8 °.

How to order:

– Order with the device

4)

– Order as an accessory: → 77

• Alignment unit for FMR67

Flanges sized 4" / DN100 and higher are optionally available with an alignment unit

5)

They allow

the sensor to be optimally aligned to suit conditions in the container in order to prevent

interference reflections. The maximum angle is ±15 °.

The purpose of sensor alignment is primarily to:

– Prevent interference reflections

– Increase the maximum possible measuring range in conical outlets

3) Feature 070 in the product structure "Antenna", option GA

4) Feature 100 in the product structure "Process connection", options PL, PM, PN, PO, PQ, PR

5) see feature 100 in the product structure "Process connection".

Endress+Hauser V. 4, Rev. 1, 19-03-2018 25

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT DRAFTDRAFT DRAFT DRAFT

Micropilot FMR67

D

W

D

_

=

2

2

. .

tan

W

α

α

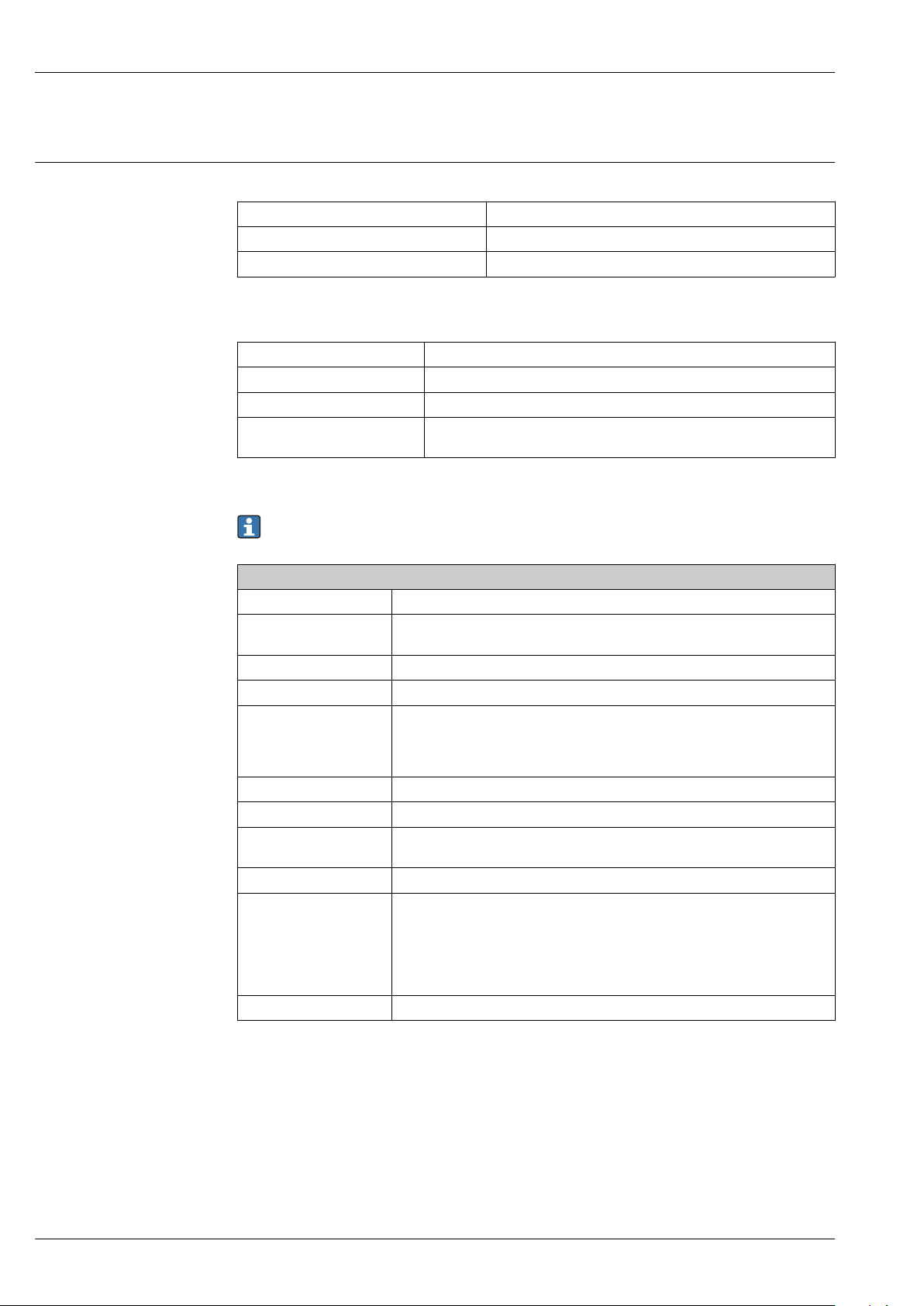

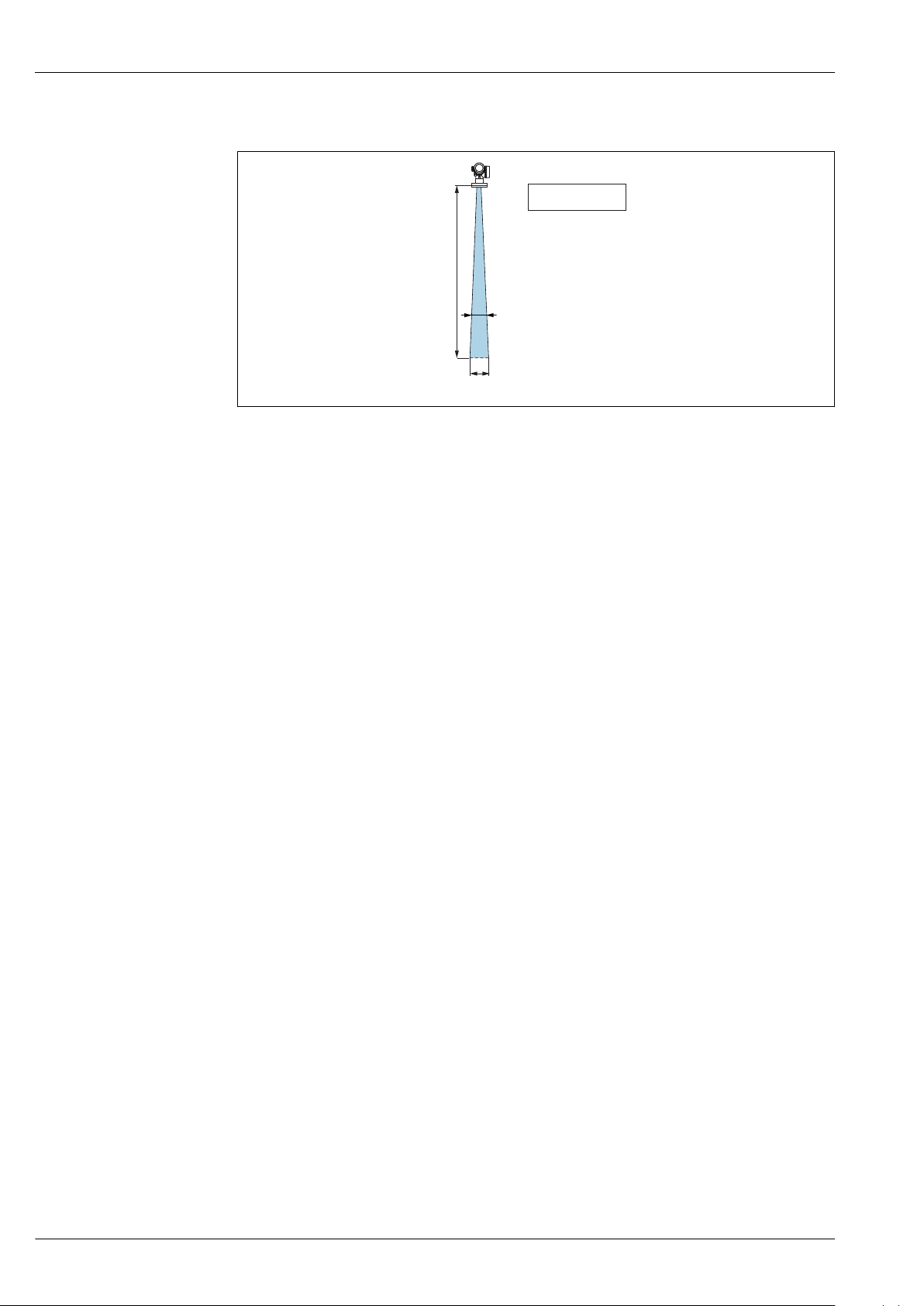

Beam angle

A0031824

9 Relationship between beam angle α, distance D and beamwidth diameter W

The beam angle is defined as the angle α where the energy density of the radar waves reaches half

the value of the maximum energy density (3dB width). Microwaves are also emitted outside the

signal beam and can be reflected off interfering installations.

26 V. 4, Rev. 1, 19-03-2018 Endress+Hauser

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT DRAFTDRAFT DRAFT DRAFT

Micropilot FMR67

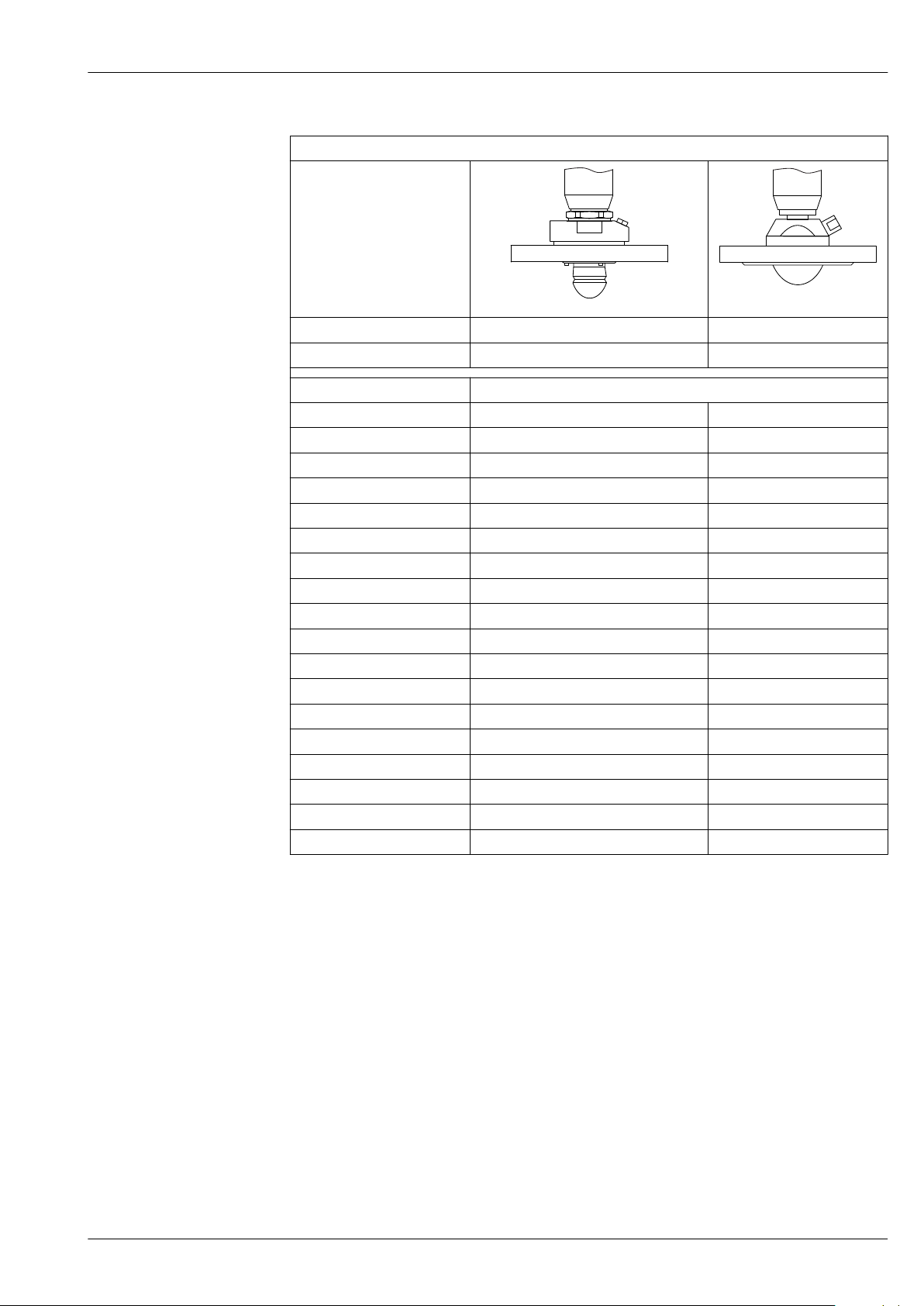

FMR67

A0032083

Antenna

Beam angle α 6 ° 4 °

Distance (D) Beamwidth diameter W

5 m (16 ft) 0.52 m (1.70 ft) 0.35 m (1.15 ft)

10 m (33 ft) 1.05 m (3.44 ft) 0.70 m (2.30 ft)

15 m (49 ft) 1.57 m (5.15 ft) 1.05 m (3.44 ft)

20 m (66 ft) 2.10 m (6.89 ft) 1.40 m (4.59 ft)

25 m (82 ft) 2.62 m (8.60 ft) 1.75 m (5.74 ft)

30 m (98 ft) 3.14 m (10.30 ft) 2.10 m (6.89 ft)

35 m (115 ft) 3.67 m (12.04 ft) 2.44 m (8.00 ft)

40 m (131 ft) 4.19 m (13.75 ft) 2.79 m (9.15 ft)

45 m (148 ft) 4.72 m (15.49 ft) 3.14 m (10.30 ft)

50 m (164 ft) 5.24 m (17.19 ft) 3.49 m (11.45 ft)

60 m (197 ft) - 4.19 m (13.75 ft)

70 m (230 ft) - 4.89 m (16.04 ft)

80 m (262 ft) - 5.59 m (18.34 ft)

90 m (295 ft) - 6.29 m (20.64 ft)

100 m (328 ft) - 6.98 m (22.90 ft)

110 m (361 ft) - 7.68 m (25.20 ft)

120 m (394 ft) - 8.38 m (27.49 ft)

125 m (410 ft) - 8.73 m (25.64 ft)

1)

Drip-off, PTFE 50 mm / 2" PTFE flush mount 80 mm / 3"

A0032084

1) Feature 070 in the product structure

Measuring through plastic tank ceilings or dielectric windows

• Dielectric constant of the medium: εr ≥ 10

• The distance from the lower edge of the antenna to the tank ceiling or window should be about

100 mm (4 in).

• If possible, avoid mounting locations where condensation or build-up might occur.

• In case of outdoor mounting, the space between antenna and vessel has to be protected from the

elements.

• Do not mount any potential reflectors (e.g. pipes) outside the tank in the signal beam.

Endress+Hauser V. 4, Rev. 1, 19-03-2018 27

Loading...

Loading...