Endress and Hauser and Co FMR25X Users Manual

Operating Instructions

Micropilot M FMR250

Level-Radar

6

BA284F/00/en/08.04

Nr. 52025089

Valid as of software version:

V 01.01.00 (amplifier)

V 01.01.00 (communication)

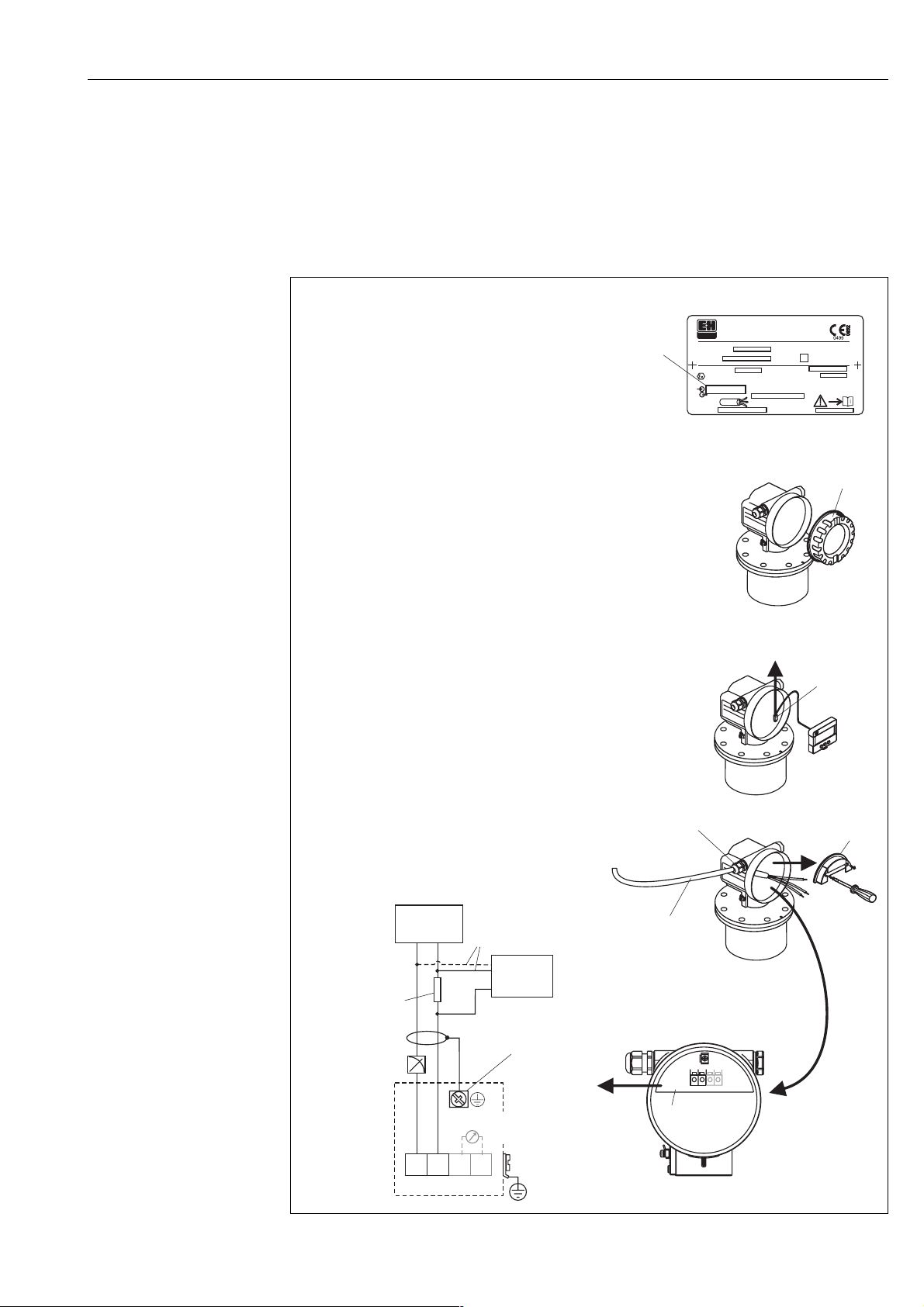

Micropilot M FMR250 with HART/4...20 mA

Brief overview

For quick and simple commissioning:

Safety Instructions

Explanation of the warning symbols

You can find special instructions at the appropriate position in the chapter in

question. The positions are indicated with the icons Warning #, Caution " and

Note !.

Æ

Installation

The steps for installing the device and installation conditions (e.g. dimensions)

can be found here.

Æ

Wiring

The device is virtually completely wired on delivery. → Page 25 ff.

Æ

Display and Operating Elements

An overview of the position of the display and operating elements can be found

here.

→ Page 6 ff.

→ Page 11 ff.

→ Page 33 ff.

Æ

Commissioning

In the "Commissioning" section, you learn how to switch on the device and

check the functioning.

Æ

Commissioning via Display VU 331

In the "Operating" section, you become familiar with the operating elements

and the various setting options.

Basic Setup with the VU331.

Æ

Commissioning via Operating Software ToF Tool

Basic Setup with the ToF Tool.

Additional information on the operation of the ToF Tool can be found in the

operating instructions BA224F/00, which can be found on the enclosed

CD-ROM.

Æ

Fault Tracking / Trouble Shooting

If faults occur during operation, use the checklist to localise the cause.

Here you can find measures you can take yourself to take remedial action

against the fault.

→ Page 41 ff.

→ Page 31 ff.

→ Page 44 ff.

→ Page 59 ff.

→ Page 66 ff.

Æ

Index

You can find important terms and keywords on the individual sections here.

Use the keyword index to find quickly and efficiently the information you need.

2 Endress + Hauser

→ Page 92 ff.

Micropilot M FMR250 with HART/4...20 mA

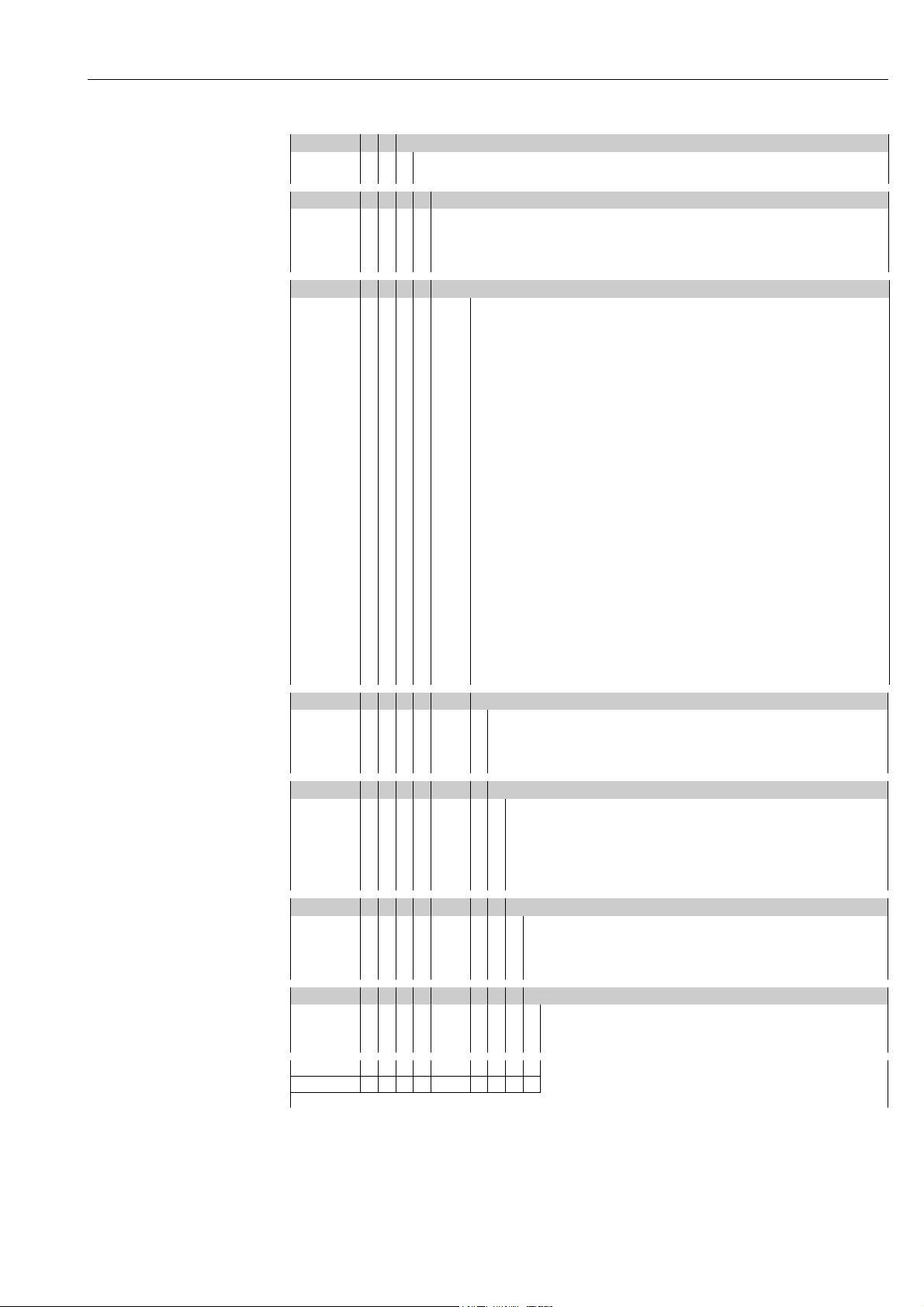

Brief operating instructions

KA 235F/00/a2/08.04

52025245

000

measured

value

E

+

-

Group

selection

00

basic

+

setup

01

safety

settings

04

linearisation

05

extended

calibr.

06

output

09

display

0E

envelope

curve

-

0A

diagnostics

0C

system parameter

001

media

type

- liquid

- solid

092

language

0E1

plot settings

- envel. curve

- incl. FAC

- incl. cust. map

0A0

present error

00A

vessel /

silo

- unknown

- metal silo

- concrete

silo

- bin / bunker

…

Micropilot M FMR250 - Brief operating instructions

Contrast: +or +

+

-

002

002

tank

tank

shape

shape

- dome

ceiling

- horizontal

cyl.

- bypass

…

00B

medium

cond.

- unknown

- DC: 1.6...1.9

- DC: 1.9 …2.5

- DC: 2.5 …4

...

… …

0E2

recording

curve

- single curve

- cyclic

0A1

previous error

003

medium

cond.

- unknown

- DC: <1.9

- DC: 1.9 … 4

- DC: 4 … 10

- DC: >10

00C

proscess

cond.

- standard

- fast change

- slow change

- test: no filter

… …

004

process

cond.

…

005

empty

calibr.

input E

(see sketch)

input E

(see sketch)

- standard

- calm

surface

- add.

agitator

0A4

unlock parameter

= 100: unlocked

100: locked≠

005

empty

calibr.

006

full

calibr.

input F

(see sketch)

flange:

referencepoint of

measurement

… …

HART

}

006

full

calibr.

input F

(see sketch)

threaded

connection

1 ½” (R 1

or 1½ NPT

reference point of

measurement

only for

bypass +

stilling well

BSPT ½”)

:

007

pipe

diameter

E

008

dist./

meas value

D and L are

displayed

(see sketch)

flange:

referencepoint of

measurement

E

F

051

check

distance

- ok

- too small

- too big

- unknown

- manual

D

L

008

E

dist./

052

range of

mapping

confirm

suggestion

or specify

range

meas value

053

start

mapping

20 mA

100%

4mA

0%

E

52025245

!

L00-FMR250xx-19-00-00-en-020

Note!

This operating manual explains the installation and initial start-up for the level transmitter. All

functions that are required for a typical measuring task are taken into account here. In addition, the

Micropilot M provides many other functions that are not included in this operating manual, such as

optimising the measuring point and converting the measured values.

An overview of all device functions can be found on Page 86.

The operating manual BA291F/00/en "Description of the instrument functions for Micropilot M"

provides an extensive description of all device functions, which can be found on the enclosed

CD-ROM.

Endress + Hauser 3

Micropilot M FMR250 with HART/4...20 mA

4 Endress + Hauser

Micropilot M FMR250 with HART/4...20 mA Table of contents

Table of contents

1 Safety instructions . . . . . . . . . . . . . . . . 6

1.1 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Installation, commissioning and operation . . . . . . . . 6

1.3 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4 Notes on safety conventions and symbols . . . . . . . . . 7

2 Identification . . . . . . . . . . . . . . . . . . . . 8

2.1 Device designation . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 Certificates and approvals . . . . . . . . . . . . . . . . . . . 10

2.4 Registered trademarks . . . . . . . . . . . . . . . . . . . . . . 10

3 Installation . . . . . . . . . . . . . . . . . . . . . 11

3.1 Quick installation guide . . . . . . . . . . . . . . . . . . . . . 11

3.2 Incoming acceptance, transport, storage . . . . . . . . . 11

3.3 Installation conditions . . . . . . . . . . . . . . . . . . . . . . 12

3.4 Installation instructions . . . . . . . . . . . . . . . . . . . . . 19

3.5 Post-installation check . . . . . . . . . . . . . . . . . . . . . . 24

4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . 25

4.1 Quick wiring guide . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2 Connecting the measuring unit . . . . . . . . . . . . . . . 27

4.3 Recommended connection . . . . . . . . . . . . . . . . . . 30

4.4 Degree of protection . . . . . . . . . . . . . . . . . . . . . . . 30

4.5 Post-connection check . . . . . . . . . . . . . . . . . . . . . . 30

9.7 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

9.8 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

9.9 Software history . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

9.10 Contact addresses of Endress+Hauser . . . . . . . . . . . 81

10 Technical data . . . . . . . . . . . . . . . . . . . 82

10.1 Additional technical data . . . . . . . . . . . . . . . . . . . . 82

11 Appendix. . . . . . . . . . . . . . . . . . . . . . . 86

11.1 Operating menu HART (display modul), ToF Tool . 86

11.2 Description of functions . . . . . . . . . . . . . . . . . . . . . 88

11.3 Function and system design . . . . . . . . . . . . . . . . . . 89

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

5 Operation. . . . . . . . . . . . . . . . . . . . . . 31

5.1 Quick operation guide . . . . . . . . . . . . . . . . . . . . . . 31

5.2 Display and operating elements . . . . . . . . . . . . . . . 33

5.3 Local operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.4 Display and acknowledging error messages . . . . . . 38

5.5 HART communication . . . . . . . . . . . . . . . . . . . . . . 39

6 Commissioning. . . . . . . . . . . . . . . . . . 41

6.1 Function check . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.2 Switching on the measuring device . . . . . . . . . . . . 41

6.3 Basic Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.4 Basic Setup with the VU331 . . . . . . . . . . . . . . . . . 44

6.5 Basic Setup with the ToF Tool . . . . . . . . . . . . . . . . 59

7 Maintenance. . . . . . . . . . . . . . . . . . . . 63

8 Accessories. . . . . . . . . . . . . . . . . . . . . 64

9 Trouble-shooting . . . . . . . . . . . . . . . . 66

9.1 Trouble-shooting instructions . . . . . . . . . . . . . . . . 66

9.2 System error messages . . . . . . . . . . . . . . . . . . . . . . 67

9.3 Application errors in liquids . . . . . . . . . . . . . . . . . . 69

9.4 Application errors in solids . . . . . . . . . . . . . . . . . . . 71

9.5 Orientation of the Micropilot . . . . . . . . . . . . . . . . . 73

9.6 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Endress + Hauser 5

Safety instructions Micropilot M FMR250 with HART/4...20 mA

1 Safety instructions

1.1 Designated use

The Micropilot M FMR250 is a compact level radar for the continuous, contactless measurement of

predominantly solids. The device can also be freely mounted outside closed metal vessels because

of its operating frequency of about 26 GHz and a maximum radiated pulsed energy of 1mW

(average power output 1 µW). Operation is completely harmless to humans and animals.

1.2 Installation, commissioning and operation

The Micropilot M has been designed to operate safely in accordance with current technical, safety

and EU standards. If installed incorrectly or used for applications for which it is not intended,

however, it is possible that application-related dangers may arise, e.g. product overflow due to

incorrect installation or calibration. For this reason, the instrument must be installed, connected,

operated and maintained according to the instructions in this manual: personnel must be authorised

and suitably qualified. The manual must have been read and understood, and the instructions

followed. Modifications and repairs to the device are permissible only when they are expressly

approved in the manual.

1.3 Operational safety

1.3.1 Hazardous areas

Measuring systems for use in hazardous environments are accompanied by separate "Ex

documentation", which is an integral part of this Operating Manual. Strict compliance with the

installation instructions and ratings as stated in this supplementary documentation is mandatory.

• Ensure that all personnel are suitably qualified.

• Observe the specifications in the certificate as well as national and local standards and regulations.

1.3.2 FCC approval

This device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause

undesired operation.

Caution!

"

Changes or modifications not expressly approved by the part responsible for

compliance could void the user’s authority to operate the equipment.

6 Endress + Hauser

Micropilot M FMR250 with HART/4...20 mA Safety instructions

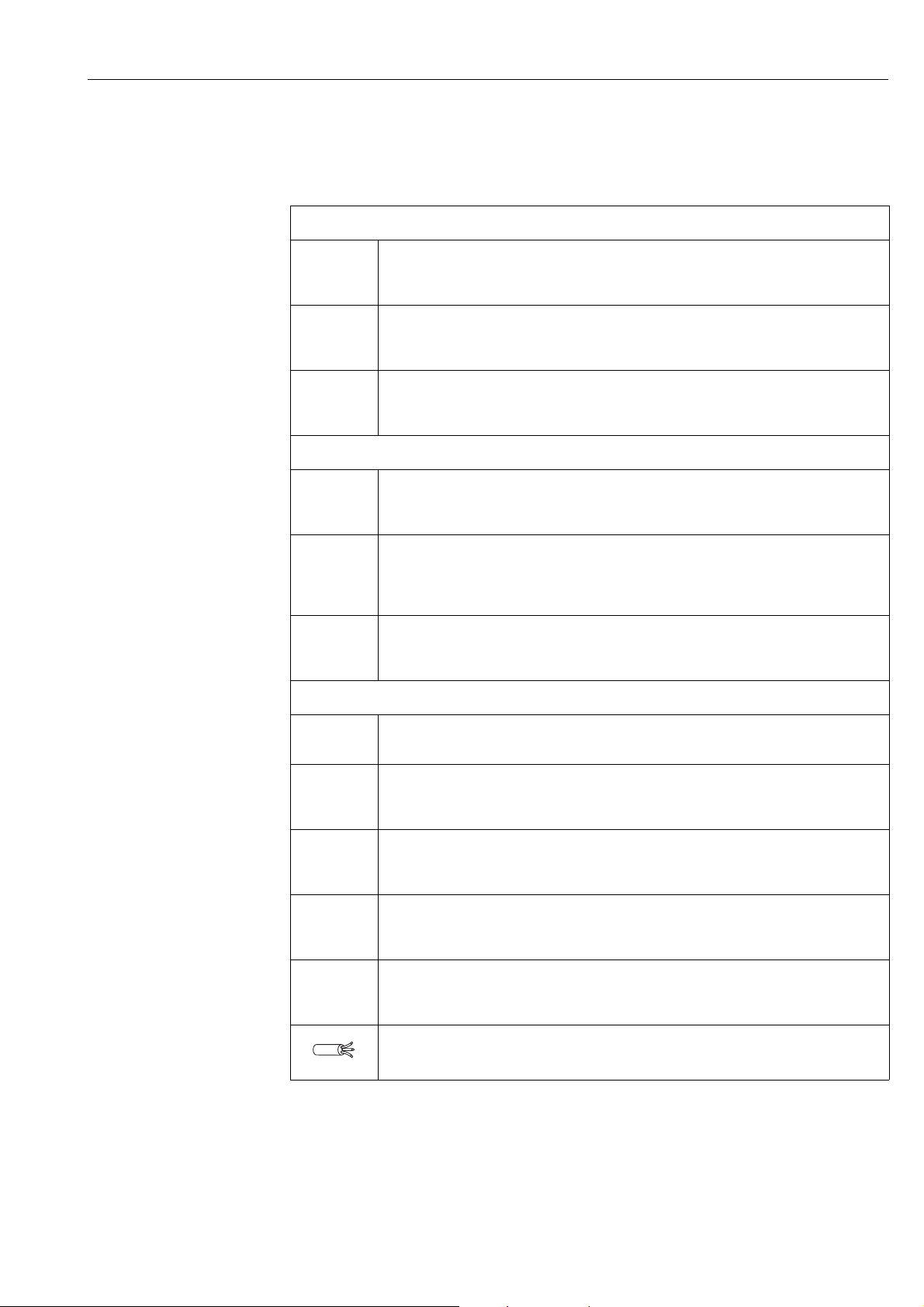

1.4 Notes on safety conventions and symbols

In order to highlight safety-relevant or alternative operating procedures in the manual, the following

conventions have been used, each indicated by a corresponding symbol in the margin.

Safety conventions

Warning!

#

"

!

Explosion protection

0

A warning highlights actions or procedures which, if not performed correctly, will lead to personal

injury, a safety hazard or destruction of the instrument

Caution!

Caution highlights actions or procedures which, if not performed correctly, may lead to personal

injury or incorrect functioning of the instrument

Note!

A note highlights actions or procedures which, if not performed correctly, may indirectly affect

operation or may lead to an instrument response which is not planned

Device certified for use in explosion hazardous area

If the device has this symbol embossed on its name plate it can be installed in an explosion hazardous

area

-

.

Electrical symbols

%

&

)

*

+

Explosion hazardous area

Symbol used in drawings to indicate explosion hazardous areas. Devices located in and wiring

entering areas with the designation “explosion hazardous areas” must conform with the stated type

of protection.

Safe area (non-explosion hazardous area)

Symbol used in drawings to indicate, if necessary, non-explosion hazardous areas. Devices located in

safe areas still require a certificate if their outputs run into explosion hazardous areas

Direct voltage

A terminal to which or from which a direct current or voltage may be applied or supplied

Alternating voltage

A terminal to which or from which an alternating (sine-wave) current or voltage may be applied or

supplied

Grounded terminal

A grounded terminal, which as far as the operator is concerned, is already grounded by means of an

earth grounding system

Protective grounding (earth) terminal

A terminal which must be connected to earth ground prior to making any other connection to the

equipment

Equipotential connection (earth bonding)

A connection made to the plant grounding system which may be of type e.g. neutral star or

equipotential line according to national or company practice

t >85°C

Endress + Hauser 7

Temperature resistance of the connection cables

States, that the connection calbes must be resistant to a temperature of at least 85 °C.

Identification Micropilot M FMR250 with HART/4...20 mA

2 Identification

2.1 Device designation

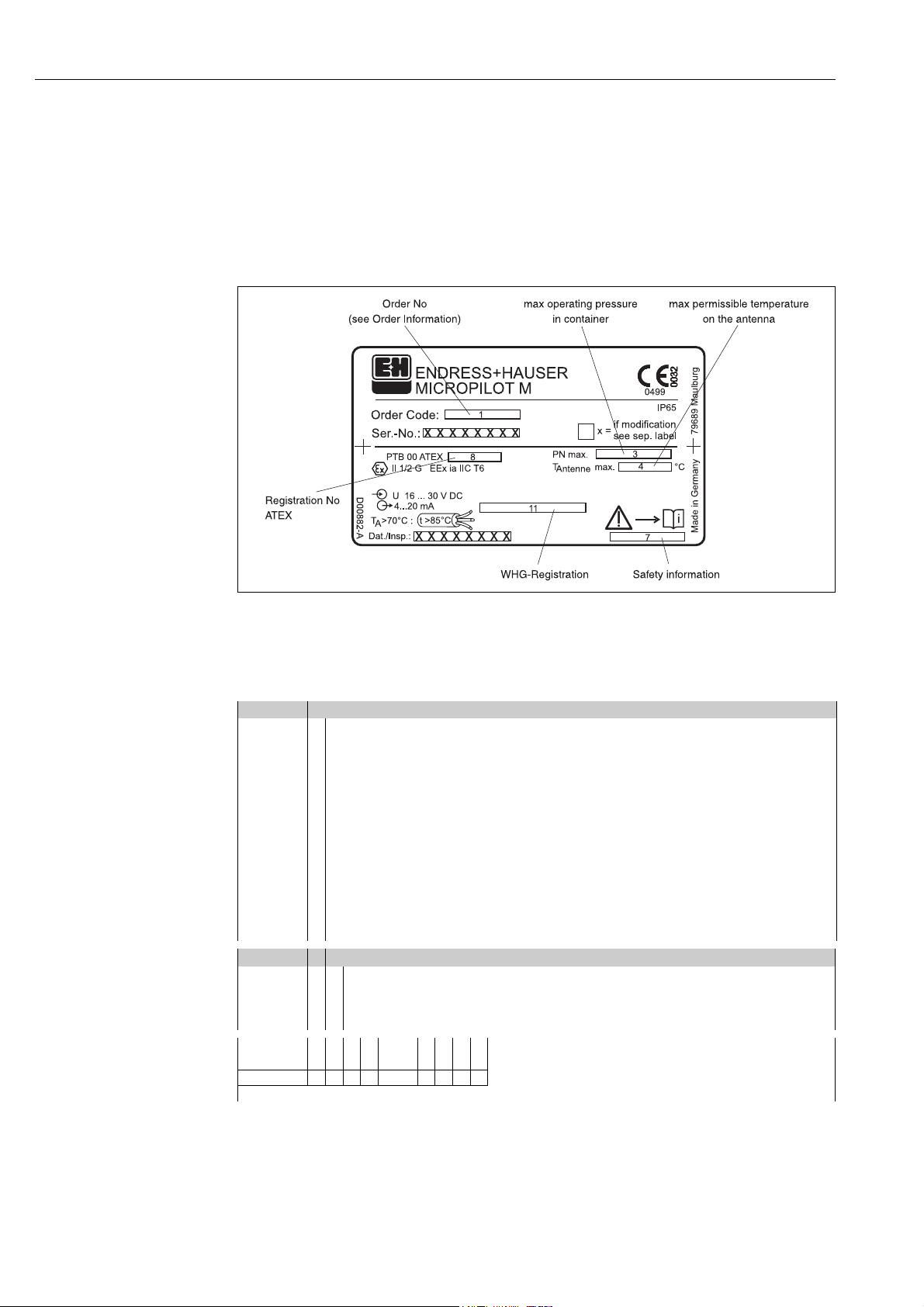

2.1.1 Nameplate

The following technical data are given on the instrument nameplate:

Fig. 1: Information on the nameplate of the Micropilot M (example)

2.1.2 Ordering structure

Ordering structure Micropilot M FMR250

10 Approval:

A Non-hazardous area

1 ATEX II 1/2G EEx ia IIC T6

4 ATEX II 1/2G EEx d [ia] IIC T6

G ATEX II 3G EEx nA II T6

B ATEX II 1/2GD EEx ia IIC T6, Alu blind cover

C ATEX II 1/2G EEx ia IIC T6, ATEX II 1/3D

D ATEX II 1/2D, Alu blind cover

E ATEX II 1/3D

S FM IS-Cl.I/II/III Div.1 Gr.A-G

T FM XP-Cl.I/II/III Div.1 Gr.A-G

N CSA General Purpose

U CSA IS-Cl.I/II/III Div.1 Gr.A-G

V CSA XP-Cl.I/II/III Div.1 Gr.A-G

YSpecial version

20 Antenna:

4 Horn 80mm/3"

5 Horn 100mm/4"

6 Parabolic 200mm/8"

9 Special version

L00-FMR2xxxx-18-00-00-en-001

FMR250- Product designation (part 1)

8 Endress + Hauser

Micropilot M FMR250 with HART/4...20 mA Identification

Ordering structure Micropilot M FMR250 (continued)

30 Antenna seal; Temperature:

E FKM Viton GLT; -40...200°C/-40...392 °F

Y Special version

40 Antenna extension:

1Not selected

2 250mm/10"

3 450mm/18"

9Special version

50 Process connection:

– Threaded boss –

GGJ Thread DIN2999 R1-1/2, 316L

GNJ Thread ANSI NPT1-1/2, 316L

– Universal-Flanges –

X3J UNI flange DN200/8"/200A, 316L

max PN1/14.5LBS/1K, compatible DN200 PN10/16, 8" 150LBS, 10K 200A

XCJ Top target pos., UNI DN100/4"/100A, 316L

max PN1/14.5LBS/1K, compatible DN100 PN10/16, 4" 150LBS, 10K 100A

XEJ Top target pos., UNI DN200/8"/200A, 316L

max PN1/14.5LBS/1K, compatible DN200 PN10/16, 8" 150LBS, 10K 200A

– EN-Flanges –

CMJ DN80 PN10/16 B1, 316L

CQJ DN100 PN10/16 B1, 316L

– ANSI-Flanges –

ALJ 3" 150LBS RF, 316/316L

APJ 4" 150LBS RF, 316/316L

– JIS-Flanges –

KLJ 10K 80A RF, 316L

KPJ 10K 100A RF, 316L

YY9 Special version

60 Output; Operation:

A 4-20mA HART; 4-line display VU331, envelope curve display on site

B 4-20mA HART; w/o display, via communication

K 4-20mA HART; prepared for FHX40, remote display (Accessory)

Y Special version

70 Housing:

A F12 Alu, coated IP65 NEMA4X

B F23 316L IP65 NEMA4X

C T12 Alu, coated IP65 NEMA4X, separate connection compartment

D T12 Alu, coated IP65 NEMA4X + OVP, separate connection compartment,

OVP = overvoltage protection

Y Special version

80 Cable entry:

2Gland M20

3Thread G1/2

4Thread NPT1/2

9Special version

90 Additional option:

K Air purge connection G1/4

M Air purge connection NPT1/4

YSpecial version

FMR250- Complete product designation

Endress + Hauser 9

Identification Micropilot M FMR250 with HART/4...20 mA

2.2 Scope of delivery

Caution!

"

It is essential to follow the instructions concerning the unpacking, transport and storage of

measuring instruments given in the chapter "Incoming acceptance, transport, storage" on Page 11!

The scope of delivery consists of:

!

• Assembled instrument

• 2 ToF Tool - FieldTool

– CD 1: ToF Tool - FieldTool

Program including Device Descriptions (device drivers) and documentation for all

Endress+Hauser devices wich are operable using ToF Tool

– CD 2: ToF Tool - FieldTool

Utility program (e.g. Adobe Acrobat Reader, MS Internet Explorer)

• Accessories (→ Chap. 8)

Accompanying documentation:

• Short manual (basic setup/troubleshooting): housed in the instrument

• Operating manual (this manual)

• Approval documentation: if this is not included in the operating manual.

Note!

The operating manual "Description of Instrument Functions" you can be found on the enclosed CRROM.

®

Package CD-ROMs

®

Program

®

Utilities

2.3 Certificates and approvals

CE mark, declaration of conformity

The instrument is designed to meet state-of-the-art safety requirements, has been tested and left the

factory in a condition in which it is safe to operate. The instrument complies with the applicable

standards and regulations and thus complies with the statutory requirements of the EG directives.

Endress+Hauser confirms the successful testing of the instrument by affixing to it the CE mark.

2.4 Registered trademarks

KALREZ®, VITON®, TEFLON

Registered trademark of the company, E.I. Du Pont de Nemours & Co., Wilmington, USA

TRI-CLAMP

Registered trademark of the company, Ladish & Co., Inc., Kenosha, USA

HART

Registered trademark of HART Communication Foundation, Austin, USA

®

ToF

Registered trademark of the company Endress+Hauser GmbH+Co. KG, Maulburg, Germany

PulseMaster

Registered trademark of the company Endress+Hauser GmbH+Co. KG, Maulburg, Germany

PhaseMaster

Registered trademark of the company Endress+Hauser GmbH+Co. KG, Maulburg, Germany

®

®

®

®

®

10 Endress + Hauser

Micropilot M FMR250 with HART/4...20 mA Installation

90°

90°

90°

90°

9

3 Installation

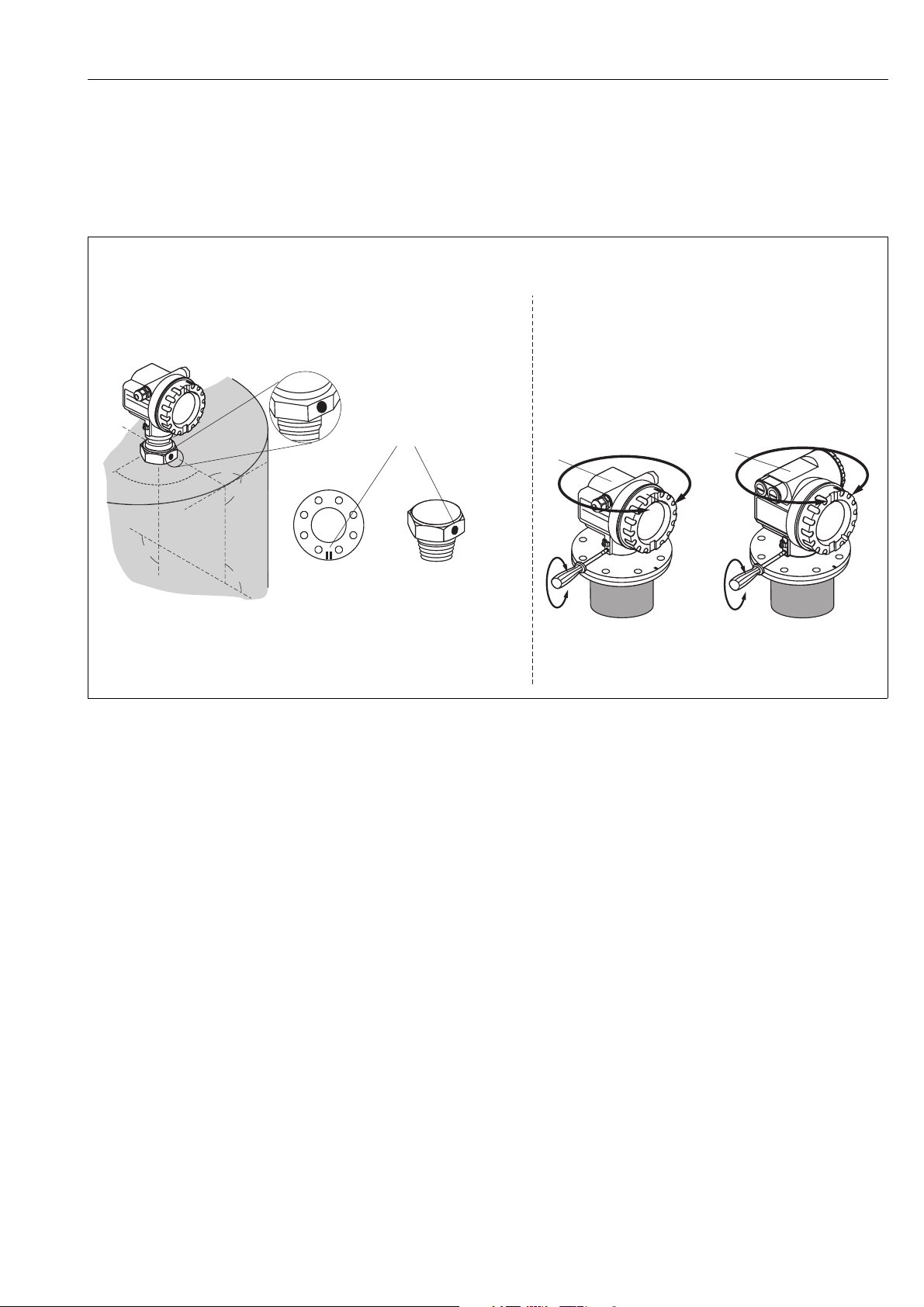

3.1 Quick installation guide

At mounting adjust the marking at the instrument flange!

#

Installation in vessel (free space):

Mark on process connector facing the nearest vessel wall!

The housing can be turned 350° in order to simplify access to the

Turn housing

display and the terminal compartment

mark at instrument flange

or threaded boss

90°90

°

90°

Note!

At version with top target positioner, the marker is at the housing adapter

(opposite the air purge connection).

90°

90°

90°

DN80…200

ANSI 3…8”

1½” BSPT (R 1½”),

or

1½ NPT

3.2 Incoming acceptance, transport, storage

3.2.1 Incoming acceptance

Check the packing and contents for any signs of damage.

Check the shipment, make sure nothing is missing and that the scope of supply matches your order.

F12/F23 housing

2

3

1

T12 housing

2

3

1

Allen key 4 mm / 0.1"

L00-FMR250xx-17-00-00-en-011

3.2.2 Transport

Caution!

"

Follow the safety instructions and transport conditions for instruments of more than

18 kg.

Do not lift the measuring instrument by its housing in order to transport it.

3.2.3 Storage

Pack the measuring instrument so that is protected against impacts for storage and transport. The

original packing material provides the optimum protection for this.

The permissible storage temperature is -40 °C…+80 °C.

Endress + Hauser 11

Installation Micropilot M FMR250 with HART/4...20 mA

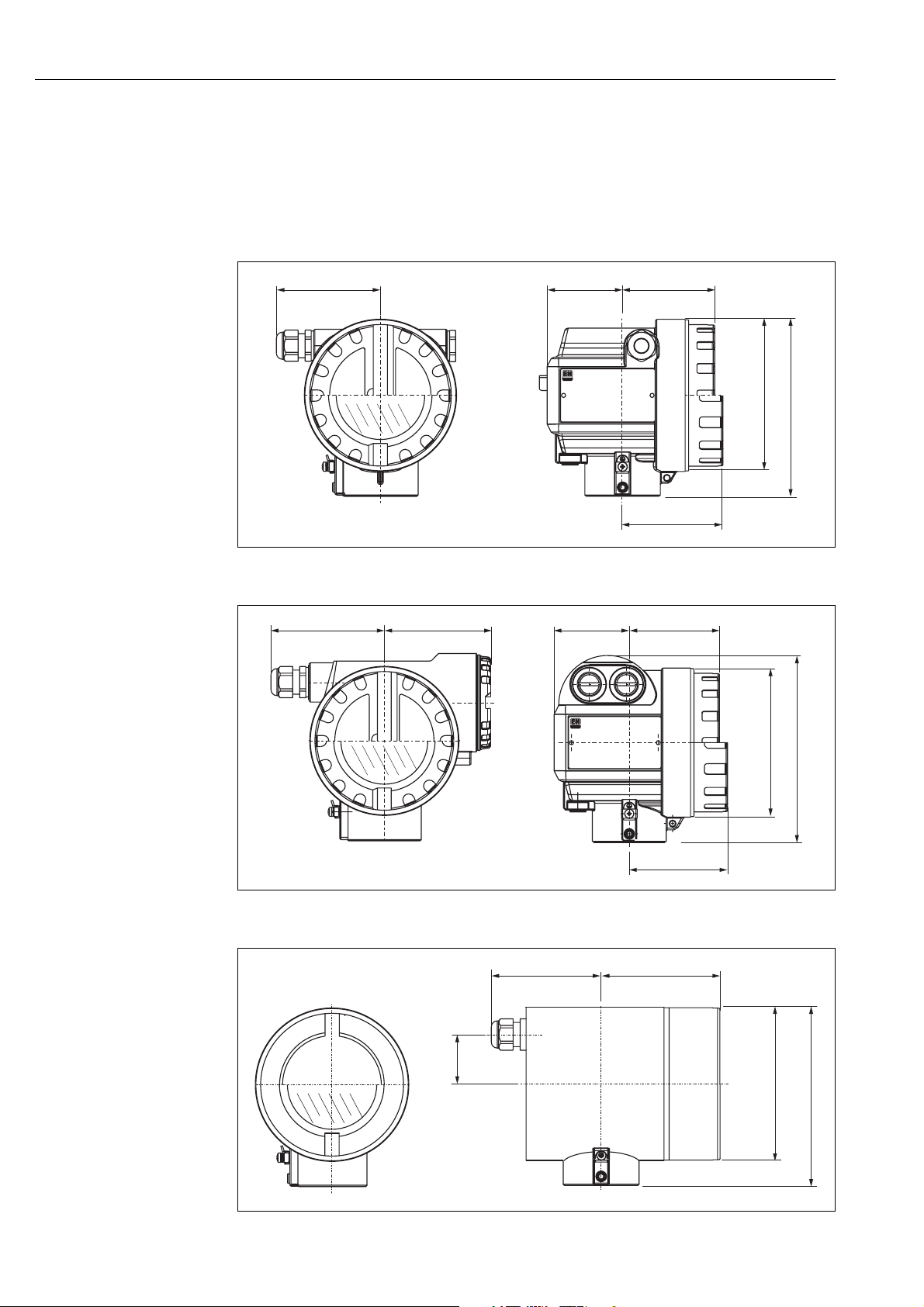

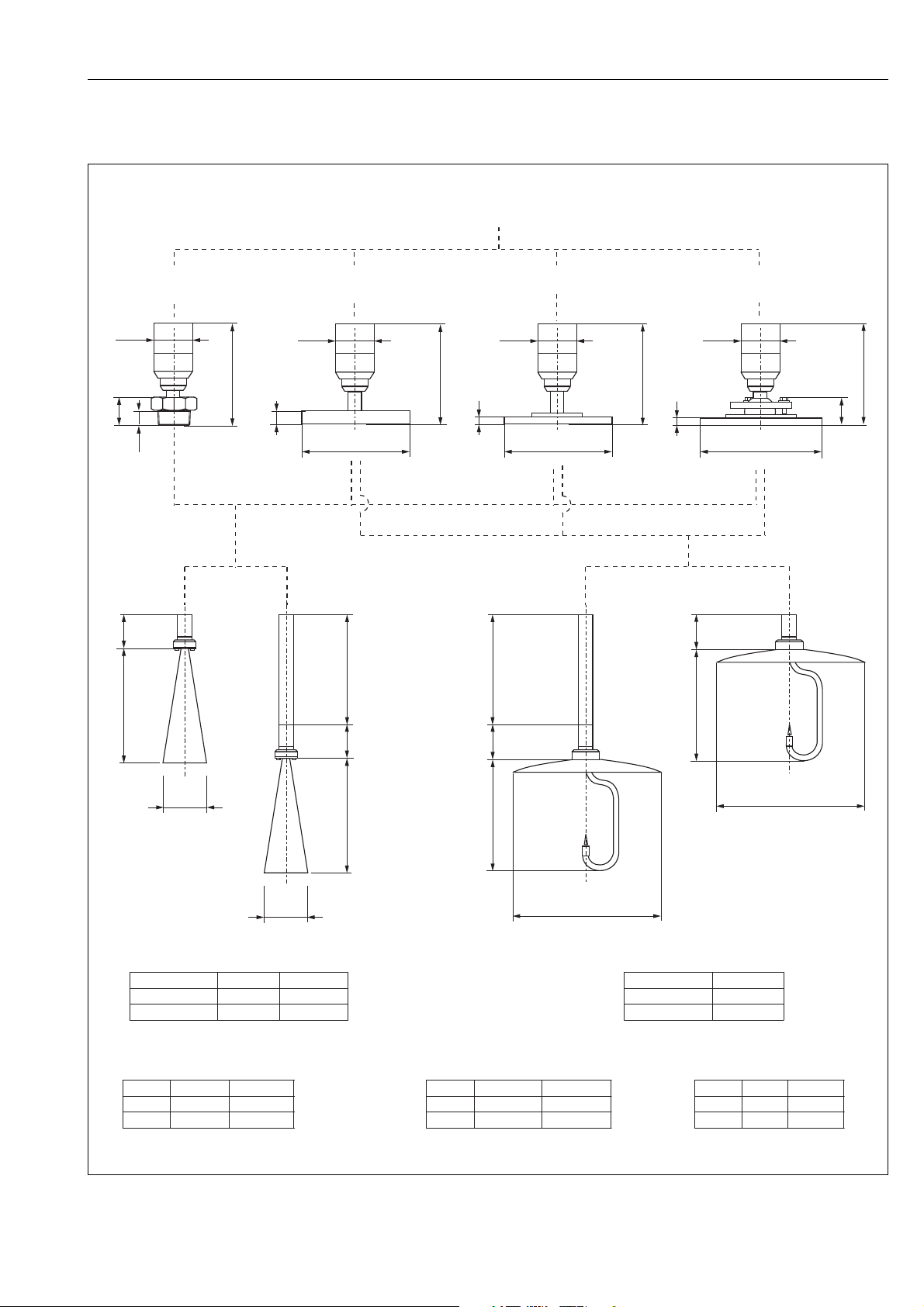

3.3 Installation conditions

3.3.1 Dimensions

Housing dimensions

max. 110

max. 100 94

F12 housing

(Aluminium)

65

ENDRESS+HAUSER

65

ENDRESS+HAUSER

78

Ø 129

150

85

L00-F12xxxx-06-00- 00-en-001

78

T12 housing

(Aluminium)

40

F23 housing

(316L)

max. 94

104

162

Ø 129

85

L00-T12xxxx-06-00-0 0-en-001

Ø 129

150

L00-F23xxxx-06-00- 00-en-001

12 Endress + Hauser

Micropilot M FMR250 with HART/4...20 mA Installation

Micropilot M FMR250 - process connection, type of antenna

F12 / T12 / F23 housing

Threaded connection

BSPT (R 1 ½”)

1 ½”

or 1 ½ NPT

Ø 60

43

23

50

L

135

Ø 60

b

Flange DN80…100

or equivalent

135

Ø D Ø 340

250/450

E+H UNI flange DN 200 Alignment unit with

8

250/450

Ø 60

135

Parabolic antennaHorn antenna

E+H UNI flange DN 100/200

Ø 60

8

Ø 225 (DN100)

340 (DN200)Ø

50

L

135

40

50

Ø d

Ø d Ø d

Horn antenna Parabolic antenna

Antenna size Antenna size

L [mm] L [mm]

d [mm] d [mm]

Flange to EN 1092-1 (agreeable to DIN 2527)

Flange

b [mm] b [mm]b [mm]

D [mm] D [mm]D [mm]

for PN10/16

80mm/3” 200mm/8”

211

DN 80 DN 803”

20 1823.9

200

100mm/4”

75

DN 100 DN 1004”

20 1823.9

220 210228.6

L

282 195

95 197

Flange to ANSI B16.5

Flange

for 150 lbs

50

L

Ø d

Flange to JIS B2210

Flange

185190.5

for 10K

L00-FMR250xx-06-00-00-en-005

Endress + Hauser 13

Installation Micropilot M FMR250 with HART/4...20 mA

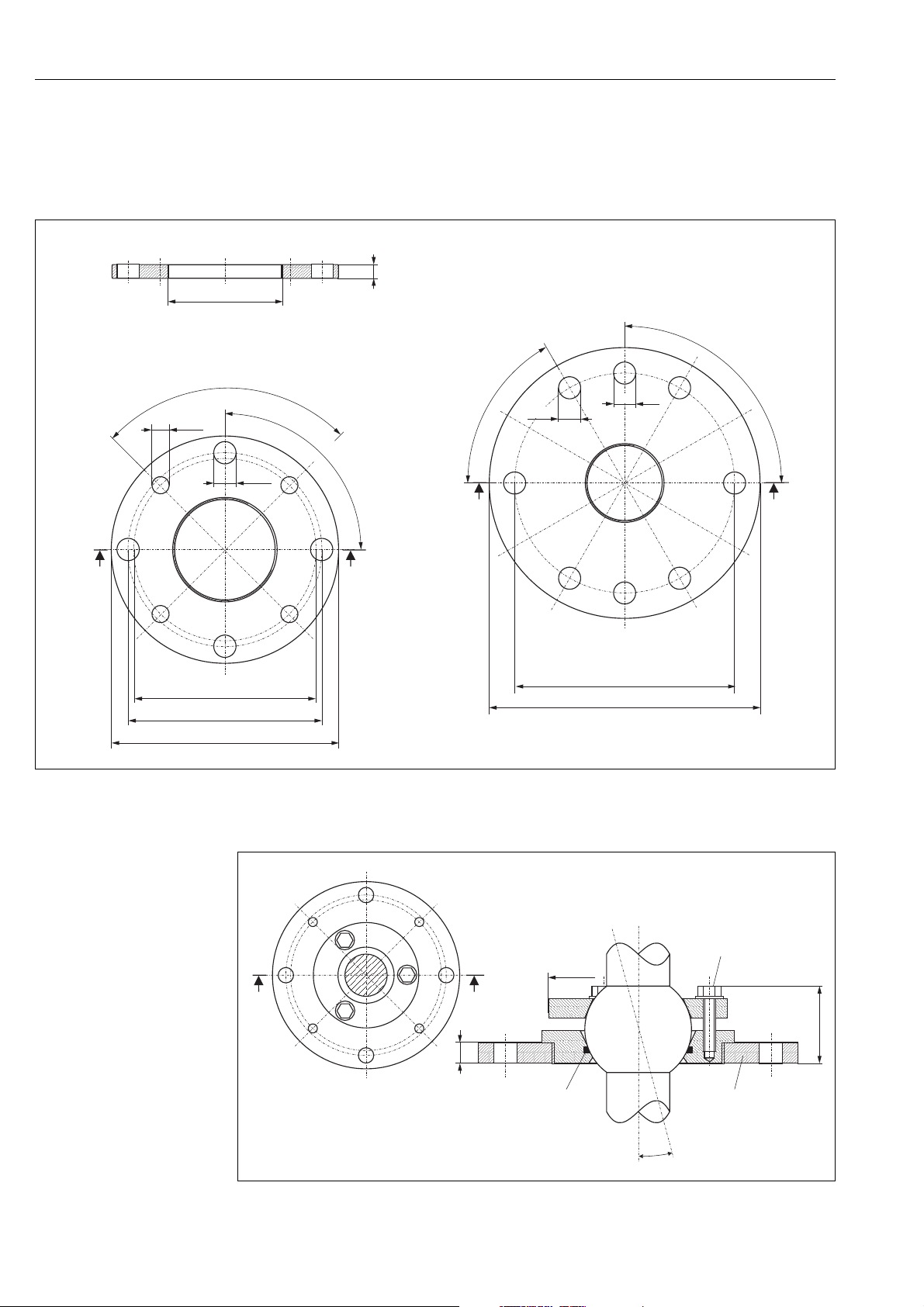

E+H UNI flange

The number of bolts has sometimes been reduced. The bolt-holes have been enlarged for adaption

of dimensions, therefore, the flange needs to be properly aligned to the counterflange before the

bolts are tightened.

A-A

E+H UNI flange DN100

compatible with:

- DN100 PN10/16,

- ANSI 4" 150 lbs,

- JIS 10K 100A

Ø 19

A

M80x1.5

4x90

175

185.5

225

°

Ø 23

4x90°

A

8

material: 316L

E+H UNI flange DN200

compatible with:

- DN200 PN10/16,

- ANSI 8" 150 lbs,

- JIS 10K 200A

°

6x60

A

Ø 26

4x90°

Ø 26

A

294.5

340

Top target positioner with E+H UNI flange

A

A

8

A-A

Ø 85

Viton seal

L00-FMR250xx-06-00- 00-en-006

clamping screw

3 x M8 shifty at 120°

40

E+H UNI flange

DN100/DN200

±15°

L00-FMR250xx-06-00- 00-en-007

14 Endress + Hauser

Micropilot M FMR250 with HART/4...20 mA Installation

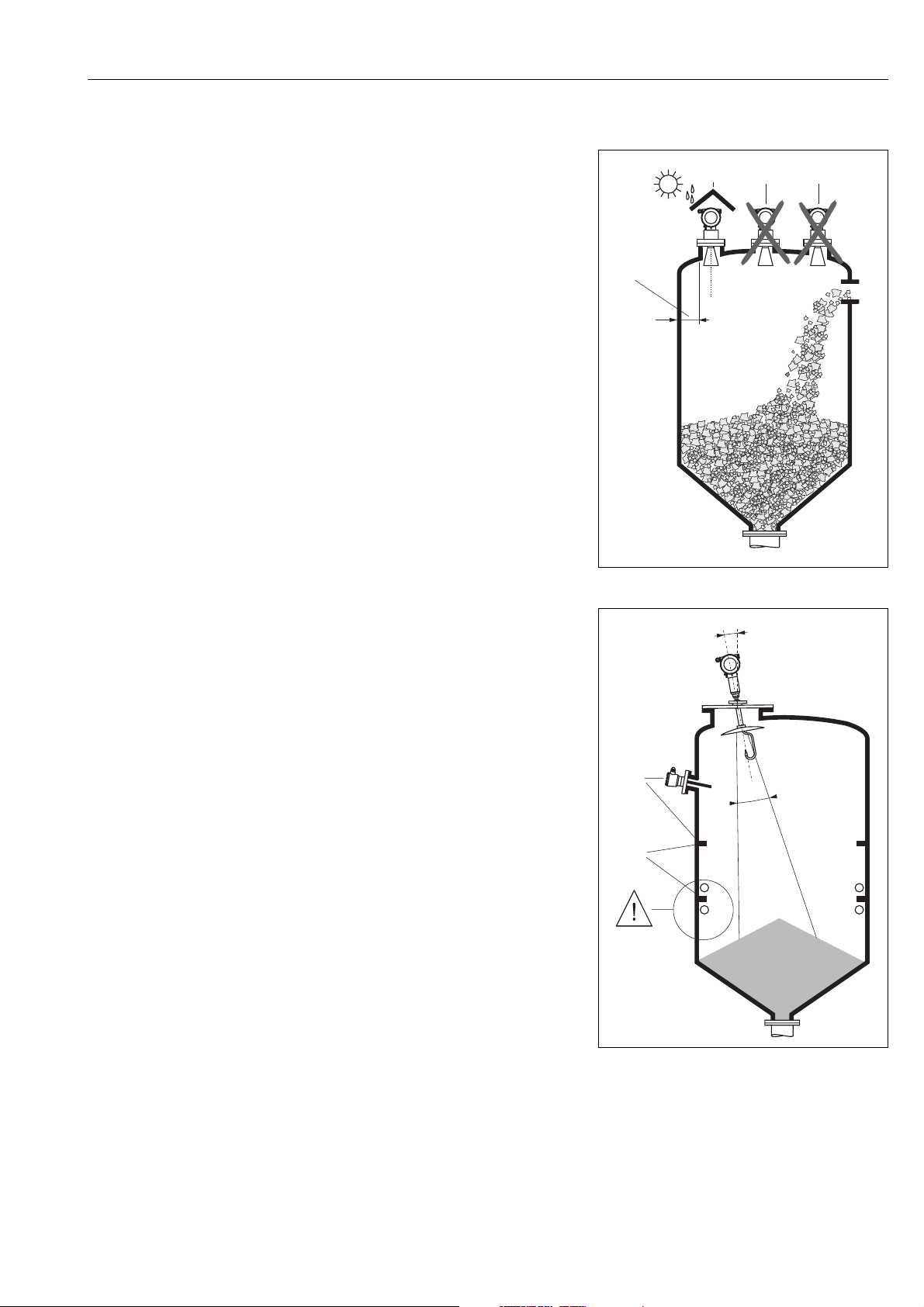

3.3.2 Engineering hints

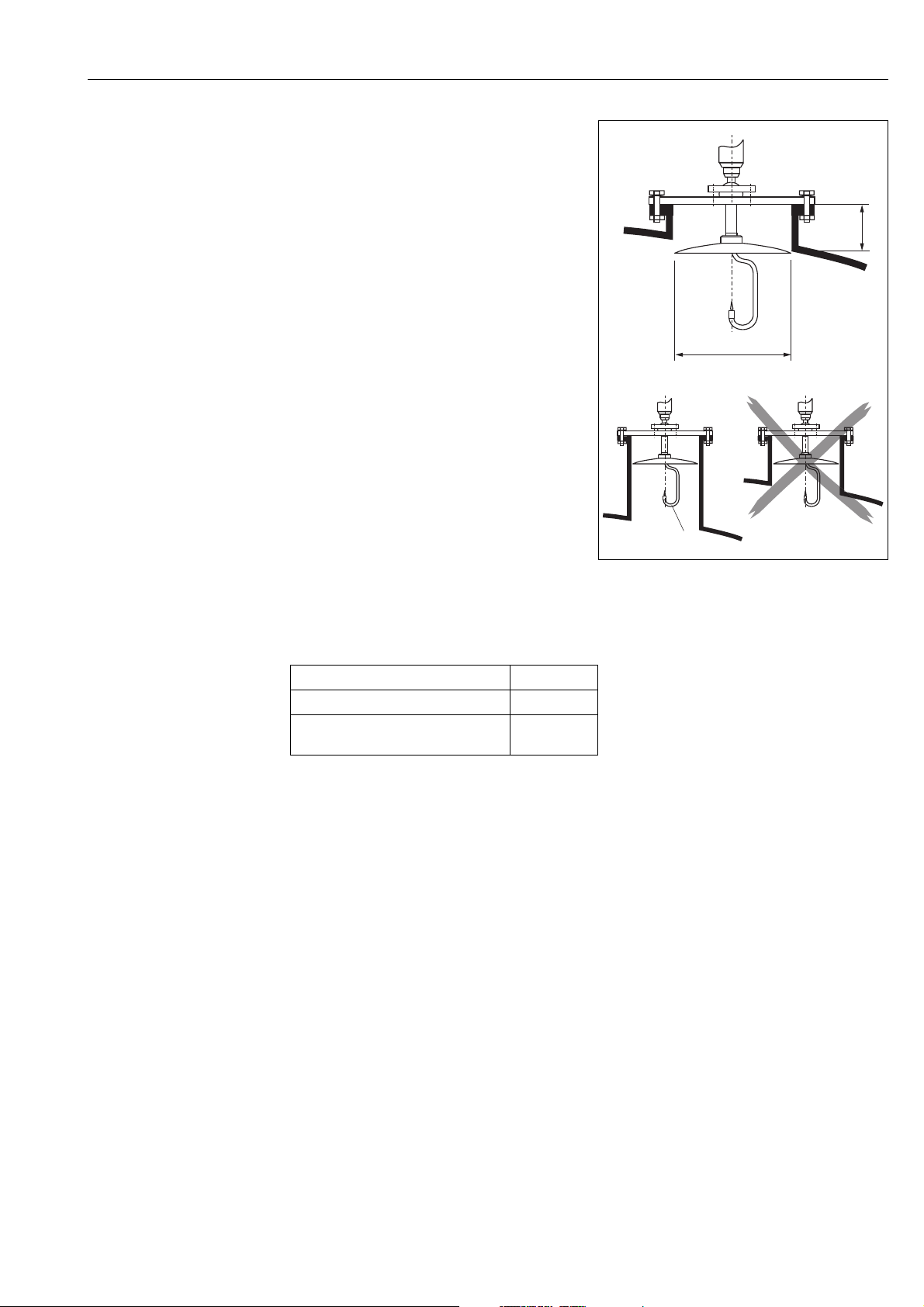

Orientation

• Recommended distance (1) wall – outer

edge of nozzle: ~1/6 of vessel diameter.

However, the device should not, under any

circumstances, be mounted less than 20 cm/

8“ from the vessel wall.

• Not in the centre (3), interference can cause

signal loss.

• Not above the fill stream (4).

• It is recommended to use a weather

protection cover (2) in order to protect the

transmitter from direct sun or rain. Assembly

and disassembly is simply done by means of a

tension clamp (→ Chap. 8 on Page 64).

• In extremely dusty applications, the

integrated air purge connection can prevent

clogging of the antenna.

1

234

L00-FMR250xx-17-00 -00-xx-003

Vessel installations

• Avoid any installations (1), like limit switches,

struts, etc., inside the signal beam (refer to

beam angle see "Beam angle" on Page 16).

• Symmetrical installations (2), i.e. reinforcing

rings, heating coils, etc., can also interfere

with the measurement.

Optimization options

• Antenna size: the bigger the antenna, the

smaller the beam angle, the less interference

echoes.

1

• Mapping: the measurement can be optimized

by means of electronic suppression of

interference echoes.

• Antenna alignment: refer to "Optimum

mounting position"

2

• In devices with top target positioner, the

sensor can be optimally aimed within the

vessel and/or interference reflections can be

avoided.

The max. angle β is ±15°.

Please contact Endress+Hauser for further

information.

L00-FMR250xx-17-00 -00-xx-002

Endress + Hauser 15

Installation Micropilot M FMR250 with HART/4...20 mA

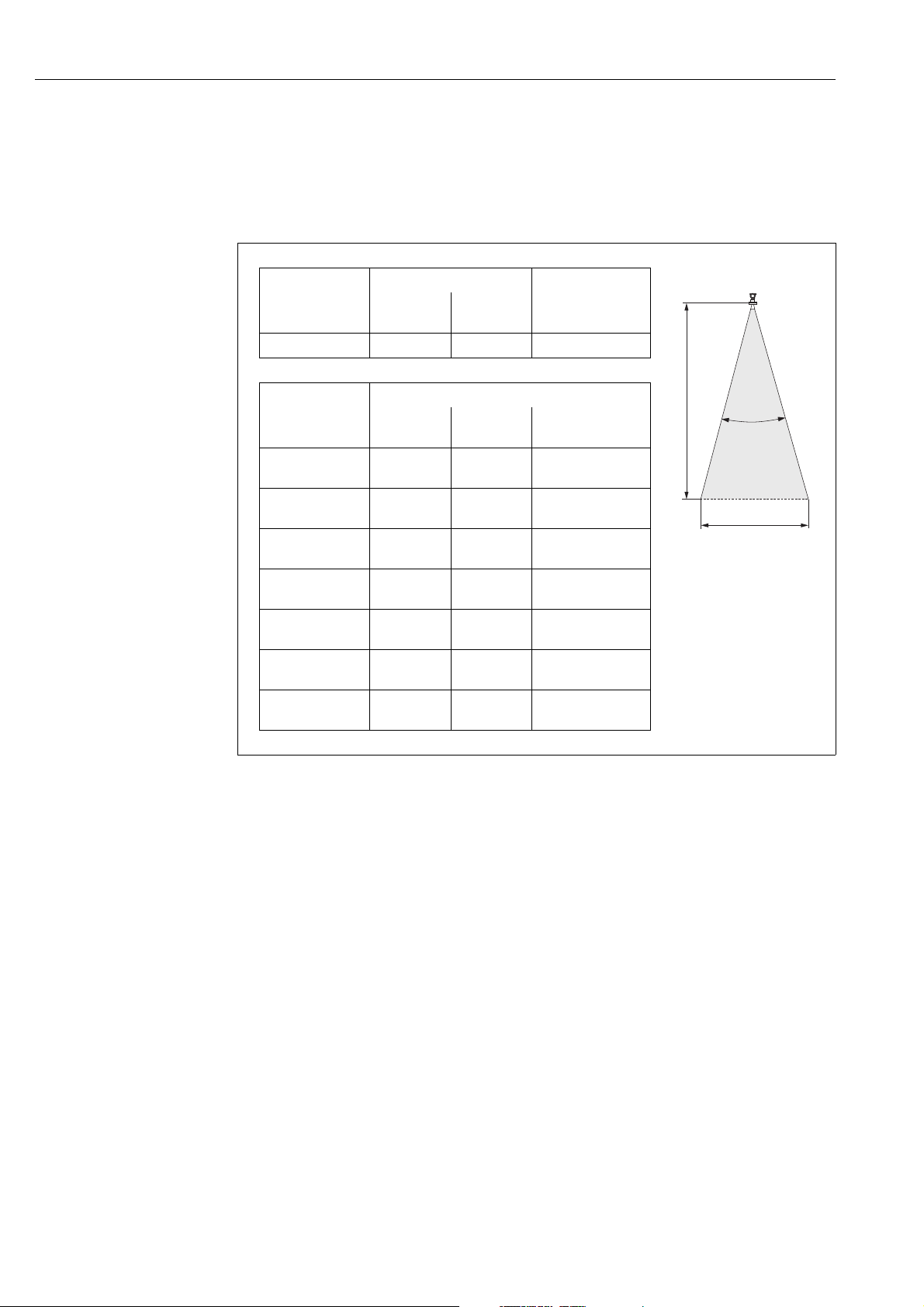

Beam angle

The beam angle is defined as the angle a where the energy density of the radar waves reaches half

the value of the maximum energy density (3dB-width). Microwaves are also emitted outside the

signal beam and can be reflected off interfering installations. Beam diameter W as function of

antenna type (beam angle α) and measuring distance D:

Antenna size

FMR250

Beam angle α 10° 8° 4°

Measuring

distance (D)

5m / 16 ft

10 m / 32 ft

15 m / 49 ft

20 m / 65 ft

30 m / 98 ft

40 m / 131 ft

50 m / 164 ft

Horn antenna Parabolic antenna

80 mm

3"

80 mm

3"

0.87 m /

2.80 ft

1.75 m /

5.60 ft

2.62 m /

8.57 ft

3.50 m /

11.37 ft

5.25 m /

17.15 ft

7.00 m /

22.92 ft

8.75 m /

28.70 ft

100 mm

4"

Beamwidth diameter (W)

100 mm

4"

0.70 m /

2.24 ft

1.40 m /

4.48 ft

2.10 m /

6.85 ft

2.80 m /

9.09 ft

4.20 m /

13.71 ft

5.59 m /

18.32 ft

6.99 m /

22.94 ft

200 mm

200 mm

0.35 m /

1.12 ft

0.70 m /

2.23 ft

1.05 m /

3.42 ft

1.40 m /

4.54 ft

2.10 m /

6.84 ft

2.79 m /

9.15 ft

3.50 m /

11.45 ft

8"

D

8"

W

L00-FMR2xxxx-14-00 -06-de-027

16 Endress + Hauser

Micropilot M FMR250 with HART/4...20 mA Installation

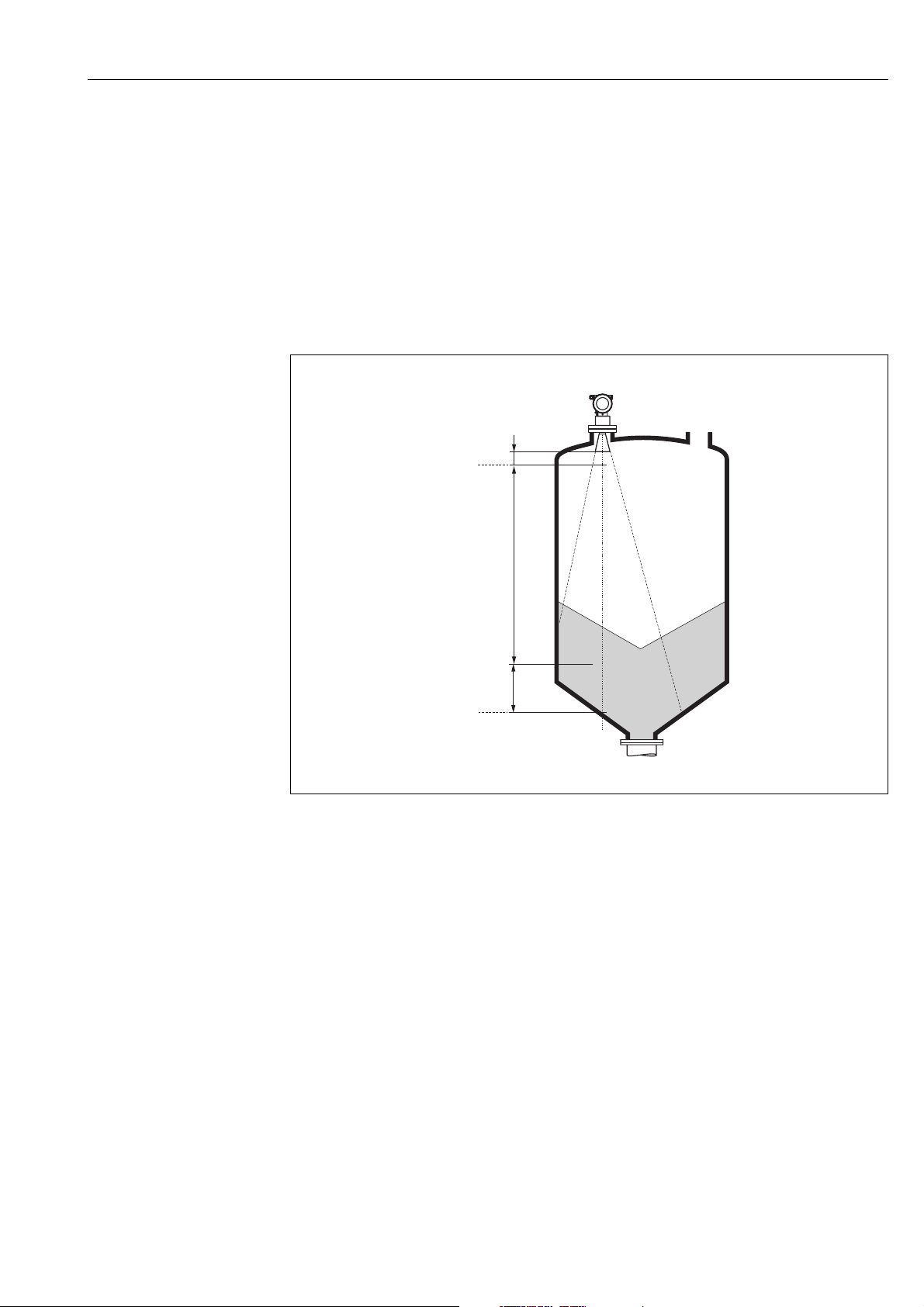

Measuring conditions

• The measuring range begins, where the beam hits the vessel bottom. Particularly with dish

bottoms or conical outlets the level cannot be detected below this point.

• In case of media with a low dielectric constant (groups A and B), the vessel bottom can be visible

through the medium at low levels. In order to guarantee the required accuracy in these cases, it

is recommended to position the zero-point at a distance C =50...150 mm above the vessel bottom

(see Fig.).

• In principle it is possible to measure up to the tip of the antenna with FMR250. However, due to

considerations regarding abrasion and build-up, the end of the measuring range should not be

chosen any closer than A=400 mm (see Fig.) to the tip of the antenna.

• The smallest possible measuring range B=500 mm (see Fig.).

100%

0%

A

B

C

L00-FMR250xx-17-00-00-en-001

Endress + Hauser 17

Installation Micropilot M FMR250 with HART/4...20 mA

Measuring range

The usable measuring range depends on the size of the antenna, the reflectivity of the medium, the

mounting location and eventual interference reflections. The maximum configurable range is 70 m

(229 ft) for Micropilot M FMR250.

To achieve an optimised Signal strength it is recommended to use an antenna with as large as

possible diameter (DN200/8" parabolic antenna, DN100/4" horn).

Reduction of the max. possible measuring range through:

• Media with poor reflection properties (= small DC). For examples refer to table 1.

• Angle of repose.

• Extremely loose surfaces of bulk solids, e.g. bulk solids with low bulk weight for pneumatic filling.

• Build-up, above all of moist products.

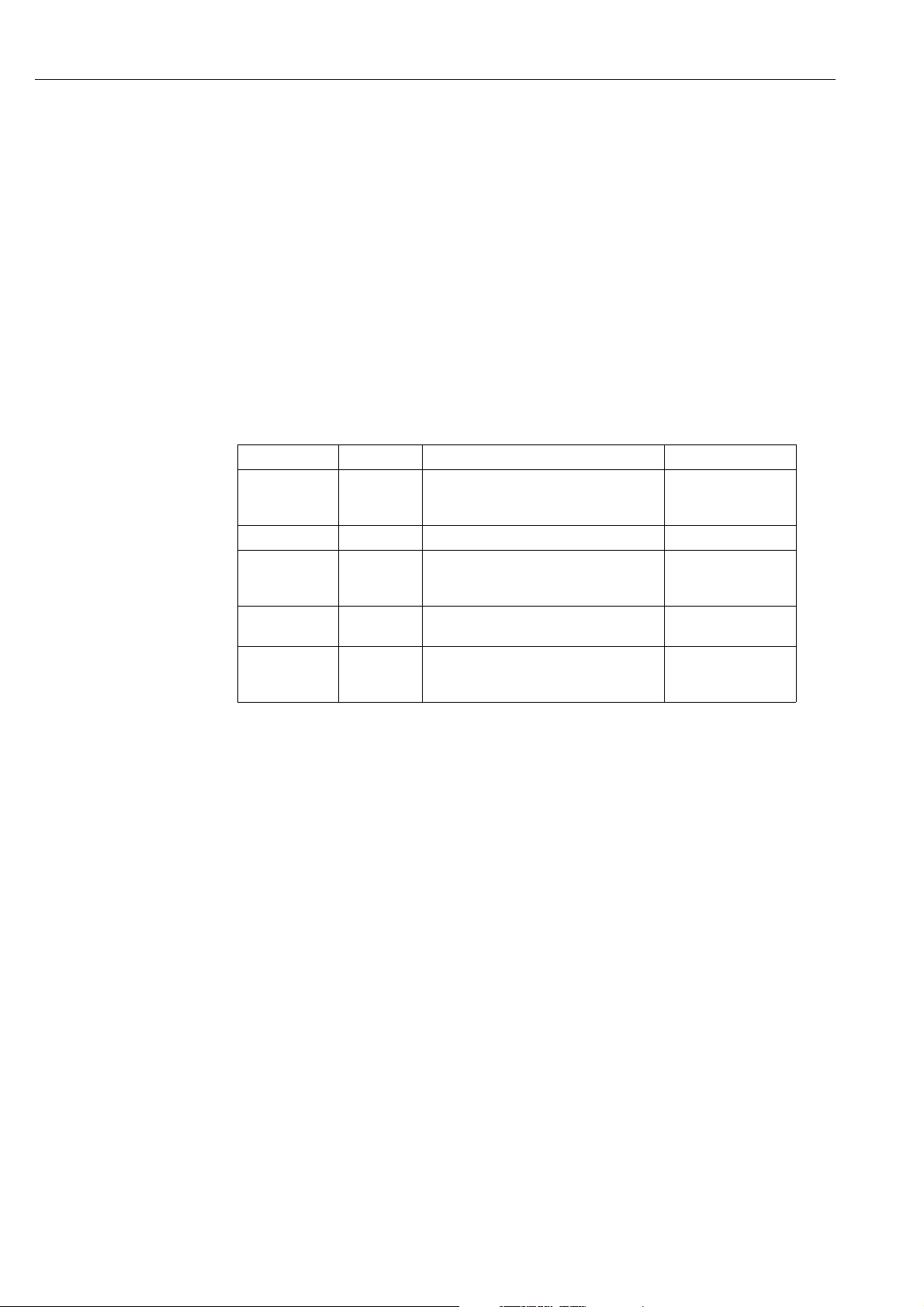

Table 1:

The following table describes the media groups and the dielectric constant

Media group DC (εr) Examples Signal attenuation

A 1.6...1.9

B 1.9...2.5 – Portland cement, plaster 16...13 dB

C 2.5...4

D 4...7

E >7

– Plastic granulate

– White lime, special cement

–Sugar

–Grain, seeds

–Ground stones

–Sand

– Naturally moist (ground) stones, ores

–Salt

– Metallic powder

– Carbon black

–Coal

εr.

19...16 dB

13...10 dB

10...7 dB

< 7 dB

The respective lower group applies for very loose or loosened bulk solids.

18 Endress + Hauser

Micropilot M FMR250 with HART/4...20 mA Installation

90°

90

°

90°

90°

9

3.4 Installation instructions

3.4.1 Mounting kit

For the mounting , you will require the following tool:

• The tool for flange mounting or

• a key AF60 for threaded boss and

• 4 mm/0.1" Allen wrench for turning the housing.

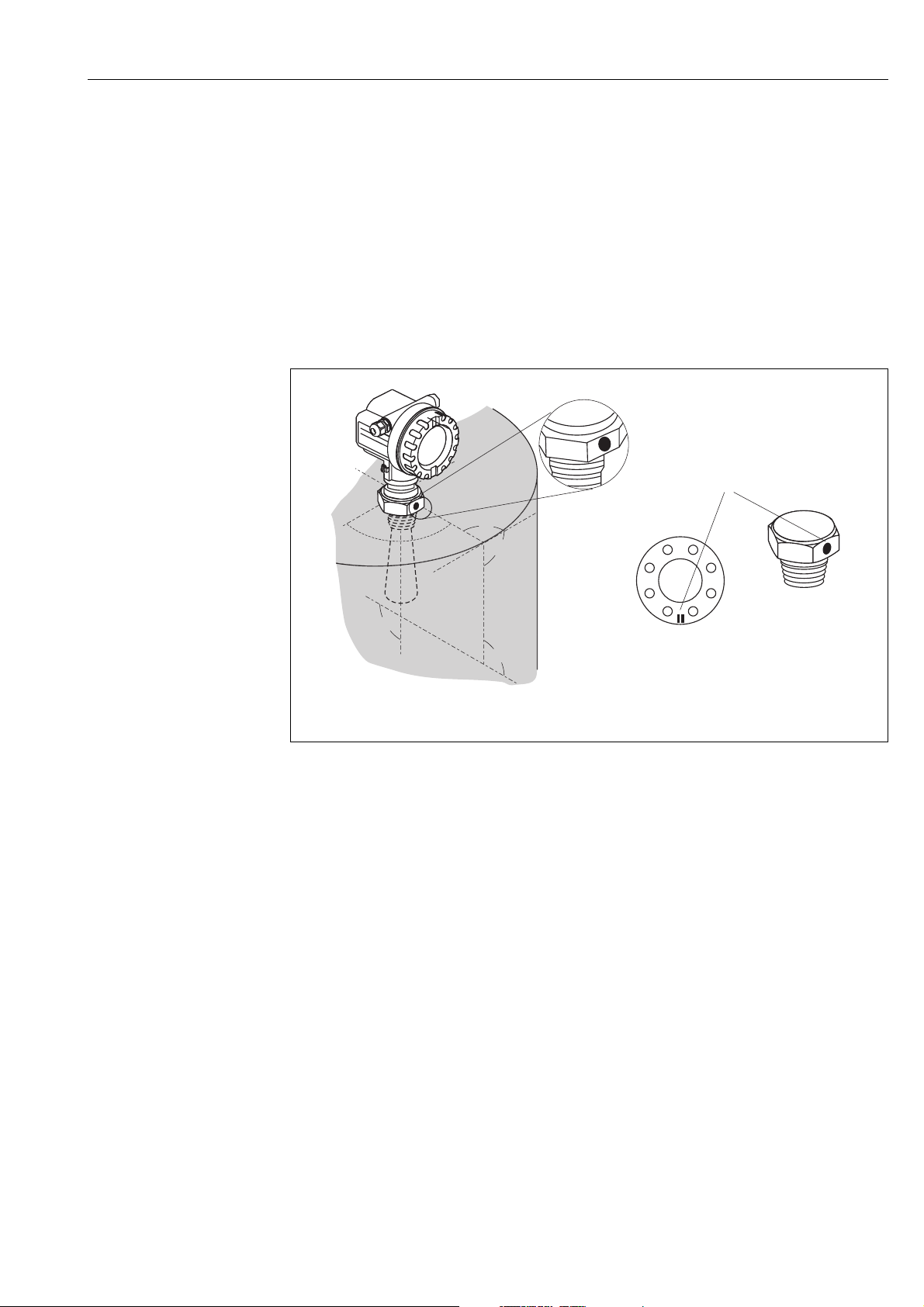

3.4.2 Installation in vessel (free space)

Optimum mounting position

marker at instrument

flange or threaded boss

90

°

90°

1)

at version with top target positioner, the marker is at the housing adapter

90°

°

90

90°

(opposite the air purge connection)

DN80…200

ANSI 3…8”

1)

1½” BSPT (R 1½”)

or

1½ NPT

L00-FMR250xx-17-00-00-en-009

Endress + Hauser 19

Installation Micropilot M FMR250 with HART/4...20 mA

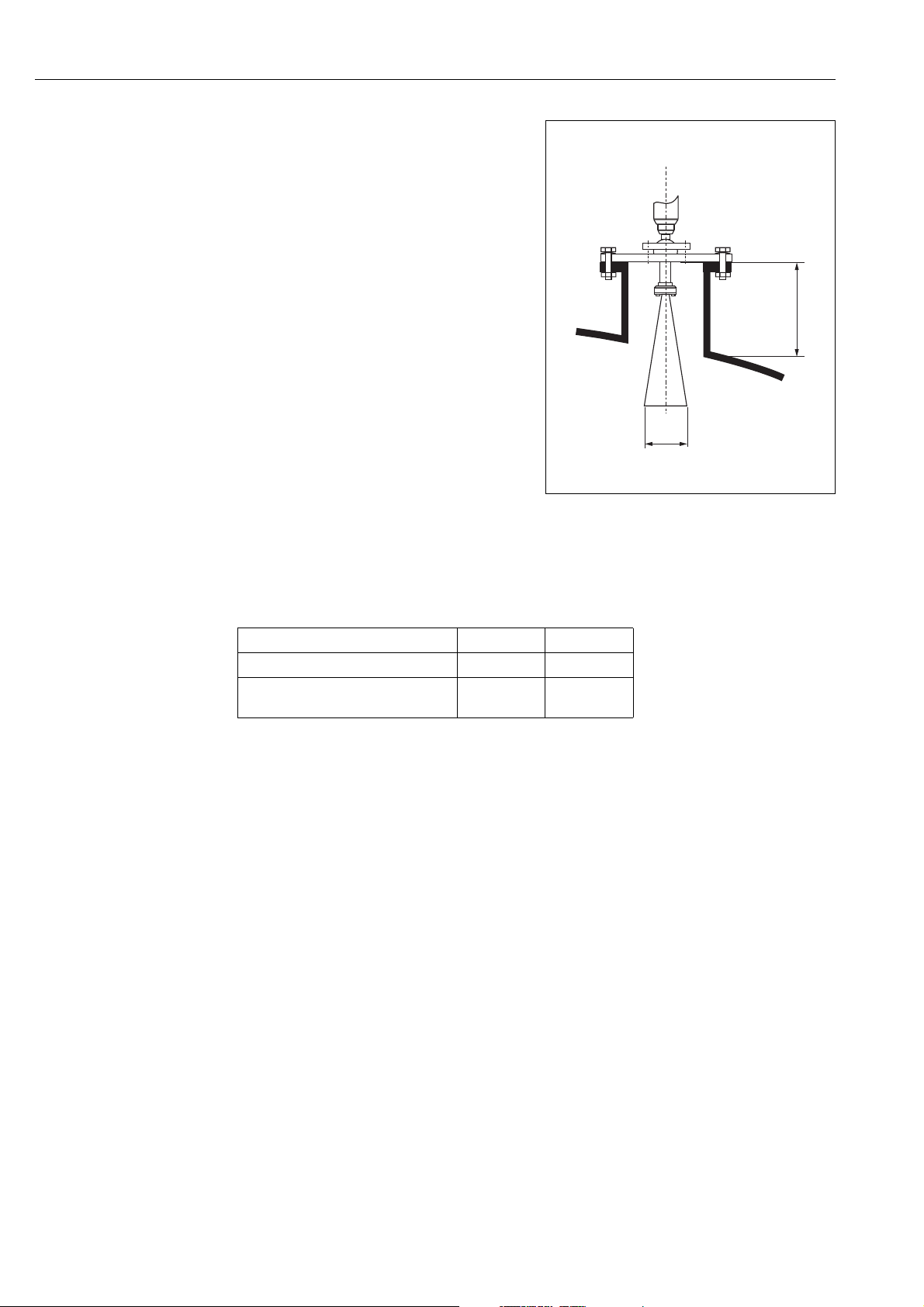

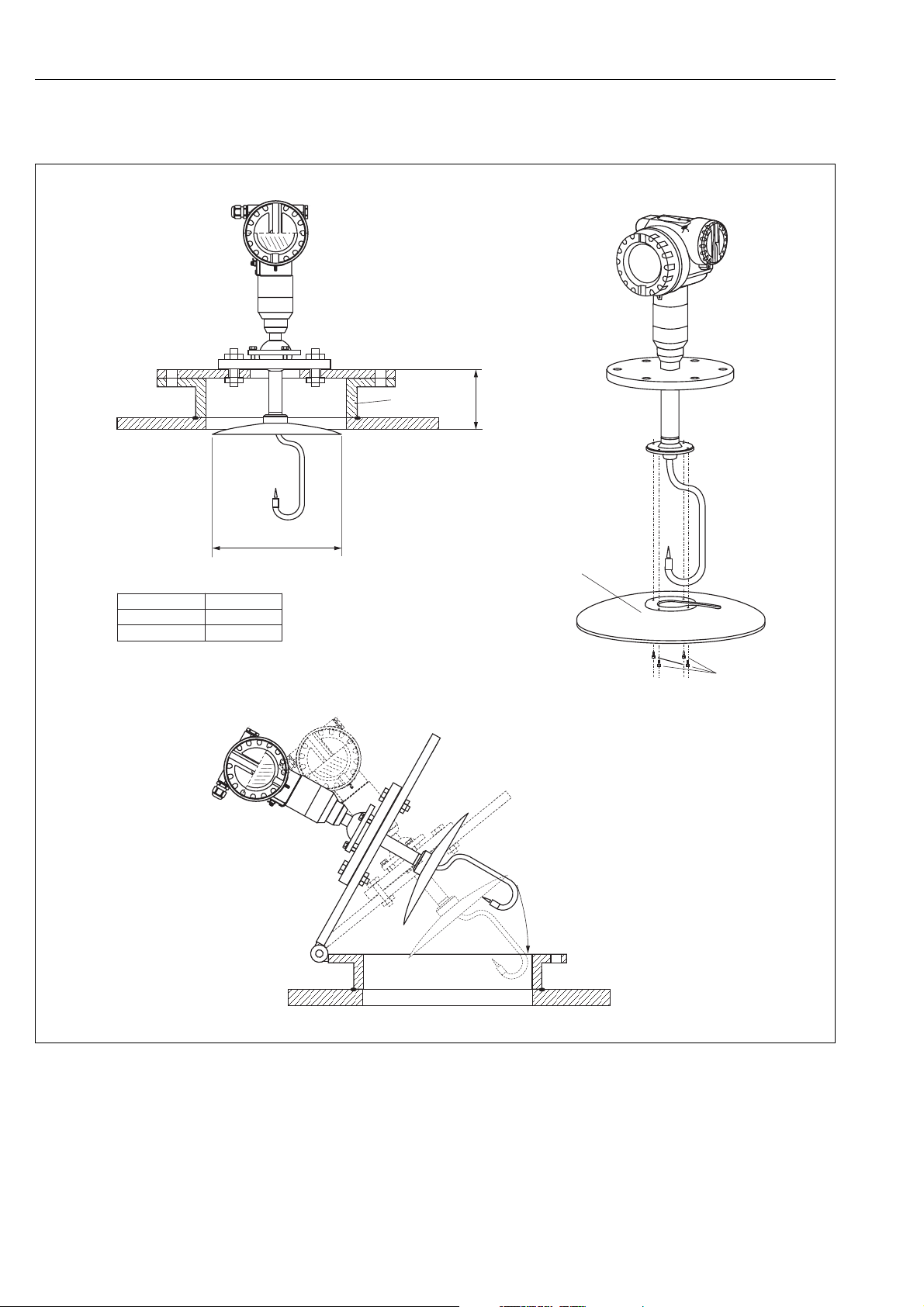

Standard installation FMR250 with horn

antenna

• Observe installation instructions on Page 15.

• Marker is aligned towards vessel wall.

• The marker is always exactly in the middle

between two bolt-holes in the flange.

• After mounting, the housing can be turned

350° in order to simplify access to the display

and the terminal compartment.

• The horn antenna should protrude from the

nozzle. If necessary, choose version with

H

antenna extension (see Page 13).

If this is not possible for mechanical reasons,

nozzle heights up to 500 mm can be

accepted.

Note!

Please contact Endress+Hauser for application

with higher nozzle.

Ø D

• Vertical horn antenna.

Ideally, the horn antenna should be installed

vertically.

L00-FMR250xx-17-00- 00-en-004

To avoid interference reflections or for

optimum alignment within the vessel, the

FMR250 with optional top target positioner

can be swiveled by 15° in all directions.

Antenna size 80 mm / 3" 100 mm / 4"

D [mm / inch] 75 / 3 95 / 3.7

H [mm / inch]

(without antenna extension)

< 260 / < 10.2 < 330 / < 12.9

20 Endress + Hauser

Micropilot M FMR250 with HART/4...20 mA Installation

Standard installation FMR250 with

parabolic antenna

• Observe installation instructions on Page 15.

1

• Marker is aligned towards vessel wall.

• The marker is always exactly in the middle

between two bolt-holes in the flange.

• After mounting, the housing can be turned

H

350° in order to simplify access to the display

and the terminal compartment.

• Ideally the parabolic antenna should protrude

from the nozzle (1). If necessary, choose

version with antenna extension (see Page 13).

Particularly when using the top target

Ø D

positioner, please ensure that the parabolic

reflector is protruding from the nozzle/roof so

as not to inhibit alignment.

2

Note!

For application with higher nozzle install

parabolic antenna completely in the

nozzle (2), including RF-wave guide (3).

• Vertical parabolic antenna.

Ideally, the parabolic antenna should be

installed vertically.

To avoid interference reflections or for

optimum alignment within the vessel, the

3

L00-FMR250xx-17-00-00-en-005

FMR250 with optional top target positioner

can be swiveled by 15° in all directions.

Antenna size 200 mm / 8"

D [mm / inch] 197 / 7.75

H [mm / inch]

(without antenna extension)

< 50 / < 1.96

Endress + Hauser 21

Installation Micropilot M FMR250 with HART/4...20 mA

Examples for installation with small flange (< parabolic reflector)

standard installation

Antenna size

D [mm]

H [mm]

1)

without antenna extension

200mm/8”

1)

197

< 50

nozzle

D

H

for installation

in nozzle

you can dismantle

the parabolic reflector

4 bolts

Caution!

At hinged flanges, the length of the antenna

must be taken into account!

L00-FMR250xx-17-00- 00-en-007

22 Endress + Hauser

Micropilot M FMR250 with HART/4...20 mA Installation

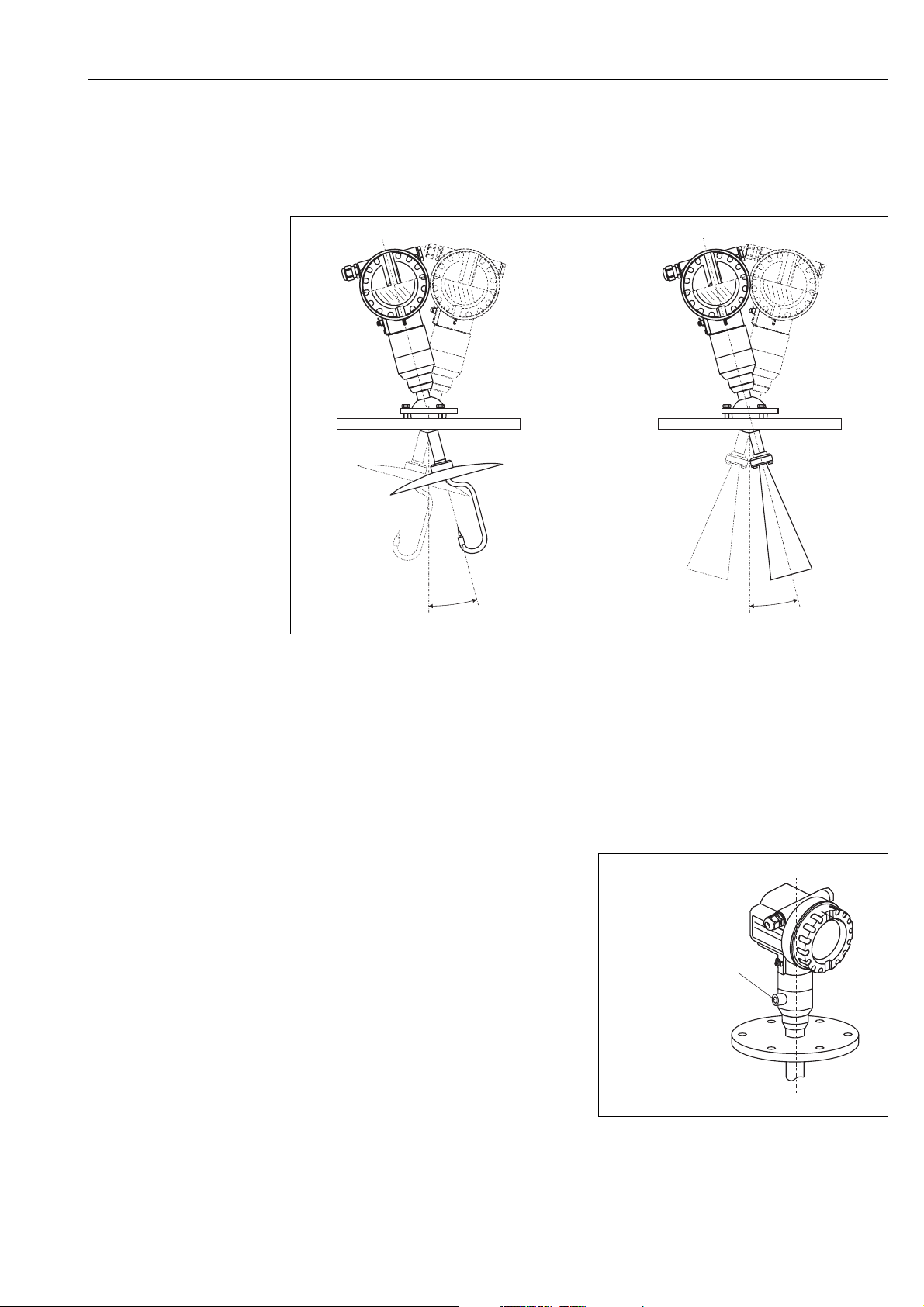

FMR250 with top target positioner

Using top target positioner it is possible to tilt the antenna axis by up to 15° in all directions. The

top target positioner is used for the optimum alignment of the radar beam with the bulk solids

surface.

±15°

Align antenna axis:

1. Loosen screws.

2. Align antenna axis (here this is possible up to max. ±15° in all directions).

3. Tighten screws.

Integrated air purge connection

In extremely dusty applications, the integrated

air purge connection can prevent clogging of the

antenna.

• Permanent operation:

recommended pressure range of the purge air:

1.2...1.5 bar abs.

• Pulsed operation:

max. pressure of purge air: 6 bar abs.

air purge connection:

NPT

¼

G (max. torque 3.5 Nm)

¼

or

Caution!

Make sure to use dry purge air.

±15°

L00-FMR250xx-17-00 -00-de-008

L00-FMR250xx-17-00-00-en-010

Endress + Hauser 23

Installation Micropilot M FMR250 with HART/4...20 mA

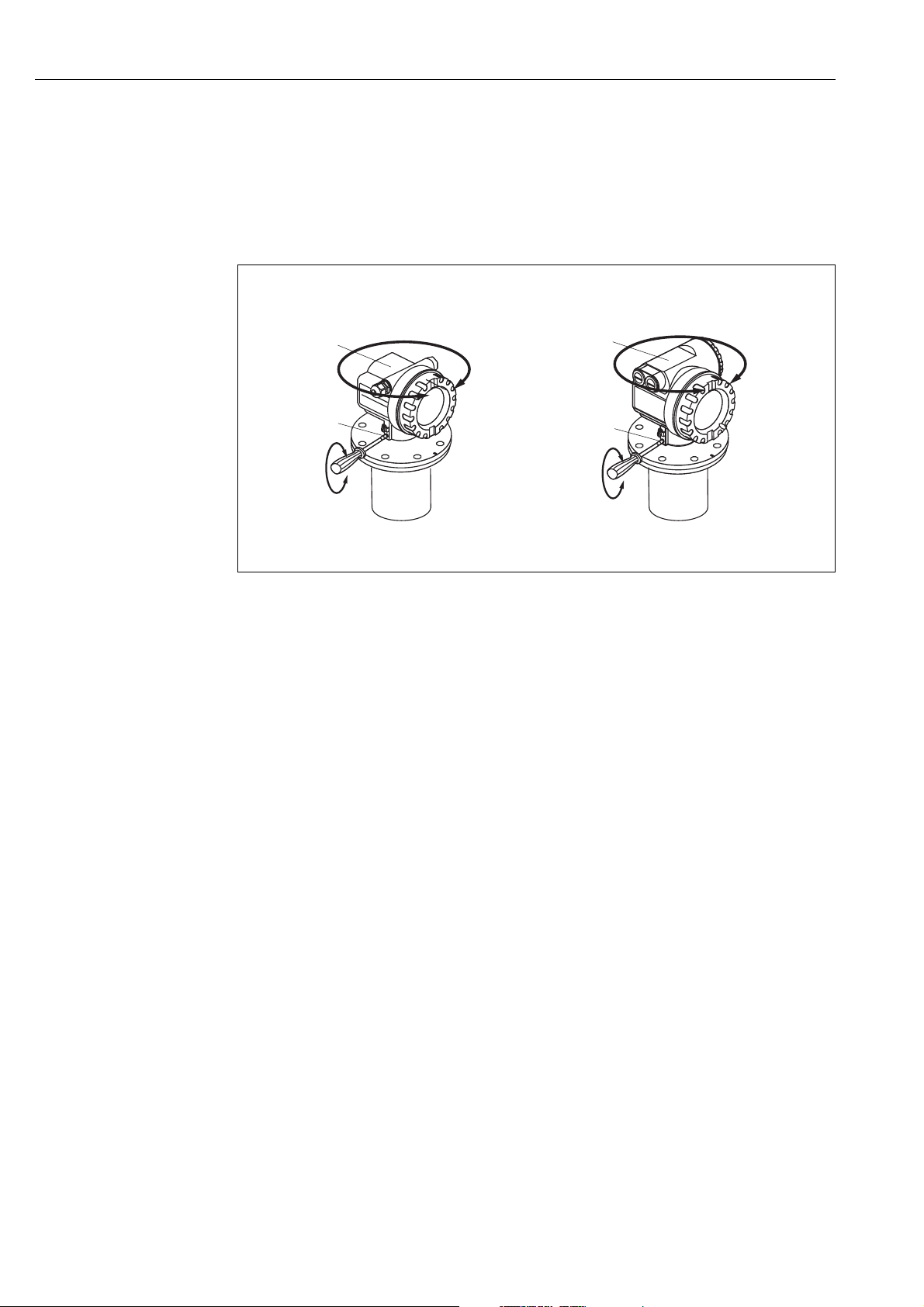

3.4.3 Turn housing

After mounting, the housing can be turned 350° in order to simplify access to the display and the

terminal compartment. Proceed as follows to turn the housing to the required position:

• Undo the fixing screws (1)

• Turn the housing (2) in the required direction

• Tighten up the fixing screws (1)

F12 / F23 housing T12 housing

2

2

1

1

allen key

4 mm/0.1”

L00-FMR2xxxx-17-00-00-en-010

3.5 Post-installation check

After the measuring instrument has been installed, perform the following checks:

• Is the measuring instrument damaged (visual check)?

• Does the measuring instrument correspond to the measuring point specifications such as process

temperature/pressure, ambient temperature, measuring range, etc.?

• Is the flange marking correctly aligned? (→ Page 11)

• Have the flange screws been tightened up with the respective tightening torque?

• Are the measuring point number and labeling correct (visual check)?

• Is the measuring instrument adequately protected against rain and direct sunlight (→ Page 64)?

24 Endress + Hauser

Micropilot M FMR250 with HART/4...20 mA Wiring

ENDRESS+HAUSER

4 Wiring

4.1 Quick wiring guide

Wiring in F12/F23 housing

Before connection please note the following:

"

●

Caution!

The power supply must be identical to the data on the

nameplate (1).

●

Switch off power supply before connecting up the device.

●

Connect Equipotential bonding to transmitter ground terminal

1

before connecting up the device.

●

Tighten the locking screw:

It forms the connection between the antenna and the housing

ground potential.

When you use the measuring system in hazardous areas, make sure you comply with

national standards and the specifications in the safety instructions (XA’s).

Make sure you use the specific cable gland.

On devices supplied with a certificate, the explosion protection

-

is designed as follows:

●

Housing F12/F23 - EEx ia:

Power supply must be intrinsically safe.

●

The electronics and the current output are galvanically

separated from the antenna circuit.

Connect up the Micropilot M as follows:

●

Unscrew housing cover (2).

●

Remove any display (3) if fitted.

●

Remove cover plate from terminal compartment (4).

●

Pull out terminal module slightly using pulling loop.

●

Insert cable (5) through gland (6).

A standard installation cable is sufficient if only the analogue signal is

used. Use a screened cable when working with a superimposed

communications signal (HART).

ENDRESS+HAUSER

MICROPILOT M

Order Code:

xxxxxxxx

Ser.-No.:

PTB 00ATEX

II 1/2 G EEx ia IIC T6

D00882-A

U 16 ... 30 V DC

4...20 mA

t >85°C

T >70°C:

A

Dat./Insp.:

xxxxxxxx

#

1

PN max.

8

T

Antenne

11

IP65

if modification

x=

see sep. label

3

4

max. °C

7

79689 Maulburg

Made in Germany

2

Unplug display connector!

3

R

E

S

U

A

H

+

S

S

E

R

D

N

E

-

communication

resistor

(> 250 )Ω

Only ground screening of the line (7) on sensor side.

●

Make connection (see pin assignment).

●

Re-insert terminal module.

●

Tighten cable gland (6).

●

Tighten screws on cover plate (4).

●

Insert display if fitted.

●

Screw on housing cover (2).

●

Switch on power supply.

power

alternatively

Commubox

FXA 191

DXR 375

7

4...20 mA

test sockets

(output current)

plant

4

2

3

1

L-

L+

I+

ground

I-

6

5

1234

Sealed terminal

compartment

4

L00-FMR2xxxx-04-0 0-00-en-013

Endress + Hauser 25

Wiring Micropilot M FMR250 with HART/4...20 mA

Wiring in T12 housing

Before connection please note the following:

●

"

Caution!

When you use the measuring system in hazardous areas, make sure you comply with

national standards and the specifications in the safety instructions (XA’s).

Make sure you use the specific cable gland.

-

The power supply must be identical to the data on the

nameplate (1).

●

Switch off power supply before connecting up the device.

●

Connect Equipotential bonding to transmitter ground terminal

1

before connecting up the device.

●

Tighten the locking screw:

It forms the connection between the antenna and the housing

ground potential.

Connect up the Micropilot M as follows:

Before unscrew housing cover (2) at seperate connection room

turn off the power supply!

●

Insert cable (3) through gland (4).

A standard installation cable is sufficient if only the analogue signal is

used. Use a screened cable when working with a superimposed

communications signal (HART).

ENDRESS+HAUSER

MICROPILOT M

Order Code:

Ser.-No.:

PTB 00ATEX

II 1/2 G EEx ia IIC T6

D00882-A

U 16 ... 30 V DC

4...20 mA

t >85°C

T >70°C:

A

Dat./Insp.:

xxxxxxxx

1

xxxxxxxx

8

IP65

if modification

x=

PN max.

T

max. °C

Antenne

11

see sep. label

3

4

7

79689 Maulburg

Made in Germany

2

-

communication

resistor

(> 250 )Ω

Only ground screening of the line (5) on sensor side.

●

Make connection (see pin assignment).

●

Tighten cable gland (4).

●

Screw on housing cover (2).

●

Switch on power supply.

power

alternatively

Commubox

FXA 191

DXR 375

4...20 mA

5

test sockets

(output current)

plant

4

2

3

1

L-

L+

I+

ground

I-

4

3

1234

L00-FMR2xxxx-04-00-00-en-014

26 Endress + Hauser

Micropilot M FMR250 with HART/4...20 mA Wiring

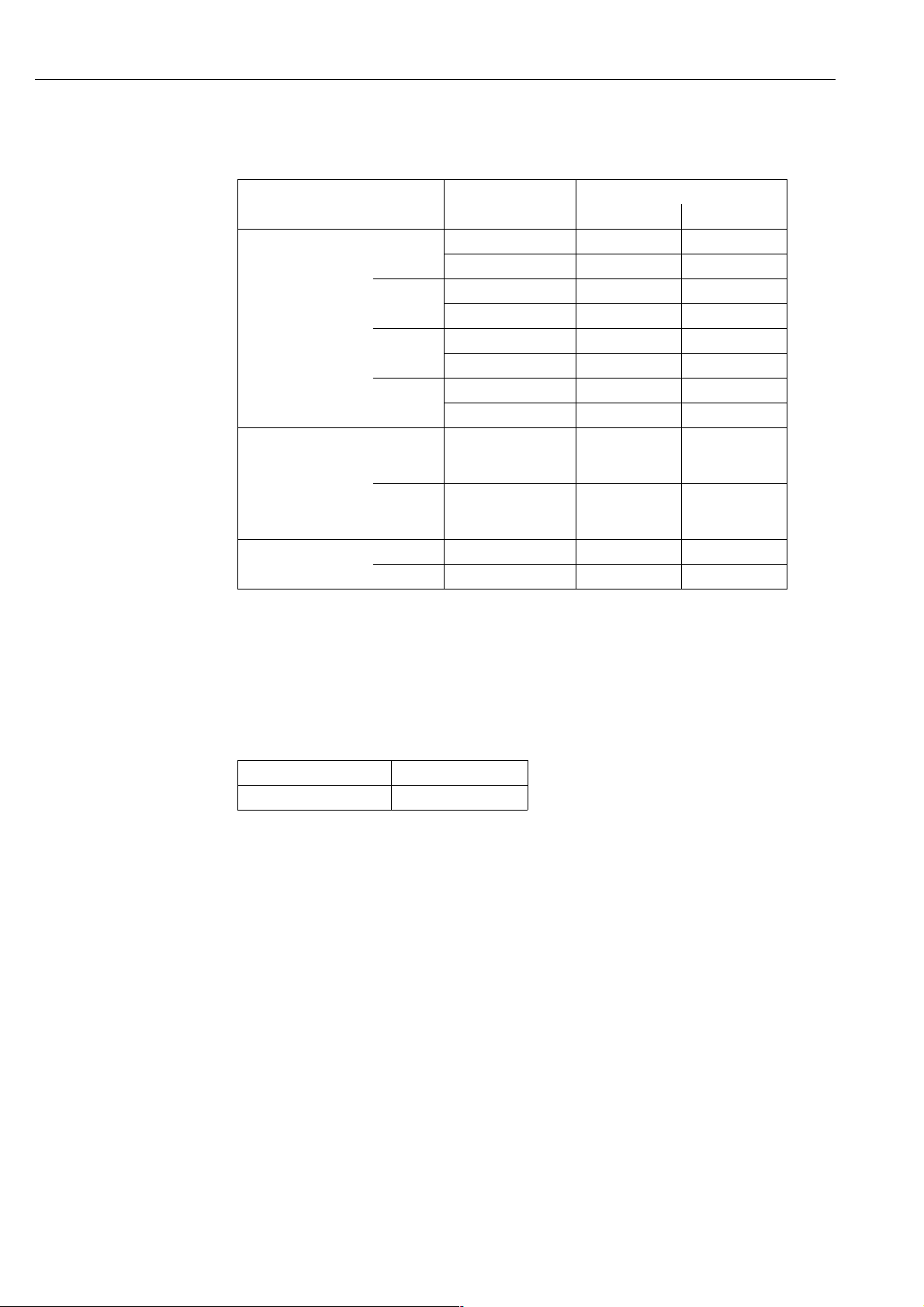

4.2 Connecting the measuring unit

Terminal compartment

Three housings are available:

• Aluminium housing F12 with additionally sealed terminal compartment for:

–standard,

–EEx ia,

– EEx ia with dust Ex.

• Aluminium housing T12 with separate terminal compartment for:

–standard,

–EEx d,

– EEx ia (with overvoltage protection),

– dust Ex.

• 316L housing F23 for:

–standard,

–EEx ia,

– EEx ia with dust Ex.

The electronics and current output are galvanically isolated from the antenna circuit.

F12 housing F23 housing

1 1

4 4

2 2

3 3

sealed terminal

compartment

T12 housing

1

2

3

4

The instrument data are given on the nameplate together with important information regarding the

analog output and voltage supply. Housing orientation regarding the wiring, (→ Page 24).

Load HART

Minimum load for Hart communication: 250 Ω

Cable entry

L00-FMR2xxxx-04-0 0-00-en-019

Cable gland: M20x1.5

Cable entry: G ½ or ½ NPT

Endress + Hauser 27

Wiring Micropilot M FMR250 with HART/4...20 mA

Supply voltage

The following values are the voltages across the terminals directly at the instrument:

Communication

HART

Fixed current, adjustable

e.g. for solar power

operation (measured

value transferred at

HART)

Fixed current for HART

Multidrop mode

1) Start up current 11 mA.

Current

consumption

standard

EEx ia

EEx d

dust Ex

standard 11 mA 10 V 36 V

EExia 11mA 10V 30V

standard 4 mA

EEx ia 4 mA

4mA 16V 36V

20 mA 7.5 V 36 V

4mA 16V 30V

20 mA 7.5 V 30 V

4mA 16V 30V

20 mA 11 V 30 V

4mA 16V 30V

20 mA 11 V 30 V

1)

1)

Terminal voltage

minimal maximal

16 V 36 V

16 V 30 V

Power consumption

Normal operation: min. 60 mW, max. 900 mW

Current consumption

Communication Current consumption

HART 3.6...22 mA

28 Endress + Hauser

Micropilot M FMR250 with HART/4...20 mA Wiring

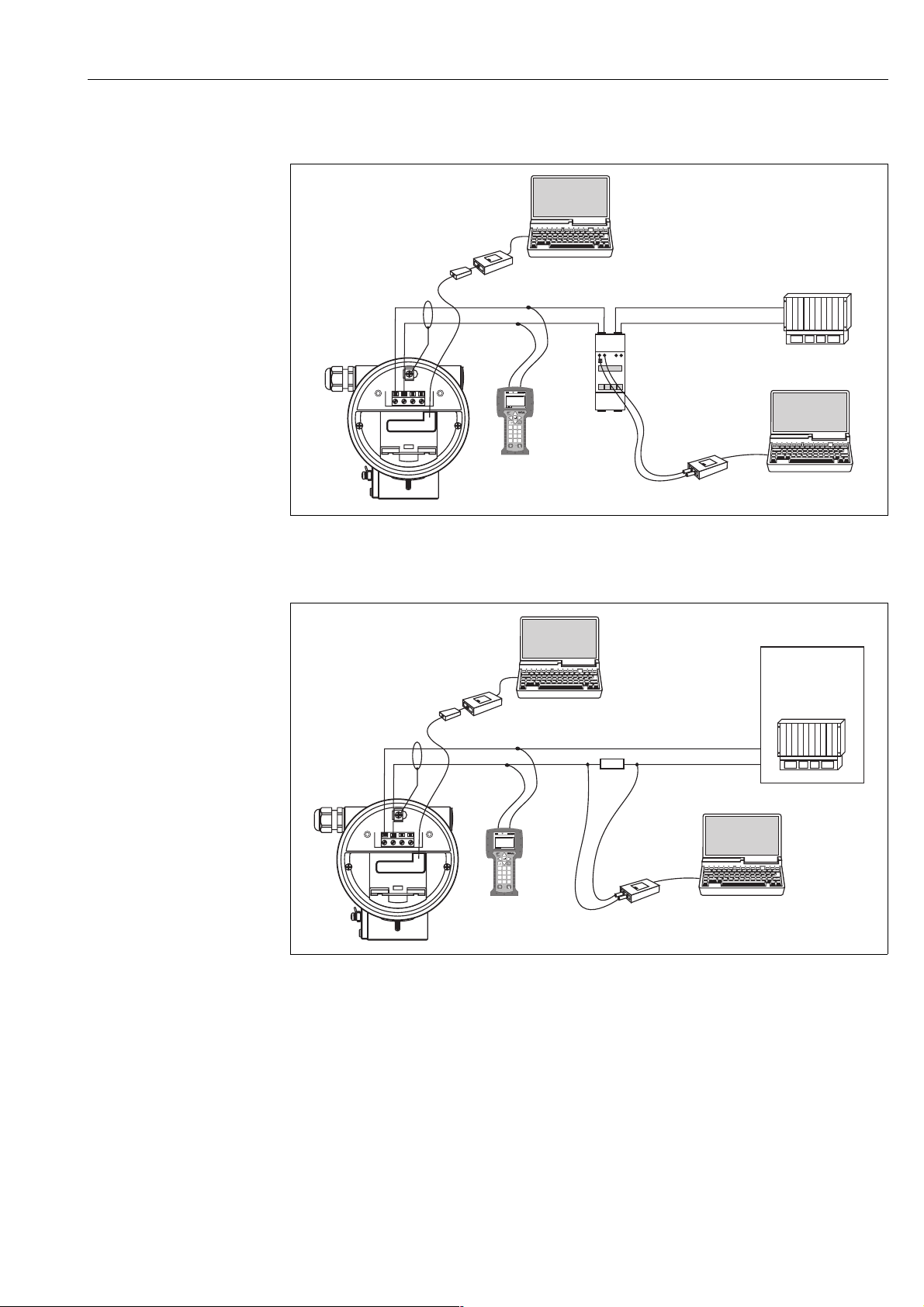

4.2.1 HART connection with E+H RMA422 / RN221N

- ToF Tool FieldTool

Package

FXA193

4...20 mA

ENDRESS + HAUSER

RMA 422

RMA422

1

234

dsdmdm

df das.

asdas fa

asas la.

FMP40:LIC0001

ONLINE

1 GROUP SELECT

2 PV 8.7 m

HELP SAVE

Page

Up

DeleteBksp

Page

On

# % &

A B C

D E F

2

1

3

Copy

Paste

Hot Key

M N O

G H I

J K L

4

5

6

+ Hot Key

Insert

W XY Z

P Q R S

T UV

8

7

9

+ * /

, ( )‘

_ < >

.

0

-

375

FIELD COMMUNICATOR

HART

DXR375

RN221N

- ToF Tool FieldTool

Package

- FieldCare

Commubox

FXA191

L00-FMR2xxxx-04-0 0-00-en-009

4.2.2 HART connection with other supplies

- ToF Tool FieldTool

Package

FXA193

4...20 mA

≥Ω250

1

234

FMP40:LIC0001

ONLINE

1 GROUP SELECT

2 PV 8.7 m

HELP SAVE

# % &

1

Copy

G H I

4

P Q R S

7

, ( )‘

FIELD COMMUNICATOR

dsdmdm

df das.

asdas fa

asas la.

Page

Up

DeleteBksp

Page

On

D E F

A B C

3

2

Hot Key

Paste

M N O

J K L

6

5

+ Hot Key

Insert

W XY Z

T UV

8

9

+ * /

_ < >

-

.

0

375

HART

DXR375

Caution!

"

If the HART communication resistor is not built into the supply unit, it is necessary to insert a

communication resistor of 250 Ω into the 2-wire line.

- ToF Tool FieldTool

Package

- FieldCare

Commubox

FXA191

DC power supply

unit

or

PLC

L00-FMR2xxxx-04-0 0-00-en-008

Endress + Hauser 29

Loading...

Loading...