Technical Information

Micropilot S FMR540

Level-Radar

Smart Transmitter for continuous and non-contact precision level

measurement. For custody transfer and inventory control

applications with NMi and PTB approvals.

Application

The Micropilot S is used for highly accurate level

measurement in storage tanks and can be applied in

custody transfer applications. It meets the relevant

requirements according to OIML R85 and API 3.1B.

Typical areas of application are:

• The with parabolic antenna is excellently suited for

free space applications up to 40 m (131 ft).

• The with horn antenna is suitable for free space

applications that disallow the use of a parabolic

antenna due to tank/nozzle geometry.

The FMR540 with DN200 (8") parabolic antenna offers

high beam focussing of 4° and is therefore ideally suited

to applications with nozzles situated close to the tank

wall.

The FMR540 with DN100 (4") horn antenna is designed

for all small nozzles sizes.

Your benefits

• Better than 1 mm accuracy.

• National approvals (NMi, PTB) for custody transfer.

• Applicable as stand-alone system or tied into tank

gauging systems via the Tank Side Monitor NRF590.

• Cost-effective and simple installation via 4-wire cable

with HART and 24V DC intrinsically safe power

supply.

• low cost, low weight UNIversal flanges

• top target positioners to compensate any flange

inclination

• easy on-site operation via menu-driven alphanumeric

display

• easy commissioning, documentation and diagnostics

via operating software (ToF Tool - Fieldtool Package or

FieldCare)

• HART communication.

TI412F/00/en/09.06

Table of contents

Micropilot S FMR540

Function and system design. . . . . . . . . . . . . . . . . . . . . 3

Measuring principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Equipment architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Custody transfer applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Integrated in tank gauging system . . . . . . . . . . . . . . . . . . . . . . . . . 6

Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Measured variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Antenna selection for Micropilot S-series . . . . . . . . . . . . . . . . . . . 7

Measuring range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Measuring range depending on sensor type and media group . . . . . 8

Measuring conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Operating frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Output signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Signal on alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Linearization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Galvanic isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Auxiliary energy . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Terminal assignment 4…20 mA with HART . . . . . . . . . . . . . . . . 11

Load HART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Cable entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Current consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Residual ripple HART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Max noise HART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

mm accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Overvoltage protector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Performance characteristics. . . . . . . . . . . . . . . . . . . . 13

Note . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Reference operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Maximum measured error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Software reliability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Hysteresis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Long-term drift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Influence of ambiente temperature . . . . . . . . . . . . . . . . . . . . . . . 13

Proof of accuracy of custody transfer versions . . . . . . . . . . . . . . . 13

Non-repeatability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Inventory control versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Operating conditions: Installation . . . . . . . . . . . . . . . 14

Installation instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Beam angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Installation on tank FMR540 . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

FMR540 with top target positioner . . . . . . . . . . . . . . . . . . . . . . . 18

Integrated air purge connection . . . . . . . . . . . . . . . . . . . . . . . . . 18

Operating conditions: Environment . . . . . . . . . . . . . . 19

Ambient temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Storage temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Climate class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Degree of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Vibration resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Cleaning of the antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Electromagnetic compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Approvals for custody transfer applications . . . . . . . . . . . . . . . . . 19

Operating conditions: Process . . . . . . . . . . . . . . . . . . 19

Process temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Process pressure limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Antenna core . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Wetted parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Optional (top target positioner) . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Mechanical construction . . . . . . . . . . . . . . . . . . . . . . 20

Design, dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Type plate / type plate for custody transfer applications . . . . . . . 22

Endress+Hauser UNI flange . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Human interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Operation concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Display elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Operating elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

On-site configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Remote configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Certificates and approvals . . . . . . . . . . . . . . . . . . . . . 29

CE approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Ex approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

External standards and guidelines . . . . . . . . . . . . . . . . . . . . . . . . 29

Type approvals for custody transfer approvals . . . . . . . . . . . . . . . 29

RF approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Ordering information. . . . . . . . . . . . . . . . . . . . . . . . . 30

Micropilot S FMR540 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Ordering structure (continued) . . . . . . . . . . . . . . . . . . . . . . . 31

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Weather protection cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Sensor alignment tool for Target Positioner (alignment device option)

only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Commubox FXA191 HART . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Commubox FXA195 HART . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Commubox FXA291 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

ToF Adapter FXA291 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Fields of activities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Technical Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Certificates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Patents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2 Endress+Hauser

Micropilot S FMR540

Function and system design

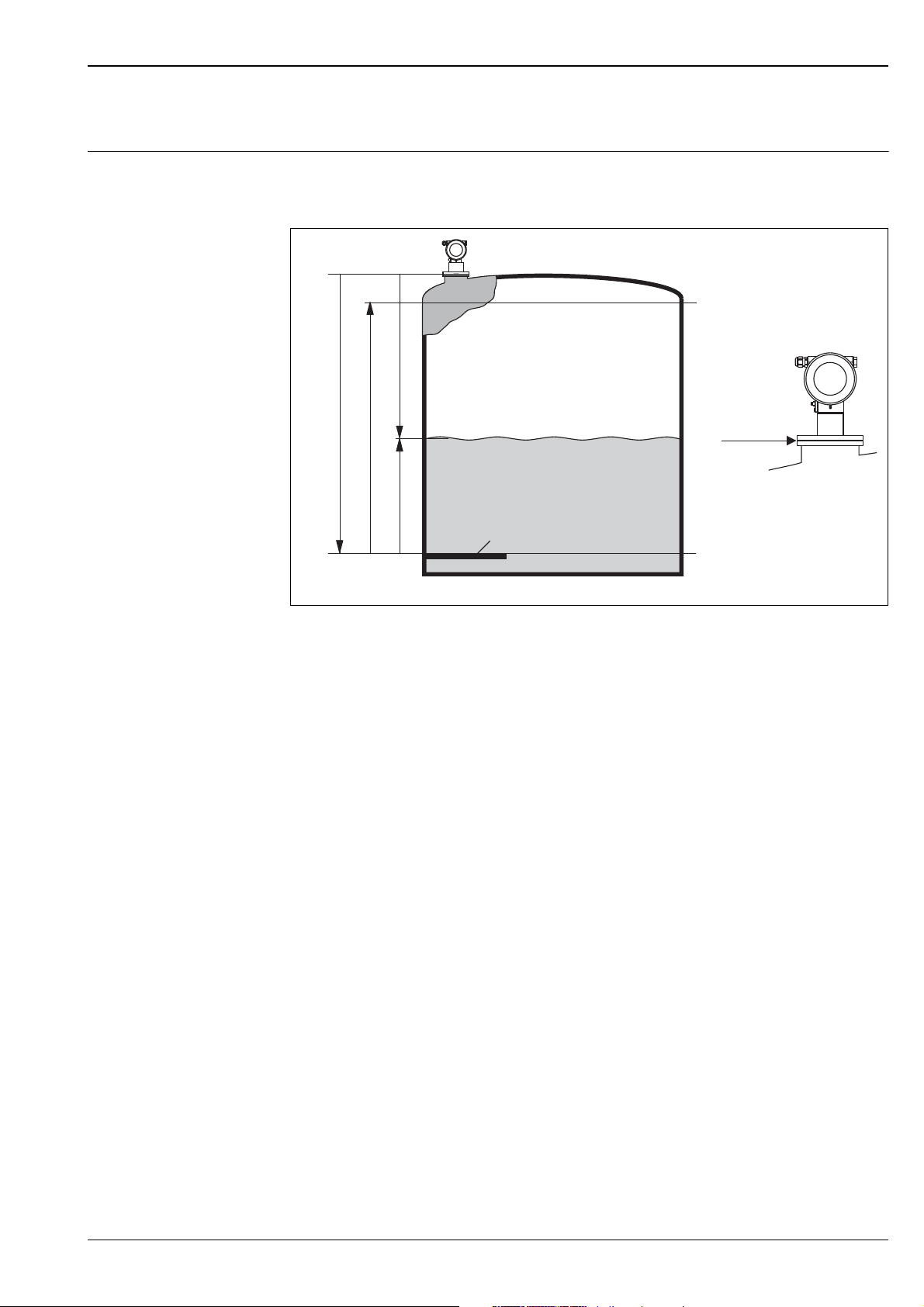

Measuring principle The Micropilot is a "downward-looking" measuring system, operating based on the time-of-flight method. It

measures the distance from the reference point (process connection) to the product surface. Radar impulses are

emitted by an antenna, reflected off the product surface and received again by the radar system.

gauge reference height

(GRH)

D

20 mA

100%

E

F

flange:

referencepoint of

measurement

L

datum plate (Gauge Reference plate)

4mA

0%

L00-FMR250xx-15-00-00-en-001

Input

The reflected radar impulses are received by the antenna and transmitted into the electronics. A microprocessor

evaluates the signal and identifies the level echo caused by the reflection of the radar impulse at the product

surface. The unambiguous signal identification is accomplished by the PulseMaster® software, based on many

years of experience with time-of-flight technology.

The distance D to the product surface is proportional to the time of flight t of the impulse:

D = c · t/2,

with c being the speed of light.

Based on the known empty distance E, the level L is calculated:

L = E – D

Reference point for "E" is the lower surface of the process connection. For highly precise level measurements,

it is of crucial importance to have a stable mounting position (GRH) of the radar gauge or to compensate for

the effects of tank movements during filling and emptying cycles. This can be done by either using the dip table

integrated in the Micropilot S FMR53x / 540 or by using the compensation methods integrated into the Tank

Side Monitor NRF590.

The Micropilot is equipped with functions to suppress interference echoes. The user can activate these

functions. They ensure that interference echoes (e.g. from edges and weld seames) are not interpreted as level

echo.

Output

The Micropilot is commissioned by entering an empty distance E (=zero), a full distance F (=span) and an

application parameter. The application parameter automatically adapts the instrument to the measuring

conditions. The data points “E” and “F” correspond with 4mA and 20mA for instruments with current output.

They correspond with 0 % and 100 % for digital outputs and the display module. For inventory control or

custody transfer applications, the measurement should always be transferred via digital communication

(HART).

A linearization with max. 32 points, based on a table entered either manually or semi-automatically, can be

activated locally or remotely. This function provides a measurement in engineering units and a linear output

signal for spheres, horizontal cylindrical tanks and tanks with conical outlet.

Endress+Hauser 3

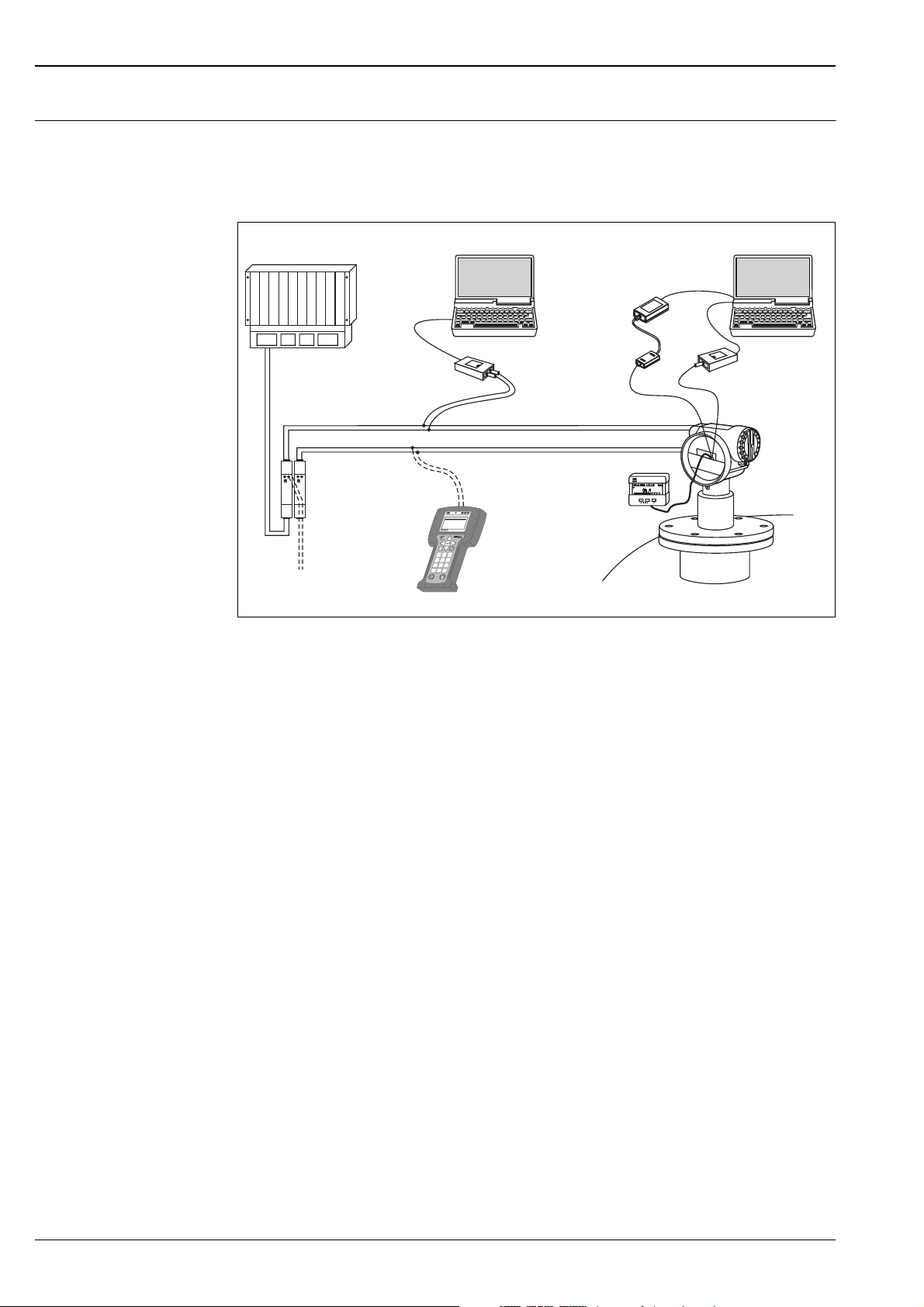

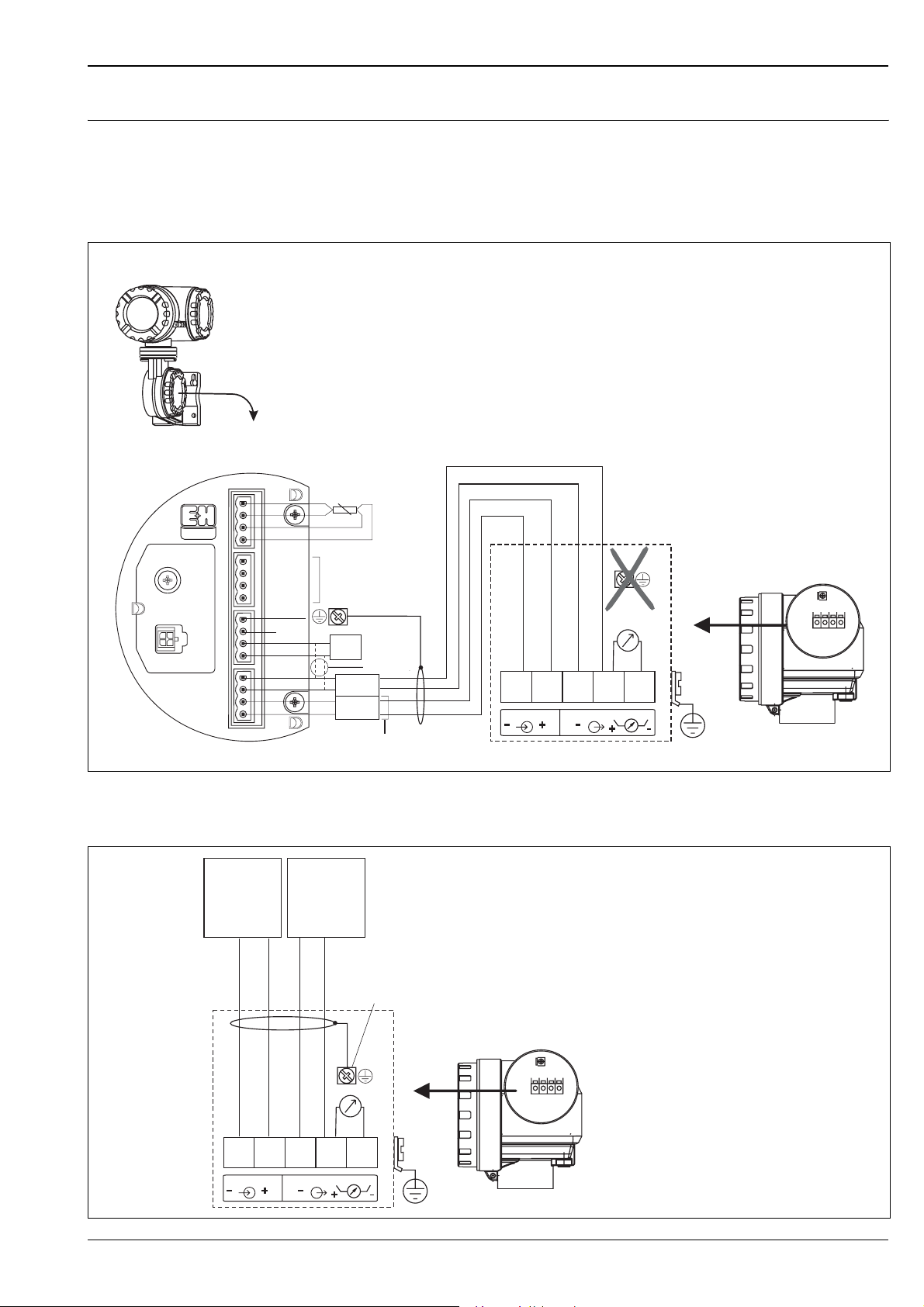

Equipment architecture Stand-alone

The instrument provides a 4…20 mA output with HART protocol.

The complete measuring system consists of:

Micropilot S FMR540

PLC

- Fieldcare

- ToF Tool - Field Tool Package

Commubox

FXA191 (RS232C)

or FXA195 (USB)

Commubox

FXA291 (USB)

ToF Adapter

FXA291

- Fieldcare

- ToF Tool - Field Tool Package

service adapter

FXA193 (RS232C)

HART

HART

2x transmitter power

supply unit

RN221N

FXA195

or

DXR375

FIELD COMMUNICATOR

FIELD COMMUNICATOR

DELTABAR:* * * * * * * *

DELTABAR:* * * * * * * *

ONLINE

ONLINE

1 QUICK SETUP

1 QUICK SETUP

2 OPERATING MENU

2 OPERATING MENU

3 PV 352 mbar

3 PV 352 mbar

4 SV 0 °C

4 SV 0 °C

HELP SAVE

HELP SAVE

Page

Page

Up

Up

DeleteBksp

DeleteBksp

Page

Page

On

On

A B C

D E F

A B C

D E F

# % &

# % &

1

3

1

3

2

2

Paste

Hot Key

Paste

Hot Key

Copy

Copy

G H I

J K L

M N O

G H I

J K L

M N O

6

6

5

5

4

4

Insert

+ Hot Key

Insert

+ Hot Key

P Q R S

T UV

W XY Z

P Q R S

T UV

W XY Z

8

8

9

9

7

7

, ( )‘

_ < >

+ * /

, ( )‘

_ < >

+ * /

-

-

.

0

.

0

375

375

dsdmdm

dsdmdm

df das.

df das.

asdas fa

asdas fa

asas la.

asas la.

HART handheld

DXR375

operating and

display modull

VU331

ENDRESS + HAUSER

%

+–

E

L00-FMR53xxx-14-00-06-en-002

On-site Configuration

• with display and operating module VU331,

• with a Personal Computer, FXA193 and the operating software "ToF Tool - FieldTool Package" respectively

"FieldCare".

The ToF Tool is a graphical operating software for instruments from Endress+Hauser that operate based on

the time-of-flight principle (radar, ultrasonic, guided micro-impulse). It assists with commissioning, securing

data, trouble shooting and documentation of the measuring point.

Remote Configuration

• with HART handheld DXR375,

• with a Personal Computer, Commubox FXA195 and the operating software "ToF Tool - FieldTool Package"

respectively "FieldCare".

Remote operation

• With a Personal Computer, NRF590 (Tank Side Monitor) and the inventory management software, e.g.

"FuelsManager".

4 Endress+Hauser

Micropilot S FMR540

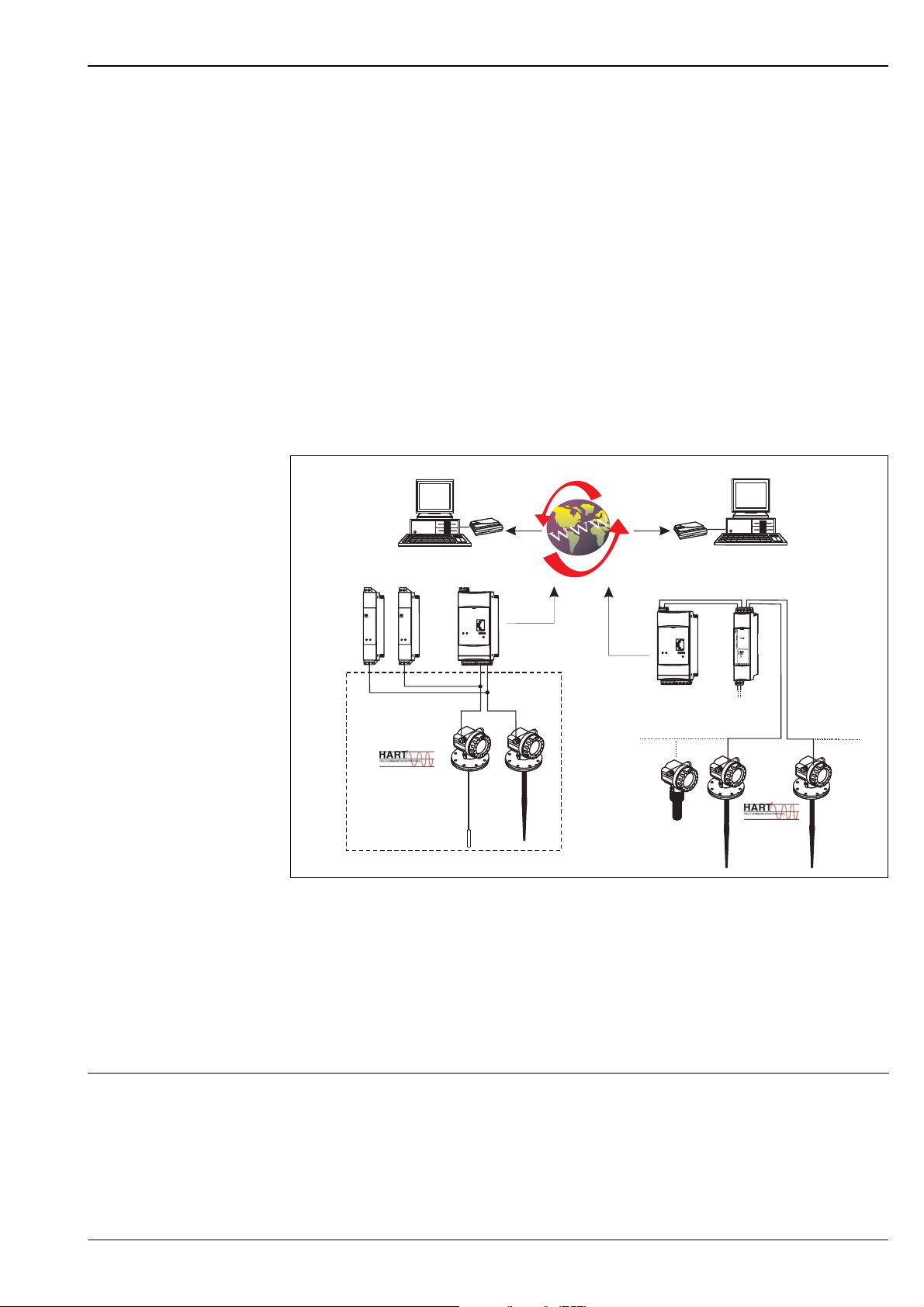

System integration via Fieldgate

Vendor Managed Inventory

By using Fieldgates to interrogate tank or silo levels remotely, suppliers of raw materials can provide their

regular customers with information about the current supplies at any time and, for example, account for them

in their own production planning. For their part, the Fieldgates monitor the configured level limits and, if

required, automatically activate the next supply. The spectrum of options here ranges from a simple purchasing

requisition via e-mail through to fully automatic order administration by coupling XML data into the planning

systems on both sides.

Remote maintenance of measuring equipment

Fieldgates not only transfer the current measured values, they also alert the responsible standby personnel, if

required, via e-mail or SMS. In the event of an alarm or also when performing routine checks, service

technicians can diagnose and configure connected HART devices remotely. All that is required for this is the

corresponding HART operating software (e.g. ToF Tool - FieldTool Package, FieldCare, ...) for the connected

device. Fieldgate passes on the information transparently, so that all options for the respective operating

software are available remotely. Some on-site service operations can be avoided by using remote diagnosis and

remote configuration and all others can at least be better planned and prepared.

Remote configuration/diagnostics

via HART Client:

- ToF Tool - FieldTool

Package

- FieldCare

...

e.g. 2 x RN221N-B …

ENDRESS+HAUSER

RN 221N

ENDRESS+HAUSER

RN 221N

Channel 1 Channel 2

-

Fieldgate

FXA520

Analogue

Ethernet

GSM

Remote monitoring

Multidrop-Connector

Fieldgate

FXA520

FXN520

FXN520

FXN520

20...45 V

DC

.

HTTP script

Web browser

…

L00-FXA520xx-14-00-06-en-009

Note!

The number of instruments which can be connected in mutidrop mode can be calculated by the "FieldNetCalc"

program. A description of this program can be found in Technical Information TI 400F (Multidrop connector

FXN520). The program is available form your Endress+Hauser sales organisation or in the internet at:

"www.endress.com É Download" (Text Search = "Fieldnetcalc").

Integration into the Asset Management System

The HART interface allows the integration into the AMS® (Asset Management System) from Emerson.

Custody transfer applications The Micropilot S is suitable for custody transfer and inventory control applications.The on-site testing has to be

done in compliance with the applicable regulatory standards.The Micropilot S can be sealed after successful onsite calibration to be protected against any access to the electronics compartment and any changes of software

settings. If the Micropilot S is used for custody transfer or inventory control, any temperature influence on the

tank shell height can be compensated for using the Tank Side Monitor. In addition, the vertical movement of

the gauge reference point due to the hydrostatic tank deformation can be compensated in the Tank Side

Monitor. A Tank Side Monitor can provide 24 VDC for a Micropilot S. The Tank Side Monitor can

communicate with up to 6 devices via HART Multidrop.

Endress+Hauser 5

Micropilot S FMR540

Integrated in tank gauging system

The Endress+Hauser Tank Side Monitor NRF 590 provides integrated communications for sites with multiple

tanks, each with one or more sensors on the tank, such as radar, spot or average temperature, capacitive probe

for water detection and/or pressure sensors. Multiple protocols out of the Tank Side Monitor guarantee

connectivity to nearly any of the existing industry standard tank gauging protocols. Optional connectivity of

analog 4...20 mA sensors, digital I/O and analog output simplify full tank sensor integration. Use of the proven

concept of the intrinsically safe HART bus for all on-tank sensors yields extremely low wiring costs, while at

the same time providing maximum safety, reliability and data availability.

Fuels Manager

Software

RTU 8130

(remote

terminal

unit)

Supply voltage:

16…253 VAC

HART

4 wire

Tank Side Monitor

Pressure

Micropilot S Prothermo

L00-FMR53xxx-14-00-06-en-004

6 Endress+Hauser

Micropilot S FMR540

Input

Measured variable The measured variable is the distance between the reference point (GRH, refer to fig. → ä 3) and a reflective

surface (i.e. medium surface).

The level is calculated based on the tank height entered.The level can be converted into other units (volume,

mass) by means of a linearization. In order to compensate for non-linear effects like movement of the tank roof,

an additional correction table (diptable) can be entered.

Antenna selection for Micropilot S-series

It is essential for each and every application and installation to select the right antenna type.

The antenna selection depends on the following criteria:

• Type of application (i.e. free space vs. stilling well)

• Installation possibilities (size, location and height of nozzle)

• Properties of the product stored in the tank (radar reflectivitiy, vapor pressure, temperature, etc.)

• The Micropilot S FMR540 offers 2 radar antennas

For stilling well applications, FMR532 should be selected (see TI344F)

For measuring mediums with a low reflectivity (i.e. asphalts, bitumen and etc.), FMR533 should be selected

(see TI344)

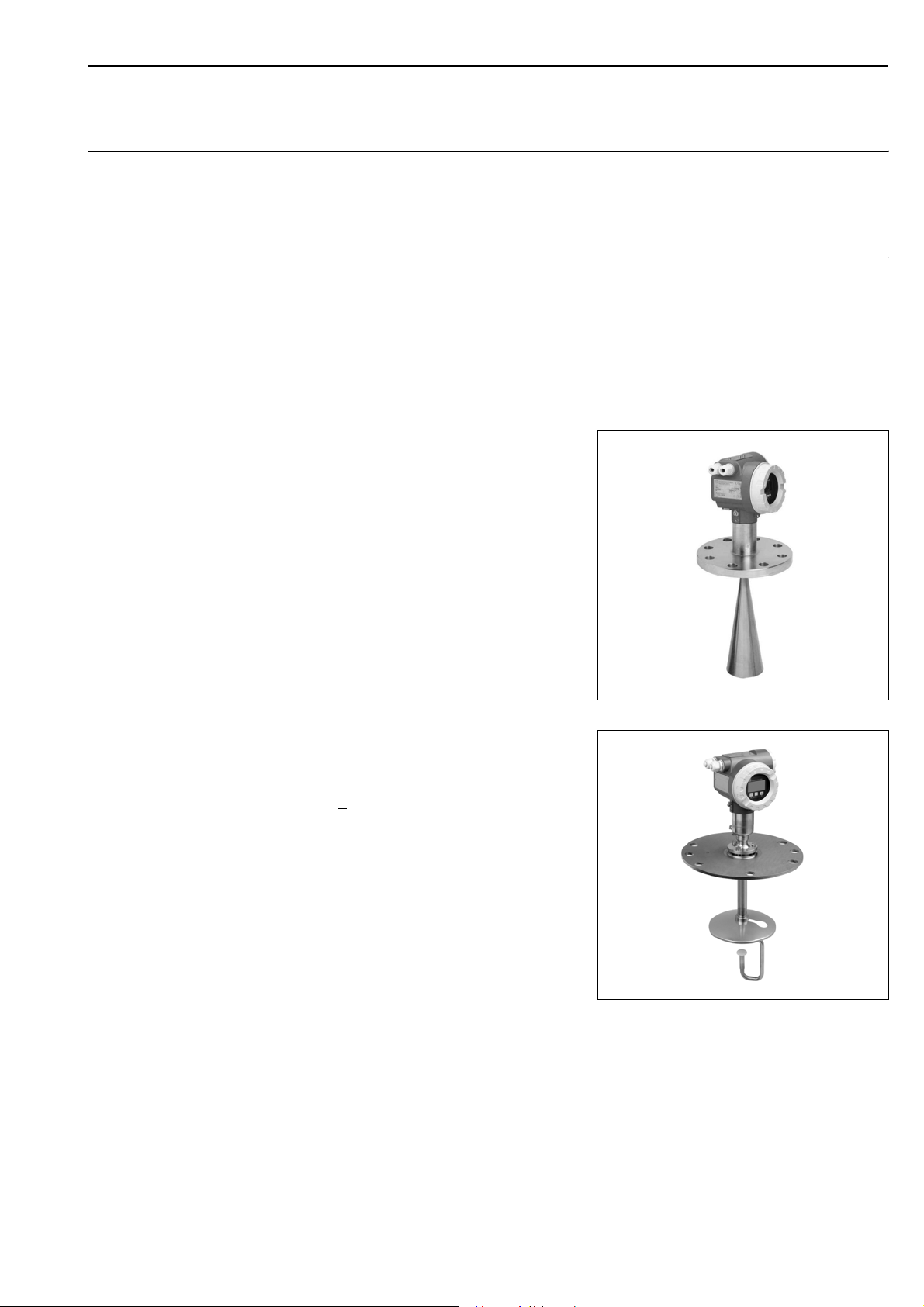

Horn antenna

With DN100 (4") horn, this antenna is suitable for

most of custody transfer applications up to the

measuring distance of 20m/30m (depending on

dielectric constant). With the narrow beam angle (8

deg) , compared to FMR530, this horn antenna is

suitable for closer to tank wall application (→ ä 15)

When installing, it is essential that the horn extends

below the nozzle (→ ä 16).

L00-FMR530-10-00-00-yy-001

Parabolic antenna

The parabolic antenna offers the smallest beam angle

(4 deg) for free space applications. It also covers

longest measuring distance of 40m (dielectric

constant >

1.8). It is ideal for applications close to the

tank walls, where nozzles are available. When

installing, it is ideal that the parabolic antenna is

installed in the position where the reflector protrude

from the nozzle (→ ä 18). For measuring mediums

with a low reflectivity, such as asphalts and bitumen,

FMR533 (please, refer to TI344F) is recommended.

L00-FMR540xx-10-08-06-xx-001

Endress+Hauser 7

Micropilot S FMR540

Measuring range The usable measuring range depends on the size of the antenna, the reflectivity of the medium, the mounting

location and possible interference reflections.

To achieve an optimised signal strength it is recommended to use an antenna with as large as possible diameter

(DN200/8" parabolic antenna).

The following tables describe the groups of media as well as the achievable measuring range as a function of

application and media group. If the dielectric constant of a medium is unknown, it is recommended to assume

media group B to ensure a reliable measurement.

Table 1:

The following table describes the media groups and the dielectric constant

Media group DC (εr) Examples

A 1.4 ... 1.8 non-conducting liquids, e.g. liquefied gas, ...

B 1.8 ... 4

C 4 ... 10 e.g. concentrated acids, organic solvents, esters, aniline, alcohol, acetone, …

D > 10 conducting liquids, e.g. aqueous solutions, dilute acids and alkalis

1) Treat Ammonia NH3 as a medium of group A.

non-conducting liquids, e.g. benzene, oil, toluene, white products, black products,

crudes, bitumen/asphalts, ...

εr.

1)

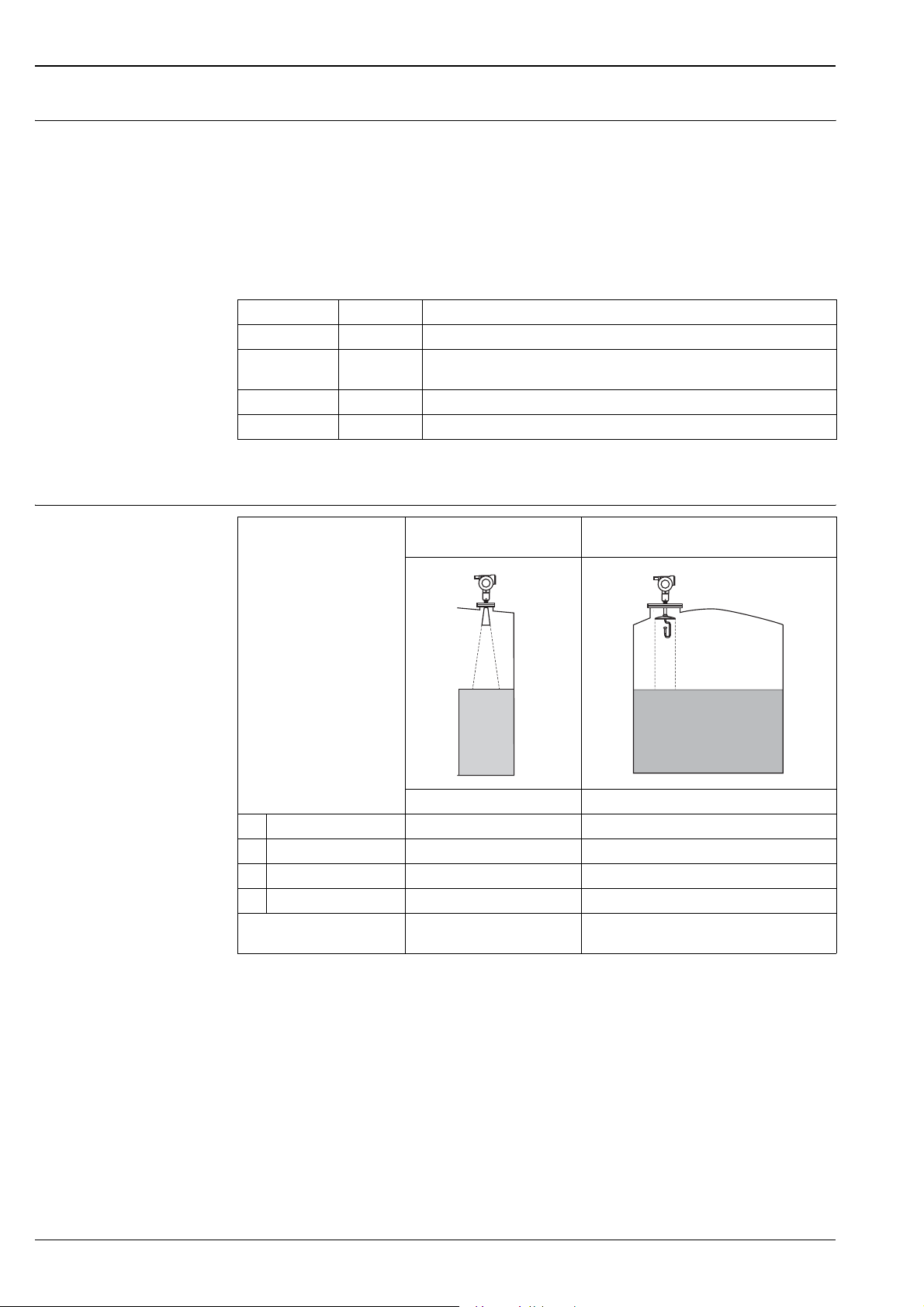

Measuring range depending on sensor type and media group

Media group Horn antenna

without sensor extension

Measuring range Measuring range

A DC (

B DC (

C DC (

D DC (εr) > 10 0.6 ... 30 m 0.8 ... 40 m

Max. measuring range with

cudstody transfer approval

εr) = 1.4 ... 1.8 −−

εr) = 1.8 ... 4 0.6 ... 20 m 0.8 ... 40 m

εr) = 4...10 0.6 ... 30 m 0.8 ... 40 m

NMi: 20 m / 65 ft

PTB: 20 m / 65 ft

Parabolic antenna

without sensor extension

NMi: 25 m / 82 ft

PTB: 30 m / 98 ft

Note!

For stilling well applications Micropilot S FMR532 is recommended (see Technical Information TI344F).

8 Endress+Hauser

Micropilot S FMR540

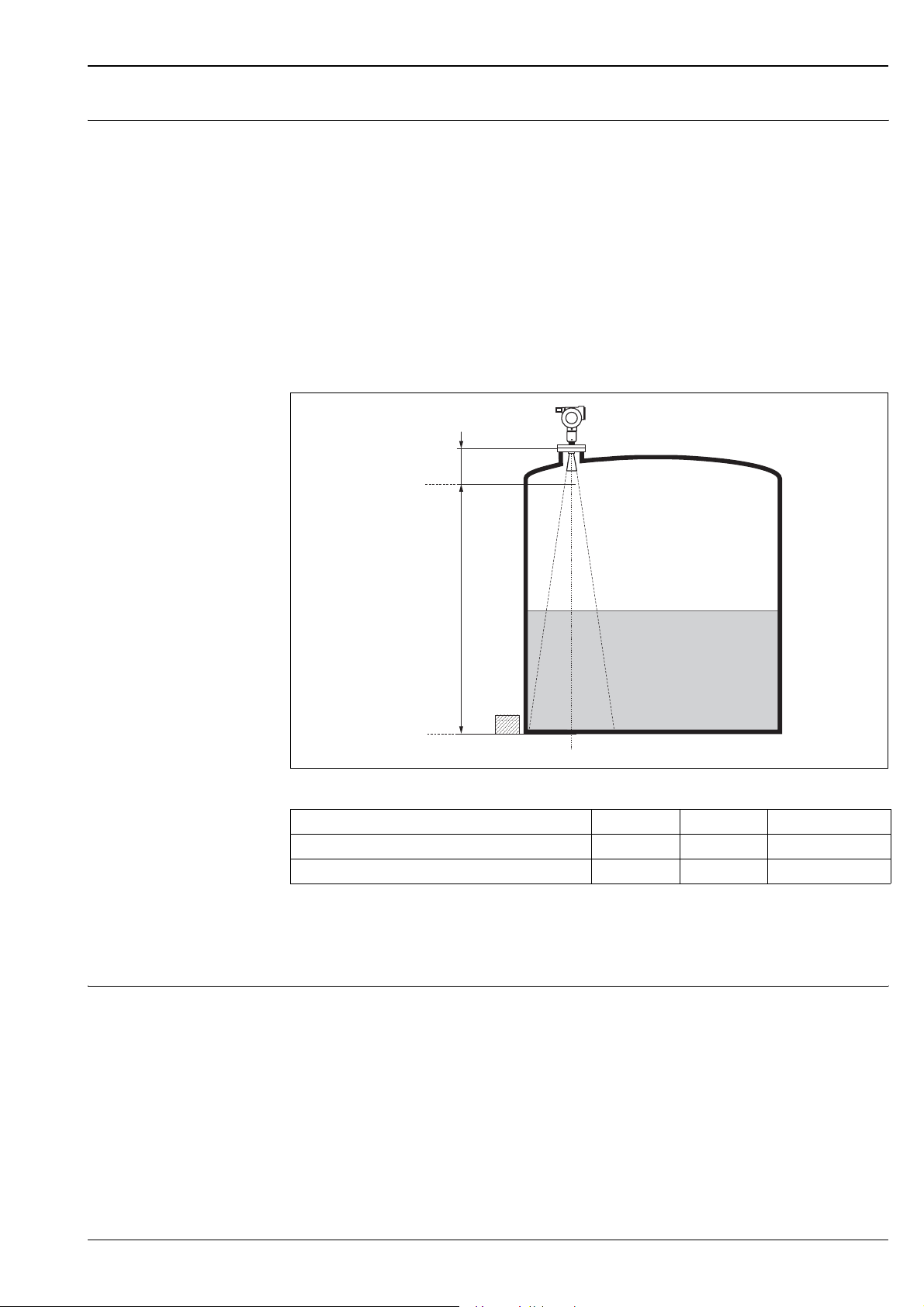

Measuring conditions • The measuring range begins, where the beam hits the tank bottom. Particularly with dish bottoms or conical

outlets the level cannot be detected below this point.

• In case of media with a low dielectric constant (groups A and B), the tank bottom can be visible through the

medium at low levels (low height C). Reduced accuracy has to be expected in this range. If this is not

acceptable, we recommend positioning the zero point at a distance C (see Fig.) above the tank bottom in

these applications.

• In principle it is possible to measure up to the tip of the antenna with FMR540. However, due to

considerations regarding corrosion and build-up, the end of the measuring range should not be chosen any

closer than A (see Fig.).

• B requests the smallest possible measuring range (see fig.).

• Tank diameter and height should be at least dimensioned such that a reflection of the radar signal on both

sides of the tank can be avoided.

• Depending on its consistence, foam can either absorb microwaves or reflect them off the foam surface.

Measurement is possible under certain conditions.

A

100%

B

0%

FMR540 (Horn Antenna without extension) 0.6 (23.6) > 0.5 (> 20) > 300 (> 12)

FMR540 (parabolic Antenna without extension) 0.8 (31.5) > 0.5 (> 20) > 300 (> 12)

C

Behaviour if measuring range is exceeded

The behaviour in case of the measuring range being exceeded can be freely set: the default setting is a current

of 22 mA and the generation of a digital warning (E651).

Operating frequency • FMR540: 26 GHz ultra wideband system

L00-FMR54xxx-17-00-00-yy-009

A [m (inch)] B [m (inch)] C [mm (inch)]

Endress+Hauser 9

Micropilot S FMR540

132

4

5

132

4

5

Output

Output signal • 4…20 mA with HART protocol (e.g. for multidrop connection to the Tank Side Monitor NRF590): this

version can be operated via the PC operating software ToF Tool and FieldCare. The instrument supports both

point-to-point and multidrop operation.

Signal on alarm Error information can be accessed via the following interfaces:

• Local display:

– Error symbol

– Plain text display

– LED’s: red LED continuously on = alarm, red LED flashes = warning

• Current output

• Digital interface

Linearization The linearization function of the Micropilot S allows the conversion of the measured value into any unit of

length or volume. Linearization tables for calculating the volume in cylindrical tanks are pre-programmed.

Other tables of up to 32 value pairs can be entered manually or semi-automatically.

Galvanic isolation 500 V towards ground.

500 V between power supply and signal.

Auxiliary energy

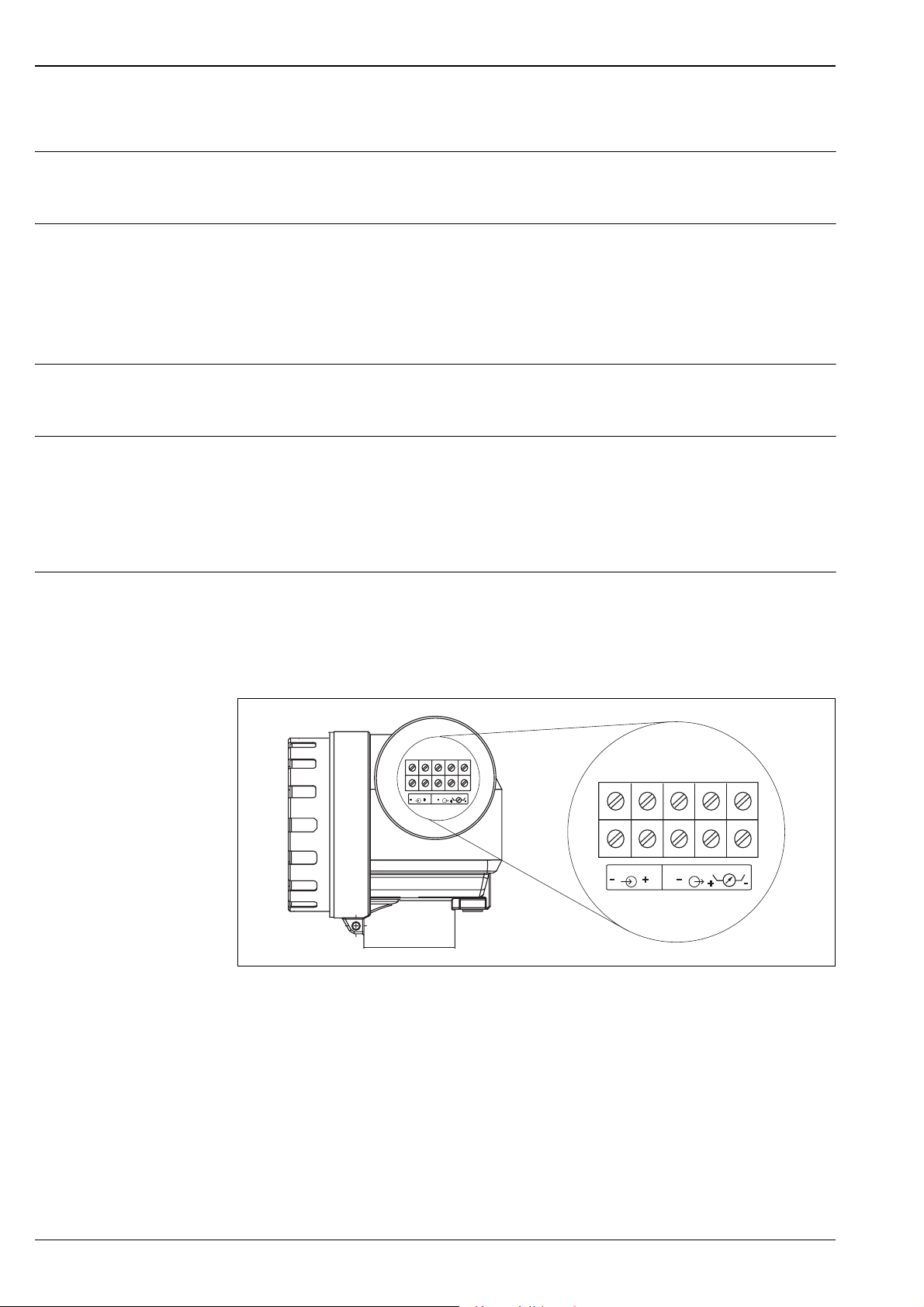

Electrical connection Terminal compartment

• Aluminium housing T12 with separate terminal compartment for:

– standard,

– EEx ia (with overvoltage protection),

The electronics and current output are galvanically isolated from the antenna circuit.

5

4

power supply signal

L00-FMR53xxx-04-00-00-en-001

10 Endress+Hauser

Micropilot S FMR540

1

3

2

4

5

1

3

2

4

5

Terminal assignment 4…20 mA with HART

Tank Side Monitor

NRF590

intrinsicaly safe

NRF 590 i.s. terminal board

terminal board

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

The 4-wire cable is connected to the screw terminals (wire diameter 0.5…2.5 mm) in the terminal

compartment. Use 4-wire twisted pair cable with screen for the connection.Protective circuitry against reverse

polarity, RFI, and over-voltage peaks is built into the device (refer to TI241F »basics for EMC-tests«). Refer to

TI374F for connection to the Tank Side Monitor NRF590.

Connection to Tank Side Monitor NRF590

The Micropilot S is - possibly in combination with other devices - connected

to a tank side monitor in a hazardous area. In this case, it is recommended

D+

S+

SD-

OPT1

OPT2

OPT3

OPT4

+

H

-

+

H

-

+

H

-

+

P

-

RTD

grounding single sided

i.s. module wiring

on Tank Side Monitor

NRF590

Internally

HART

interconnected

sensor

as one HART

fieldbus loop

+

4

-

3

+

2

-

1

For Micropilot

only for

S-series only!

Micropilot S

that you ground the cable screen centrally at the and

connect all devices to the same potential matching line (PML). If, for functional

reasons, a capacitive coupling is required between local earth and screen

(multiple grounding), ceramic condensers with a dielectric strength of min. 1500 V

must be used, whereby the total capacitance of 10 nF must not be exceeded.

Notes on grounding interconnected intrinsically safe devices are provided by

the FISCO model.

12345

Tank Side Monitor

grounding not on

Micropilot S

plant

ground

1234

l00-fmr54xxx-04-00-00-en-002

eff

Connection as a stand alone device

power:

24 VDC

(16…30 V)

12345

Endress+Hauser 11

signal:

24 VDC

A Micropilot S situated in a hazardous area is connected as a

to a situated outside of the

device power supply unit and transmitter

hazardous area. In this case, it is recommended that the screen be

connected directly to the Micropilot at the housing's earth, whereby

the Micropilot S and the power supply unit are connected to the same

5

potential matching line (PML).

plant

ground

1234

single

l00-fmr54xxx-04-00-00-en-001

Loading...

Loading...