Instructions for Use

938321WEB-GB/1-1012

1 Description and purpose

2

The AqualimbTF is a prosthetic knee designed for above knee users.

The knee is water resistant and is intended for use as a shower limb ONLY.

Application:

These instructions are for use by the Clinician/Practitioner

The product is to be used exclusively as part of a lower limb prosthesis

Intended for single user

Maximum user weight 100kg

Ensure that the user has understood all instructions for use, drawing particular

attention to the section regarding safety and maintenance.

Features:

• Geometrically stable 4 bar knee

• Hand operated knee lock, HOKL

• Corrosion resistant

Activity level:

Although intended for Activity Level 2 this device will benet Activity Level 3 and 4 users for

the purpose of showering only.

Contra-indications:

This device may not be used for any activity above level 2.

As the AqualimbTF is a free swinging device when the lock is not engaged , only users who

can oer some control of the swing should be prescribed with the knee.

Not for use by transtibial users.

Checking the package contents:

1. Shin/Foot

2. Top Housing

3. Knee

4. Distal attachment nut, bolt and washer

5. Instructions for Use

6. User Guide

938321WEB-GB/1-1012

3

Available from size 22 to size 27:

AQTF22L to AQTF27R

Size/Side

Order Example:

e.g. AQTF25L

AQTF

25L

Safety Information

1. Any changes in performance for example ‘play’, instability, lock not engaging,

or changes in swing resistance should immediately be reported to your service

provider.

2. Take all necessary safety precautions and due care on wet and slippery surfaces.

3. Avoid exposure to extreme heat and/or cold.

4. The product is not suitable for activities such as sports, running or cycling, ice and

snow sports, slopes and steps. Any such activities are undertaken completely at the

users’ own risk.

5. The user must not adjust or tamper with the set-up of the product.

6. The user should be advised to contact their clinician if their condition changes.

7. The freedom of swing of the knee will vary slightly between when the knee is dry

and when it is wet and /or contaminated with soap for example.

Be aware of a potential nger trap hazard at all times

938321WEB-GB/1-1012

4

2 Construction

Principal parts:

• Knee mechanism

• (Acetal Homopolymer, Stainless Steel)

• Top housing

• (Glass bre reinforced Nylon)

• Foot keel /shin

• (Glass bre reinforced Nylon/PU)

• Attachment parts

• (Stainless Steel/ Aluminium Alloy)

Knee mechanism

Top housing

Foot keel/shin

Attachment parts

Lock

Actuator

938321WEB-GB/1-1012

5

3 Function

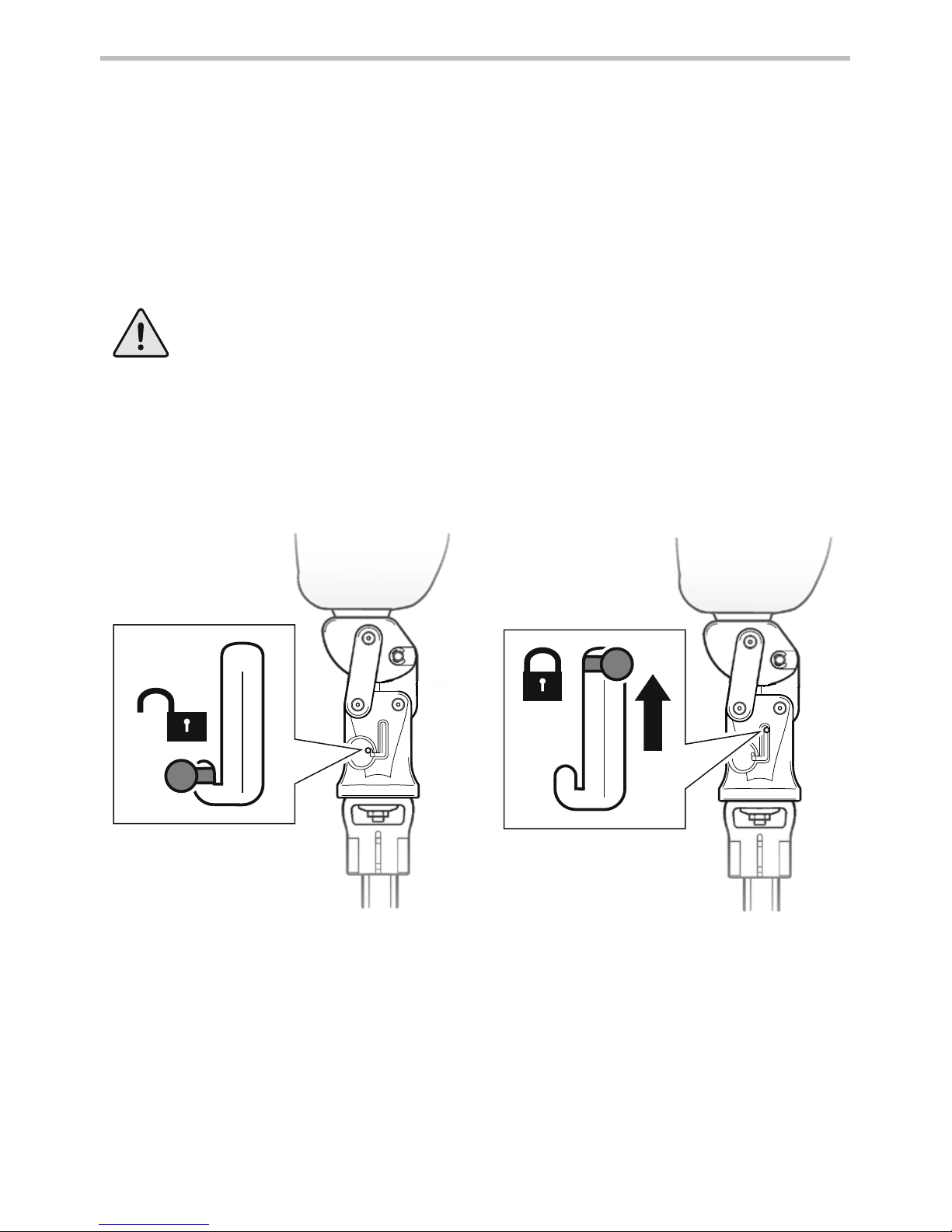

Knee shown with lock in place.Knee shown in free mode.

The lock will not engage at full knee

extension.

Knee locked:

Actuator fully engaged in top position

Knee lock operation

The knee has a polycentric design comprising pivots connecting a chassis to a main

body via three link arms. A hand operated spring loaded pin operates within a latched

slot in the body. The pin may be located to engage into the chassis and lock the knee

in full extension. A housing is bolted to the distal aspect of the knee into which is

clamped a foot/shin component. The shin may be shortened to suit the user . The sole

of the foot features an anti-slip tread pattern.

If lock mode is required ensure that the lock actuator is fully engaged

before walking or showering.

Knee unlocked:

Actuator in down position

The lock is hand operated. To lock the knee release the acuator from the down position,

fully extend the knee and push the actuator up to the top position and ensure the

actuator is fully engaged as shown.

938321WEB-GB/1-1012

6

4 Maintenance

Maintenance must be carried out by competent personnel.

It is recommended that the following maintenance is carried out annually:

• Check the security of the proximal attachment nut and distal alignment bolt.

• Check for satisfactory function of knee lock and freedom of swing.

• Visually check for wear. Some surface damage may occur after a period of use; this

does not aect the function or strength of the device.

The wearer should be advised:

Any changes in performance of this device must be reported to the practitioner.

Changes in performance may include:

• ‘Play’ in moving parts

• Lock not engaging

• Instability

Check condition of knee bumper and replace if necessary.

Cleaning:

Use a damp cloth and mild soap to clean outside surfaces, DO NOT use aggressive

cleansers, wipe dry.

5 Limitations on use:

Intended life:

Service life of the product is covered by the warranty period - a local risk assessment

should be carried out based upon activity and usage.

Lifting loads:

User weight and activity is governed by the stated limits.

Load carrying by the user should be based on a local risk assessment.

Environment:

Avoid excessive contact with abrasive environments such as those containing sand for

example, and rinse thoroughly after any such exposure.

Exclusively for use between -15˚C and 50˚C.

It is recommended that only Endolite products be used in conjunction with the

product.

938321WEB-GB/1-1012

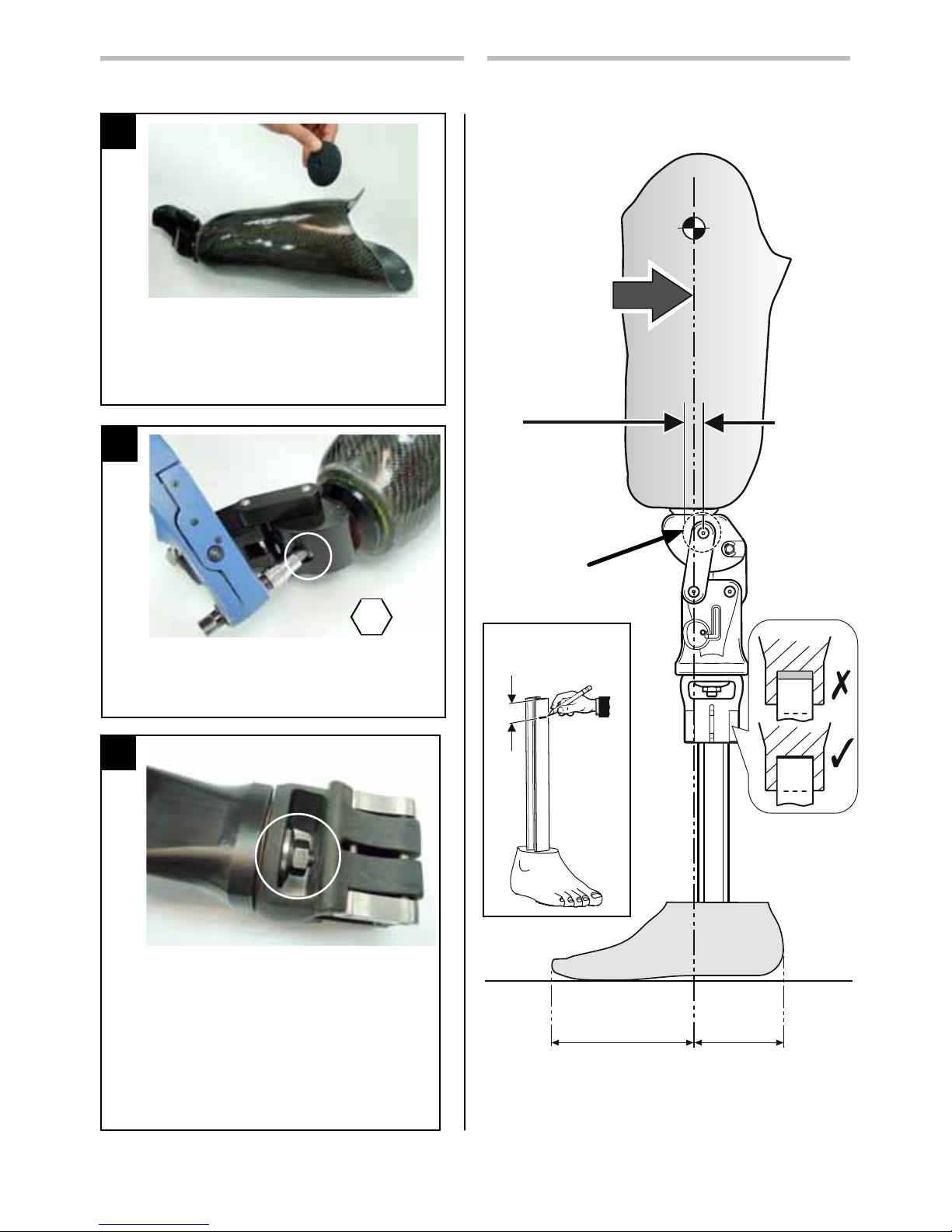

1

2

3

7

7 Alignment

Top

Pivot Pin

0-12mm

anterior of

Top Pivot Pin

Build

Line

approx.

2

/

3

1

/

3

Build Line

Passes through the

Proximal

Attachment Bolt

6 Assembly Instructions

Manufacture the socket using the appropriate

Endolite single bolt former. Cut a 27mm

diameter hole in distal end of socket. Place

socket plate inside socket. Assemble alignment

parts supplied. Minimum socket thickness 6mm

Apply Loctite 243 and torque the proximal

alignment bolt to 35Nm.

Apply Loctite 243 to bolt threads. Assemble the

distal top housing using the nut and washer

as shown and torque tighten to 35Nm after

alignment.

It may be easier to t the shin before

assembling the top housing.

Ensure full engagement of shin, see diagram

Section 7.

8

35Nm

45mm

Full engagement

938321WEB-GB/1-1012

32

1

8

9 Dynamic Alignment

Set-up as shown in Bench Alignment if the user requires adjustment length, shift,

rotation and angular adjustments are available by loosening, adjusting and retightening of distal and proximal alignment xings.

Ensure after any adjustments are made, that the load line is not posterior to the top

pivot pin.

8 Fitting Instructions

Fit shin to housing ensuring full

engagement. Measure length

to determine amount to be cut

from shin.

Determine nal cut length

required. Remove shin from

housing, cut to length and

reassemble then check

measurement.

Check length and alignment.

Finalise the screw settings

during dynamic alignment.

Tighten clamp screws evenly, applying a torque

of 5Nm at least twice to each screw. Example

order of tightening shown to evenly spread load.

1

2

4

3

45mm

938321WEB-GB/1-1012

9

10 Technical Data

Operating and

Storage Temperature Range:

-15˚C to 50˚C

5˚F to 122˚F

Total Component Weight [size 24]: 2.0kg ( 4.4lbs)

Recommended Activity Level: 2

Maximum User Weight: 100kg

Proximal Alignment attachment: Endolite single bolt alignment

Build Height:

[See diagram below]

400 - 585mm

Fitting Length

135mm

30mm

207mm

15mm

450mm max.

265mm min.

22mm

585mm max.

400mm min.

938321WEB-GB/1-1012

10

This product meets the requirements of 93/42/EEC guidelines for medical products.

This product has been classied as a Class 1 Product according to the classication

criteria outlined in Appendix IX of the guidelines. The Declaration of Conformity was

therefore created by Blatchford Products Limited with sole responsibility according to

Appendix VII of the guidelines.

The manufacturer recommends using the device only under the specied conditions

and for the intended purposes. The device must be maintained according to the

instructions for use supplied with the device. The manufacturer is not liable for damage

caused by the component combinations that were not authorized by the manufacturer.

The aqualimbTF is warranted for 24 months from original date of purchase unless

otherwise stated.

See Endolite catalogue for details.

Liability

CE Conformity

Warranty

Blatchford Products Ltd. and ENDOLITE are companies and trademarks of Chas. A. Blatchford and Sons Ltd.

11 Replacement Parts

Part Part No.

Knee Bumper 622310

Screw Proximal M10 55 ST STL 910420

938321WEB-GB/1-1012

Head Office

Chas A Blatchford & Sons Ltd

Lister Road

Basingstoke

Hampshire

RG22 4AH

United Kingdom

Tel: +44 (0) 1256 316600

Fax: +44 (0) 1256 316617

Email: sales@blatchford.co.uk

www.endolite.co.uk

Customer Services UK

Prosthetic and Orthotic Products

11 Atlas Way

Atlas North

Shefeld

S4 7QQ

United Kingdom

Tel: +44 (0) 114 263 7900

Fax: +44 (0) 114 263 7901

Email: sales@blatchford.co.uk

www.endolite.co.uk

endolite North America

1031 Byers Road

Miamisburg

Ohio 45342

USA

Tel: 800.548.3534

Fax: 800.929.3636

Email: info@endolite.com

www.endolite.com

Distributor/Distributeur/Händler/Distributore/Distribuidor/ Поставщик

endolite Germany

Endolite Deutschland GmbH

Holzstr. 5

95336 Mainleus

GERMANY

Tel: +49 9229 9737 001

Fax: +49 9229 9737 006

Email: info@endolite.de

www.endolite.de

endolite France

Parc d’Activités de l’Aéroport, 125 Impasse

Jean-Baptiste Say

34470 PEROLS

FRANCE

Tel: 00 33 (0) 467 820 820

Fax: 00 33 (0) 467 073 630

Email: contact@endolite.fr

www.endolite.fr

endolite India Ltd

A4 Naraina Industrial Area

Phase - 1

New Delhi

INDIA – 110028

Tel: 91 11 45689955

Fax: 91 11 25891543

Email: endolite@vsnl.com

www.endoliteindia.com

endolite Russia

ООО «Эндолайт Центр»

141011, Московская обл.

г. Мытищи, ул. Октябрьская, д. 10

РОССИЯ

Тел.: +7 495 787 5280

Факс: +7 495 787 5280

Email: sales@endolite.ru

www.endolite.ru

Loading...

Loading...