endolite 4 Bolt ESK+ 239150 User Manual

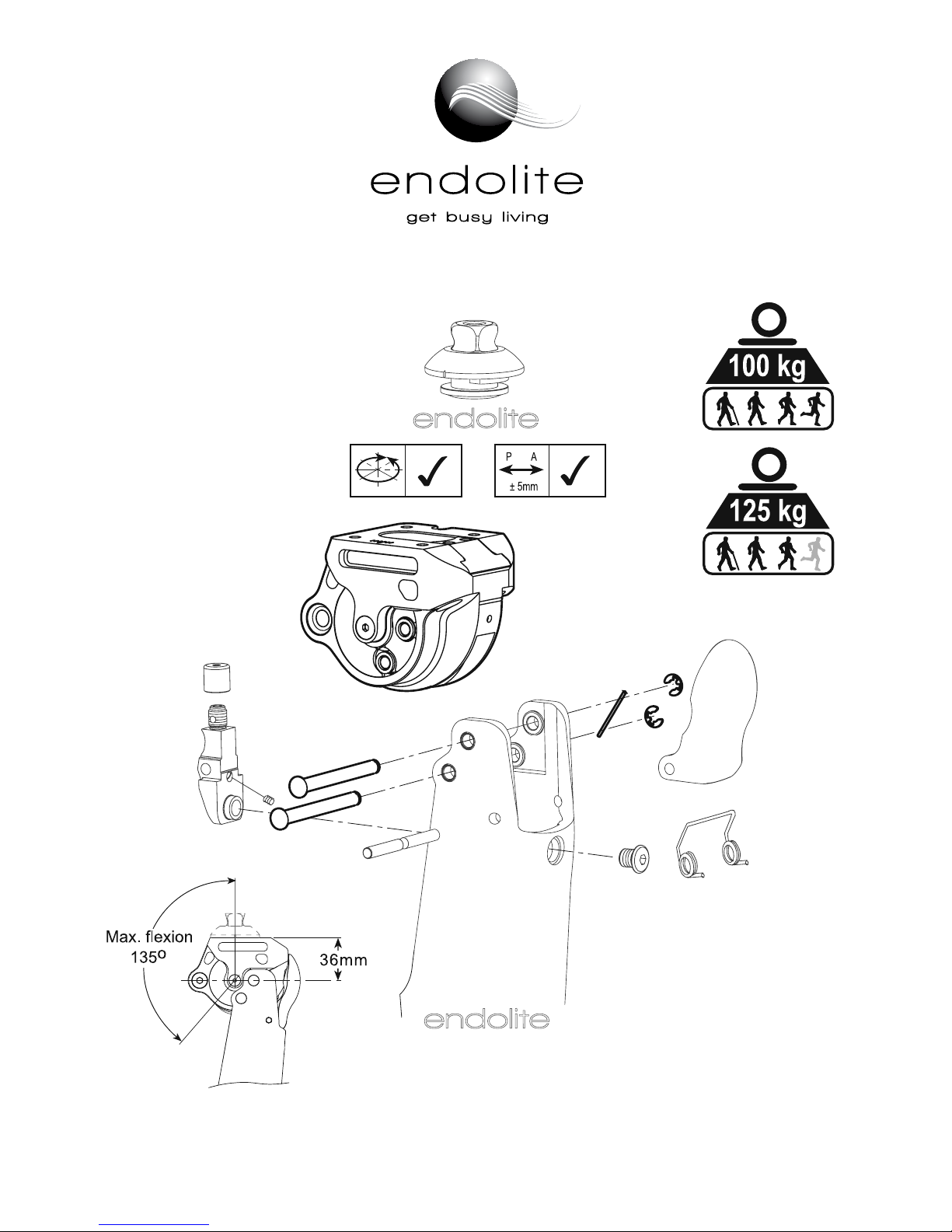

4 Bolt ESK+ 239150

2

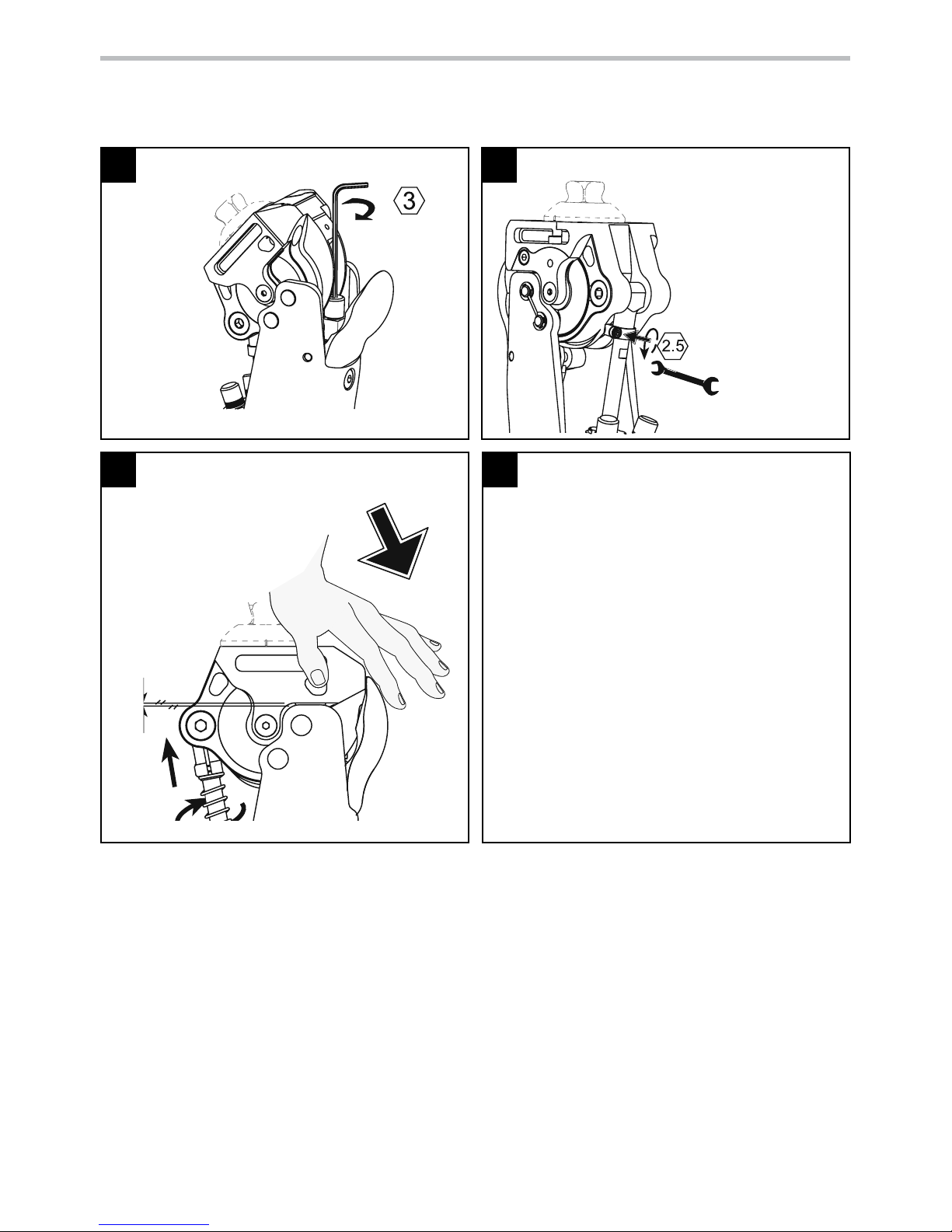

Fully extend limb to access the adjuster.

Rotate the SPRING STACK ADJUSTER to

achieve the required stability for the

individual user. Note: Audible clicks

should be heard upon adjustment, and the

adjuster is self locking.

Tighten the SPRING STACK to reduce

stability. Release the SPRING STACK to

increase stability - See above diagram.

If required, the adjuster may be reset to

the factory setting. This can be achieved

by reducing stability by six audible clicks

from the maximum setting.

underside view of chassis

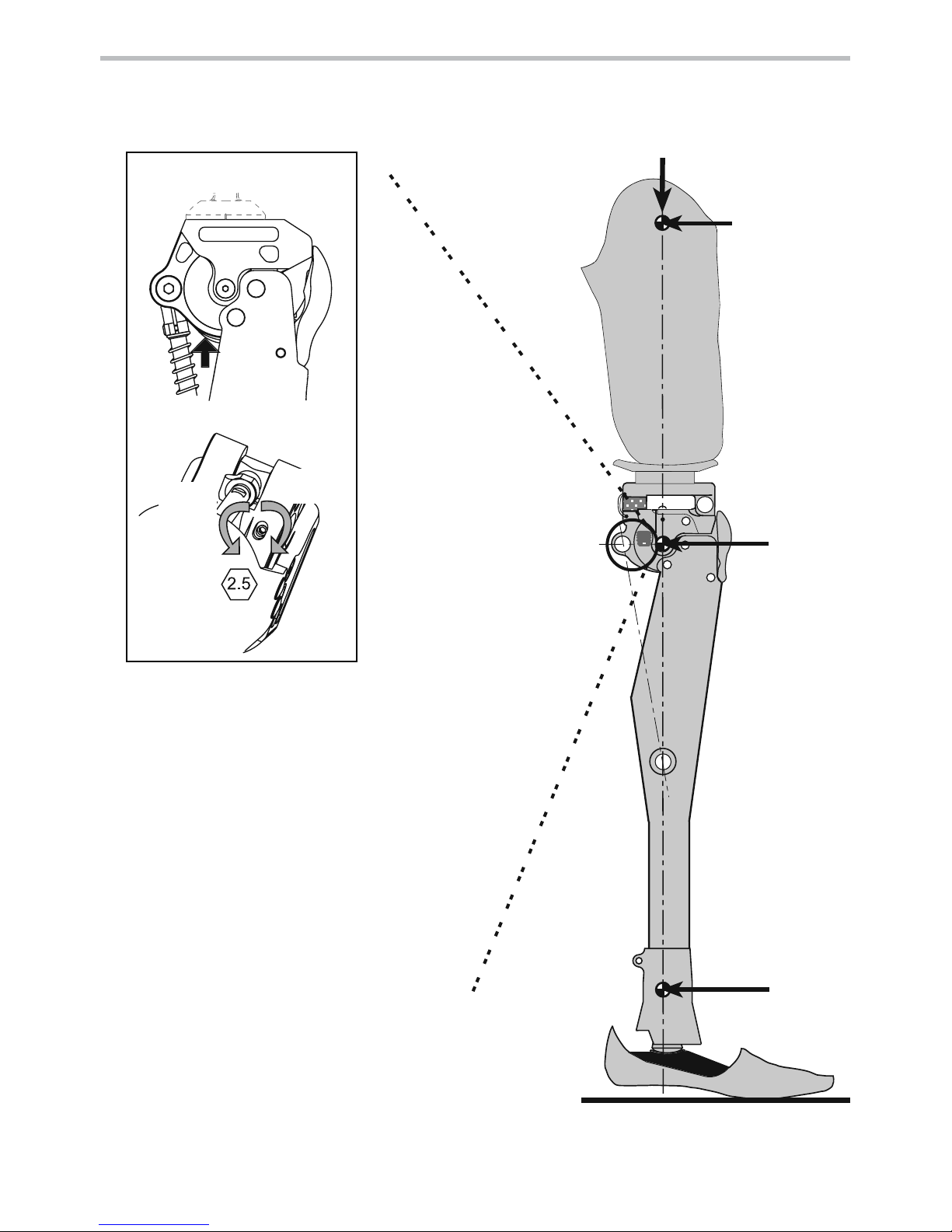

Walking trials

Ankle

Centre

Knee

Pivot

Trochanter

Weight Line

increase

stability

decrease

stability

SPRING STACK ADJUSTER

938205WEB-GB/4-0712

1 Static Alignment Guide

1

3 4

2

3

2 Front Stop adjustment - Adjustable Trunnion

As tted to the PSPC and Servo PSPC

Note:The stop pads mounted in the chassis

and side plate are required to support

ML loading. Simultaneous full contact

between the stops and the shin is NOT

required.

Withdraw trunnion clamp screw and

apply LOCTITE 222 to thread, re-assemble

and tighten.

*UNDER NO CIRCUMSTANCES MUST THE

PISTON ROD WITNESS LINE BE VISIBLE

BELOW THE TRUNNION

Servo PSPC

The Servo PSPC should be adjusted as above except

the trunnion should be rotated further, if required,

until the cut-out in the piston rod is posterior.

Fully tighten

front stop

Loosen trunnion

clamp screw. Turn

piston rod to

reveal thread and

apply

Loctite 243.

Reassemble and

screw piston rod

fully home. The

chassis should

now be slightly

exed.

6 A/F - PSPC

9A/F - Servo PSPC

Apply a light extension load

to the knee and gradually

unscrew the piston rod

(lengthening the cylinder)

until the chassis edge is

parallel with the top of the

shin.

Front Stop adjustment - Non-Adjustable Trunnion

[As tted to the IP+ and Hydraulic Cylinders]

No adjustment is necessary when using these cylinders. They require the front stop to be fully tightened as

shown in Stage 1.

938205WEB-GB/4-0712

Loading...

Loading...