OPERATIONS AND MAINTENANCE

Endless Pool Swim Spa

PRE-SITE PREPARATION

Shut

Off

60 amp

220 volt

GFCI

Power

Please read all instructions in this manual prior to having the

swim spa installed in its chosen location. IMPROPER INSTALLATION MAY RESULT IN EQUIPMENT DAMAGE AND

VOID THE ENDLESS POOL SWIM SPA WARRANTY.

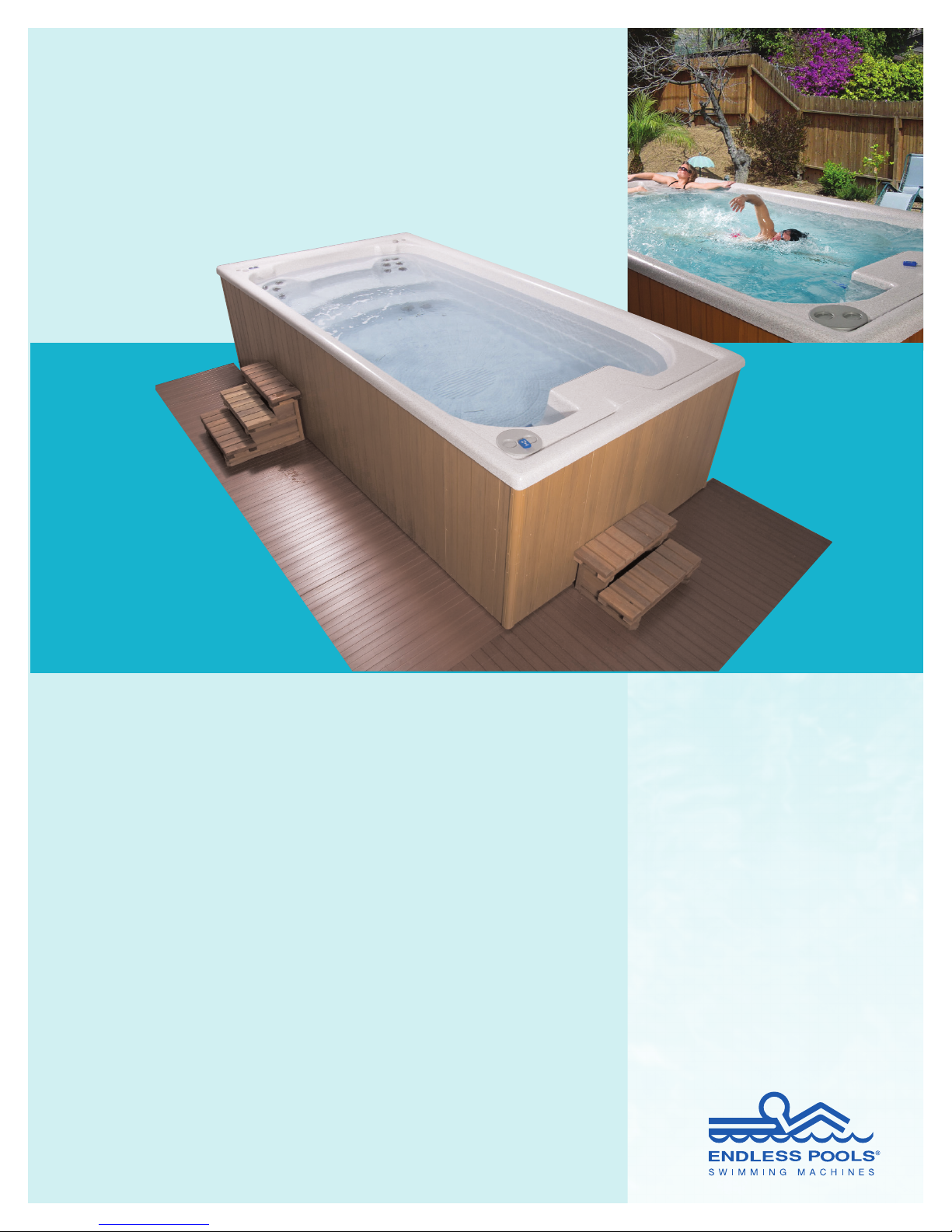

GETTING THE SPA TO YOUR SITE

Your Endless Pool Swim Spa is delivered by truck and trailer. An

empty Swim Spa weighs 2,800 lbs and will typically need to be

lifted into position with a crane. The cost of crane rental will

depend on a variety of factors including timing, location, required

reach, obstructions and possible permits. Your Swim Spa can usually be unloaded from the delivery trailer without a crane. For

installations indoors where the Swim Spa needs to be slid only a

few feet from where the driver unloads, a garage for example, the

Swim Spa can be slid or rolled into position using short sections

of pipe and a lifting bar (see the video on our website)

Our shipping coordinators work closely with you planning the

delivery. You may speak with them at any time by calling us toll

free at 800 732 8660. They will work with you once you have

made your color choices to insure a smooth delivery. The shipping

quotation you receive is mileage based. We try to group shipments

together to minimize trucking cost.

• If the spa is to be set in-ground, not skirted, even support of

bottom, sides and lip are absolutely necessary to insure proper structural support and to keep the warranties valid. A

properly constructed vault is recommended for in-ground

installations. In-ground installations also require proper

drainage of water and may require a sump pump to remove

spa and rain water from this vault.

• It is not recommended to backfill against the swim spa cabinet. This will damage the swim spa.

• If your spa is located near water sprinklers, adjust or cap

them so water will not hit the wood siding of the spa.

• During colder months, have a fill hose and water supply

thawed and ready for filling your spa upon delivery.

ELECTRICAL REQUIREMENTS

The Endless Pool Swim Spa requires one (1) 220-Volt, 60-Amp

GFCI protected circuit (circuit to contain 3 wires plus ground).

The circuit must use a minimum #6 gauge copper wire. Allow

plenty of extra wire from the Circuit Box to the Spa Equipment

Disconnect inside the cabinet.

SPA PAD REQUIREMENTS

Your Endless Pool Swim Spa MUST BE PLACED ON A UNIFORMLY FIRM AND LEVEL SURFACE. A concrete pad foundation 4 inches thick is recommended. As an alternative, a peagravel foundation pad could be used, but this pad must be contained in a secure wood or concrete restraining border to prevent

loose gravel from shifting once the swim spa is placed. If a concrete pad is poured, this is the logical time to “plumb-in” your

electrical conduit (refer to the diagram on page 7). Be sure the

concrete has cured for at least one (1) week before setting the

swim spa in place. AN UNEVEN OR CRACKED CONCRETE

PAD, OR THE USE OF SHIMS OF ANY KIND MAY CAUSE

THE SWIM SPA TO BUCKLE, DISTORT AND/OR CRACK,

CAUSING THE WARRANTY ON YOUR SPA TO BE VOIDED.

ADDITIONAL REQUIREMENTS

• All installations require the equipment system to be shielded

from the weather. If the equipment system is placed away

from the spa, then an enclosure for the equipment will be

required. The customer is responsible for providing such an

enclosure.

• Balconies and decks must be constructed to current state and

local codes to safely support the maximum load of your

water-filled swim spa and the number of people using the

swim spa. Check with your construction contractor for these

specifications.

• It is the responsibility of the owner to provide appropriate

access at the rear and front right corner of the swim spa

once it is set in place for ease of repair and maintenance.

Otherwise, additional costs to service and repair the swim

spa may be incurred.

THE SENSIBLE WAY TO ENJOY YOUR

ENDLESS POOL SWIM SPA

Swim spas are fun, but along with the fun comes serious

responsibility. Be sure good times are safe times. Establish

rules and enforce them. It is your responsibility to be sure that

you, your family and guests use your Endless Pool Swim Spa

sensibly and safely.

Children are not waterproof! Drowning is one of the largest

causes of accidental death for infants and children under the

age of five.

• There is no substitute for adequate supervision.

• Never leave a child alone or out of eye contact in/near

the swim spa – not even for a second.

• Always completely remove the cover before using your

swim spa to avoid the possibility of someone being trapped

under the swim spa cover.

• Insist there be no running, pushing or rough housing near the

swim spa.

• Never consider young children “water-safe” despite their

swimming skills, previous instructions or experience.

1

Common sense should prevail.

• Never use the swim spa when you are alone.

• One (1) individual must assume the responsibility for supervising the swim spa.

• Never use the swim spa while or after using narcotics or

other drugs that may cause sleepiness, drowsiness or

raise/lower blood pressure.

• Never use the swim spa while or after using alcohol.

• Be sure you check the water temperature before and while

you are in the swim spa.

• Persons with heart disease, diabetes, high or low blood pressure or any serious illness, and pregnant women – indeed

persons with any doubt – should not enter the swim spa

without prior consultation with their doctor.

• To maintain clean spa water, it is a good idea to shower with

soap and water before using your swim spa to wash off skin

oils, lotions and deodorants.

• Plan ahead to prevent accidents and injuries and make your

entertaining or workout truly enjoyable. Use only unbreakable items around your swim spa.

• At least one (1) responsible person should be trained in

artificial respiration and/or cardiopulmonary resuscitation

(CPR).

Spa Preparation.

• Have a licensed electrician wire the spa equipment through a

GFCI (Ground Fault Circuit Interrupter).

• Where possible, use battery-operated appliances around the

swim spa. Electrocution from appliances in contact with the

water is a real danger.

• Carefully read, understand and follow operating and maintenance instructions supplied by EPI. It is a good general rule

to visually inspect your swim spa and equipment regularly.

If you detect something unusual, contact our Customer

Service Department at 1-800-910-2714.

• Never perform work on your swim spa or filter equipment

without turning the entire system off at the breaker(s).

• Carefully follow the instructions for maintaining, servicing

or repairing your swim spa. If you are at all unsure of how

to proceed, call our Customer Service Department at 1-800910-2714.

• For health reasons, make sure the spa water is properly

cleaned and disinfected.

USING CHEMICALS IN YOUR ENDLESS

POOL SWIM SPA

The chemicals needed for your Endless Pool Swim Spa help make

it clean, disinfected and more attractive to use. Remember, these

chemicals are potentially dangerous and may be hazardous if not

used properly. Follow the manufacturer’s instructions carefully

for proper use and storage of chemicals.

Outlined are some general tips for proper chemical use

and storage:

• Before using chemicals, read the labels and directions fully

and carefully.

• Follow label use on instructions.

• Keep all chemicals out of reach of children.

Storage:

• Chemicals for test kits should be replaced every year.

• Keep the original lids on all chemical containers and make

sure the lids are closed tightly when not in use.

• Do not stack different chemicals on top of one another.

• Store your swim spa chemicals in a clean, cool, dry, wellventilated area preferably off the floor to prevent contamination from other materials. Keep them away from the chemicals and equipment used for garden and/or lawn maintenance.

• Keep liquid chemicals away from dry chemicals. Keep apart

chemicals that are different forms of oxidizing compounds.

Physically separate all different forms of chemicals.

• Do not store your swim spa chemicals where other flammable items may mix with them. For example, a mixture of

these chemicals and fertilizer can cause a fire or an explosion.

Usage:

• Always add chemicals directly to the swim spa water, either

in a suitable feeder, distributed across the surface of the

water or diluted and poured into the water. Follow label use

instructions.

• When preparing water solutions for feeder applications, pour

the chemical slowly into the appropriate amount of water,

stirring constantly to provide mixing and dilutions.

• Always add chemicals to water. NEVER ADD WATER TO

CHEMICALS.

• Carefully clean up any spilled chemicals with large amounts

of water to dilute and wash away the chemicals.

Disinfectants and pH adjustment chemicals can usually be

sent to the sewer with large quantities of water since they are

intended for use at low levels.

• Wash out empty disinfectant containers before disposing to

eliminate danger of fire, explosion or poisoning.

• Test the water in your swim spa with a reliable test kit. Add

the necessary chemicals according to the test results and the

manufacturer’s instructions. The hotter the water, the faster

disinfectants may break up and spread out requiring more

frequent water testing. In addition, the more people who use

the swim spa, the more frequently you should test the water.

• Do not inhale dust or fumes from any chemicals. If necessary, use proper protective devices for breathing, handling

and eye protection. Promptly wash off any residues that

come in contact with your skin.

• Never reuse old chemical containers unless specified by the

manufacturer.

2

INITIAL START UP

1. Fill the Endless Pool Swim Spa with water from a garden hose

or water truck.

(any brand is fine as long as it does not have an added scent to it) to

an indoor swim spa. If you have an outdoor swim spa, add the

appropriate amount of granules out of the bag of “stabilized” chlorine. Test for chlorine in a day or two and add more if necessary.

2. Once filled with water, turn power ON at Disconnect Box.

3. Check that the Circulating Pump is operating (water flowing

into the skimmer). NOTE: If water is not flowing into your

skimmer, there may be an air lock in your plumbing line. Turn

off the power at the breaker immediately. Use the hose bib in

the equipment cabinet to, “bleed off” some water. You should

notice air and then water coming through the hose bib. Once a

steady stream of water is draining, close the hose bid and turn

the power back on.

4. Run jets for two to three minutes. Check the equipment cabinet

to ensure no water is leaking from the union joints. Tighten any

joints as necessary.

5. Use your remote control to turn the swim current on and run for

two to three minutes. Check the equipment cabinet to ensure no

hydraulic fluid is leaking from the hydraulic connections.

Tighten any fittings as necessary.

6. Check Alkalinity and pH with test strips or test kit – adjust

accordingly.

7. Visit www.myendlesspool.com or contact our Customer

Service Department at 1-800-910-2714 to answer any questions

that you may have.

Special Note:

It is extremely important that you check and re-tighten your

pump couplers several times during the initial weeks of ownership of your new swim spa. We have done this during the delivery process, but they will need to be re-tightened after the initial

fill and warm up of the water. Additionally, you will need to

check them once a month to insure they stay tight. If you have

any questions, please call our Customer Service Department at

1-800-910-2714.

BALANCING THE WATER CHEMISTRY

Included with your Endless Pool Swim Spa are products to help

with start-up and on-going maintenance. These include:

(1) Container calcium hardness increaser

(1) Container water clarifier

(1) Container pH decreaser

(1) Container pH increaser

(1) Container total alkalinity increaser

(1) Container stabilized chlorine (outdoor pools)

(1) Test Kit

The following steps need to be followed when the swim spa is

first filled, as well as anytime the swim spa is partially drained

and refilled. They will walk you through testing and adjusting

the factors affecting the “balance” of the water i.e., the water’s

total alkalinity, pH and calcium hardness levels.*

The level of chlorine inside the swim spa, as long as it is not above

5ppm, will not significantly affect the following tests and procedures used to balance the pool water. Therefore, if there is no chlorine in the pool at this time, add some. Add 1-2 cups of liquid bleach

1) Balance Total Alkalinity (TA)

Ideal reading: 100ppm

Acceptable range: 80-120ppm

Raise with: Sodium Bicarbonate (TA increaser)

Lower with: Sodium Bisulfate (pH decreaser)

Method of chemical application:

• Adjusting the level of TA in the swim spa requires that the

chemical be “slugged” i.e. pour chemical in four different

spots around the swim spa with the water calm. Let the

water remain calm until the next filtration cycle.

• Retest TA and adjust again if necessary.

• Add less chemical than you think is necessary to effect the

desired change. Keep track of how much chemical it took to

make that change.

Notes:

Many regions of the country and world will have water with a TA

higher than our recommended range. In a lot of cases, it will be

desirable to leave the TA alone as any adjustment to it will also

tend to affect the pH. The TA is mainly serving as a buffer for the

pH. If it is above 120ppm, but lower than 200-250ppm, leave the

level alone. It will simply over-stabilize the pH, which is not a

problem, especially if the pH is within range or close to being

within range.

If the TA is lower than our recommended range, though, we would

recommend increasing it to at least 80ppm. Once again, the TA

serves mainly as a buffer for the pH and if the TA is too low, the

pH level in the pool can change very rapidly causing bather discomfort and damage to the pool and pool equipment.

Once the TA is within a tolerable range, move on to adjusting the

pH in the swim spa. You should find that the TA will be pretty

slow to change—for this reason, test for it once a week as detailed

in the “Maintenance and Use of your Endless Pool” instructions

found later in this guide.

2) Balance pH

Ideal reading: 7.5

Acceptable range: 7.4-7.8

Raise with: Sodium Carbonate (pH increaser)

Lower with: Sodium Bisulfate (pH decreaser)

Method of chemical application:

• Measure out and pour your dosage of chemical directly into the

swim current. Afterwards, make sure you wash some water on

the propulsion housing to ensure that no granules are resting on

the benches. Test and apply more chemical as necessary.

Notes:

It is very important to keep the pH within range. If the level is too

low, severe damage can occur to the submerged hydraulic motor

and the pool equipment. If the level is too high, the water can be

prone to “scaling,” when minerals and metals dissolved in the

water will be dropped out of solution and on to the swim spa surfaces. Having the pH too high or too low may cause bather discomfort in the form of eye or skin irritation.

* It is important to maintain properly balanced water. Under balanced water can be corrosive or cause scaling, which can damage

the spa components and void any warranties

3

The pH will change slowly over the course of a week or two. The

number of bathers and the type of chlorine used are just two factors that will cause the pH to change. For this reason, pH should

be tested three times a week and adjusted as needed. See the

“Maintenance and Use of your Endless Pool Swim Spa” instructions found later in this guide for further details.

Once the pH is within range, move on to adjusting the calcium

hardness.

3) Balance Calcium Hardness (CH)

Ideal reading: 180ppm

Acceptable range: 175-250ppm

Raise with: Calcium Chloride (calcium hardness increaser)

Lower with: water containing less calcium (softened water)

Method of chemical application:

• Fill a clean, five gallon bucket with water and dissolve the

dosage of calcium into this water. Do not mix this solution

with your hands. Pour the solution in to the swim current,

and let the current circulate the water in the pool for a few

minutes. Wait a few hours, test again, and add more calcium

if necessary. Once again, always add less chemical than you

think will be necessary to effect the desired change.

Notes:

As with TA, many regions will have higher CH than what is specified by our recommended range. If it is available, partially filling

the pool with softened water will dilute the calcium content and

essentially lower the CH level inside the swim spa. If softened water

is unavailable, perhaps water tanked-in from an outside source

would be the best option for you. If this not possible either, we

would strongly suggest adding a “sequestering agent” which can be

purchased at any local swimming pool retail center. This chemical

helps the water hold all of its dissolved materials in solution, including metals and calcium content. The main concern with having CH

levels too high is that the calcium may deposit out of solution—a

sequestering agent will help prevent this.

Calcium hardness will tend to slowly increase over time as water

evaporates from the swim spa and leaves its calcium behind.

Periodic testing of CH is detailed in the “Maintenance and Use of

your Endless Pool Swim Spa” instructions below.

RECOMMENDED MAINTENANCE SCHEDULE

Daily:

• Test for free chlorine (FC) after you swim, or at least a few

times a week. Add chlorine to maintain FC levels between

0.5 - 1.5 ppm. As you become familiar with the chlorine

demand for your pool, you will find that you may not have to

test for chlorine as frequently in order to maintain a minimum level of 0.5ppm.

Twice a week:

• Check and adjust water level. Water should completely

cover the honeycomb grill where the current is produced.

Water 1/2” lower than this can create a choppy current and

may cause your skimmer to draw air into the plumbing lines.

Having the water level 1” or more higher that honey comb

grill will cause more water to get splashed out of the swim

spa, and may cause the air relief port on the top of the skimmer body to leak water.

• Test for pH at least twice a week. Broadcast (i.e. pour chemical into current) pH increaser or pH decreaser to maintain

levels between 7.4-7.8.

Weekly:

• Test for total alkalinity (TA) once a week. Slug (i.e. pour

chemical in 4 spots around pool with water calm) TA

increaser or pH decreaser to maintain levels between 80-120.

If TA is too high, it is usually not necessary to decrease as it

merely serves as a buffer for the pH and will not cause damage in the pool.

• Test for total chlorine (TC) once a week. If the test for TC

yields a result that is significantly higher than level of FC

(i.e. the solution gets noticeably more pink) then you have a

significant amount of combined chlorine (CC) in the pool

water. Combined chlorine generates a heavy chlorine odor,

and can cause bather discomfort in the form of eye and skin

irritation. If you have significantly more total chlorine than

you do free chlorine, then it is time to shock the pool (i.e.

add enough chlorine to get the FC between 3-5ppm, but

don’t swim until FC falls below 3ppm). Shocking the pool

should burn off the combined chlorine.

MAINTENANCE AND USE OF YOUR

ENDLESS POOL SWIM SPA

We recommend getting into a routine that involves adding a measured amount of chlorine either after you swim or at the very least

every other day. This measured amount depends on pool use. One

person swimming every day for 30 minutes might add 1/2 cup of

Clorox after each swim. This small amount should maintain the

required 0.5 to 1.5 ppm chlorine residual. Heavier use and use by

children generally requires more chlorine. Adding 1 cup of Clorox

bleach raises the chlorine level by about 1 ppm. It is safe to swim

in any pool where the chlorine level is between 0.5 to 3.0 ppm

free chlorine.

If you intend to keep your swim spa at a temperature above 95ºF,

then the use of bromine should be considered. Bromine is a more

effective sanitizer at higher temperatures. The acceptable range of

bromine for your swim spa if 2.0 to 5.0 ppm. The easiest way to

introduce Bromine into your Swim Spa is by a floating feeder. A

floating feeder allows Bromine to dissolve at a slow and constant

rate. Remember to remove the floating feeder when the swim spa

is in use. Too high a bromine level can cause corrosion to the

swim spa.

Every two weeks:

• Test for calcium hardness (CH) once every two weeks.

Predissolve calcium hardness increaser (i.e. fill a 5-gallon

bucket with pool water and dissolve calcium in bucket) then

pour the solution into the current to keep levels between 175250 ppm. If CH is too high, it can only be decreased by

adding water with less calcium (i.e. softened water).

• If you have an outdoor pool, or if you use stabilized chlorine

(i.e. sodium dichlor or sodium trichlor), test the cyanuric acid

(CYA) level every two weeks. Maintain levels between 2050 ppm. If CYA is above 80 ppm, the pool should be partially drained and refilled, or un-stabilized chlorine should be

temporarily used in place of the stabilized. If CYA is above

100ppm, the pool should be partially drained and refilled. If

you use bromine, then this step is unnecessary.

Every two months:

• Remove and clean the filter cartridge. After several uses, the

cartridge will need to be replaced, and new filter cartridge

can be purchased on our Customer Service website, myendlesspool.com.

4

Remove Your Filter with the Power OFF

7

4

1

2

5

3

Cartridge filter exploded view

• Bleed air from the filter housing, turn knob (1) counterclockwise.

• Pull on the gray tab (2) and rotate filter ring (3) counterclockwise and remove.

• Pull on filter lid handle (4) and remove filter (5) to clean

or replace.

• Check o-ring (6) for damage.

Replace Your Filter with the Power OFF

• Replace ring (7) and reverse steps above turning filter ring

(3) clockwise until hand tight.

• Turn power ON.

• When water comes out of bleed knob (1), close, turn clockwise and hand tighten.

Annually:

After 1 year (9000hrs) the bulb of your UV Sanitizer must be

replaced. Start by turning off the circulation pump. Hold the

P1 button on your keypad for 5 seconds. Then unplug the UV

Sanitizer from the Heater Controller.

Unthread the electrical connector assembly (1) from the electrical tee assembly (2). Note that there is an O-Ring (3)

between the electrical connector and the plastic body. Set the

o-ring aside for re-installation later.

Once the electrical connector has been unthreaded from the tee

assembly, carefully remove the UV bulb (4) from the UV

body. Note: pulling on the bulb too quickly could cause the

bulb to separate from the electrical connector. If this happens,

then the entire UV body will have to be removed and the bulb

will have to be carefully dropped out of the UV body. If this

occurs, it is very important to prevent the bulb from breaking.

When the bulb has been removed from the UV body separate

the bulb from the electrical connector.

Do not touch the new UV bulb with your bare hands. Skin

oils can remain on the bulb creating hotspots, which will

shorten the life of the bulb. Make sure that the bulb cushion

(5) and the 2 bulb o-rings (6) are in place. Connect the new

bulb to the electrical connector, making sure that the pins in

the bulb are aligned with the pin connectors.

Carefully insert the bulb into the UV body and thread the electrical connector back into the electrical tee assembly. It is

important that the electrical connector o-ring is in place prior

6

to this step.

Press the P1 button on your keypad once to turn the circulation pump on. Now that water is running through the system,

the UV can be plugged back into the heater controller.

Every five years:

• After five years of operation, we will send you a letter detailing our recommendation that the submerged hydraulic motor

be changed. This procedure does require the swim spa to be

drained to 6” in the standard-depth section of the pool. This

may also be a convenient time to replace the propeller or

front grill in the pool; a list of recommended and optional

replacement parts is supplied with the tune-up letter.

As Needed:

• Clean the water line around the perimeter of the swim spa

and the underside of the cover as needed. Body oils and

mold may build up slowly in these areas and should be

cleaned off periodically.

• If you happen to get cloudy water, or if the surface feels slippery, it likely means that you have algae in the pool. A pool

brush and pole may be purchased in order to wipe down all

the surfaces in the pool. Increasing free chlorine level temporarily to 5 ppm will help, as will maintaining the free chlorine level in the swim spa at 3 ppm until the water is clear.

Test the chlorine level frequently during this time.

5

DRAINING YOUR ENDLESS POOL SWIM SPA

1) Disconnect electrical power to all pool equipment.

2) Begin to drain down pool water by placing a suitable sump

pump in the pool, or by setting up a siphon using a garden hose.

If using a siphon, two or more hoses may be used simultaneously in order to expedite the process.

3) When you are ready, refill the pool using a garden hose with a

“bobby filter” on the end to screen out debris and fine sediment.

If you do not have one of these filters, contact Endless Pools

Customer Service. If you have high calcium content and/or

high metal content in you area, you should also add some

“sequestering agent” to the pool water to help prevent scaling/

staining. Once again, if you do not have a bottle of this product, contact us and we will send one out to you. You may also

be able to find both of these items at a local pool store.

4) The swim spa is full when the water completely covers the grill

at the front of the pool. Reestablish electrical power to the pool

equipment, and start balancing the pool water. Shock the pool

to 3.0 ppm free chlorine. Turn on your WQS in order to get

your new body of water filtered, circulated, and heated.

WARNINGS:

Before installing or connecting the unit, please read the following.

• FOR UNITS FOR USE IN OTHER THAN SINGLE-FAMILY DWELLINGS,A CLEARLY LABELED EMERGENCY

SWITCH SHALL BE PROVIDED AS PART OF THE

INSTALLATION. THE SWITCH SHALL BE READILY

ACCESSIBLE TO THE OCCUPANTS AND SHALL BE

INSTALLED AT LEAST 5 FEET (1.52 M) AWAY,ADJACENT TO, AND WITHIN SIGHT OF THE UNIT.

• ANY DAMAGED CABLE MUST BE IMMEDIATELY

REPLACED.

• TURN POWER OFF BEFORE SERVICING OR MODIFYING ANY CABLE CONNECTIONS IN THIS UNIT.

• TO PREVENT ELECTRIC SHOCK HAZARD AND/OR

WATER DAMAGE TO THIS CONTROL,ALL UNUSED

RECEPTACLES MUST HAVE A DUMMY PLUG.

• THIS CONTROLLER MUST NOT BE INSTALLED IN

PROXIMITY OF HIGHLY FLAMMABLE MATERIALS.

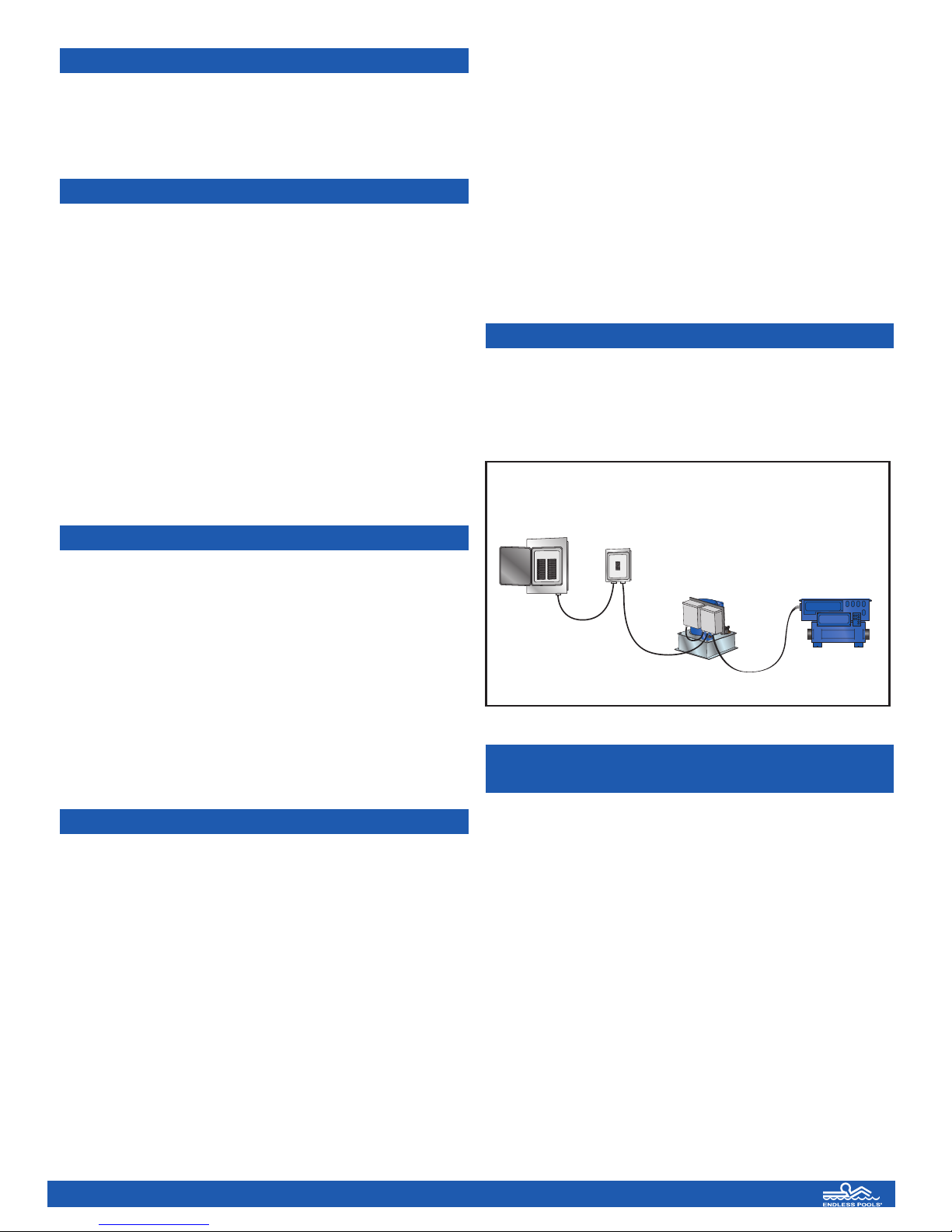

ELECTRICAL WIRING

WINTERIZING YOUR ENDLESS

POOL SWIM SPA

An Endless Pool Swim Spa may be used year round, even in colder climates. If you will not be using the swim spa during the winter in an area where freezing is a problem, special consideration

must be taken to protect the pool and ancillary equipment if either

is located outside. If you have any questions regarding precautions

to take against freezing, please call our Customer Service

Department at (800) 910-2714.

SWIM SPA HEATER/CONTROLLER

The in.xe is a heater controller used by Endless Pools to control

the following water quality features:

• Water temperature can be set between 59ºF and 104ºF.

Default set point at 84ºF. The set point is changed with the

up and down keys.

• The Circulating Pump, CP, is always on. The heater can only

turn on when CP is on.

• Pressing the light key will turn lights on/off with an on time

of 120 minutes.

• Optional Pump #1 is for a single speed Jet pump. Pressing

the first key turns pump 1 on/off, with a run time of 30-minutes. The heating element is turned off when Pump #1 is

activated. To aid in filtration there are 4-purges per day.

For 240 VAC (4 wires)

Correct wiring of the electrical service box, GFCI, and pack terminal block is essential.

Call an electrician if necessary.

Warning!

This product must always be connected to a circuit protected by

a ground fault interrupter.

Proper wiring of the electrical service box, GFCI and in.xe terminal block is essential!

Check your electrical code for local regulations. Only copper wire

should be used, never aluminum.

To install the wiring for the in.xe heater controller, you'll need a

Phillips screwdriver and a flat screwdriver.

Loosen the 2 screws of the spa pack door and open it. Remove 5

1/2" of cable insulation. Strip away 1" of each wire insulation. Pull

the cable through the cutout of the box and secure it with a strain

relief (1" NTP strain relief; hole diameter: 1.335"). Make sure that

only the uncut sheathing is clamped at this opening. Push the colorcoded wires into the terminals as indicated on the sticker and use

the flat screwdriver to tighten the screws on the terminals.

After making sure wire connections are secure, push them back into

the box and close the door. Tighten the 2 screws of the sp pack door.

Connect the bonding conductor to the bonding lug on the front of

the in.xe spa pack. Use a minimum 8 AWG solid copper wire.

• Optional UV always on except when Pump #1 is on and

remains off for 30-minutes after pump #1 is turned on.

• Holding first key for 5-seconds will turn off all devices for

30 minutes to allow for servicing. Pressing again will return

to normal operation.

6

15'

7'-10"

8''

24"

24"

access

SWIM SPA COMPONENTS

Skimmer:

through the filtration system. The water is pulled into the

skimmer and passed through a basket, which needs to be

cleaned periodically. If your swim spa is outdoors, this basket

may need to be cleaned more frequently.

Circulating Pump: This compact and efficient pump circulates water through the filter, heater and UV Sanitizer 24 hours

a day. Keeping the water circulating is one of the best ways to

help you keep your swim spa clean while requiring very little

attention from you.

Heater Controller: The heater controller warms the water

before it goes through the filter and re-enters your swim spa. It

also controls the operation of the UV sanitizer, lights, and jets.

As in the case of the motor, the heater does not need much

maintenance.

UV Sanitizer:

Although Bromine and Chlorine are the most commonly used

sanitizers, we also use a UV sanitizer. Water is pumped through

a chamber that contains a bulb that produces ultra-violet light.

Algae, bacteria, and other microorganisms pass through the

chamber and are eradicated by the UV light. A UV system drastically reduces the need for a chemical sanitizer (chlorine or

bromine). Since the high-efficiency circulating pump is running

continuously, your swim spa is being filtered, heated, and sanitized 24 hours a day reducing the likelihood of bacterial growth.

Cartridge Filter:

through the filter. The filter is a 25 square foot cartridge-type

filter located at the front of the pool. The filter needs to be

cleaned or replaced periodically to ensure that your swim spa

stays sparkling clear. Please refer to the “Recommended

Maintenance Schedule” portion of this manual for more information on your filter.

The skimmer is where the water begins its travel

The water then passes through the UV Sanitizer.

The circulating pump then moves the water

Jet Pump:

the two-jetted seats. The jet pump pulls from two ports under

the seats and then pushes the water through 6 jets in each of

the two seats. Pushing the pump 1 button twice turns the jets

on. Pressing the pump 1 button once turns the jets off.

Electrical Disconnect Box:

which is attached to the hydraulic power unit is where your

incoming 220volt 60amp GFCI service is attached. If you are

going to bury your electrical conduit, please refer to the above

drawing for ideal placement of the conduit inside of the spa

skirting. Please refer to the “Electrical Requirements” for

more information.

Hydraulic Power Unit:

your swim current system. It pumps high-grade vegetable

based hydraulic fluid to the underwater hydraulic motor to

create the swim current.

Keypad:

ture of the swim spa as well as controlling the lights and jets.

Please refer to the, “Spa Functions” section in this manual for

more information.

Electrical Supply Conduit:

spa through underground conduit it should penetrate the floor

at the swim spa 8" from the back and side of the swim spa

(220V, 60Amp GFCI).

Your swim spa has a larger jet pump, which feeds

The electrical disconnect box,

The hydraulic power is the heart of

The keypad is how you change the desired tempera-

If bringing power to the swim

7

HEATER CONTROLLER

C

98

Connections simply snap into appropriate color coded receptacles.

TYPICAL SETTINGS

Set Point : 59°F to 104°F / Factory set at 84°F

Filter Cycle Duration: 0 to 24 hrs / Factory set at 24 hrs

Jet Pump Run Time: 1 to 255 min. / Factory set at 30 min.

Light Timeout: 1 to 255 min. / Factory set at 120 min.

Max Set Point: 59°F to 104°F / Factory set at 104°F

Purge Cycle Frequency: 1 to 4 times a day / Factory set at 4

Input wiring shown above

KEYPAD DOESN’T SEEM TO WORK

If a keypad doesn’t seem to work:

• Verify keypad connections.

• Replace keypad if problem is corrected.

• Replace in.xe if problem is not corrected.

in.xe UL/CSA electrical specifications:

Input rating: 120/240 VAC

(2-phase required, with neutral) 48 A maximum, 60Hz.

Software limited to 24A. Install on a 30A GFCI circuit.

Output ratings:

Output Voltage Current Typical Device

Out 1 120/240V 17FLA Pump 1

Out 3 120/240V 0.8 A Circulation

Pump/Blower

Out 4 120/240V 1 A Ozone Generator

Out 5 120/240V 5 A Audio/Video device

Keypad connection

L1 Light, 12VAC, 0.1 A

CO Communications port *

C1 Top side controller *

*CO: Comm.connector (in.stik).

8

heat.wav ratings:

Voltage: 120/240VAC

Current: 17A resistive (4 kW heater at 240V)

Frequency: 50 / 60 Hz

in.k200 full-function keypad

The Quick Reference Card provides a quick overview of your

spa’s main functions and the operations accessible with your

digital control pad.

heat.wav heater flow rate:

Minimum of 18 GPM is required

Important:

• All low voltage accessories use + 5Vdc and/or + 12 Vdc.

• All low voltage accessories combined:

150 mA max, on + 12 Vdc.

GENERAL SPECIFICATIONS:

Environmental:

Operating temperature: -20°C (-4°F) to 60°C (140°F)

Storage temperature: -25°C (-13°F) to 85°C (185°F)

Humidity: up to 85% RH, non condensing

IPx5 level of waterproofing is conditional on 3 items:

• Both front covers (heater and input wiring) are closed and

screwed shut.

• A waterproof strain-relief/bushing is used for the cable entry

into the pack.

• Any unused in.link connections (HC, LC, or low voltage) is

plugged with the appropriate blank plug.

Spa Functions

Key 1

98

The “Pump 1” indicator lights up when

Pump 1 is on.

Light Key

98

The “Light” indicator lights up when light is on.

Up/Down Keys

Press Key 1 key twice to turn

the jet pump on. Press a third

time to turn jets off.

A built-in timer automatically

turns pump off after 30 minutes,

unless pump has been manually

deactivated first.

Press Light key to turn light on.

Press a second time to turn light

off. A built-in timer automatically turns light off after 2

hours, unless it has been

manually deactivated first.

Mechanical:

Weight: 4.76 kg (10.5 lbs)

Dimensions (W x H x D):

Chassis: 441.5mm x 298.5mm x 129mm

(17.38" x 11.75" x 5.1")

UL/CSA Standards:

UL 1563 Fifth Ed.

File: E182156

CSA No. 22.2 - 218.1-M89.

TUV Standards:

EN/IEC 60335 - 2 - 60

EN55014-1

EN55014-2

EN61000-3-2

EN61000-3-3

The in.xe is lab tested to IPx5 enclosure protection levels.

Use Up or Down key to set

desired water temperature.

The temperature setting

98

The “Set Point” icon indicates that the display

shows the desired temperature, NOT the current

water temperature!

Off Mode

While the Off mode is engaged, the display will toggle between

OFF and the water temperature.

will be displayed for 5 seconds

to confirm your new selection.

This mode allows you to stop all

outputs for 30 minutes to perform a quick spa maintenance.

Press and hold Key 1 key for 5

secs to activate the Off mode.

Quick press Key 1 key to reactivate the system before the expiration of the 30-minute delay.

9

TROUBLESHOOTING

SMART WINTER MODE

Hr

An internal hardware error has been detected in

in.xe. Contact Customer Service.

HL

The system has shut the heater down because

HL

AOH

FLO

OH

UPL

WATER TEMPERATURE

In a heating cycle, the system first generates water flow through

the heater housing and the plumbing, in order to ensure accurate

water temperature readings as well as avoiding heater activation in

dry conditions.

After verifying pump activation and taking a water temperature

reading if required, the system automatically turns the heater on to

reach and maintain water temperature at Set Point.

The “Heater” indicator lights up when the heater is on. It

flashes when there is a request for more heat but the

heater has not yet started.

the temperature at the heater has reached 119°F

(48°C). Do not enter the water! Remove the

spa cover and allow the water to cool down,

then shut power off and power your spa up

again to reset the system.

AOH

Temperature inside the spa skirt is too high,

causing the internal temperature in the in.xe to

increase above normal limits. Open skirt and

wait until error clears.

FLO

The system does not detect any water flow

while the primary pump is running. Check

and open water valves. Check for water level.

Clean filter. If the problem persists, call

Customer Service.

Prr

A problem is detected with the temperature

probe.Call Customer Service.

OH

The water temperature in the spa has reached

108°F (42°C). Do not enter the water! Remove

the spa cover and allow the water to cool down

to a lower temperature. Call Customer Service if

problem persists.

UPL

No low level configuration software has been

installed into the system. Call Customer Service.

Our Smart Winter Mode protects your system from the cold by

turning pumps on several times a day to prevent water from freezing in pipes.

The “Smart Winter Mode” indicator lights up when

the Smart Winter Mode is on.

PURGE CYCLES

The system is programmed to automatically turn on the optional

jet pump 4 times daily, for 60 seconds, in order to purge the

plumbing lines and keep plumbing lines filtered clean.

REMOTE CONTROL TRANSMITTER

The remote control transmitter has three buttons. Press and hold the

On/Off button to turn the swim current on. Press and hold the Up or

Down button to adjust the current to the desired speed. Press and

hold the On/Off button while the current is on to turn off.

This device complies with Part 15 of the FCC Rules. Operation is

subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received, including

interference that may cause undesired operation. WARNING:

Changes or modifications not expressly approved by the party

responsible for compliance could void the user's authority to

operate the equipment.

MODEL: EP-1g - 230 VAC, 24 AMPS, 60 Hz.

IP25 RATED RAINPROOF (TYPE 3R) ENCLOSURE SUITABLE FOR INDOOR OR OUTDOOR USE

THIS UNIT REQUIRES 60 AMP 230 VOLT AC, SINGLE

PHASE WITH NEUTRAL, 60 Hz. (THREE COPPER WIRES

PLUS GROUND)

Hydraulic Power Unit

5 HP 21 FLA Amps 230 VAC 60 Hz

6 HP 23 FLA Amps 230 VAC 60 Hz

HEATER CONTROLLER (optional)

24 Amps 230 VAC 60 Hz

Controller

IMPORTANT SAFETY INSTRUCTIONS: Read and follow all

instructions. To reduce the risk of injury, do not permit children to

use this product unless supervised at all times. This control panel

must be installed according to local electric code requirements. A

GFCI (Ground Fault Circuit Interrupter) or RCD (Residual

Current Device) circuit breaker must be used in the service panel

and tested before each use in accordance with the manufacturer's

instructions. The line in wire whip should be connected to a safety disconnect in sight of all equipment, but at least 5 feet away

from the pool. This controller must be installed at least 5 feet away

from the pool and all conductors must not share boxes, conduits or

enclosures with non GFCI or RCD protected wiring. All wires

must be copper. Box must be mounted with conduit down.

10

CABINET & COVER CARE OF YOUR

ENDLESS POOL SWIM SPA

HOW TO SWIM IN AN

ENDLESS POOL SWIM SPA

Cabinet Care: The natural cedar wood cabinet on your Endless

Pool Swim Spa is made of the finest quality outdoor wood available. This wood needs to “breathe” therefore a traditional sealer

should not be used on its exterior. It is best to use a wood preservative, such as “boiled linseed oil”, or a semi transparent stain, like

“Cuprinol” that is available at Sherwin Williams stores.

Cover Care: The optional 4”-thick bi fold coordinating cover was

custom made for your Endless Pool Swim Spa with top of the line

materials. Aluminum channel bars form the structure of the cover

for superior strength. Inside, the high-density polystyrene foam

core provides excellent insulation preventing heat loss. Hard

working, 4-mil extruded plastic covers the foam core. The outside

is made off Marine grade vinyl, safe from “cold-cracking” down

to 10 degrees below zero. In addition, it is treated with UV stabilized pigments so the color will not fade.

The swim current is turned on through the use of a remote control,

which also adjusts the speed of the current faster or slower. When

changing speed, you must press and hold the buttons on the remote,

then wait a few seconds for the current to adjust. Our standard

pool's top speed is roughly equivalent to a 1:08 100 yard pace -- a

speed for expert swimmers only. Set the water speed at a comfortable level for your needs. Remember, since you don't have to turn

in an Endless Pool, your workout is continuous and you will tire

faster than when swimming laps in a traditional pool.

To stop swimming, simply press the on/off button on the remote.

If left running, the power unit will turn off automatically after thirty minutes and can be restarted by pressing the on/off button

again. Once you have found an optimal speed for yourself, you

may leave the system at that setting. The controller for the swim

machine is designed with a “ramp-up” feature which forces the

swim machine to start slowly, but will increase to the last setting

at which someone swam.

TROUBLESHOOTING WATER QUALITY

Symptom Possible Cause Solution

Algae Growth Low sanitizer levels. Shock the water, brush spa walls, and add

an algaecide.

Cloudy Water High calcium hardness levels. High Test all chemical levels and make the

total alkalinity levels. High pH levels. appropriate adjustments.

High TDS levels. Algae growth, low

sanitizer levels, rain, high bather load, and pets.

Colored Water For green or blue: High pH levels. For green or blue green: Test the pH level

For brown to red: Overall water imbalance. and make the appropriate adjustments.

For brown to red: Test pH, total alkalinity and

calcium hardness levels. If necessary, drain all

or part of water and refill with fresh water.

Corrosion Low pH levels. Low total alkalinity levels. Test chemical levels, make the appropriate

An excessively high Bromine/Chlorine level. adjustments and consult our Customer Service

Department at 1-800-910-2714.

Foaming A buildup of organic dirt, soaps, Drain and clean the swim spa and filter

shampoos and oils. Limit clarifier use

Low calcium hardness. Raise calcium hardness levels.

pH Bounce Low total alkalinity levels. Test total alkalinity levels and make the appro-

priate adjustments.

pH Resistance High total alkalinity levels. Test total alkalinity levels and make the appro-

priate adjustments.

Poor Sanitizer Efficiency High pH levels. High total alkalinity levels. Test pH and total alkalinity levels and make

appropriate adjustments.

Scale Formation High pH levels. High total alkalinity levels. Test pH and total alkalinity levels

High TDS levels. High calcium hardness levels. make the appropriate adjustments.

If necessary, drain the swim spa, scrub down

the walls and refill with fresh water.

Skin and Eye Irritation Low or high pH levels. Low or high total Test pH and total alkalinity levels and

alkalinity levels. Low sanitizer levels. make the appropriate adjustments. Test

sanitizer levels and, if extremely low,

shock the swim spa water.

Stains Low pH levels. Low total alkalinity levels. Test ph and total alkalinity levels and

High TDS levels make the appropriate adjustments. If

11

necessary, drain the swim spa, scrub

down the walls and refill with fresh water.

TROUBLESHOOTING

None of the Equipment Main breaker is set at OFF Set main breaker to ON.

is Operating Sub-panel breakers are set to OFF Set sub-panel breakers to ON. .

Equipment GFCI set at OFF. Reset GFCI.

Power switch set at OFF (if available). Set power switch to ON.

Components not plugged in. Plug in components.

Power cord not plugged in. Plug in power cord.

Leaking couplers allowing water in Check and tighten any loose couplers.

the equipment area.

No Water Flow, Air lock in plumbing system. “Bleed” system issue - refer to

Low Water Flow, Restricting flow. initial start-up procedure.

or Surging Flow Clogged or Dirty Skimmer Basket. Ensure the water Shut-Off Valves are open.

(Keypad is reading, “FLO”) Dirty filter. Low water level. Ensure suction fittings are not blocked

by debris and clean skimmer basket.

Clean or replace filter

Increase water level to recommended level.

Therapy Jets Not Operating Component not plugged into heater controller. Plug component into P1 on Heater/Controller.

Therapy Jets Not Operating Shut-off valves closed. Open valves.

Jets not properly adjusted. Adjust jets properly.

Diverter valve not properly adjusted. Adjust diverter valve properly.

UV Sanitizer Not Working UV bulb has gone bad. Replace bulb.

Component not plugged into heater controller. Plug in component.

Lighting Not Operating Light bulb defective. Replace bulb.

Not plugged in. Plug in cord.

Light cord not connected. Connect cord.

Water Leaks Swim Spa over filled or too many people in spa. Adjust swim spa water level.

Couplings or unions loose. Tighten couplers.

Incorrect water chemistry. Correct chemistry.

Pump seal leaking. Fix leak, contact local Spa Technician.

Loose Plumbing connections. Check connections and tighten.

Water dripping from topside control buttons. Seal topside control panel.

Water in air blower plumbing. “Bleed” system issue - refer to

initial start-up procedure.

No Heat Thermostat not set correctly. Adjust thermostat setting.

Overheat protection switch tripped. Reset Hi-Limit Switch.

No power to heater. Reset breaker at service panel.

Low water flow. Clean or replace filter.

Improper water flow. Refer to “No Water Flow, Low

Water Flow, or Surging Flow” section.

High Heat Temperature sensor not in drywell. Place sensor in drywell.

Jets left running continually. Turn OFF jets pump.

Thermostat set too high/maximum. Adjust thermostat setting.

High air temperature. Remove Swim Spa Cover.

GFCI Tripped Occasionally Lightning/Electrical storm. Reset GFCI.

Power Surge. Reset GFCI.

Extremely humid conditions. Reset GFCI.

Radio frequency interference. Reset GFCI.

Water spraying on electrical components. Reset GFCI.

NOTE: Ensure that the equipment is properly grounded and bonded.

GFCI Trips Repeatedly Water spraying on electrical components. Make sure all couplers are tight.

Defective component.

Should you need further assistance, please call our Customer Service Department at 1-800-910-2714.

12

WIRING DIAGRAM: EP-1 CONTROLLER WITH SWIM SPA

Line in on 60 amp Ground Fault Circuit Breaker

13

ENDLESS POOL SWIM SPA™ LIMITED WARRANTY

ENDLESS POOLS, INC. WARRANTS TO THE ORIGINAL PURCHASER OF THE ENDLESS POOL SWIM SPA MANUFACTURED BY US TO BE FREE FROM DEFECTS IN MATERIALS AND WORKMANSHIP UNDER NORMAL USE FOR TWO

YEARS FROM PURCHASE.

Our obligation under the warranty shall be limited to the repair or exchange (at our option) of any part or parts which may thus prove

defective under normal use within two years from date of purchase by the original purchaser, and which our examination shall disclose

to our satisfaction to be thus defective. All labor costs for removal and re-installation of the defective part and all freight charges shall

be paid by the purchaser and will not be reimbursed by Endless Pools, Inc. This warranty is expressly in lieu of all other warranties

expressed or implied including the warranties of merchantability and fitness for use and of all other obligations or liabilities for all damages direct or consequential to person, property or business whether or not occasioned by our negligence, and we neither assume for

us any other liability in connection with the sale of this Endless Pool Swim Spa.

IN ADDITION, ENDLESS POOLS, INC. OFFERS A TEN-YEAR STRUCTURAL WARRANTY ON THE ACRYLIC SHELL

STRUCTURE. If the acrylic shell should deteriorate beyond structural use in this ten-year period, we will repair or replace the component at our option after inspection of the defective shell. The structural warranty is voided when suitable drainage is not provided.

THE ACRYLIC SURFACE OF THE SWIM SPA SHELL IS WARRANTED NOT TO SPLIT, BREAK, CRACK, BLISTER OR

MILDEW FOR A PERIOD OF FIVE YEARS. This warranty does not include cosmetic damage or minor surface imperfections.

THIS WARRANTY SHALL NOT APPLY TO THIS ENDLESS POOL SWIM SPA OR ANY PART THEREOF, WHICH HAS BEEN

SUBJECT TO SALT CHLORINE GENERATORS, ACCIDENT, NEGLIGENCE, FREEZING, IMPROPER INSTALLATION OR

OPERATION, ALTERATION, ABUSE OR MISUSE. THIS INCLUDES, BUT IS NOT LIMITED TO, FLOW RESTRICTIONS OR

OBSTRUCTIONS ON ALL WATER AND HYDRAULIC SYSTEMS AND NOT MAINTAINING PROPER WATER CHEMISTRY

(pH level must be maintained between 7.4 and 7.8 and total alkalinity between 80 and 120 ppm. Total dissolved solids (TDS) must be

no greater than 3,000 ppm).

We make no warranty whatsoever in respect to accessories or parts not supplied by Endless Pools, Inc. directly. The term “original

purchaser”, as used in this warranty, shall be deemed to mean the person for whom the Endless Pool Swim Spa was originally installed.

We DO NOT warrant this machine to meet requirements of any safety code of any state, municipality, or other jurisdiction. Purchaser

assumes all risk and liability whatsoever resulting from the use thereof.

In order to claim this warrant, original purchaser must promptly notify our Customer Service Department in writing of the existence

of the claim and then follow our written instructions regarding the procedures for remedying the defect. Endless Pools, Inc. shall not

be responsible for cartage, transportation, removal and/or reinstallation labor or any other such costs relating to performance of the warranty. In the event any portion of this warranty shall be deemed unenforceable by a court of law, the remainder of this warranty shall

remain in full force and effect as if the voided portion were never included.

Prepaid returns of all Endless Pool products are accepted less a 10% restocking fee, up to 30 days from the date of purchase if undamaged and in its original shipping containers. Accessories, options and equipment that have been used are non-refundable. Before

returning any product, you must call our Customer Service Department to receive proper return authorization.

Endless Pools, Inc., 1601 Dutton Mill Rd., Aston, PA 19014

14

Endless Pools, Inc. • 1601 Dutton Mill Rd • Aston, PA 19014-2931

800-910-2714 • 610-497-8693 fax • www.myendlesspool.com

B31 5-09

Loading...

Loading...