Endless Pools FASTLANE Owner's Manual

FASTLANE

By Endless Pools, Inc.

OWNER’S MANUAL

®

F a s t l a n e®S w i m U n i t I n s t a l l a t i o n

Section 1 GENERAL OVERVIEW OF AN ENDLESS POOL FASTLANE

The Fastlane®swimming machine by Endless Pools, Inc. is a hydraulically-powered system that creates a

smooth, adjustable-speed swim current in a conventional pool. The Fastlane has been fabricated with the

finest, most durable materials and designed to meet the most stringent safety standards including VGB

2008. The swim current produced is wider than your body and deeper than your stroke — far superior to

currents created by one or more jets. Two 3/8" hydraulic hoses carrying a non-food grade, biodegradable

vegetable oil run between the hydraulic Power Unit and the Fastlane Swim Unit, thus eliminating the need

for electricity poolside. When pumped at high pressure, this hydraulic fluid creates a swim current by turning the shaft of a submerged stainless steel hydraulic motor in the Fastlane Swim Unit, which in turn rotates

a 16" diameter propeller. The Power Unit is activated using a 3-button radio frequency remote control that

can turn the unit on and off and adjust the speed. It is best if the Power Unit is within 25' of the Swim Unit

to minimize pressure loss. An optional 6" LED swim pace display is available to monitor your speed. Also,

customers often place our swim mirror on the bottom of the pool to observe their swim stroke.

Note: all of the 316L stainless steel screws provided for the assembly of this unit should be tightened to

the recommended 25 in-lbs of torque.

W

= Wall Mount Fastlane = Deck Mount Fastlane

D

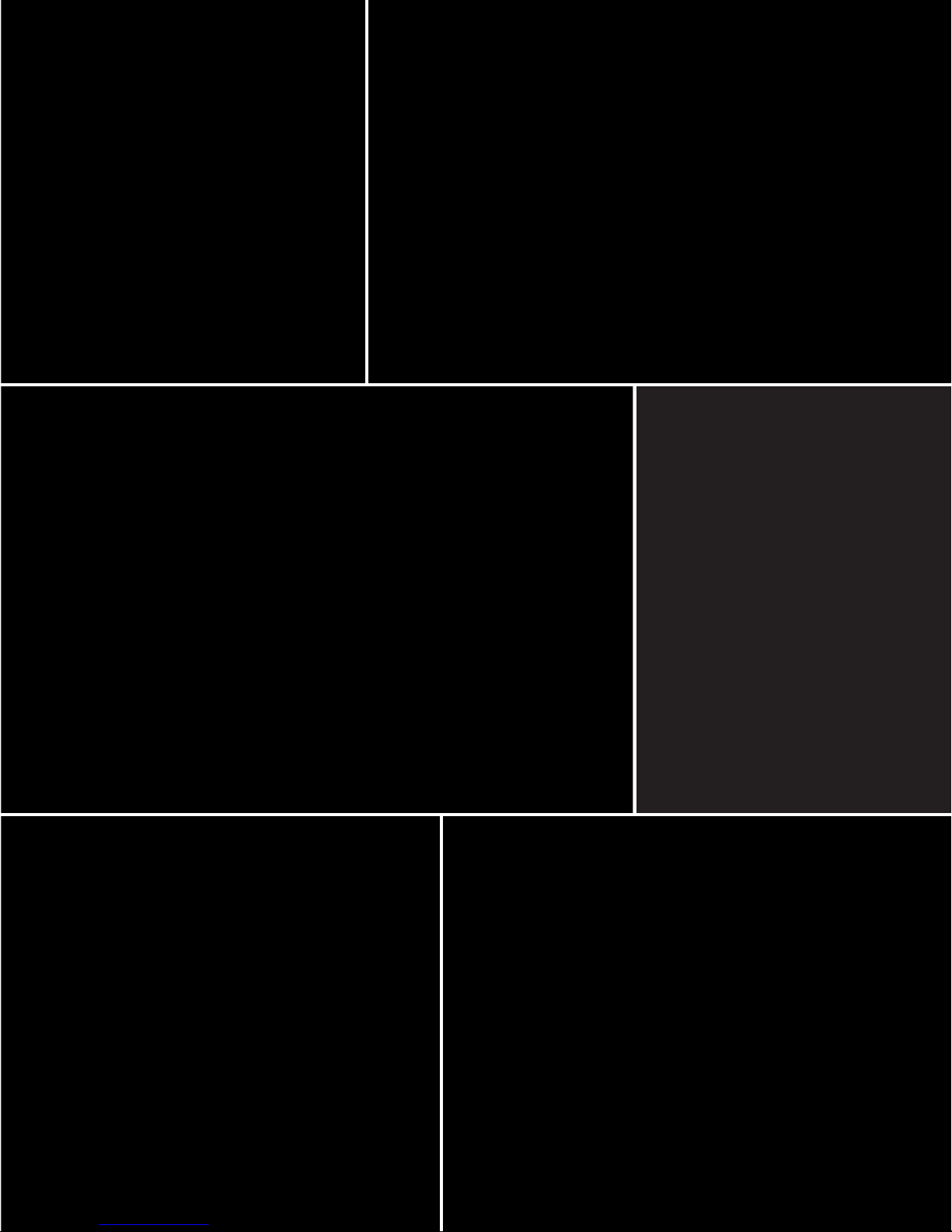

The Fastlane can be mounted one of two ways:

The Wall Mount Fastlane fastens to the wall of the pool using the bracket provided. Two 1" polyethylene

W

pipes (or 1 1/2" PVC pipe) which serve as conduits for the hydraulic hoses run under the pool deck to a remotely located, 5-horsepower, hydraulic Power Unit, as shown in Figure 1.1.

Fig 1.1

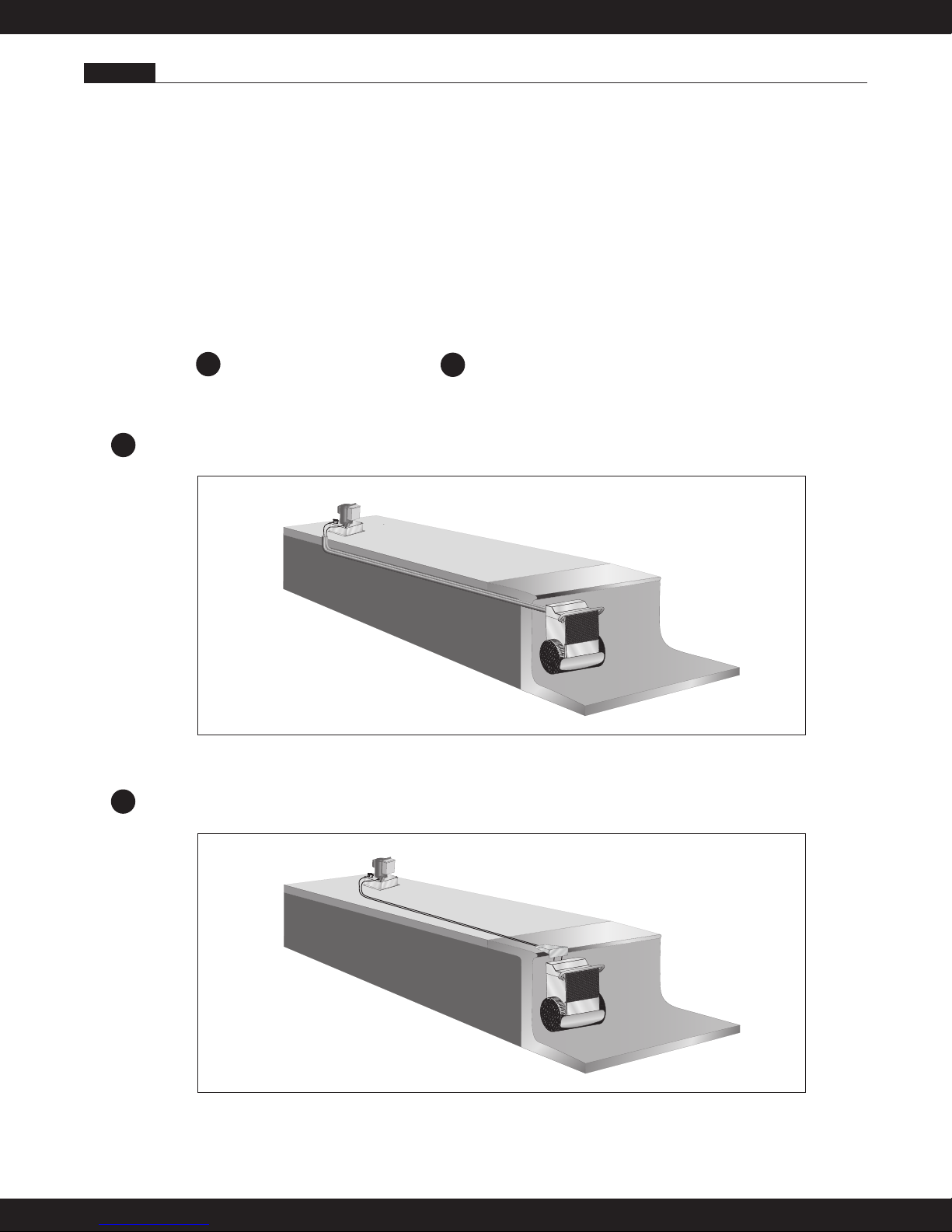

The Deck Mount Fastlane fastens to the pool deck using the hanger bracket provided. The two hydraulic

D

lines then run back to the remotely located, 5-horspower, hydraulic Power Unit. The hydraulic hoses can

be run through a conduit or run aboveground, as shown in Figure 1.2.

Fig 1.2

1

F a s t l a n e®S w i m U n i t I n s t a l l a t i o n

Section 2 CHOOSING A LOCATION FOR YOUR FASTLANE

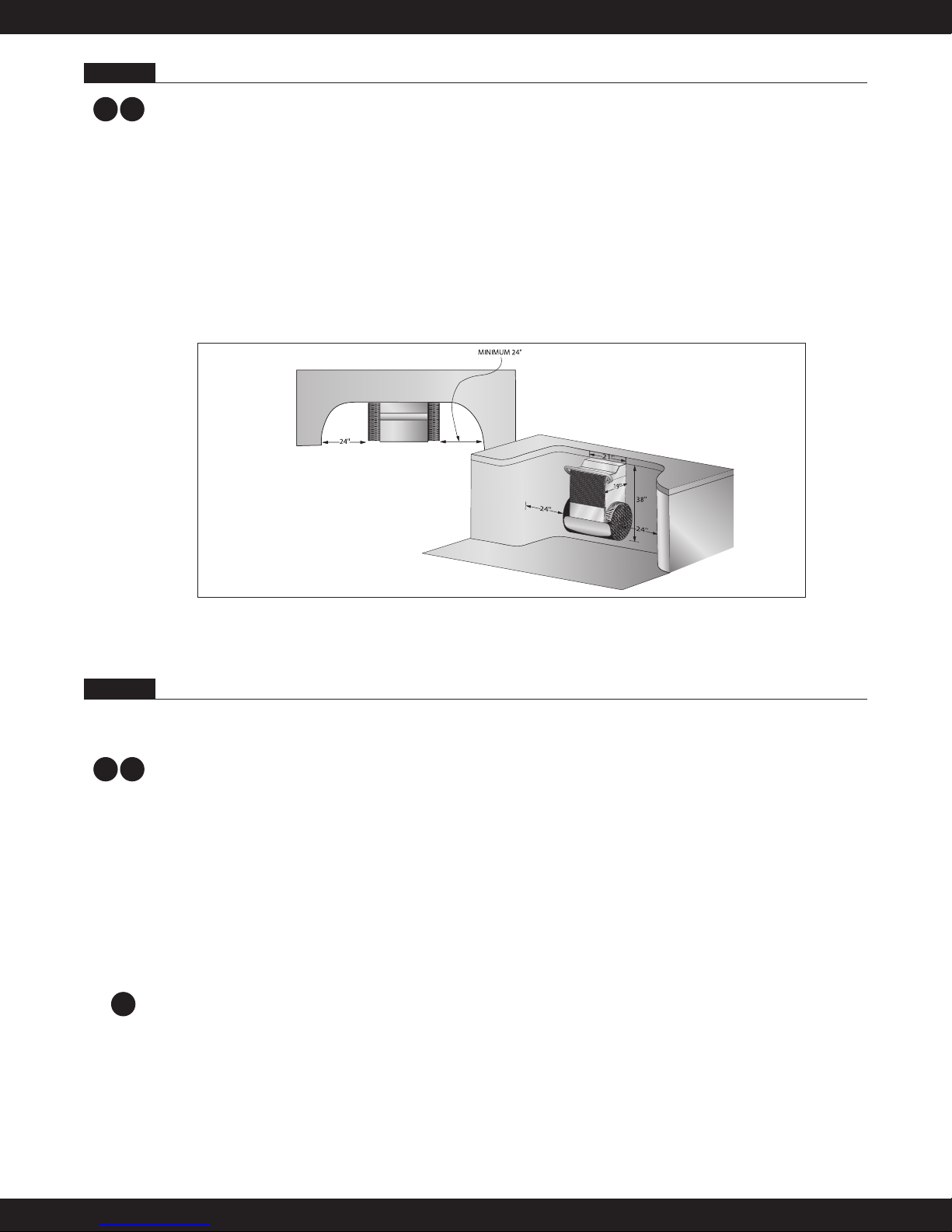

The Fastlane can fit in virtually any swimming pool. For optimal water flow, we recommend that you allow

D

W

at least 12 feet between the wall on which the Fastlane is installed and the opposing wall in line with the

Swim Unit. The Fastlane has more than 9 square feet of water intake to eliminate any entrapment hazards.

The water depth where the Fastlane is installed must be at least 35" deep. In addition, the Fastlane must be

installed no closer than 24" from any adjacent wall as shown in Figure 2.1, Minimum Clearance Guidelines.

When choosing a location for your Fastlane, you should also consider the route for the hydrualic hoses to

run back to the Power Unit. The Power Unit needs to sit on a solid, level surface, preferably not on wet

ground, and requires a 30-amp, 220-volt GFCI electric service. For UK and international electrical requirements, please refer to Section 11. The optional Outdoor Power Unit with Weather Guard may be located

outside, but should not be subject to driving rain. Typically, the Power Unit is located with the other pool

equipment and, if possible, long hydraulic runs should be avoided because of pressure loss. If you wish to

have a run greater than 25', you must transition from 3/8" hydraulic hoses to 1/2" run hoses with the addition of a junction box as reviewed in Section 5.

Fig 2.1

Section 3 RECEIVING YOUR FASTLANE

Minimum Clearance Guidelines

The Endless Pools Fastlane is comprised of a minimum of five (5) parcels. Additional parcels may be

shipped as appropriate. All items will be shipped via UPS Ground.

Items shipped UPS

D

W

Parcel 1: Fastlane Swim Unit – propulsion housing

Parcel 2: Fastlane Swim Unit – base with pre-installed,

25 feet of hydraulic hoses, grab bar

Parcel 3: 5-hp Power Unit with 2 Wireless Remote Controls and Antenna located inside the controller

(Heavy Box) Note: If the Outdoor Power Unit was purchased as an option, the Weather Guard

will come pre-assembled to the Power Unit.

Parcel 4: Five (5) Gallons of Hydraulic Fluid (Non-Food Grade Vegetable Oil)

Parcel 5: Accessories Kit (Wall Mount or Deck Mount)

Wall Mount Accessories Kit

- Owner’s Manual Kit including:

W

- (2) –8 JIC Female x –6 JIC Male Hydraulic Adapters

- (8) 3/4" stainless steel screws for Fastlane assembly

- (10) 1/2" stainless steel screws for Fastlane assembly

- (6) 3/4" stainless steel screws for Grab Bar installation

- (6) stainless steel nuts for Grab Bar installation

- (2) Protective Hat Channels

- (16) 3/4" stainless steel screws to attach Hat Channels to Upper Housing

- (1) Fastlane Acrylic Top

2

F a s t l a n e®S w i m U n i t I n s t a l l a t i o n

D

Deck Mount Accessories Kit

- Owner’s Manual Kit including:

- (2) –8 JIC Female x –6 JIC Male Hydraulic Adapters

- (8) 3/4" stainless steel screws for Fastlane assembly

- (10) 1/2" stainless steel screws for Fastlane assembly

- (6) 3/4" stainless steel screws for Grab Bar installation

- (6) stainless steel nuts for Grab Bar installation

- (20) 1/2" stainless steel screws for Hanger bracket installation & deck plate assembly

- (1) 3/16" x 2-1/4” Masonry Screws

- (1) 5/32" Masonry Bit

- (4) Hose Clips

- (2) Protective Hat Channels

- (16) 3/4" stainless steel screws to attach Hat Channels to Upper Housing

- (1) Deck Plate Bottom with 3/16" bonding lug attached

- (1) Deck Plate Top

- (1) Fastlane Acrylic Top

The Following two packages will be included ONLY if a Wall Mount Fastlane was purchased:

W

Parcel 6: Wall Mount Bracket Assembly

Parcel 7: Two (2) 24' 6" rolls of 1" Polyethylene Pipe

Optional Equipment

W

D

• Outdoor Power Unit with Weather Guard

• Floor Mirror

• Swim Pace Display

Section 4 WALL MOUNT BRACKET AND 1" POLYETHYLENE PIPE INSTALLATION

NOTE: Please read instructions fully before beginning bracket installation.

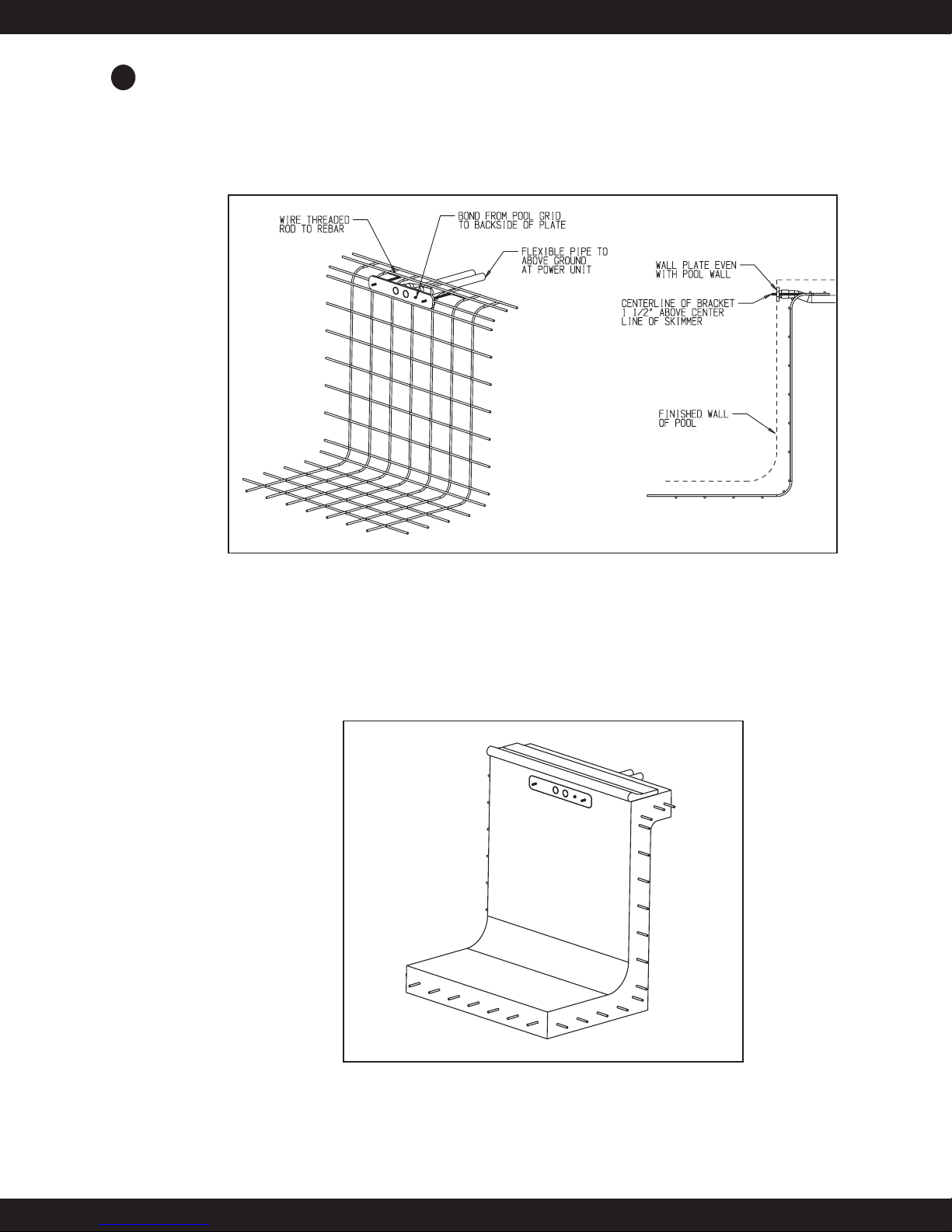

4.A. Gunite/Concrete Pool

W

If the pool being constructed is gunite or concrete, please follow the instructions below.

Parcel 6 includes the Wall Mount Fastlane bracket for concrete or gunite pools. Two (2) 24' 6" rolls of 1"

poly pipe are shipped separately. The standard bracket is comprised of the following components

(refer to Photo 4.A.1):

• Two (2) 3/8" threaded 316L stainless steel mounting rods with hardware

• One (1) 3/8" PVC bracket plate

• Two (2) thru-wall Liquid-Tite fittings

• One (1) bonding lug set

3/8" Stainless Steel Mounting

Rod. Firmly secure these

rods to the rebar grid.

Hang and secure Fastlane

on these SS threaded rods.

Wall Mount Fastlane Bracket.

Install this side flush with the

finished pool surface.

Cover 1" poly pipe end with duct

tape to prevent gunite from clog-

Photo 4.A.1

ging the 1" poly pipe.

Attach SS bonding wire from

inside the Fastlane housing to

the bonding lug.

Example of 1" poly pipe.

1" poly pipe connects to this

Liquid-Tite fitting and runs to

the hydraulic Power Unit

or junction box.

Bonding

Lug Set

Bracket Plate

3

F a s t l a n e®S w i m U n i t I n s t a l l a t i o n

The bracket is to be installed into the pool wall as shown in Figure 4.2 so that the two mounting rods are 1-

W

1/2" above the intended waterline for the pool, which is typically halfway up the skimmer. (The bottom

edge of the Wall Mount Bracket will sit along the pool’s intended waterline.) The rods penetrate 1-1/4" to

1- 1/2" into the finished pool and will be used to hang the Wall Mount Fastlane. These rods must be tied

back to the rebar of the bond beam in the pool and, once encased in concrete, will serve as a suitable

hanger. Additionally, a #8 or larger, solid copper bonding wire must be connected from the pool bonding

grid to the bonding lug located on back of the wall mount bracket.

Fig. 4.2

Level and position the bracket so that the PVC surface of the bracket plate will be flush with the finished

surface of the pool wall as shown in Figures 4.2 and 4.3. The area below the bracket plate should be no

more than 5 degrees less than vertical down to at least 35" below the waterline. The Fastlane is 21" wide.

Consequently, the 21" section of wall where the bracket is located should be straight or near straight. Any

variations from this requirement should be discussed with your design representative. Additionally, it is imperative that the Fastlane not be installed less than 24" from an adjacent wall to allow for proper water

flow. Please refer back to Figure 2.1, Minimum Clearance Guidelines, for clarification.

Install two (2) complete 1" poly pipes back to the Hydraulic Power Unit or junction box. The two (2) 1"

poly pipes may be partially buried and/or covered with concrete. Care should be taken when rounding corners not to use tighter than 18" radius bends. It is imperative that this 1" poly pipe not be kinked given

the close tolerance of the fittings sliding through later (Section 9.4). Do not use couplers with this 1"

Fig. 4.3

4

F a s t l a n e®S w i m U n i t I n s t a l l a t i o n

W

poly pipe, but rather use a single length for each of the two hydraulic hoses that will run through them. The

goal is to provide an easy route for each of the two 3/8" hydraulic hoses — a route free of obstructions and

unlikely to bind. The hydraulic hoses may run on the surface outside the 1" poly pipe, but care must be

taken not to damage them. It is always best to use the 1" poly pipe provided as it protects the hydraulic

hoses from chafing as well as UV damage. The 1" poly pipe is chosen because of its slipperiness and the

ease with which the 3/8" hydraulic hose slides through it. At the same time, this 1" poly pipe can be easily

kinked which will make it difficult to slide the hydraulic hoses through later.

When planning for these two runs of 1" poly pipe, recognize that they penetrate the pool wall 1-1/2" above

the waterline and as a consequence will be flooded if the water level rises to that point. We strongly rec-

ommend that the 1" poly pipe rise to a point above which the water level will never rise to avoid any

potential flooding. This can be done during the 1" poly pipe run or back near the Power Unit. Tighten the

bracket liquid-tite fittings so that the 1" poly pipe is squeezed and water cannot leak around the 1" poly

pipe.

If you are concerned about subsidence and/or kinking, you may prefer to use a heavier 1-1/2" double run of

PVC flex pipe. To accomplish this, simply substitute the two couplings provided with the two (2) liquid-tite

fittings threaded into the PVC bracket, apply Teflon Tape to the couplings, and glue in the 1-1/2" PVC flex

pipe (refer to Photo 4.A.2).

3/8" Stainless Steel Mounting

Rod. Firmly secure these

rods to the rebar grid.

These 1-1/2" couplings may

be used if you choose to use

1-1/2" PVC flex pipe rather

than the 1" poly pipe as your

conduit to the Power Unit

and junction box.

Example of 1-1/2"

PVC Flex Pipe

Hang and secure Fastlane

on these SS threaded rods.

Bonding

Lug Set

Wall Mount Fastlane Bracket.

Install this side flush with the

finished pool surface.

Cover PVC end with duct tape

to prevent gunite from clogging

the PVC.

Photo 4.A.2

Attach SS bonding wire from

inside the Fastlane housing to

the bonding lug.

Bracket Plate

NOTE: The pool builder/installer must decide if they will be using 1" poly pipe or 1-1/2" PVC flex

pipe BEFORE spraying gunite. Once the 1" poly pipe or 1-1/2" PVC flex pipe has been run, cut, and

trenched, the gunite can be sprayed.

If installing the provided 1" poly pipe (standard installation), the Wall Mount Fastlane ships with two

(2) 24' 6" rolls of 1" poly pipe. From the rear side of the pool, feed each 1" poly pipe into the liquid-tite fittings and tighten the cord grip on the 1" poly pipe so that no water will pass between the 1" poly pipe and

the liquid-tite fitting. Unroll the 1" poly pipe to the location where the Power Unit will be located. The 1"

poly pipe is 6" shorter than the standard length of hydraulic hoses provided. As you run the 1" poly pipe, be

certain it does not kink. To ensure you have sufficient lengths of hydraulic hoses to make the necessary

connections to the Power Unit, cut off approximately 3' of each 1" poly pipe. The 1" poly pipe will need to

exit the ground near the Power Unit. If you find the 1" poly pipe is not long enough to reach the Power

Unit, a junction box and additional hydraulic hoses will need to be ordered and installed. In this case, DO

NOT CUT the length of the 1" poly pipe. Refer to Section 5 for additional information.

If installing the 1-1/2" PVC flex pipe, remove the two (2) 1-1/4" liquid-tite fittings from the wall mount

bracket. Thread and adhere with Teflon tape the two (2) 1-1/2" NPT male/slip female PVC fittings into the

wall mount bracket. Unroll the 1-1/2" PVC flex pipe from the wall mount bracket to the Power Unit. The

PVC flex pipe should exit the ground near the Power Unit. Each section of the PVC flex pipe should be no

longer than 21 feet. This will leave enough hydraulic hose to connect to the Power Unit. If you find that 21

feet of the PVC flex pipe is not long enough to reach the Power Unit, a junction box and additional hydraulic hoses will need to be ordered and installed. Refer to Section 5 for additional information.

5

F a s t l a n e®S w i m U n i t I n s t a l l a t i o n

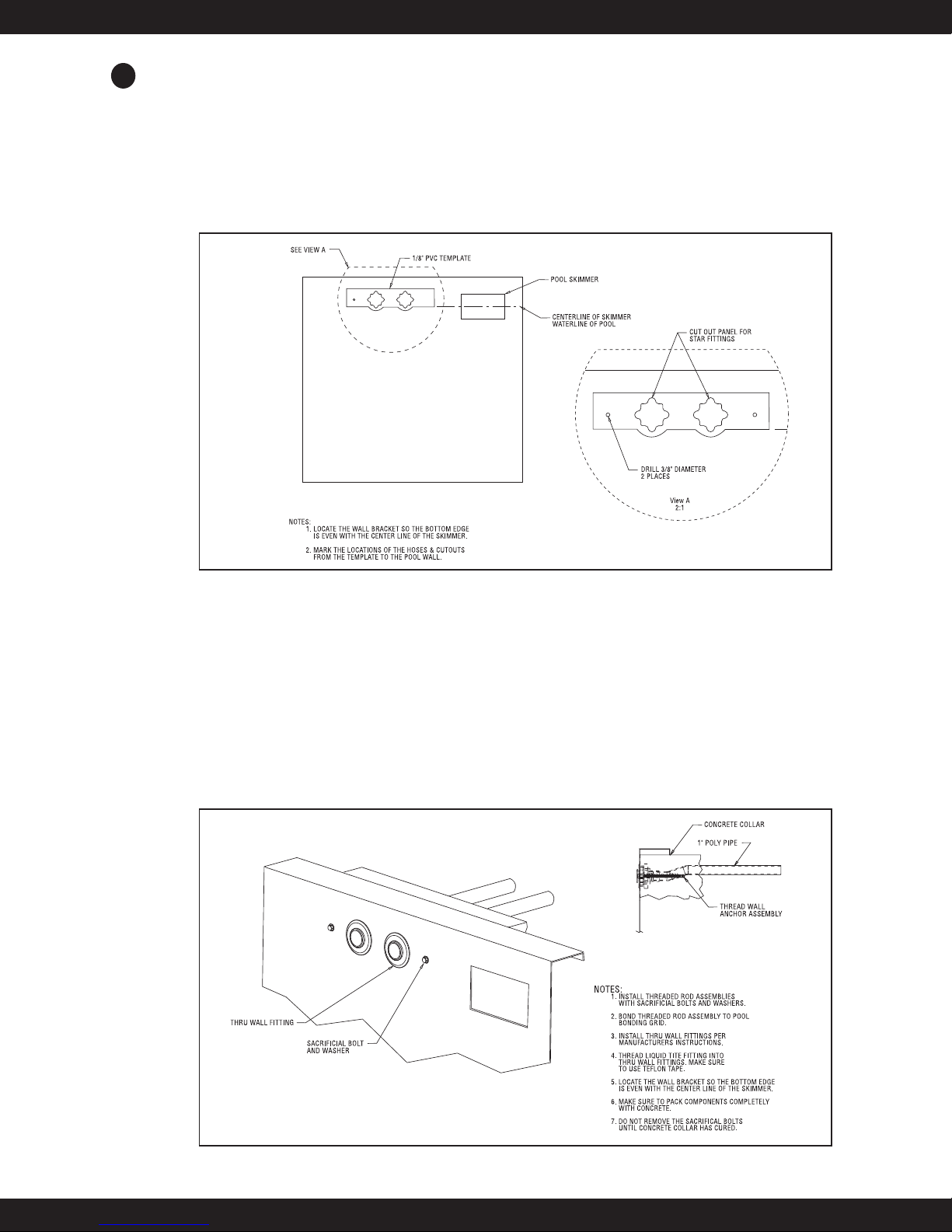

4.B. Steel/Polymer Panel Pool with a Vinyl Liner

W

If the pool being constructed is steel/polymer panel with a vinyl liner, please follow the instructions below.

Remove the star thru-wall fittings and threaded rod pieces with hex coupling nut attachments from the 1/8"-

thick, grey PVC template. Position the PVC template where the Fastlane will attach to the pool wall and

align the bottom of the template with the expected water level in the pool (which will typically be located at

the centerline of the skimmer) as shown in Figure 4.4. Use duct tape, perhaps wrapped over the top flange,

to temporarily adhere the PVC template to the pool wall. Be certain that the PVC template is level in the

pool. Trace the outline of the star thru-wall fittings and threaded rod hole penetrations that are cut in the

PVC template onto the pool wall. Remove the duct-taped PVC template from the pool wall.

Fig. 4.4

Cut (or punch) the openings for the star thru-wall fittings and threaded rod holes. Install the star thru-wall

fittings with the holes for the cover at 12, 3, 6 and 9 (clock positions). Choose the appropriate adapters to

thread into the back of the star thru-wall fittings for the type of conduit that will be used for running the hydraulic hoses from the pool to the Power Unit. Use the provided 1" poly pipe with liquid-tite fittings or a

standard 1-1/2" PVC flex pipe with the provided 1-1/2" couplings. Refer to Section 5 for length of 1" poly

pipe or 1-1/2" PVC flex pipe. The threaded rod with hex coupling assembly must now be tightened against

the backside of the pool wall. The 3/8" jam nuts should be fastened on the threaded rod so that half of the

hex coupling is threaded onto the rod and the other half facing the poolside remains empty. Use the sacrificial 3/8" bolts and washers to thread into the hex coupling from the inside of the pool through the hole that

was previously drilled in the wall as shown in Figure 4.5. Tighten the bolts to secure the assembly to the

rear of the pool wall.

Fig. 4.5

6

F a s t l a n e®S w i m U n i t I n s t a l l a t i o n

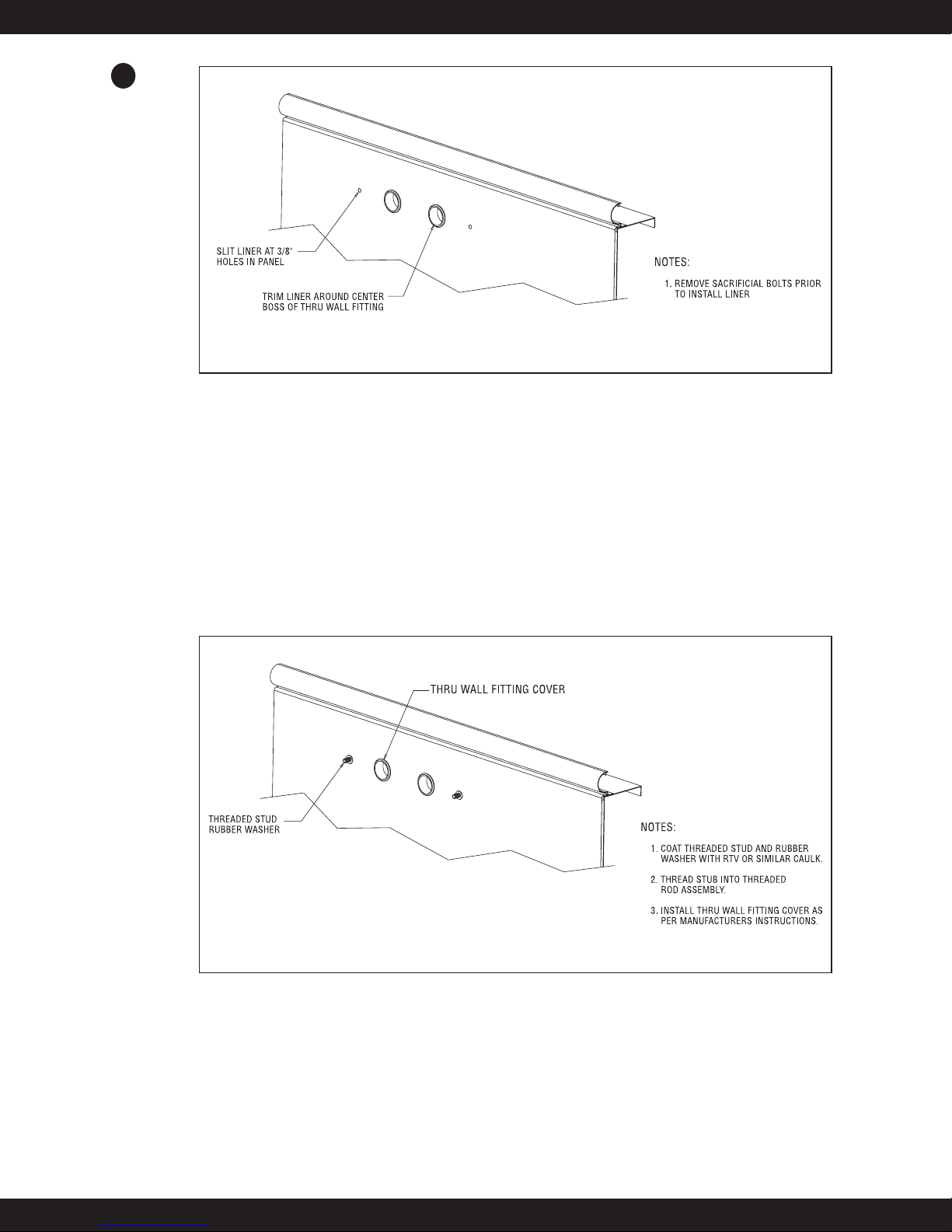

W

Fig. 4.6

If using rebar in the pool’s collar, tie and bond the bent pieces of threaded rod into the bonded rebar grid.

If no rebar is being used, be sure to bond the threaded rod to the pool’s bonding grid.

Pour the concrete collar around the top flange of the pool securely encasing the threaded rod assemblies

and conduit adapters in place. Even if a bond beam is not being poured for the pool, it is essential for the

operation of the Fastlane that this assembly be securely anchored in concrete. After the concrete has cured,

remove the 3/8" bolts and install the pool liner. Note: Before beginning the liner installation, be sure to note

the orientation of the star thru-wall holes at 12, 3, 6 and 9 (clock positions) as they will be hidden once the

liner is hung. (Refer to Figure 4.6.) Make sure there is some water in the bottom of the pool, giving weight

to the liner and pulling it tight, before the holes for the star thru-wall fittings and threaded rod pieces are

cut. When the liner is tight enough, cut the holes. Note: Keep the holes for the threaded rod as small as possible. Attach the faceplate to the star thru-wall fittings, coat the threaded stud and rubber washer with RTV

or similar caulk, and thread the stub into the threaded rod assembly. (Refer to Figure 4.7.)

Fig. 4.7

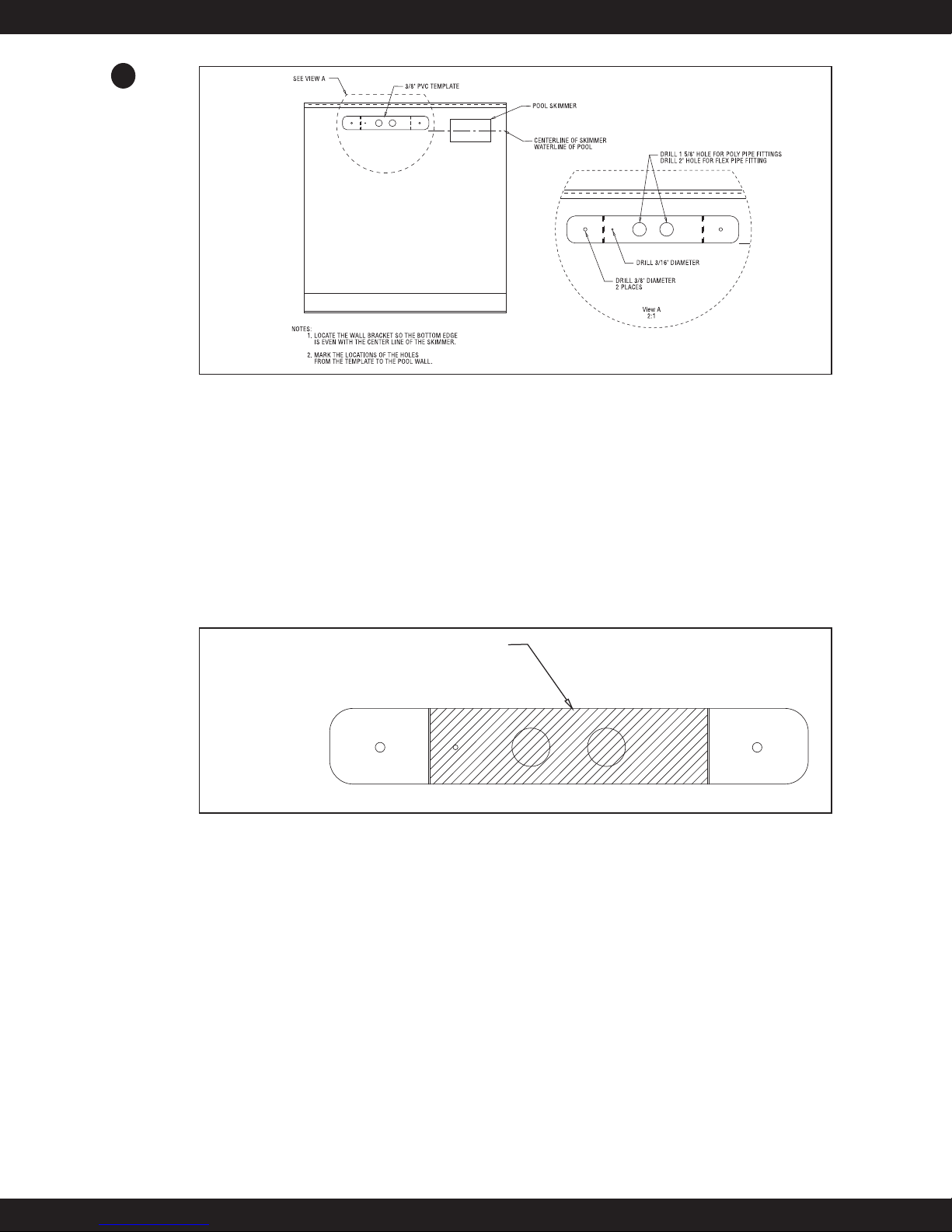

4.C. Fiberglass Pool Installation

If the pool being constructed is fiberglass, please follow the instructions below.

Remove the liquid-tite fittings, bonding lug assembly, and threaded rod pieces from the 3/8"-thick, grey

PVC bracket plate which serves as a template. Position the PVC template where the Fastlane will attach to

the pool wall and align the bottom of the PVC template with the expected water level in the pool (which

will typically be located at the centerline of the skimmer). Refer to Figure 4.8. Use duct tape, perhaps

wrapped over the top flange, to temporarily adhere the PVC template to the pool wall. Be certain that the

PVC template is level in the pool. Trace the outline of the liquid-tite fittings, bonding lug, and threaded rod

hole penetrations that are cut in the PVC bracket onto the pool wall.

7

CUT BRACKET BETWEEN NOTCHES

DISCARD MIDDLE SECTION

W

F a s t l a n e®S w i m U n i t I n s t a l l a t i o n

Fig. 4.8

Remove the duct-taped PVC template from the pool wall. Drill the openings for the liquid-tite fittings,

bonding lugs and threaded rod holes. Determine if the provided 1" poly pipe or 1-1/2" PVC flex pipe will

be used as conduit in which to run the hydraulic hoses from the pool to the Power Unit.

If using the provided 1" poly pipe:

• From the rear of the pool, attach the liquid-tite fitting to the fiberglass pool wall and firmly tighten it to

the pool wall. Silicone may be used to get a tight seal.

• Feed the 1" poly pipe into the liquid-tite fittings from the rear of the pool, and tighten the fittings on the

poly pipe (from the rear of the pool) to prevent water from passing between the poly pipe and the fittings.

• Cut the ends of the 3/8"-thick, grey PVC bracket plate along the score lines. These two ends will act as

washer/bolt heads against the back of the pool wall. Discard the center section as shown in Figure 4.9.

Fig. 4.9

• Thread the 3/8" threaded rod into the holes in the cut off end pieces, so that once permanently installed, 11/4" to 1-1/2" of threaded rod will penetrate beyond the pool wall surface. Refer to Figure 4.10. To help

prevent cross threading, thoroughly clean the exposed end of the threaded rods of any excess fiberglass

before threading nuts onto the threaded rods.

• Attach the bonding lug to the rear of the pool and thread the screw for the bonding lug through the hole in

the pool wall. The bonding lug screw should penetrate at least a 1/2" into the pool wall when permanently

installed. A #8 or larger, solid copper bonding wire must be connected from the pool bonding grid to the

bonding lug located on the back of the wall mount bracket

• Apply the provided silicone adhesive to the side of the PVC bracket plate that will mate against the pool

wall to ensure that the seal is watertight.

• Feed the poolside ends of the threaded rods through the holes drilled in the fiberglass pool wall, and using

the provided washers and jam nuts, secure the rod tightly to the pool wall. Leave nuts and washers attached until silicone cures.

8

Loading...

Loading...